Processing method for improving drawing and pressing asymmetry of magnesium alloy

A technology of tension-compression asymmetry and processing methods, which is applied in the field of magnesium alloy processing, can solve problems such as difficulty in realizing large-scale industrial production of large-scale parts, limited processing methods of magnesium alloys, and asymmetric tension-compression of magnesium alloys. Good industrial application prospects, conducive to large-scale industrial applications, and the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The cast-rolled AZ31 magnesium alloy solid round bar was homogenized and annealed at 400°C for 1h.

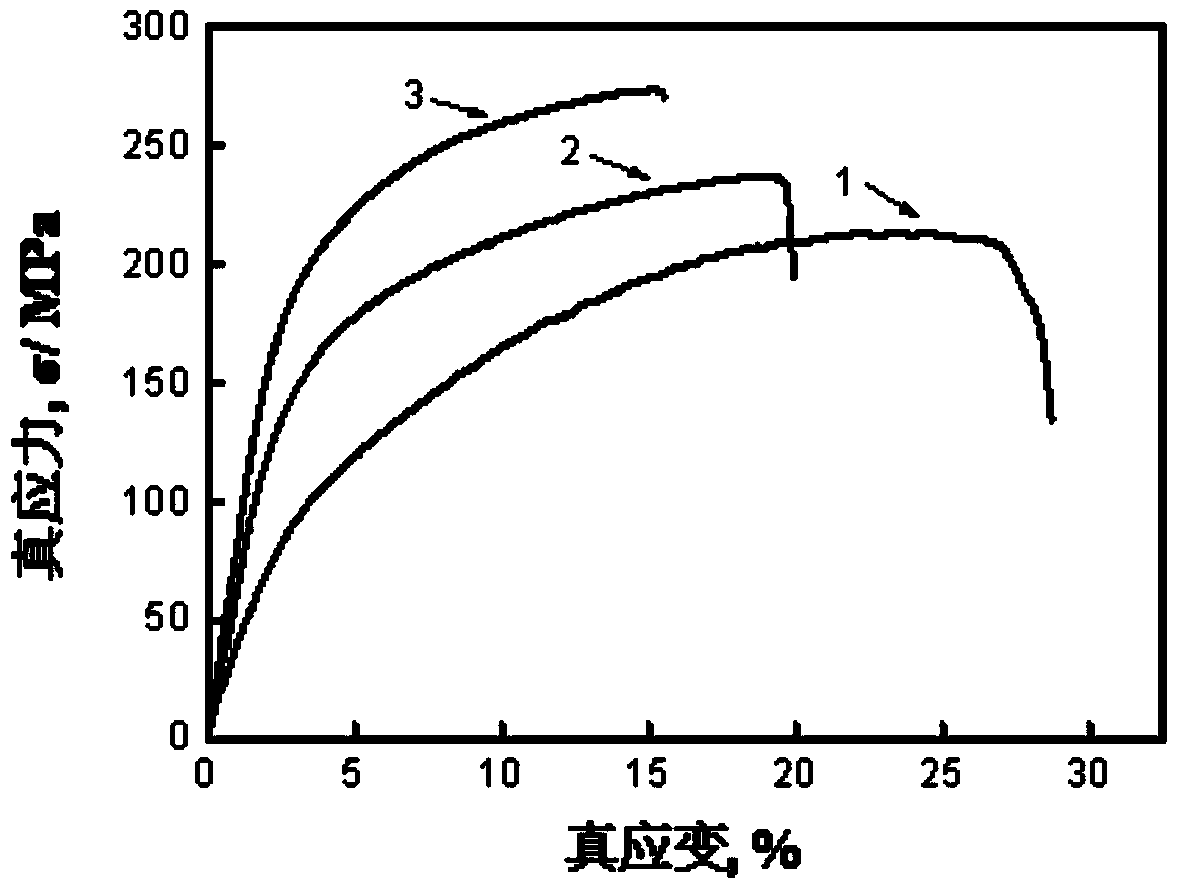

[0045] The mechanical property parameters before torsion after annealing are: compressive yield strength σ yc 57MPa, tensile yield strength σ yt 71MPa, tensile strength σ bt is 213MPa, σ yc / σ yt is 0.80, and its tensile mechanical curve is shown in the attached figure 2 Curve 1 in .

