Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6258results about "Material strength using repeated/pulsating forces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

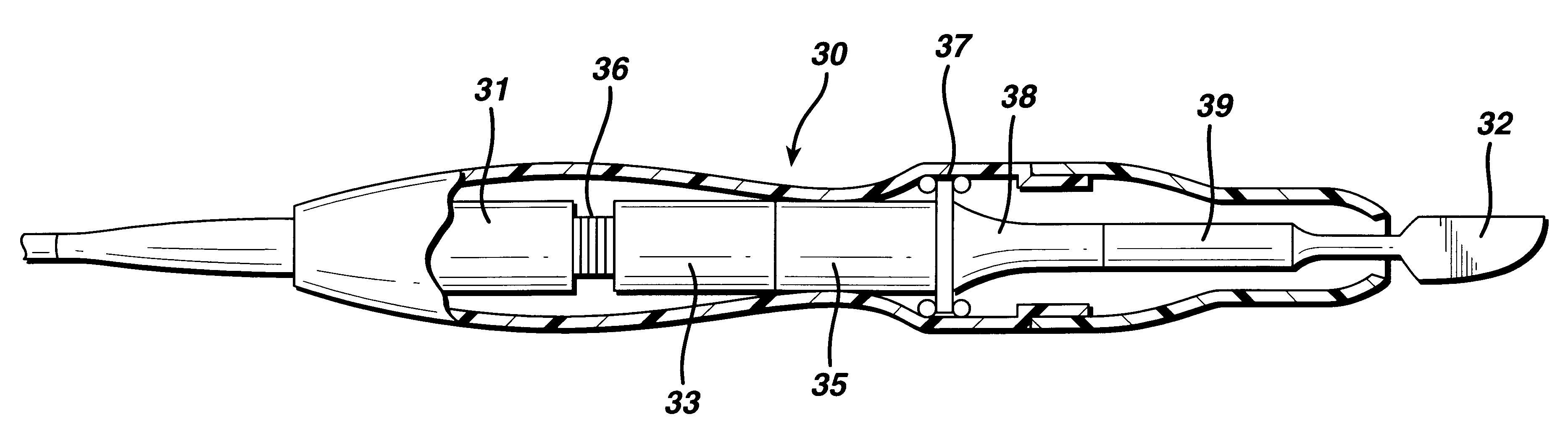

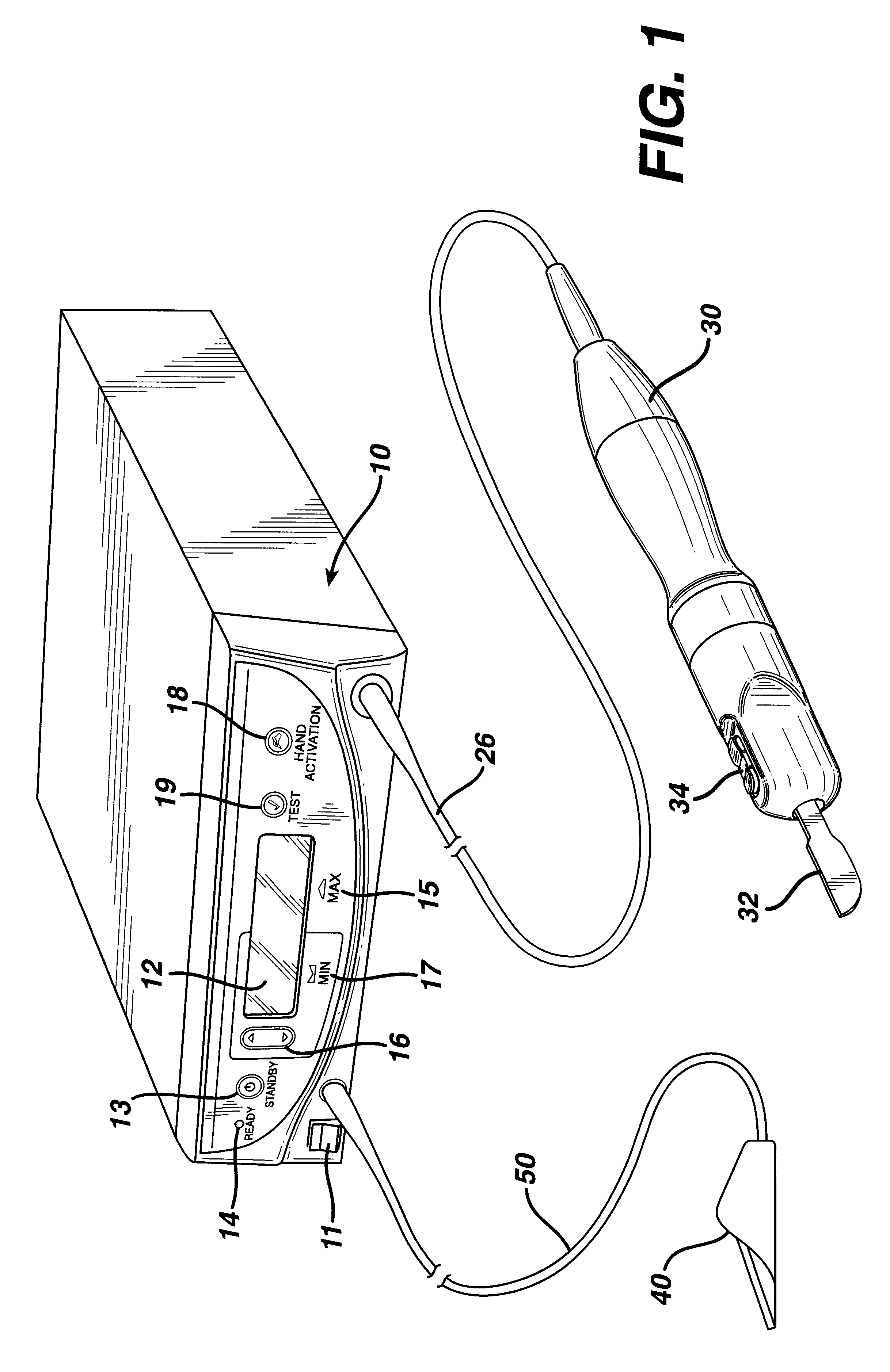

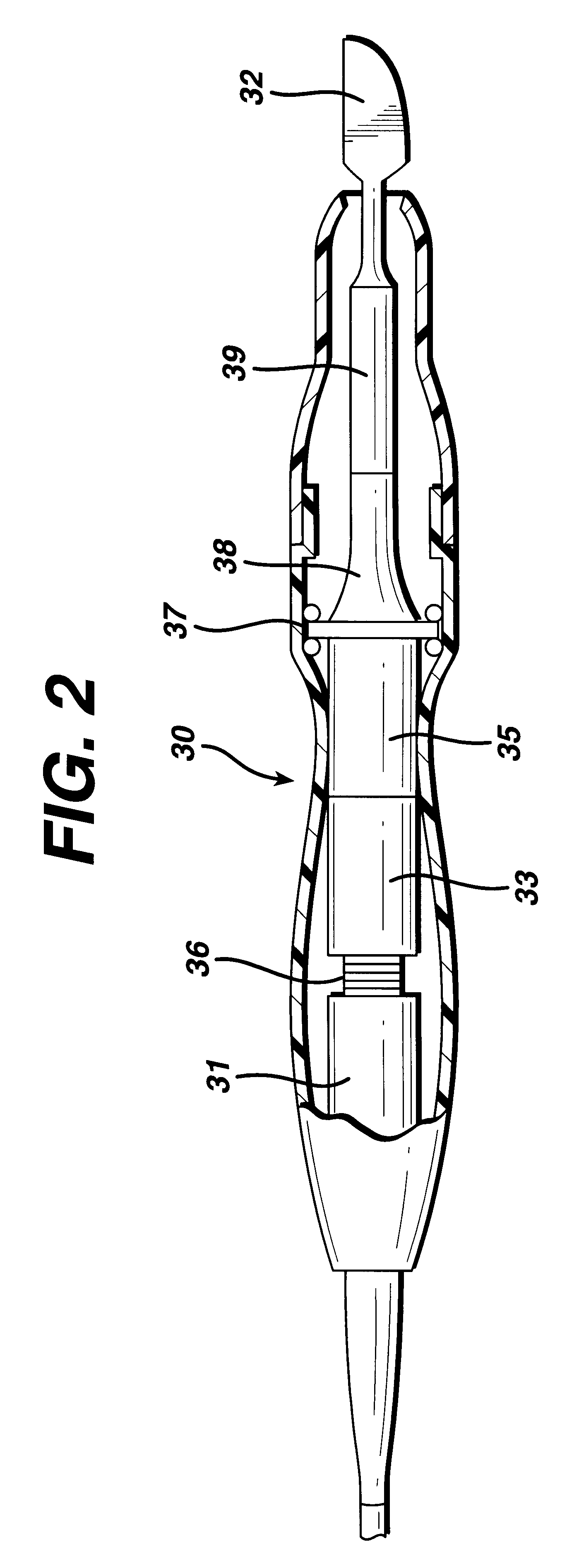

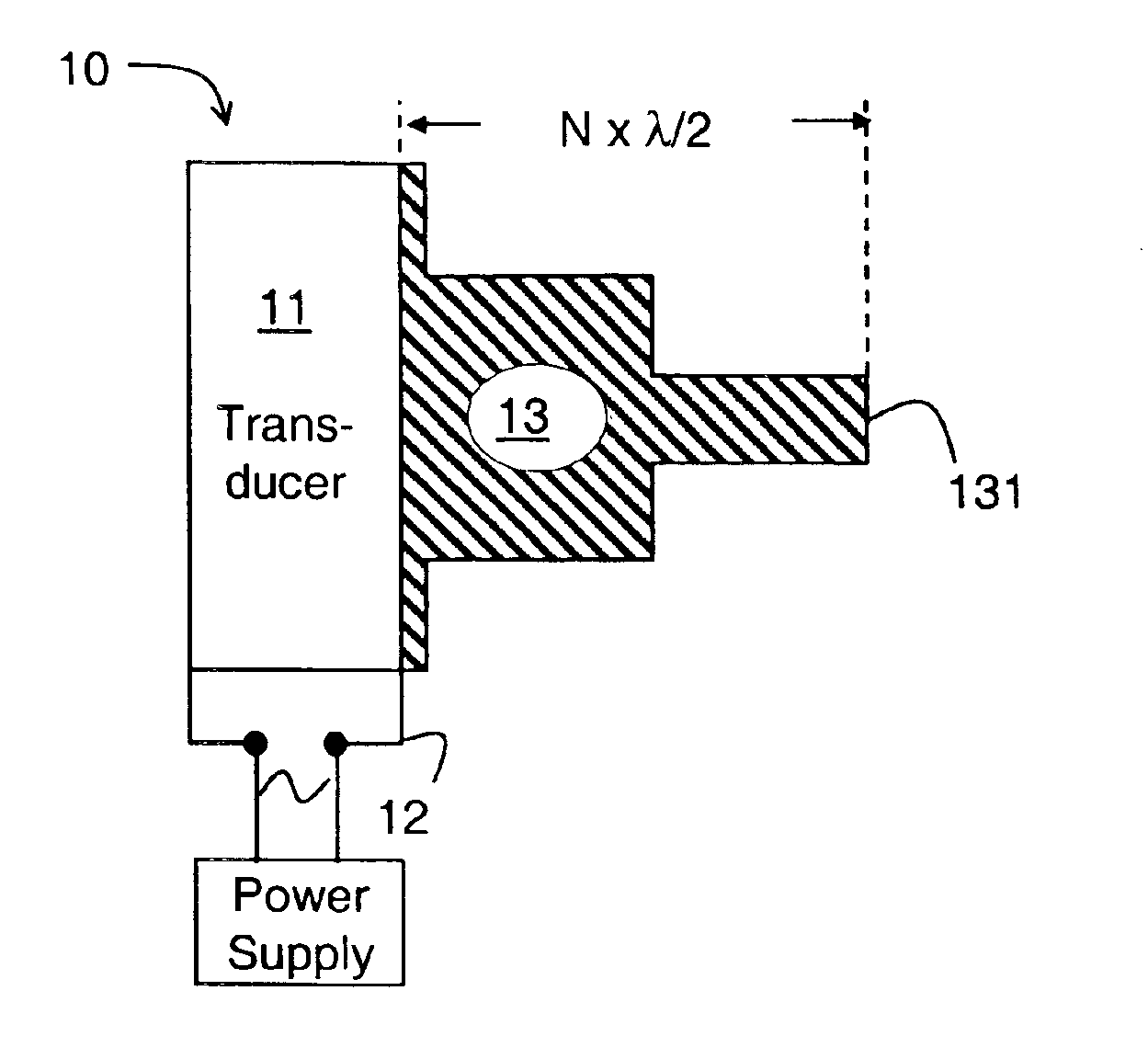

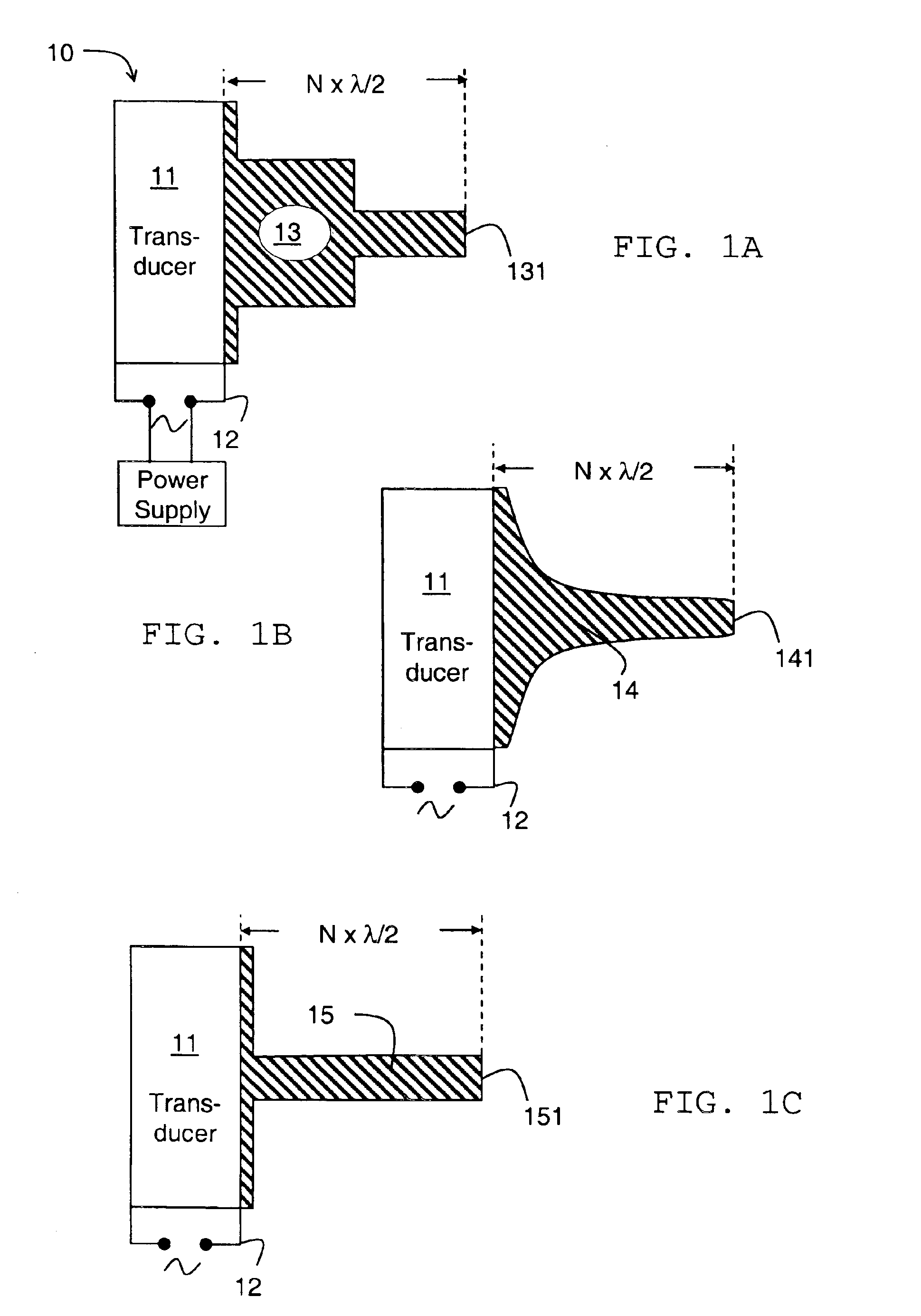

Method for detecting transverse mode vibrations in an ultrasonic hand piece/blade

InactiveUS6588277B2Low costRecuperation increasedVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesResonanceEngineering

A method for detecting transverse mode vibrations in an ultrasonic hand piece / blade for determining the existence of unwanted vibration in the hand piece / blade. A tracking filter centered at the drive frequency of the generator, is used to monitor the drive frequency of the ultrasonic generator and attenuate the drive signal when it exceeds a predetermined level. The tracking filter has a wide pass band. Alternatively, a tracking filter having a pass band which is divided into several regions is used to avoid other longitudinal resonances, such as a resonance at a second harmonic, or other spectral features that would otherwise detract from the tracking accuracy of the filter.

Owner:ETHICON ENDO SURGERY INC

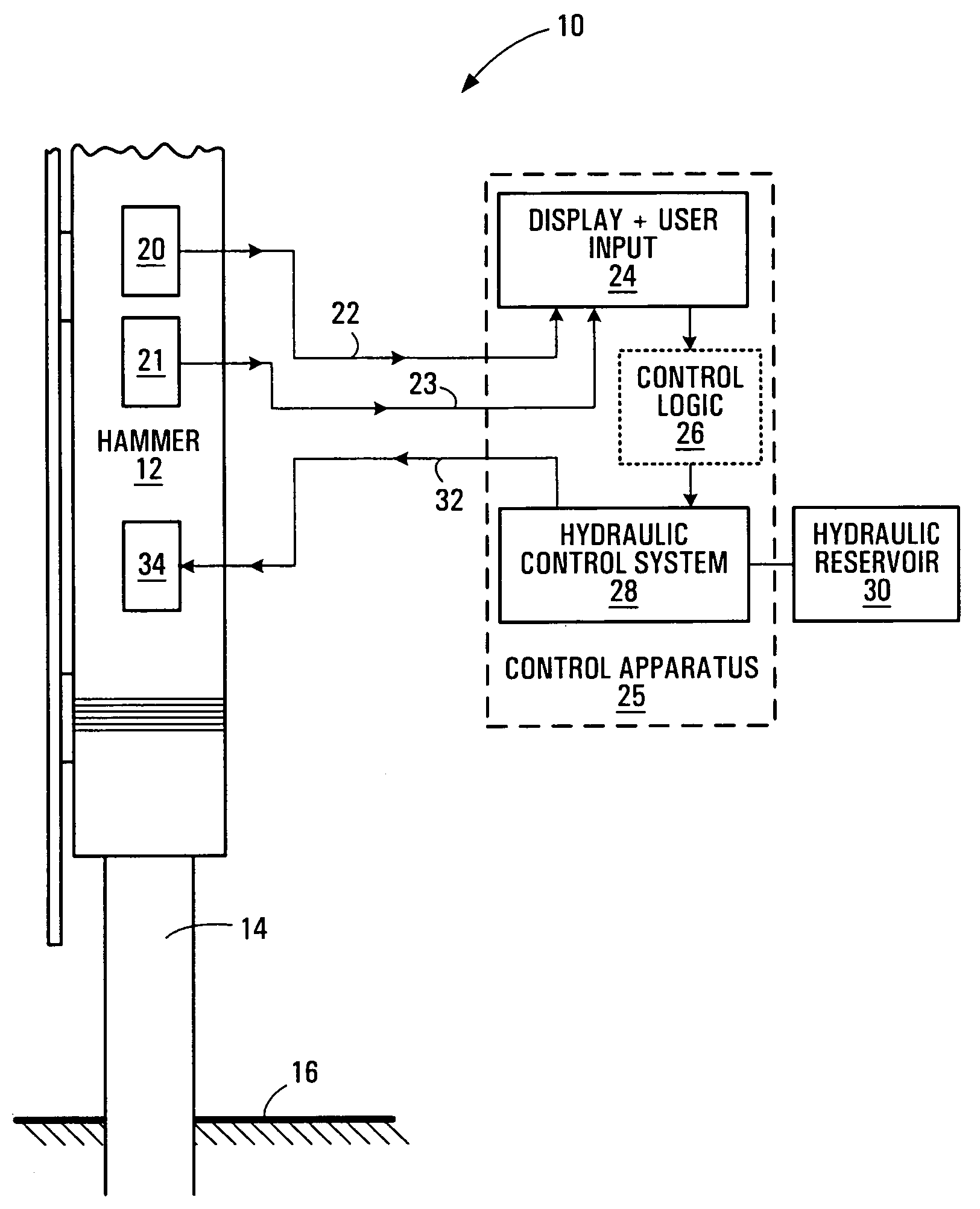

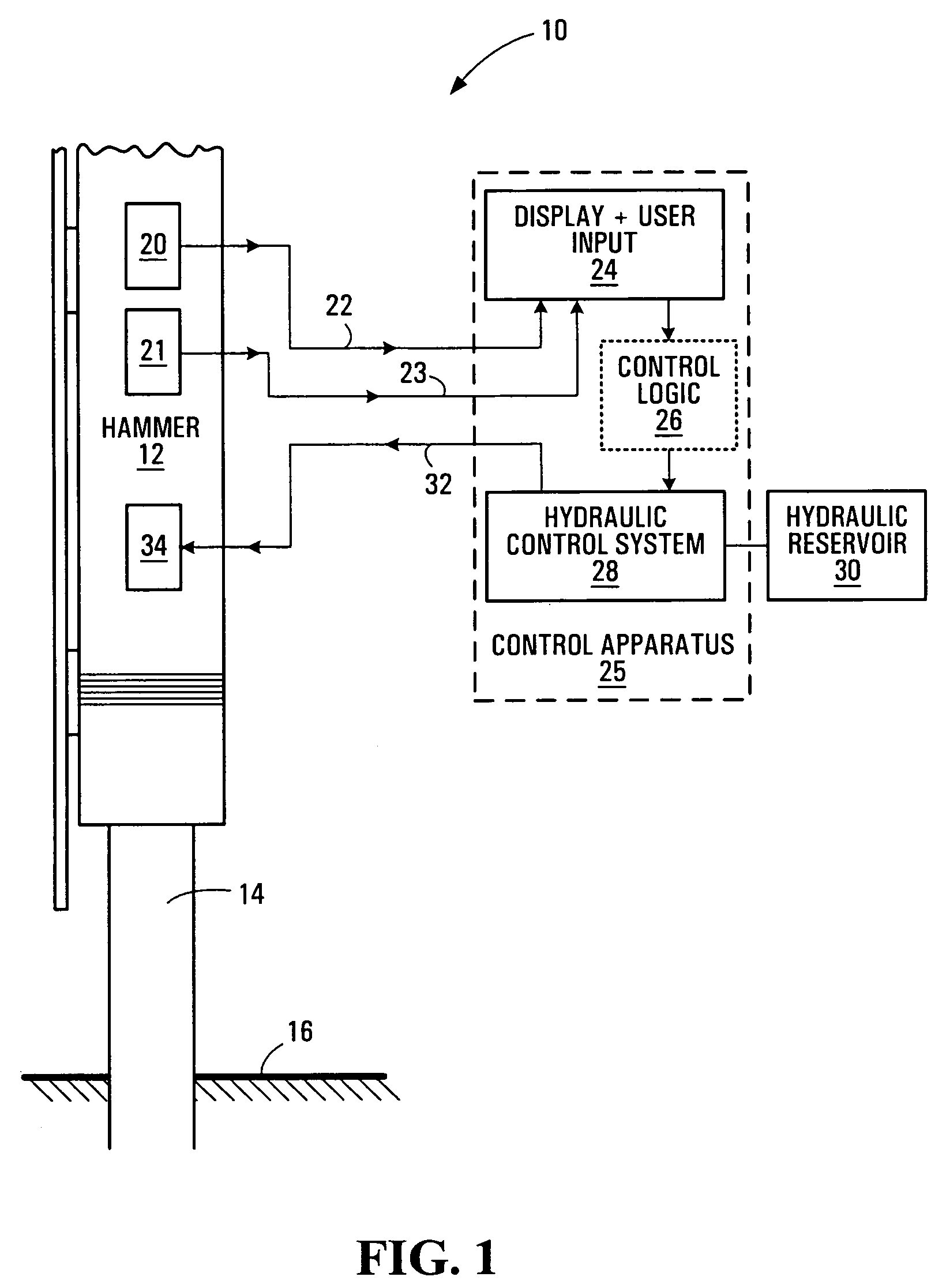

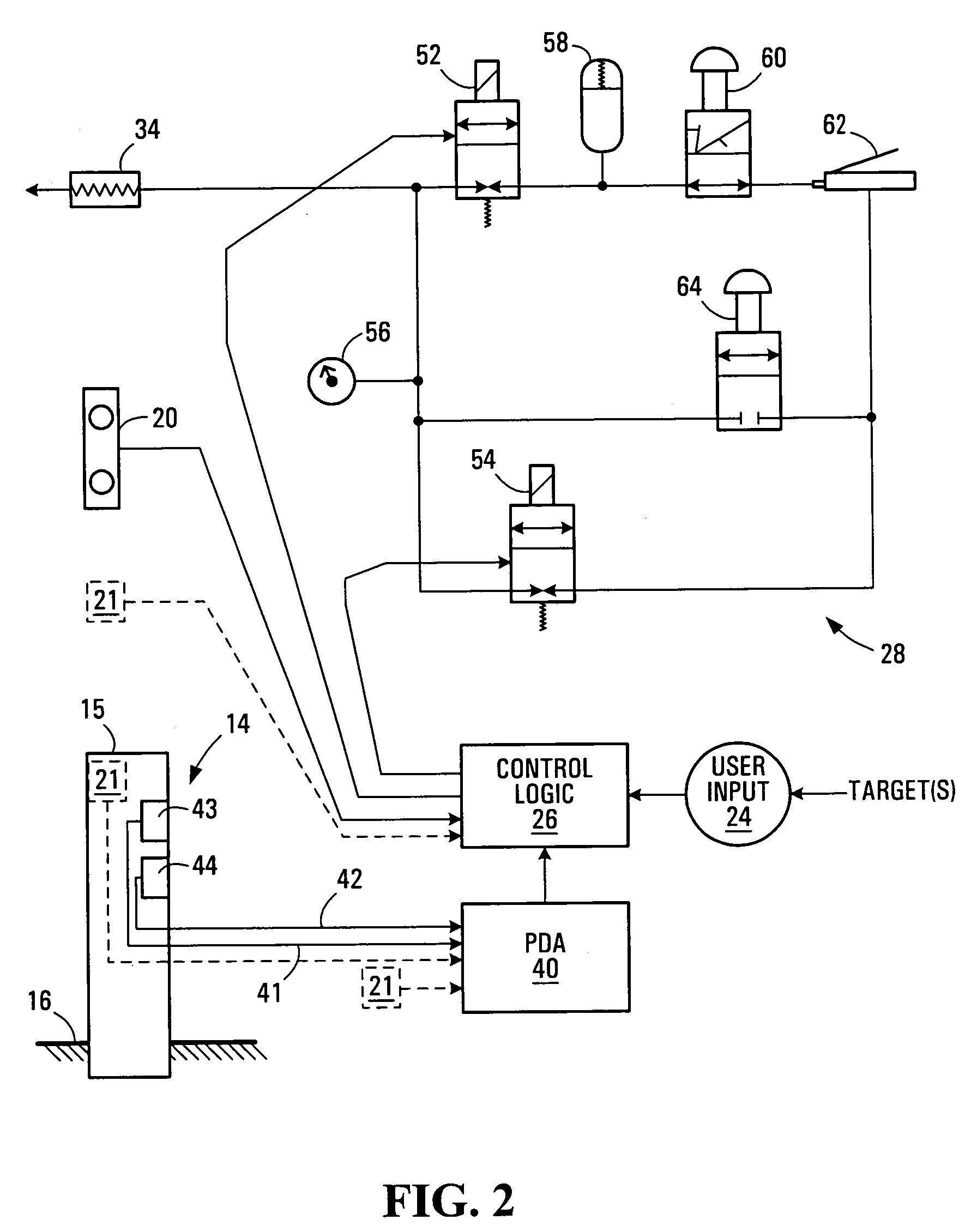

Pile driving control apparatus and pile driving system

ActiveUS7404449B2Reduce impact speedReciprocating drilling machinesDerricks/mastsVibration controlControl system

