Pure shear test loading device for boards

A loading device, pure shearing technology, applied in the measurement device, using a stable shear force to test the strength of the material, analyzing the material, etc. Guarantee and other issues to achieve the effect of preventing wrinkling and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

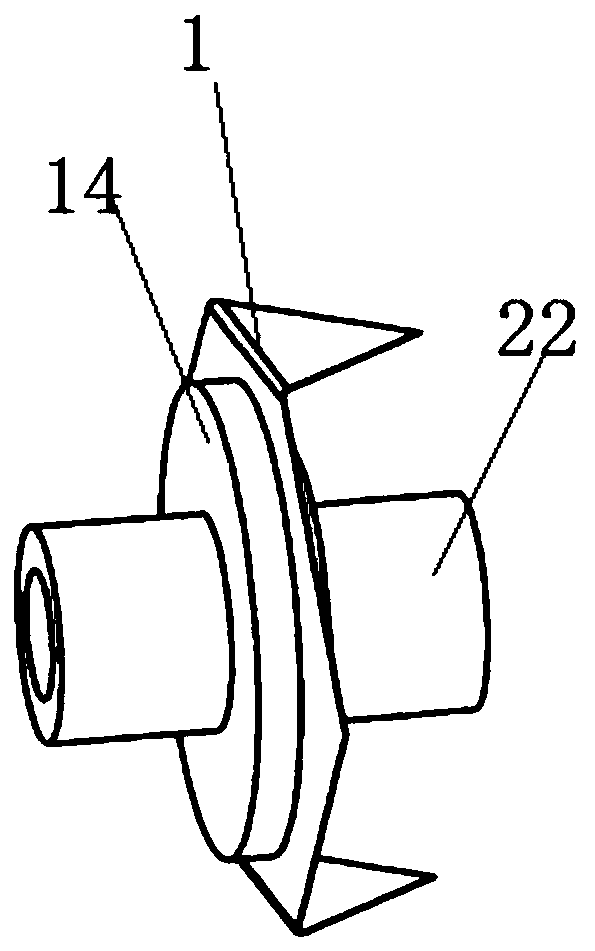

[0026] Example 1: Please refer to Figure 1-5 , a plate pure shear experiment loading device, comprising a plate test piece 1, a front loading device 14 and a rear loading device 22, the plate test piece 1 is arranged between the front loading device 14 and the rear loading device 22, to facilitate the plate test The cutting of piece 1 is convenient for use.

