Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

541results about How to "Reduce contact pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

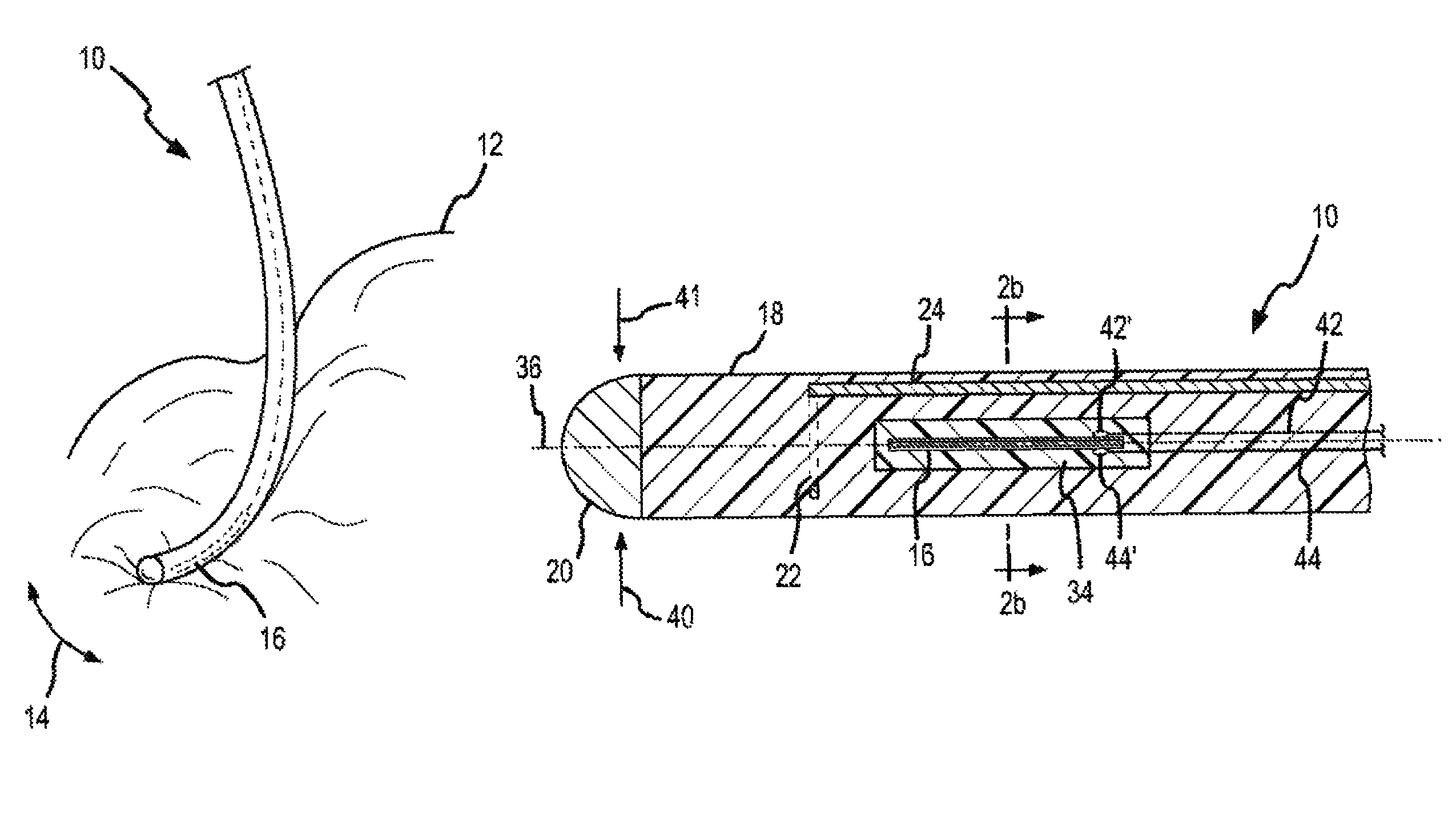

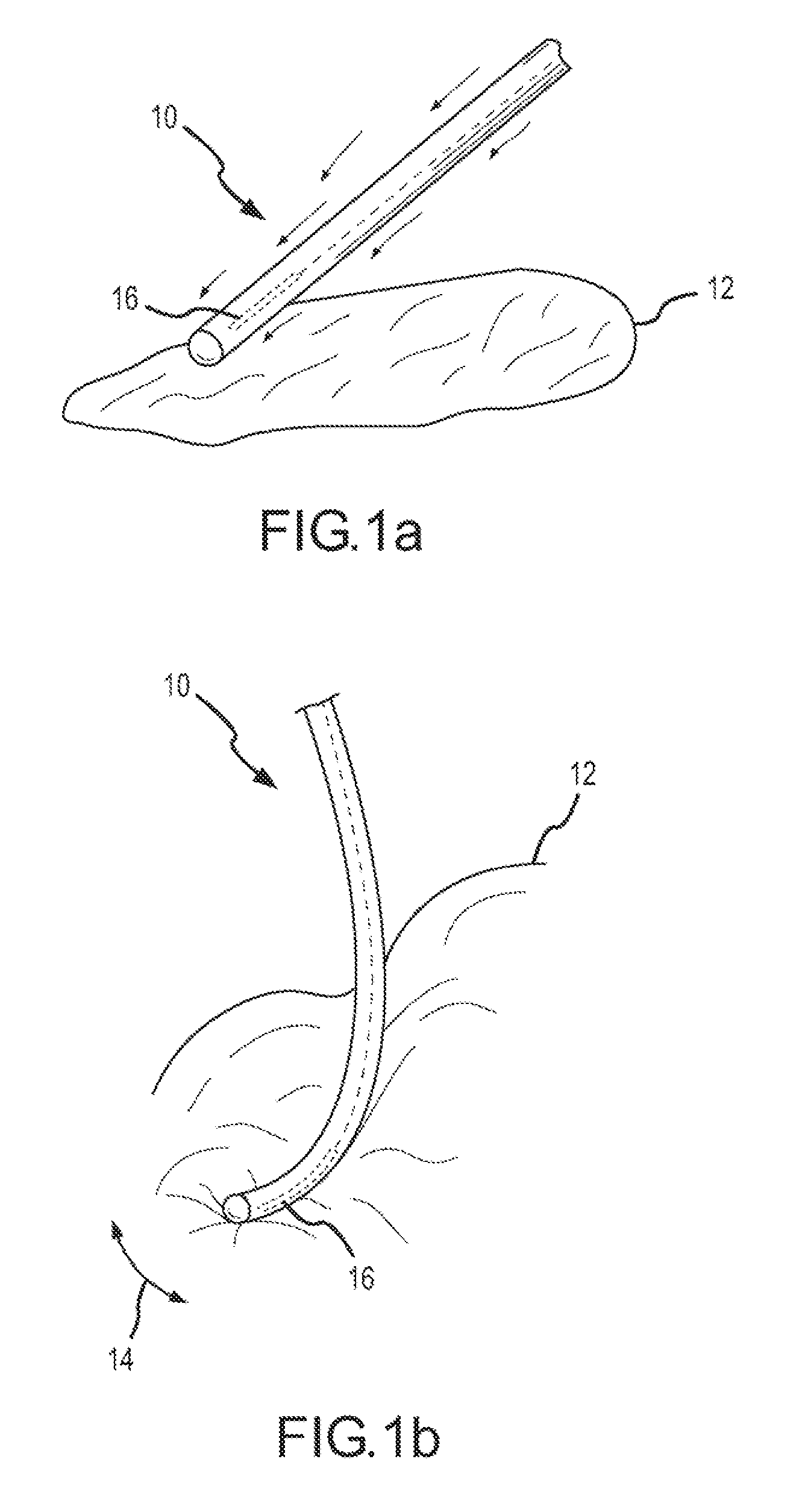

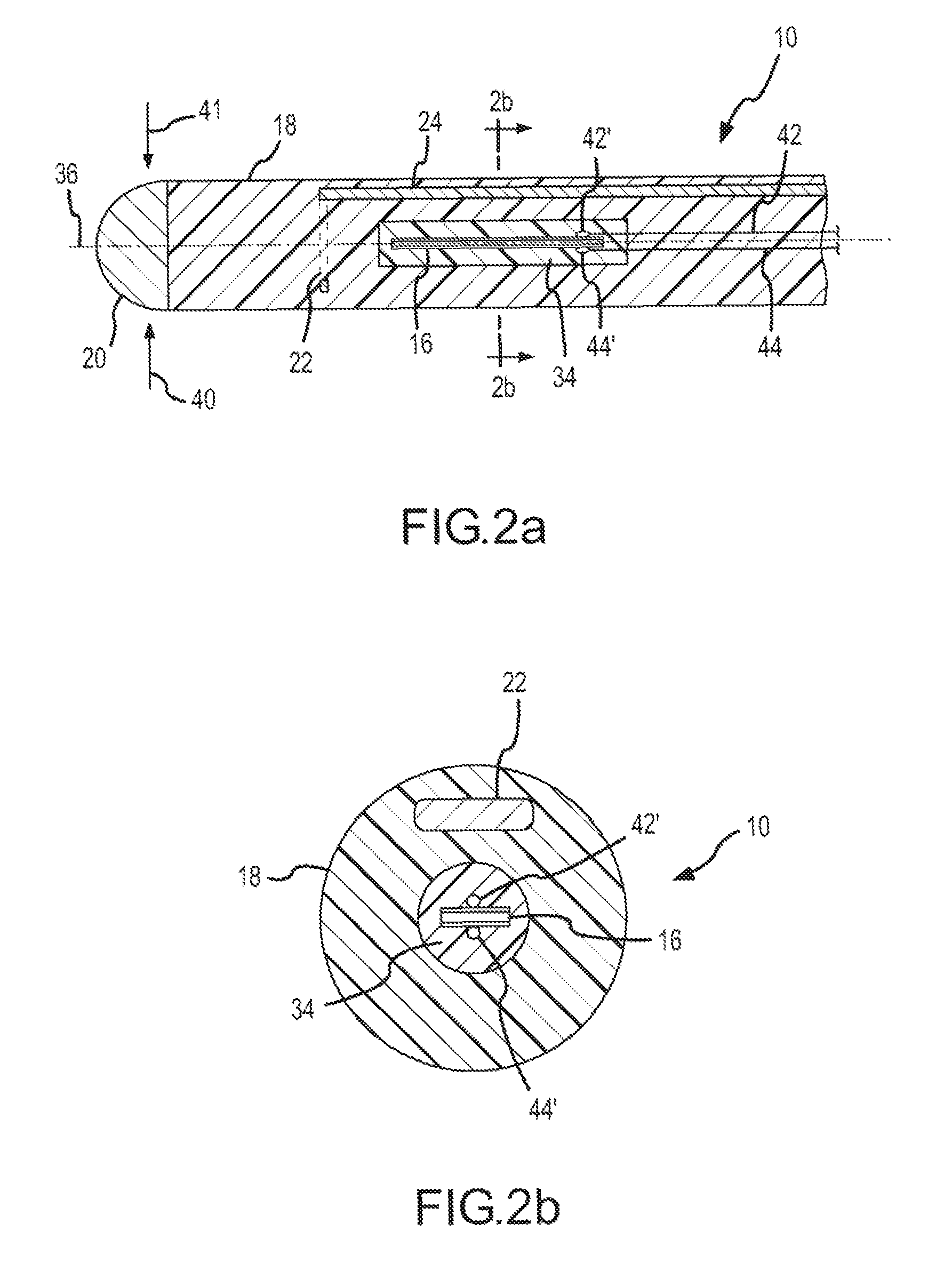

Systems and methods for electrode contact assessment

ActiveUS20070100332A1Increase contact pressureReduce contact pressureCatheterDiagnostic recording/measuringElectricityDistal portion

Systems and methods are disclosed for assessing electrode-tissue contact for tissue ablation. An exemplary electrode contact sensing system comprises an electrode housed within a distal portion of a catheter shaft. At least one electro-mechanical sensor is operatively associated with the electrode within the catheter shaft. The at least one electro-mechanical sensor is responsive to movement of the electrode by generating electrical signals corresponding to the amount of movement. The system may also include an output device electrically connected to the at least one electro-mechanical sensor. The output device receives the electrical signals for assessing a level of contact between the electrode and a tissue.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

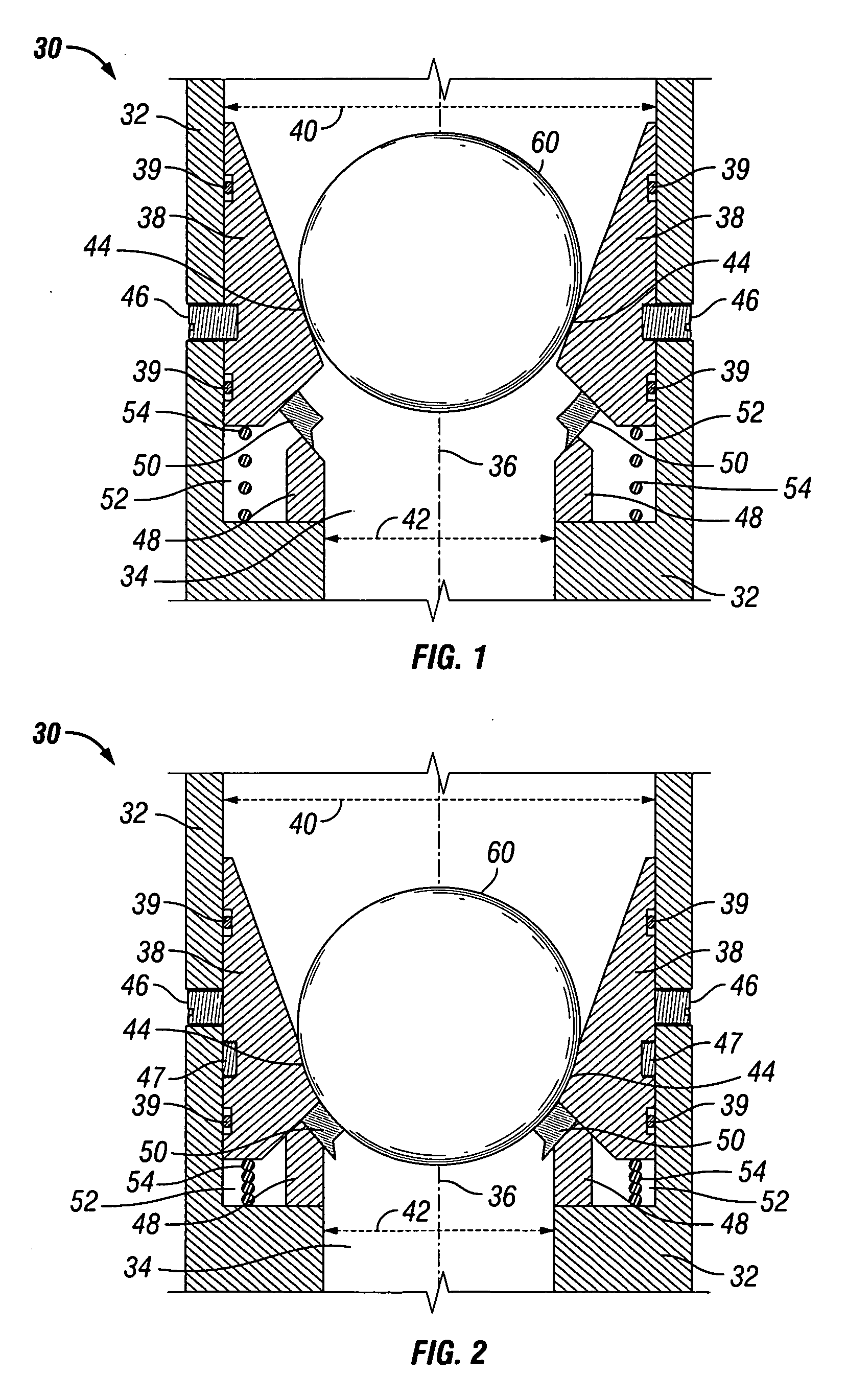

Ball seat having segmented arcuate ball support member

ActiveUS20090159289A1Increase pressureReduce the possibilityFluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

Owner:BAKER HUGHES INC

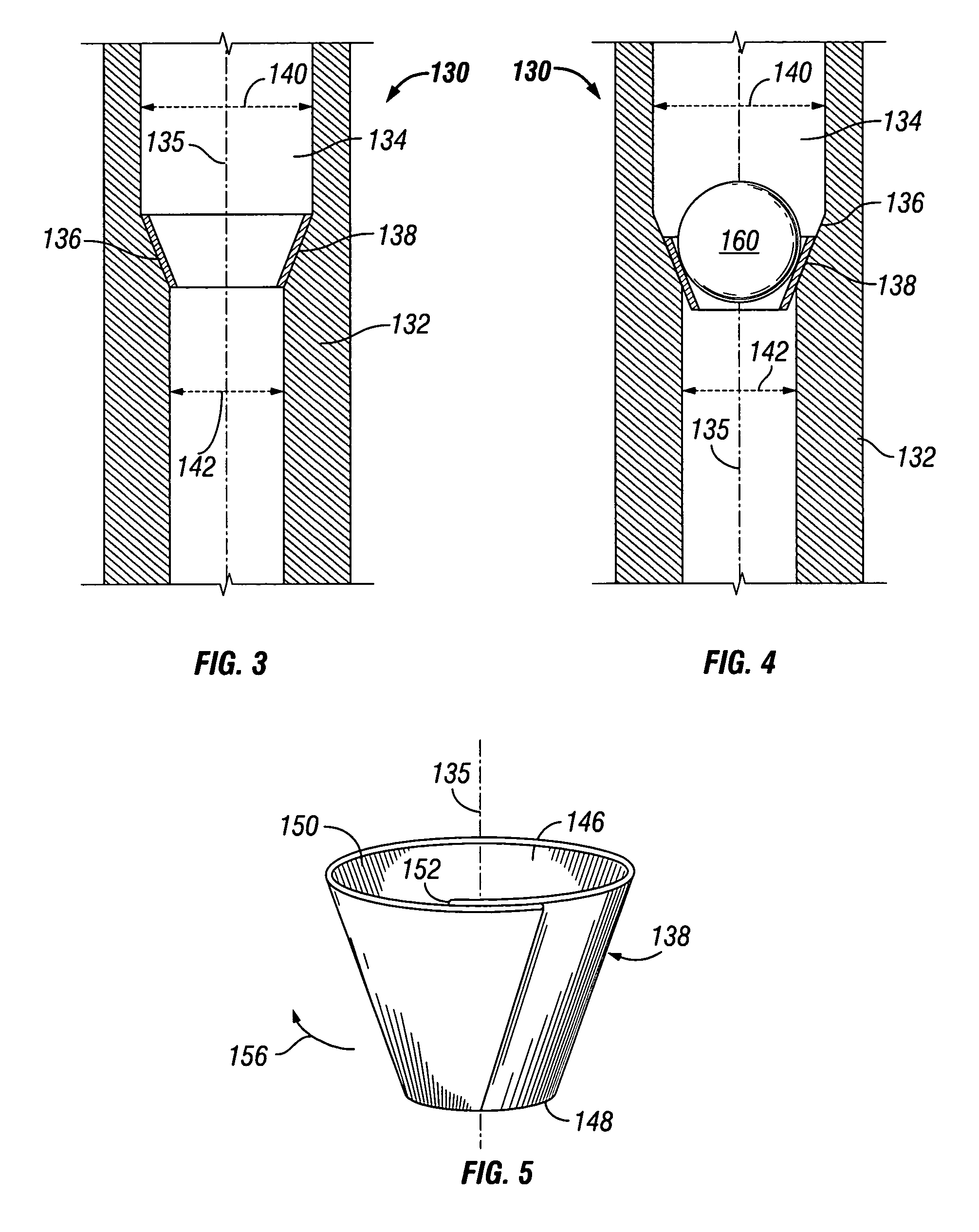

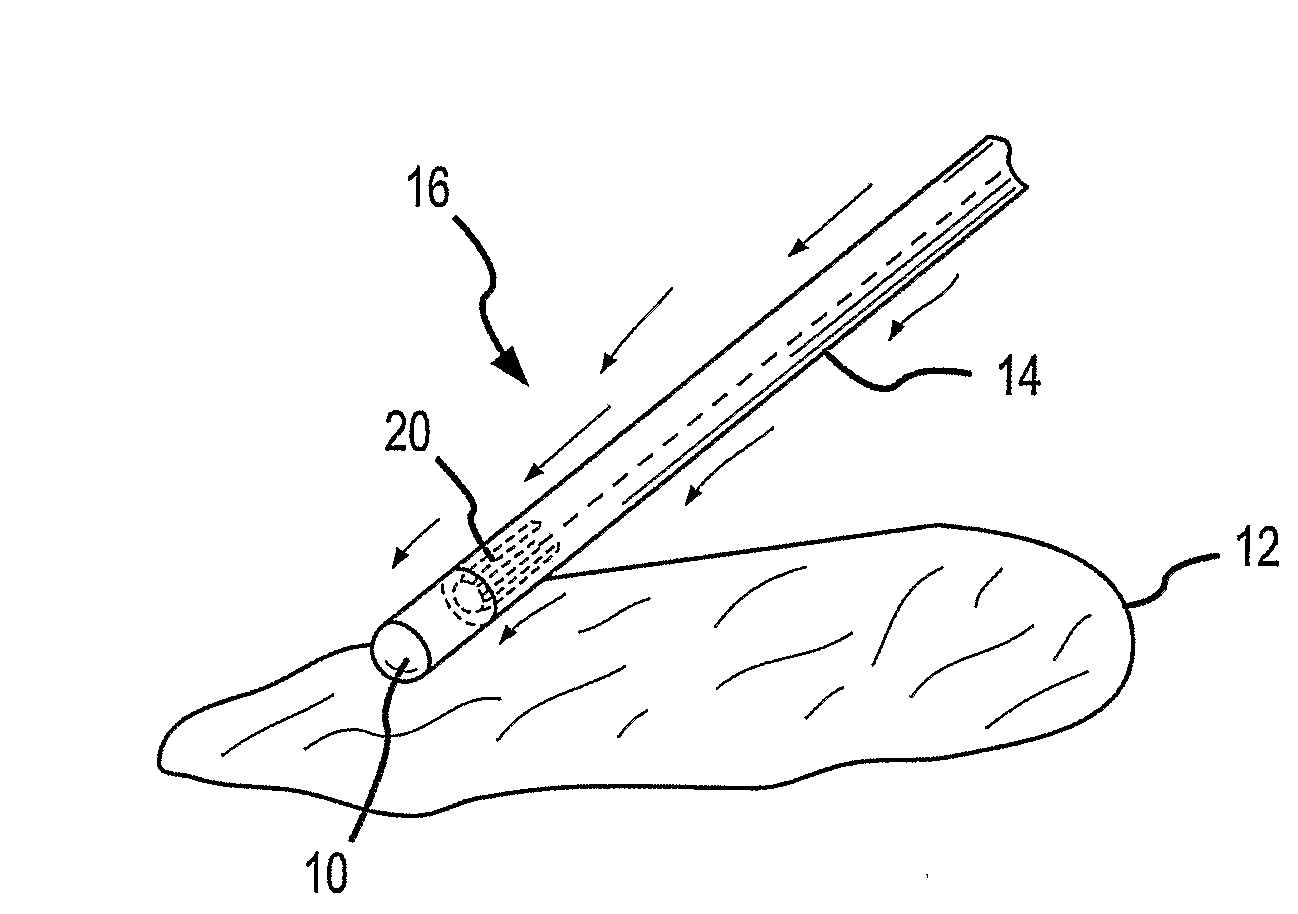

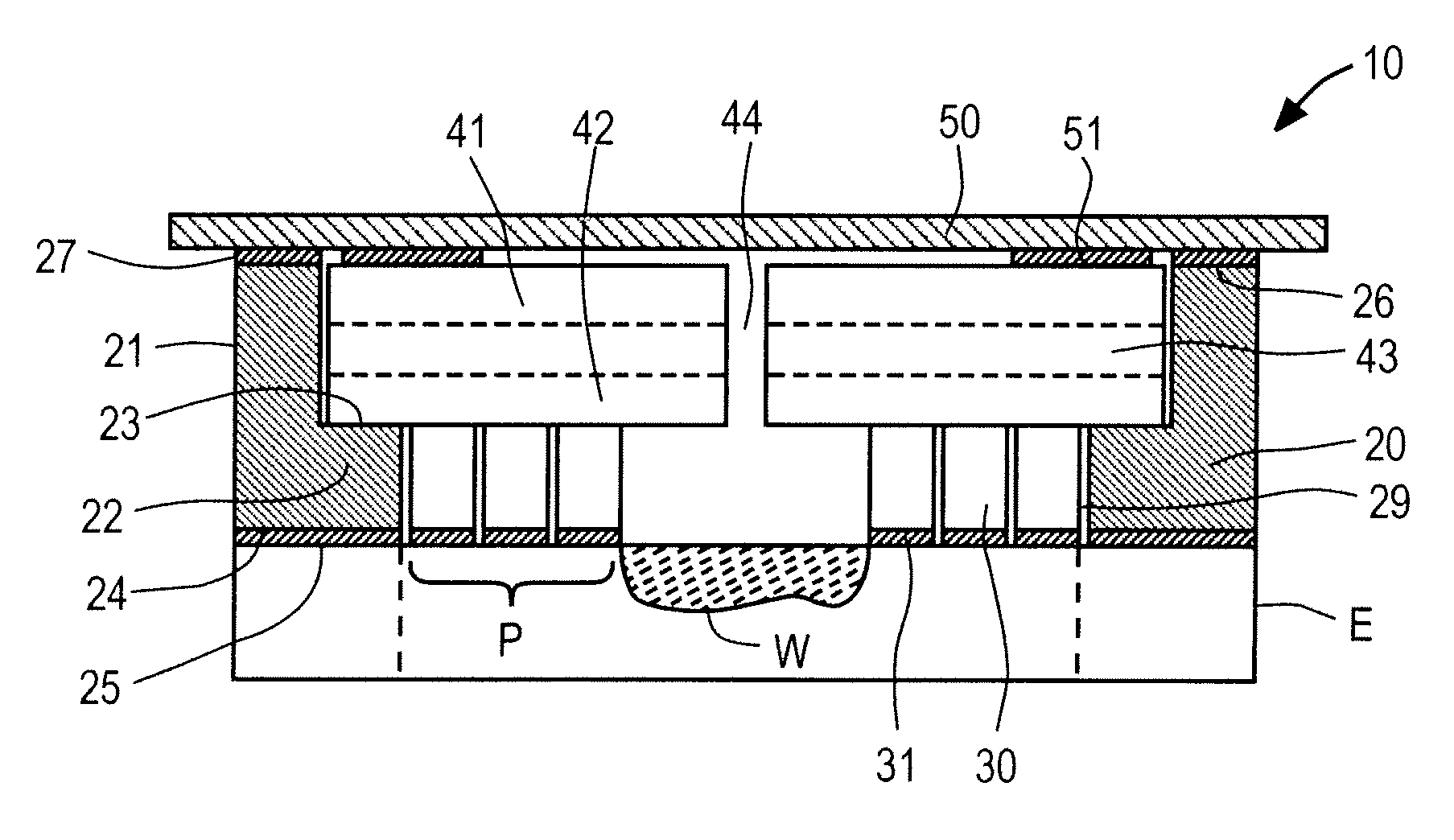

Systems and Methods for Electrode Contact Assessment

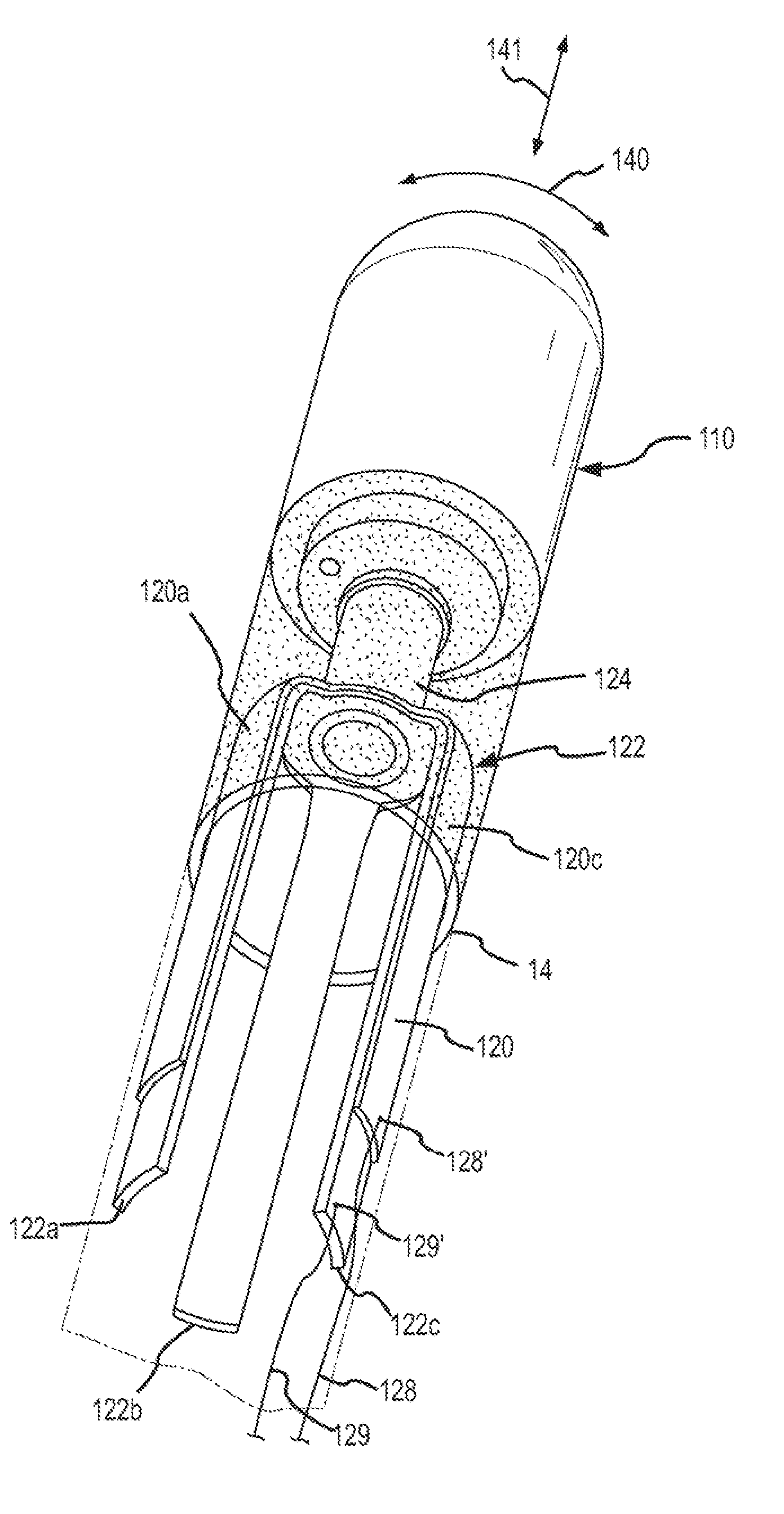

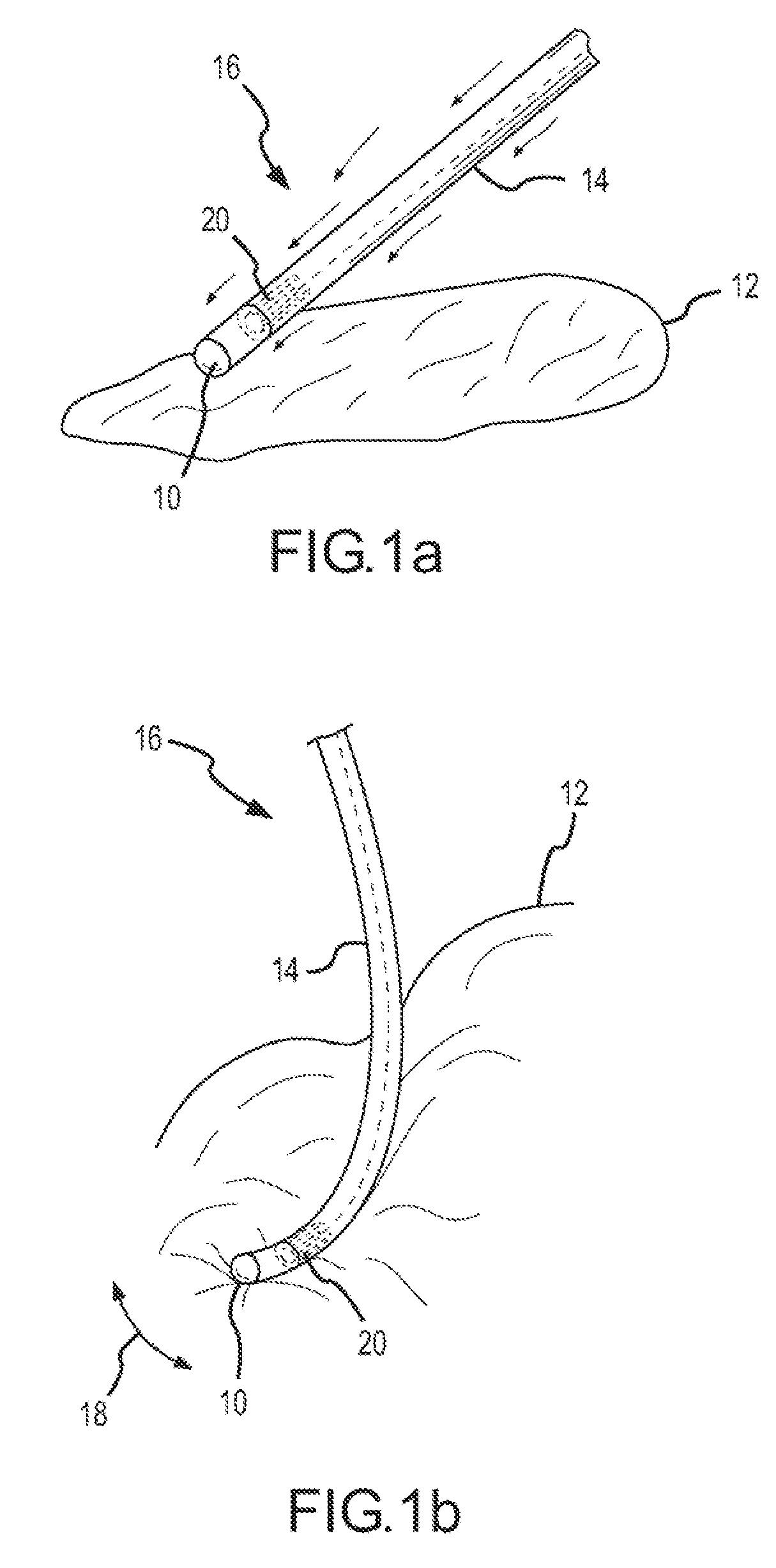

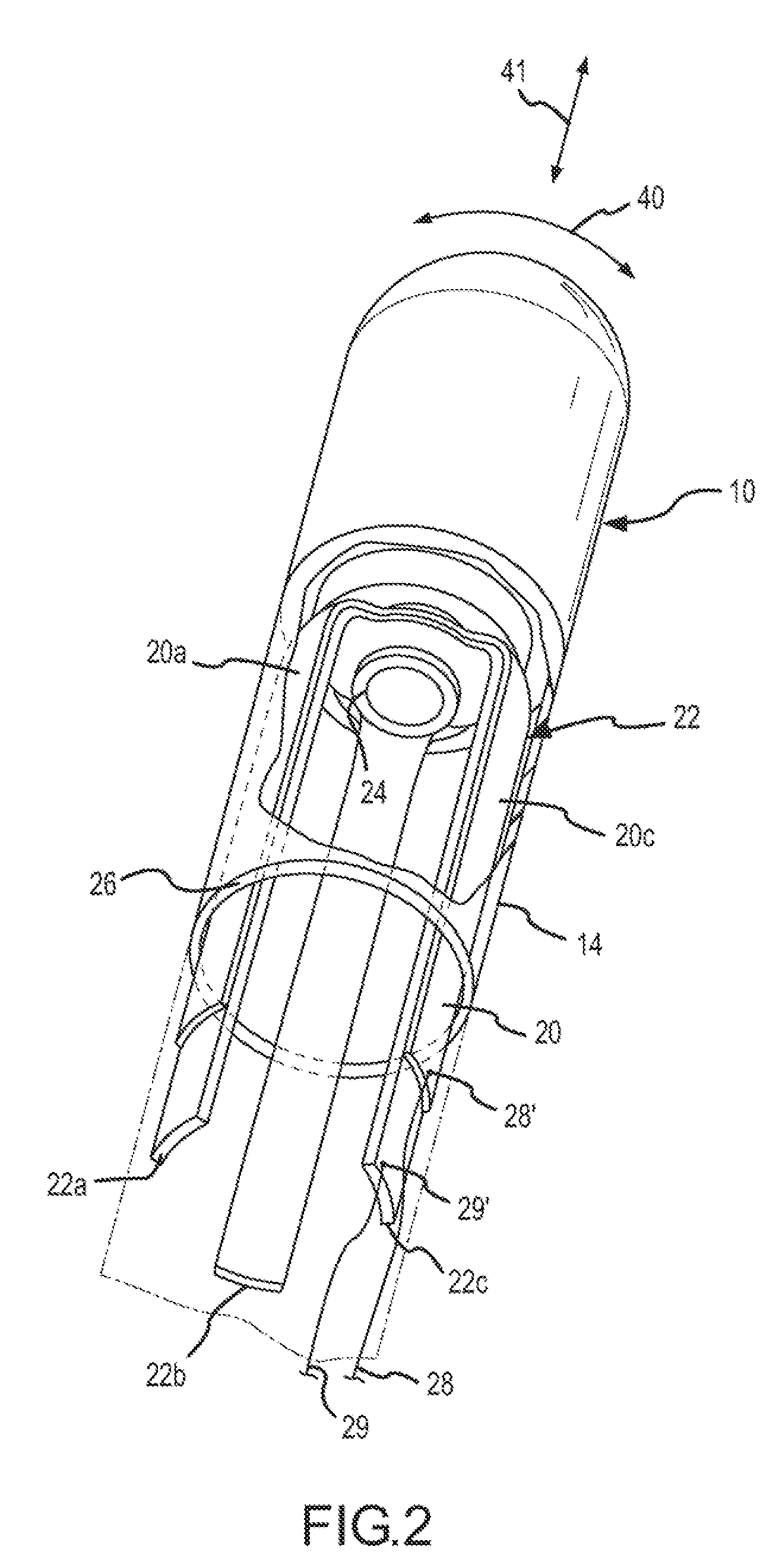

ActiveUS20080275442A1Increase contact pressureReduce contact pressureCatheterDiagnostic recording/measuringElectricityDistal portion

Systems and methods are disclosed for assessing electrode-tissue contact for tissue ablation. An exemplary electrode contact sensing system comprises an electrode 10 housed within a distal portion of a catheter shaft 14. At least one electromechanical sensor 20 is operatively associated with the electrode 10 within the catheter shaft 14. The at least one electromechanical sensor 20 is responsive to movement of the electrode 10 by generating electrical signals corresponding to the amount of movement. The system may also include an output device electrically connected to the at least one electromechanical sensor 20. The output device receives the electrical signals for assessing a level of contact between the electrode 10 and a tissue 12.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

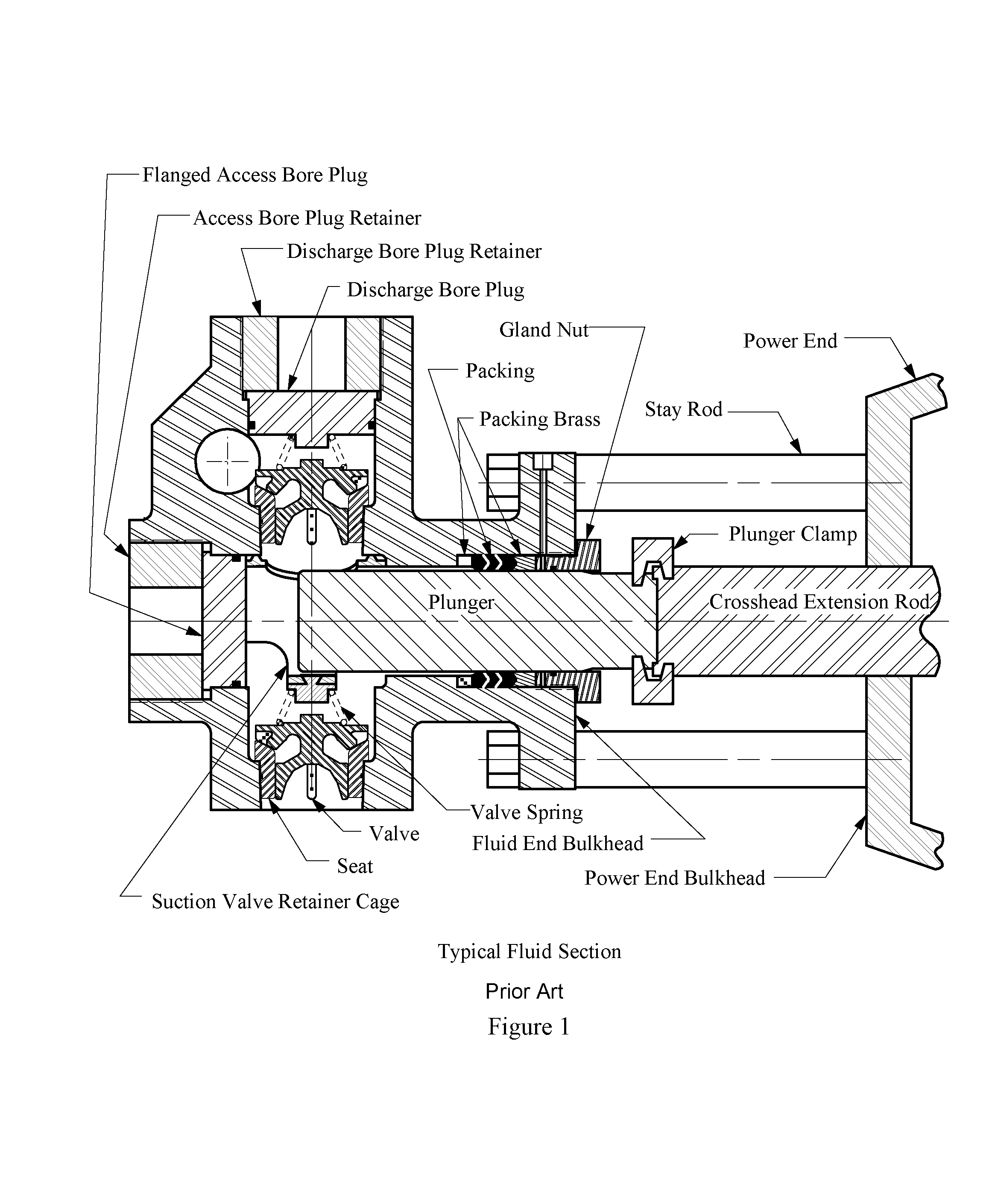

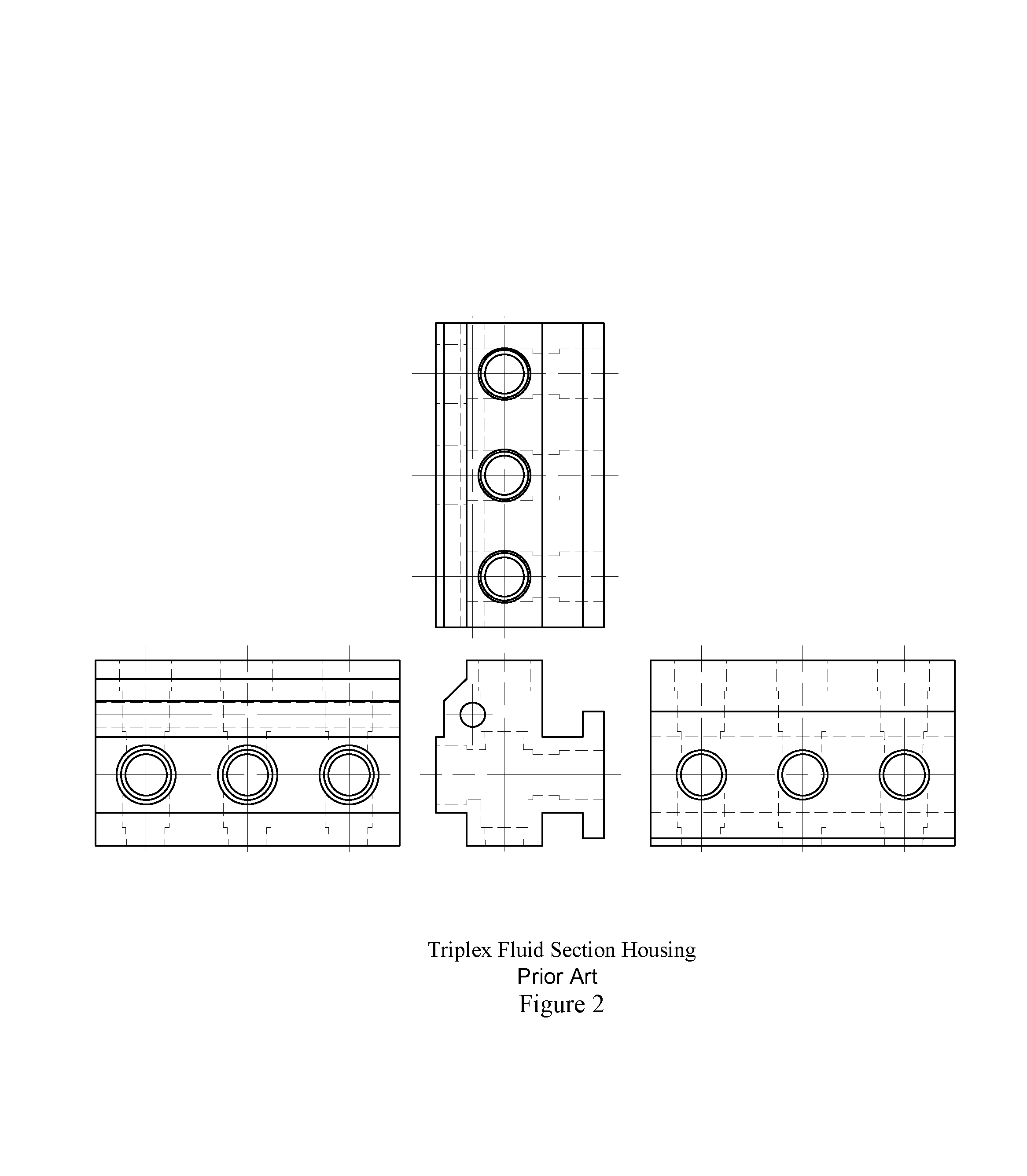

Valve body and seal assembly

InactiveUS7168440B1Longer valve service lifeStable elastomer propertyPipe supportsPositive displacement pump componentsStress concentrationElastomer

A valve body and seal assembly comprising a top-stem-guided valve body having at least one cast-in-place elastomeric seal insert in a peripheral seal retention groove and a cast-in-place top guide stem sleeve is made by pouring and curing liquid elastomer in at least one mold comprising the peripheral seal retention groove and the top guide stem. Mold surfaces contacting the poured elastomer are adhesion-inhibiting surfaces which reduce or eliminate background elastomer stress due to shrinkage during curing of the elastomer, and which allow limited relative movement of cast-in-place elastomer with respect to the valve body. Serrations on each of the opposing walls of the seal retention groove are offset to moderate differing stress concentrations in the groove walls.