A pile driving control apparatus for a pile driving system includes a hydraulic control system that controls a throttle of a pile driving hammer, and thereby controls an impact velocity of the hammer with a pile. A controller provides a control signal to the hydraulic control system. Based on the control signal, the hydraulic control system controls an impact velocity of the hammer during a subsequent hammer stroke. The controller may determine one or more control parameters such as sound pressure at a sound control location during a hammer stroke, vibration at a vibration control location during a hammer stroke, an impact force imparted to the pile during a hammer stroke, and / or actual pile capacity of the pile, and provide to the hydraulic control system a control signal based on the determined control parameter(s).

Owner:BERMINGHAM FOUND SOLUTIONS LTD

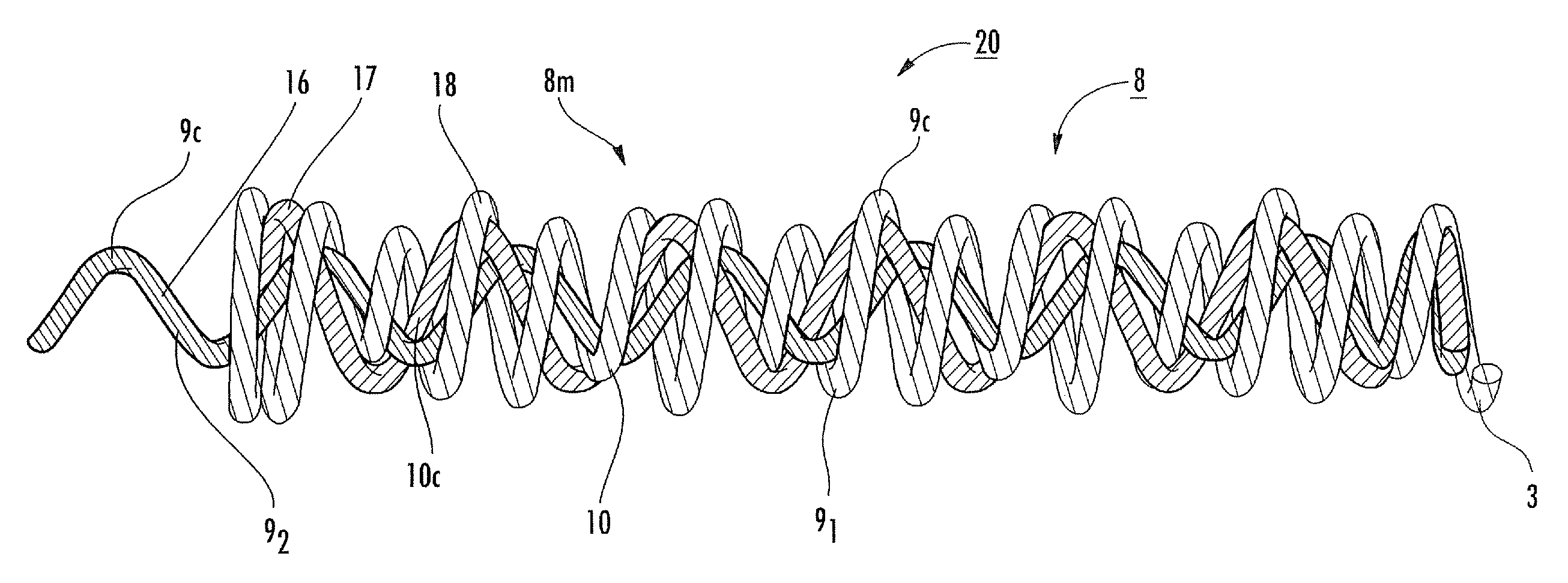

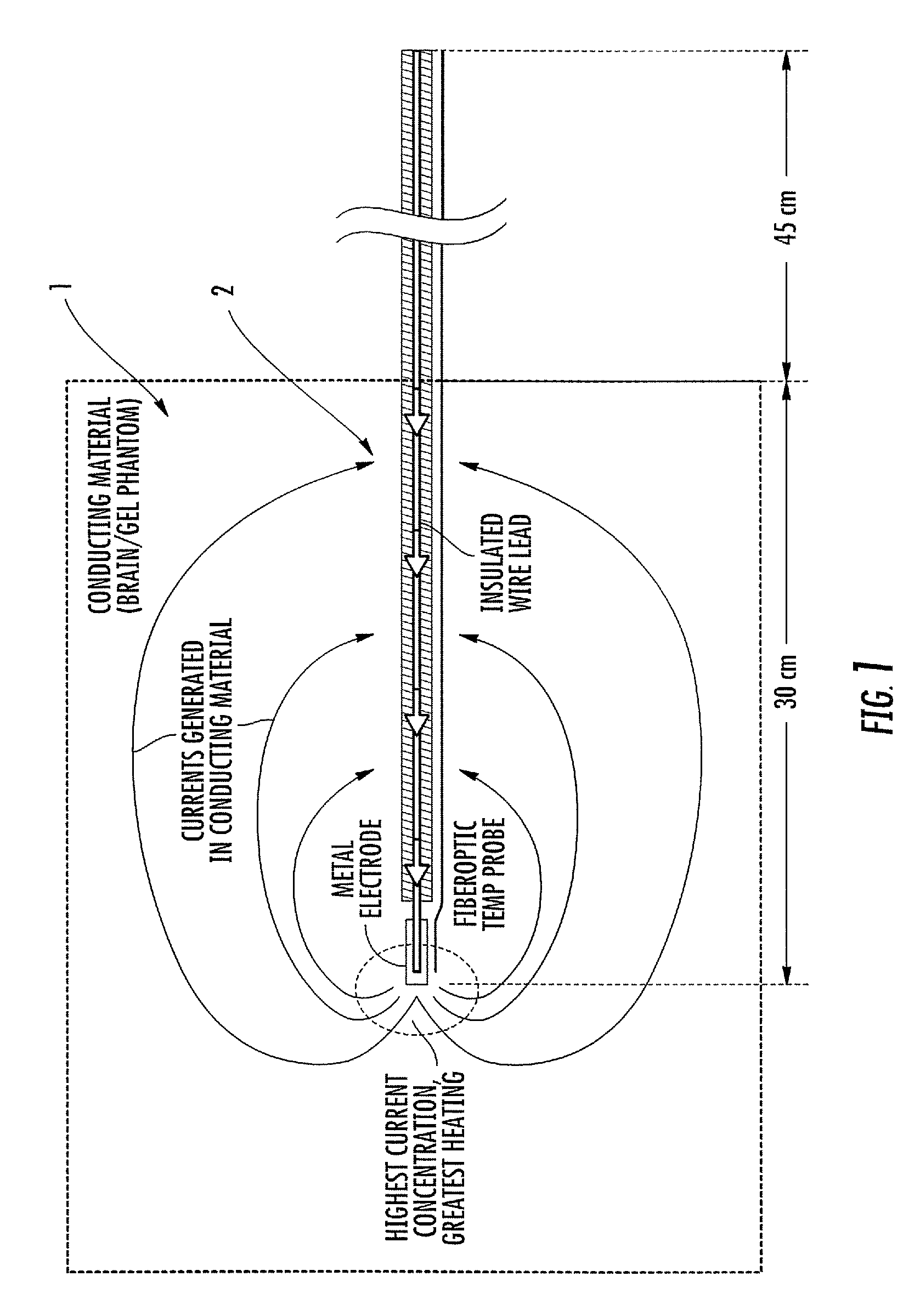

Methods and apparatus for fabricating leads with conductors and related flexible lead configurations

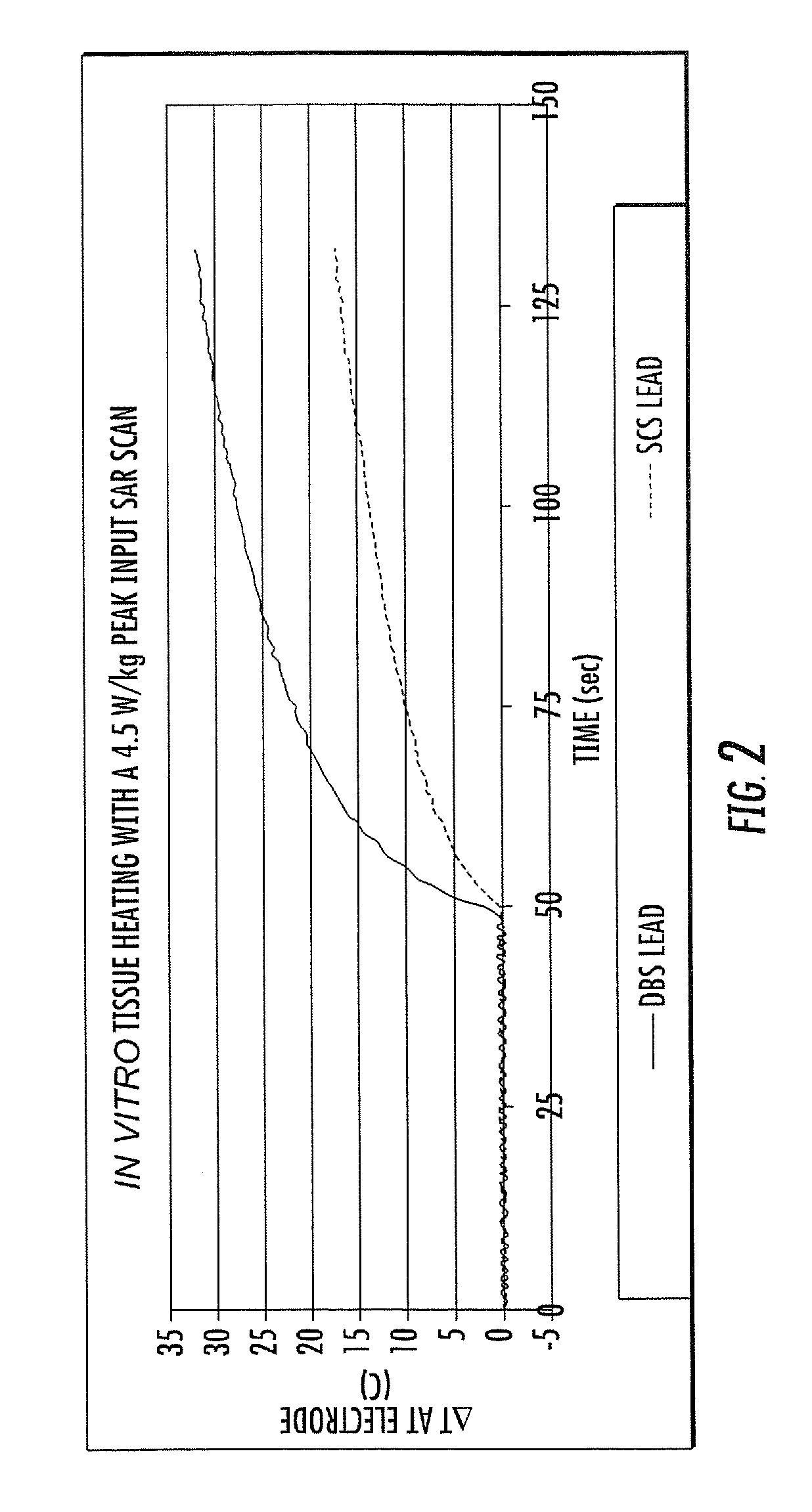

ActiveUS20080262584A1Prevent undesired heatingEasy to useInternal electrodesMaterial strength using steady bending forcesElectrical conductorDegree Celsius

MRI / RF compatible leads include at least one conductor, a respective conductor having at least one segment with a multi-layer stacked coil configuration. The lead can be configured so that the lead heats local tissue less than about 10 degrees Celsius (typically about 5 degrees Celsius or less) or does not heat local tissue when a patient is exposed to target RF frequencies at a peak input SAR of at least about 4 W / kg and / or a whole body average SAR of at least about 2 W / kg. Related leads and methods of fabricating leads are also described.

Owner:MRI INTERVENTIONS INC +1

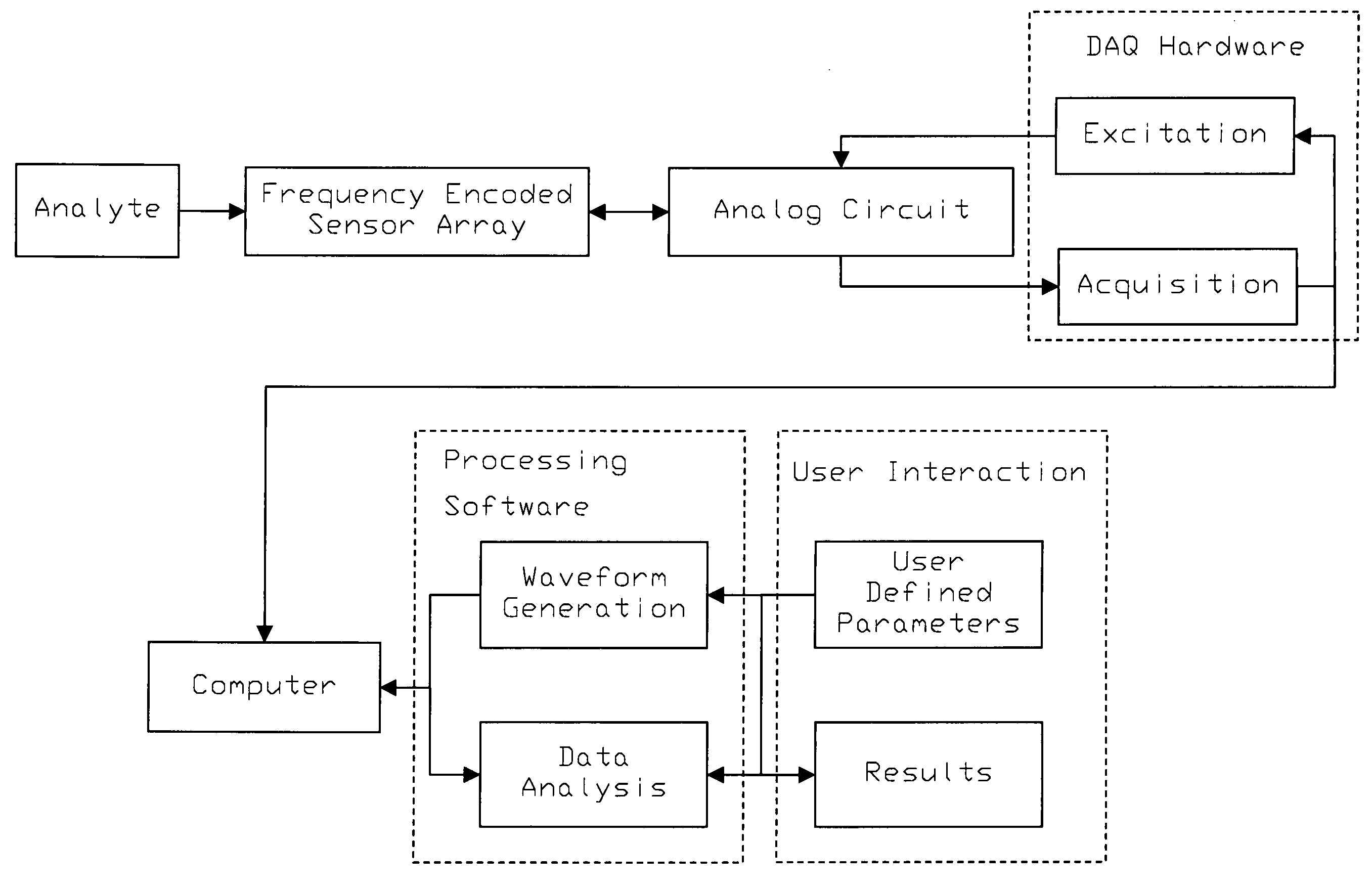

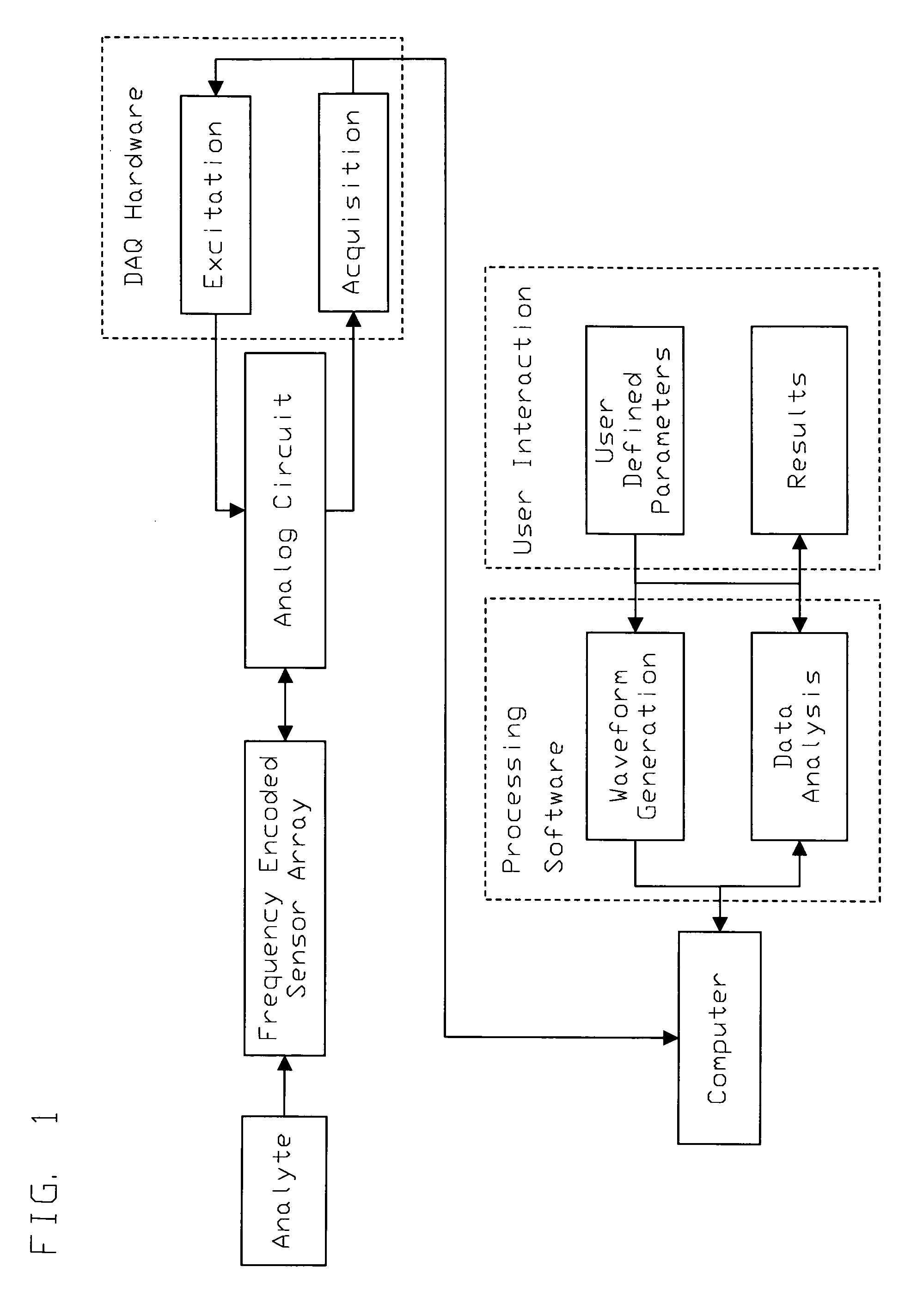

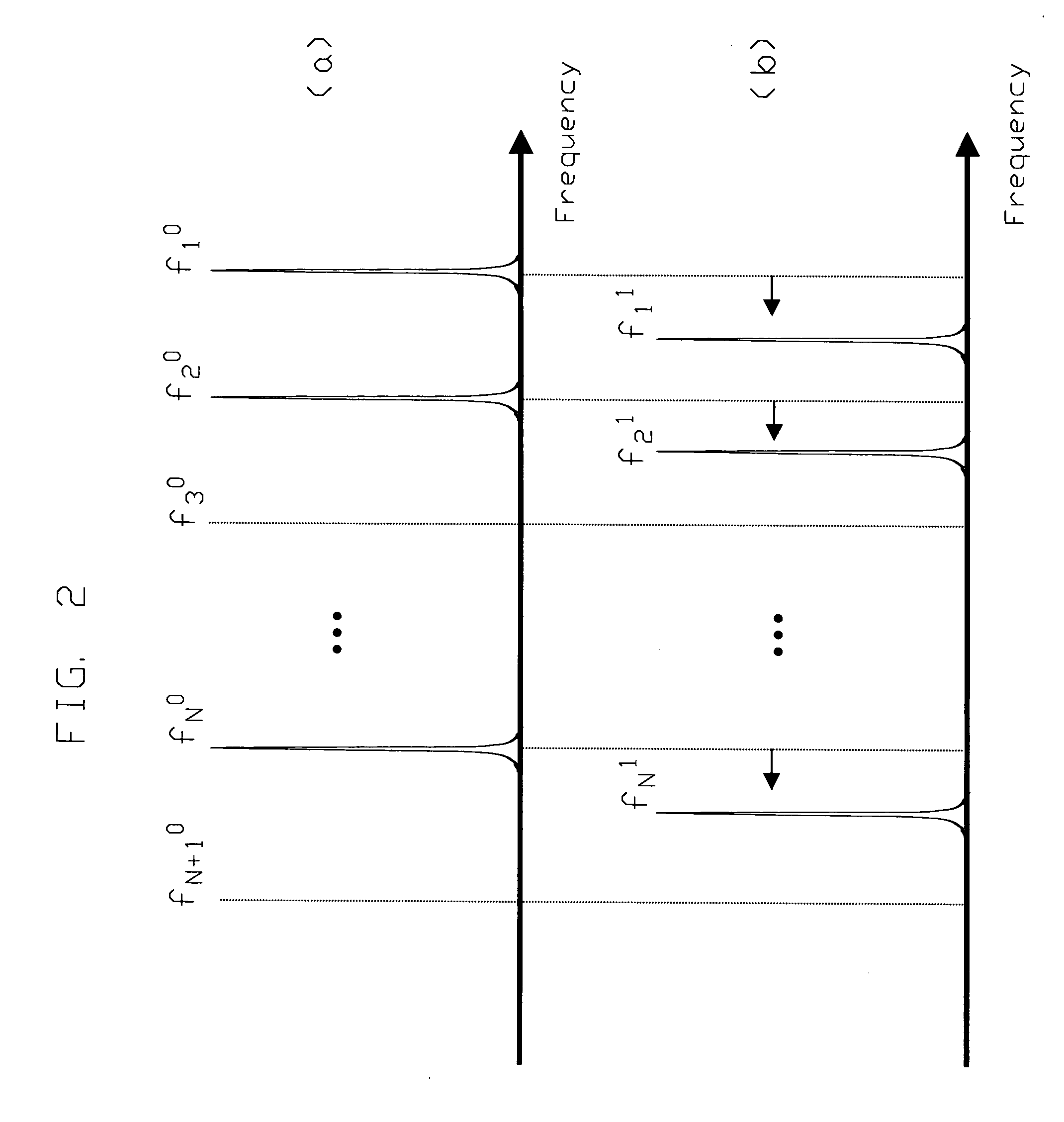

Frequency encoding of resonant mass sensors

InactiveUS20050016276A1Sufficient ring timeImprove stabilityVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesSensor arrayFrequency spectrum

A method for the detection of analytes using resonant mass sensors or sensor arrays comprises frequency encoding each sensor element, acquiring a time-domain resonance signal from the sensor or sensor array as it is exposed to analyte, detecting change in the frequency or resonant properties of each sensor element using a Fourier transform or other spectral analysis method, and classifying, identifying, and / or quantifying analyte using an appropriate data analysis procedure. Frequency encoded sensors or sensor arrays comprise sensor elements with frequency domain resonance signals that can be uniquely identified under a defined range of operating conditions. Frequency encoding can be realized either by fabricating individual sensor elements with unique resonant frequencies or by tuning or modifying identical resonant devices to unique frequencies by adding or removing mass from individual sensor elements. The array of sensor elements comprises multiple resonant structures that may have identical or unique sensing layers. The sensing layers influence the sensor elements' response to analyte. Time-domain signal is acquired, typically in a single data acquisition channel, and typically using either (1) a pulsed excitation followed by acquisition of the free oscillatory decay of the entire array or (2) a rapid scan acquisition of signal from the entire array in a direct or heterodyne configuration. Spectrum analysis of the time domain data is typically accomplished with Fourier transform analysis. The methods and sensor arrays of the invention enable rapid and sensitive analyte detection, classification and / or identification of complex mixtures and unknown compounds, and quantification of known analytes, using sensor element design and signal detection hardware that are robust, simple and low cost.

