Method for rapidly preparing large-particle-size silica sol

A large particle size, silica sol technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of unstable roughness, prolong the use time of polishing liquid, etc., to reduce the existence of small particle size particles, Quantitative control savings, the effect of accelerating the speed of polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

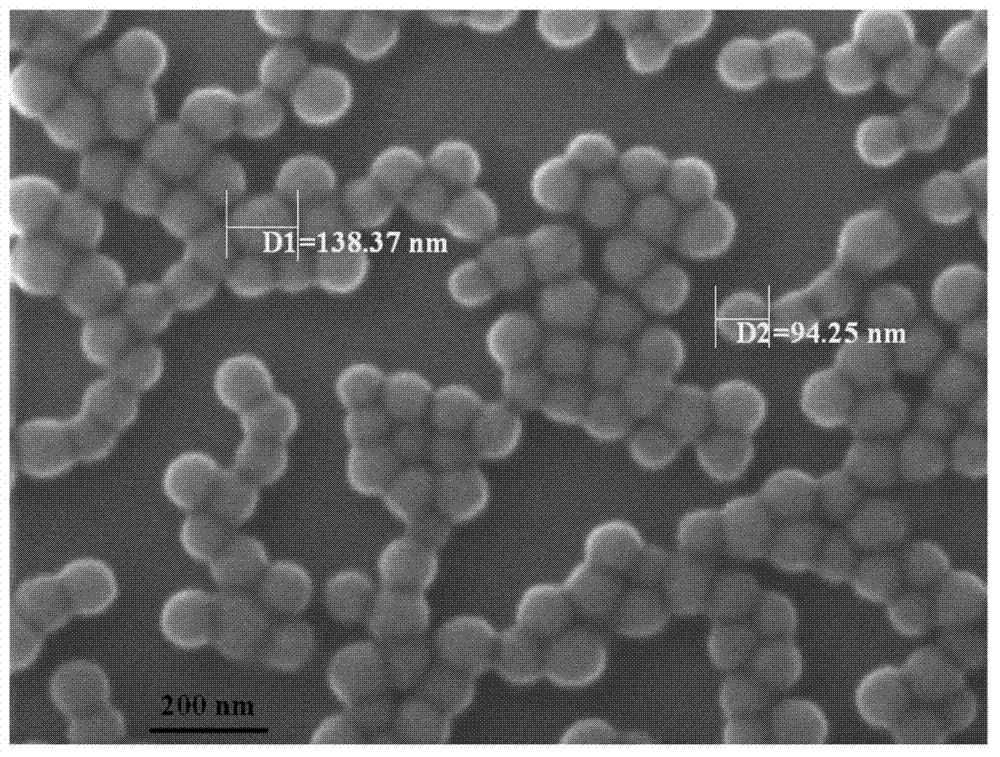

[0030] Selecting high-purity sodium silicate prepared from fumed silica as a raw material to prepare a water glass solution with a concentration of 6%, the prepared water glass solution is exchanged with a cationic resin to obtain a concentration of 5.3% active silicic acid; Silicic acid passes through anion exchange resin to obtain active silicic acid with higher purity. Take 10 wt% of the prepared active silicic acid, add alkali solution to adjust its pH value to 8.2. Add 0.1wt% stabilizer, heat to 90°C, and keep for 0.5 hours to obtain a silica sol mother solution with a particle size of 8nm. Under constant stirring, keep the silica sol mother liquor in a slightly boiling state (the temperature is 100C), add the remaining active silicic acid therein, add the mixed solution of 0.9wt% stabilizer and 10wt% polymerization inhibitor, and react for 4 hours to obtain granules Silica sol solution with a diameter of 90-140nm. During the reaction, the volume of the reaction solutio...

Embodiment 2

[0032] Selecting high-purity sodium silicate prepared from fumed silica as a raw material to prepare a water glass solution with a concentration of 10%, the prepared water glass solution is exchanged with a cationic resin to obtain a concentration of 8.6% active silicic acid; Silicic acid passes through anion exchange resin to obtain active silicic acid with higher purity. Take part 10wt% of the prepared active silicic acid, add alkali solution to adjust its pH value to 9. Add 0.5wt% stabilizer, heat to 100°C, and keep for 1 hour to obtain a silica sol mother solution with a particle size of 3.4nm. Under constant stirring, keep the silica sol mother liquor in a slightly boiling state, add the remaining active silicic acid to it, add a mixed solution of 0.5wt% stabilizer and 5wt% polymerization inhibitor, and react for 4 hours to obtain a silica sol with a particle size of 90-140nm. Sol solution. During the reaction, the volume of the reaction solution was kept constant by ad...

Embodiment 3

[0034] Select the high-purity sodium silicate prepared by fumed silica as raw material to prepare a water glass solution with a concentration of 1%, and exchange the prepared water glass solution with a cationic resin to obtain a concentration of 0.9% active silicic acid; Silicic acid passes through anion exchange resin to obtain active silicic acid with higher purity. Take part 10wt% of the prepared active silicic acid, add alkali solution to adjust its pH value to 7. Add 0.01wt% stabilizer, heat to 95° C., and keep for 1 hour to obtain a silica sol mother solution with a particle size of 10 nm. Under constant stirring, keep the silica sol mother liquor in a slightly boiling state, add the remaining active silicic acid to it, add a mixed solution of 0.1wt% stabilizer and 0.5wt% polymerization inhibitor, and react for 2 hours to obtain a particle size of 90-140nm Silica sol solution. During the reaction process, the volume of the reaction solution was kept constant by adding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com