Owner:ALTIS INVESTMENTS LLC

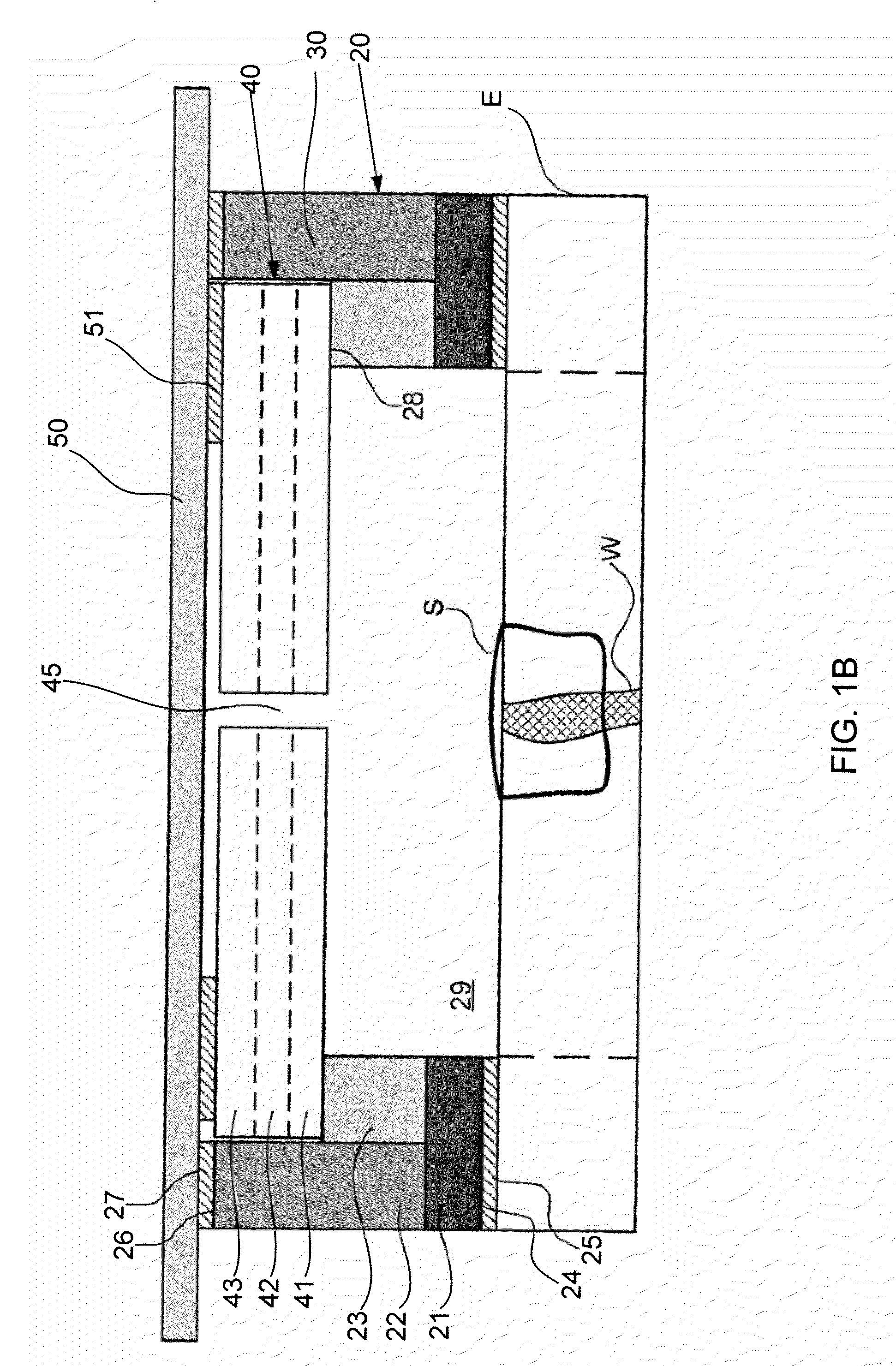

Secondary Wound Dressings for Securing Primary Dressings and Managing Fluid from Wounds, and Methods of Using Same

InactiveUS20100312159A1Improve breathabilityReduce contact pressureSurgical needlesPlastersWound dressingAdhesive

Under one aspect, an apparatus includes a primary dressing configured for application over a region of compromised skin and including fluid-absorbing material; and a secondary dressing configured for application over the primary dressing. The secondary dressing applies pressure to the primary dressing so as to maintain the primary dressing in place over the region of compromised skin and promote the flow of fluid from the region of compromised skin into the fluid-absorbing material, and allows moisture in the fluid to evaporate from the fluid-absorbing material. Under another aspect, a dressing includes a fabric layer sized to cover a region of compromised skin; a foam layer secured to the fabric layer and having an aperture defined therein sized to cover the region of compromised skin; and a biocompatible adhesive layer disposed on the foam layer. Methods of applying the dressing also are provided.

Owner:AALNEX

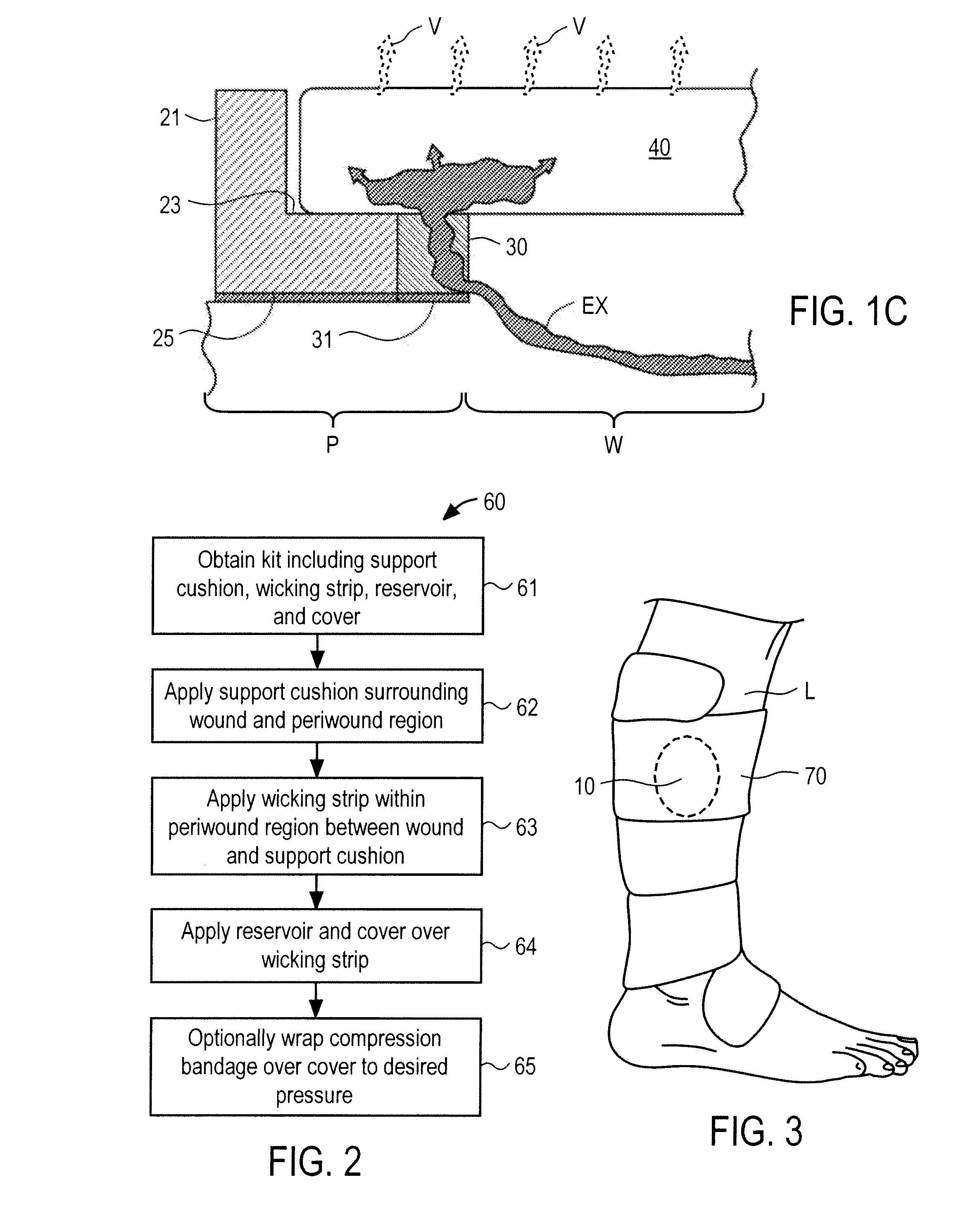

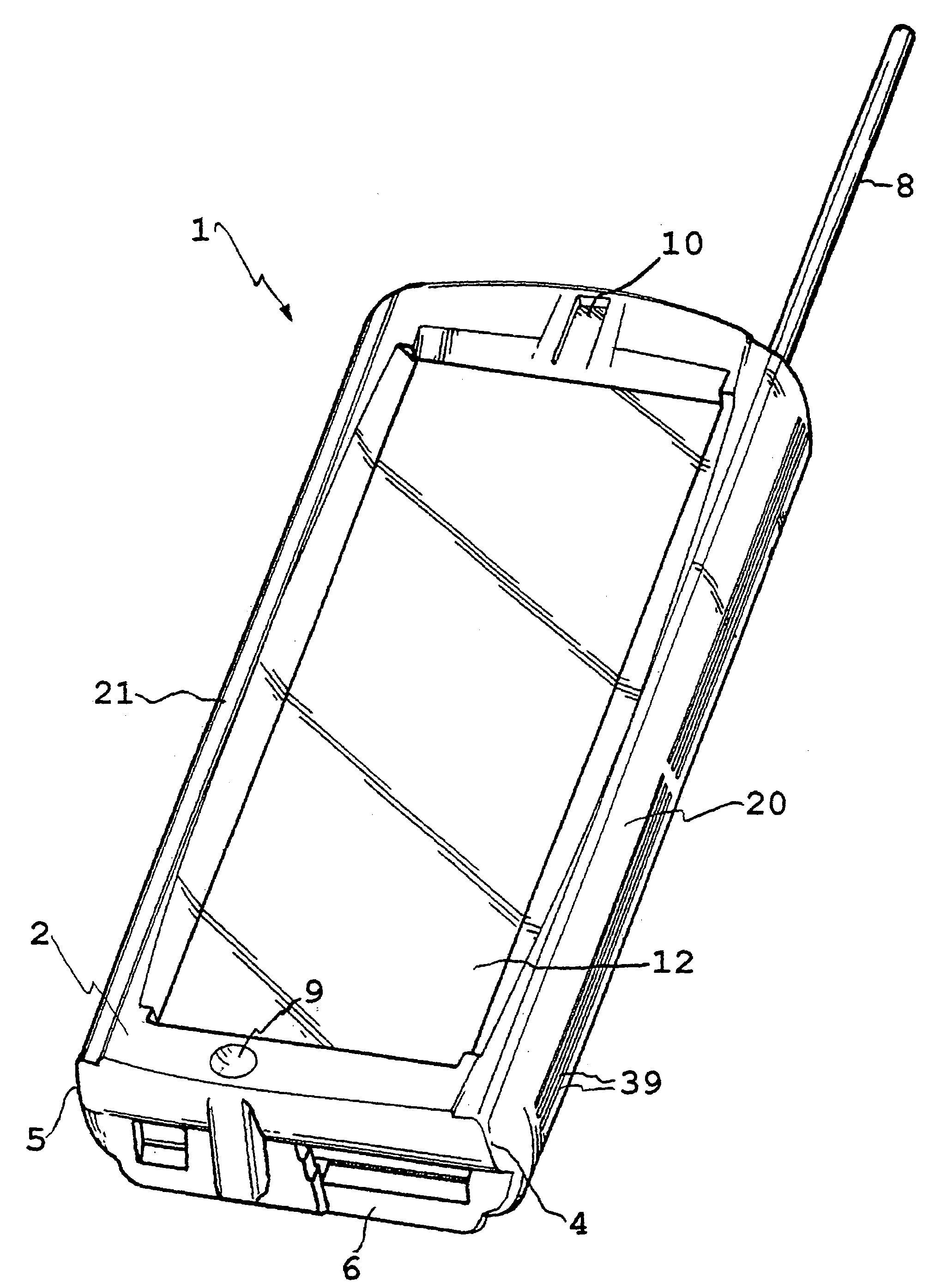

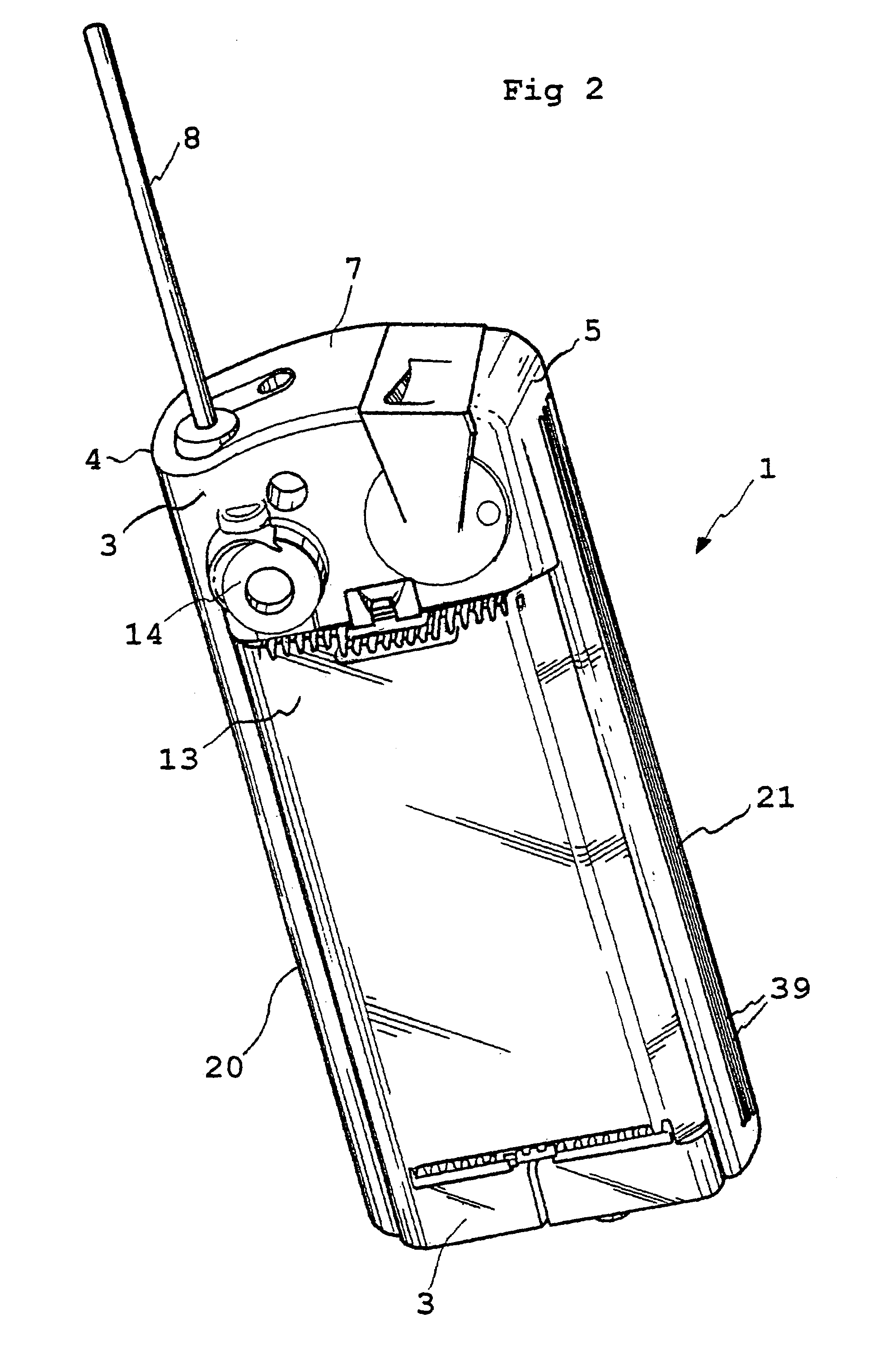

Handheld or pocketsized electronic apparatus and hand-controlled input device

InactiveUS7236159B1Small sizeReduce contact areaInput/output for user-computer interactionTransmission systemsDisplay deviceEngineering

A handheld or pocketsized electronic apparatus, such as a mobile telephone, having a display unit and a touch surface that is position-sensitive in a first and second direction for control of the electronic apparatus; the display unit having a display area taking up most of the front side of the apparatus and the touch surface being sufficiently narrow to fit on the side edge of the apparatus and curved in the first direction to convex shape, thus making it simple for a user to control the apparatus with one hand, without the display being hidden, and in an ergonomically correct manner, whereby control of the apparatus is attained without the use of a keyboard or similar input device.

Owner:SPECTRONIC

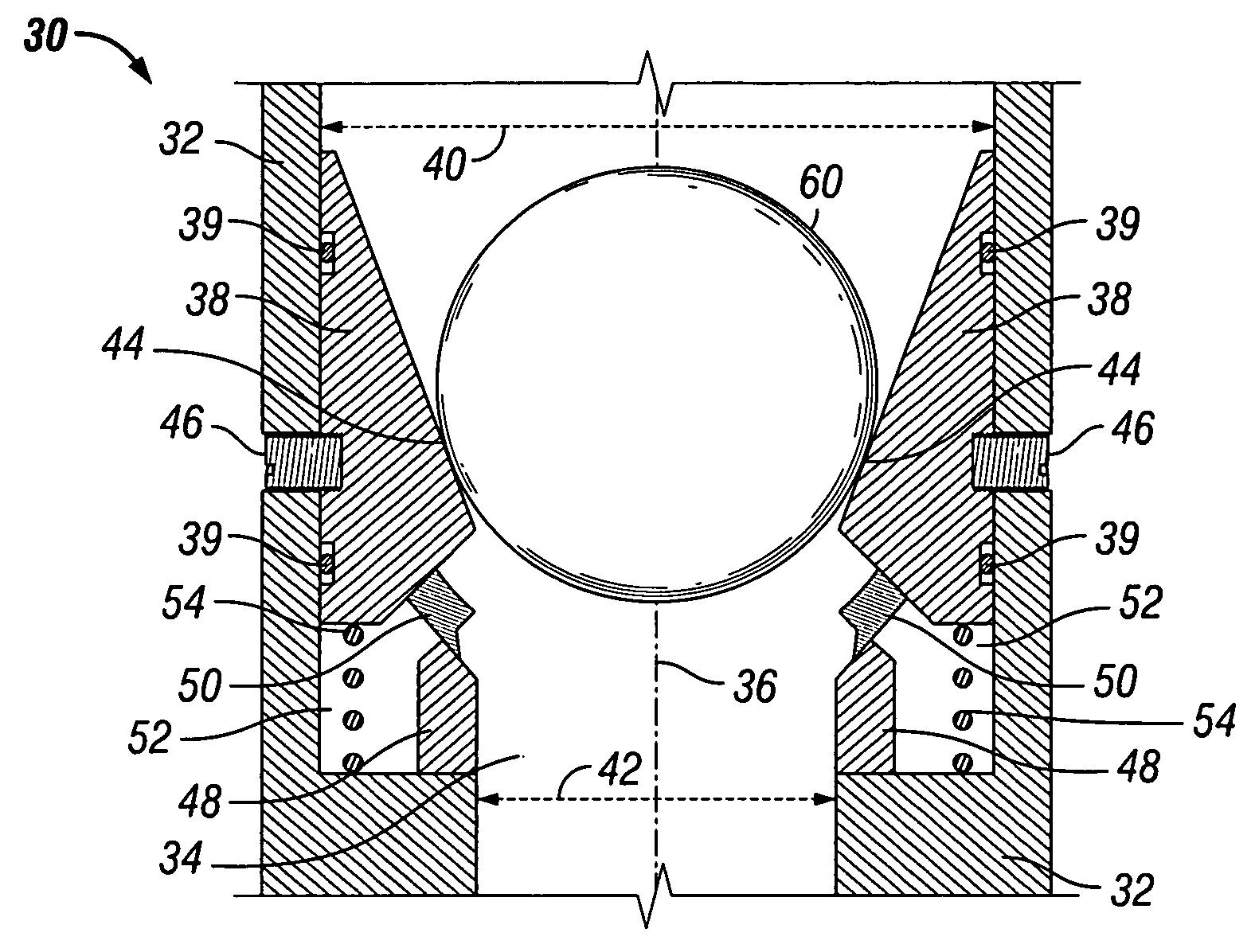

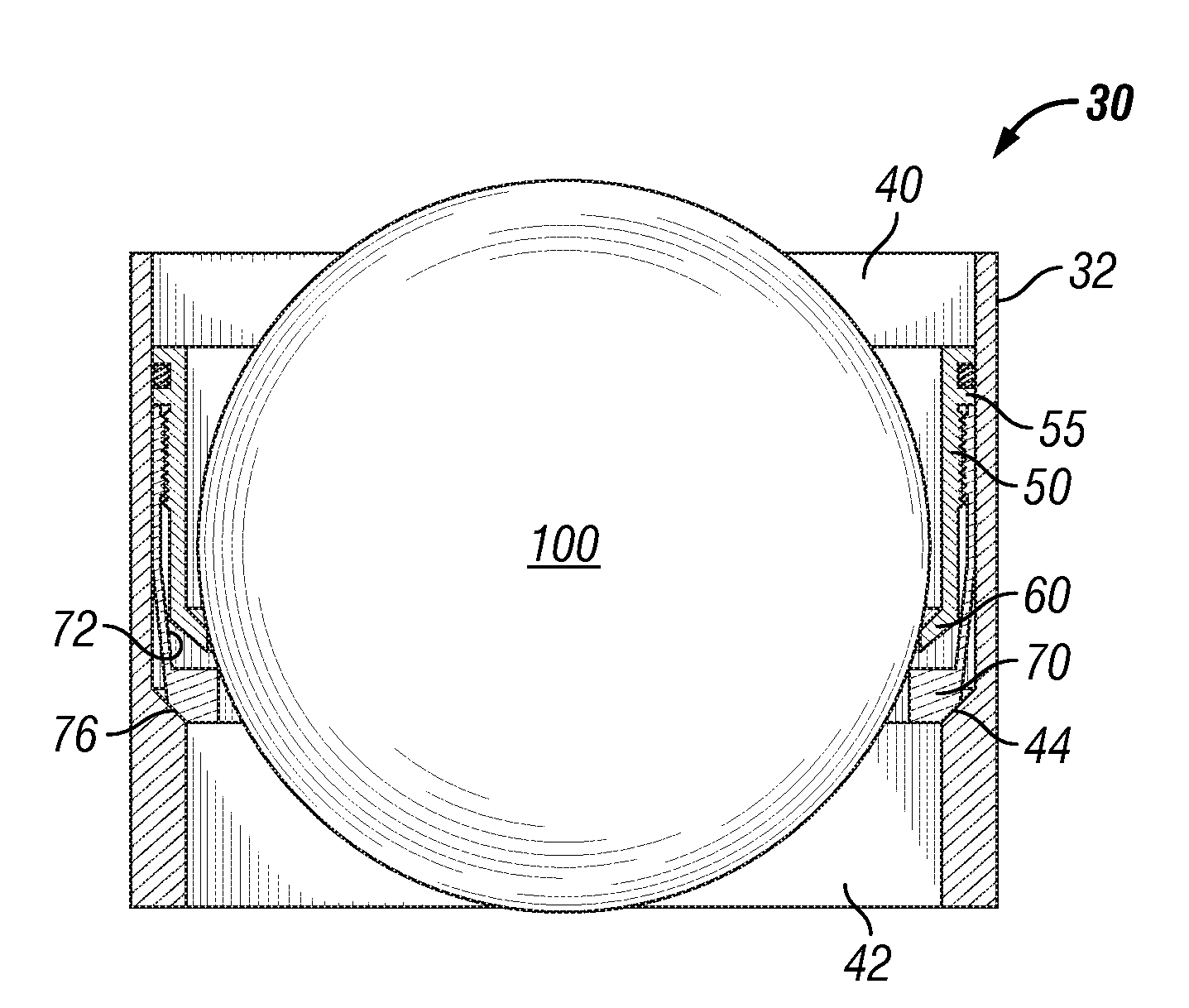

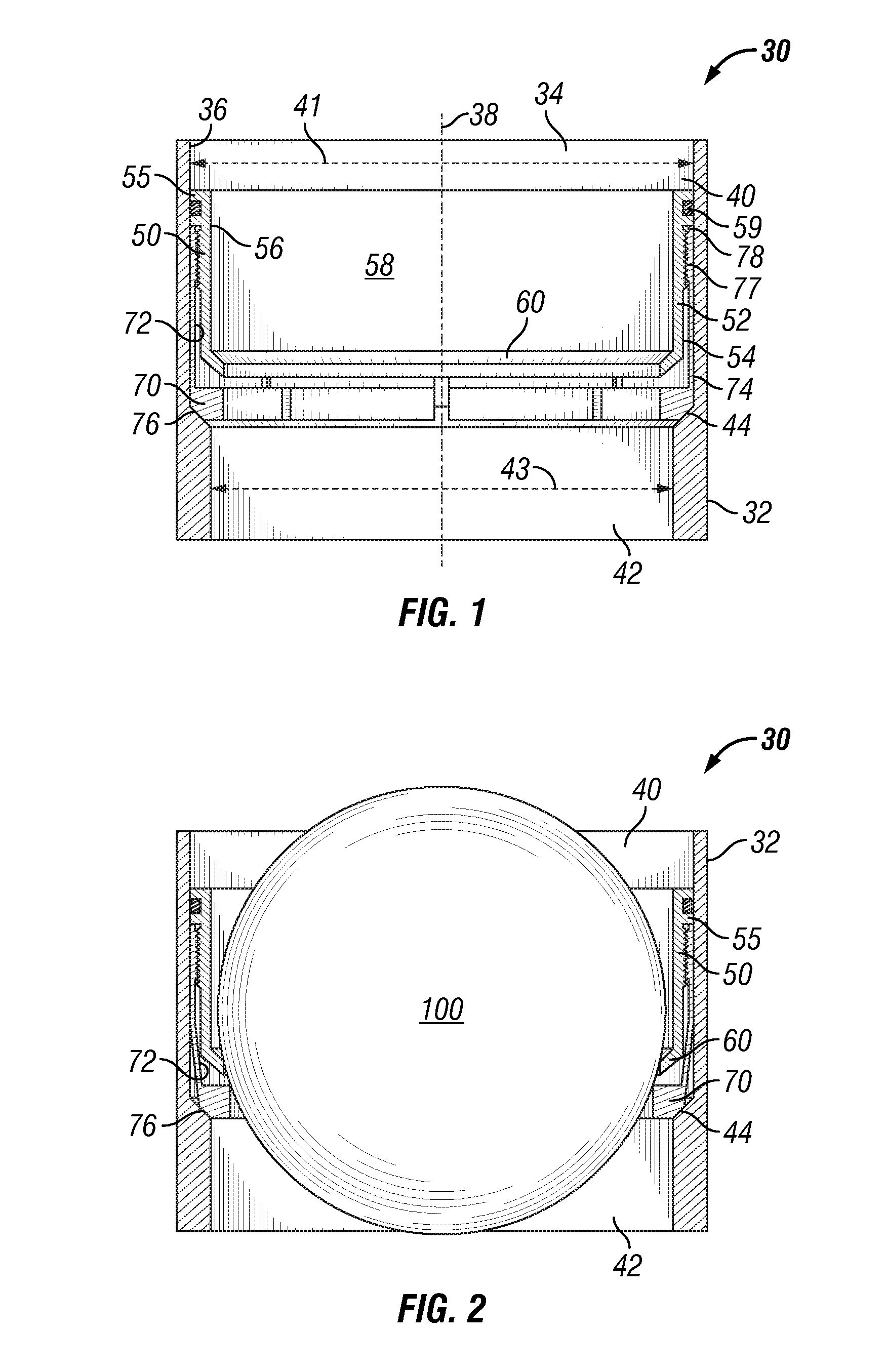

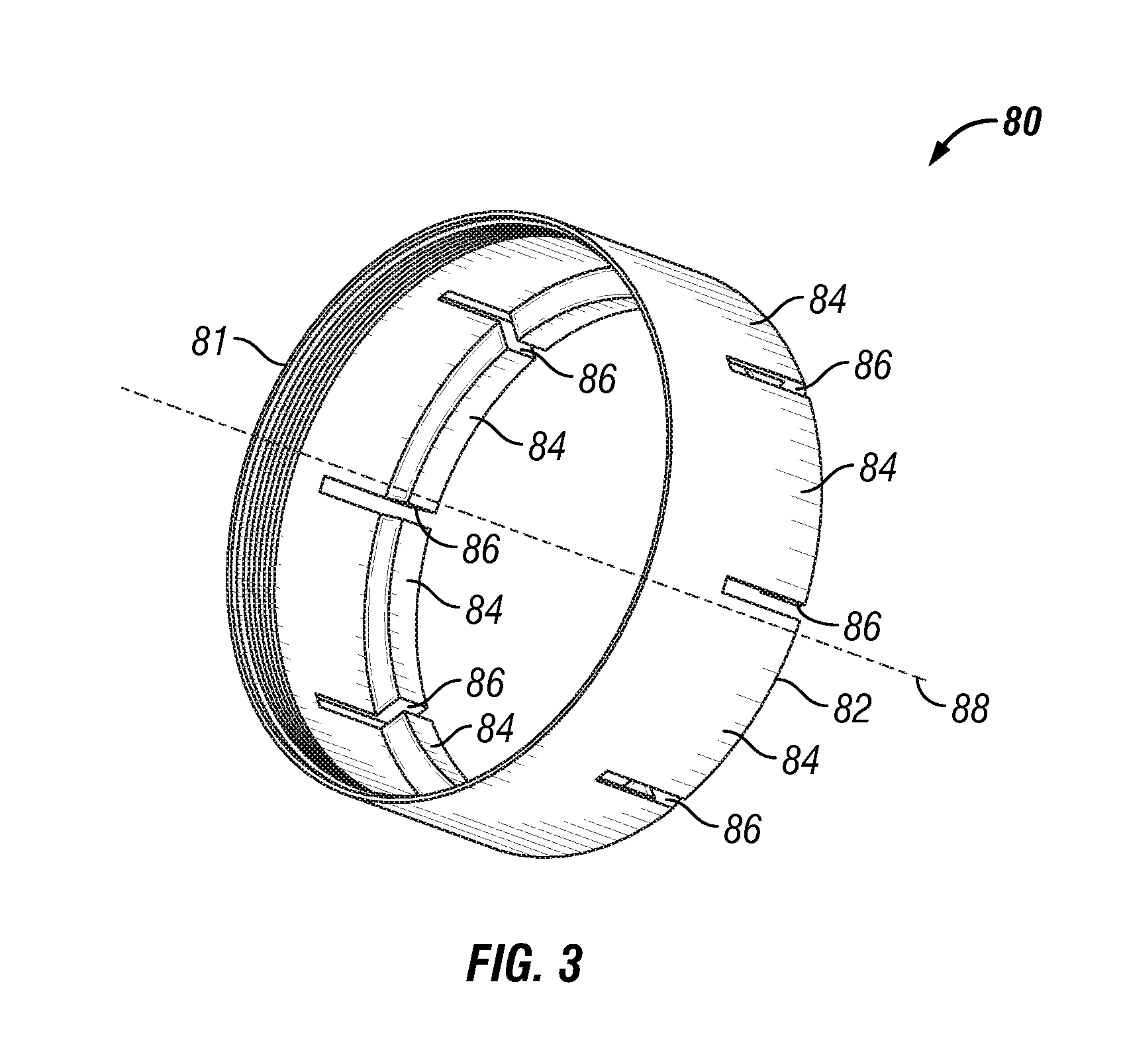

Ball seat having ball support member

ActiveUS20120261115A1Reduce the possibilityIncrease pressureFluid removalWell/borehole valve arrangementsEngineeringMechanical engineering

Apparatuses for restricting fluid flow through a well conduit comprise a tubular member having an inner wall surface defining a bore and a seat in sliding engagement with the inner wall surface. Operatively associated with the seat is a plug element support member having an expanded position when the apparatus is in a run-in position and a contracted position when the apparatus is in a set position. A plug element adapted to be disposed into the bore and landed on the seat to restrict fluid flow through the bore and the well conduit is used to move the seat which in turn moves the plug element support member from the expanded position to the contracted position, thereby providing support to the plug member landed on the seat.