Owner:PALO ALTO SENSOR TECH INNOVATION

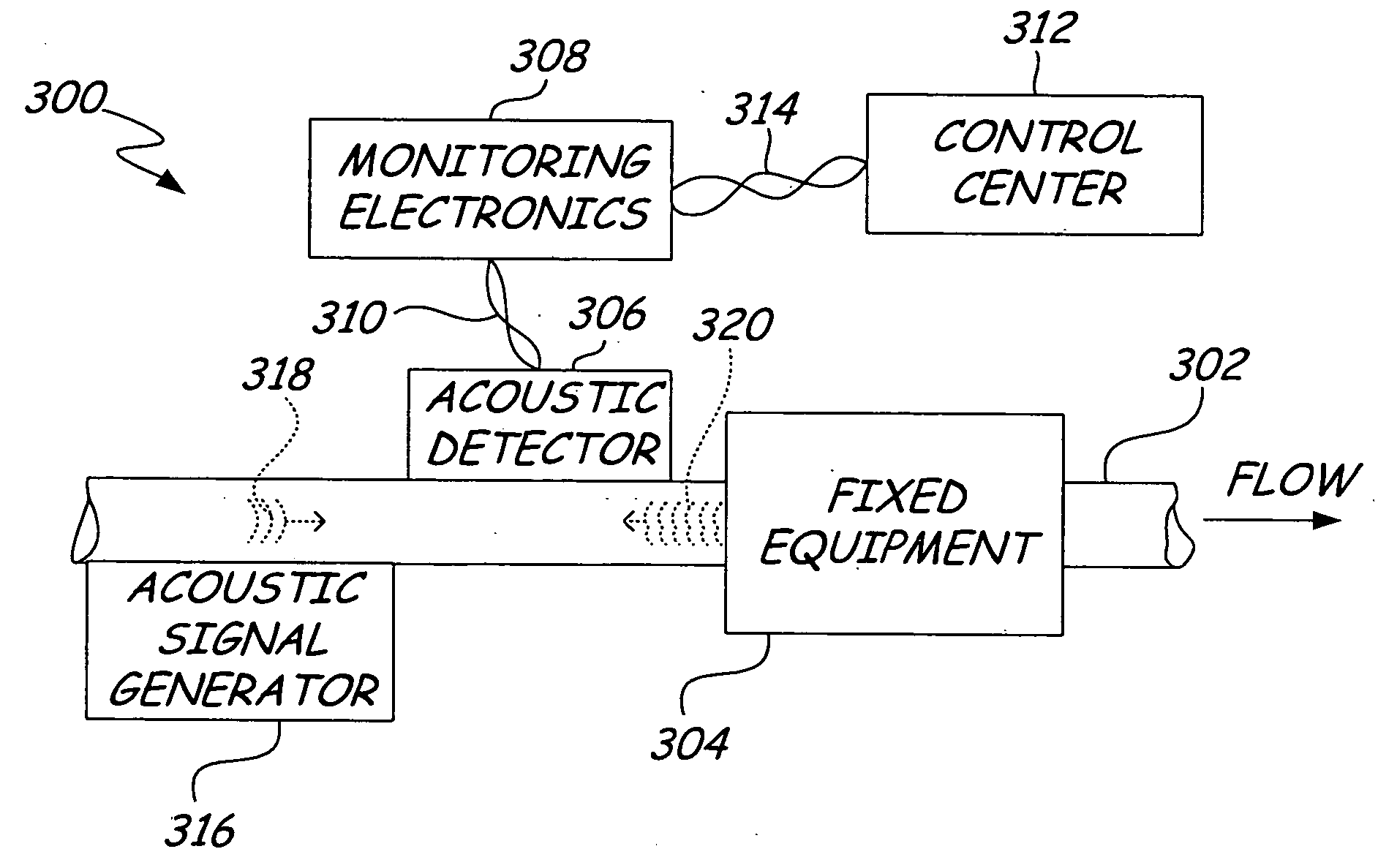

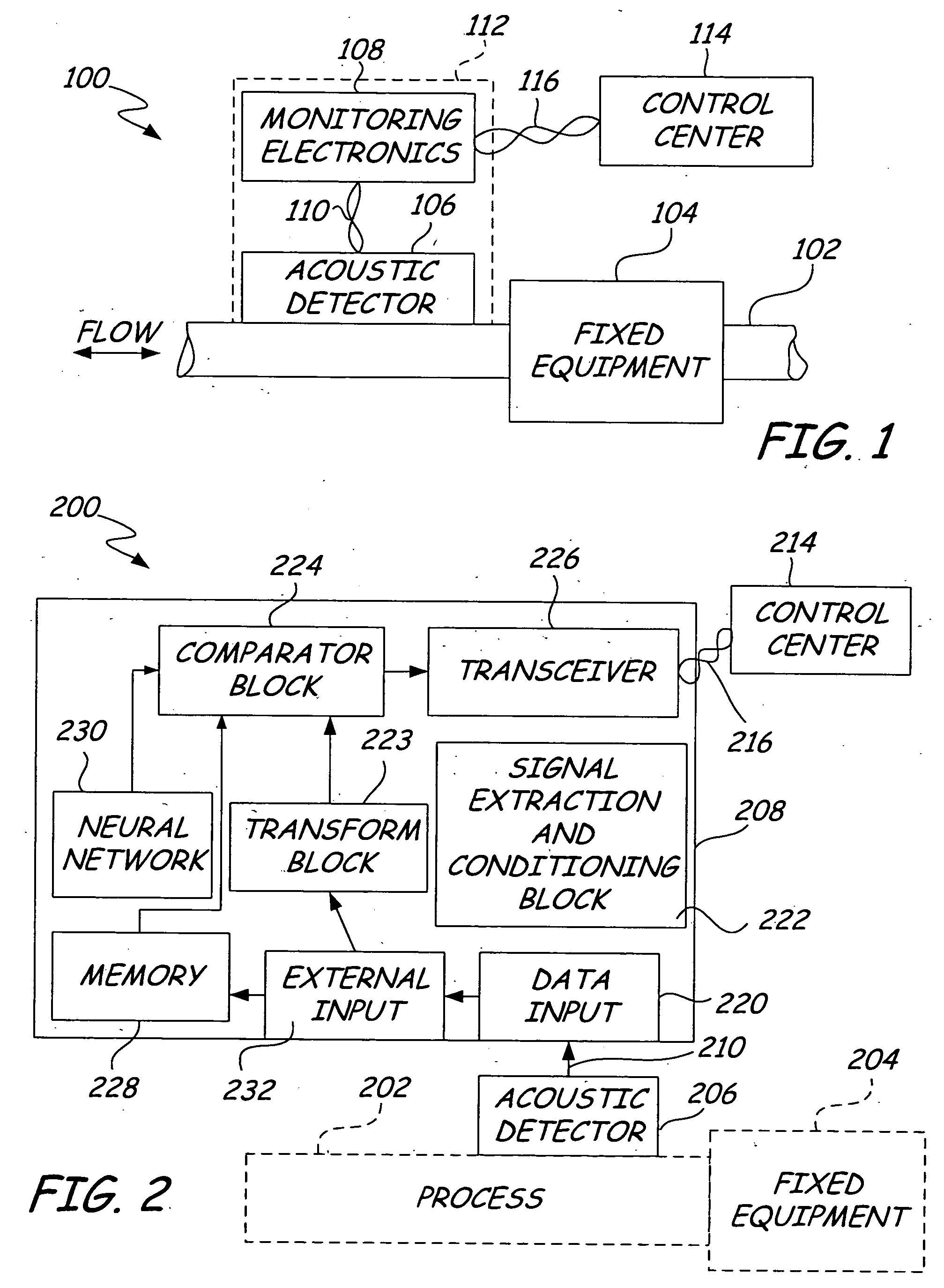

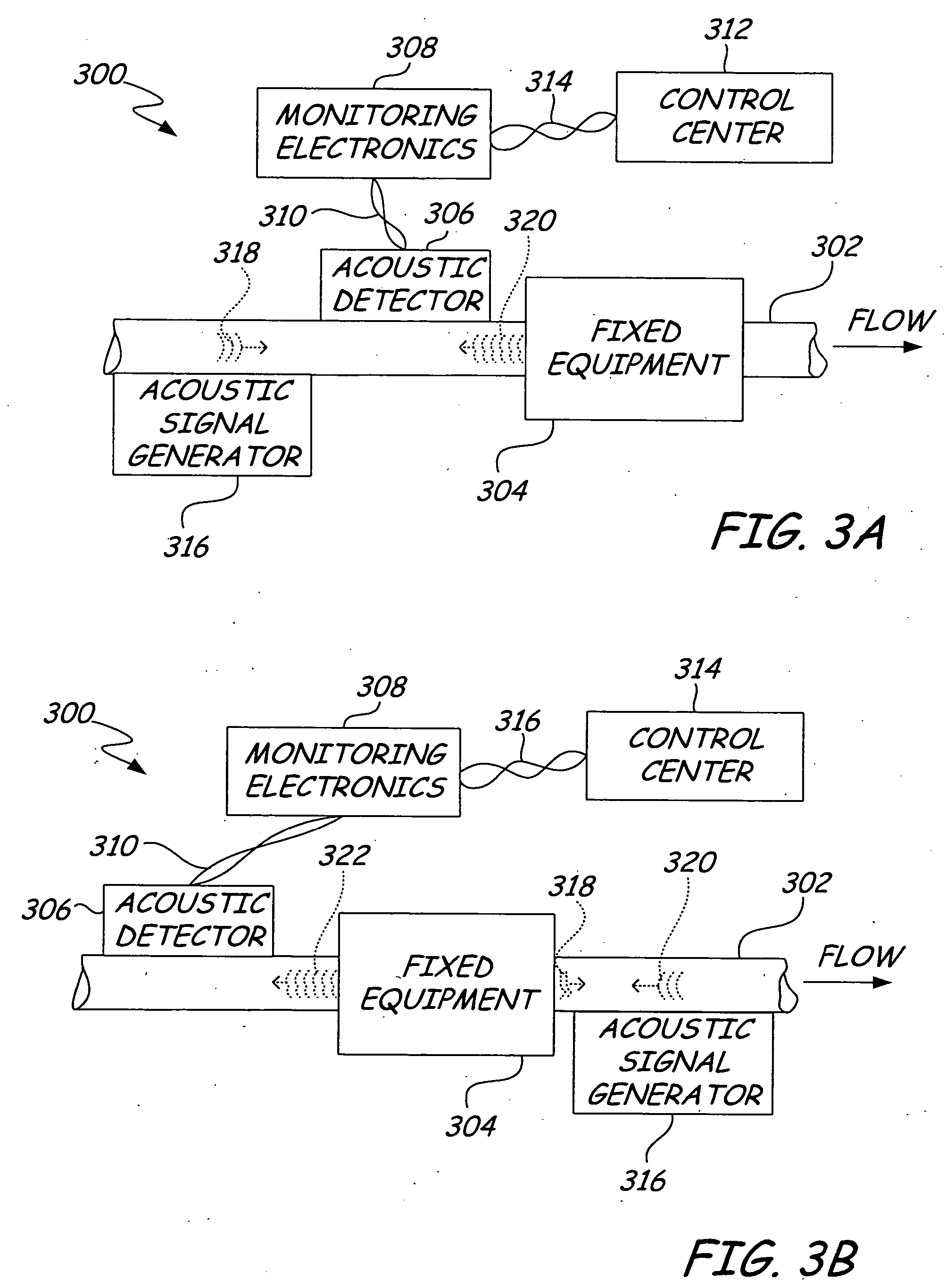

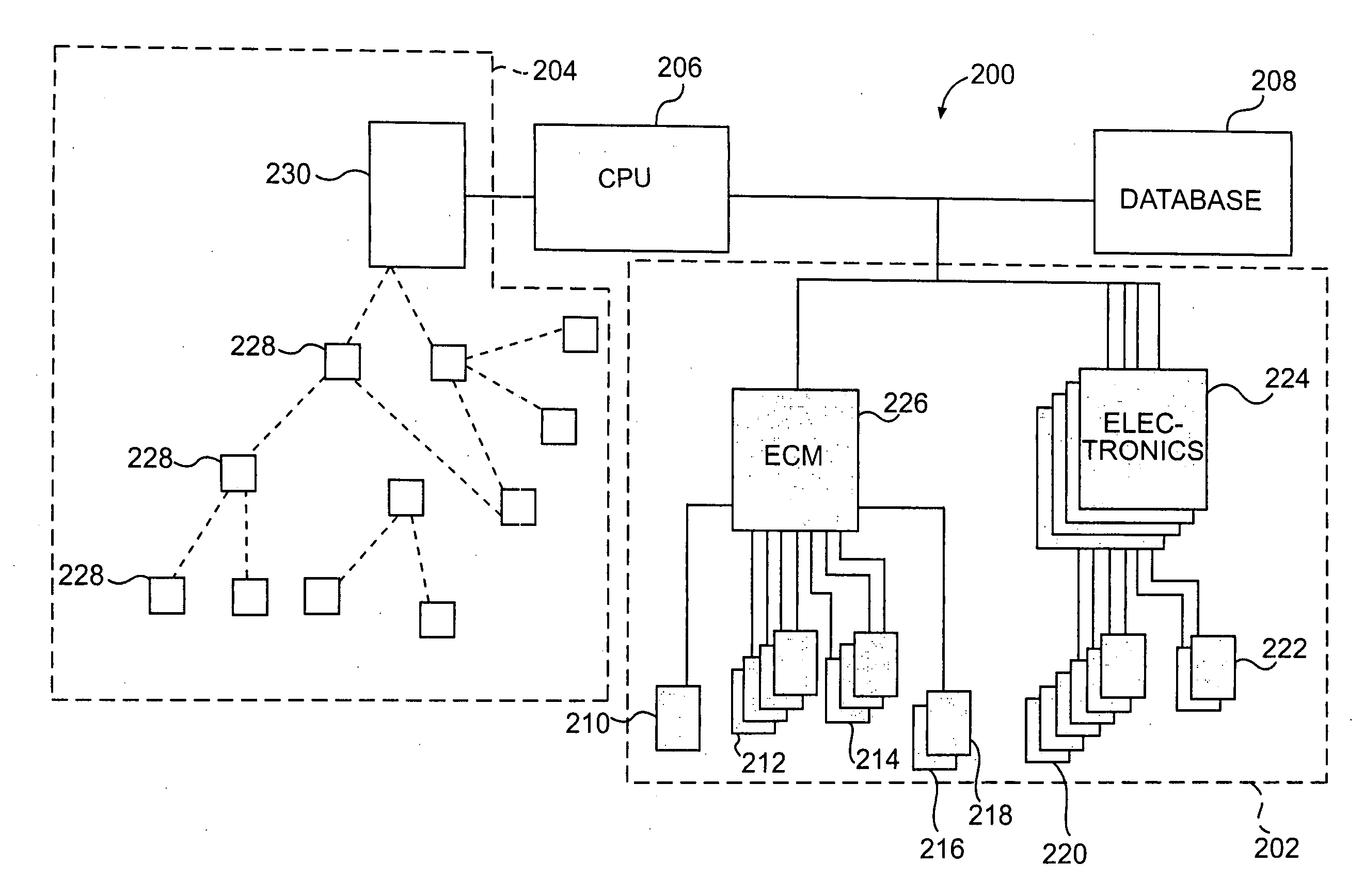

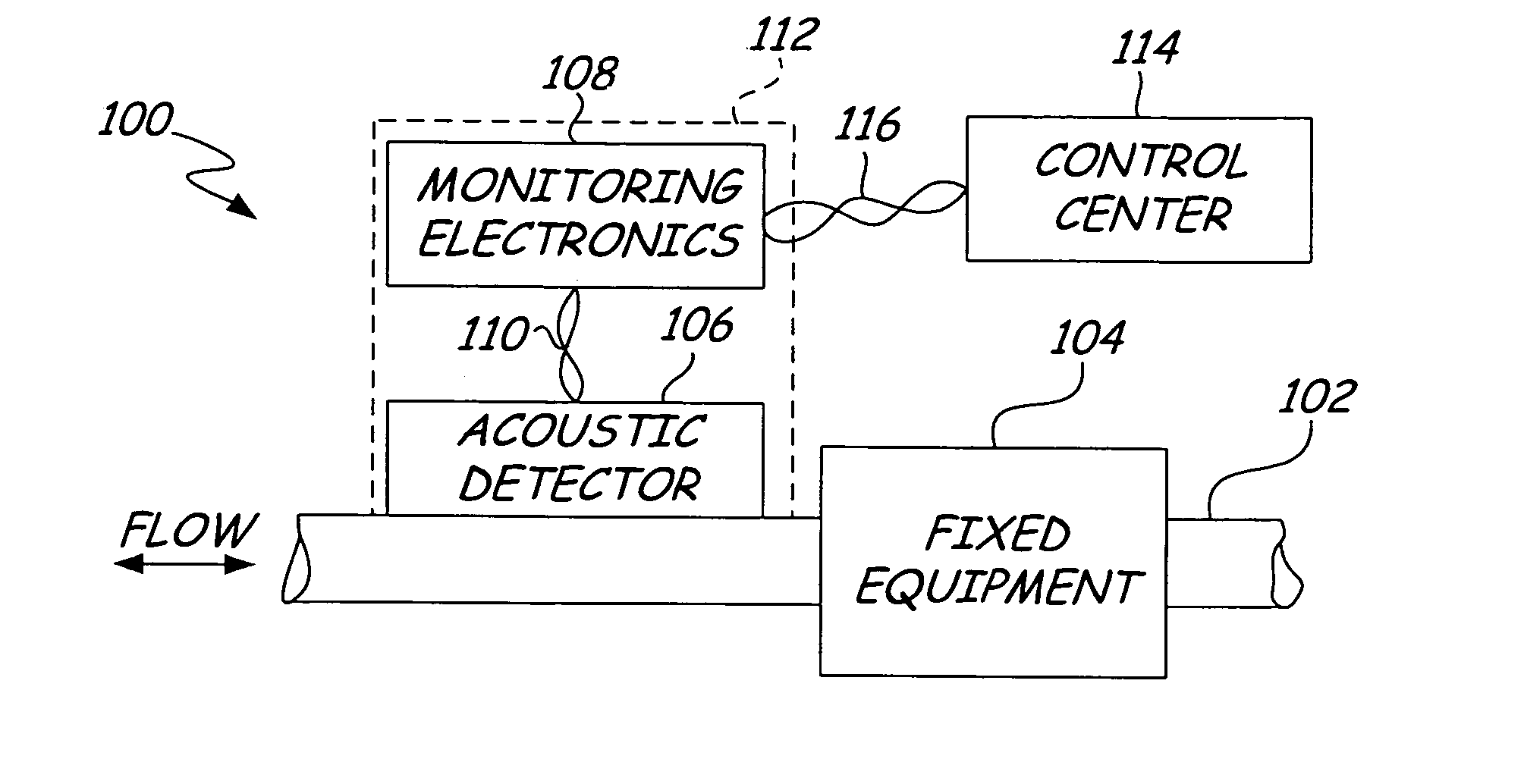

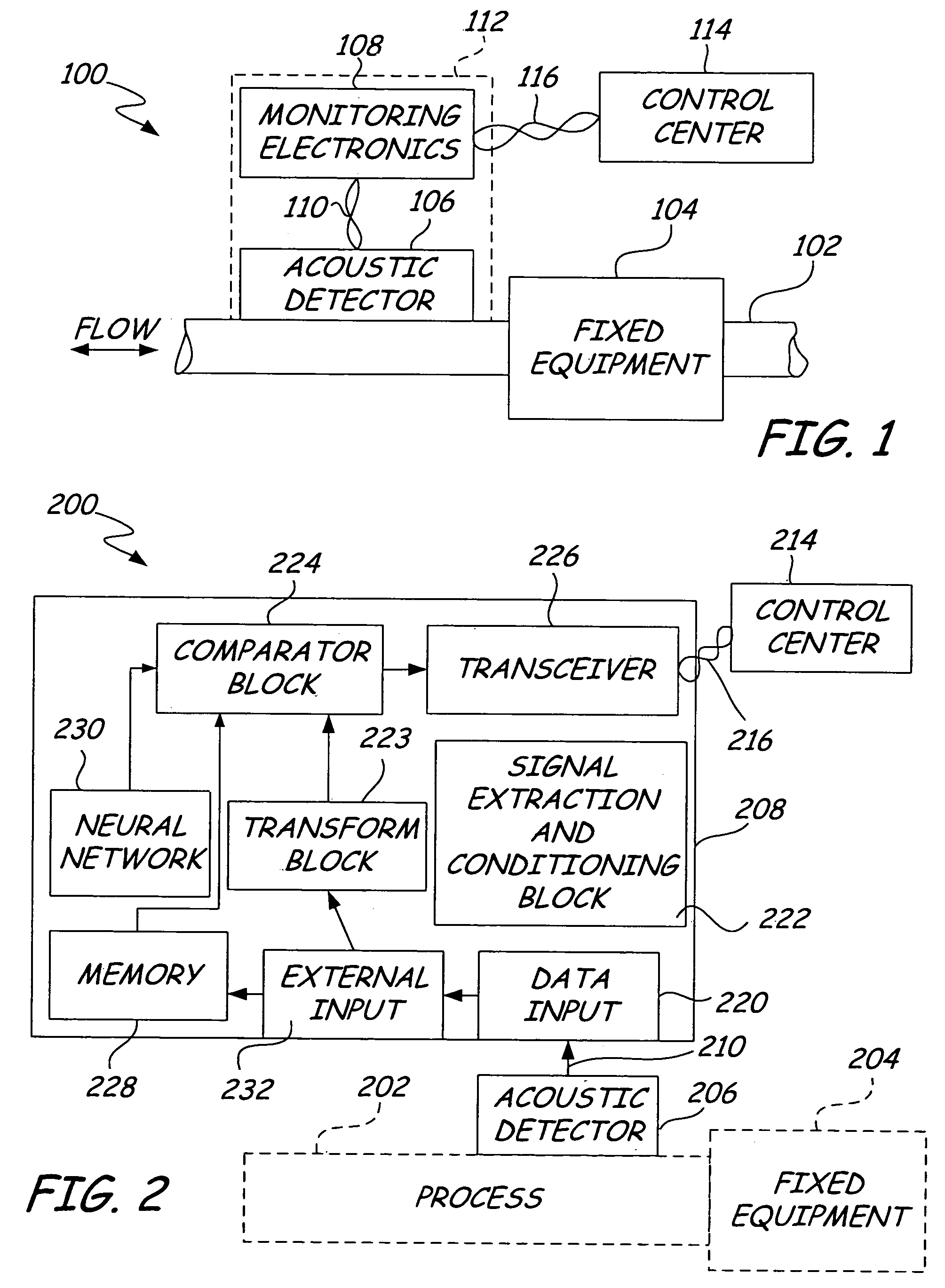

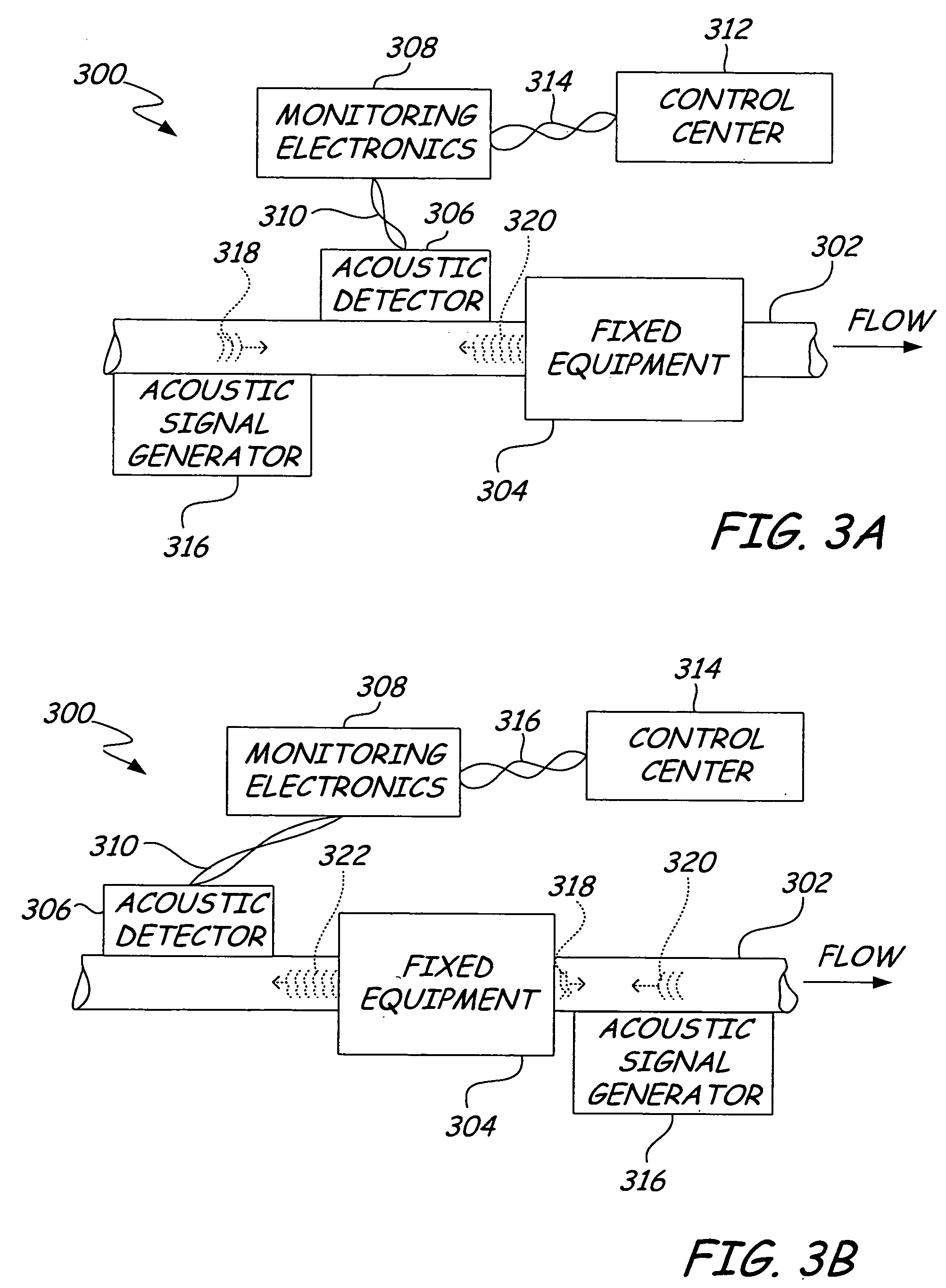

Process diagnostics

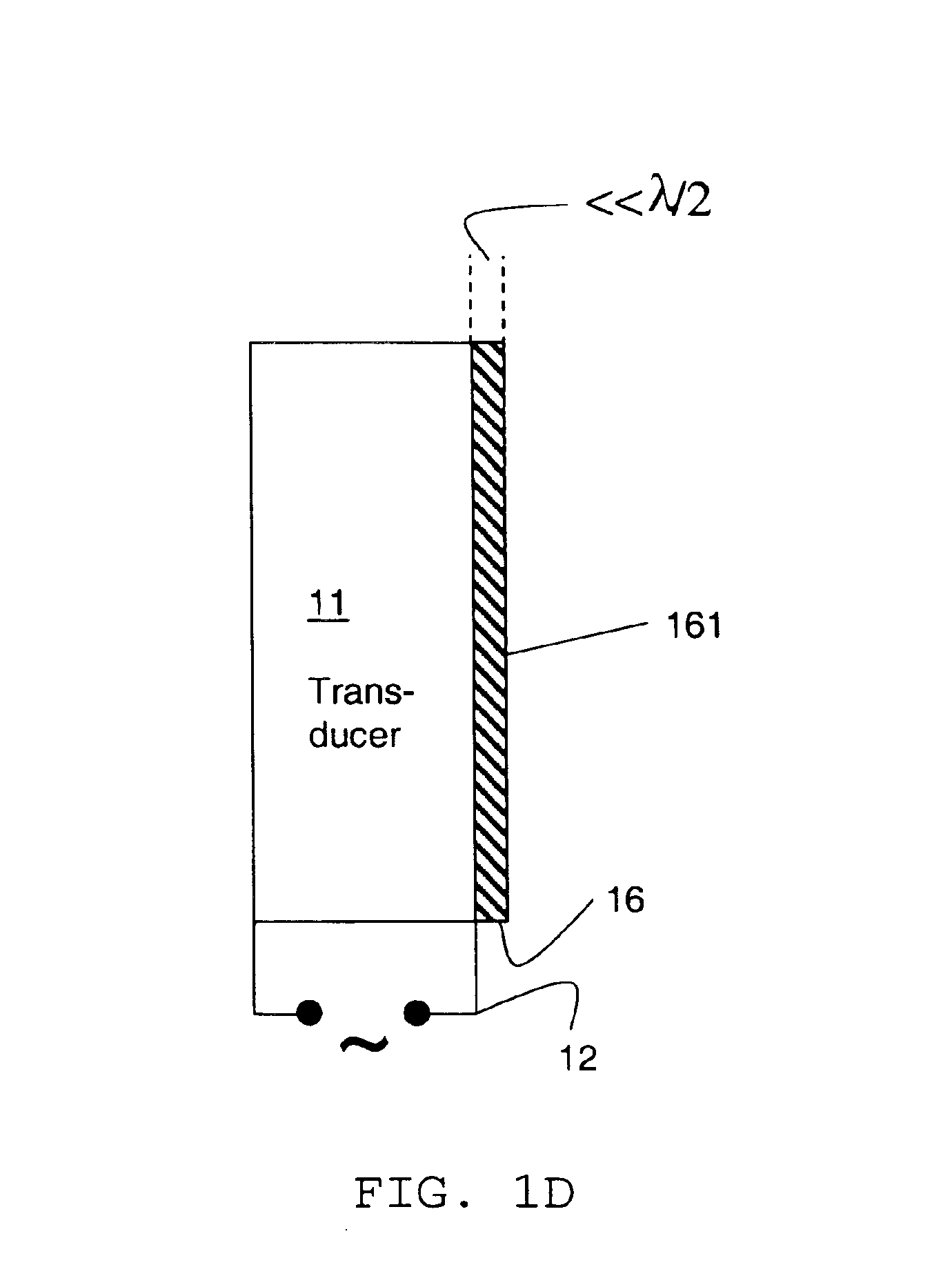

ActiveUS20050011278A1Improve abilitiesEasy to useVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTransducerEngineering

A diagnostic device for use in a industrial process includes monitoring electronics or diagnostic circuitry configured to diagnose or identify a condition or other occurrence in the industrial process. The system can be implemented in a process device such as a flowmeter, and in one example an acoustic flowmeter. A transducer can also be used and a frequency response, such as resonant frequency, can be observed.

Owner:ROSEMOUNT INC

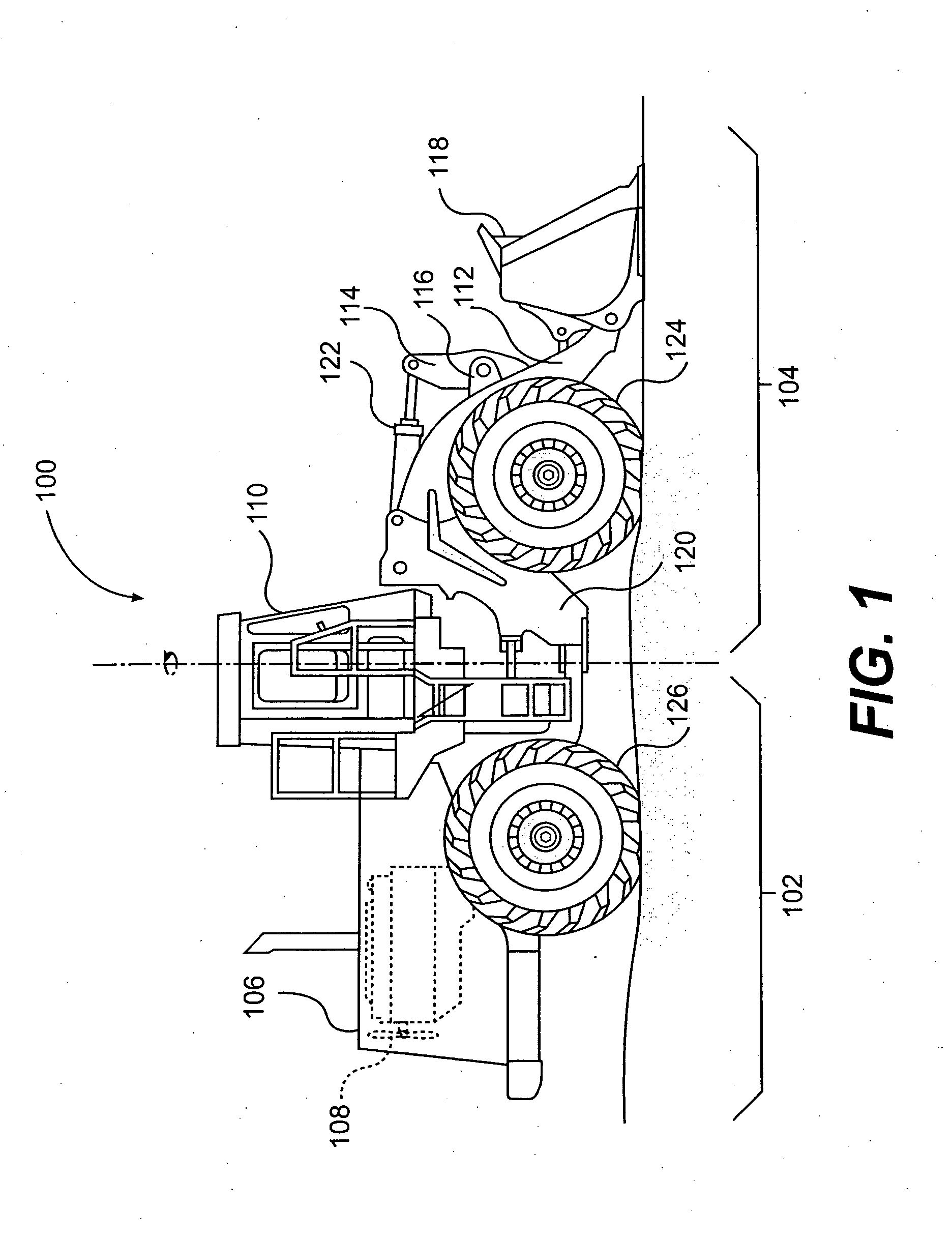

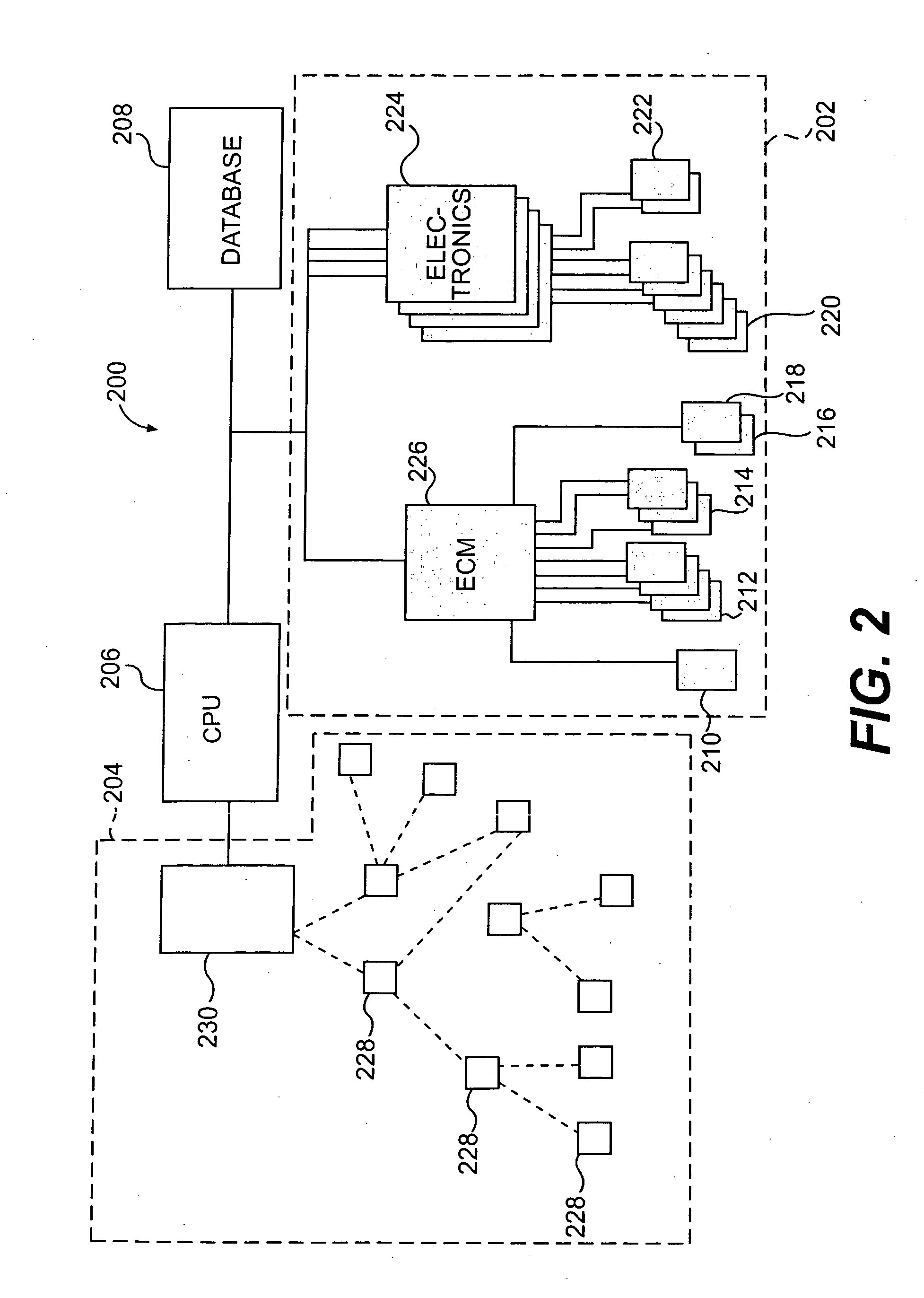

Systems and methods for maintaining load histories

Methods and systems for constructing a load history database for a structure is disclosed. In one embodiment, a method is disclosed that may include detecting a measurable parameter on the structure utilizing a sensor positioned on the structure and determining a value of external loads acting upon the structure based on the detected parameter. Further, the method may include evaluating the value of the external loads against a pre-established factor. Based on the evaluation, the value of the external loads are selectively stored in the load history database.

Owner:CATERPILLAR INC

Deposition monitoring system

InactiveUS6880402B1Increase deposition thicknessConveniently determinedVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesMonitoring systemOperation mode

Described is an apparatus for detecting and removing deposits from a surface exposed to wellbore fluids. The apparatus can monitor the rate of deposition and subsequently remove the deposited material. The combination of detection apparatus and removal apparatus provides an instrument with self-cleaning operation mode.