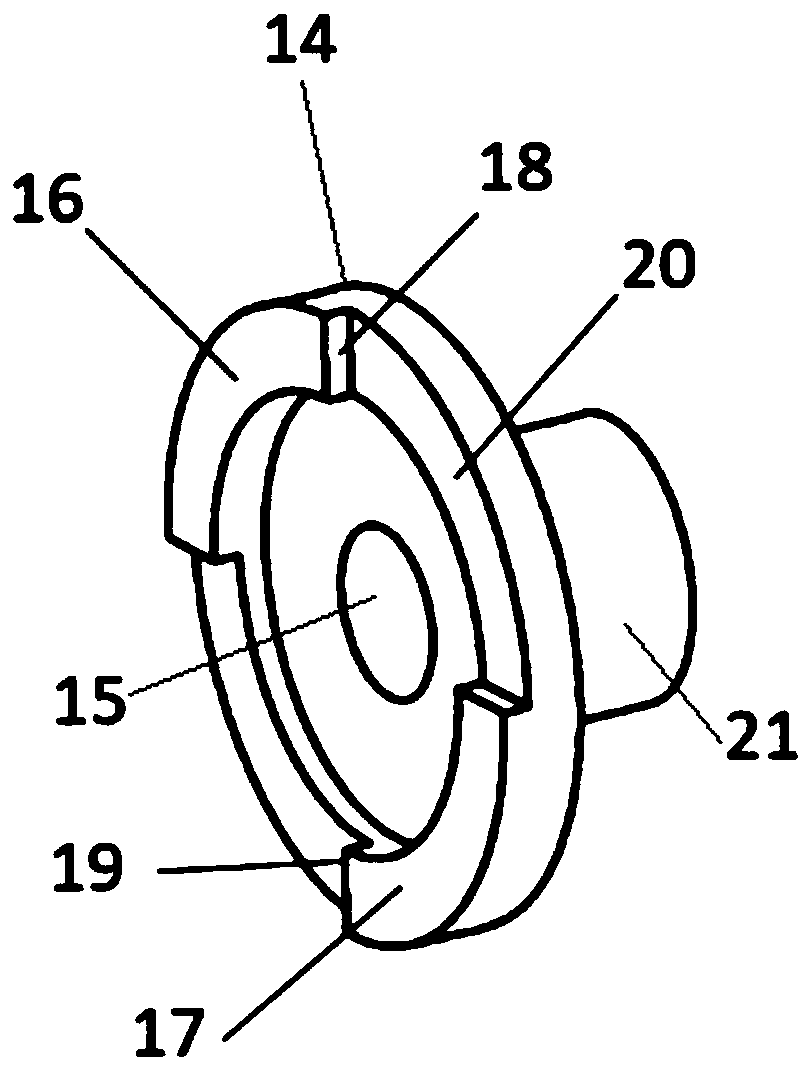

[0027] The front loading device 14 is provided with a front connection torsion testing machine area 21 outside, and the front connection torsion testing machine area 21 is provided with a front loading device positioning hole 15, and the front loading device 14 is provided with a front loading device positioning surface 20, and the front loading device positioning The surface 20 is provided with a front upper shear force application step 16 and a front lower shear force application step 17, and the front upper shear force application step 16 sidewall is a front loading upper shear force application wall 18, and the front...

Embodiment 2

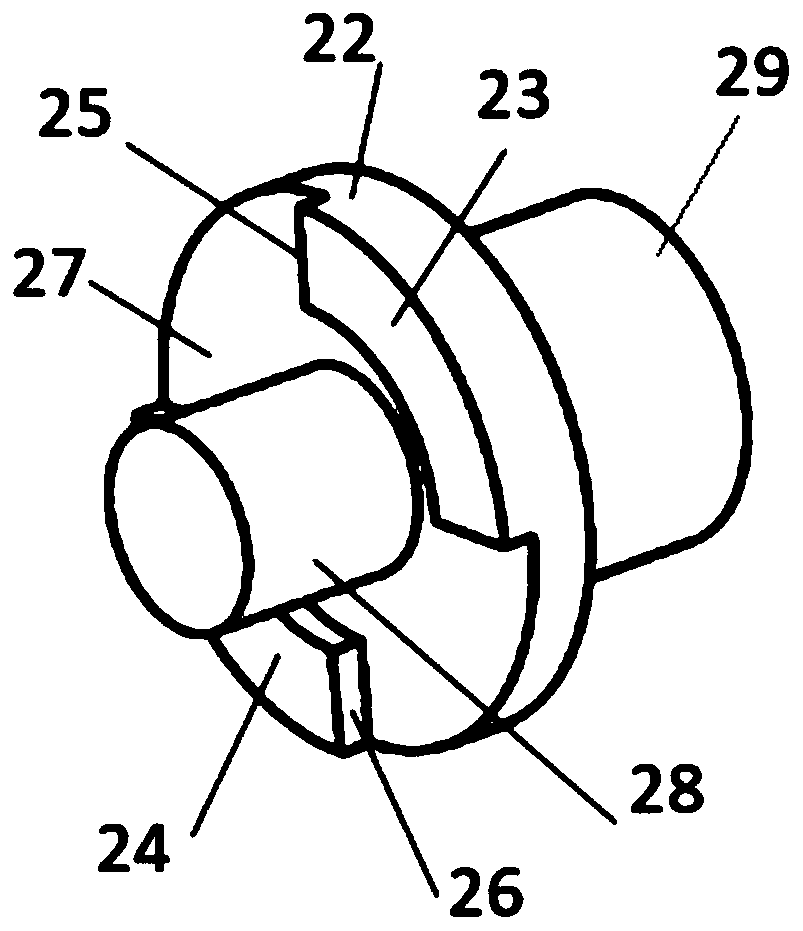

[0034] Embodiment 2: On the basis of Embodiment 1, for the connection of the plate test piece 1 and the rear loading device 22, first, connect the upper inner fan-shaped opening 3 and the lower inner fan-shaped opening 4 of the plate test piece 1 with the rear loading device 22. The upper shear force application step 23 and the rear lower shear force application step 24 are interspersed together, so that the post-load upper shear force application wall 25 and the post-load lower shear force application wall 26 of the post-loading device 22 are connected to the plate specimen 1. The upper inner fan-shaped shear loading wall 5 and the lower inner fan-shaped shear loading wall 6 are close together, and at the same time, the inner surface 13 of the plate test piece 1 and the positioning surface 27 of the rear loading device 22 are close together without gaps, and the plate test piece The outer diameter dimensions of the inner fan-shaped openings 3 and 4 of the piece 1 are the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com