Owner:BAKER HUGHES INC

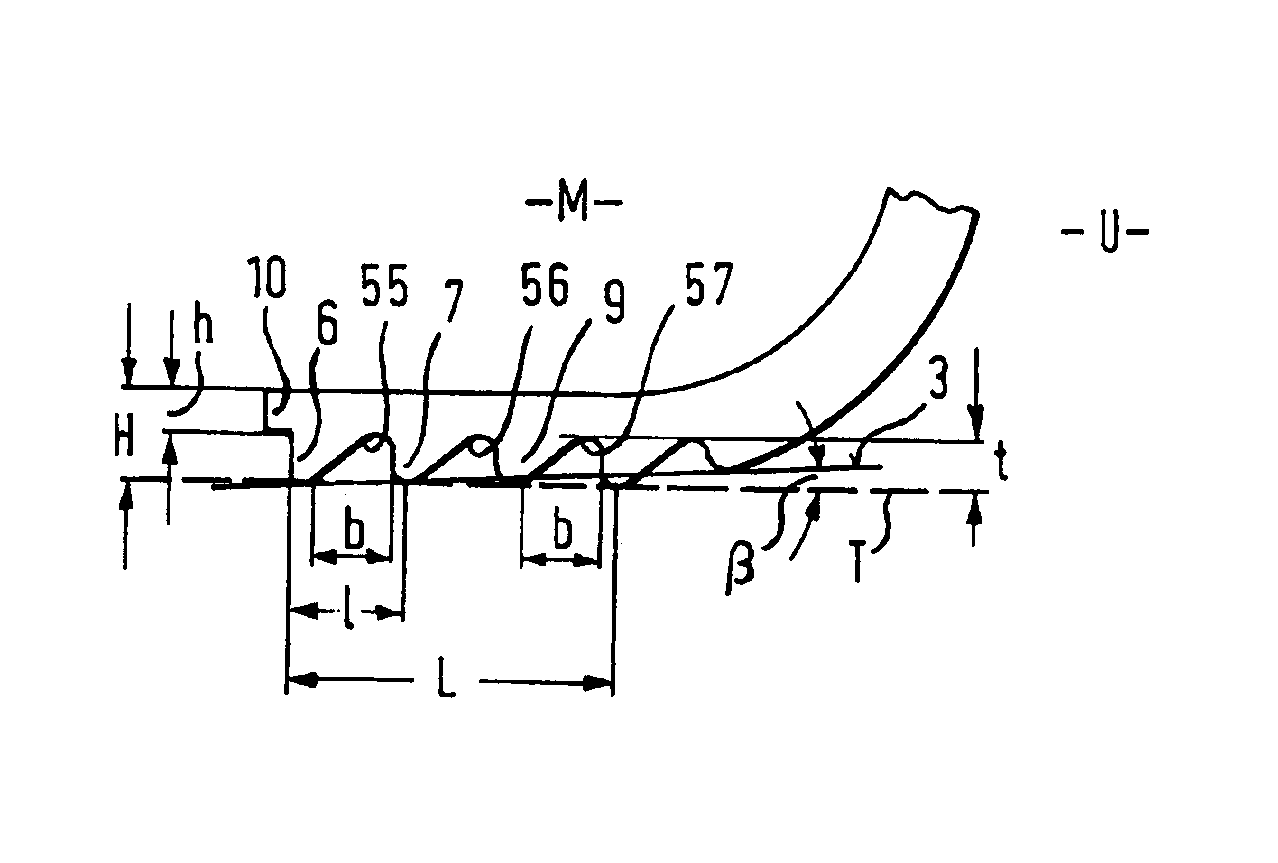

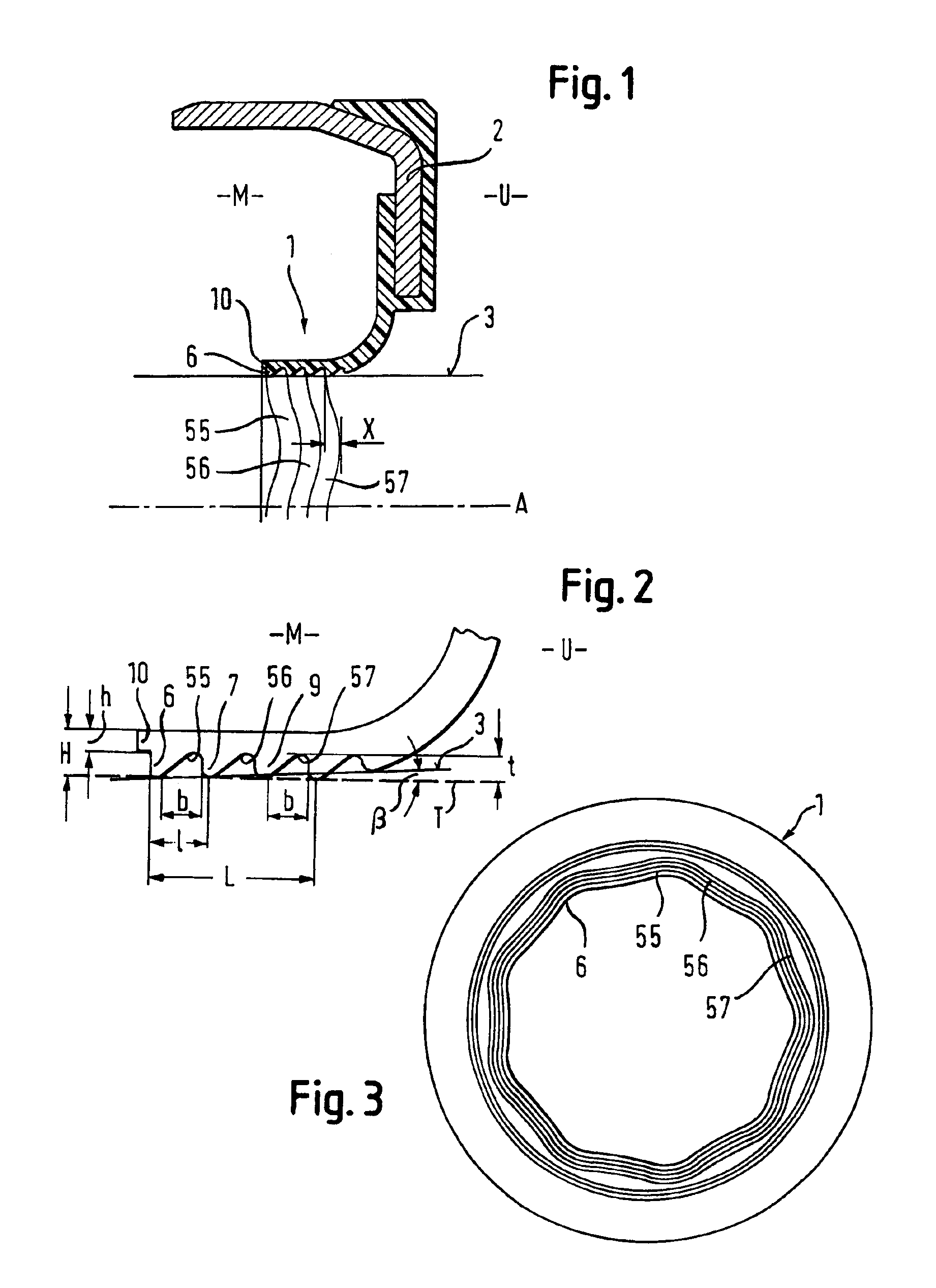

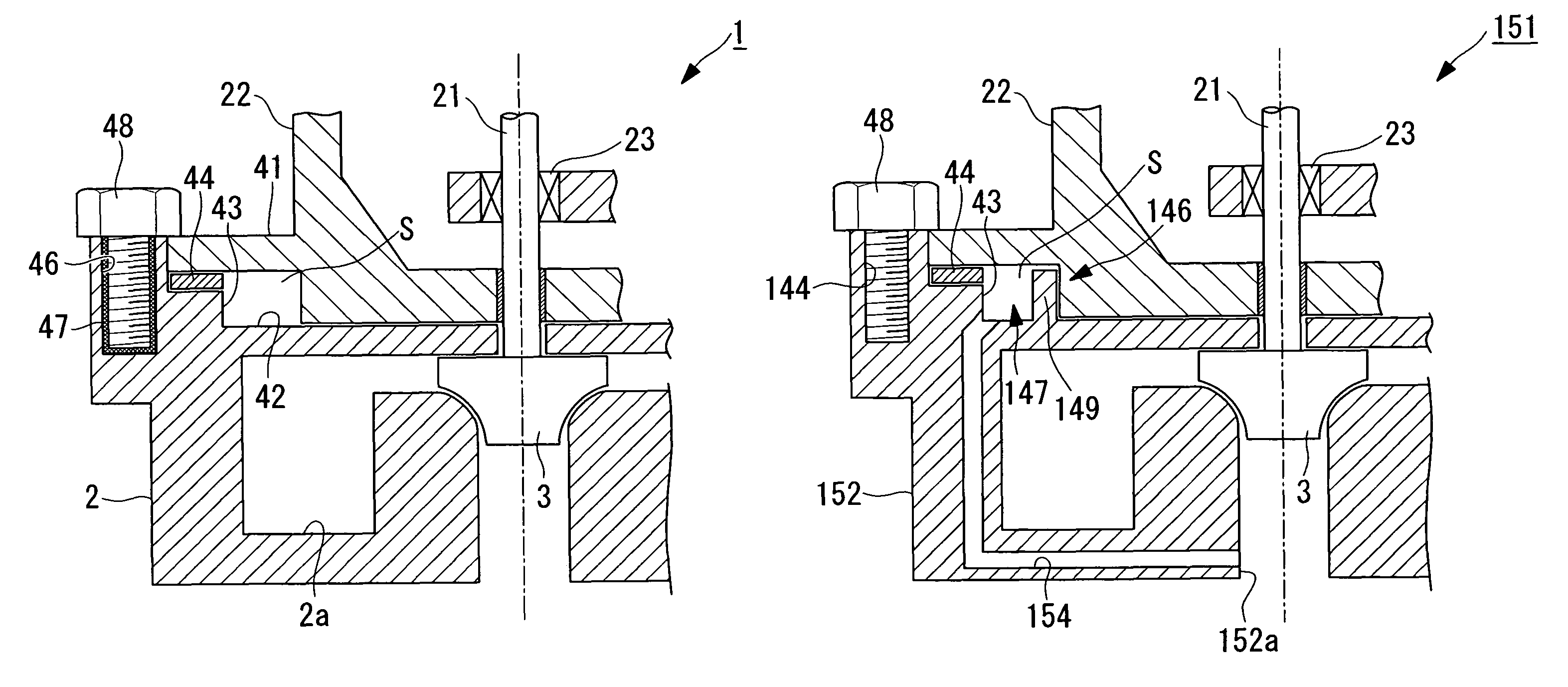

Shaft sealing ring

InactiveUS6860486B2Effective and reliable and dynamic sealingExtended service lifeEngine sealsDiagnostic recording/measuringContact pressureCoil spring

A shaft sealing ring for a shaft comprises a sealing lip made of an elastomeric material or a PTFE compound and dimensioned as to be flaccidly bendable. The flexural elasticity is selected such that it will just be sufficient to press a sealing portion of the sealing lip into sealing engagement with the periphery of the shaft. The sealing portion of the sealing lip engages the periphery for a predetermined length. In the sealing portion, the sealing lip is provided along its circumference, at the side of the shaft, with endless, undulating return channels at least throughout this length. These channels return any medium escaping during rotation of the shaft to the space to be sealed. The return channels do not communicate with the surroundings of the shaft sealing ring. No seperate contact pressure means, such as a helical ring coil spring is required to press the sealing lip into engagement with the shaft.

Owner:DICHTUNGSTECHN G BRUSS

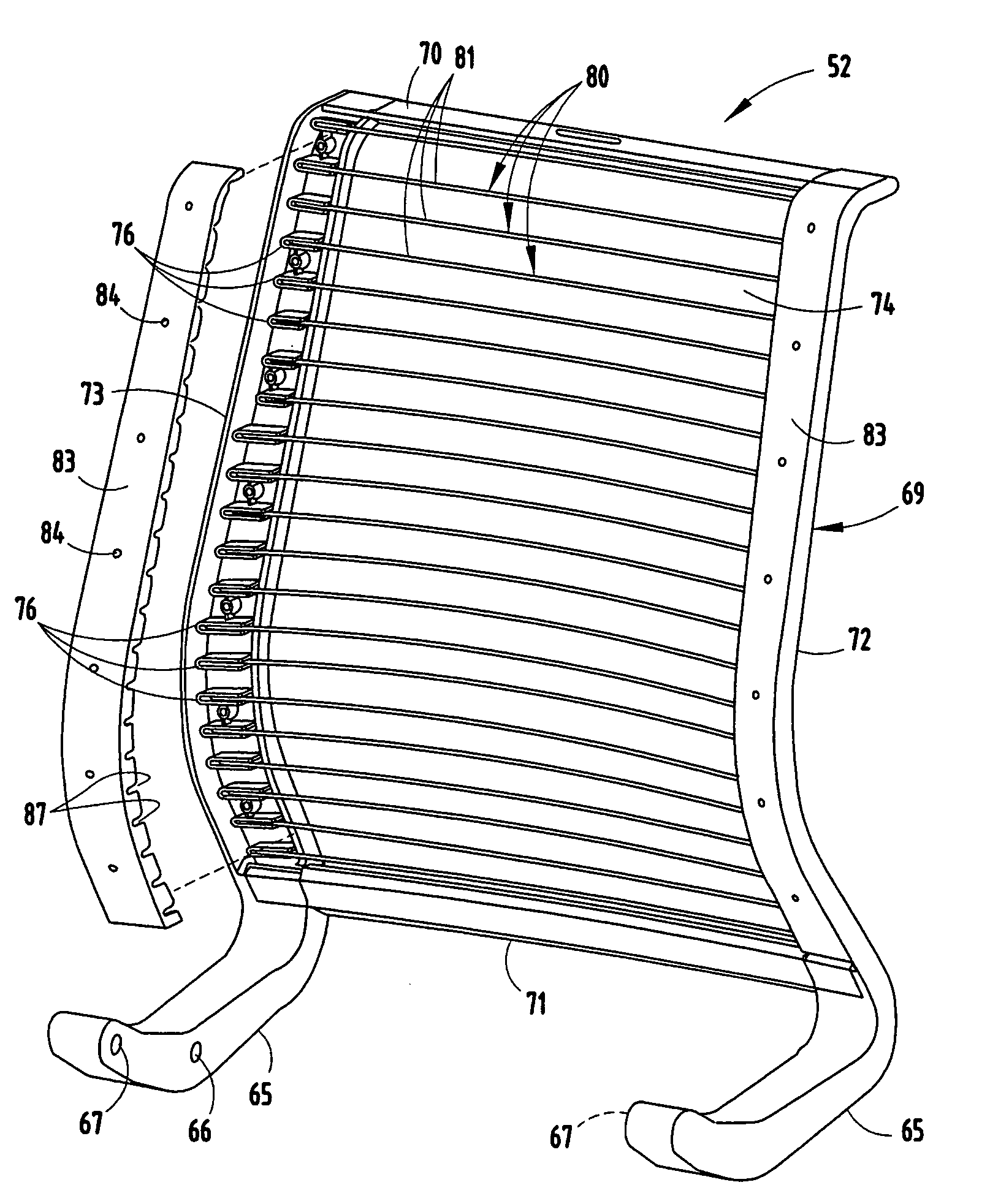

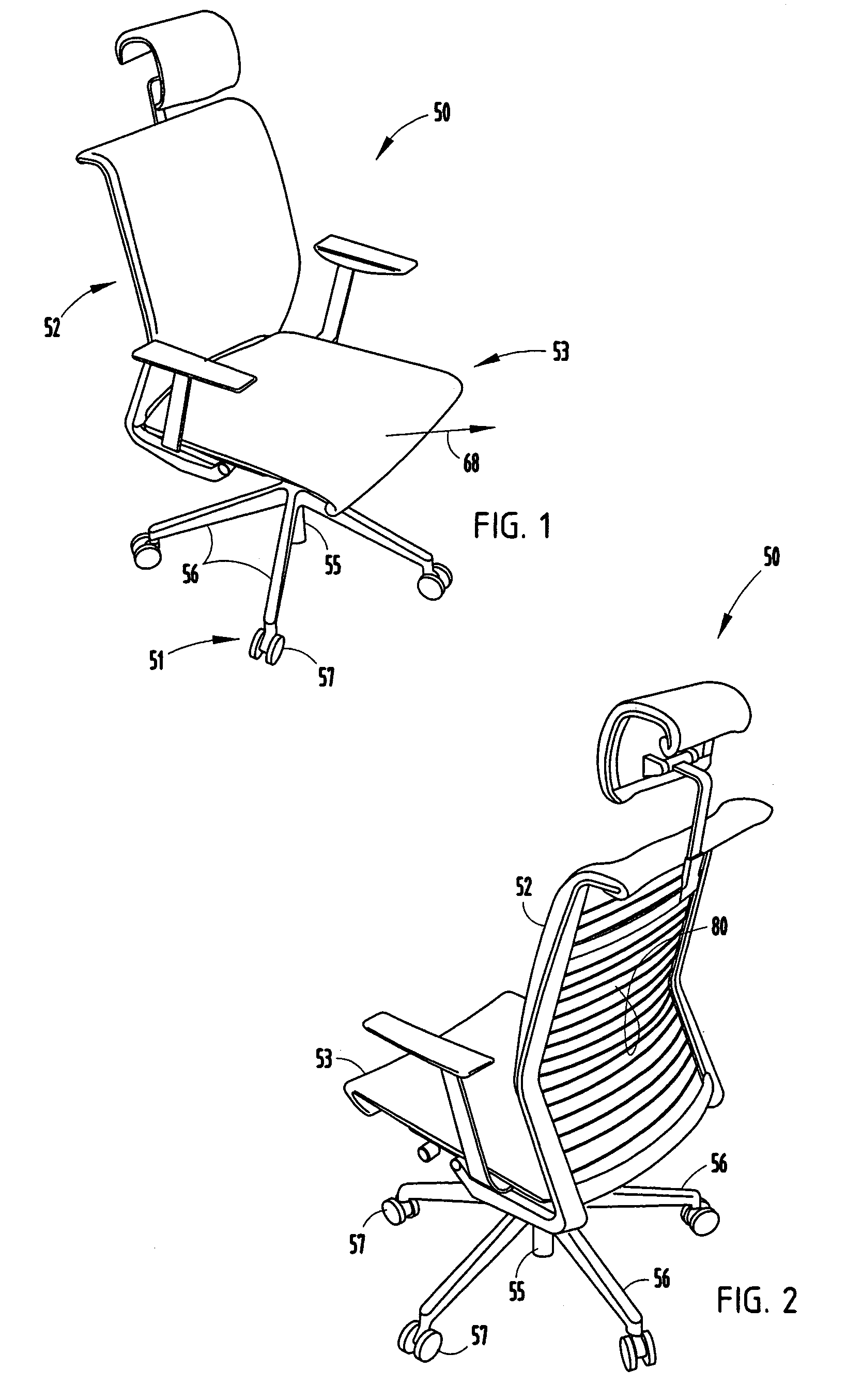

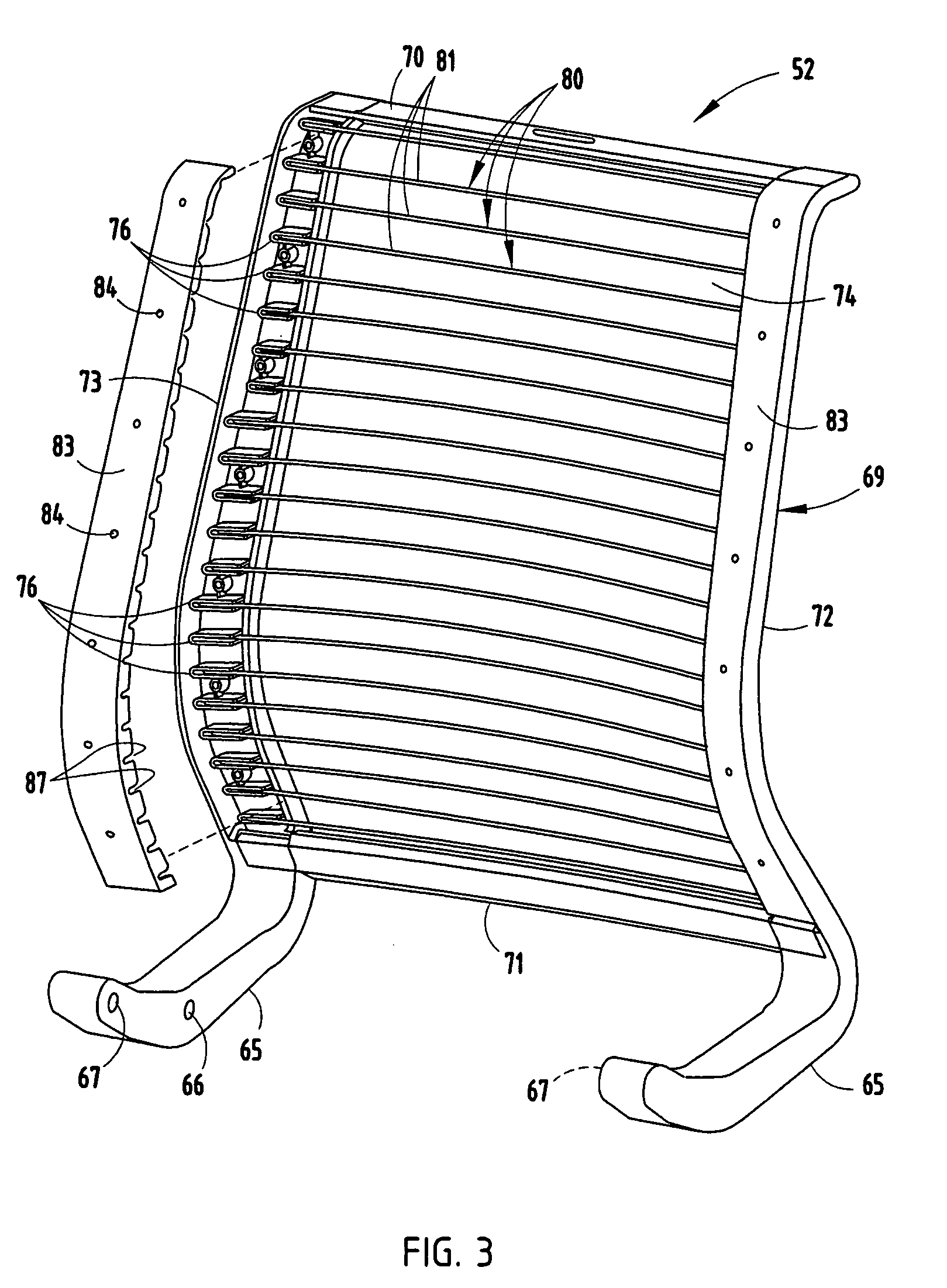

Comfort surface for seating

ActiveUS7334845B2Reduce localized deflection of seating surfaceReduce point contact pressureStoolsRocking chairsWire rodEngineering

A seating unit includes a perimeter frame, a flexible seating surface supported by the frame, and parallel elongated resilient force-distributing members coupled to the seating surface to control a contour of the seating surface when supporting a seated user. The resilient force-distributing members are bendable along their length and are sufficient in number and distribution to substantially reduce localized deflection of the seating surface and thereby reduce pressure point contact felt by the seated user. The resilient force-distributing members can be wire rods, long strips, or other resilient material with memory. The resilient force-distributing members can be supported on opposing sides of the perimeter frame in various ways to reduce inward pressure on the opposing sides during flexure of the resilient force-distributing members, such as by providing on ends of the resilient force-distributing members one or more rotatable pivots, sliding support at ends of the resilient force-distributing members, stretchable rubber supports, and / or elastic fabric.

Owner:STEELCASE INC

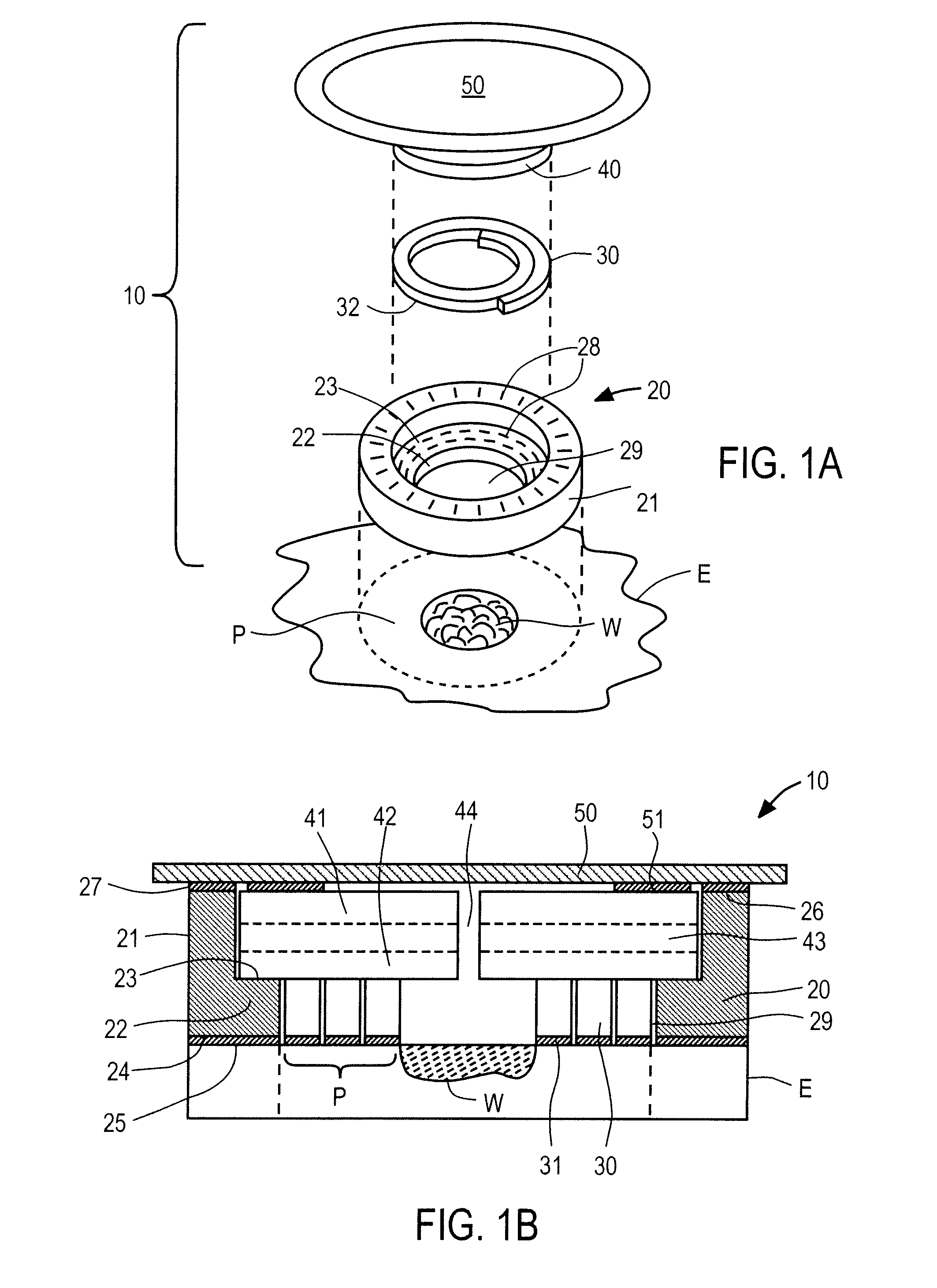

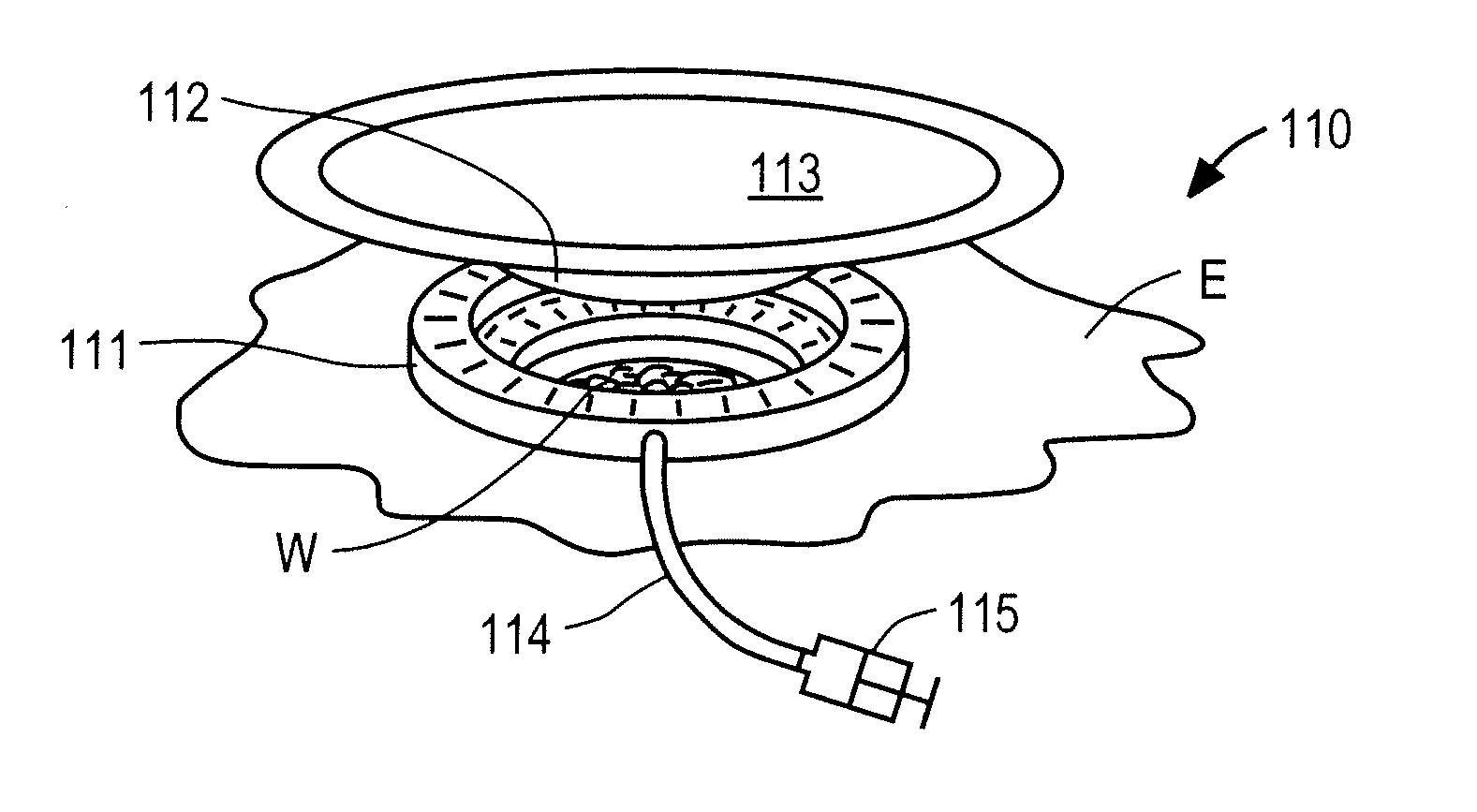

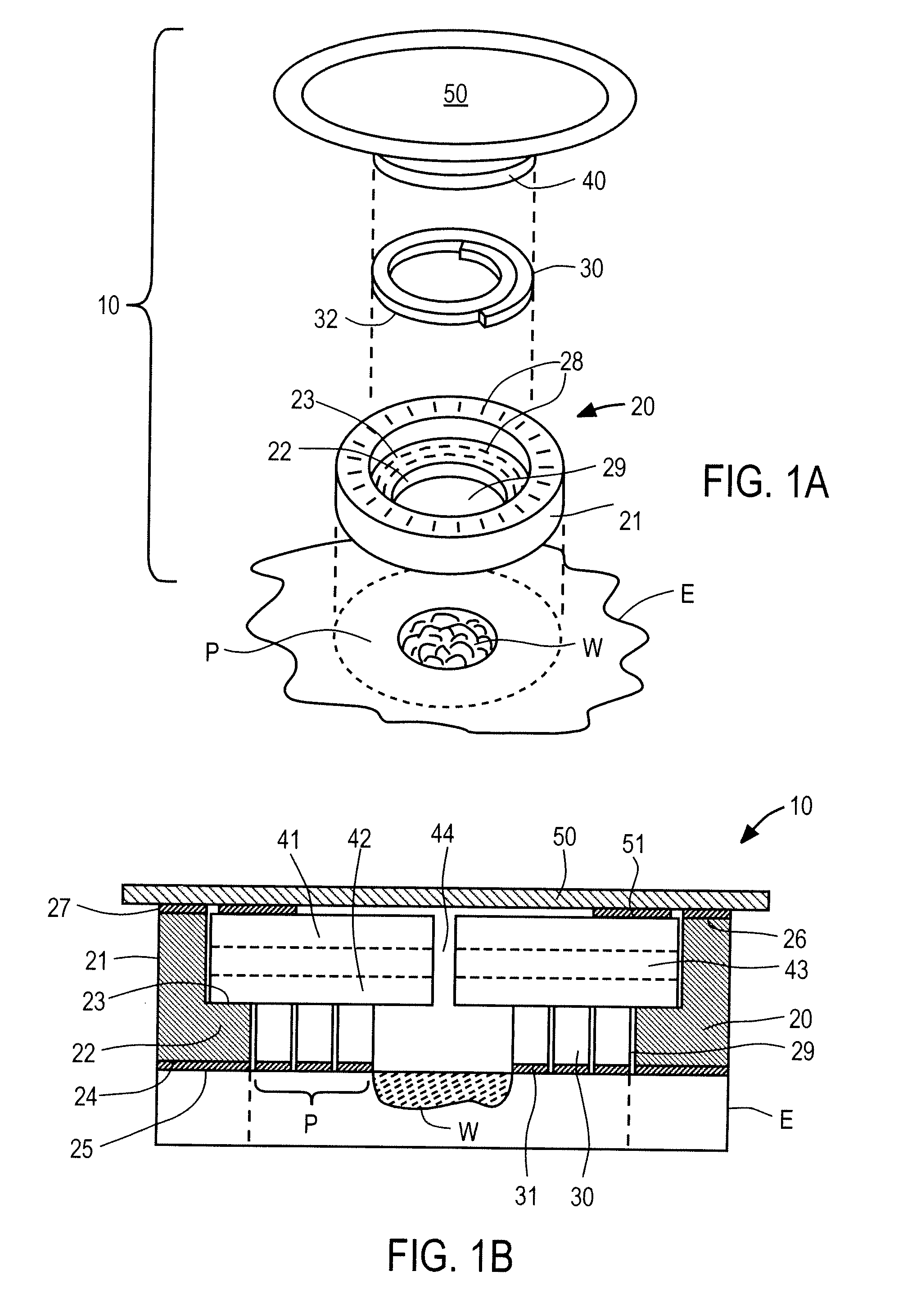

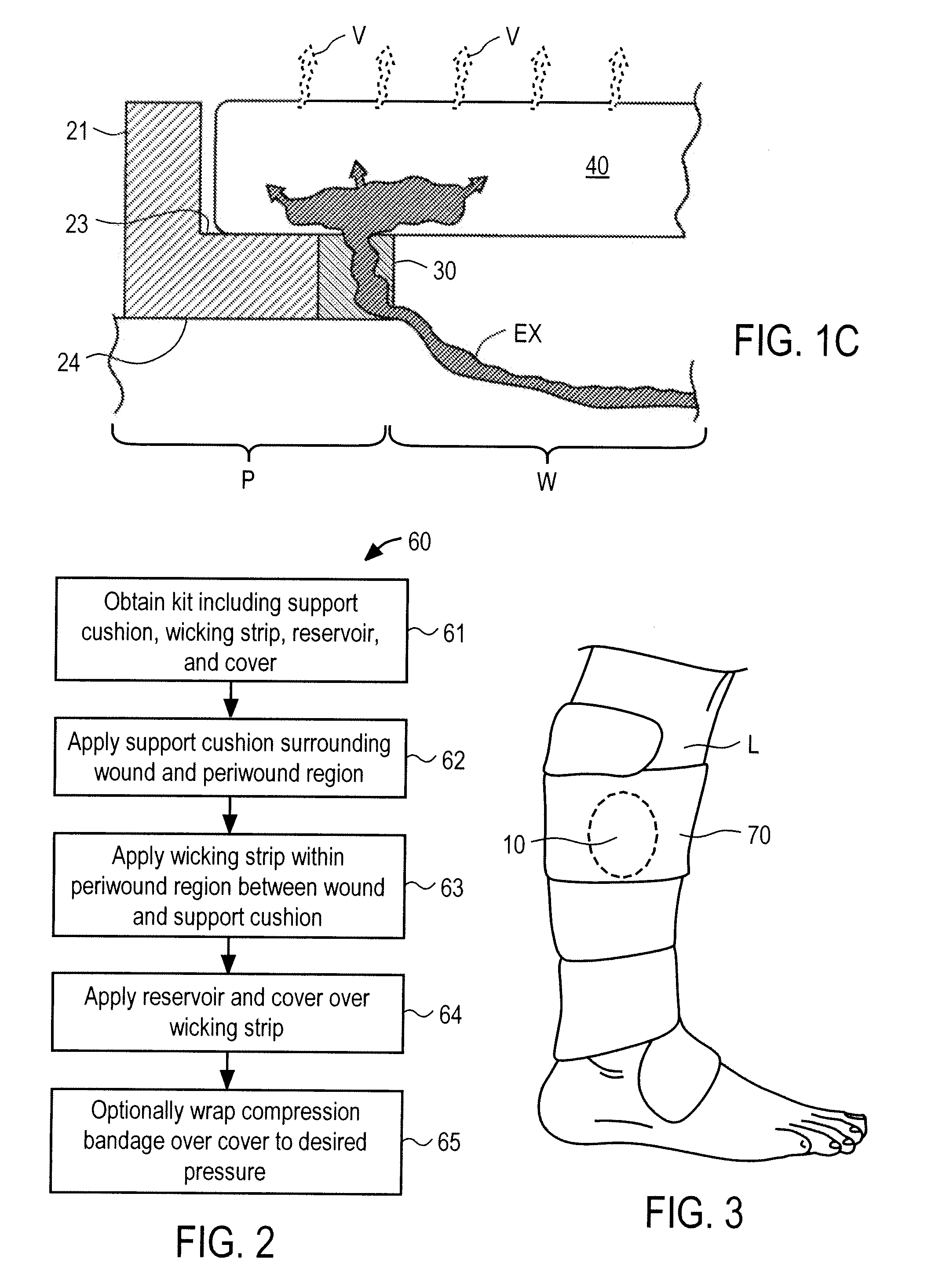

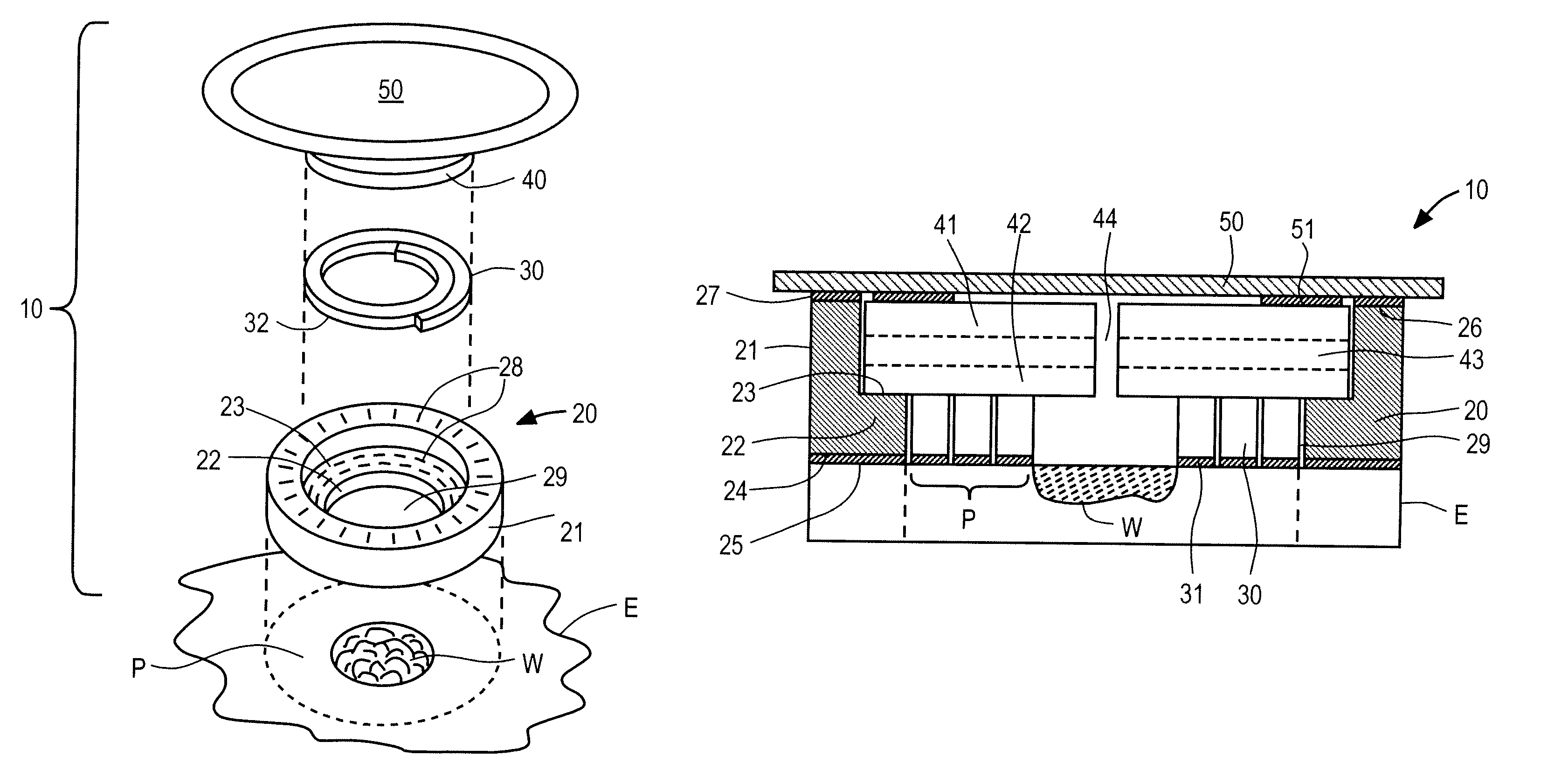

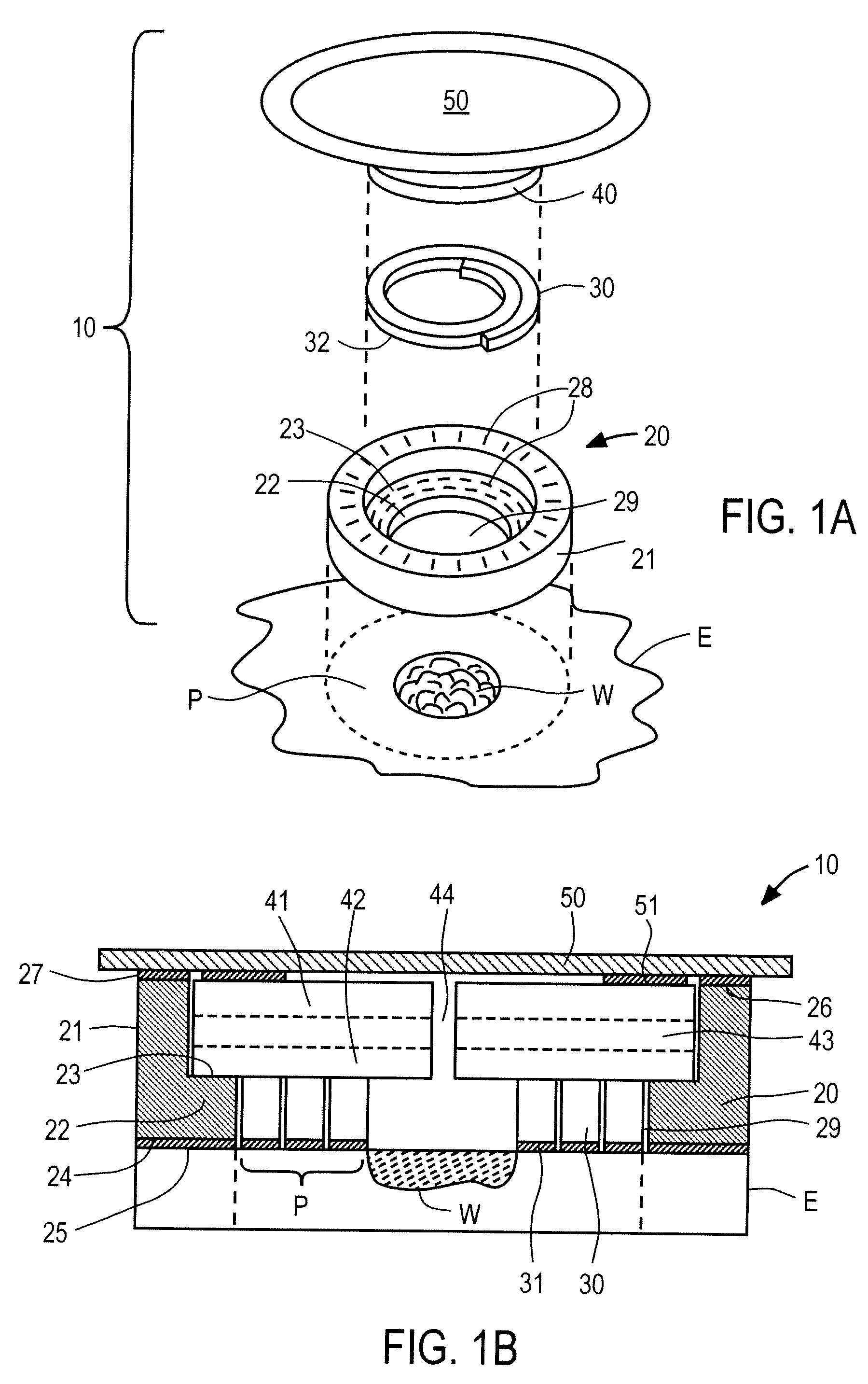

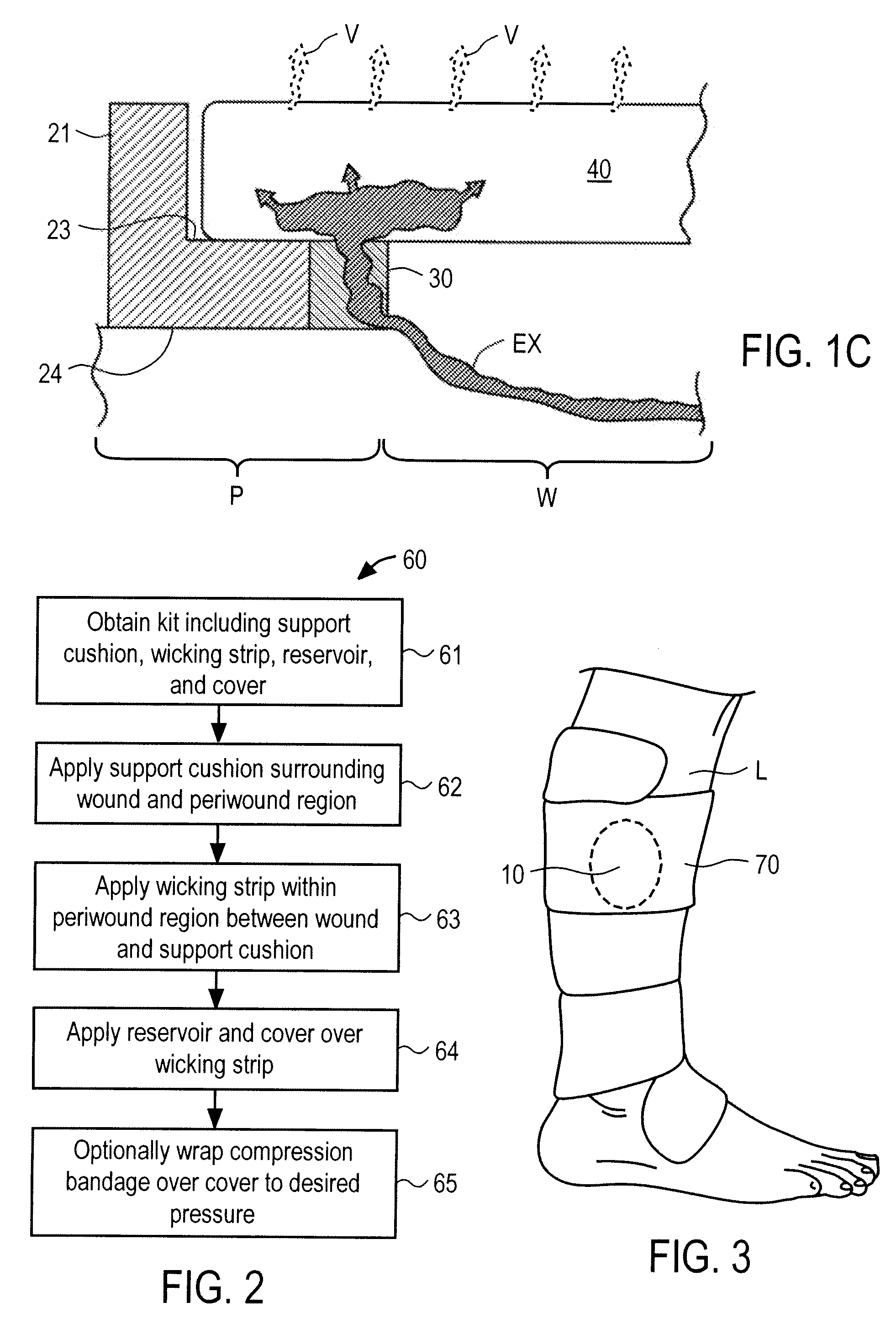

Systems And Methods For Wound Protection And Exudate Management

InactiveUS20100256545A1Protect the incisionReduce contact pressureWound drainsPlastersCustom-fitCushion

The present invention provides systems and methods for protecting a wound and managing exudate released from the wound comprising a dressing having a support cushion for surrounding the wound and periwound region; a wicking strip for application in the periwound region between the support cushion and the wound; and a reservoir for application over the wicking strip, the wicking strip configured to transfer exudate from the wound to the reservoir, where the exudate is sequestered. Various alternative embodiments are described in which the wicking strip may be custom-fit to approximate an irregular wound margin, to apply a preferred pressure gradient to the periwound regions, to periodically apply fluids to the wound bed or to apply negative pressure wound therapy. Methods of applying the dressing also are provided.