Owner:SCHLUMBERGER TECH CORP

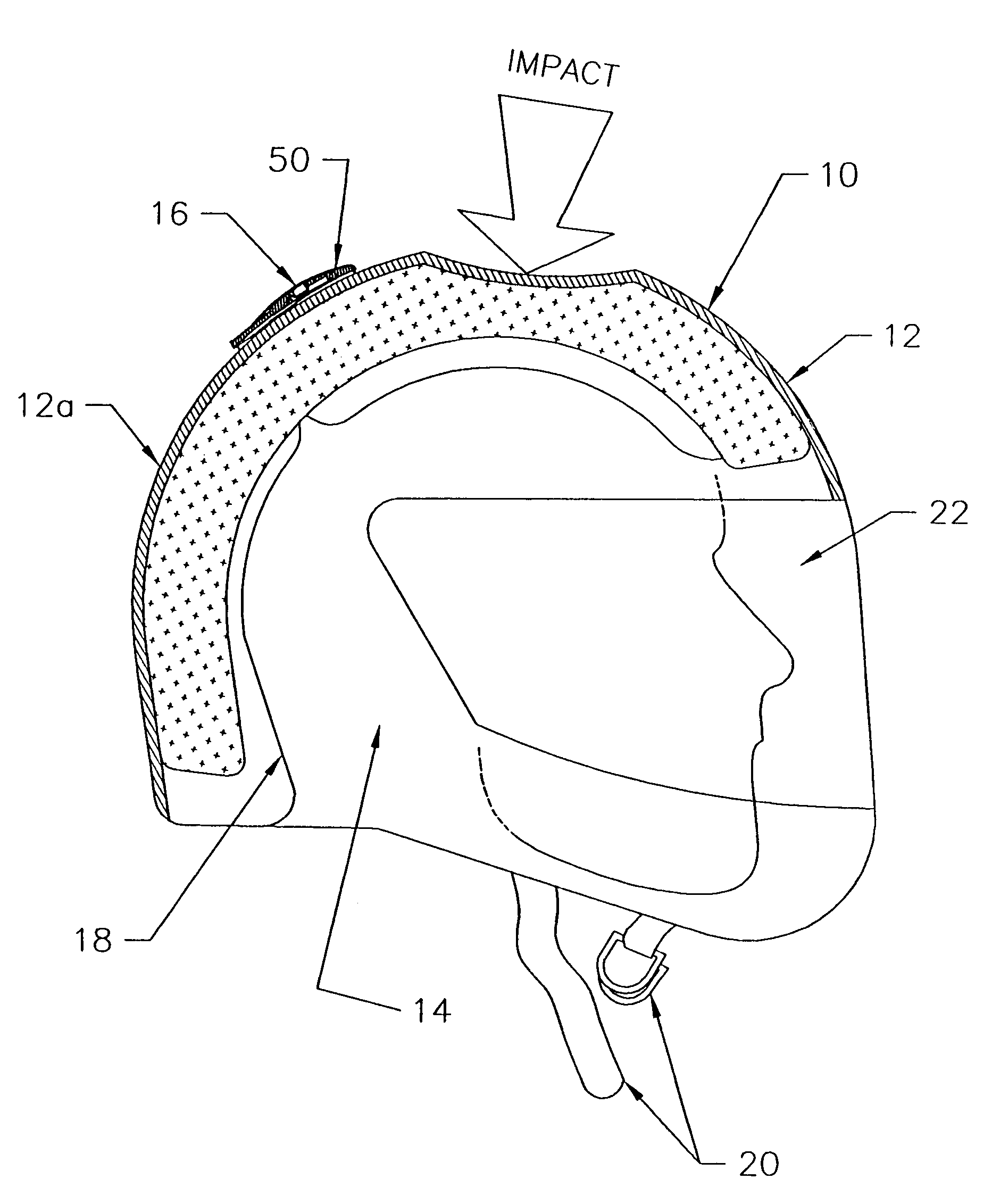

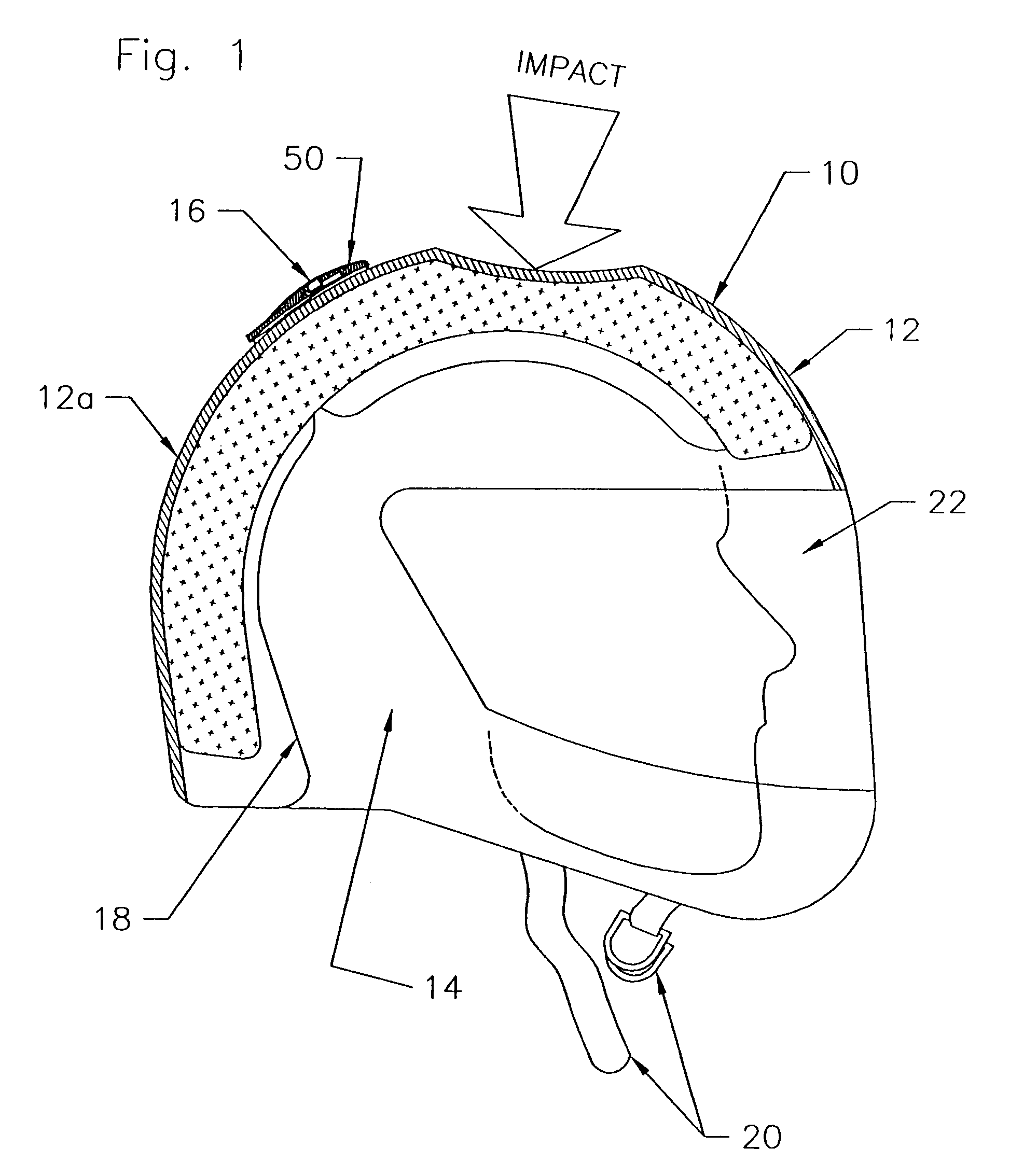

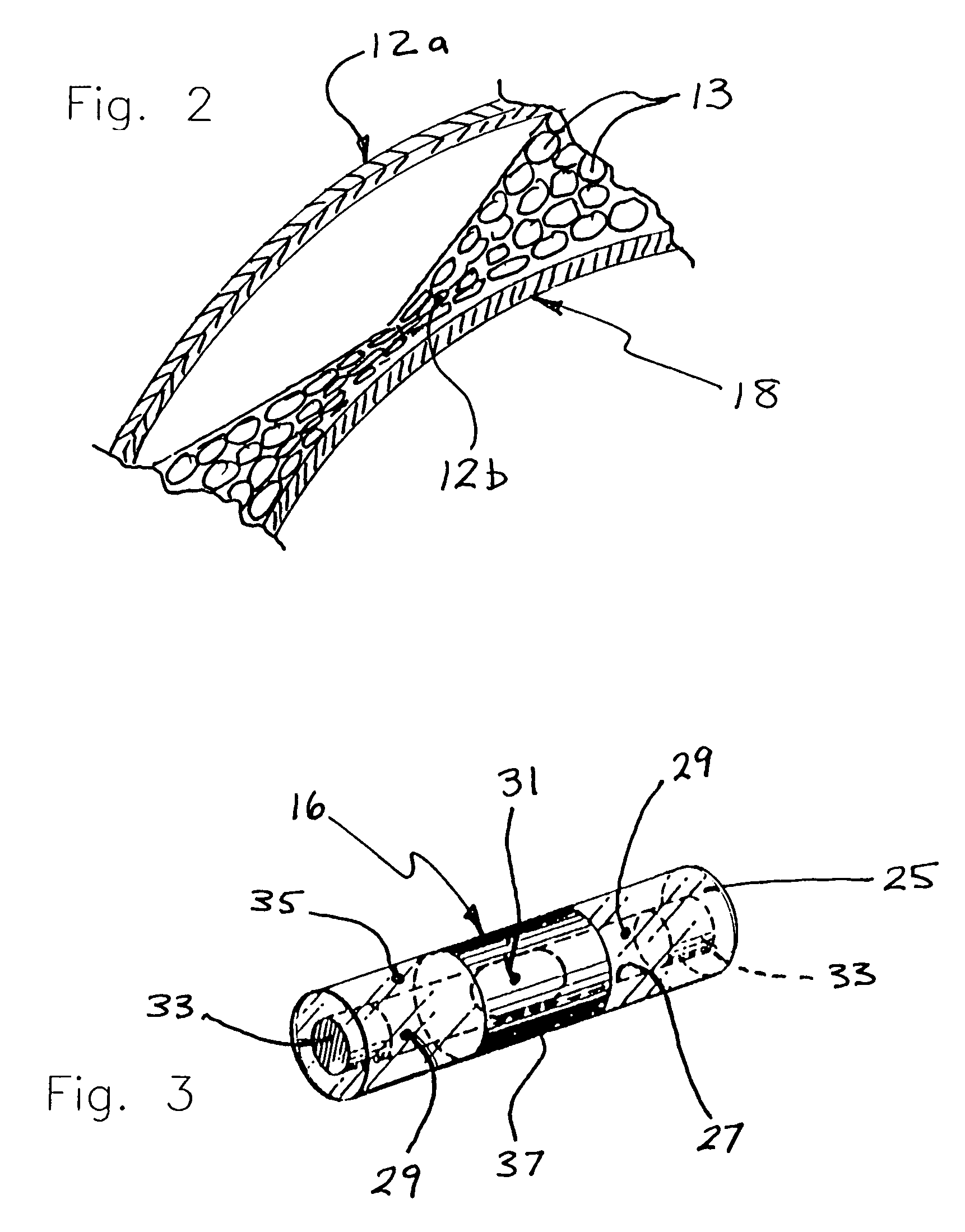

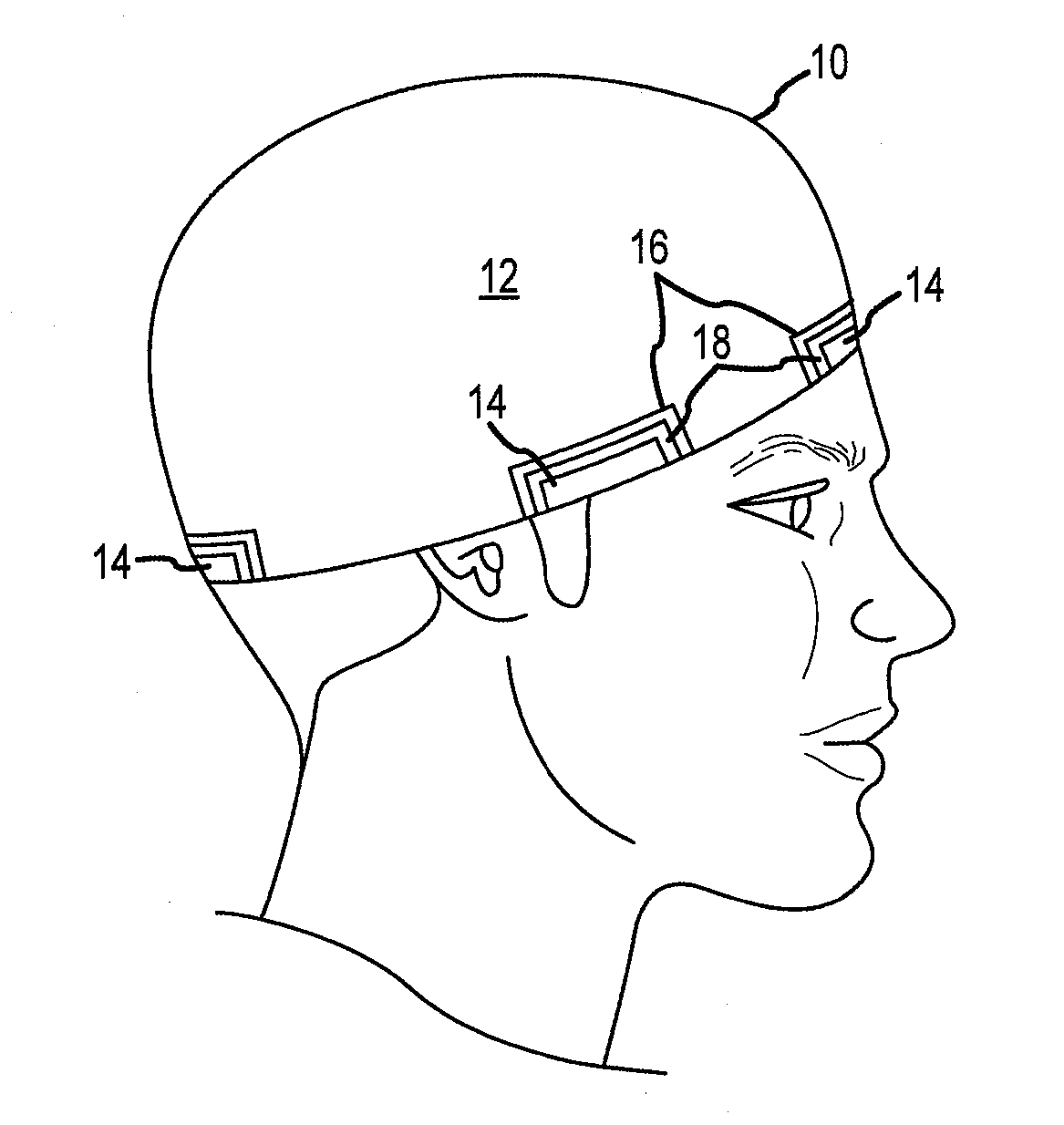

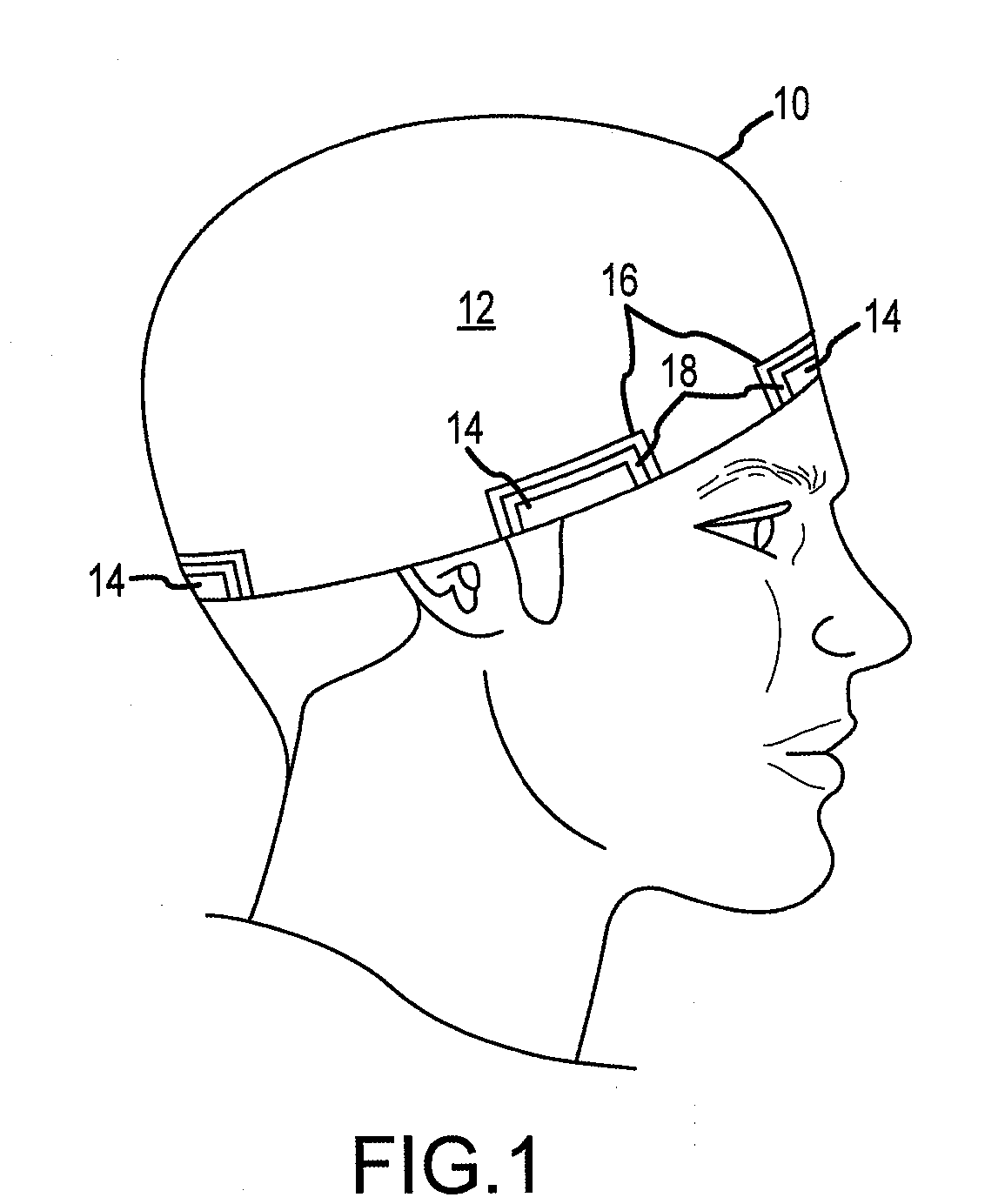

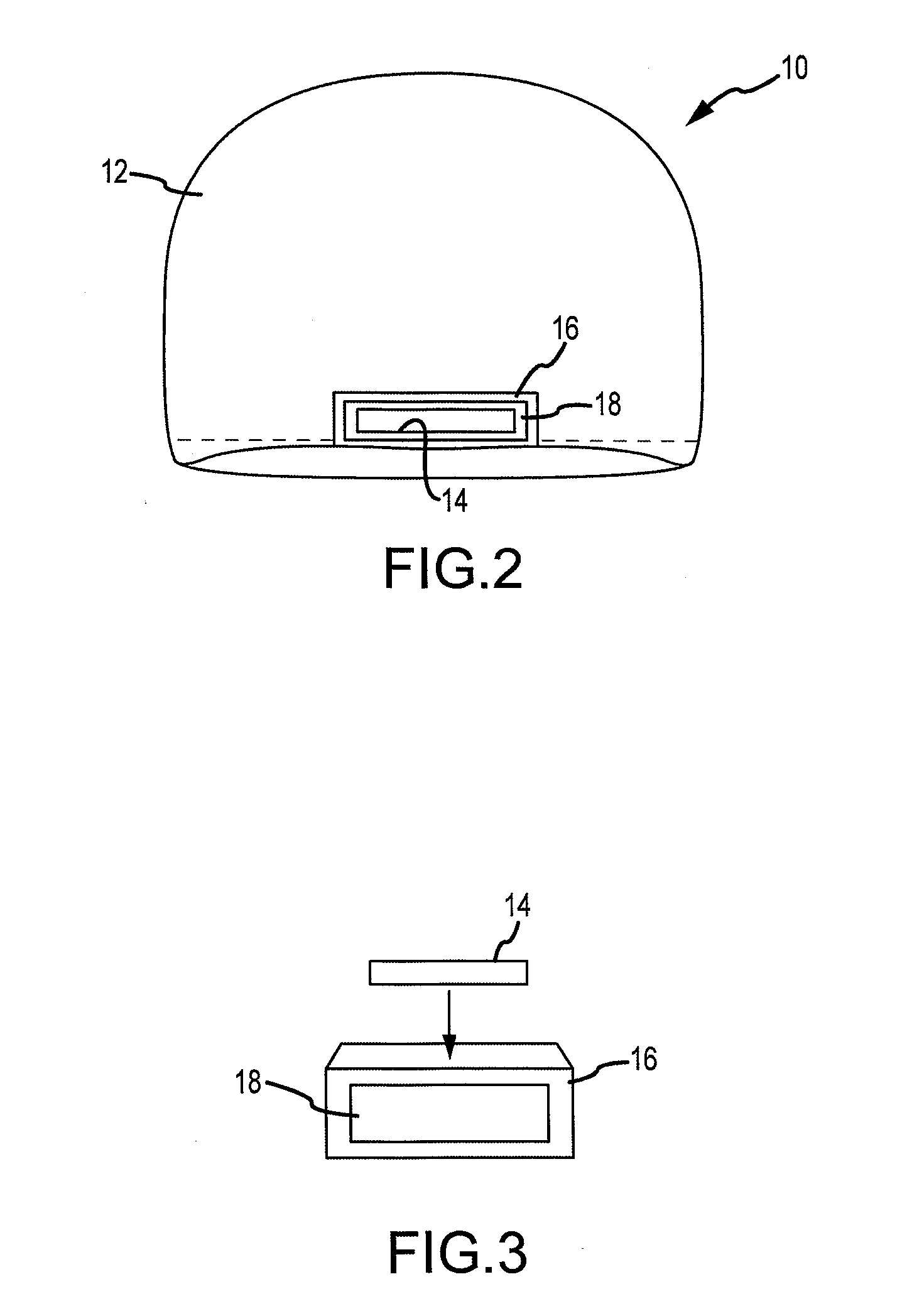

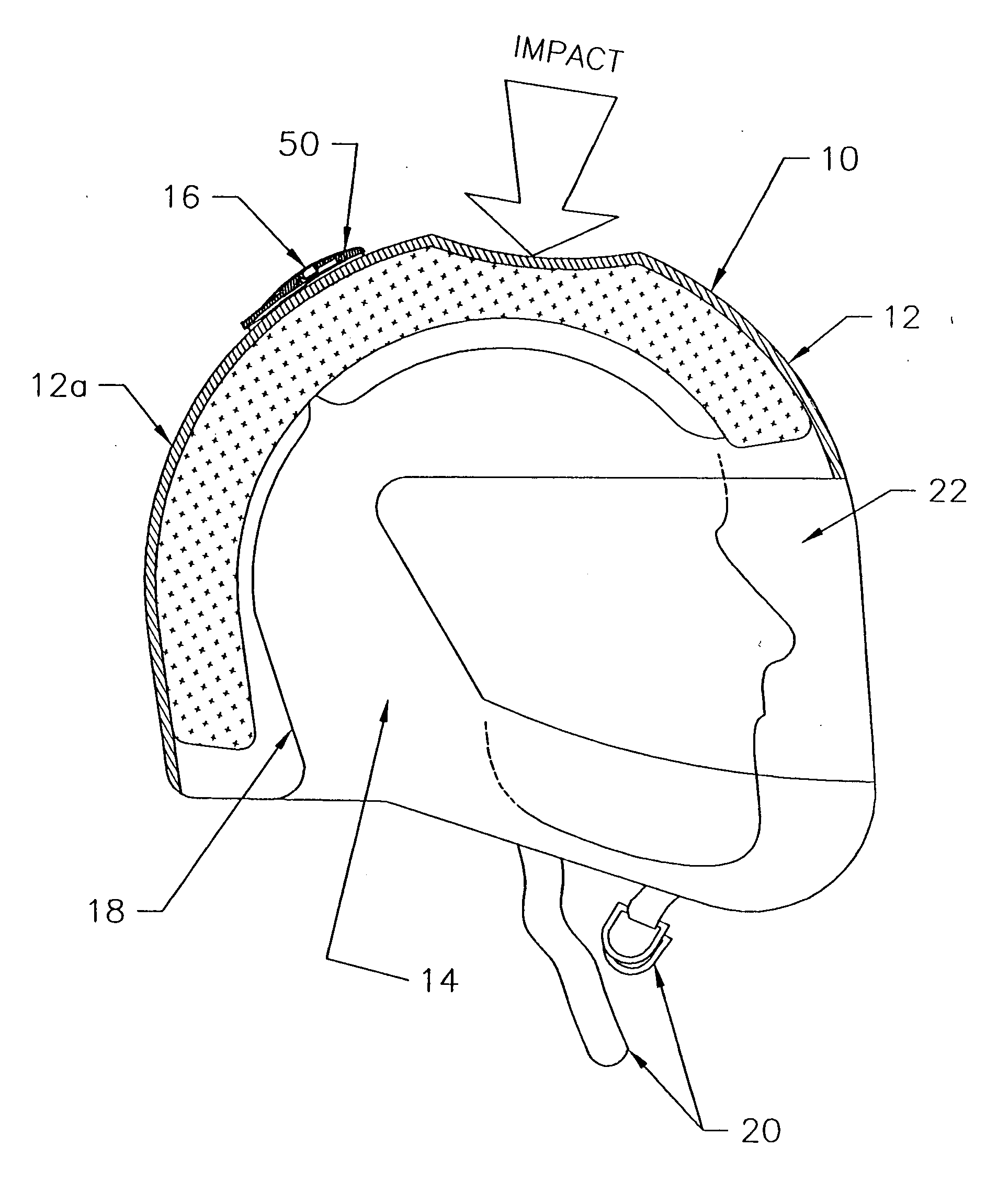

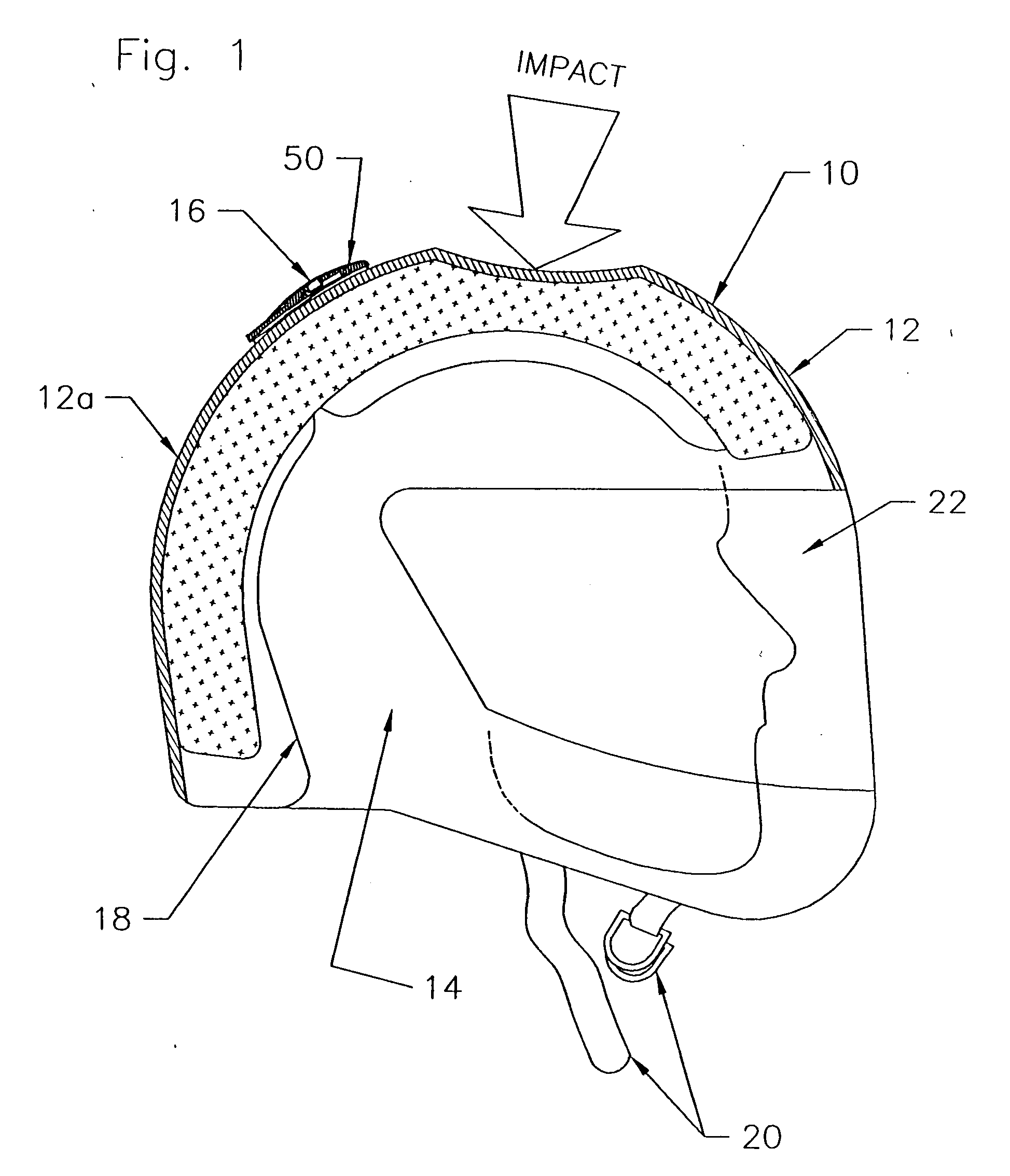

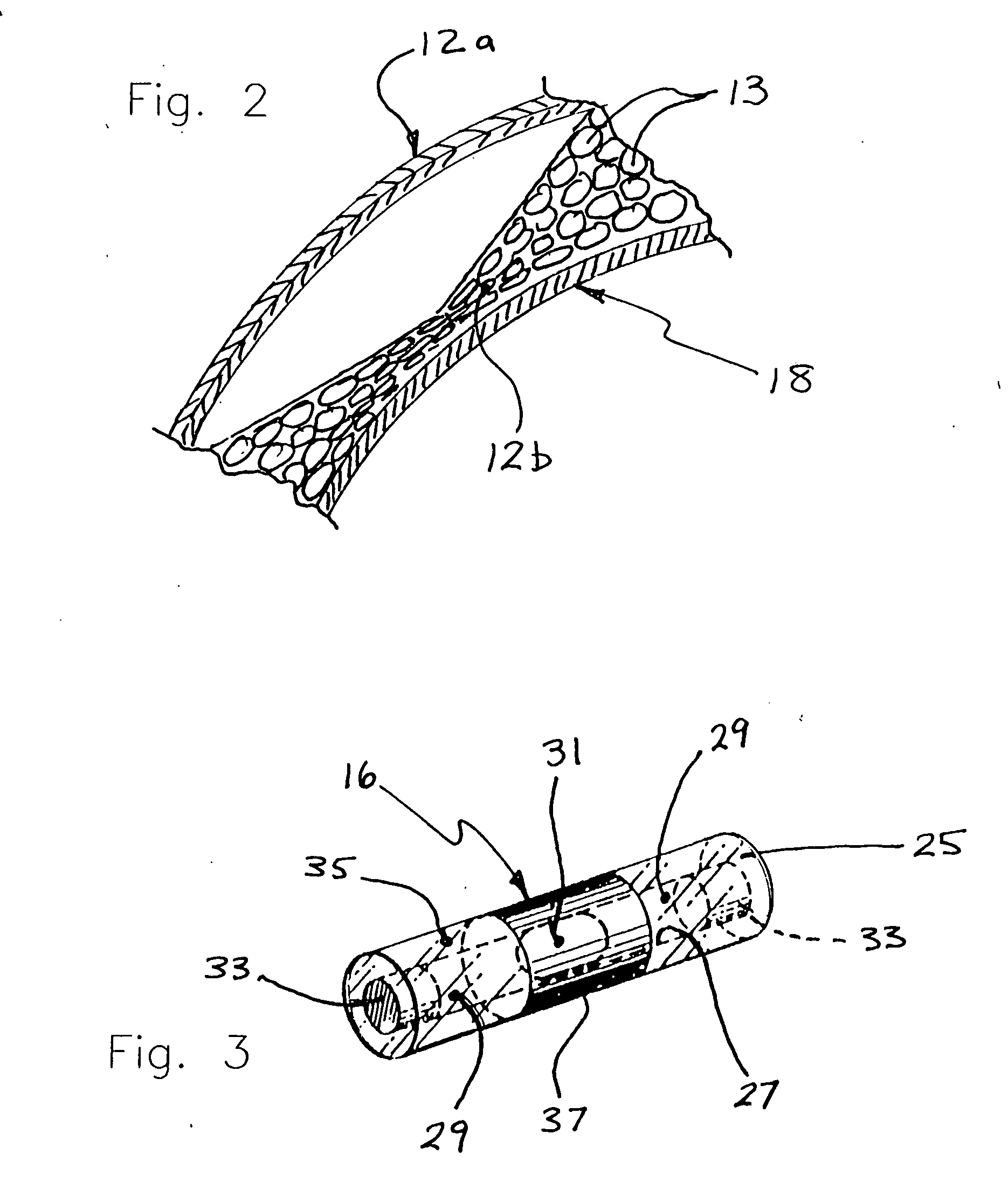

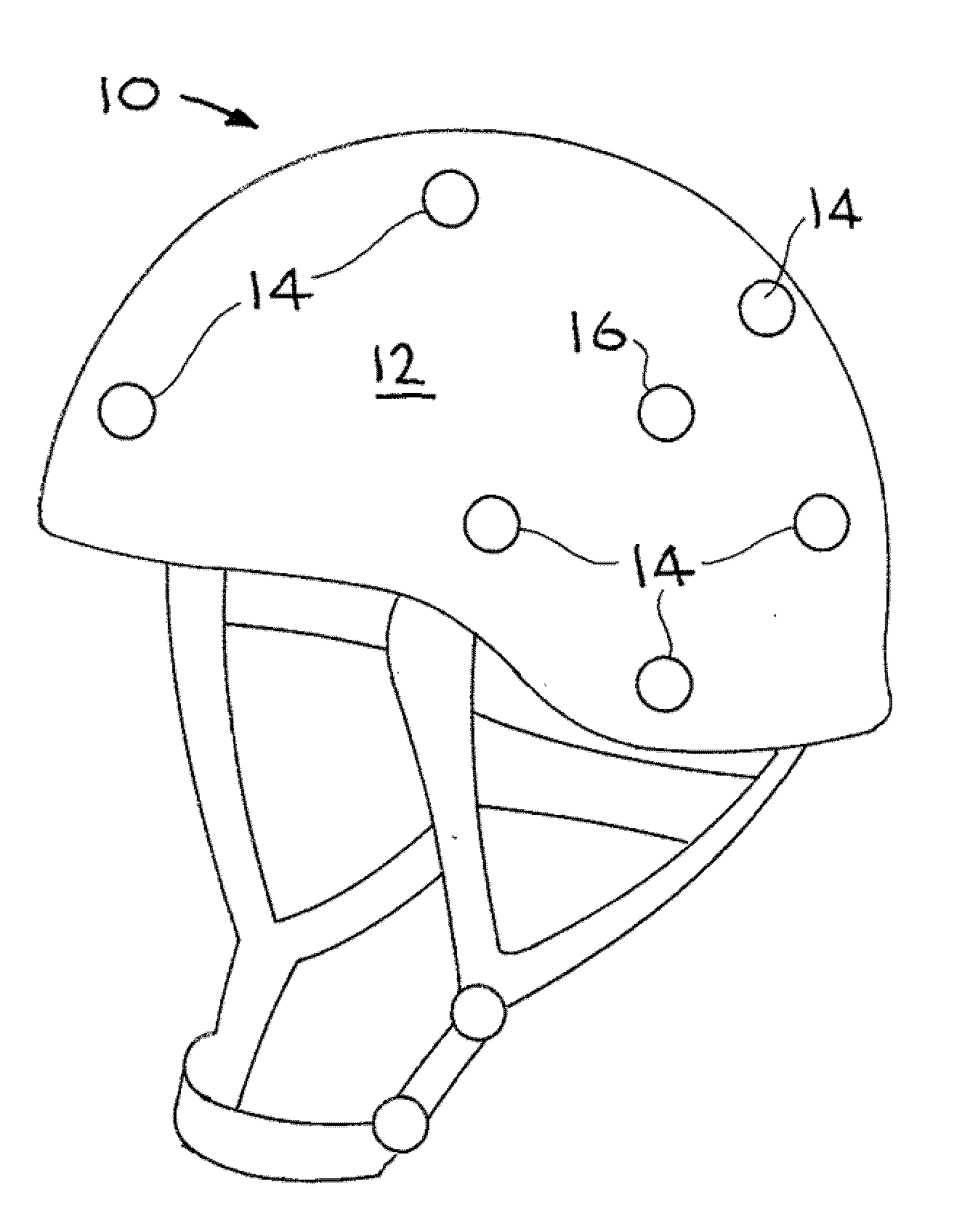

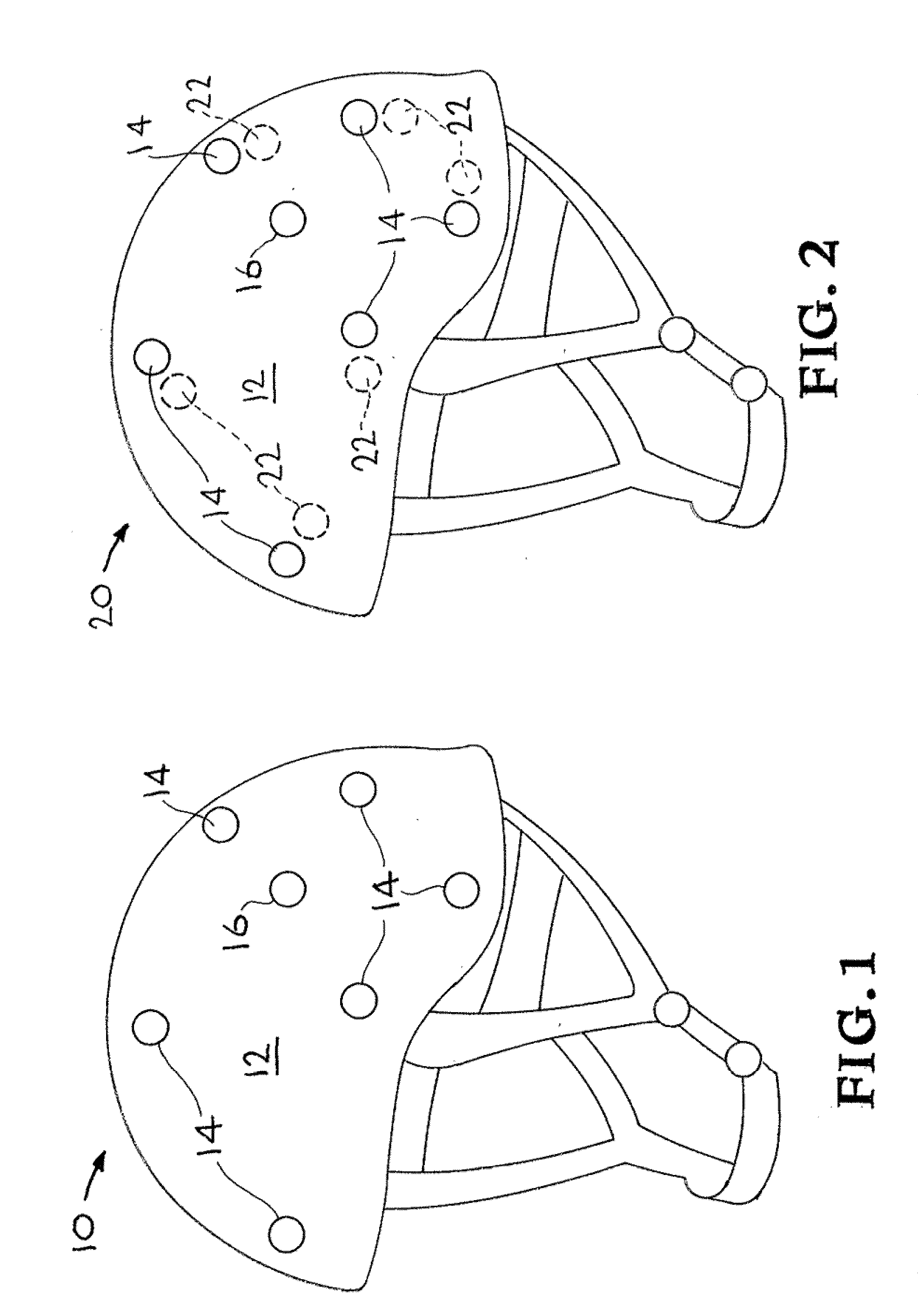

Helmet with shock detector, helmet attachment device with shock detector and methods

InactiveUS7509835B2Easy to installLow costAcceleration measurement using interia forcesSport apparatusEngineeringShock detector

A helmet includes a head enclosure with an open cavity for the head of a user and a shock detector attached to the head enclosure that provides a signal when the head enclosure is subjected an impact exceeding a predetermined level.

Owner:BECK GREGORY S

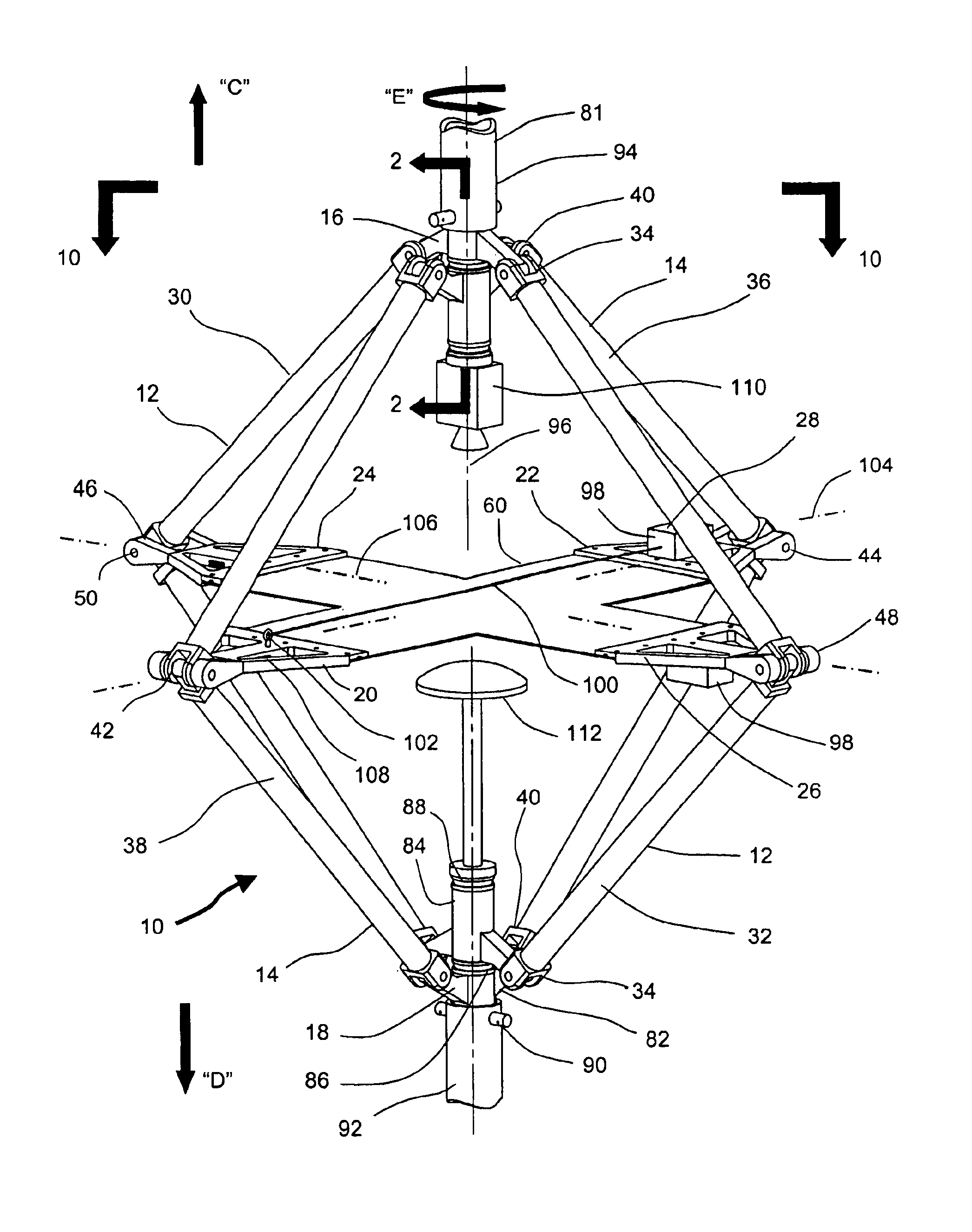

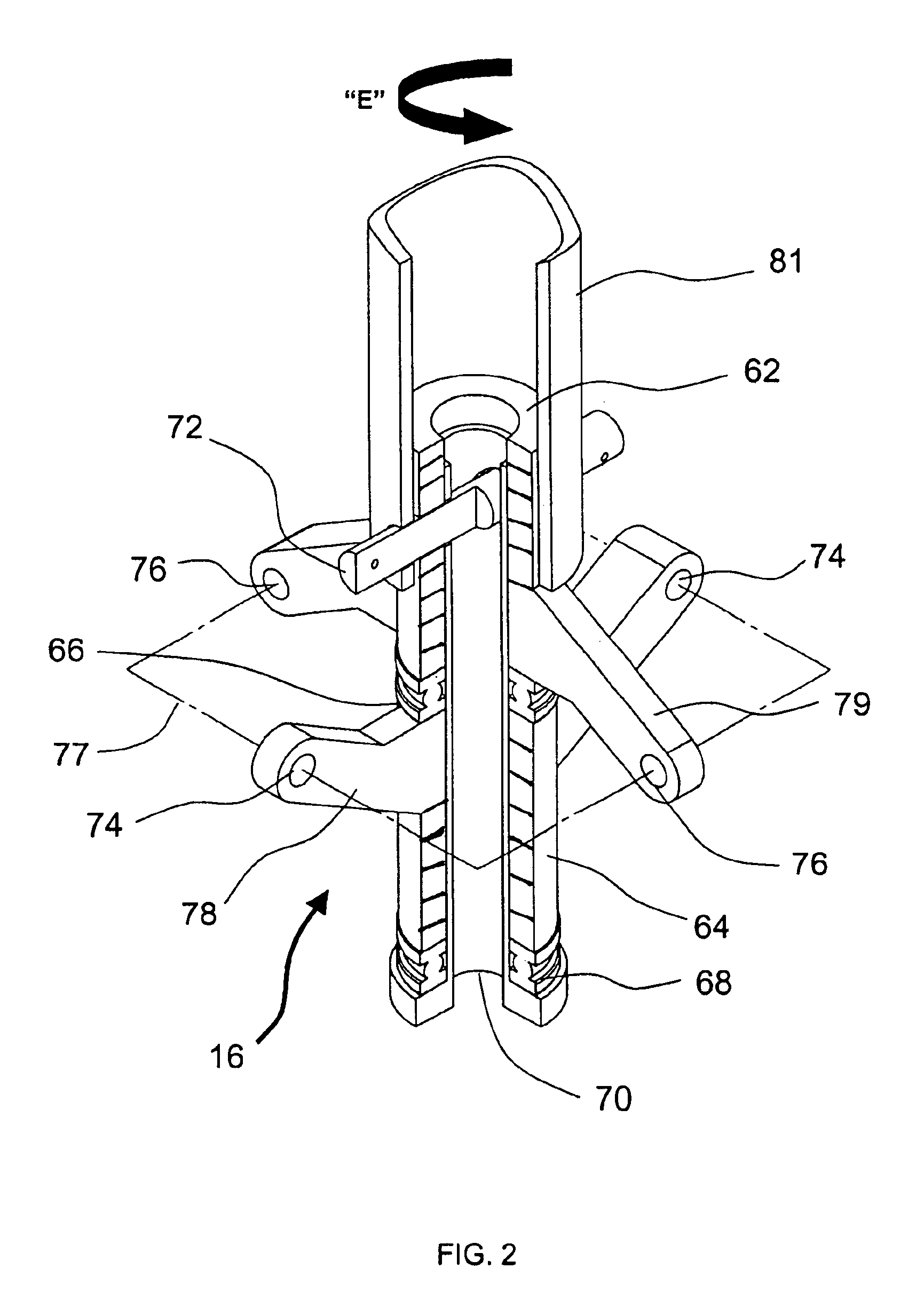

Combined in-plane shear and multi-axial tension or compression testing apparatus

ActiveUS6860156B1Provide flexibilityIncrease distanceMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesEngineeringTorsional load

An in-plane shear and multi-axial tension or compression testing apparatus having four-bar linkages pivotable to two sleeves on an opposite vertices with the sleeves of each vertex rotationally attached to each other. Lateral links of each linkage are pivotally attached to load transfer