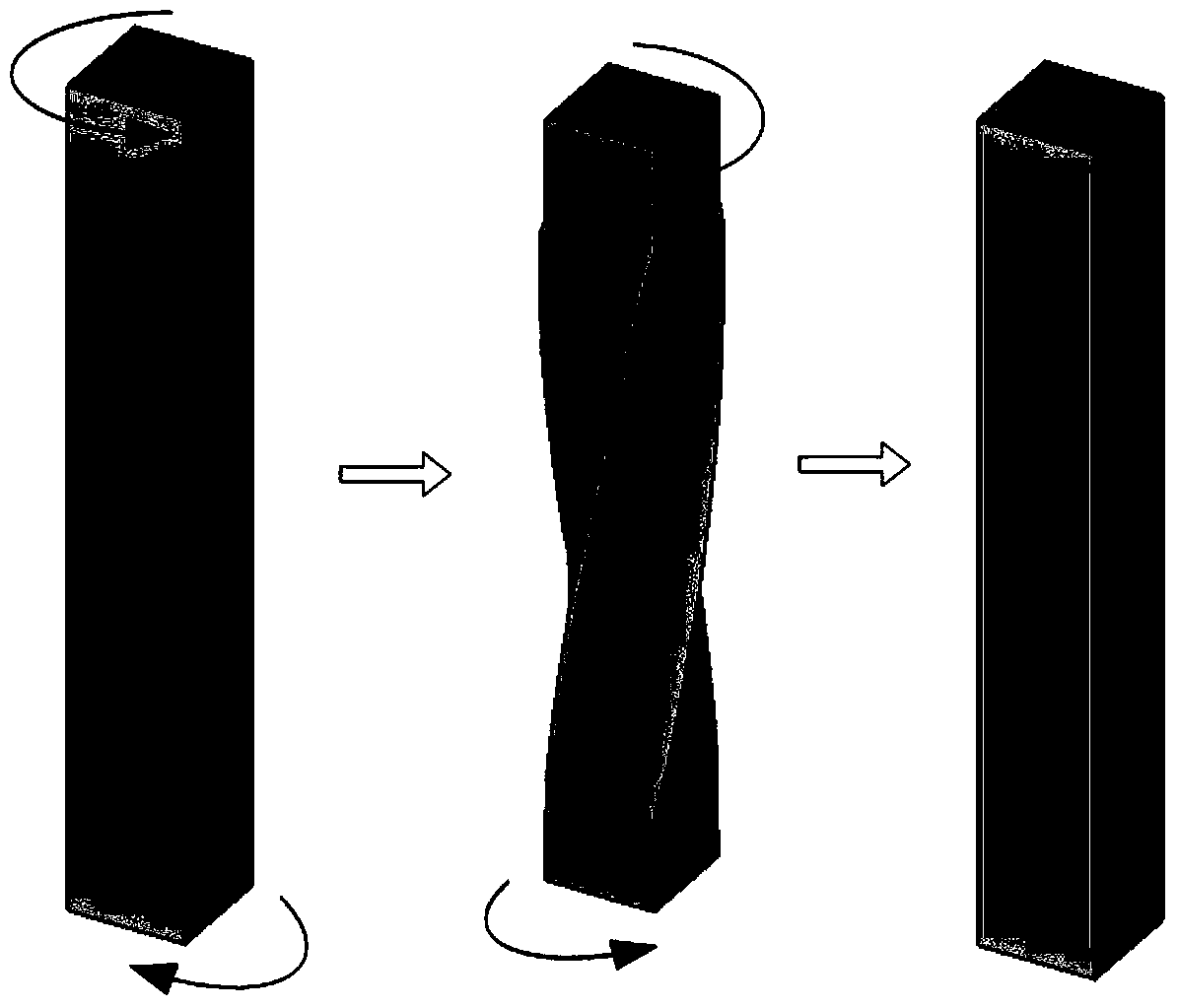

[0046] After the round bar is twisted 180° clockwise with its length direction as the axis at a speed of 1 revolution / min, its mechanical performance parameters are:

[0047] Compressive yield strength σ yc 101MPa, tensile yield strength σ yt 120MPa, tensile strength σ bt It is 237MPa, which is 11.3% higher than that before torsion; σ yc / σ yt Improved from 0.80 before torsion to 0.84 (see Table 1).

[0048] attached by figure 2 It can be seen that after being twisted and deformed by 180° (curve 2), its tensile strength and yield strength are higher than those before twisting...

Embodiment 2

[0050] The cast-rolled AZ31 magnesium alloy solid round bar was homogenized and annealed at 400°C for 1h.