Owner:AALNEX

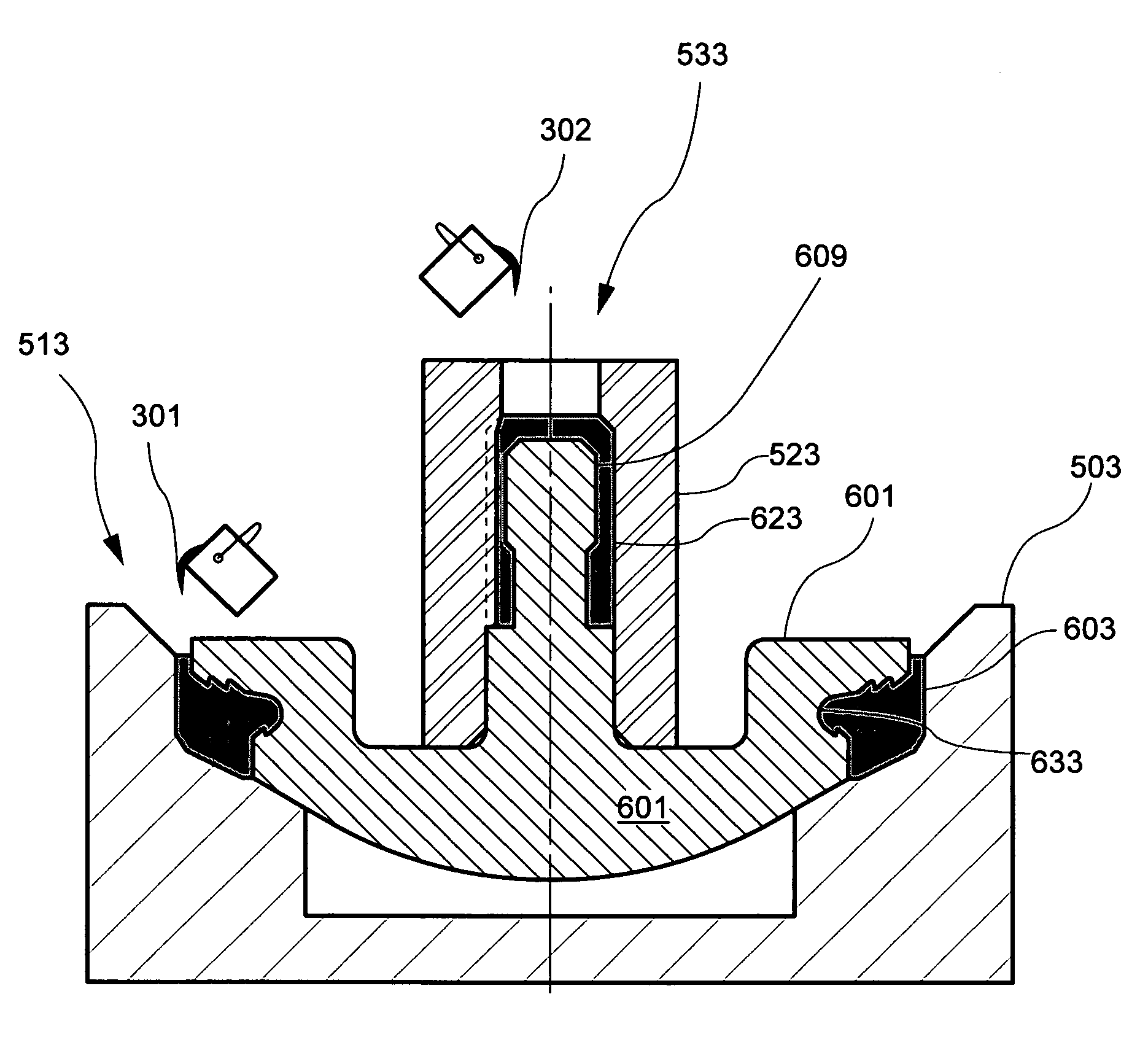

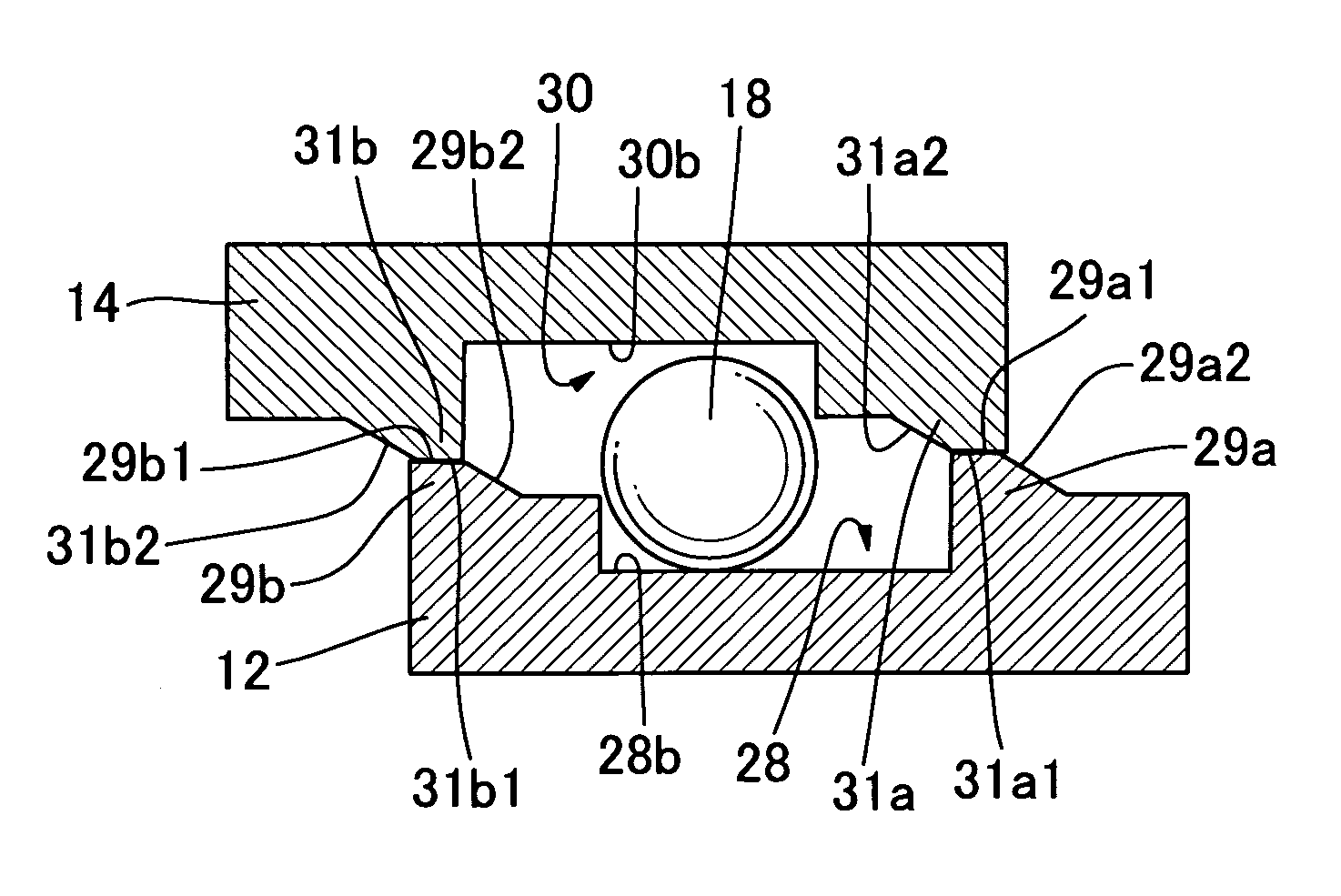

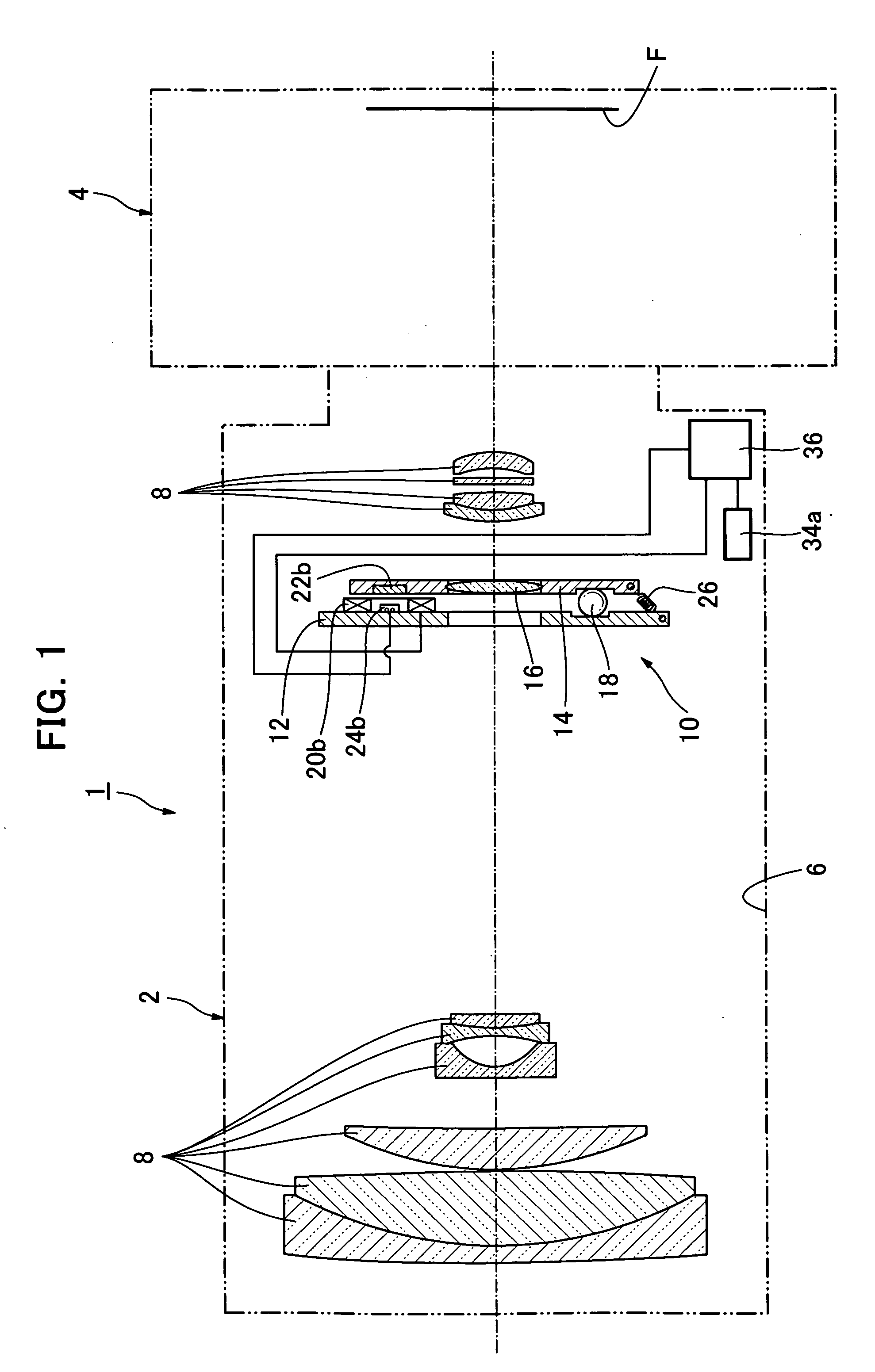

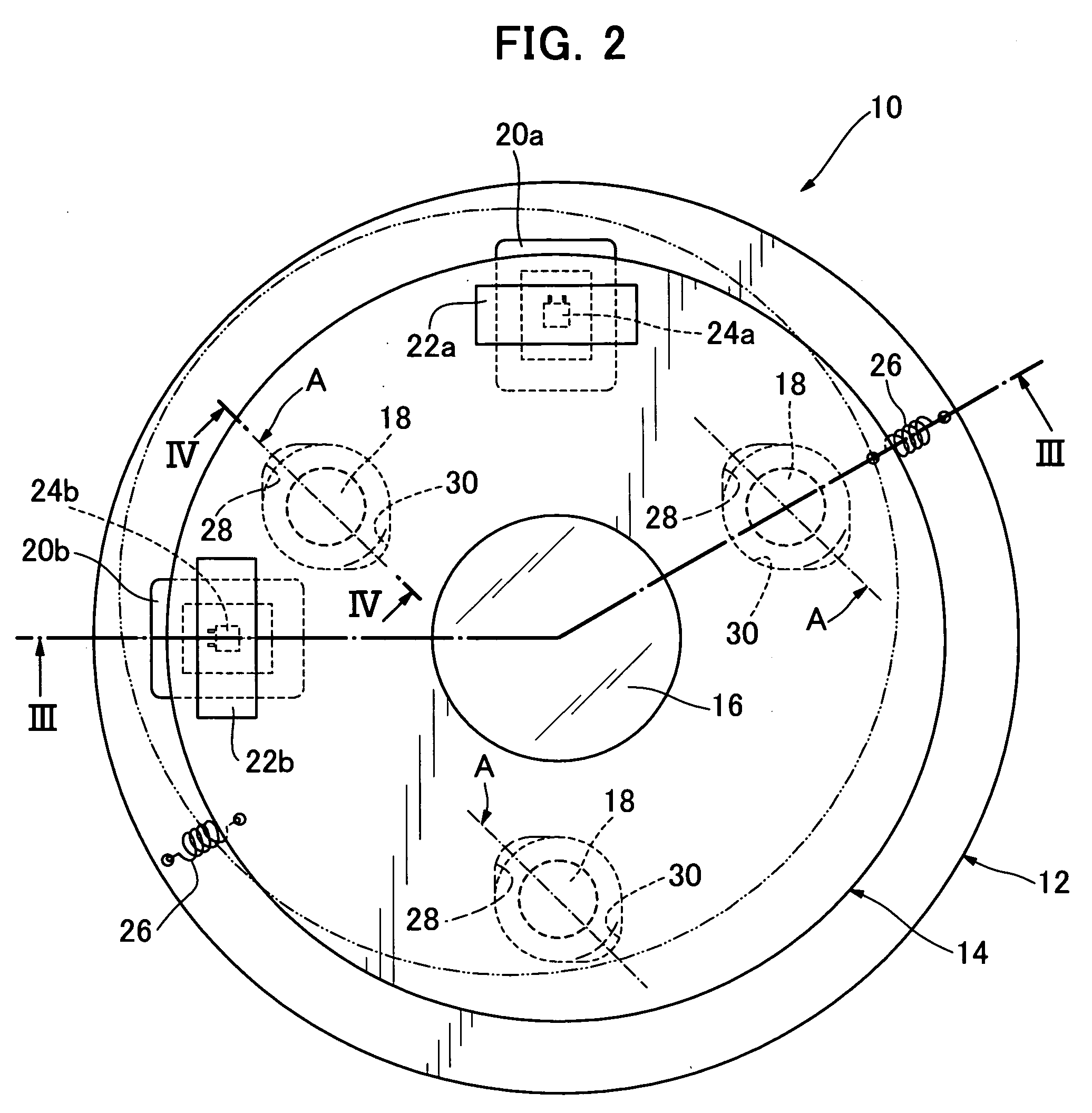

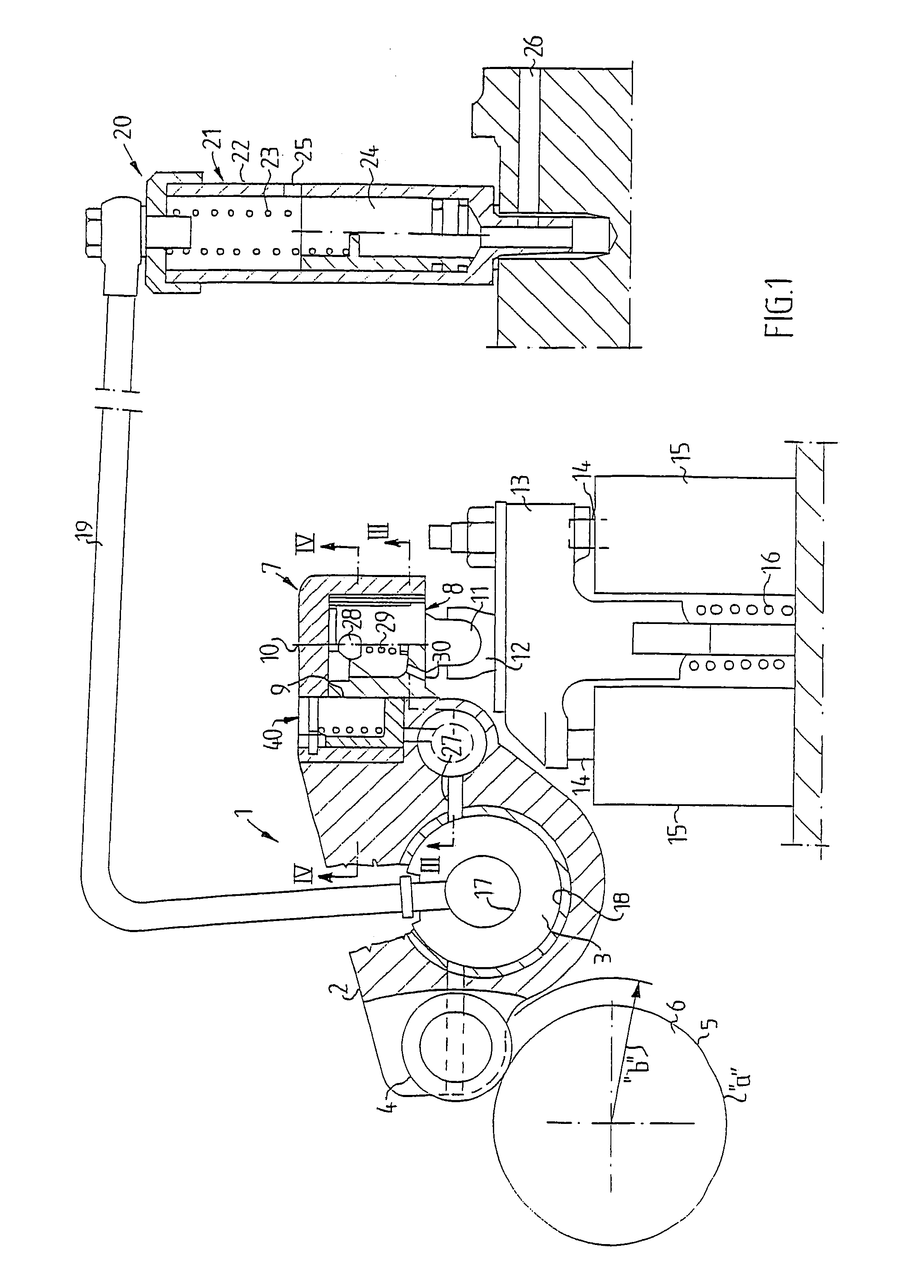

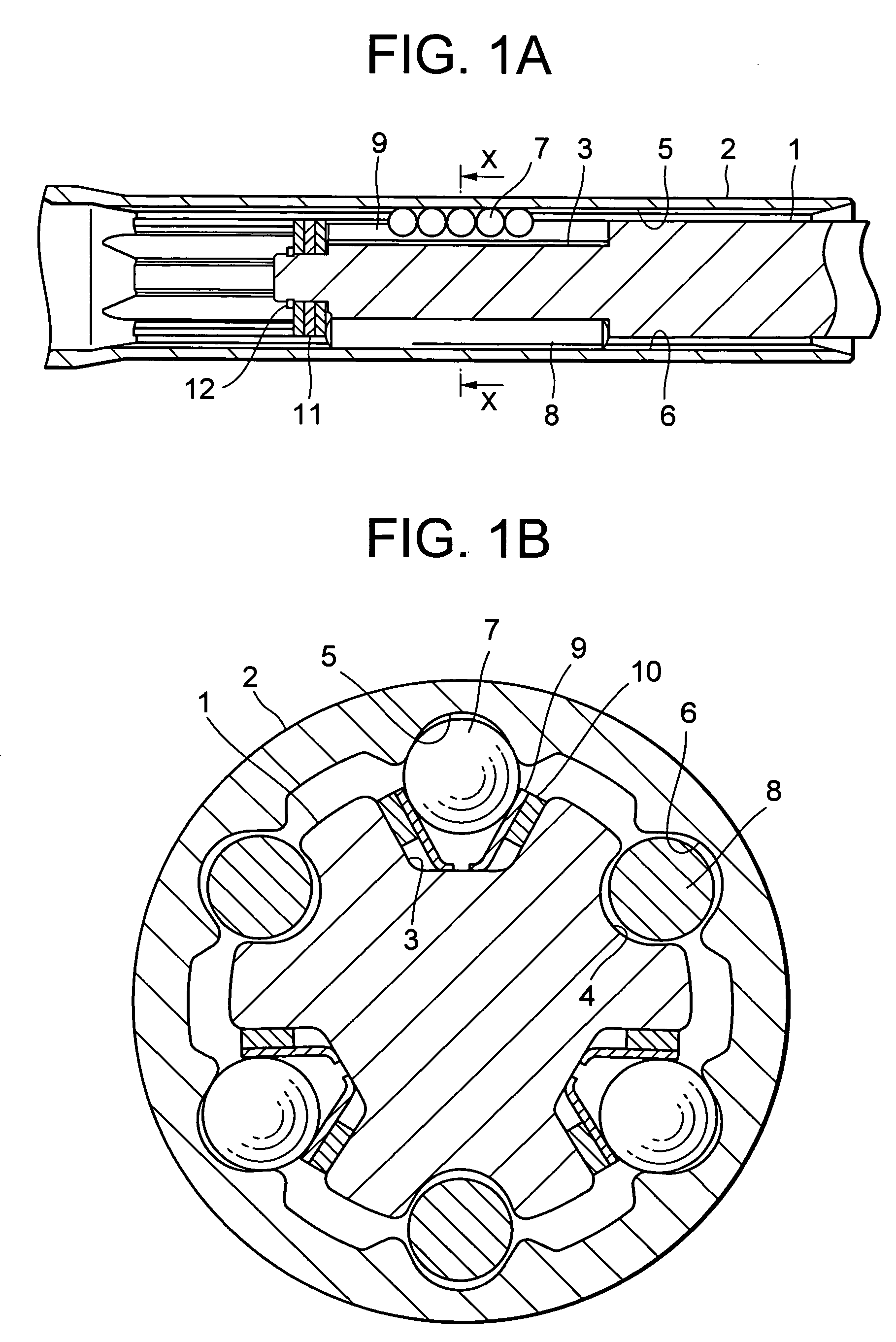

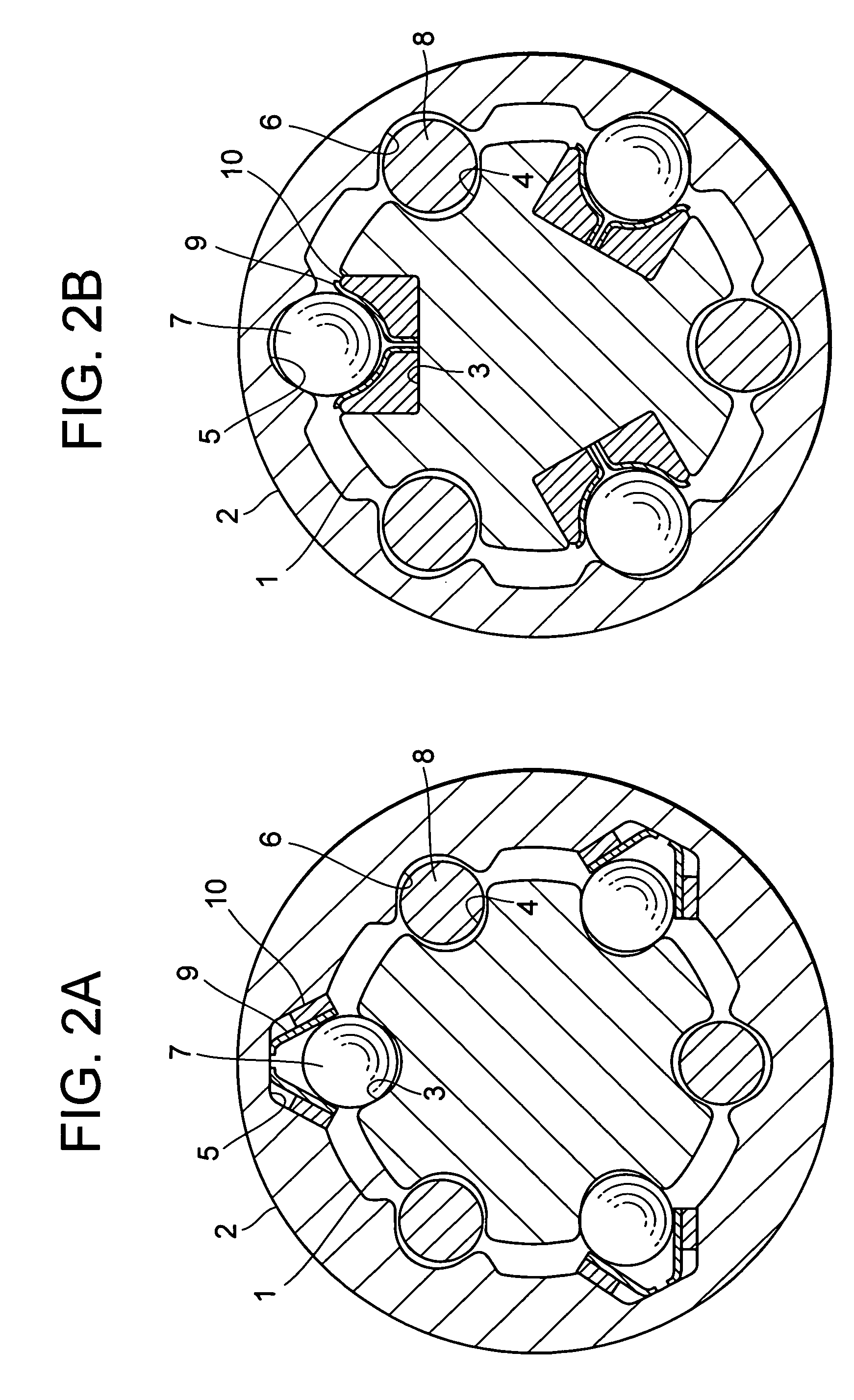

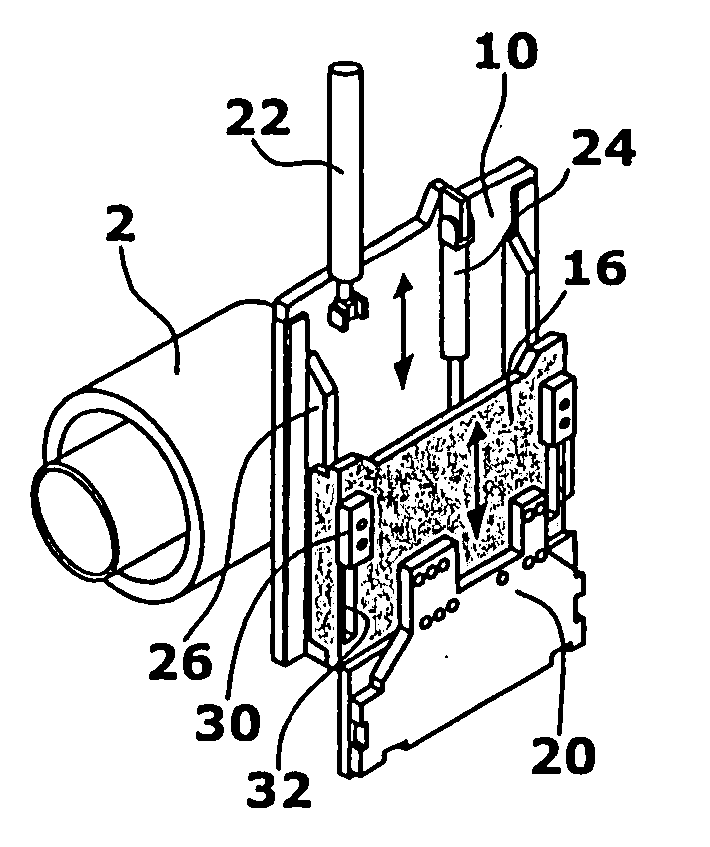

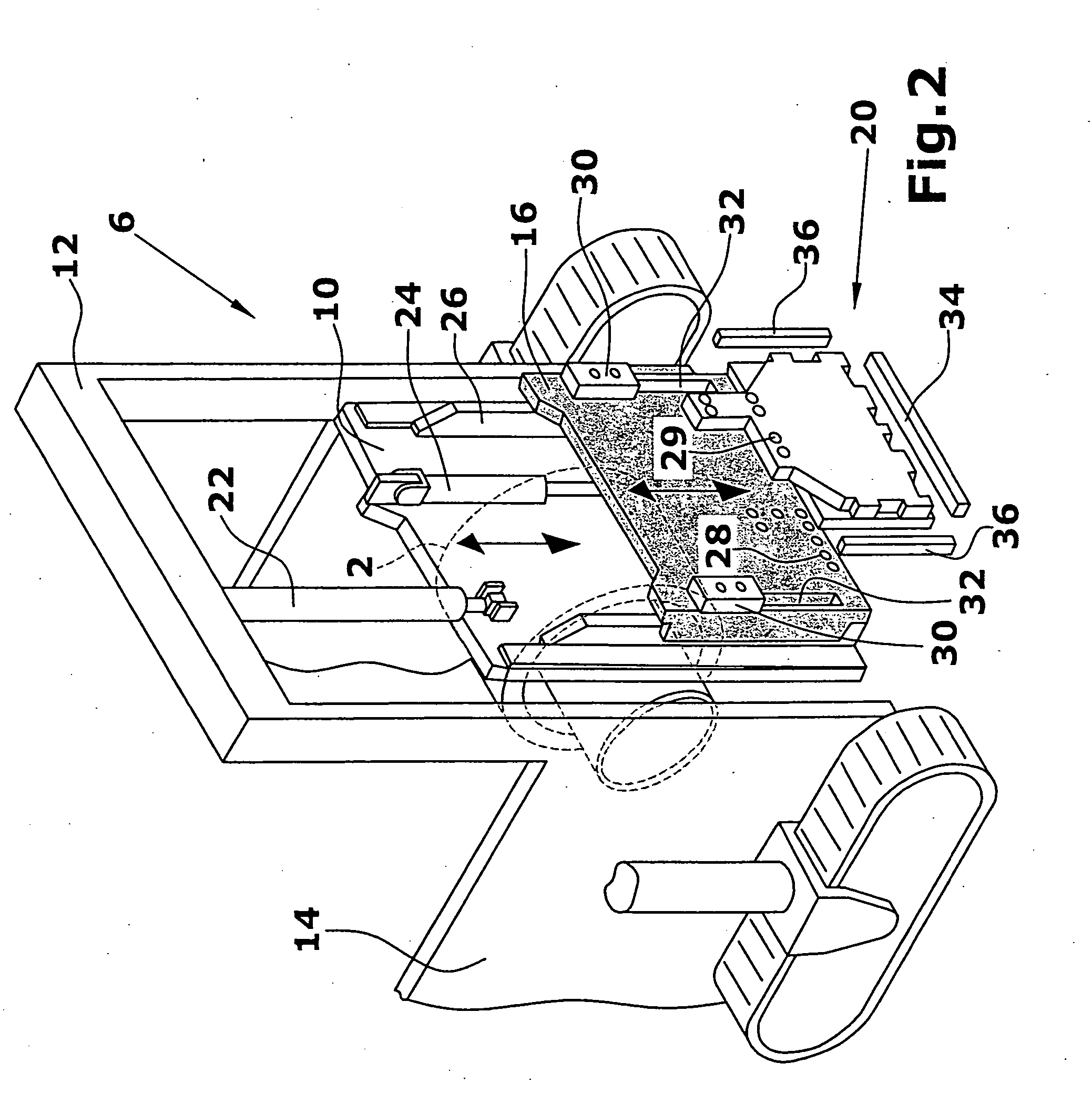

Image stabilizing actuator and camera furnished therewith

Problem: To provide an actuator capable of preventing damage to spherical bodies and their receiving surfaces when subjected to a shock force.Solution Means: The present invention is an actuator (10) for stabilizing images by moving an imaging lens, comprising a fixed portion (12), a movable portion (14) to which an imaging lens is attached, a plurality of spherical bodies (18) for supporting the movable portion, a fixed portion spherical body receiving surface (28b) disposed on the fixed portion and contacting the spherical bodies, a movable portion spherical body receiving surface (30b) disposed on the movable portion and contacting the spherical bodies, a biasing means (26) for sandwiching the spherical bodies between the fixed portion spherical body receiving surface and the movable portion spherical body receiving surface, and spherical body receiving surface protection means (29, 30) which, when image stabilization control is not in effect, reduce the contact pressure acting on the spherical bodies so as to sandwich the spherical bodies when the movable portion is moved to a predetermined protected position.

Owner:TAMRON

Systems and methods for wound protection and exudate management

InactiveUS8067662B2Reduce contact pressureAvoid injuryPlastersAdhesive dressingsWound marginBiomedical engineering

The present invention provides systems and methods for protecting a wound and managing exudate released from the wound comprising a dressing having a support cushion for surrounding the wound and periwound region; a wicking strip for application in the periwound region between the support cushion and the wound; and a reservoir for application over the wicking strip, the wicking strip configured to transfer exudate from the wound to the reservoir, where the exudate is sequestered. Various alternative embodiments are described in which the wicking strip may be custom-fit to approximate an irregular wound margin, to apply a preferred pressure gradient to the periwound regions, to periodically apply fluids to the wound bed or to apply negative pressure wound therapy. Methods of applying the dressing also are provided.