plates in which the plates secure a test specimen. Each linkage is rotatable to the other linkages while the vertices are subjected to a compression or tensile load. The vertices are also capable of rotation by a testing machine for shear testing. During compression or tension of the vertices of the apparatus, the plates respectfully move toward or away from each other thereby applying compression or tension to the specimen. The bars of one linkage can be rotated with respect to the other, thereby applying torsional loading to the specimen.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

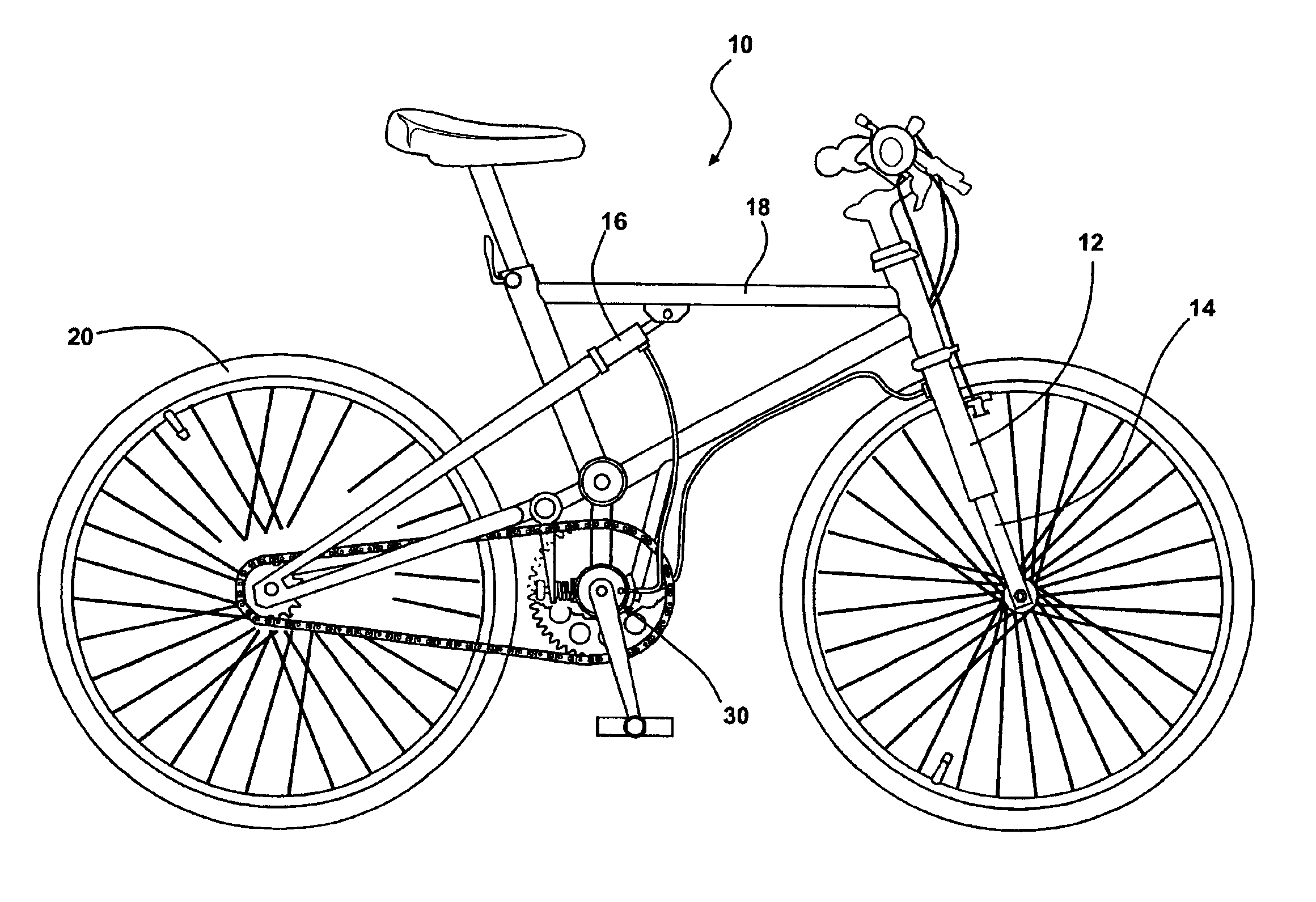

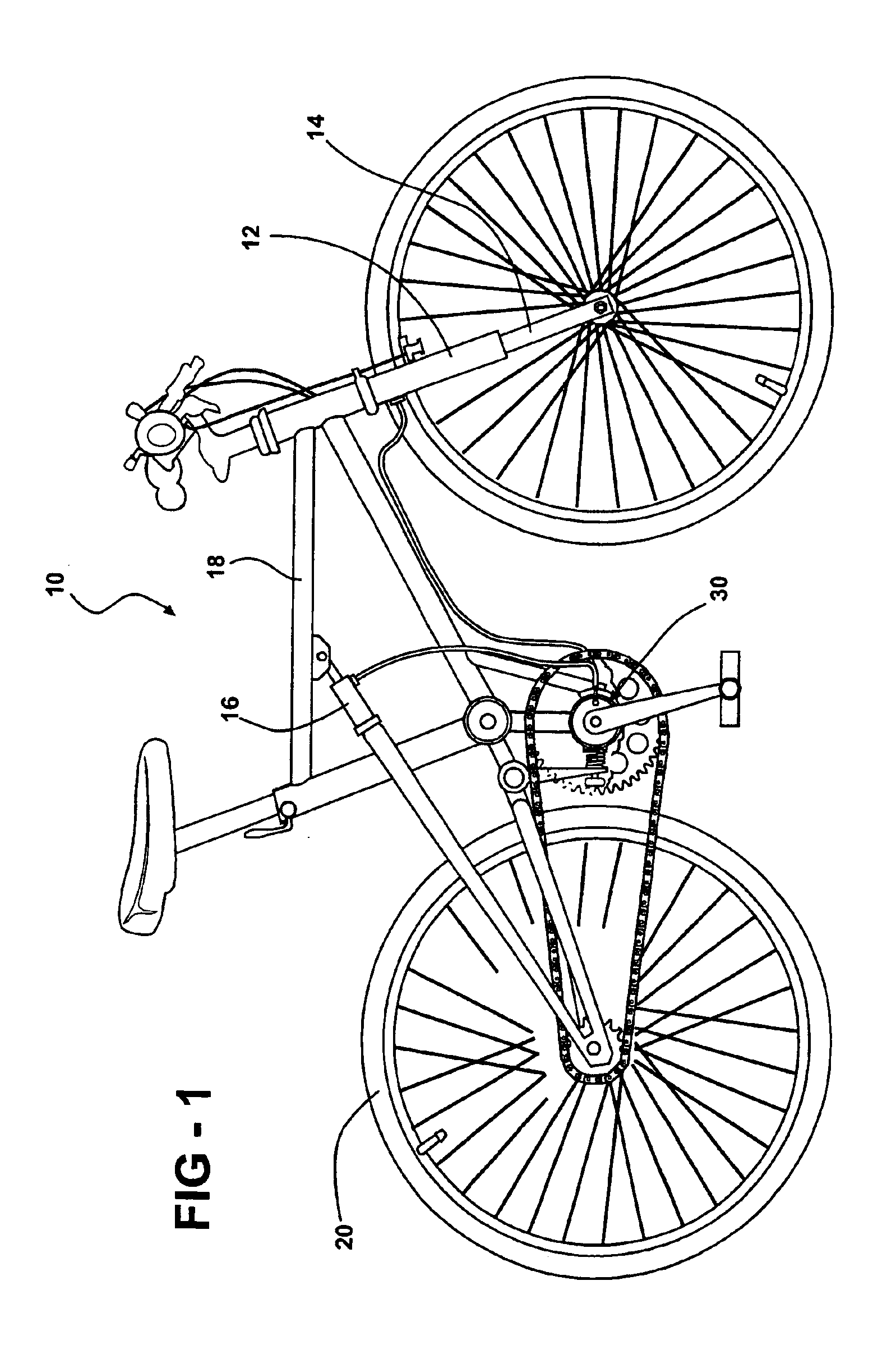

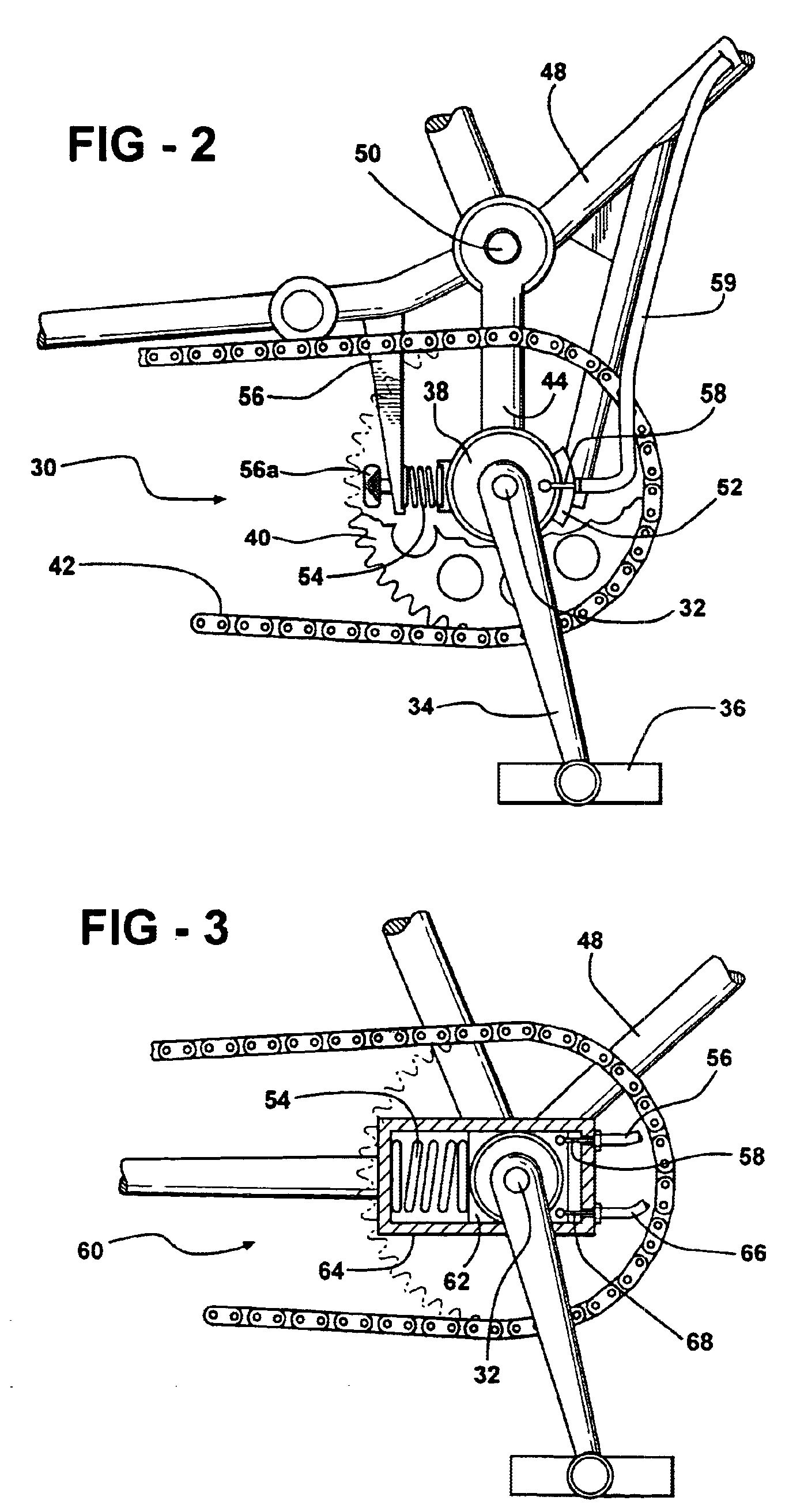

Anti-bob system for cycles

A control system is operable to selectably activate shock damping devices associated with a bicycle so as to eliminate bobbing encountered under extreme pedaling conditions. The system includes a crank axle torque detector which operates to detect a level of torque applied to a crank axle and provide a control signal corresponding to the level of torque. A shock damping device is coupled to the frame of the cycle, and functions to absorb and dampen mechanical shocks communicated to the frame. The shock damping device includes an activator for controlling its damping function. The activator is operable to receive the control signal from the crank axle torque detector and control the shock damping device in response thereto. The control signal may be an electrical or a mechanical signal.