[0051] At the speed of 1 turn / min, the round bar is repeatedly torsional and deformed with its length direction as the axis, twisted 180° clockwise and then 180° counterclockwise, and after the cumulative twist of 360°, its mechanical performance parameters are:

[0052] Compressive yield strength σ yc 141MPa, tensile yield strength σ yt 152MPa, tensile strength σ bt 274MPa, 28.6% higher than 213MPa before torsion; σ yc / σ yt Improvement from 0.80 before torsion to 0.93 (see Table 1).

[0053] attached by figure 2 It can be seen that after the cumulative torsional deformation of 360° (curve 3), its tensile strength and yield strength are significantly improved compared with those before torsion (curve 1).

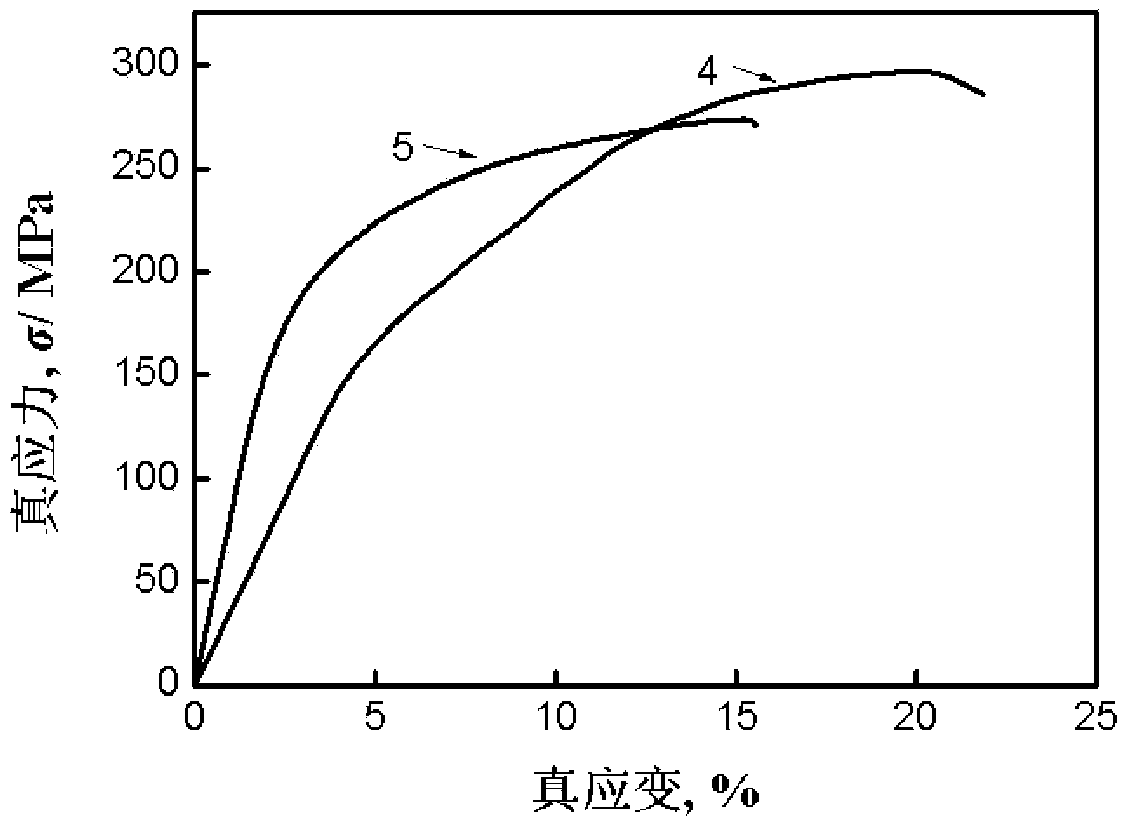

[0054] attached by image 3 (curve 4 is a compression curve, and curve 5 is a tension curve) it can be seen that the compression yield strength σ of the magne...

Embodiment 3

[0056] The AZ31 magnesium alloy hollow tube was homogenized and annealed at 450°C for 2h.

[0057] The mechanical property parameters before torsion after annealing are: compressive yield strength σ yc 73MPa, tensile yield strength σ yt 150MPa, tensile strength σ bt is 290MPa, σ yc / σ yt is 0.50.

[0058] Fill the circular tube with sand before torsion deformation. After filling, the circular tube is twisted 150° clockwise and then 150° counterclockwise at a speed of 2 turns / min. Intensity σ yc 108MPa, tensile yield strength σ yt 120MPa, tensile strength σ bt is 315MPa, which is 8.6% higher than that before torsion, σ yc / σ yt From 0.50 before torsion to 0.90 (see Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive yield strength | aaaaa | aaaaa |

| Tensile yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com