Owner:AALNEX

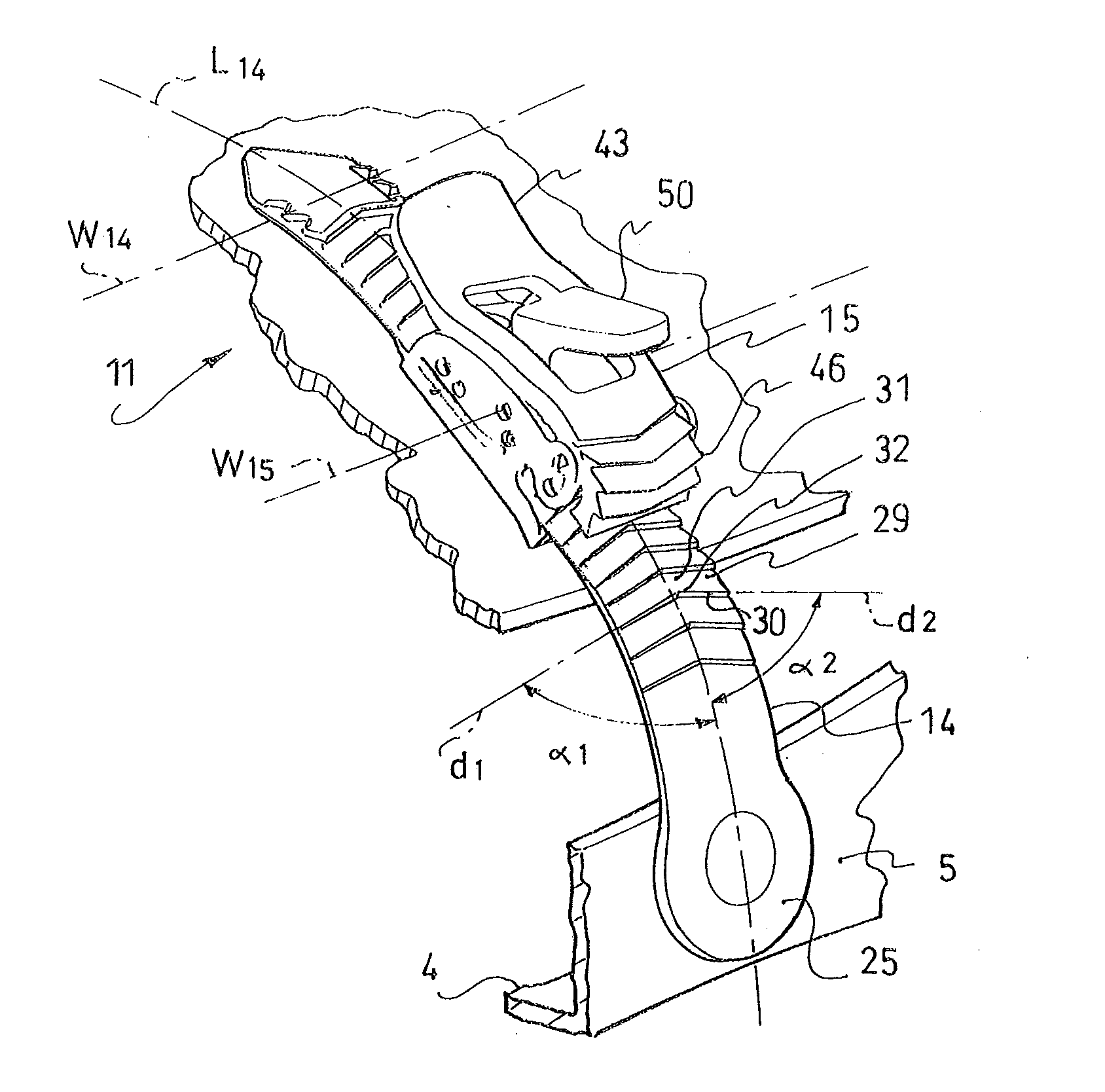

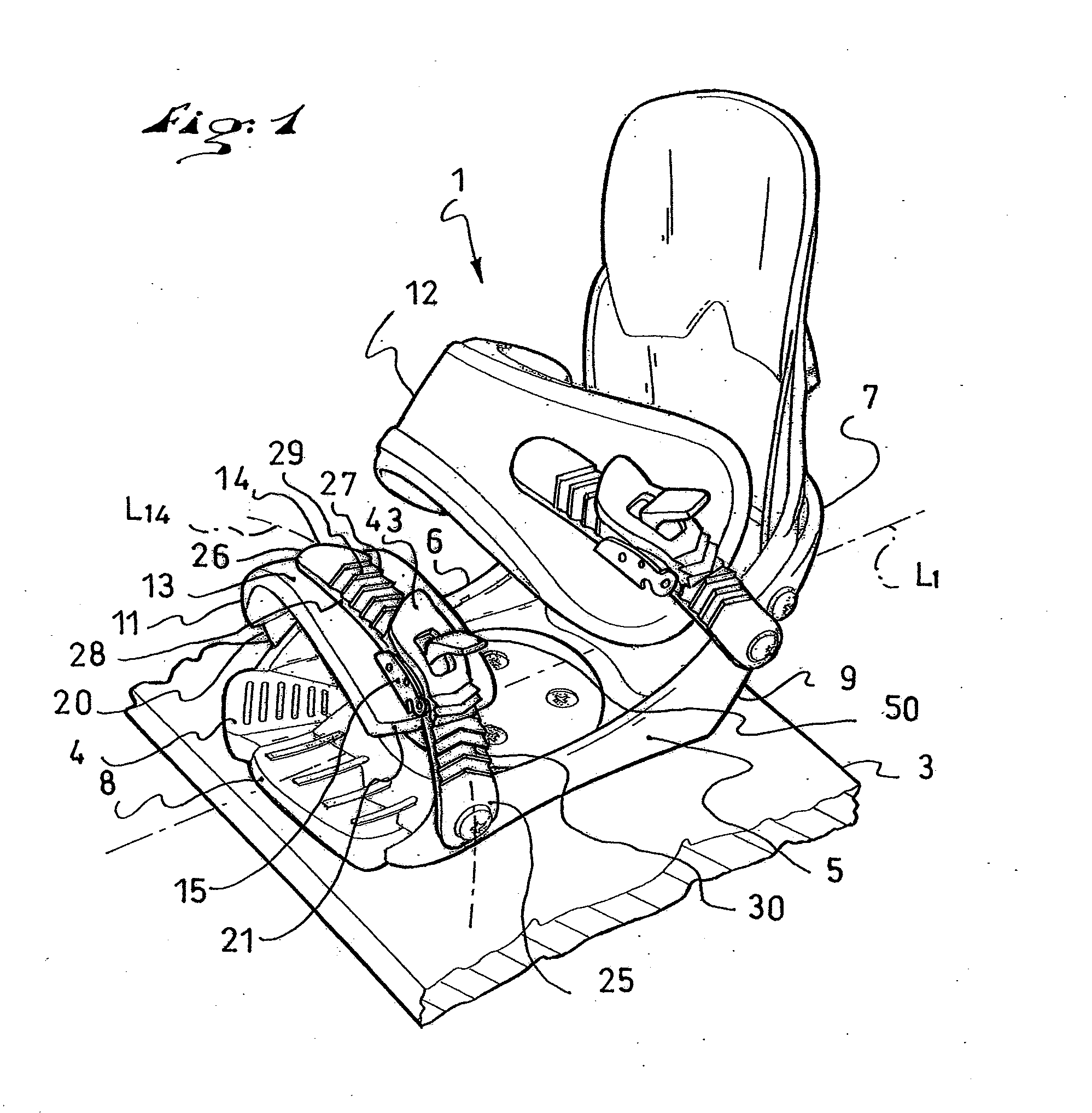

Assembly including a ratchet device and a tightening strap

InactiveUS20100162539A1Reduce wearImproves tighten efficiencySnap fastenersSki bindingsEngineeringSerration

An assembly including a ratchet tightening device and a band. The device includes a base, a driving lever, and a pawl. For at least one tooth of a series of serrations of the band, at least one straight line tangent to the meshing surface of the tooth and parallel to the band, forms, together with the longitudinal direction of the band, an angle that is less than 90 degrees. A driving end of the lever is configured to cooperate with the serrations of the band. A retaining zone of the pawl is configured to cooperate with the serrations of the band.

Owner:SALOMON SA

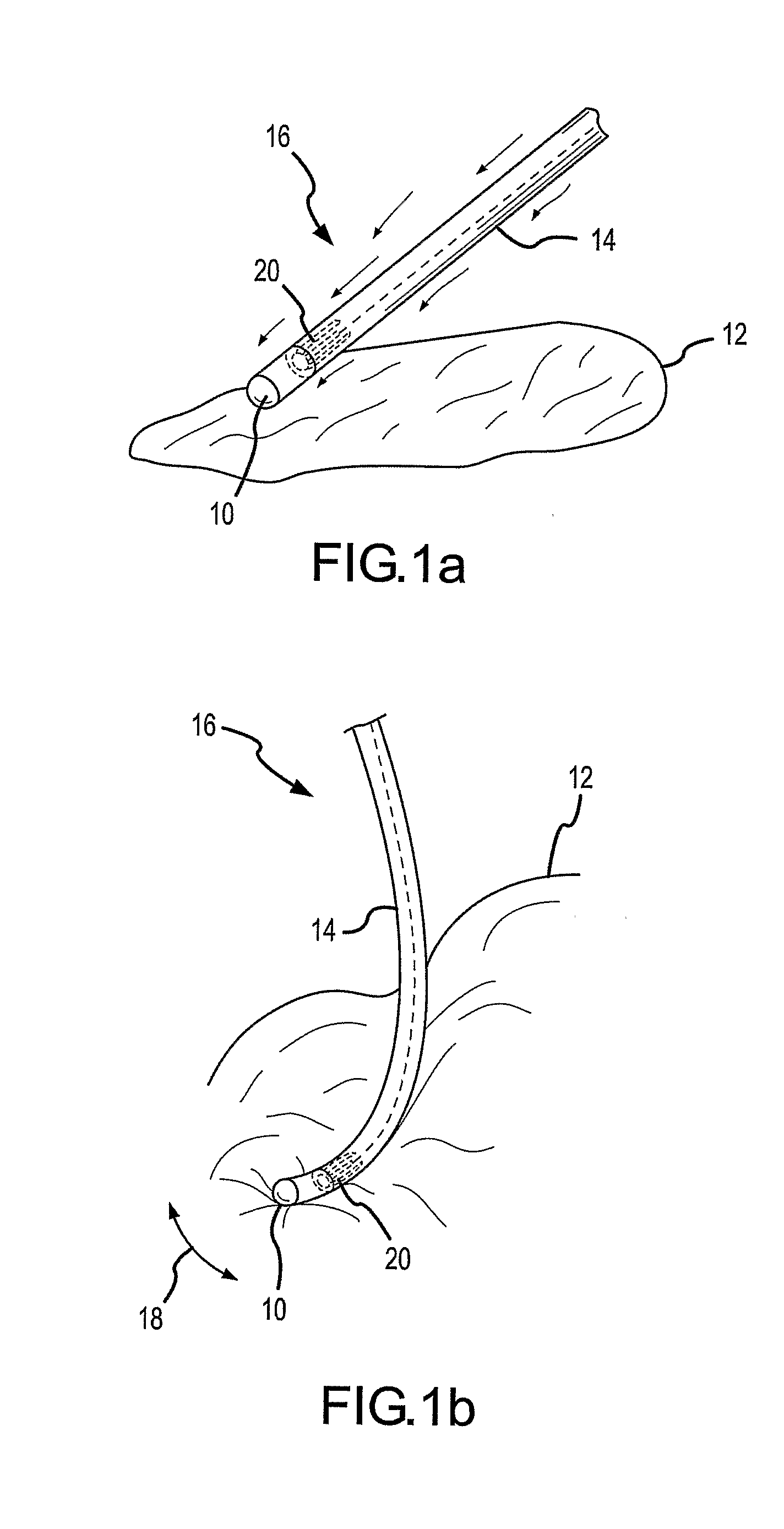

Dynamic contact assessment for electrode catheters

ActiveUS8679109B2Increase contact pressureReduce contact pressureSurgical instrument detailsDiagnostic recording/measuringElectricityOutput device

An electrode catheter and a method for assessing catheter-tissue contact for tissue ablation are disclosed. An exemplary electrode catheter comprises a flexible catheter shaft. At least one piezoelectric sensor is oriented coaxial to the flexible catheter shaft. The at least one piezoelectric sensor is responsive to movement of the flexible catheter shaft by generating electrical signals corresponding to the amount of movement. The system may also include an output device electrically connected to the at least one piezoelectric sensor. The output device receives the electrical signals for dynamically assessing a level of contact between the flexible catheter shaft and a moving tissue. In another exemplary embodiment, the system may be implemented in a hydrodynamic environment.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

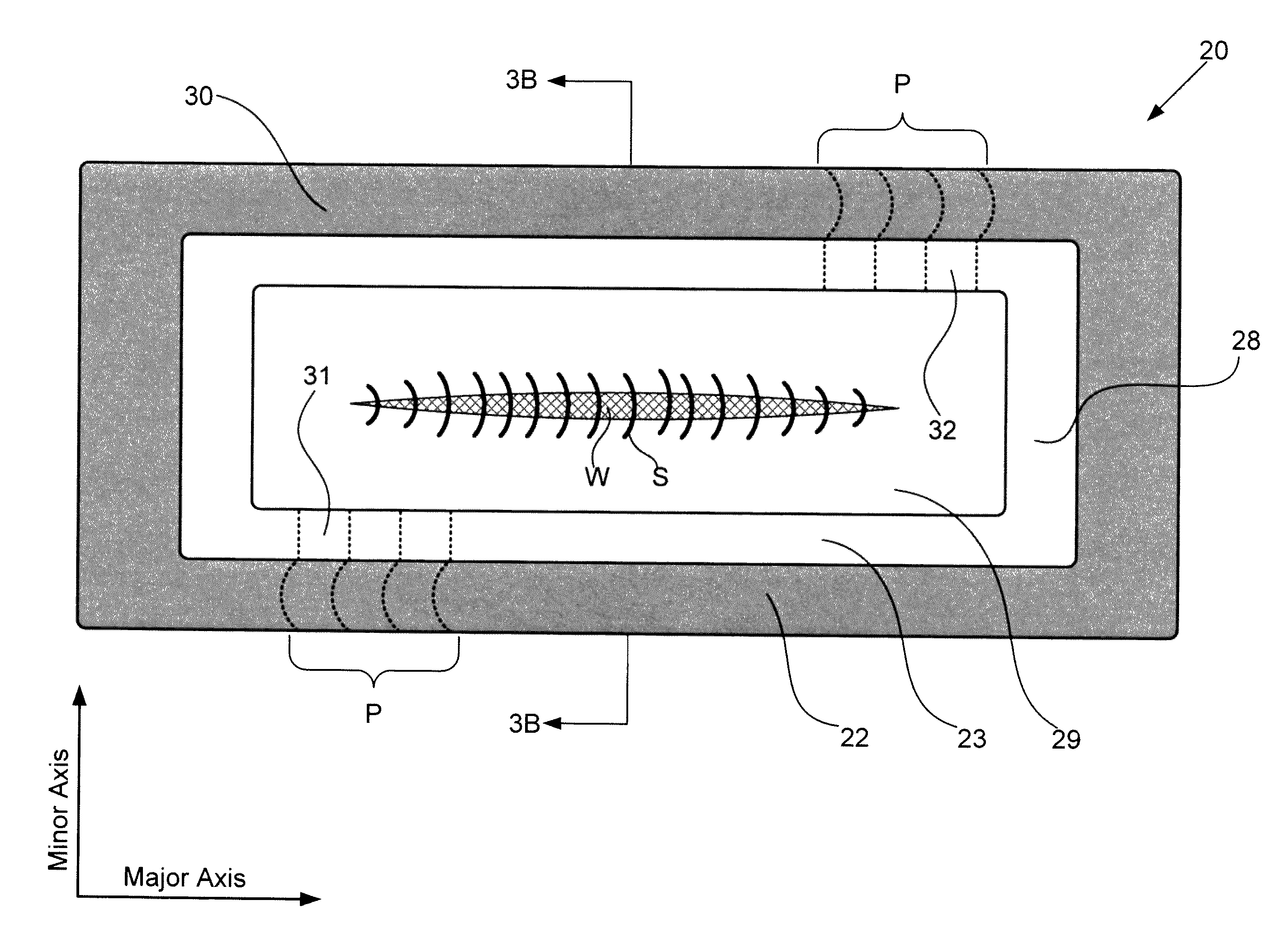

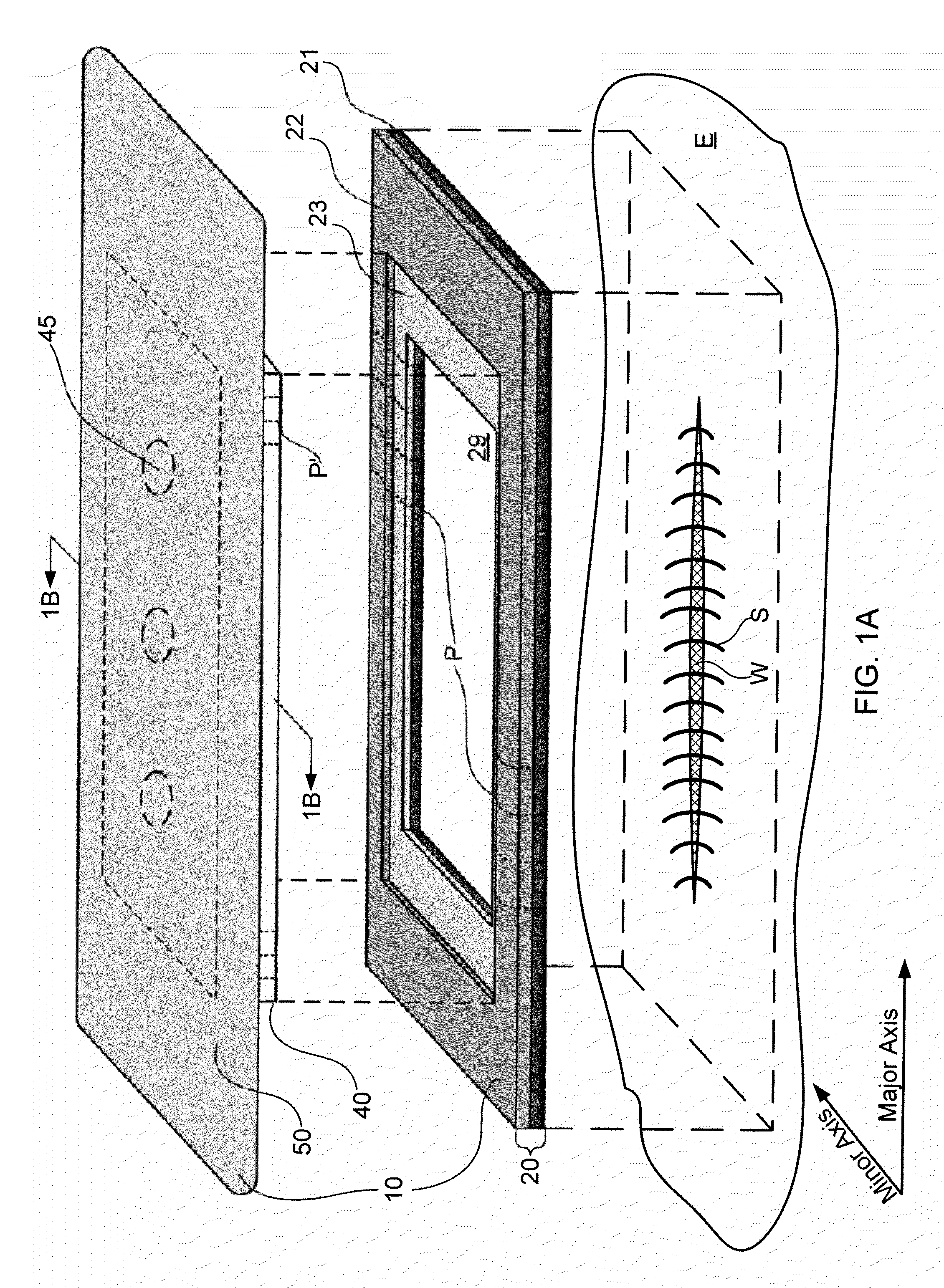

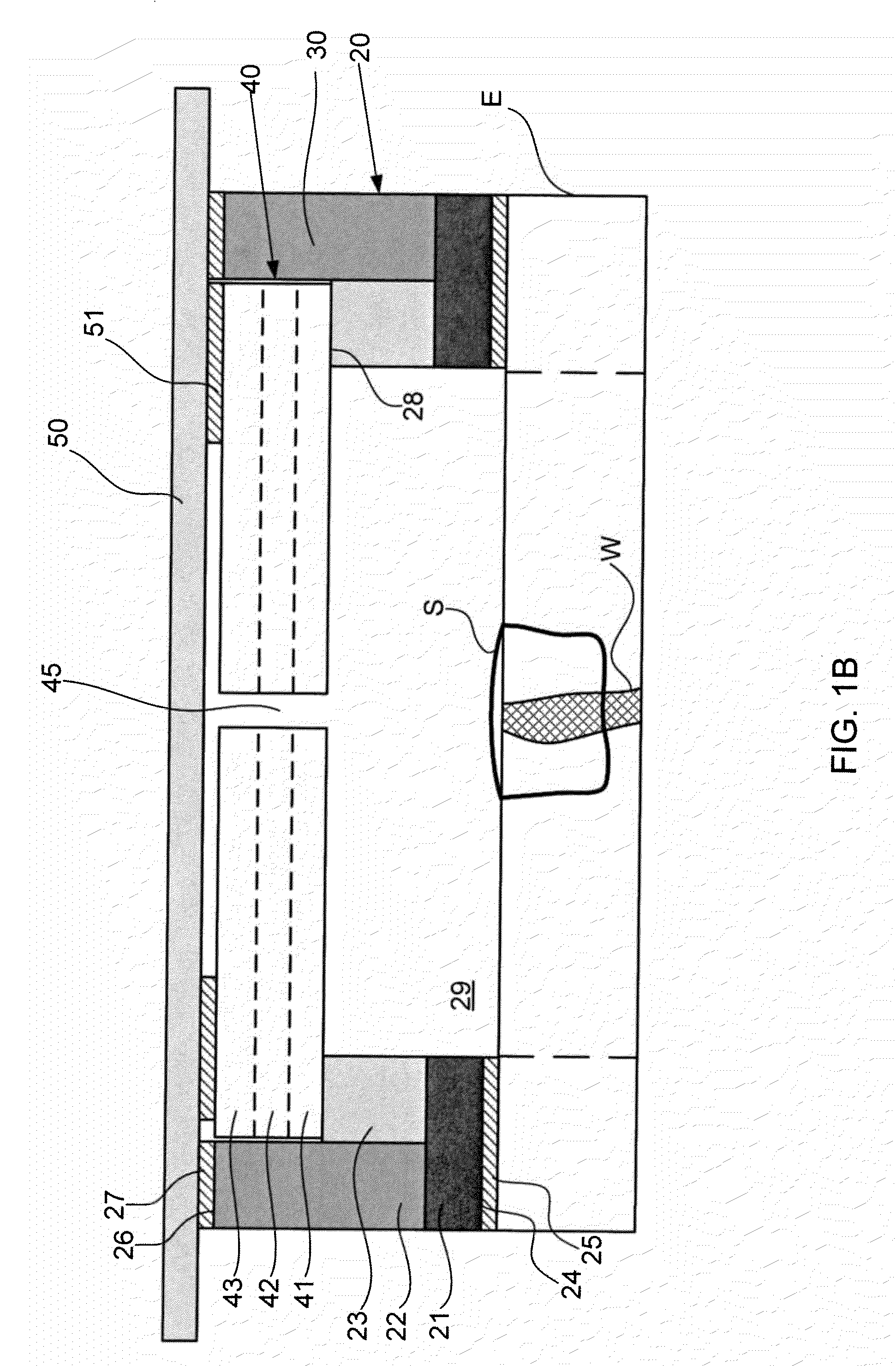

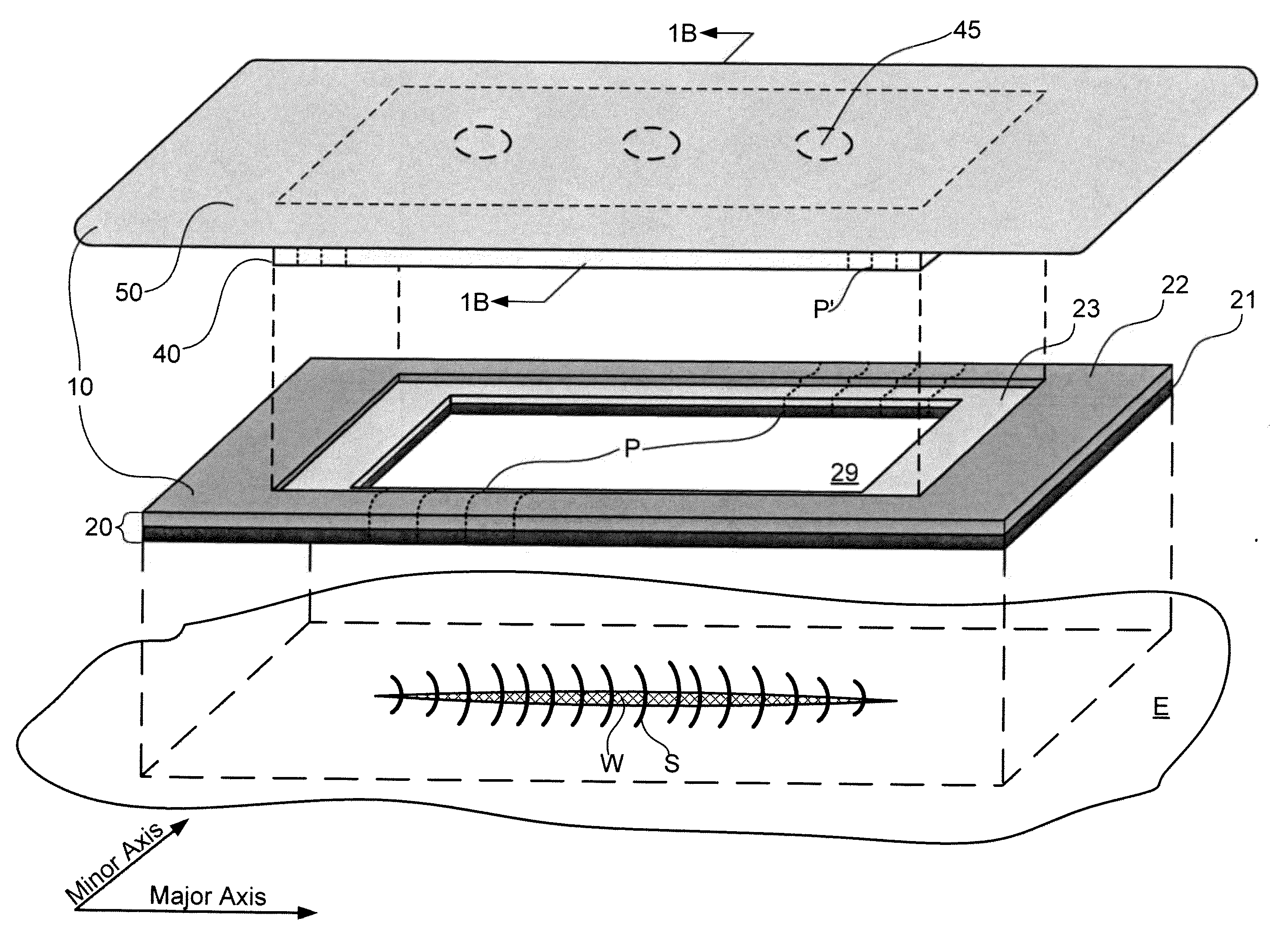

Systems and methods for protecting incisions

InactiveUS8252971B2Reduce contact pressureAvoid injurySuture equipmentsPlastersSurgical incisionMaterial Perforation

The present invention provides systems and methods for protecting wounds, such as surgical incisions. In one embodiment, a dressing for protecting a wound includes: a support cushion configured to surround the wound, the support cushion having sidewalls defining a major axis and a minor axis, the support cushion including at least two perforations that traverse the sidewalls at offset locations; a reservoir configured to be suspended over and in engagement with the support cushion; and a cover configured to be positioned over the reservoir. The at least two perforations may define first and second interlocking J-shaped portions. The support cushion may include a wicking portion configured to surround the wound and a hydrophobic portion configured to surround the hydrophobic portion. The wicking portion may be configured to transfer fluid from the wound to the reservoir. Methods of applying the dressing, and kits including the dressing, also are provided.

Owner:AALNEX

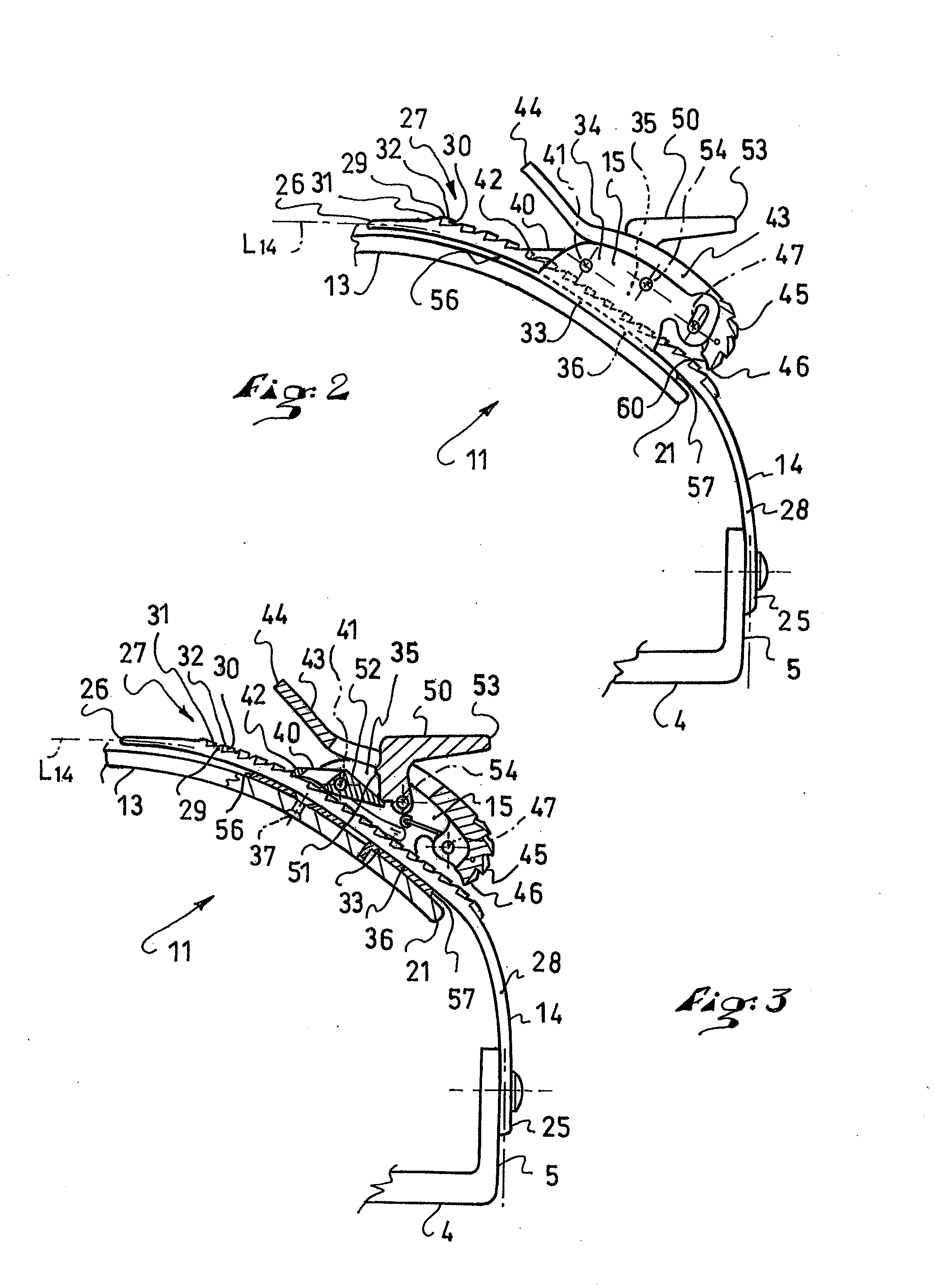

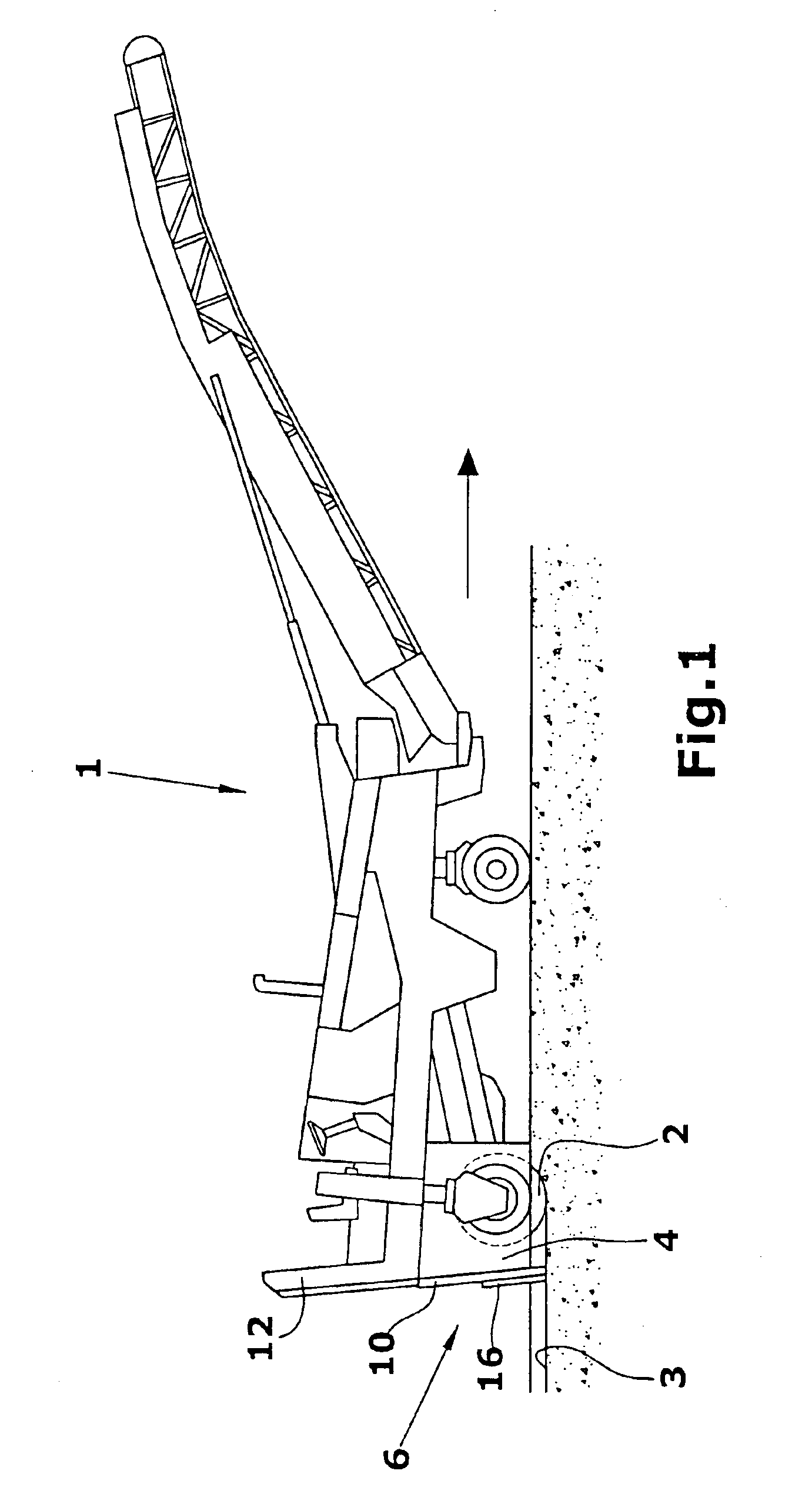

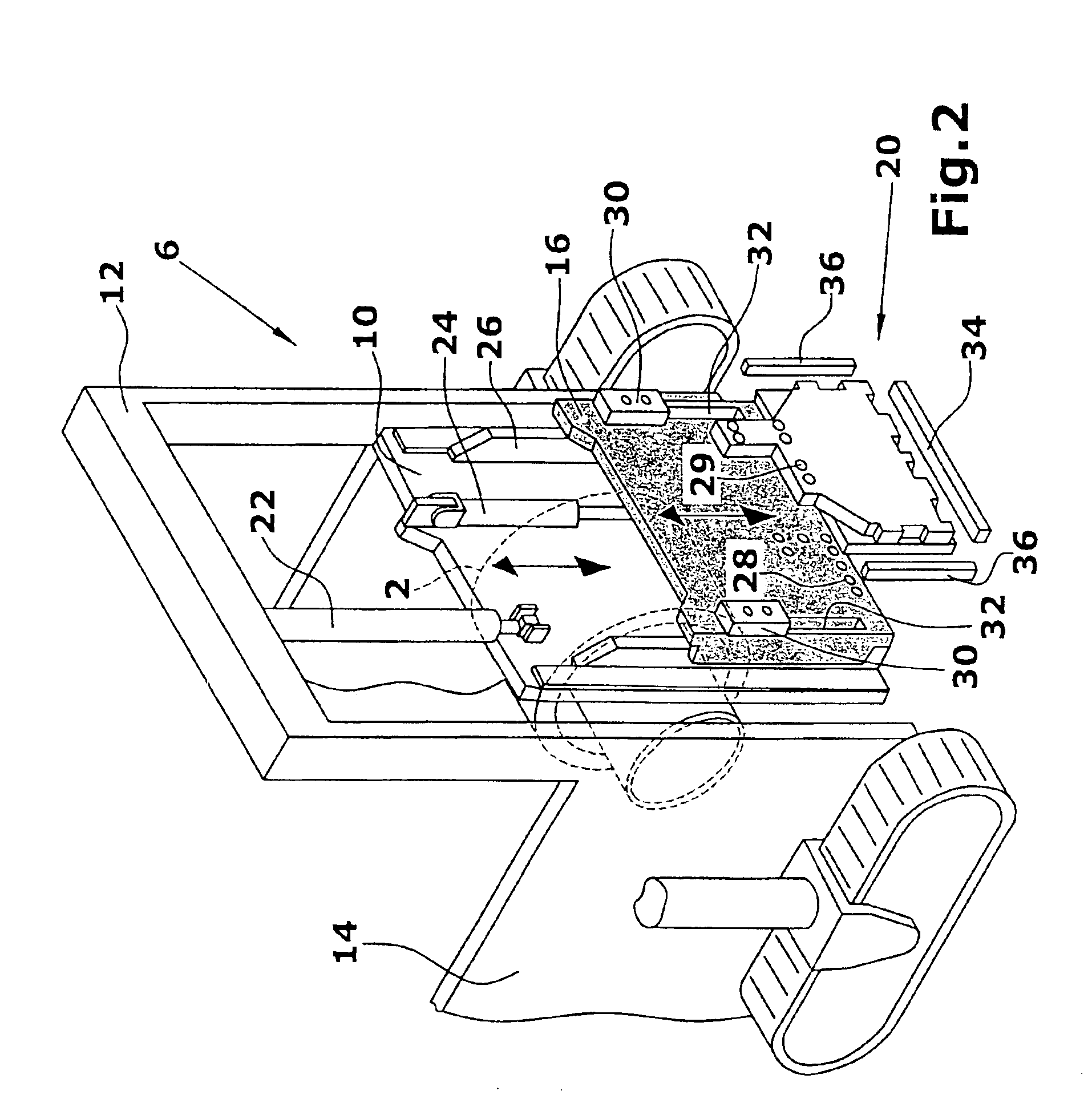

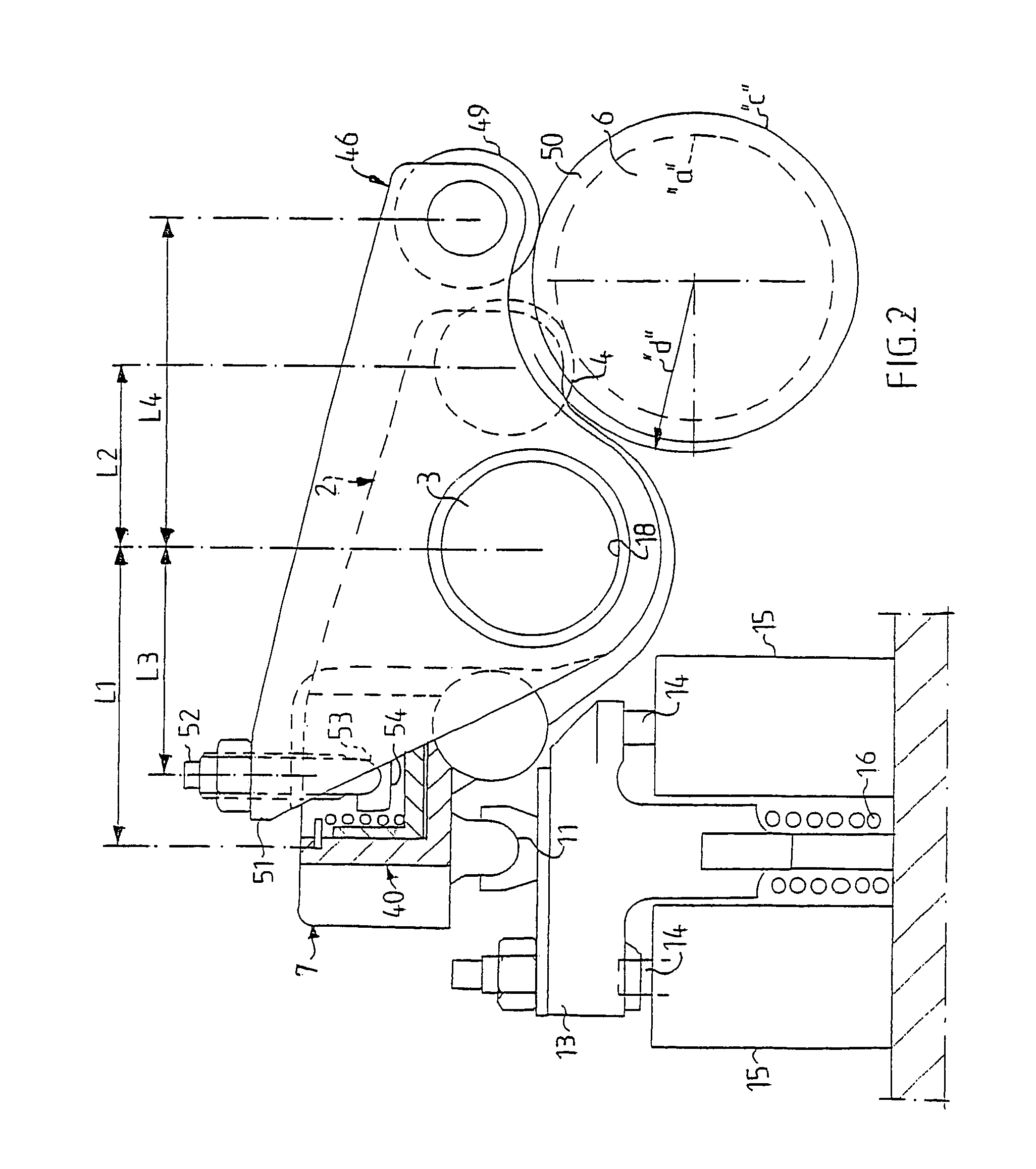

Stripping means for milling rolls of a construction machine as well as a construction machine and a method

InactiveUS6923508B2Low costLow effortMechanical machines/dredgersRoads maintainenceEngineeringMechanical engineering

Owner:WIRTGEN GMBH

Exhaust valve mechanism in internal combustion engines

InactiveUS6983725B2Avoid increasing overlapLarge back-flowValve drivesOutput powerCombustionExhaust valve

Valve mechanism in an internal combustion engine, includes a valve play-take up mechanism in the form of a piston in a cylinder chamber at one end of an exhaust rocker arm, and a hydraulic circuit with valve elements for supplying or draining off pressure fluid to and from the cylinder chamber. A second cylinder chamber with a piston acting in an opposite direction is arranged in the rocker arm and communicates with the first-mentioned cylinder chamber. A brake rocker arm is mounted on the same rocker arm shaft as the exhaust rocker arm and has an outer end, which acts against the piston in the second cylinder chamber. The brake rocker arm has its own cam element with brake cam lobes to one side of the exhaust rocker arm cam element.