Owner:THE LARRY D MILLER TRUST LARRY D MILLER & MARY L MILLER TRUSTEES DTD 06 12 98

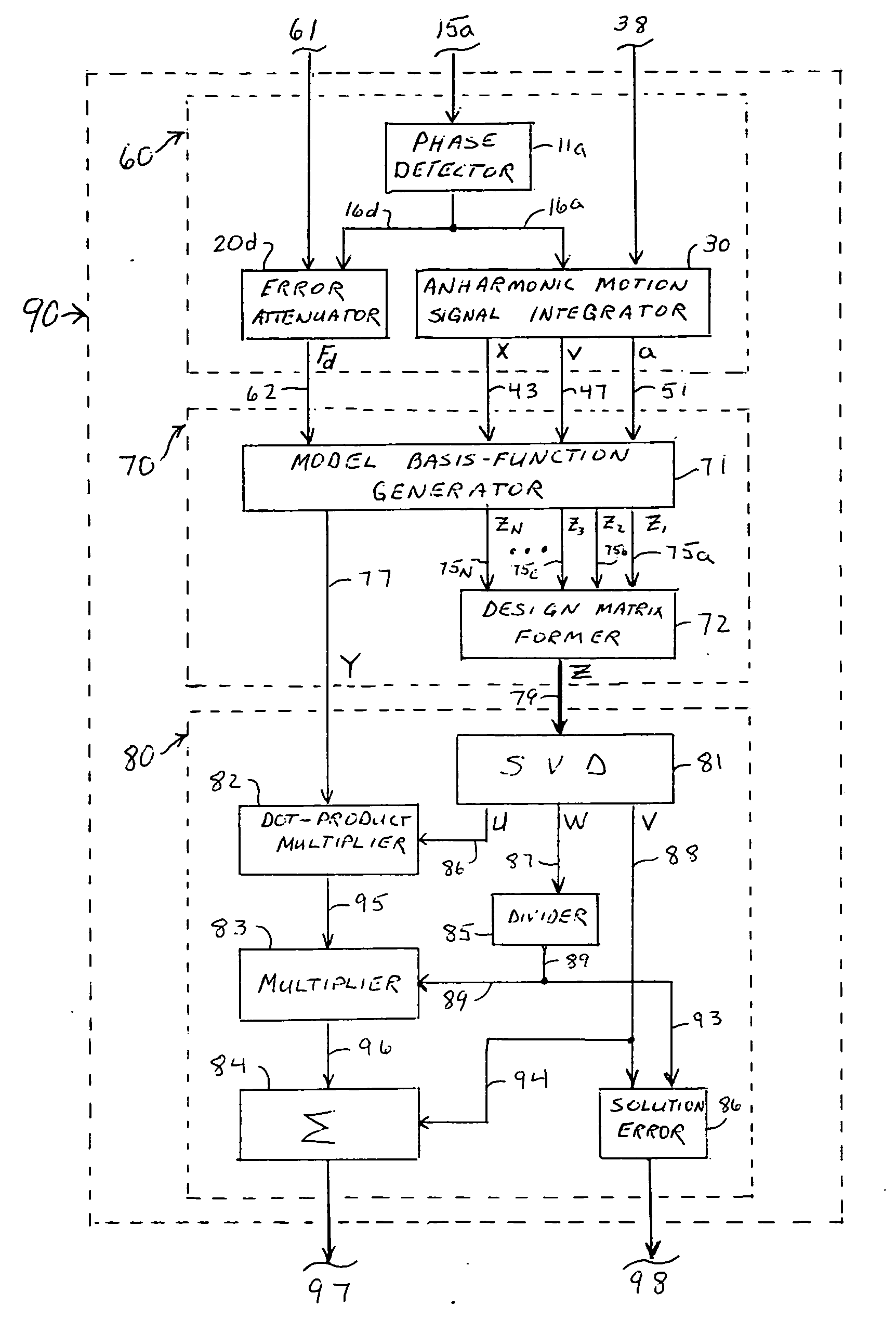

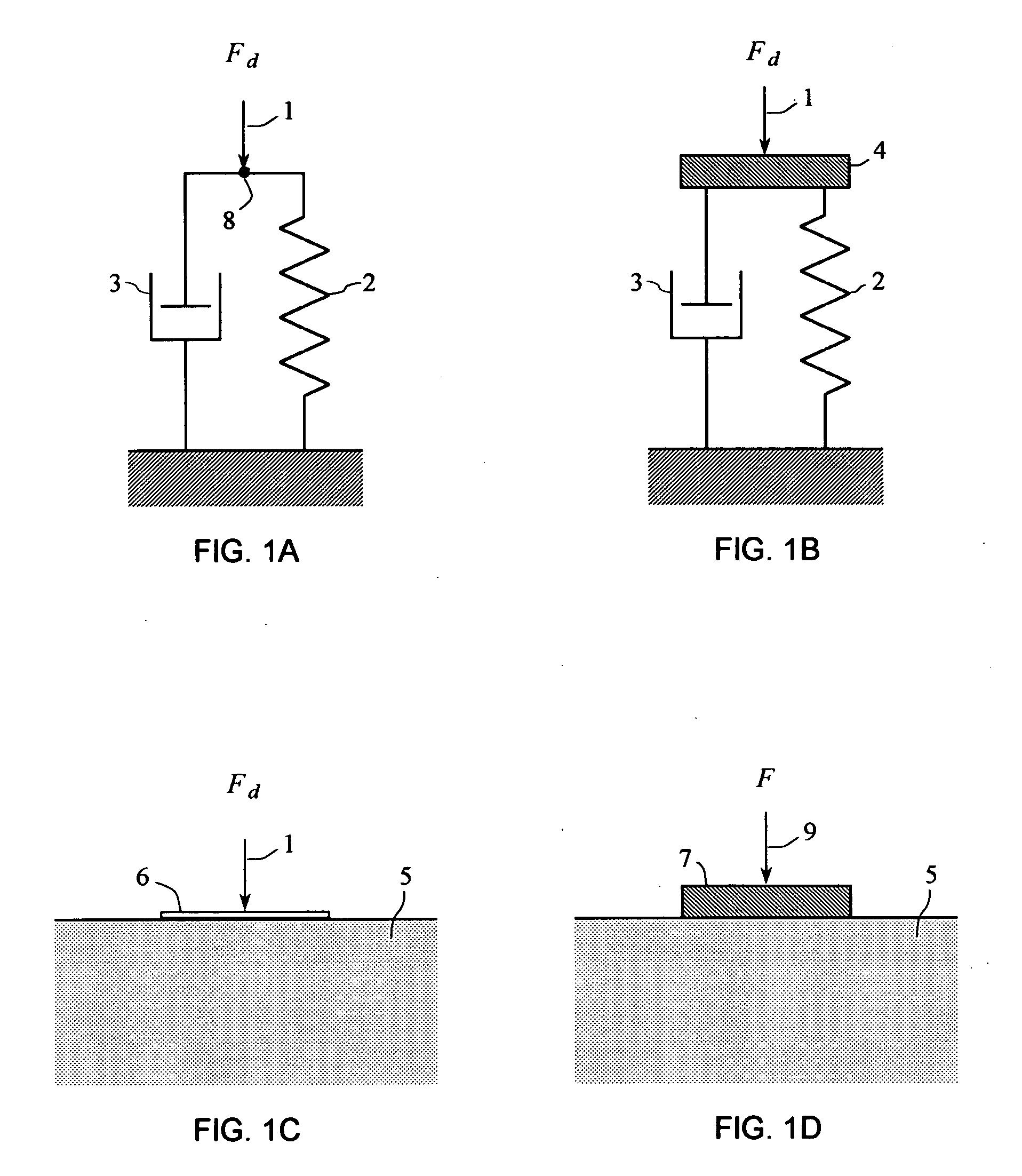

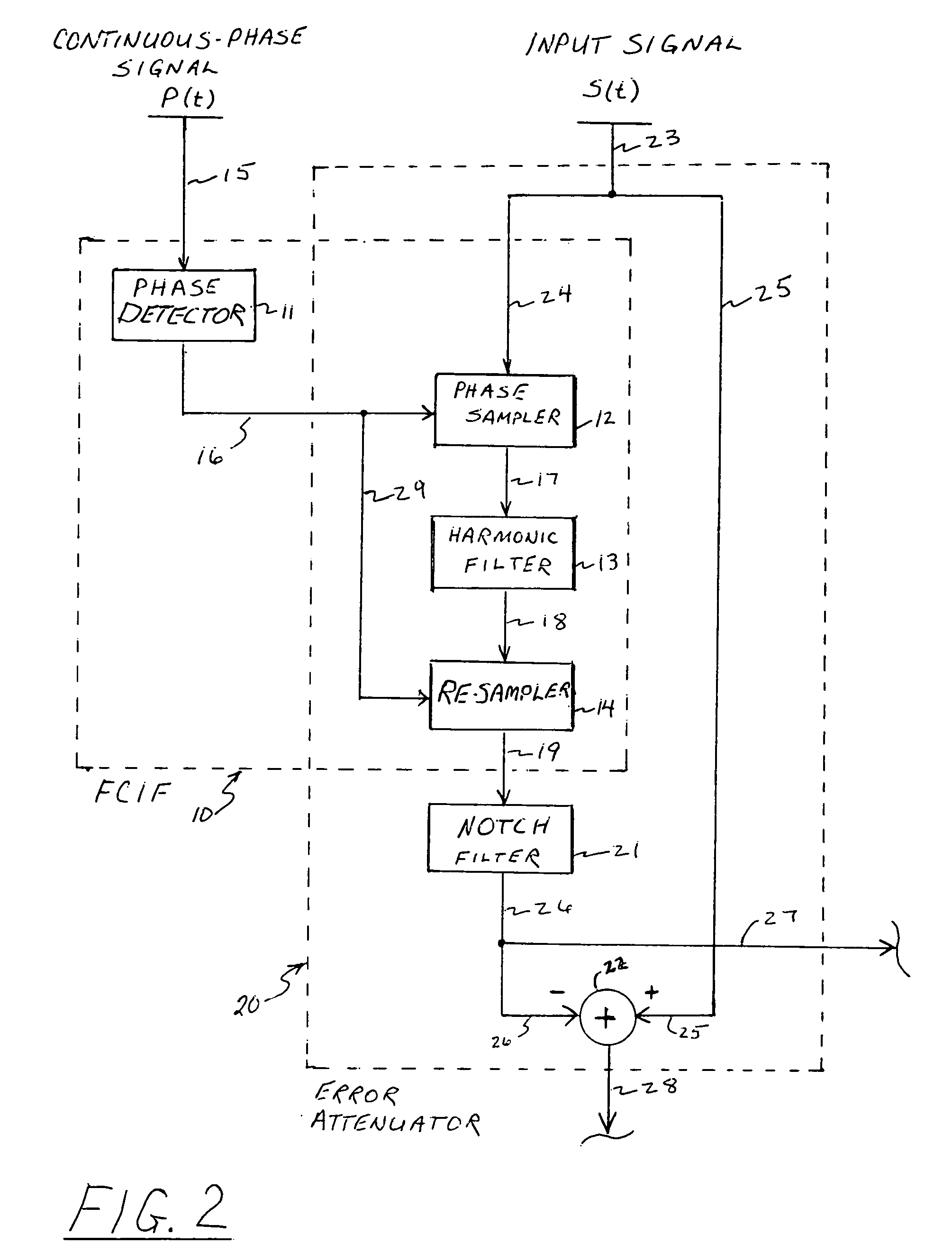

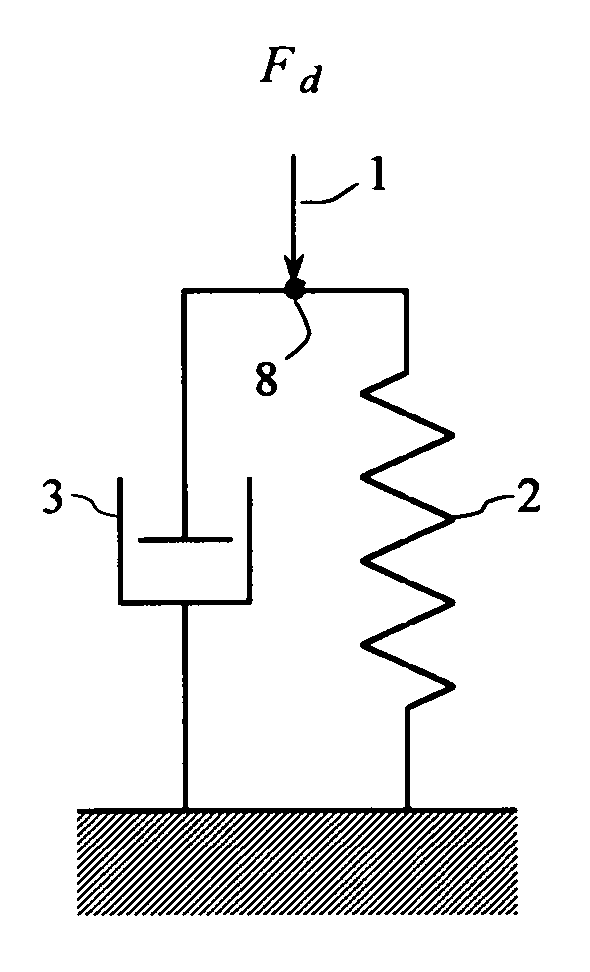

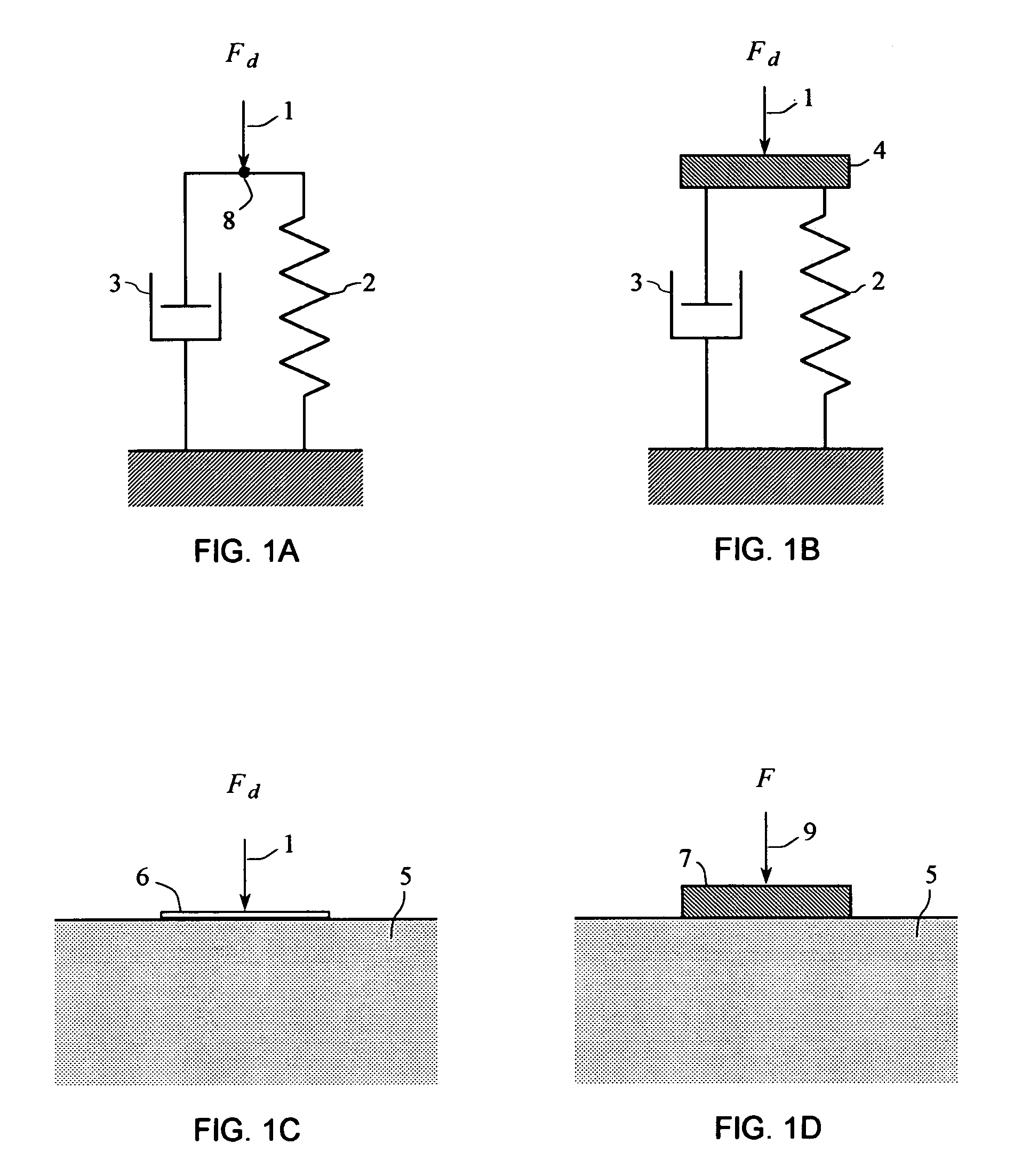

Systems and methods to determine elastic properties of materials

InactiveUS20050267695A1Elastic properties can be determinedInherent in massVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesTime domainHarmonic

The present invention provides systems and methods to use a measured driving-point response of a nonlinear material to determine one or more elastic properties of the material. The present invention takes advantage of the full information represented by the transient component, the steady-state component, the anharmonic components, and the nonlinear response components of a measured driving-point response of a real nonlinear material, without limitation in the use of large-amplitude forces. The elastic properties are determined by forming and solving a time-domain system of linear equations representing a differential equation model of the driving-point motions of the material. Based on a single, short duration, large-amplitude driving point measurement, both linear and nonlinear properties can be determined; both large-amplitude and near-zero amplitude properties can be determined; and elastic-wave speed and elastic moduli and their variation with depth can be determined. The present invention also provides a system and a method to filter an input signal to either attenuate or preserve each of one or more selected harmonic components that are harmonics of a phase reference signal.