Owner:VOLVO LASTVAGNAR AB

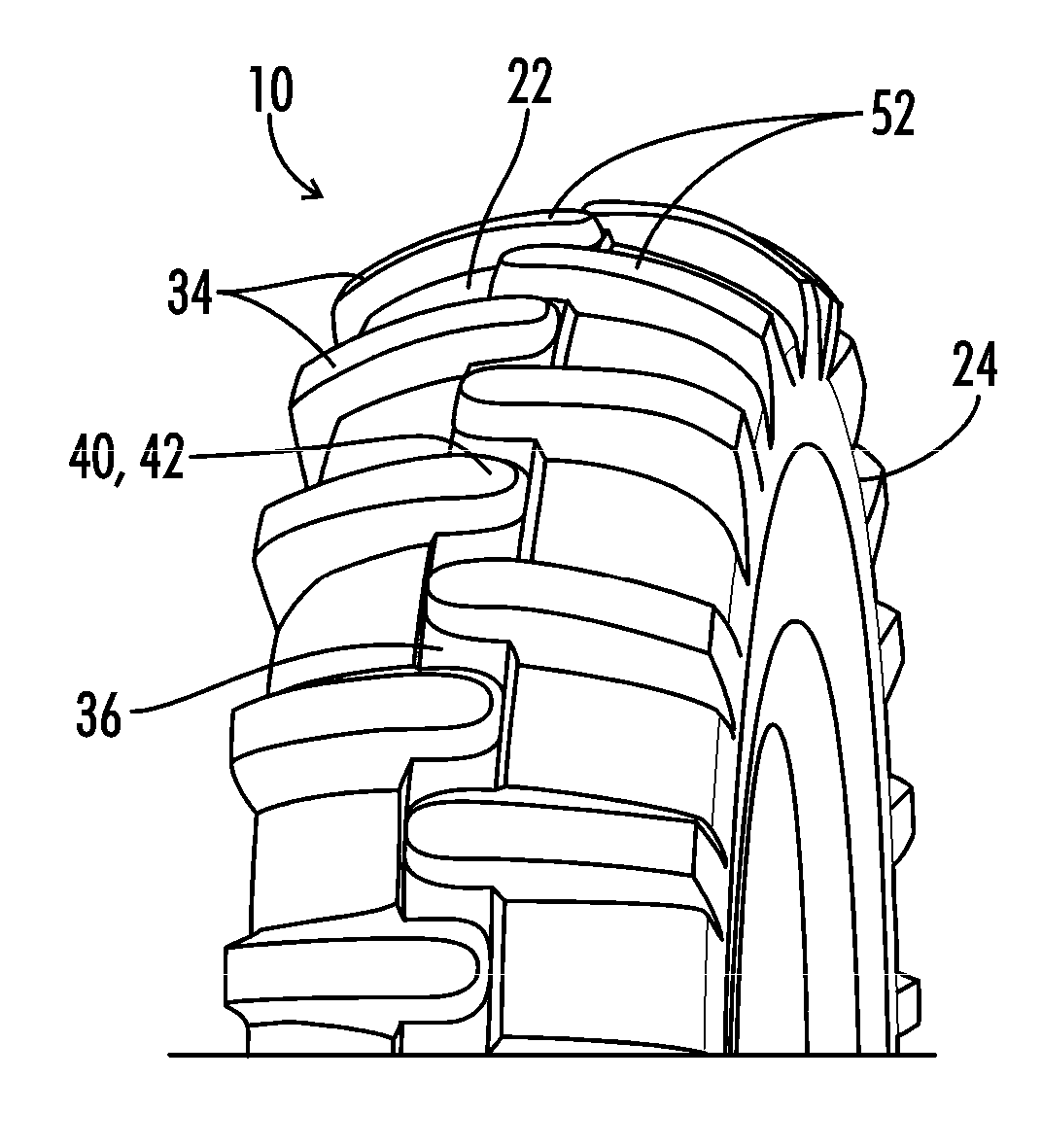

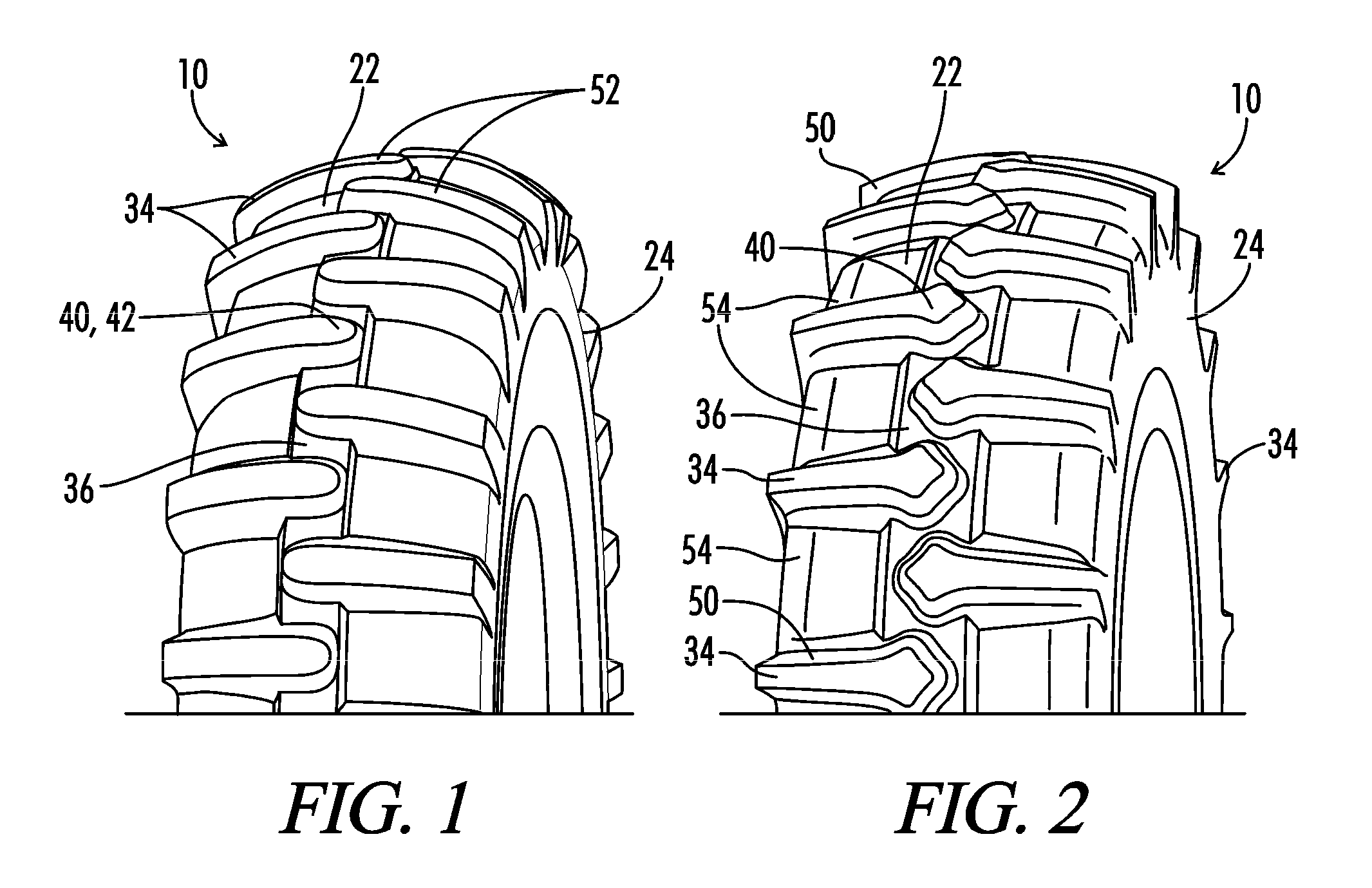

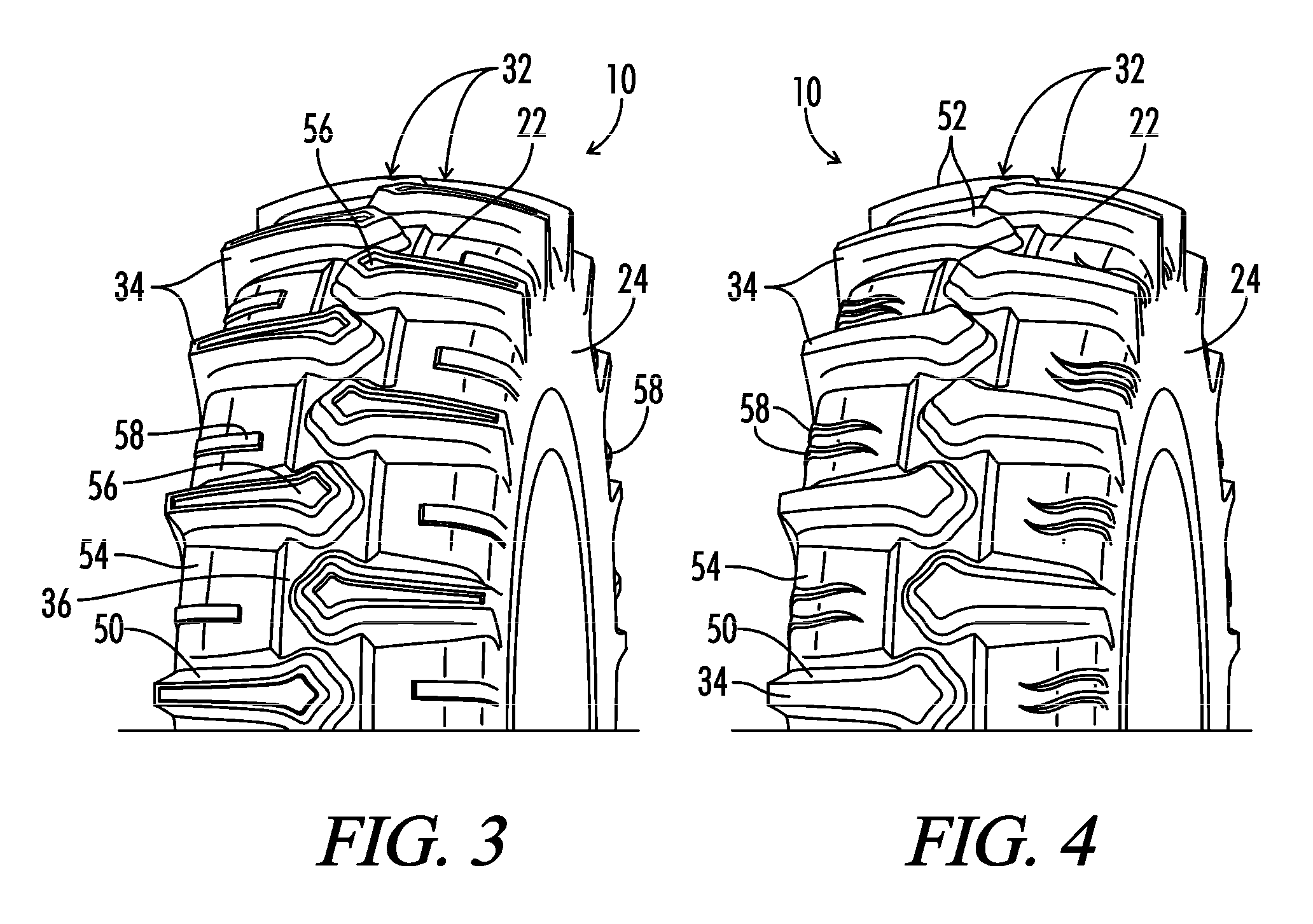

Irrigation tire

ActiveUS20090084478A1Uniform resistanceIncrease crown strengthAgricultural vehiclesAgricultural vehicle tyresRotational axisAgricultural irrigation

A non directional pneumatic tire is provided for an agricultural irrigation system. The tire includes first and second side walls and a radially outer wall defining an internal inflation chamber. A non directional tread pattern is defined on the tire and includes a plurality of longitudinal protrusions positioned substantially parallel to a rotational axis of the tire. The longitudinal protrusions are arranged in first and second rows extending from the first and second side walls toward and across the equatorial plane of the tire. The longitudinal protrusions of the first and second rows circumferentially alternate with each other and there is a circumferential spacing between adjacent longitudinal protrusions at the equatorial plane so that no portion of one longitudinal protrusion circumferentially coincides with or overlaps another.

Owner:BRIDGESTONE AMERICAS TIRE OPERATIONS LLC

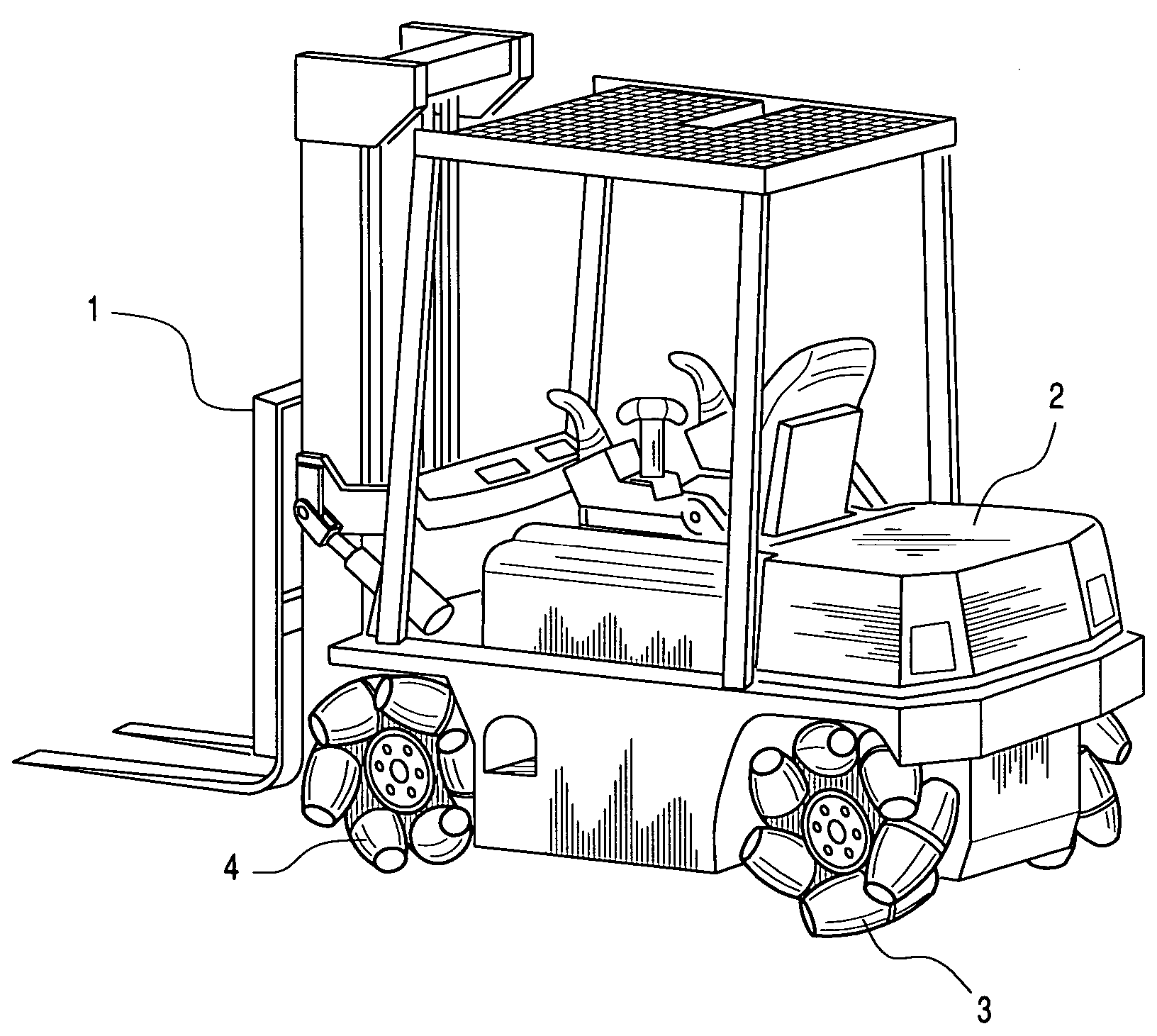

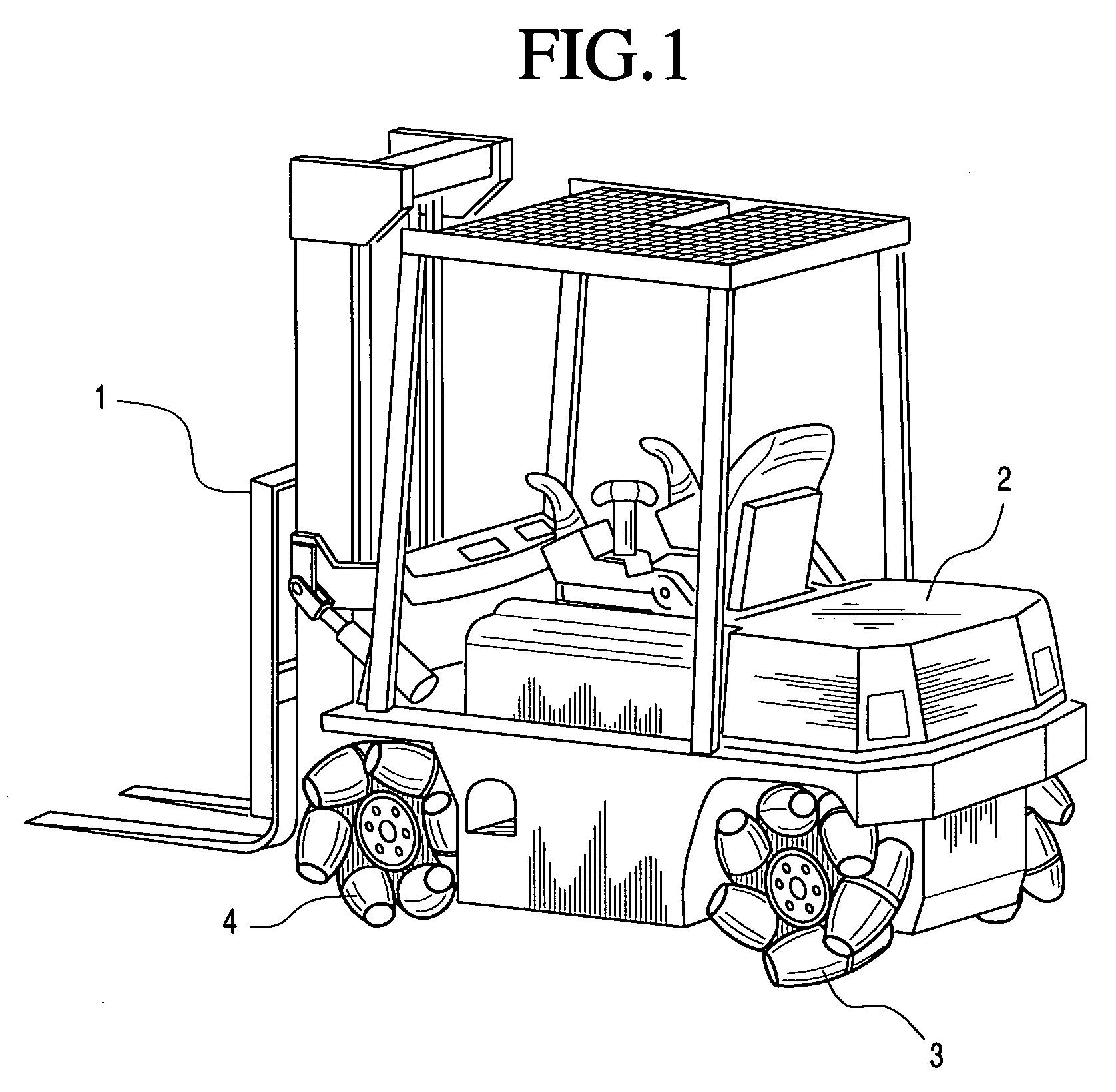

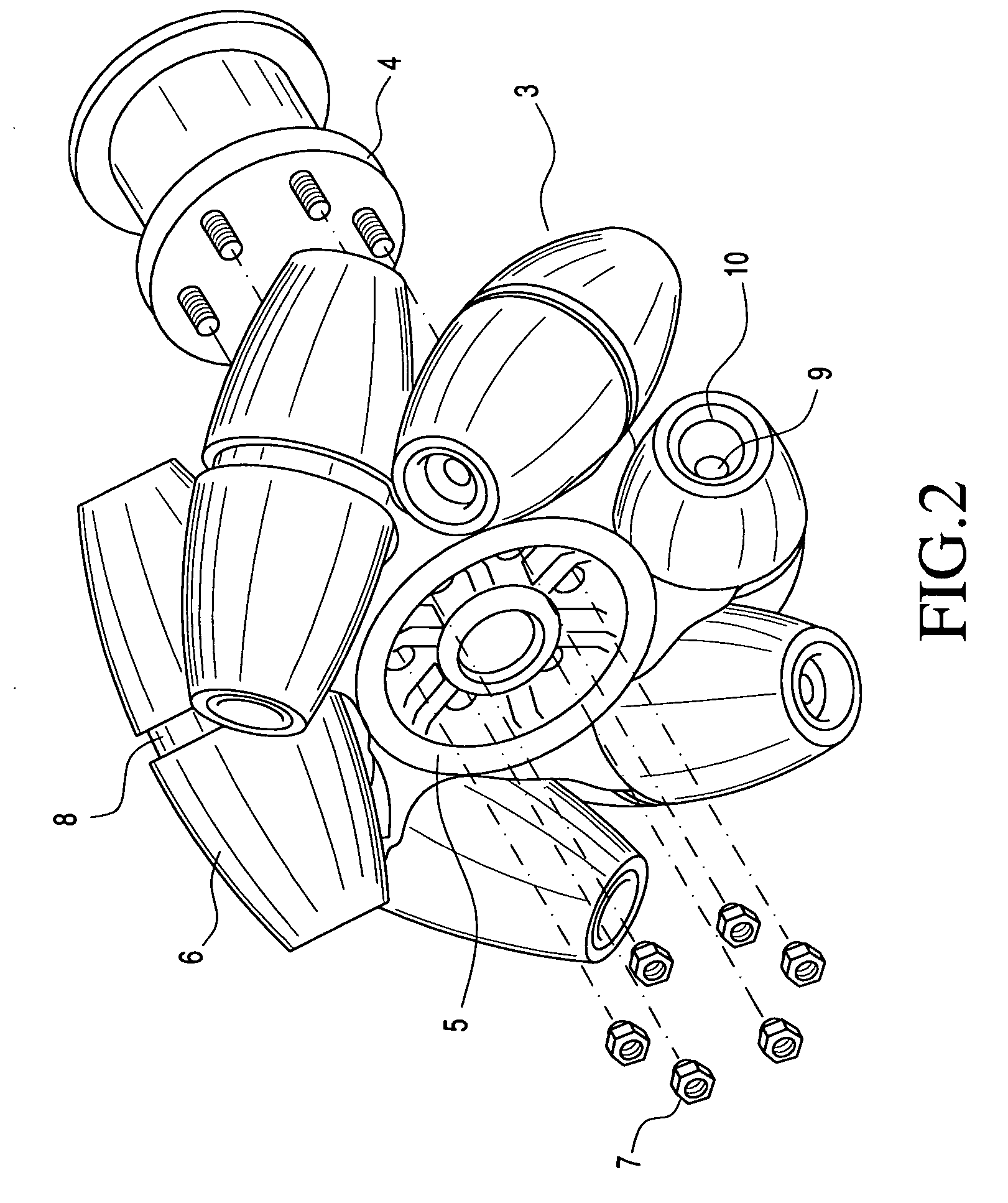

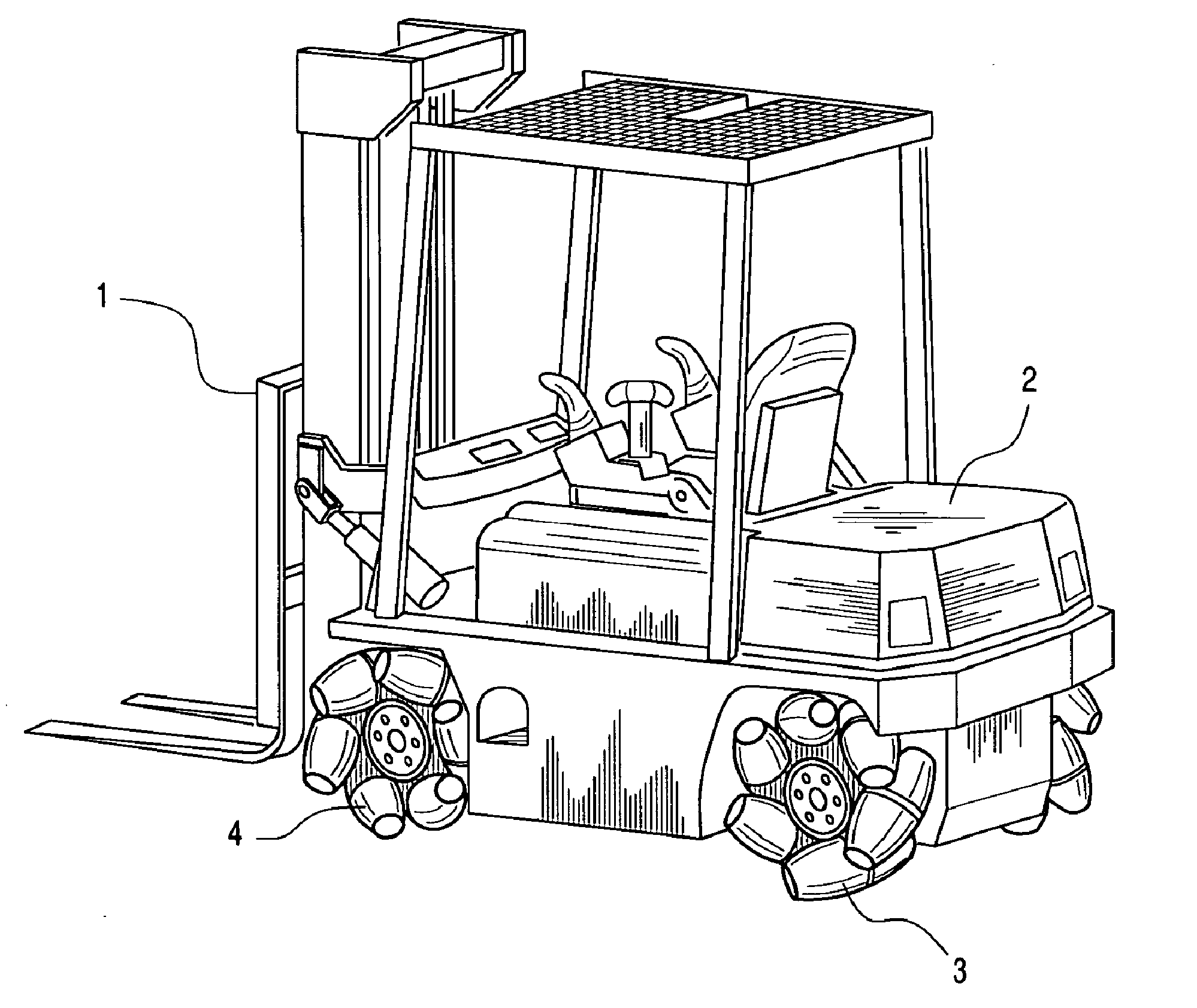

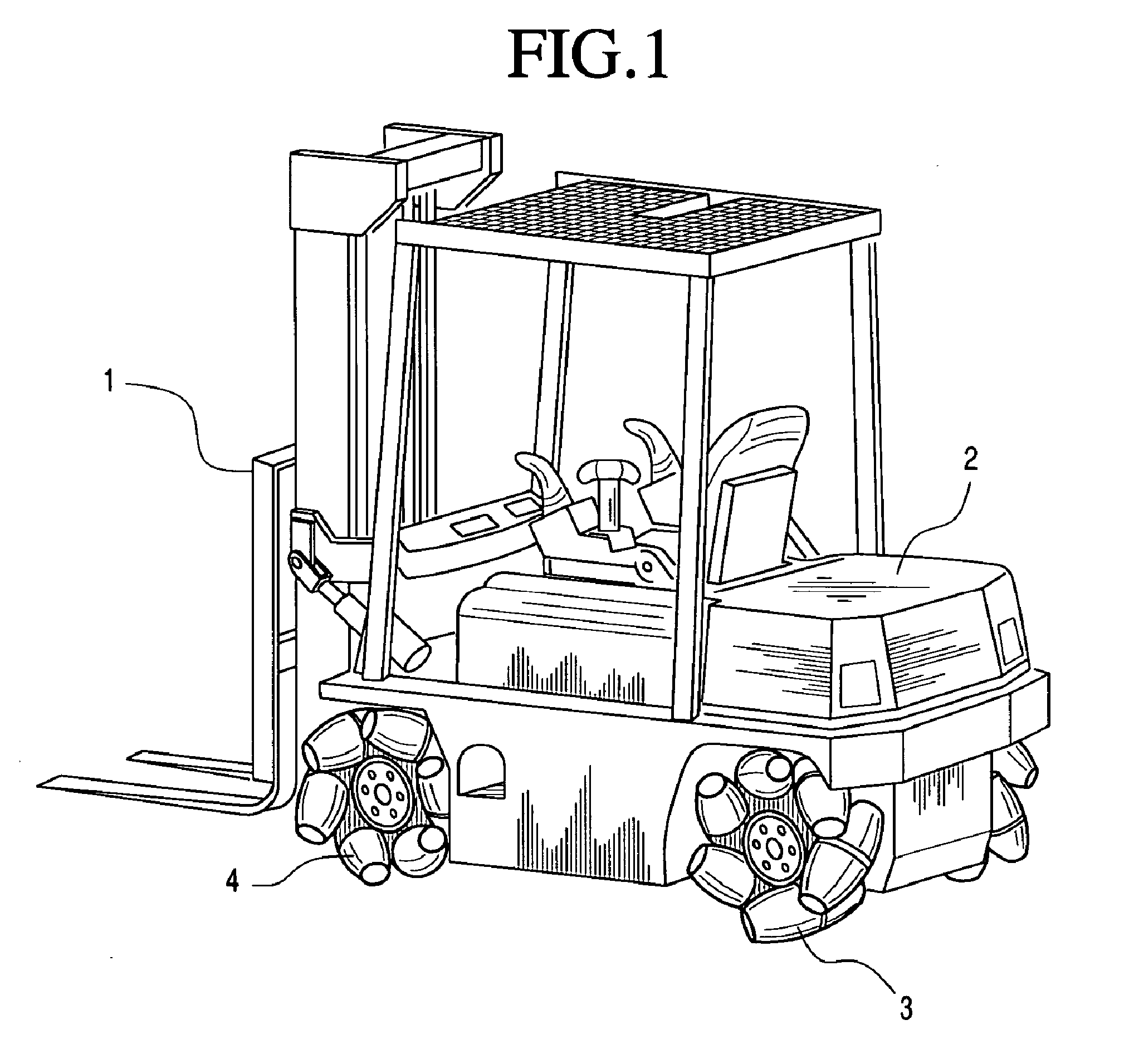

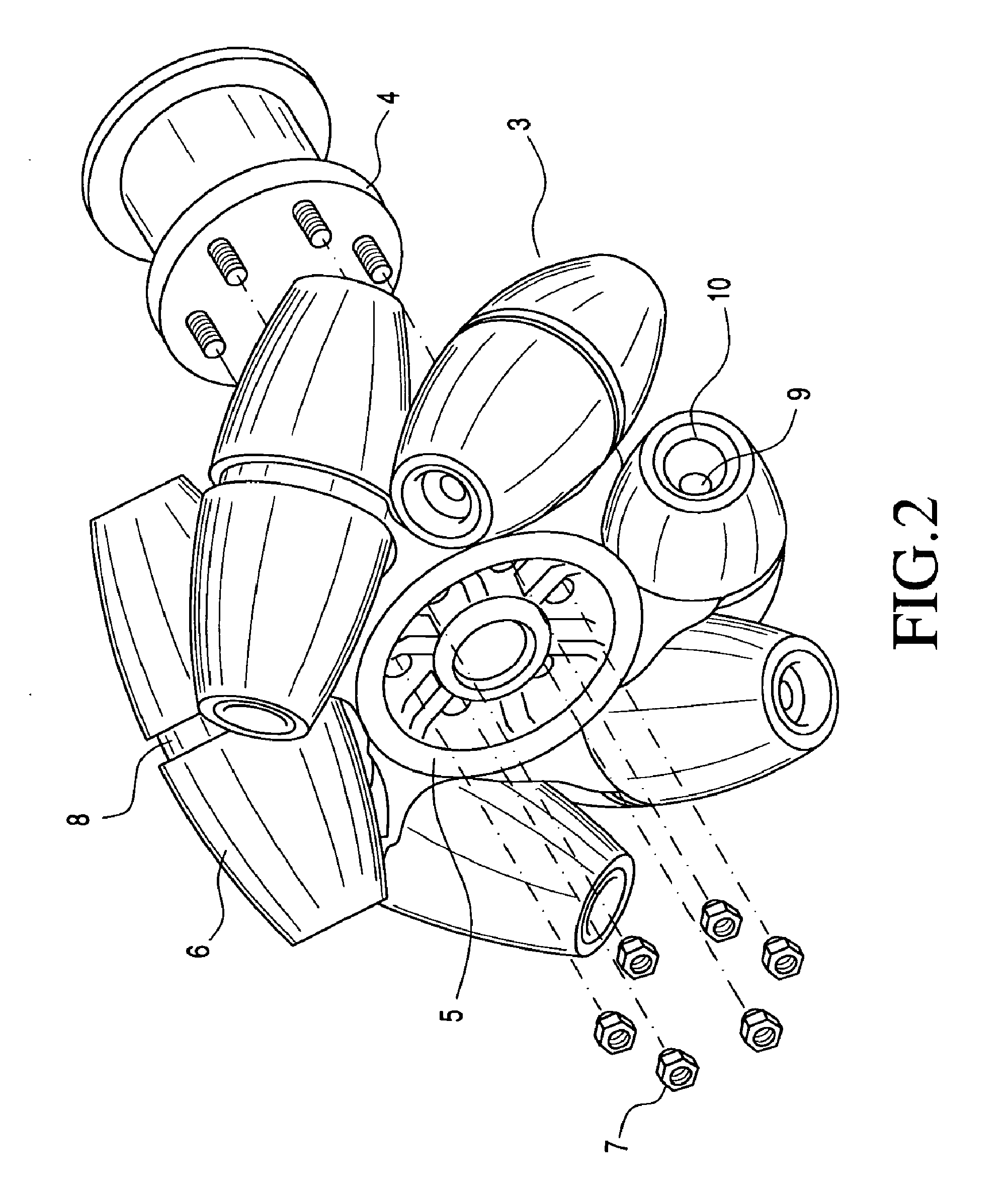

Omni-directional wheels and methods and vehicles employing same

InactiveUS20050183896A1Constant ride heightLow wheel vibrationHybrid vehiclesGas pressure propulsion mountingEngineeringOmni directional

Owner:AIRTRAX

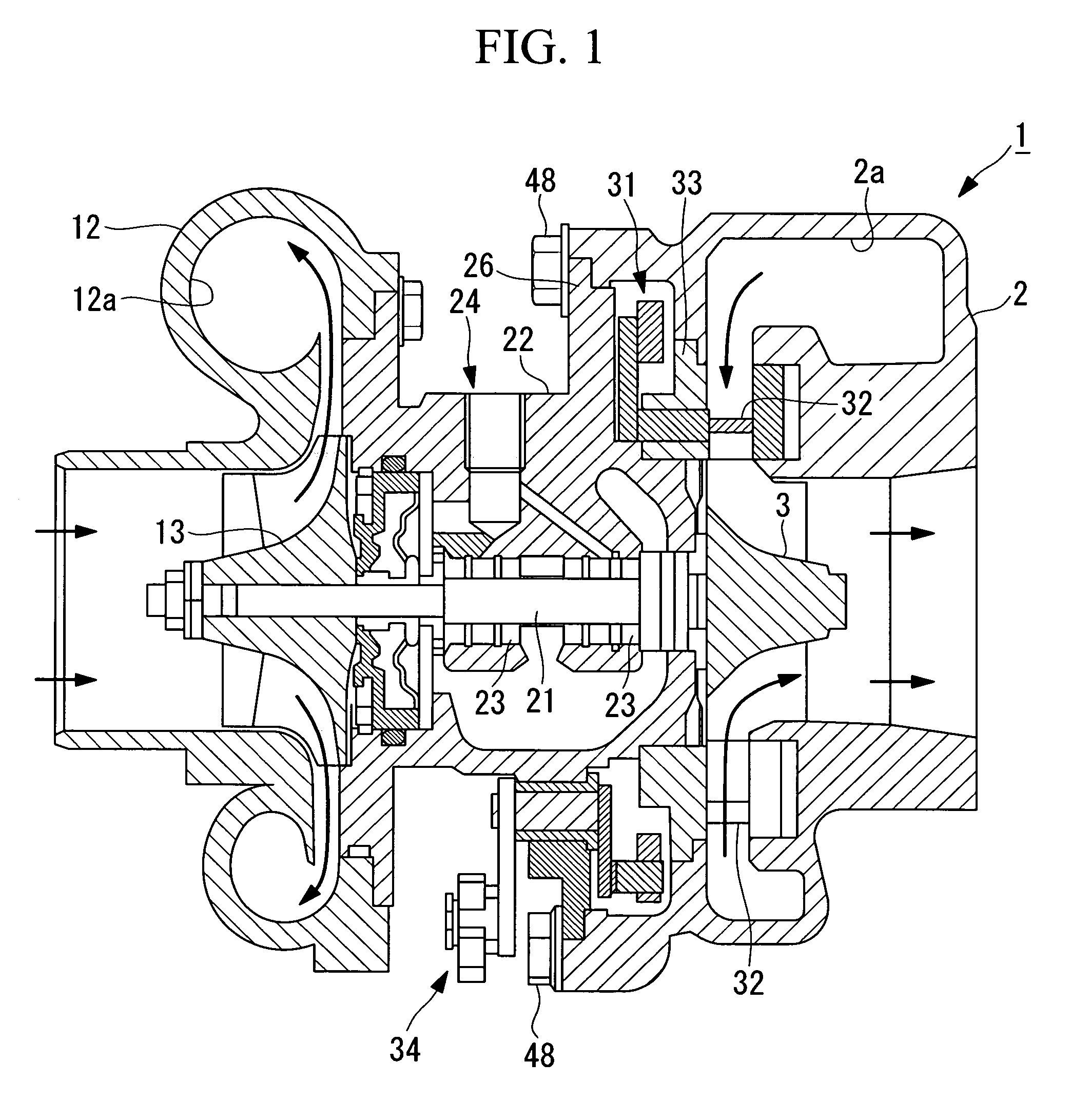

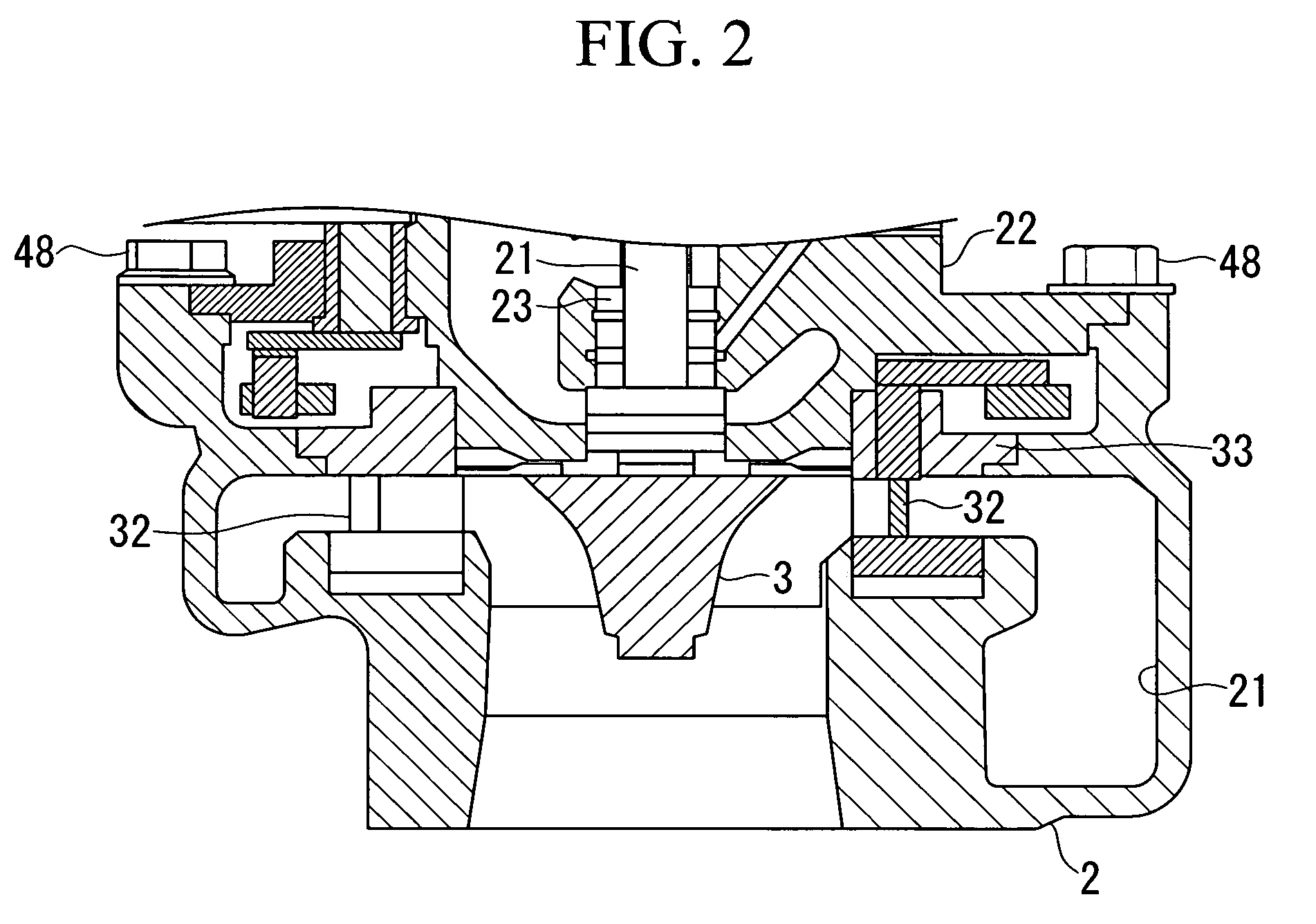

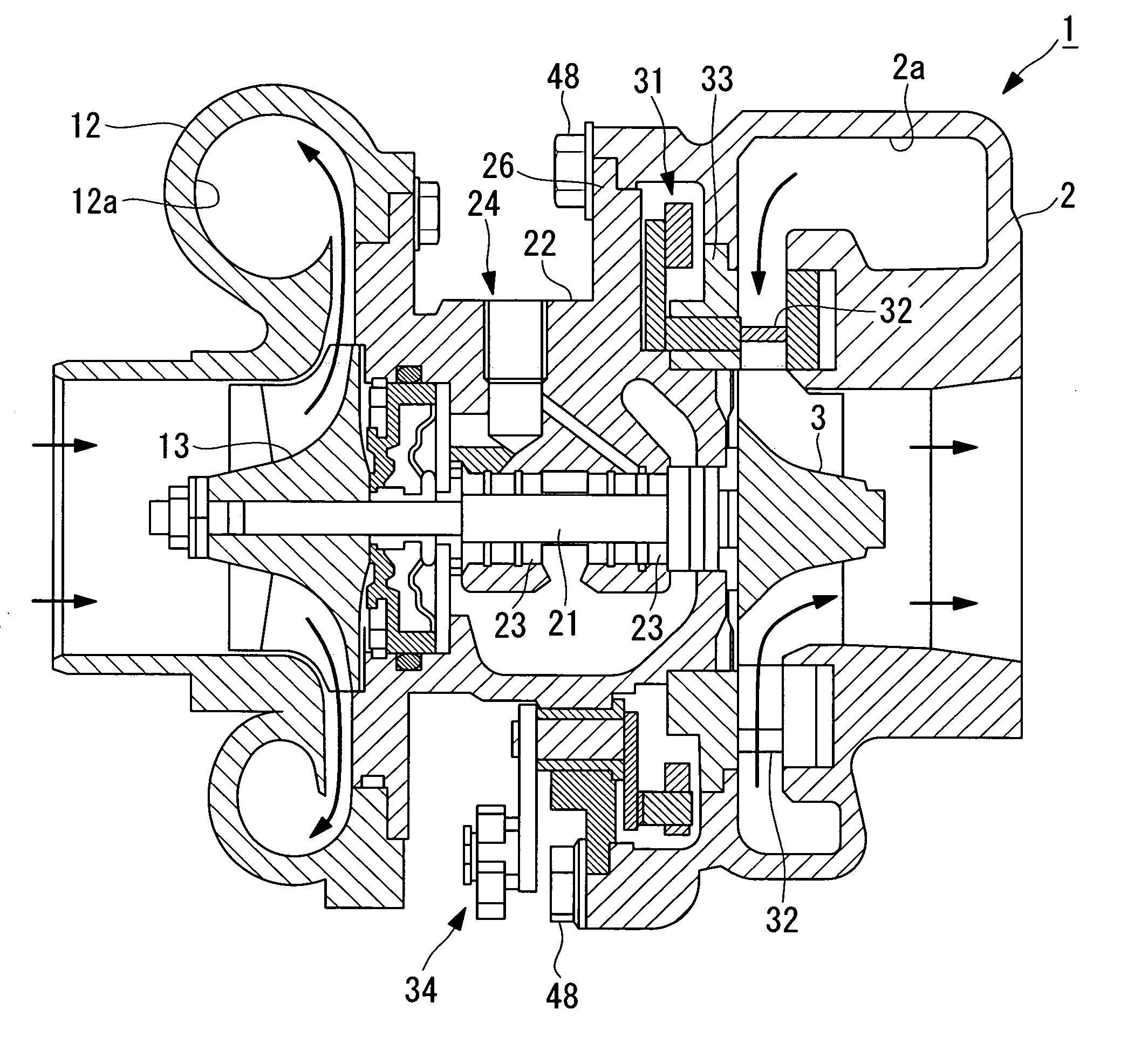

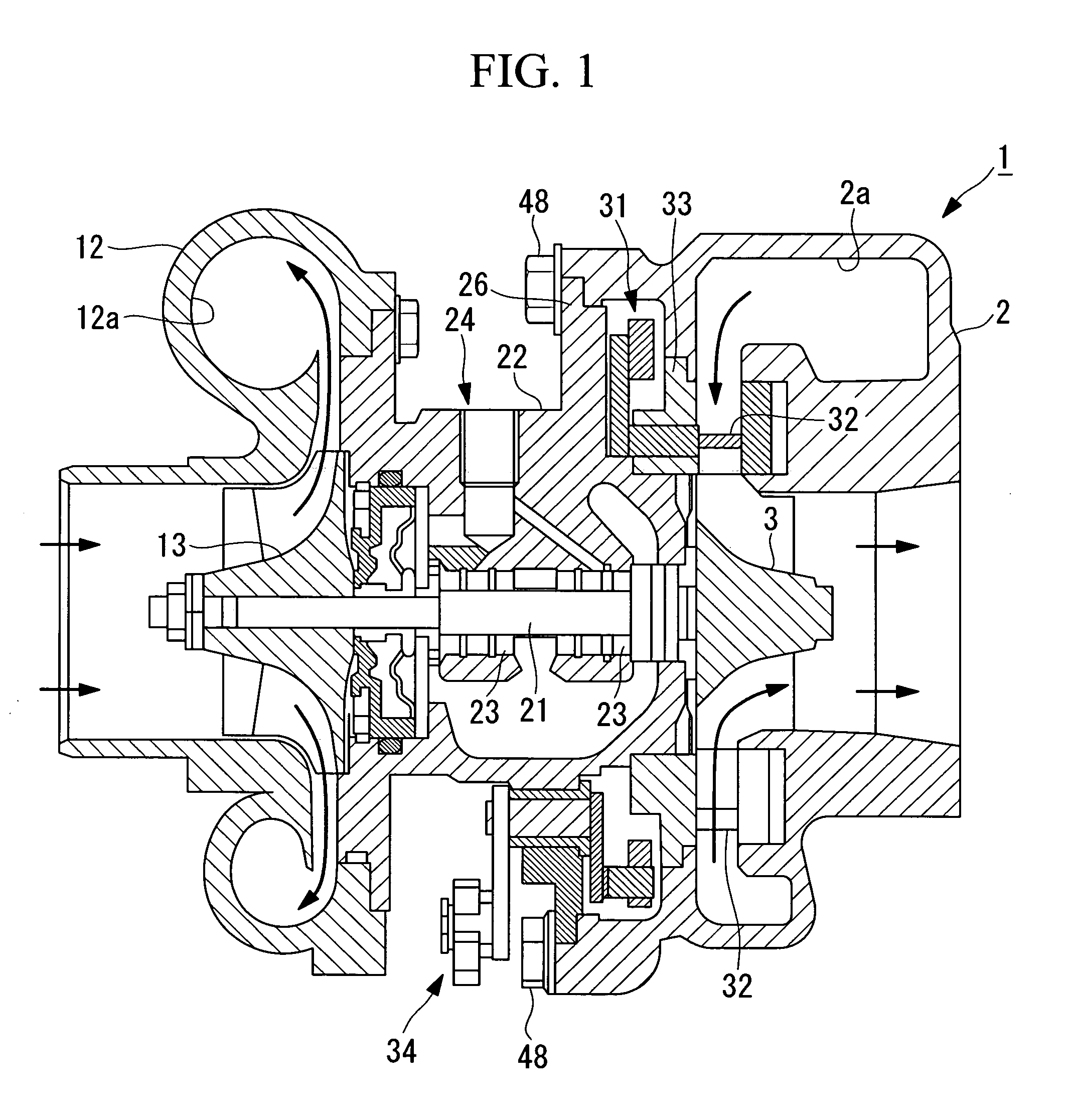

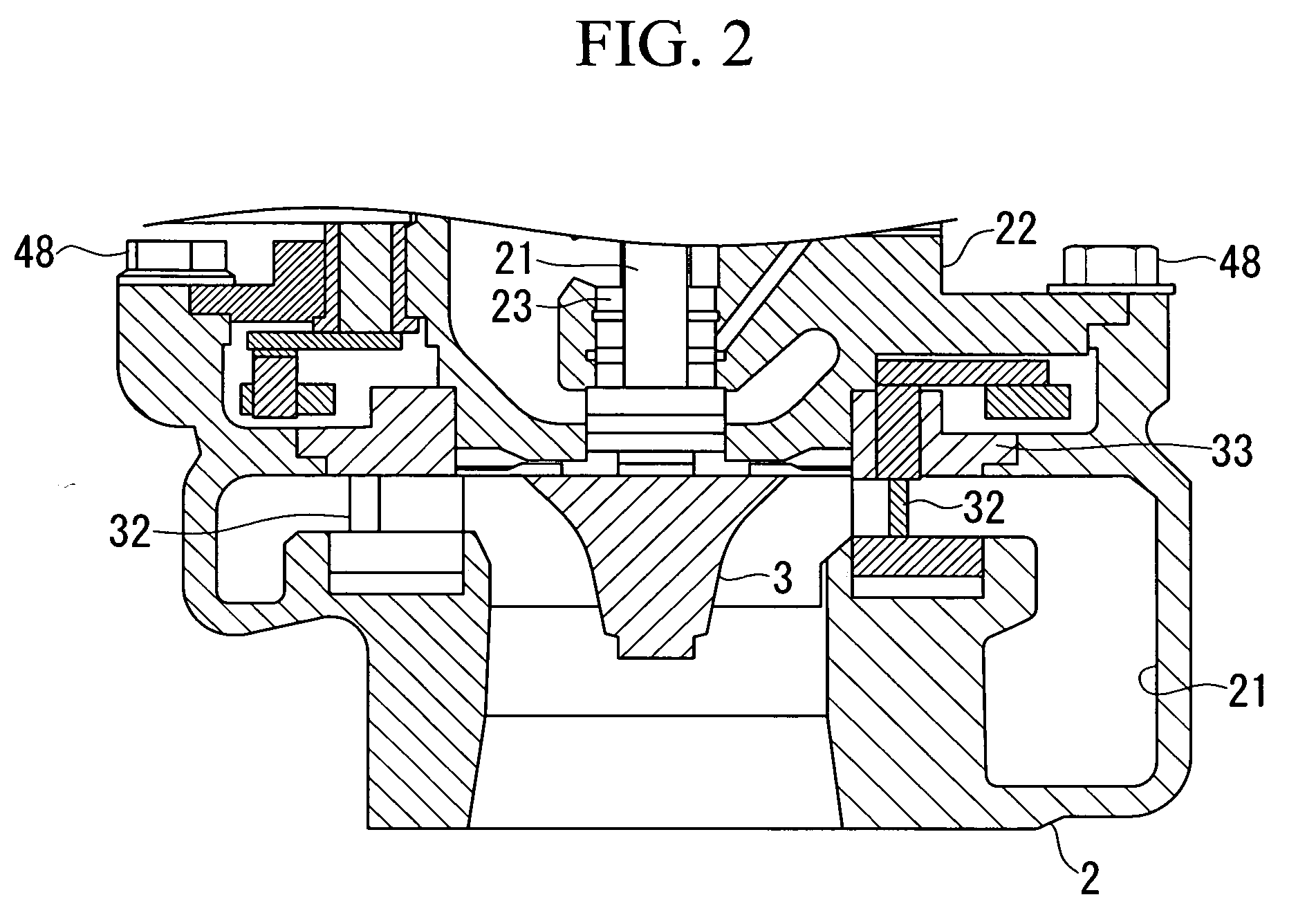

Exhaust turbo supercharger

ActiveUS7797936B2Reduce contact pressureEffectively prevent exhaust gasWind motor controlPump componentsImpellerTurbine wheel

An exhaust turbo supercharger is provided that is able to effectively prevent exhaust gas that has flowed into between a turbine housing and a bearing housing from leaking to outside of the device, while allowing an excellent level of workability in assembly and disassembly. Included is a turbine housing, into which exhaust gas from an internal combustion engine is introduced; a turbine wheel which is provided within the turbine housing and which is rotation-driven by the exhaust gas; a turbine shaft, one end of which is inserted into the turbine housing, and to which the turbine wheel is attached; a bearing which supports the turbine shaft; and a bearing housing which is connected to the turbine housing and inside of which the bearing is housed. A bolt insert hole is formed in the turbine housing, and an internal thread insert made from a heat insulating material is provided in the bolt insert hole, and the turbine housing and the bearing housing are fixed by a bolt that engages with the internal thread insert.

Owner:MITSUBISHI HEAVY IND LTD

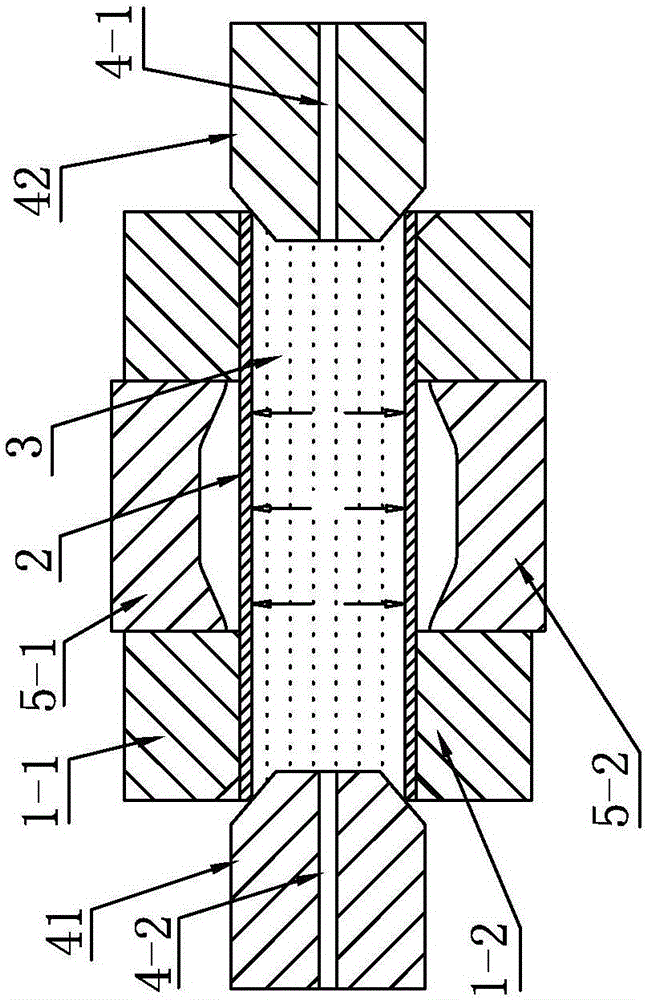

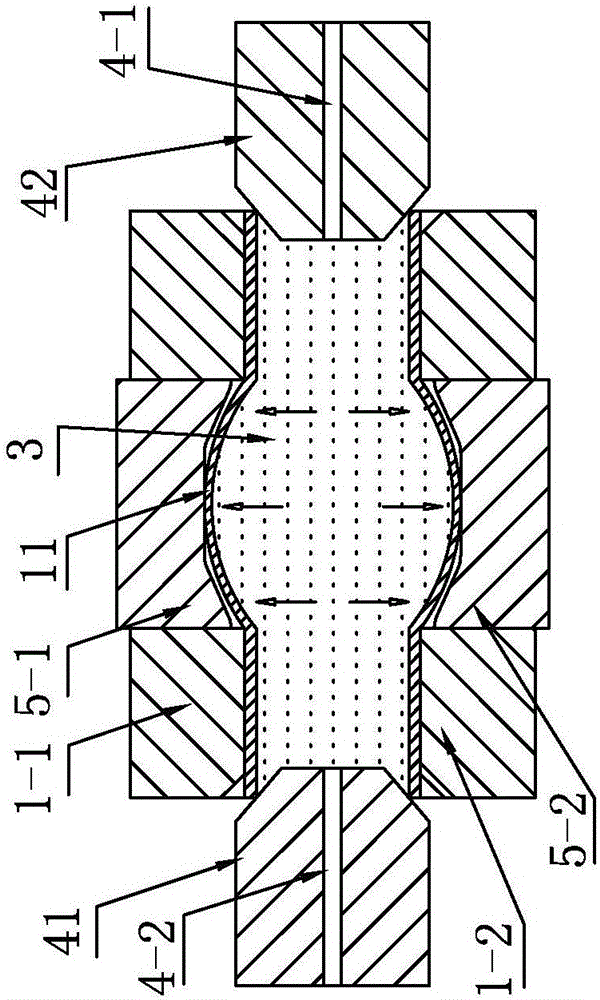

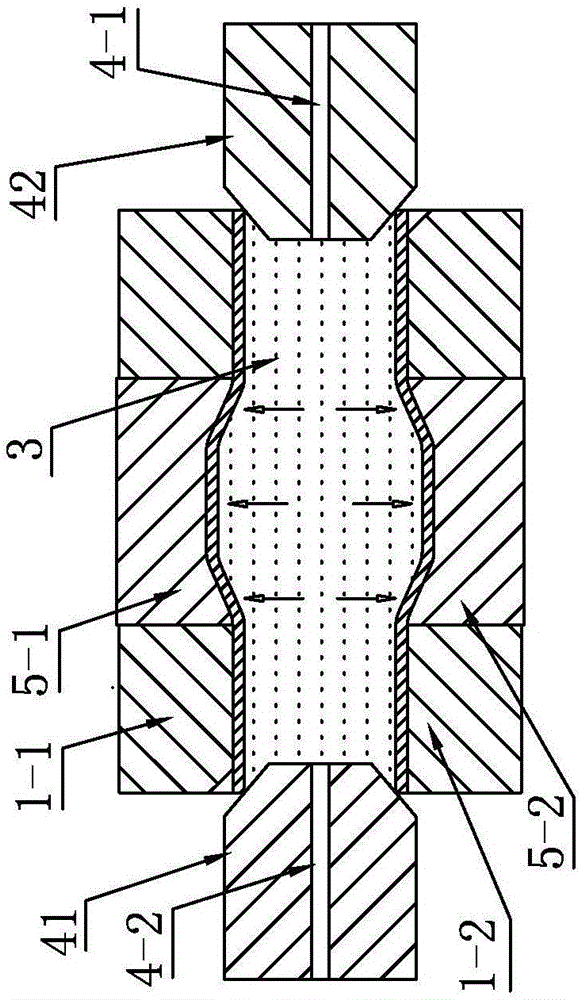

Swelling pressure composite forming method for large-section-difference special-shaped section pipe fitting

The invention provides a swelling pressure composite forming method for a large-section-difference special-shaped section pipe fitting and relates to a forming method for a large-section-difference special-shaped section pipe-shaped part. The swelling pressure composite forming method comprises the main steps that 1, the perimeters and the equivalent diameters of a plurality of cross sections on the to-be-formed large-section-difference special-shaped section pipe fitting are determined, and the structure of a swelling pressure composite forming mold and the inner cavity size and initial position of a side extrusion mold are determined; 2, an equal-diameter circular-section pipe blank with a certain length is cut and put into the swelling pressure composite forming mold; 3, the equal-diameter circular-section pipe blank is filled with a pressure medium with a certain pressure through a pressure medium inlet, and a variable-diameter circular-section pipe blank is obtained through swelling; 4, the side extrusion mold is driven to extrude the variable-diameter circular-section pipe blank, and the large-section-difference special-shaped section pipe fitting is obtained; and 5, the pressure is released, and after the swelling pressure composite forming mold is opened, the formed pipe fitting is taken out. The swelling pressure composite forming method is used for forming large-section-difference special-shaped section pipe fittings.

Owner:HARBIN INST OF TECH

Exhaust Turbo Supercharger

ActiveUS20090151348A1Reduce inner pressureReduce pressure applyWind motor controlPump componentsExhaust gasImpeller

An exhaust turbo supercharger is provided that is able to effectively prevent exhaust gas that has flowed into between a turbine housing and a bearing housing from leaking to outside of the device, while allowing an excellent level of workability in assembly and disassembly. Included is a turbine housing, into which exhaust gas from an internal combustion engine is introduced; a turbine wheel which is provided within the turbine housing and which is rotation-driven by the exhaust gas; a turbine shaft, one end of which is inserted into the turbine housing, and to which the turbine wheel is attached; a bearing which supports the turbine shaft; and a bearing housing which is connected to the turbine housing and inside of which the bearing is housed. A bolt insert hole is formed in the turbine housing, and an internal thread insert made from a heat insulating material is provided in the bolt insert hole, and the turbine housing and the bearing housing are fixed by a bolt that engages with the internal thread insert.

Owner:MITSUBISHI HEAVY IND LTD

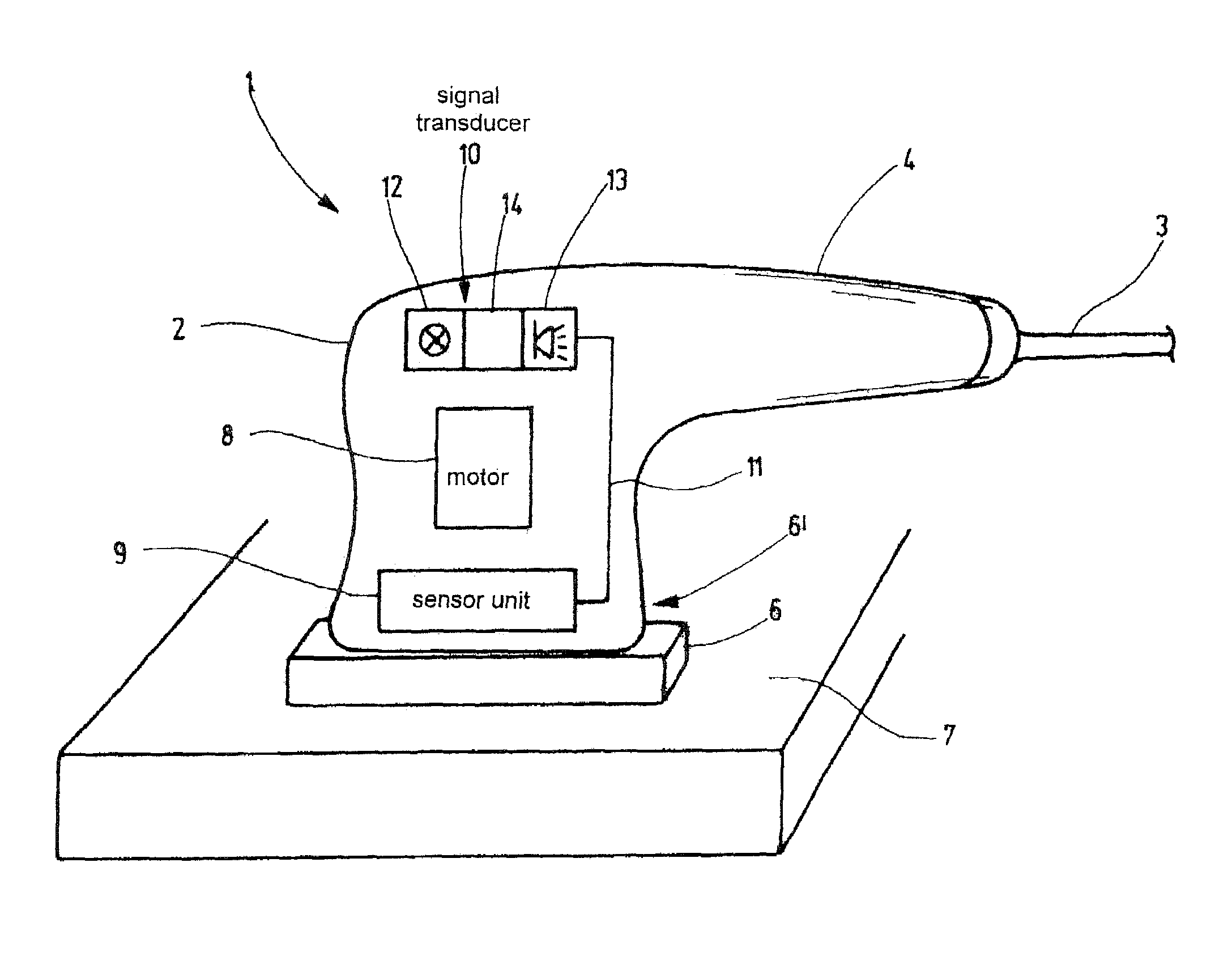

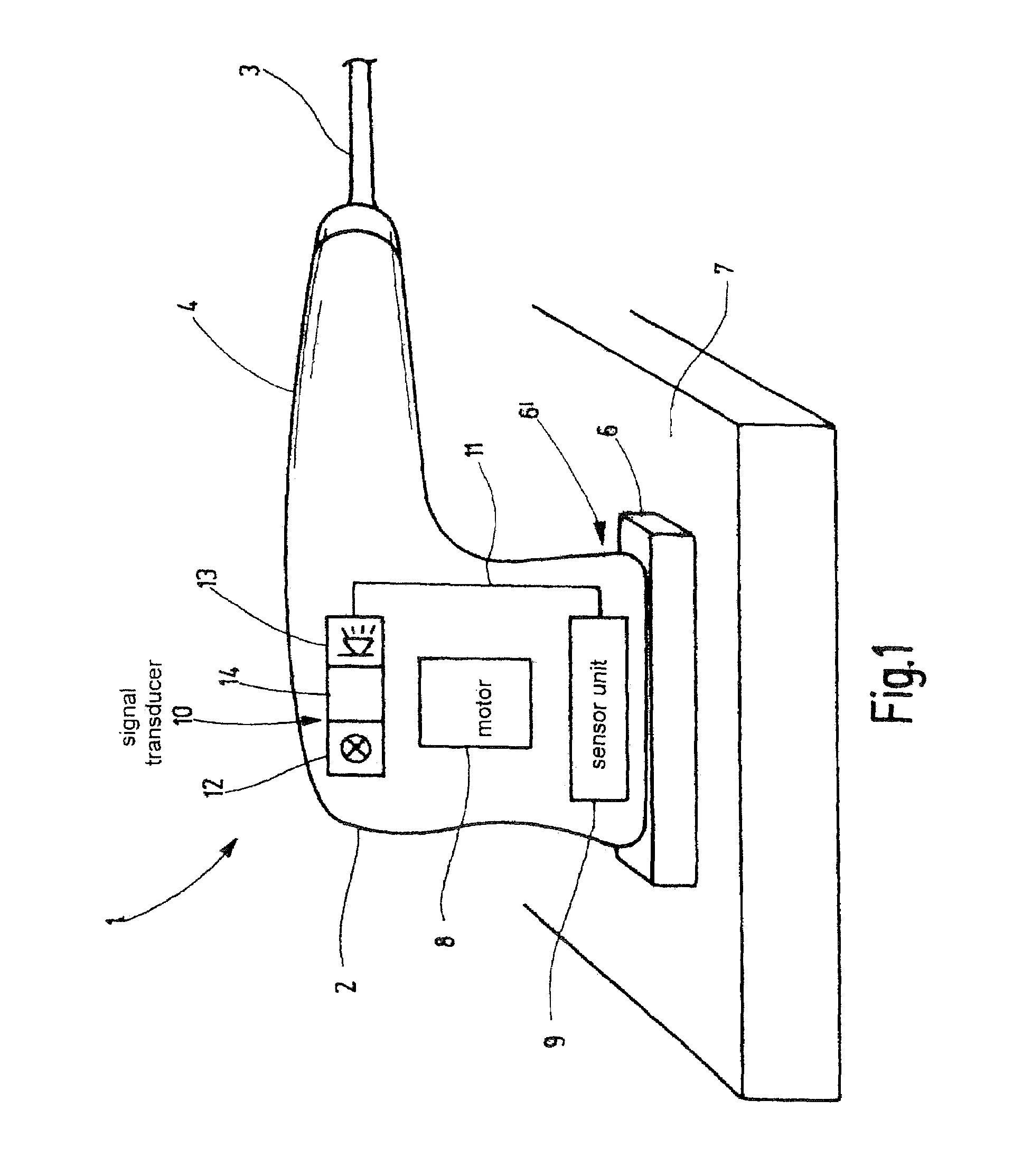

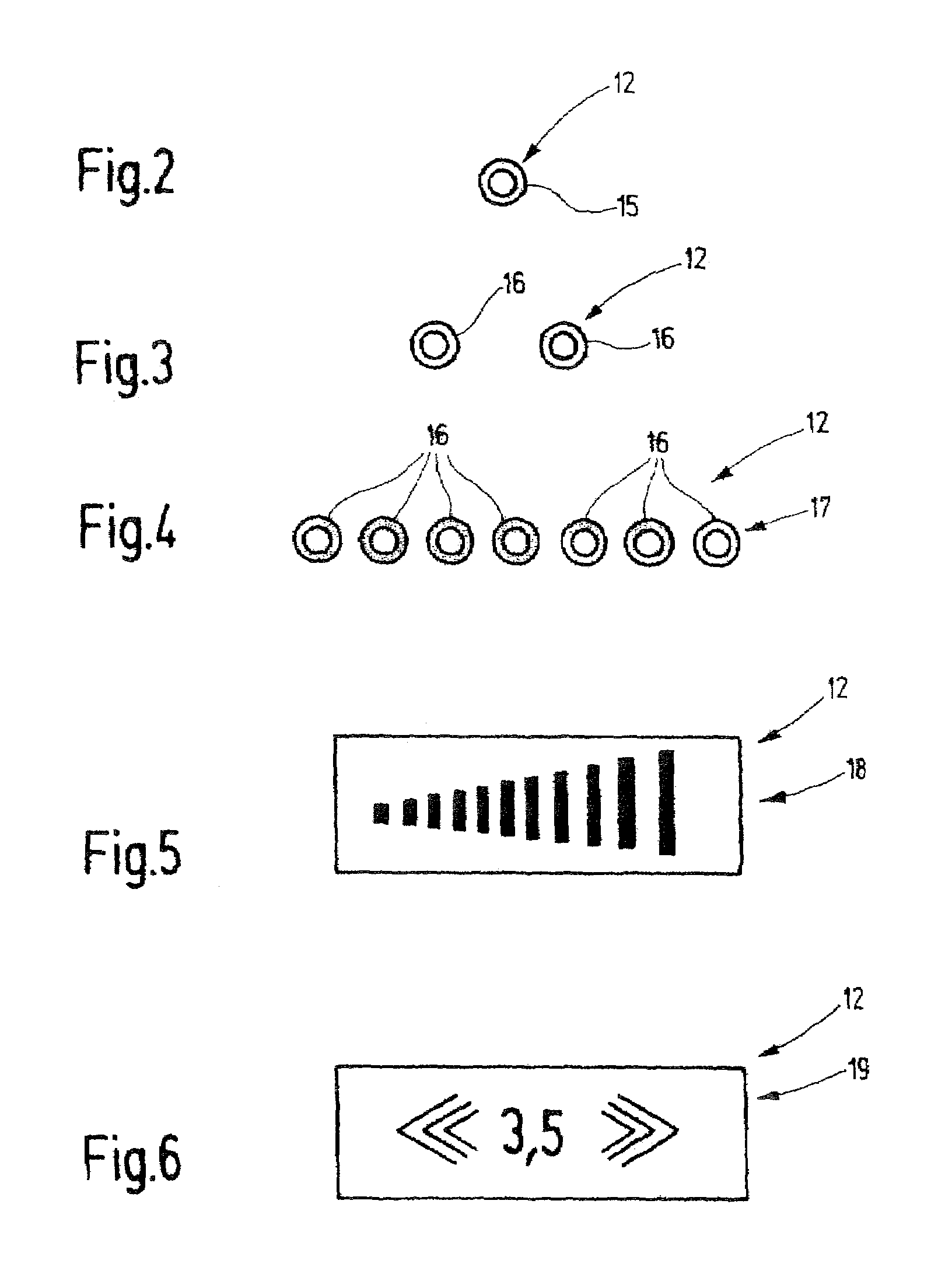

Electric power tool with optimized operating range

InactiveUS7504791B2Address bad outcomesReduce contact pressureDC motor speed/torque controlElectric motor controlContact pressureElectric power system

The invention relates to an electric power tool (1), having an electric motor (8) that serves to drive a tool (6). The electric power tool (1) is characterized in that a sensor unit (9) that detects the contact pressure of the tool (6) against a workpiece (7) cooperates with a signal transducer (10).

Owner:ROBERT BOSCH GMBH

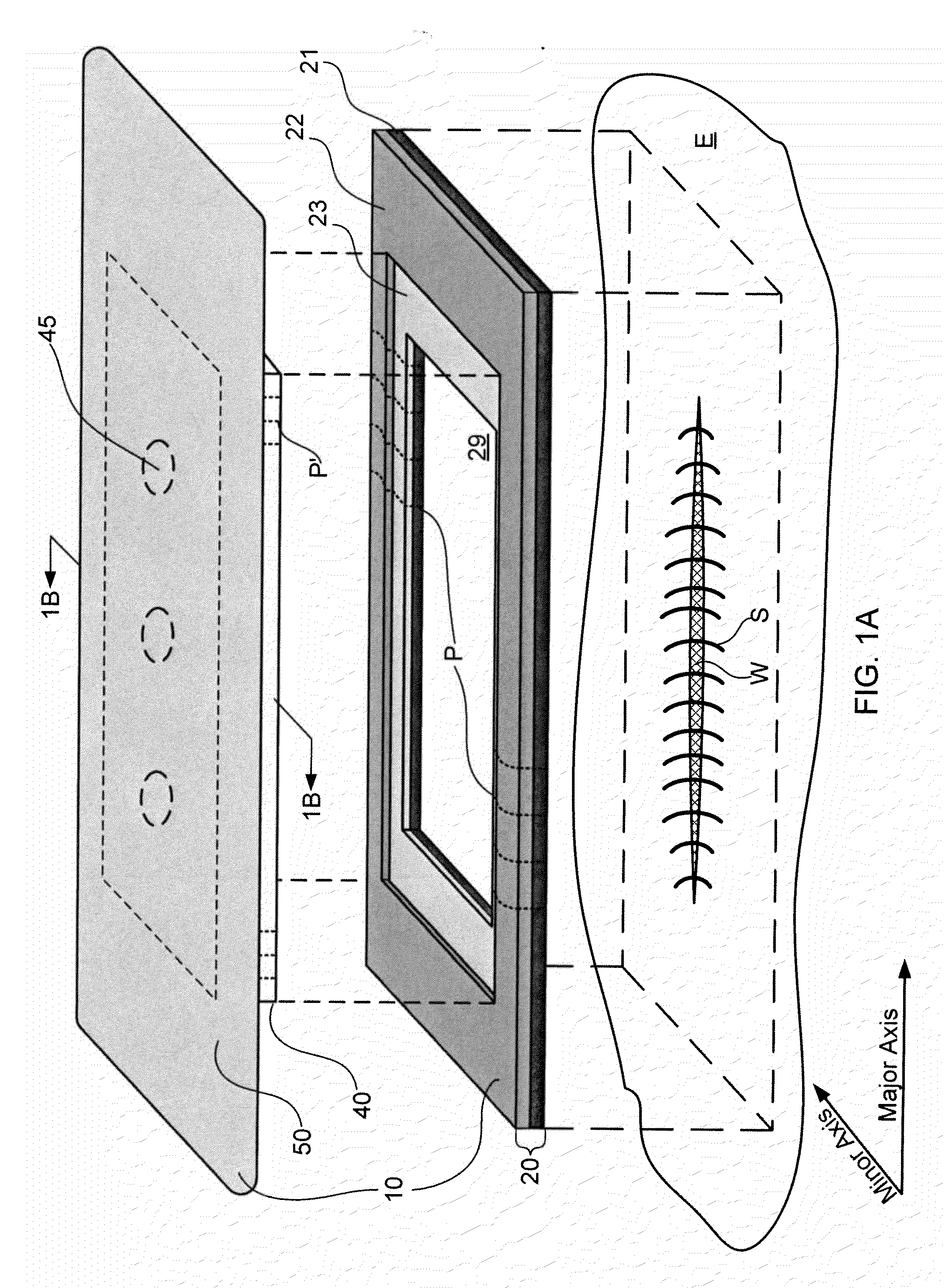

Systems And Methods For Protecting Incisions

InactiveUS20110015557A1Reduce contact pressureAvoid injurySuture equipmentsPlastersSurgical incisionLong axis

The present invention provides systems and methods for protecting wounds, such as surgical incisions. In one embodiment, a dressing for protecting a wound includes: a support cushion configured to surround the wound, the support cushion having sidewalls defining a major axis and a minor axis, the support cushion including at least two perforations that traverse the sidewalls at offset locations; a reservoir configured to be suspended over and in engagement with the support cushion; and a cover configured to be positioned over the reservoir. The at least two perforations may define first and second interlocking J-shaped portions. The support cushion may include a wicking portion configured to surround the wound and a hydrophobic portion configured to surround the hydrophobic portion. The wicking portion may be configured to transfer fluid from the wound to the reservoir. Methods of applying the dressing, and kits including the dressing, also are provided.

Owner:AALNEX

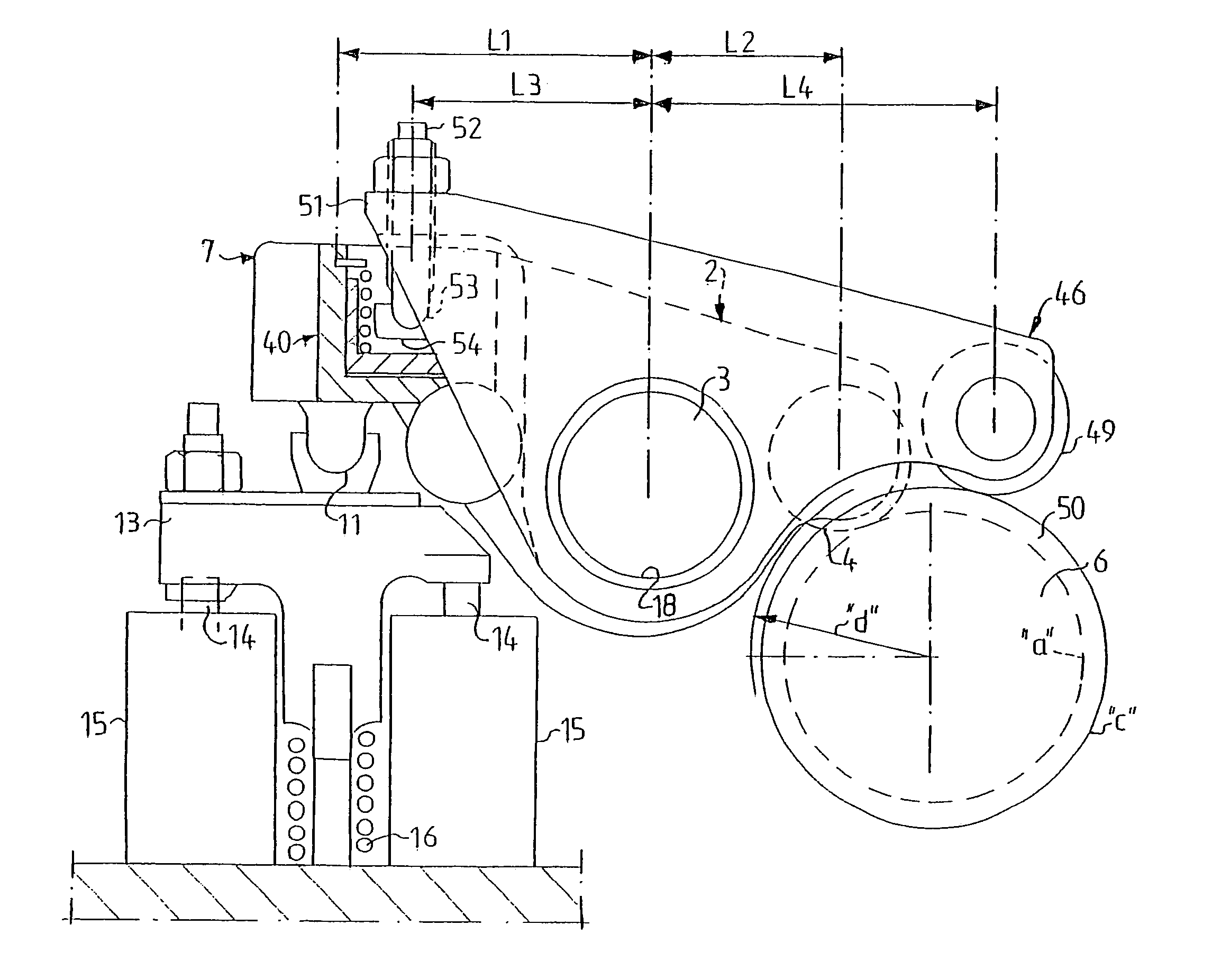

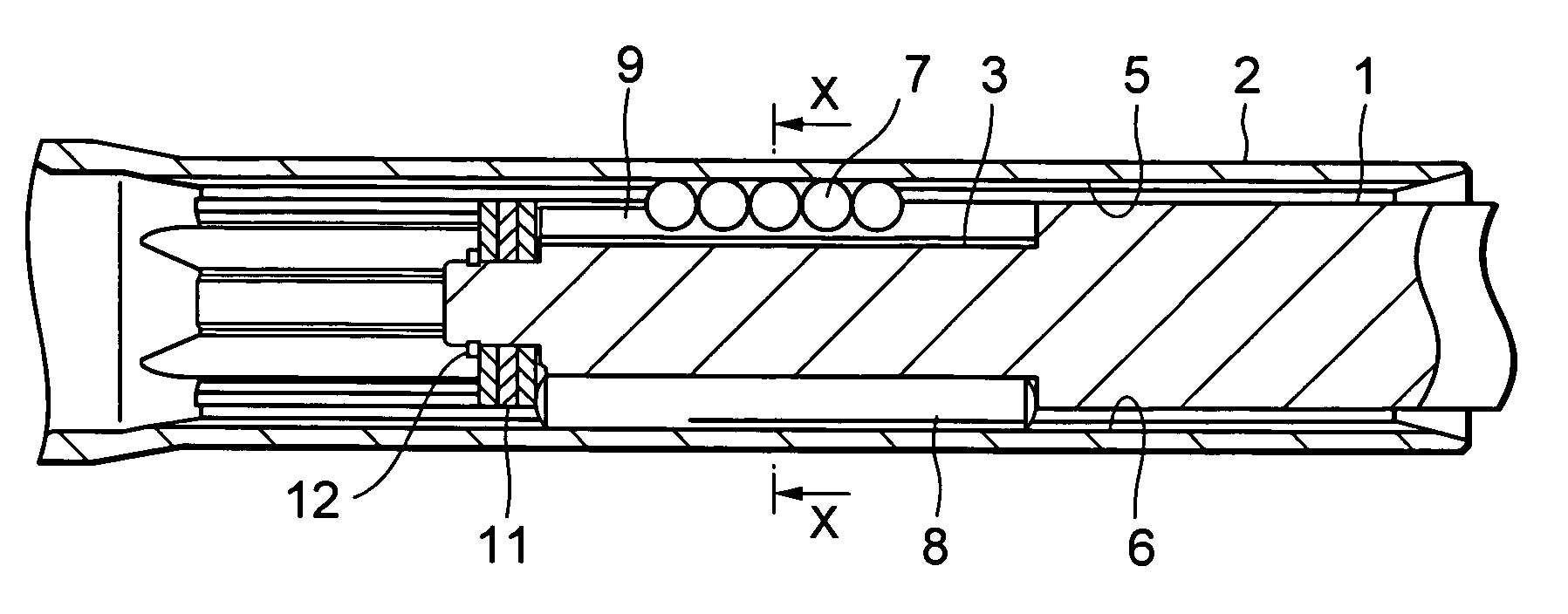

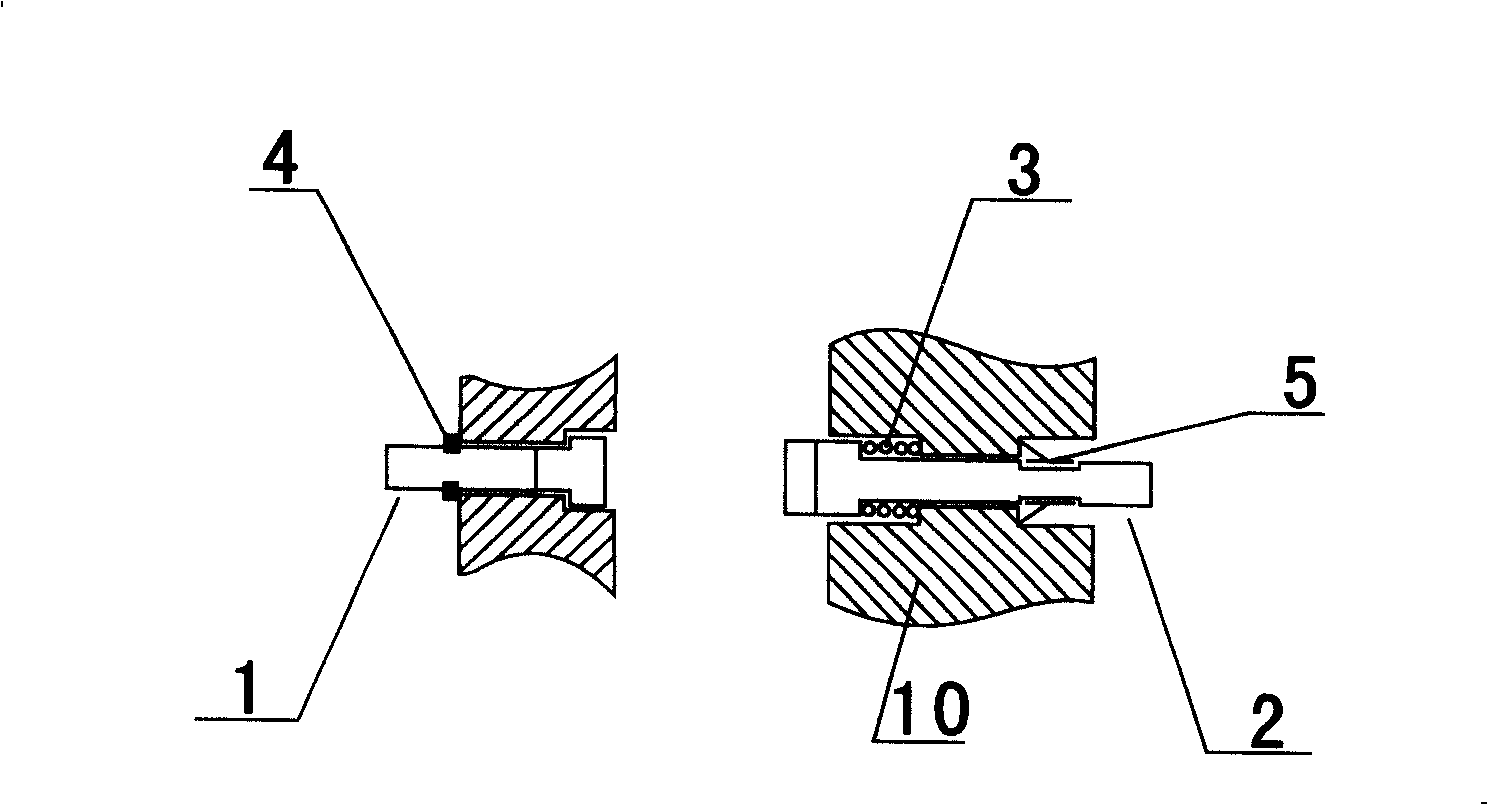

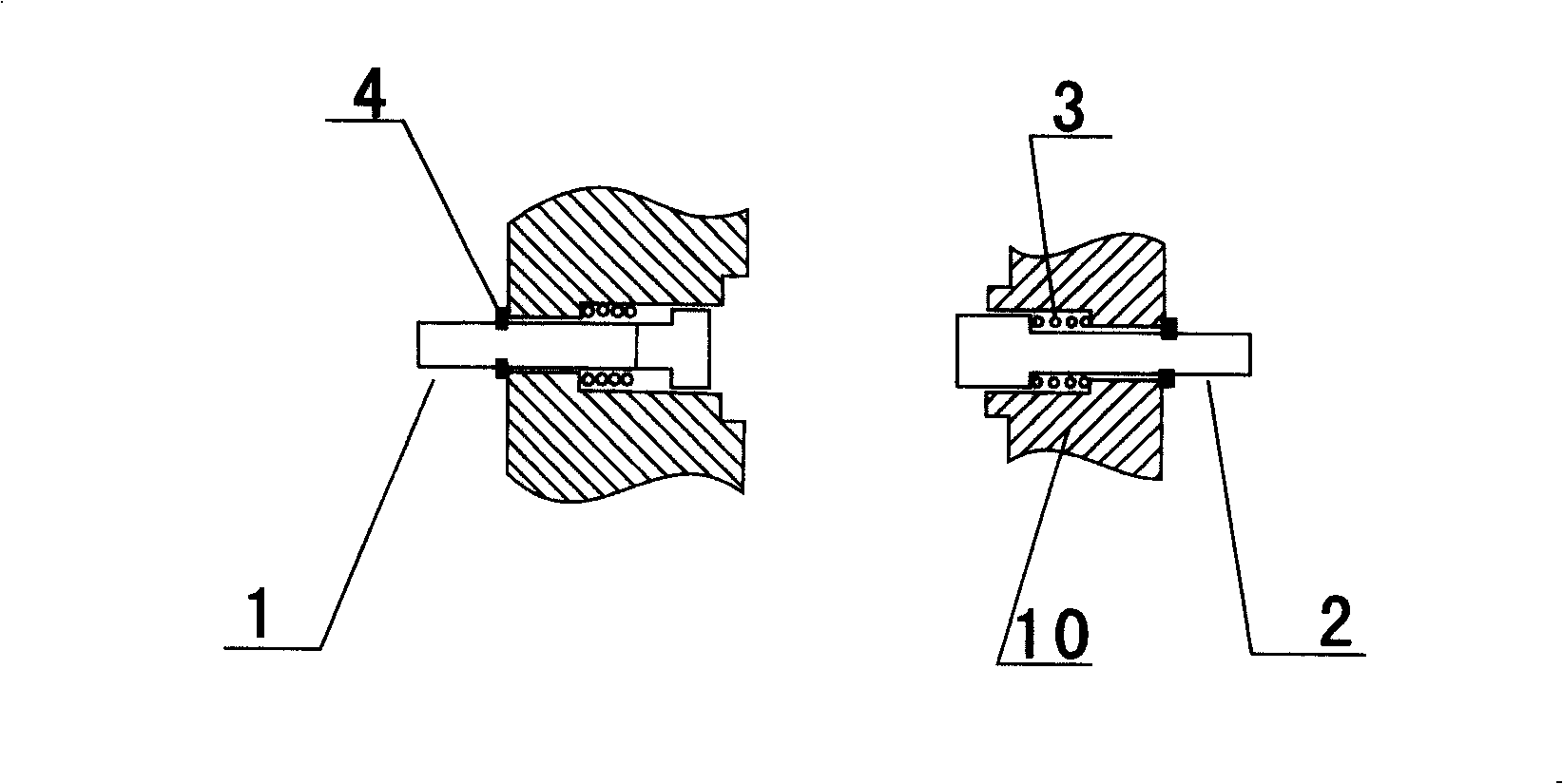

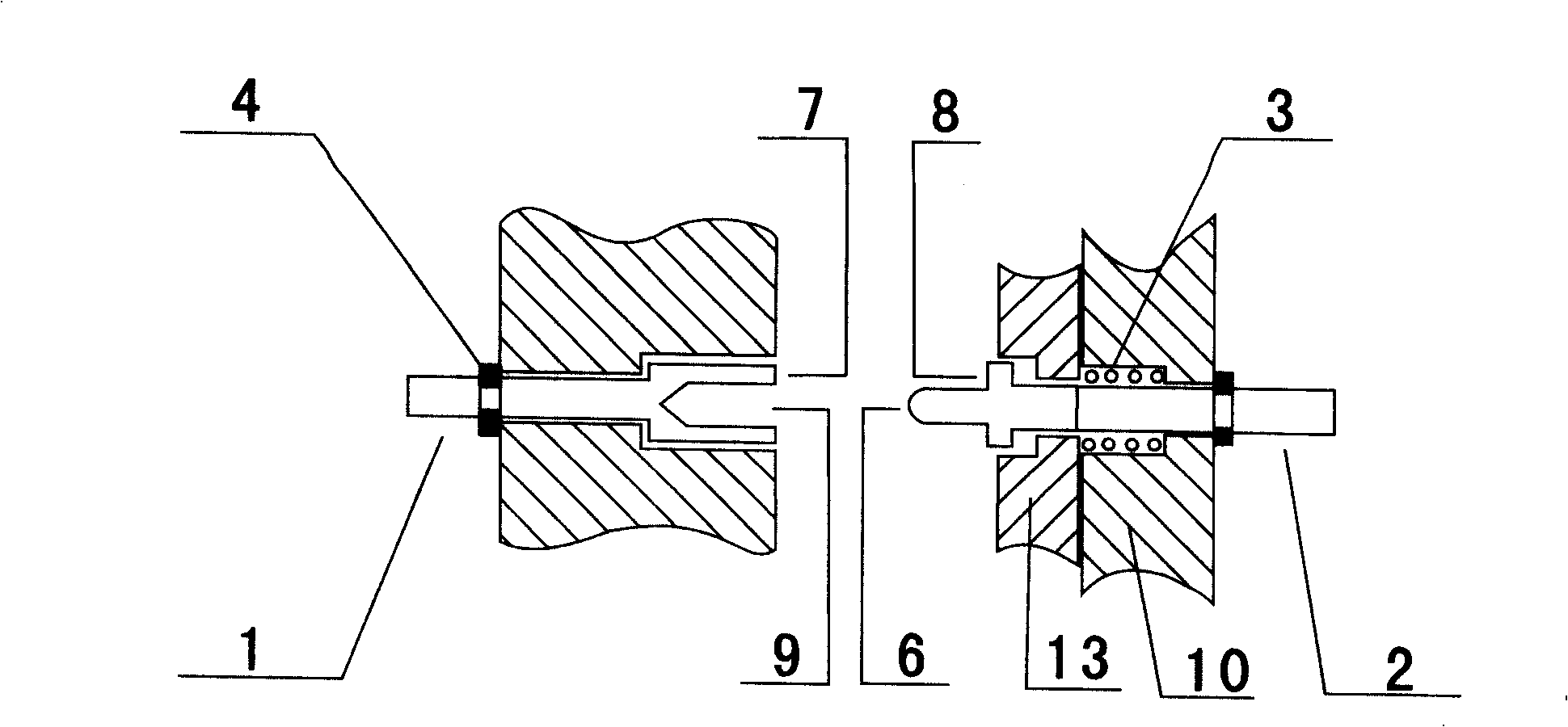

Telescopic shaft for vehicle steering

ActiveUS20060039747A1Evenly loadedPrevent reboundYielding couplingLinear bearingsEngineeringMechanical engineering

According to the present invention, a rolling element 7 for rotating upon relative movement of both shafts 1 and 2 in the axial direction is disposed between three pairs of axial grooves 3 and 5 which are formed on the outer peripheral surface of the male shaft 1 and on the inner peripheral surface of the female shaft 2, respectively, a raceway surface element 9 which is in contact with the rolling element 7 and an elastic member 10 for pressurizing the rolling element 7 against the male shaft 1 and the female shaft 2 through the raceway surface element 9 are interposed between the axial groove 3 on the male shaft side 1 and the rolling element 7, and a sliding member 8 for slidably moving upon relative movement of the both shafts 1 and 2 in the axial direction is disposed between another three pairs of axial grooves 4 and 6 which are formed on the outer peripheral surface of the male shaft 1 and on the inner peripheral surface of the female shaft 2, respectively.

Owner:NSK LTD

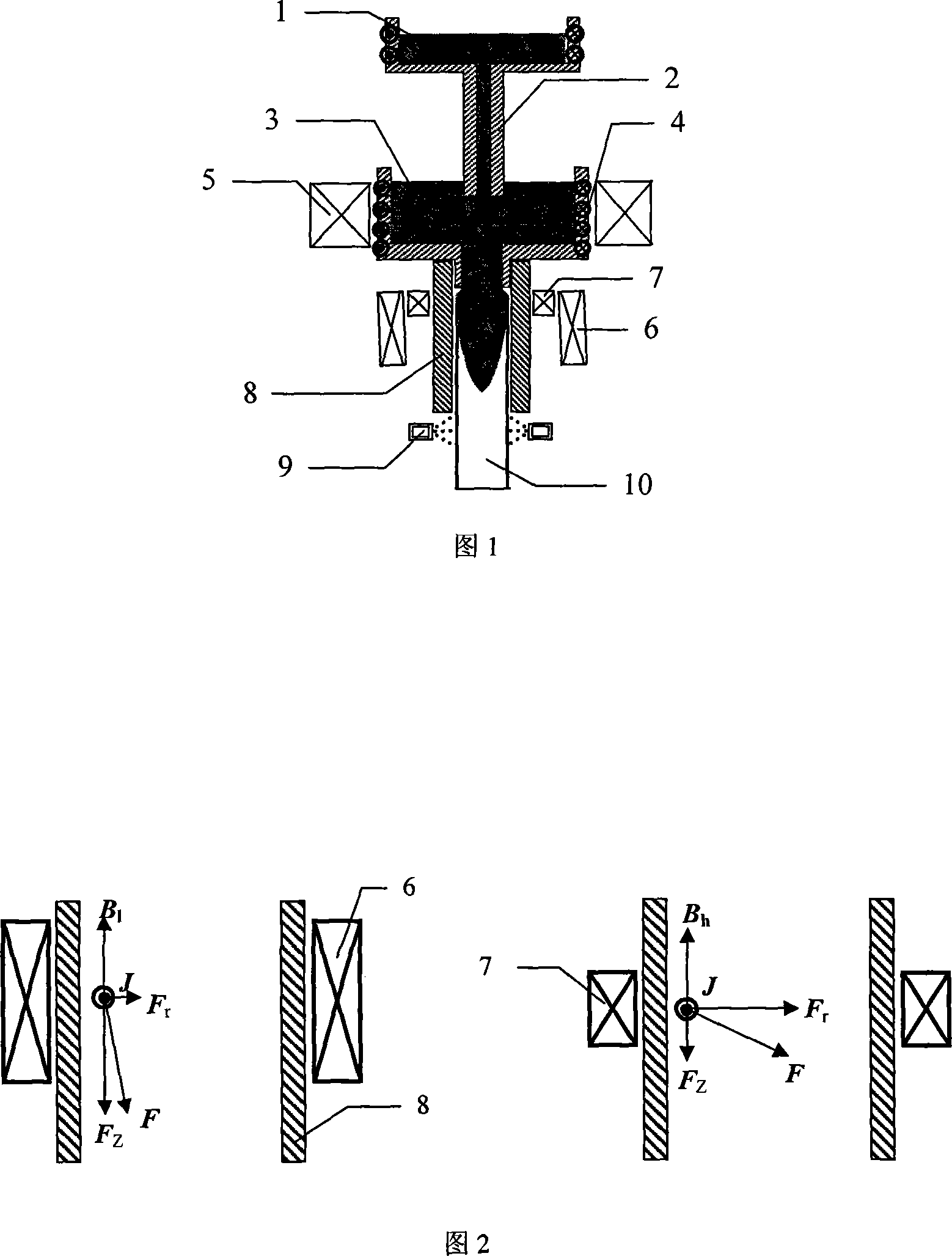

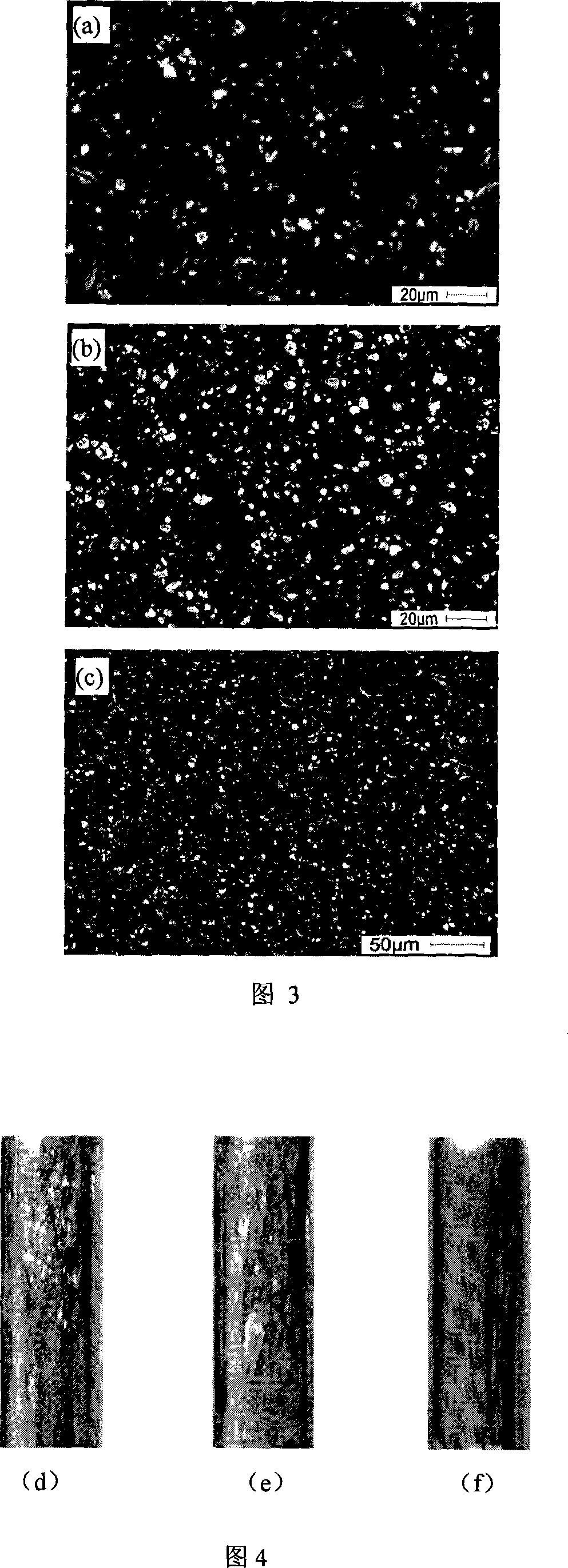

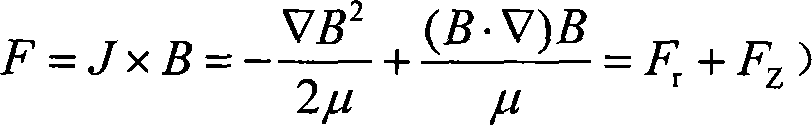

Method of continuous casting particulate reinforced metal matrix composites on different frequency multi-electromagnetic field

Disclosed is a method of particle reinforced metal matrix composite continuous casting in compound magnetic field at different frequency, relating to material processing technology field; in the process of the preparation of the composites melt, low-frequency alternating magnetic field is applied: the frequency is from 5 to 50 Hz, the power range is from 5 to 60 kW; electromagnetic stirring is carried out, making the particles to be fined and evenly distributed; in the process of continuous casting, low-frequency alternating magnetic field is applied to the crystallizer zone: the frequency is from 5 to 50 Hz, the power range is from 5 to 20 kW; electromagnetic stirring is carried out to improve the internal quality; meanwhile, the high-frequency alternating magnetic field is applied in initial solidification zone in crystallizer: the frequency is from10 to 50 kHz, the power range is from 20 to 100Kw, soft contact is applied to improve the surface quality of casting billet. The composites article reinforcement prepared by the method are evenly distributed and fined, the internal organization is compact without any structural defects such as rarefaction or shrinkage hole, the casting billet has high surface finish without any defects.

Owner:JIANGSU UNIV

Omni-directional wheels and methods and vehicles employing same

InactiveUS20080087484A1Constant ride heightLow wheel vibrationSteering linkagesLifting devicesEngineeringMechanical engineering

Owner:AIRTRAX

Axial elastic force-applying connection method for electric connector contact pair

InactiveCN101355208AEmission reductionSimple structureCoupling contact membersRelative displacementElectrical resistance and conductance

The invention provides a method for the axial elastic force application connection of electrical connector contact pairs. The method adopts an elastic element to apply axial external force to a contact pair consisting of a contact piece A (1) and a contact piece B (2), so as to combine the two tightly, thereby forming the electric connection with lower conductive resistance. One end of the elastic element is in contact with an insulating base so as to turn into a relative fixed end; and the other end of the elastic element directly acts on a preset fixed end face of an electric conductor contact piece, and is a relative displacement end during axial force application. The contact pair is independently formed by the end planes of the two contact pieces with simple structure. As axial elastic connection can not be affected by shock or other external factors, the connection reliability is higher. The contact pair can be formed by a positive contact piece and a negative contact piece as well, which ensures that the radial and axial directions of the contact pair are uniform in stress and contact.

Owner:徐志

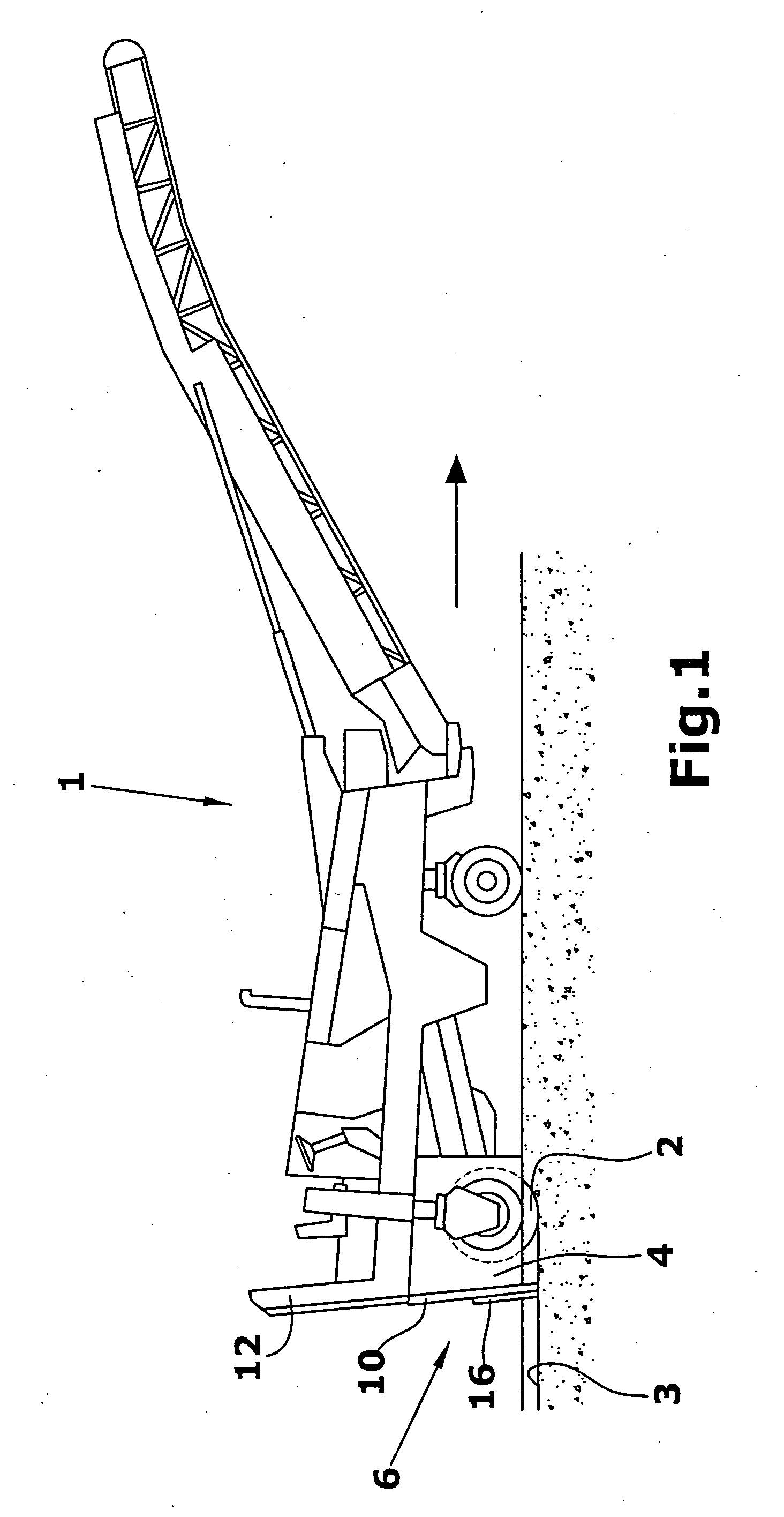

Stripping means for milling rolls of a construction machine as well as a construction machine and a method

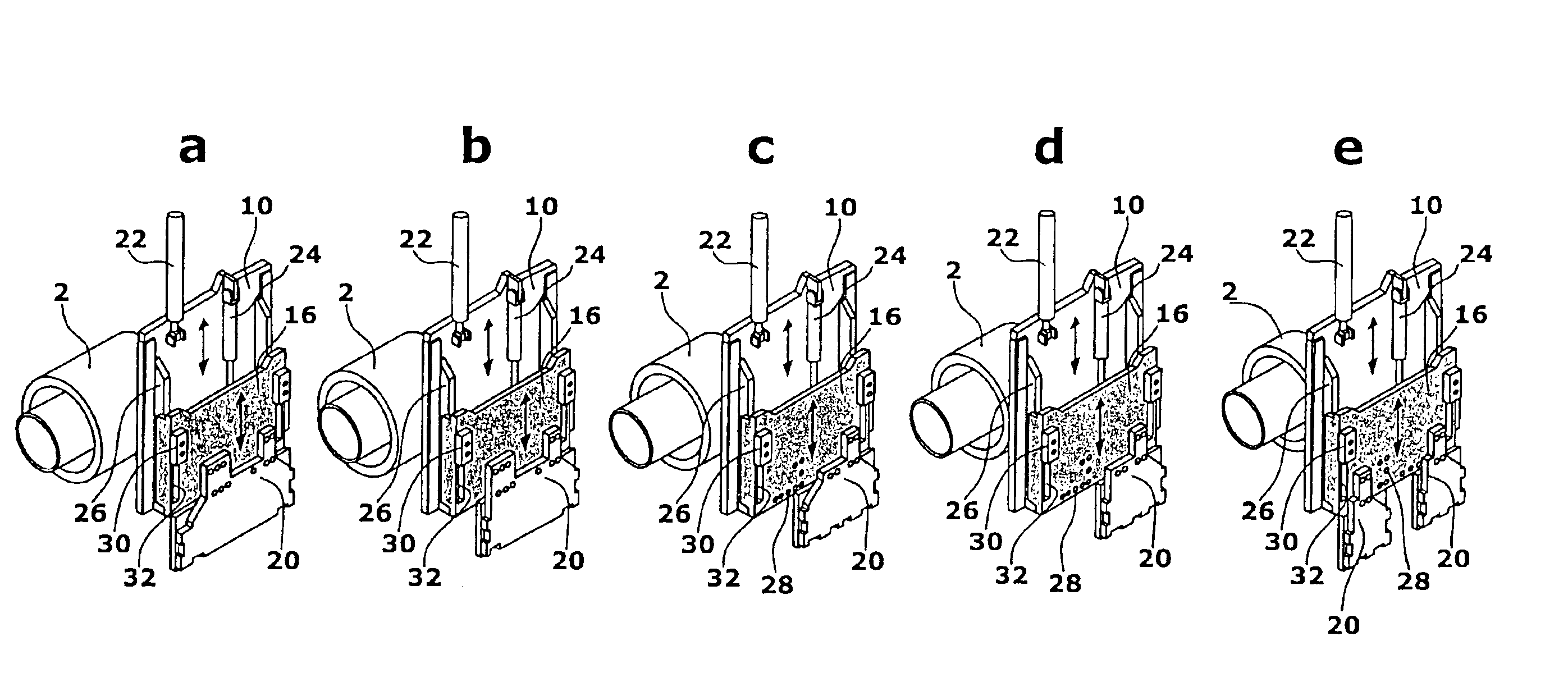

ActiveUS20040075330A1Improve cleanlinessReduce contact pressureMechanical machines/dredgersRoads maintainenceRoad surfaceMechanical engineering

In a stripping means for milling rolls (2) of a construction machine, particularly a road milling machine (1), where milling rolls (2) of different milling widths are usable within a maximum milling width, comprising at least one stripping blade (8) arranged behind the milling roll (2) in traveling direction so as to be adjustable in height, which is able to glide over the surface (3) milled or to be milled by the at least one milling roll (2), it is provided that the stripping blade (10) covers the maximum milling width, and that a mounting means (16) adjustable in height relative to the stripping blade (20) is arranged for at least one lower stripper portion (20) adapted to the respectively used milling roll (2) or milling rolls, the lower stripper portion (20) being able to be positioned, by means of the mounting means (16), in a position corresponding to the milling roll (2) within the width of the stripping blade (10).

Owner:WIRTGEN GMBH

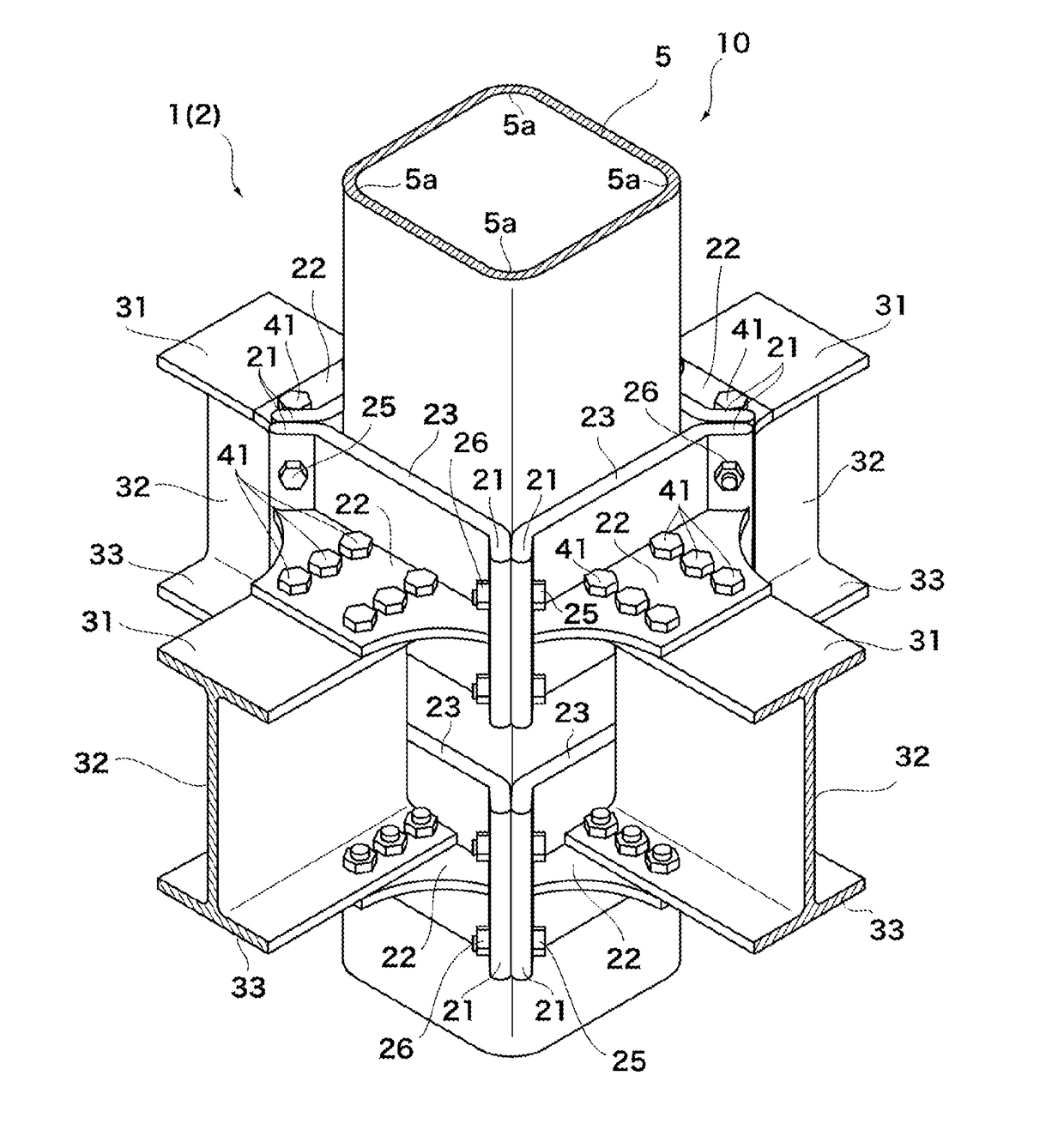

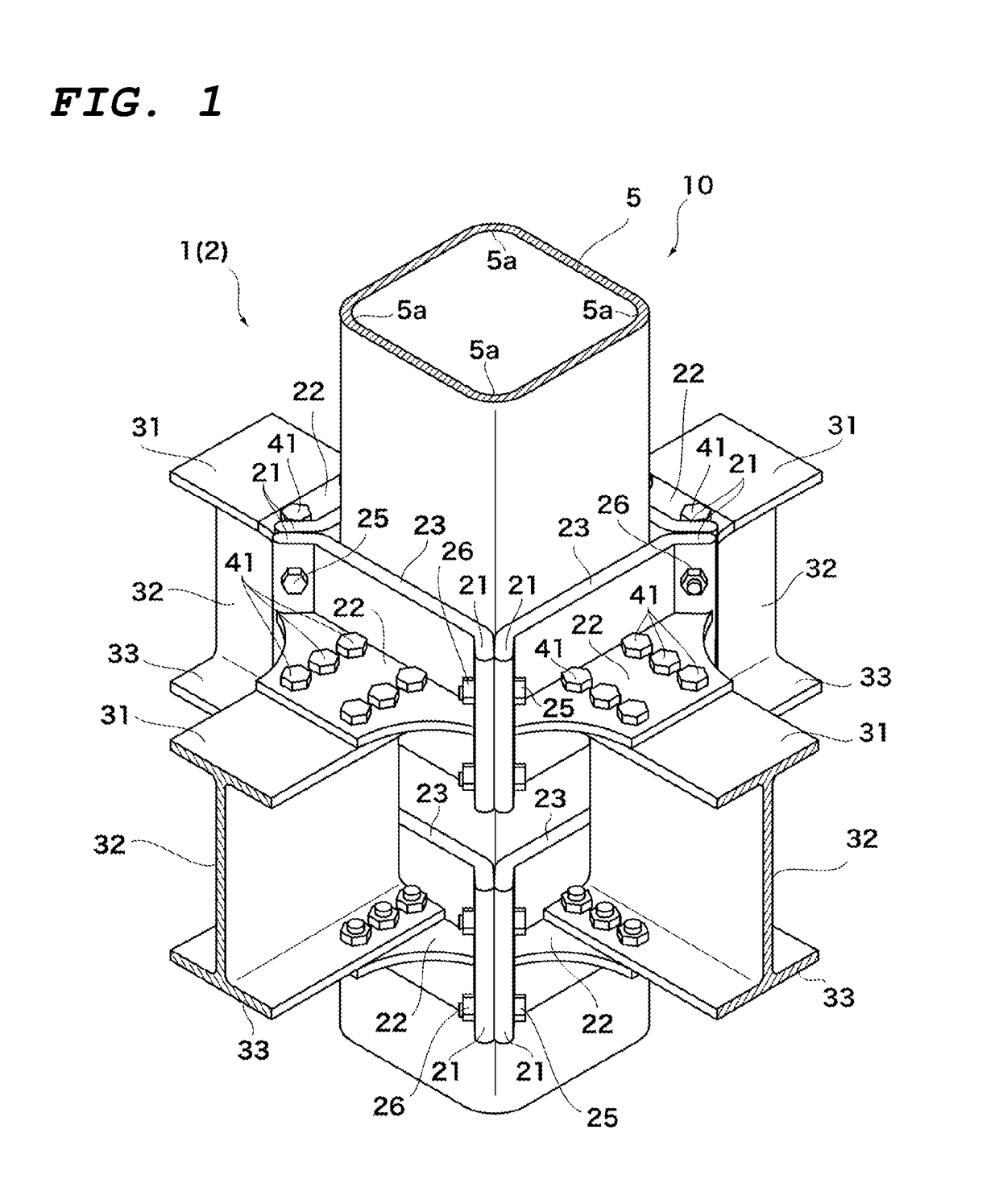

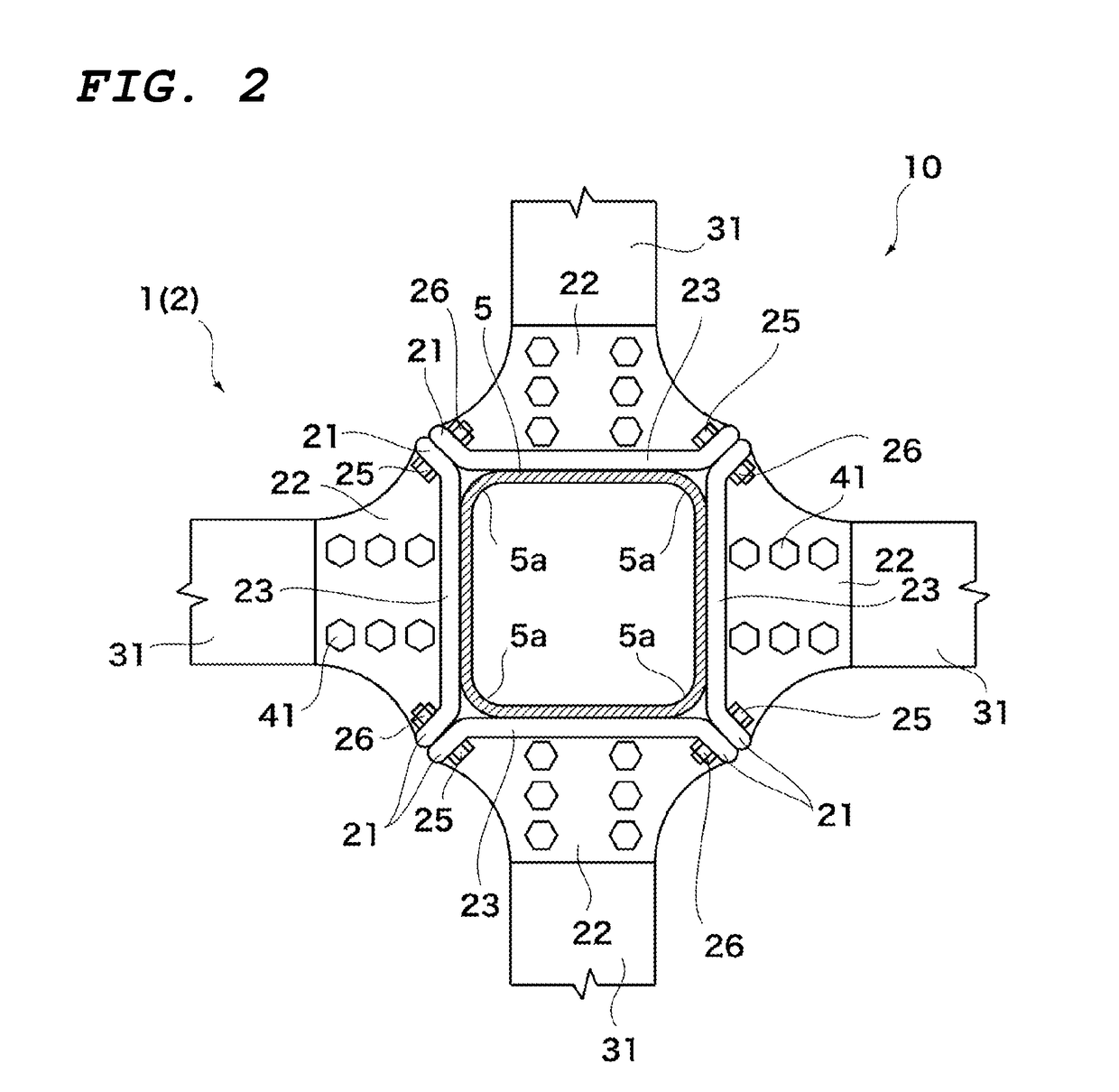

Column and beam connection structure and method

InactiveUS20180223521A1Reduce laborShorten the manufacturing cycleBuilding constructionsContact pressureFlange

A column and beam connection structure for connecting a steel H-beam to a column uses an external diaphragm. The external diaphragm includes a plurality of divided diaphragm segments such that each diaphragm segment has a column plate abutting on the column. A diaphragm segment which is arranged along the steel H-beam among the plurality of divided diaphragm segments has a beam plate installed in a flange of the steel H-beam. The beam plate has an end portion in which the column plate is provided. A joining surface between the diaphragm segments is placed in a vicinity of a corner portion of the column so that only the column plate of one of the diaphragm segments abuts on each column surface of the column. A joining member fastens to fix between the diaphragm segments such that contact pressure is applied from the column plates to the surface of the column.

Owner:NIPPON STEEL & SUMIKIN METAL PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com