Owner:GERMAN PETER THOMAS

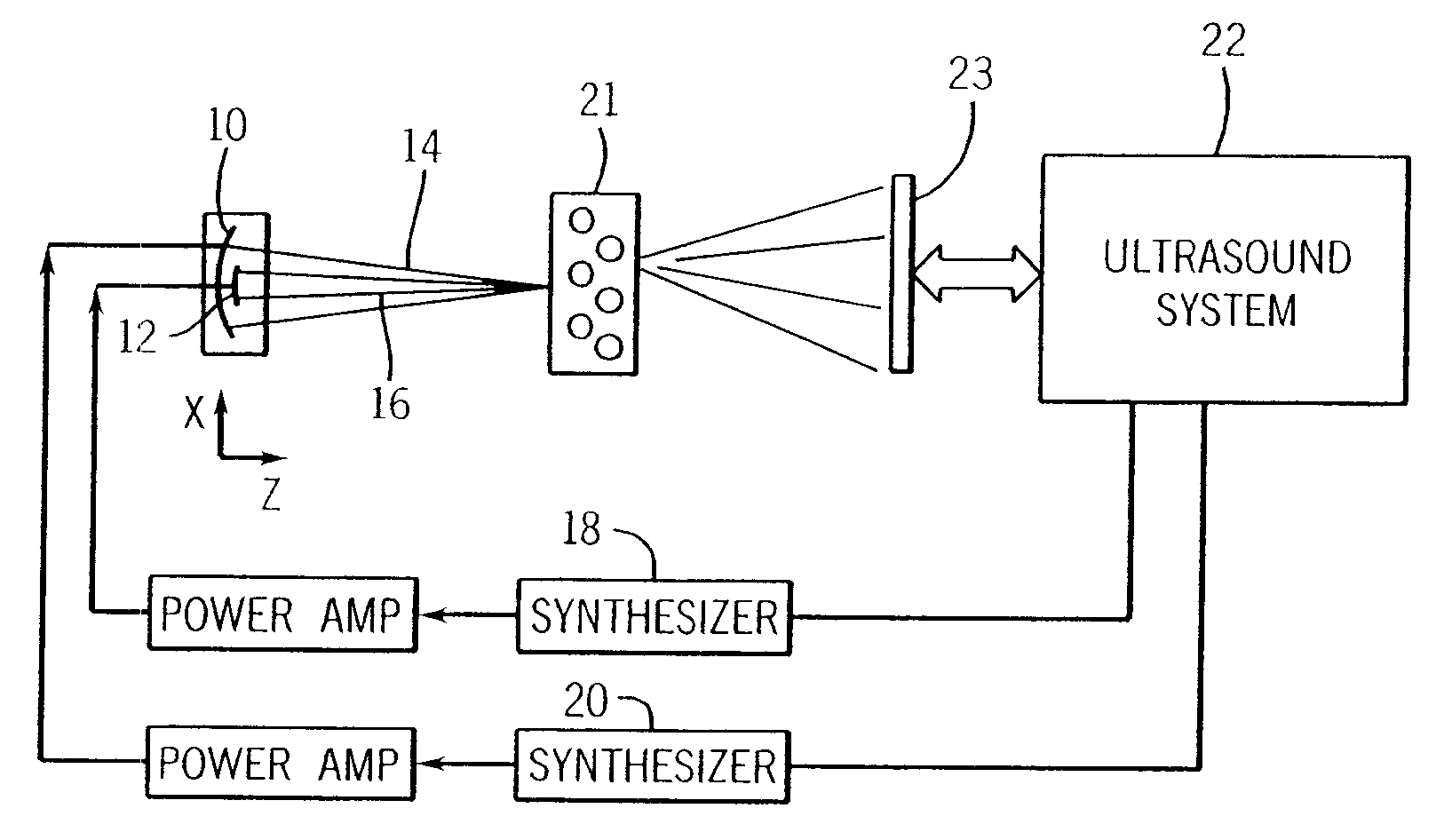

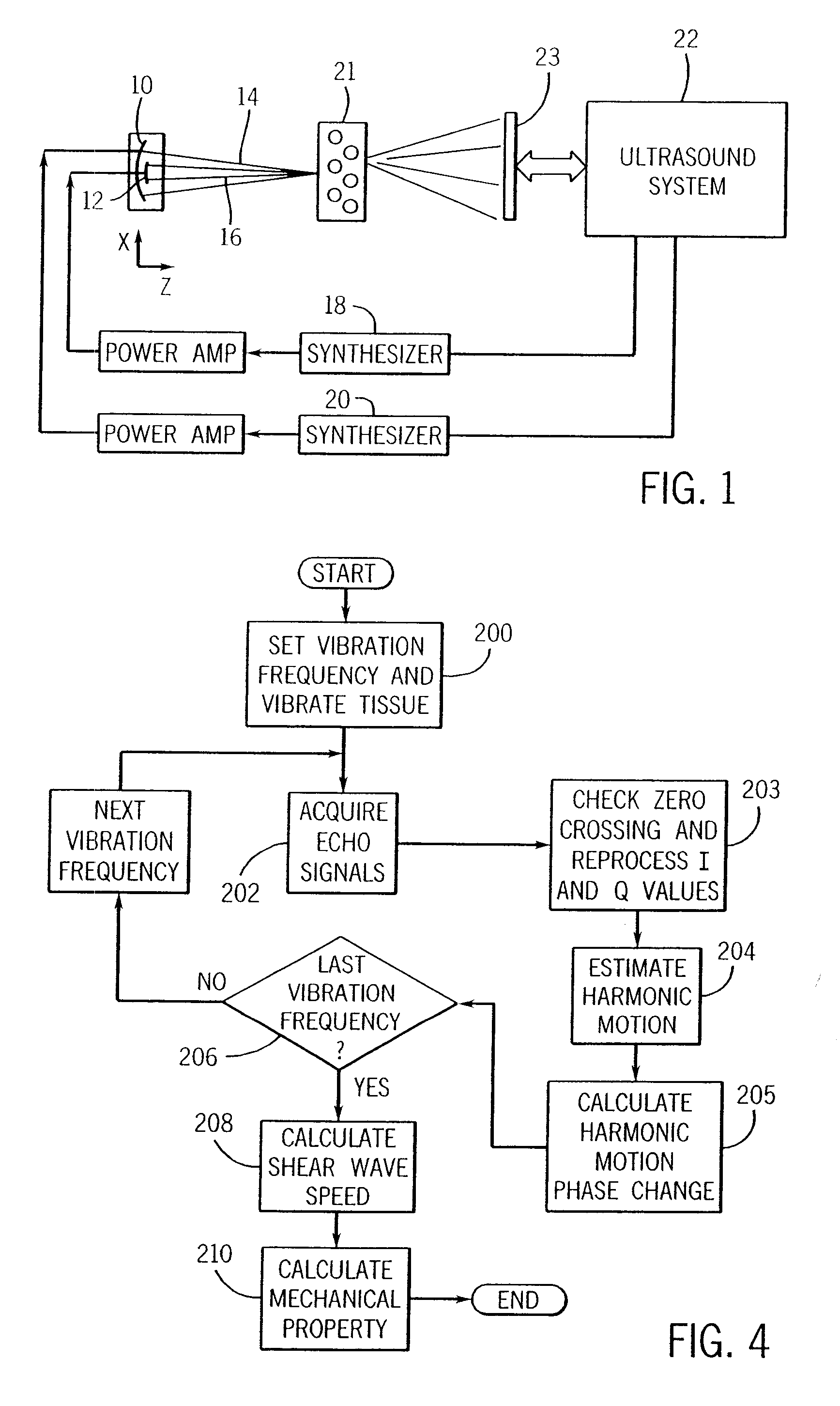

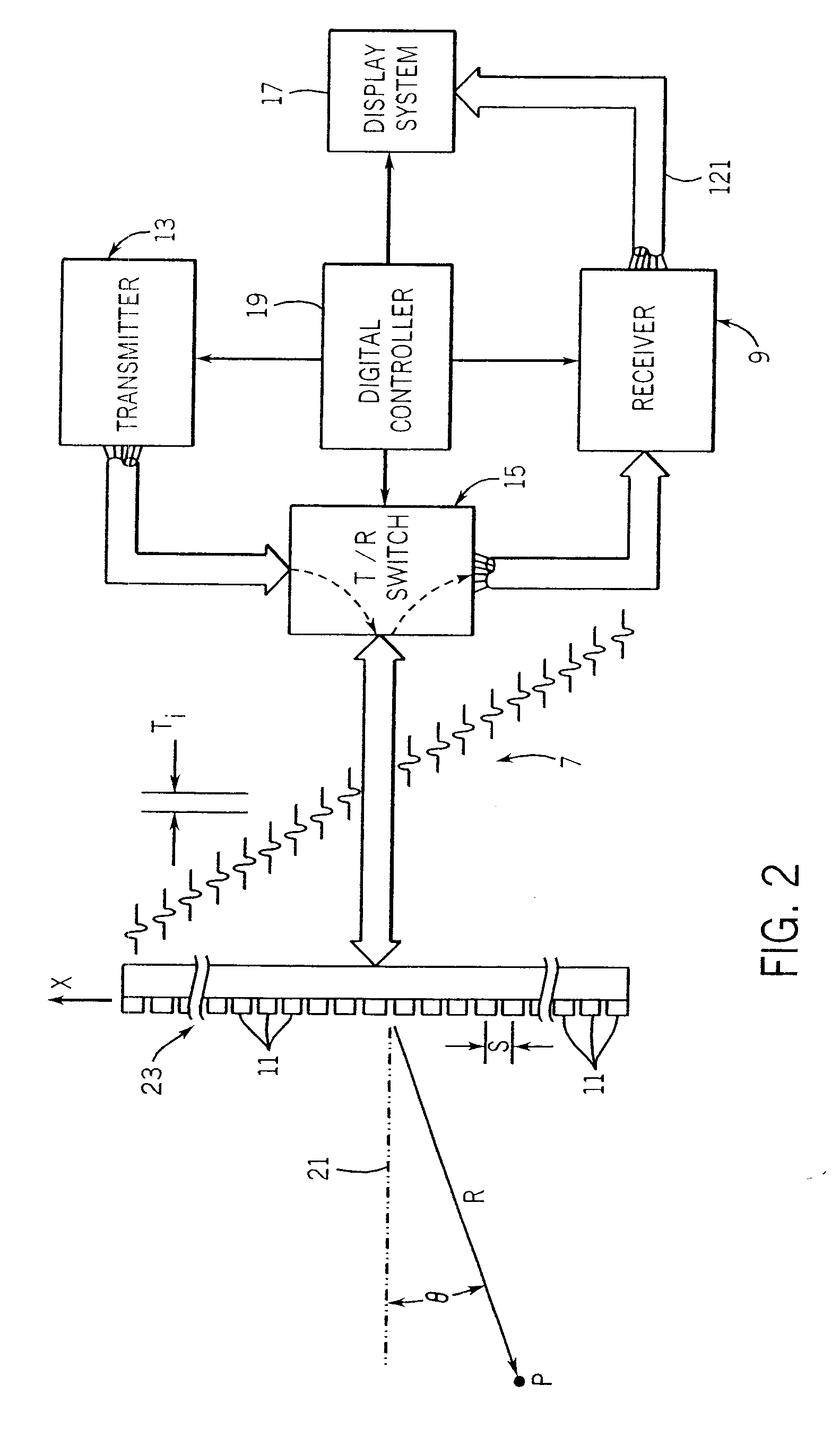

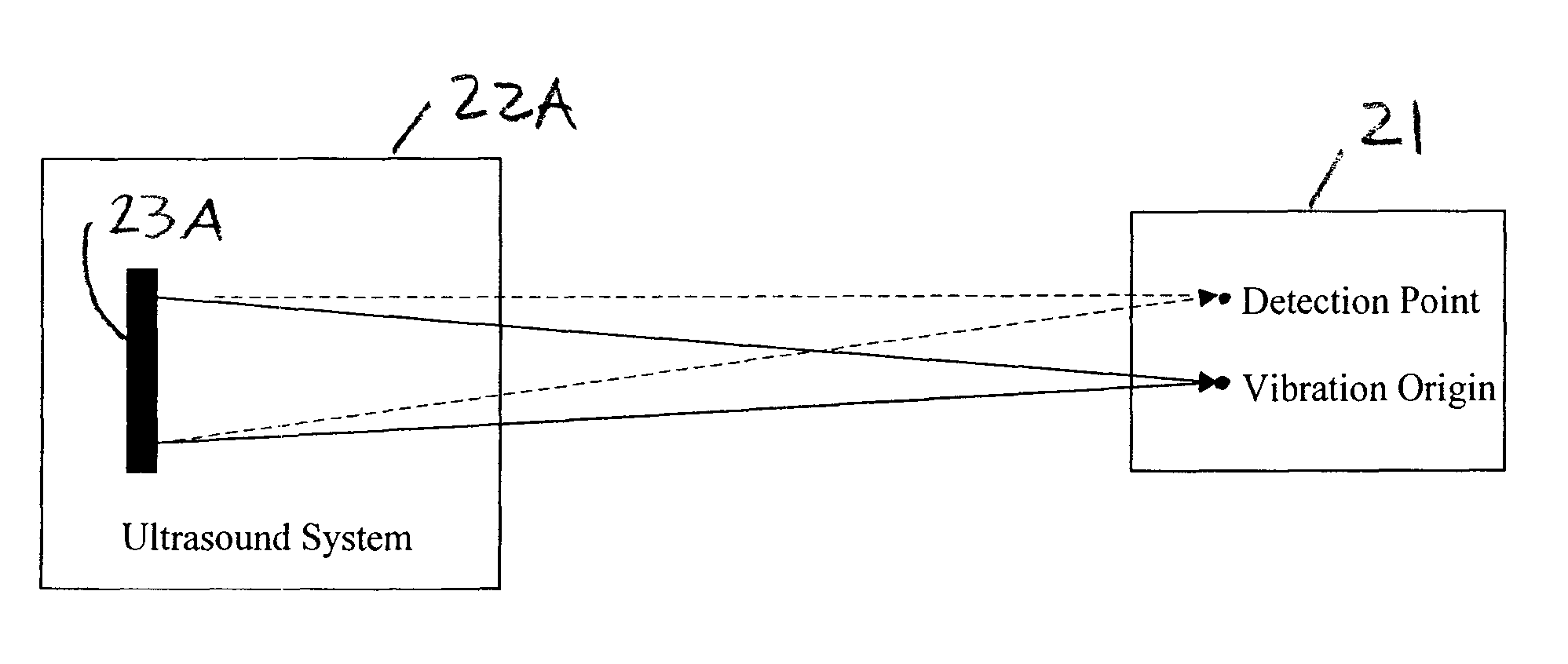

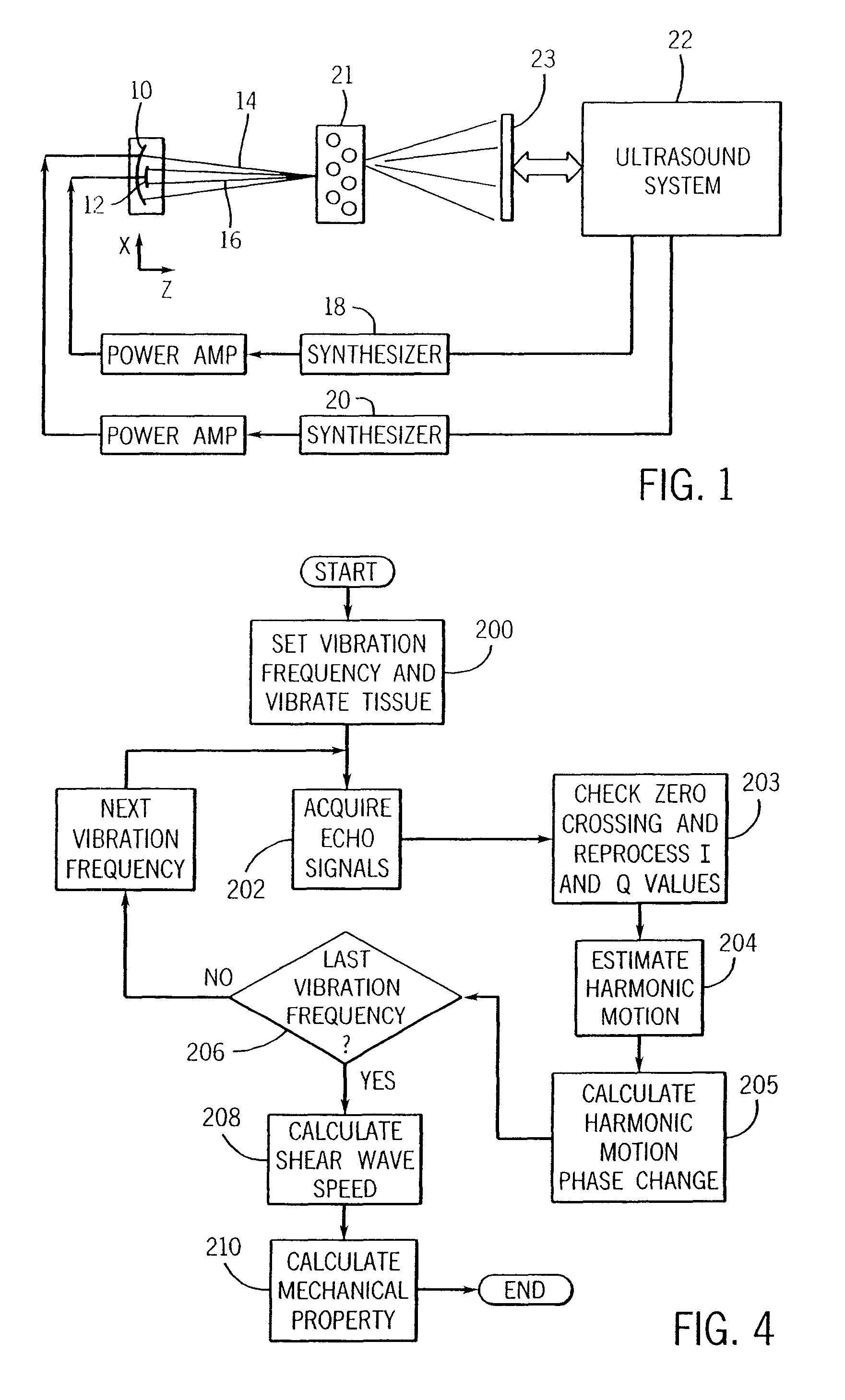

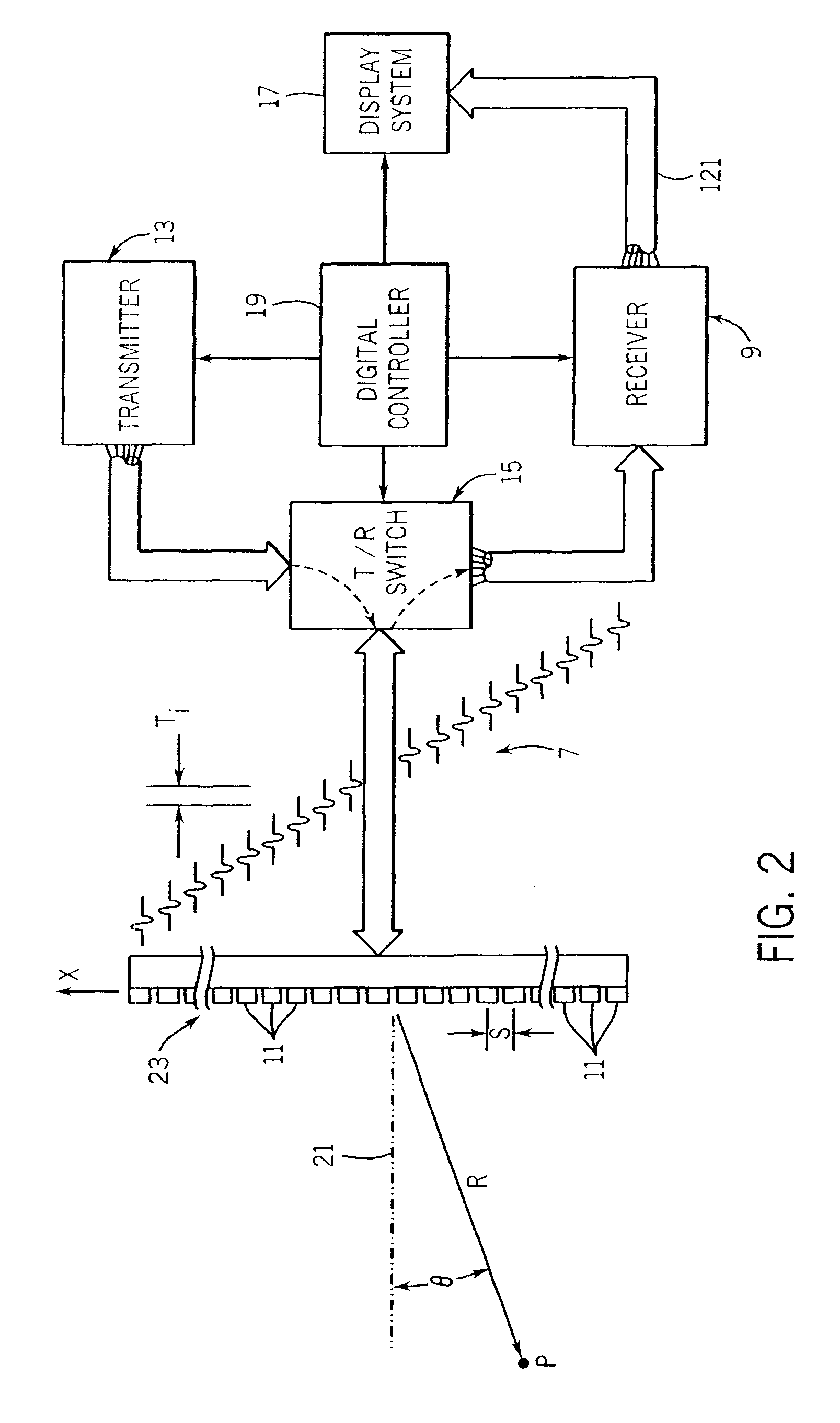

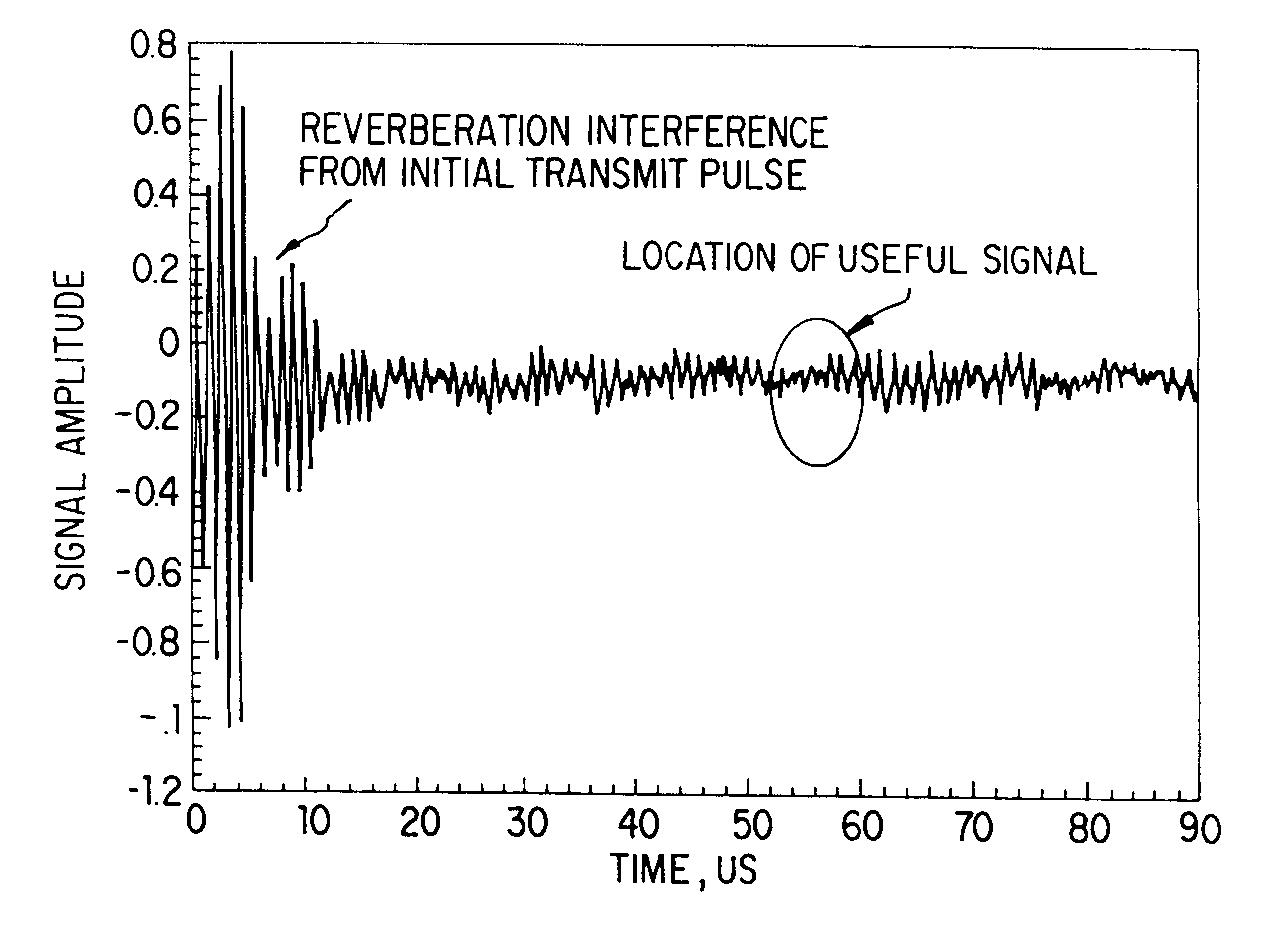

Ultrasound vibrometry

ActiveUS20070038095A1Vibration measurement in solidsUltrasonic/sonic/infrasonic diagnosticsSonificationMechanical property

A method for measuring a mechanical property of a subject includes using an ultrasonic transducer to apply ultrasonic vibration pulses to a vibration origin in the subject in an on-off time sequence in order to impart a harmonic motion at a prescribed frequency to the subject, and when the vibration pulses are off, using the same transducer to apply ultrasonic detection pulses to a motion detection point and to receive echo signals therefrom in order to sense the harmonic motion on the subject at the motion detection point. From the harmonic signal information, a harmonic signal is detected and a characteristic such as amplitude or phase of the detected harmonic signal is measured. The mechanical property is calculated using the measured characteristic using for example a wave speed dispersion method.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

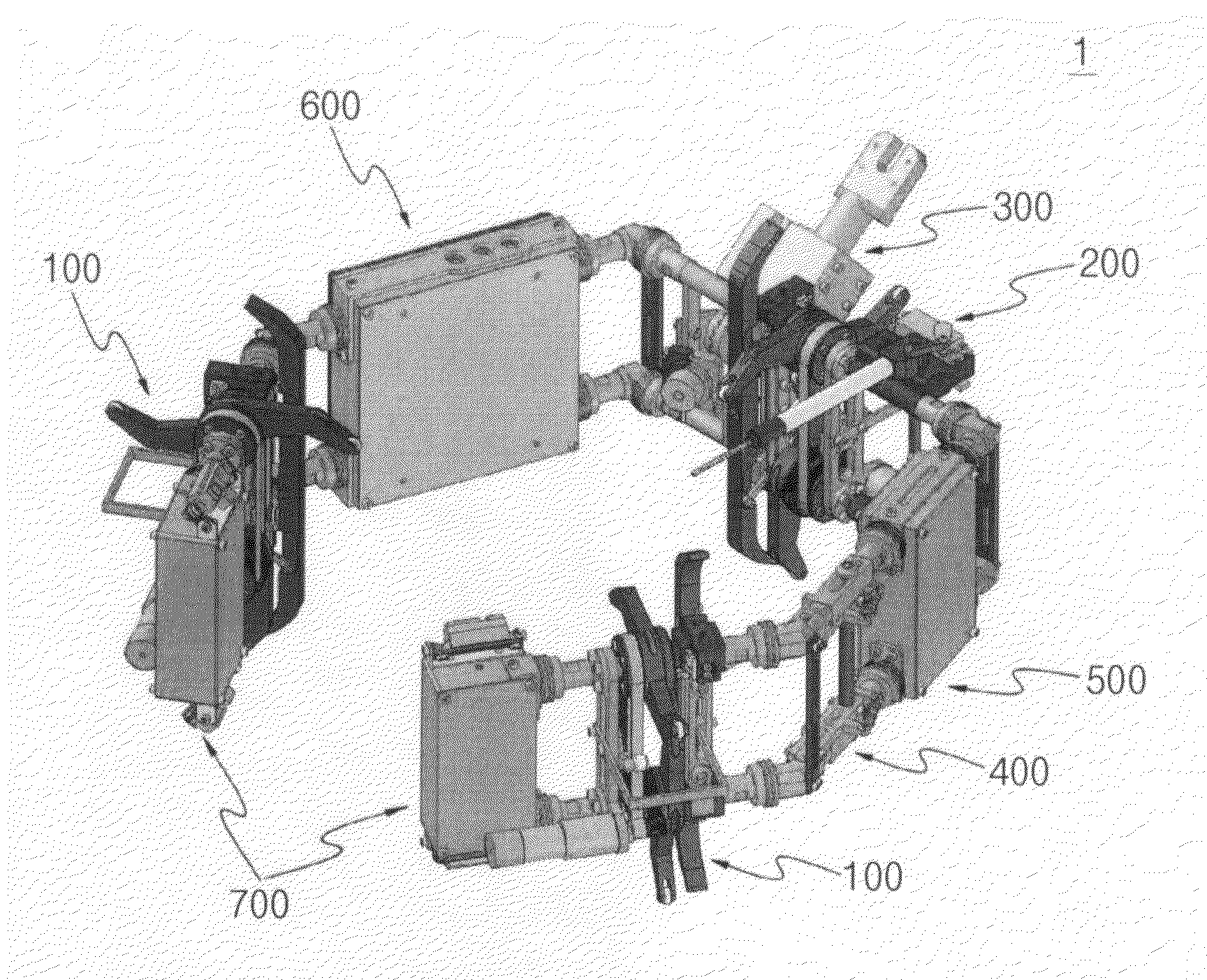

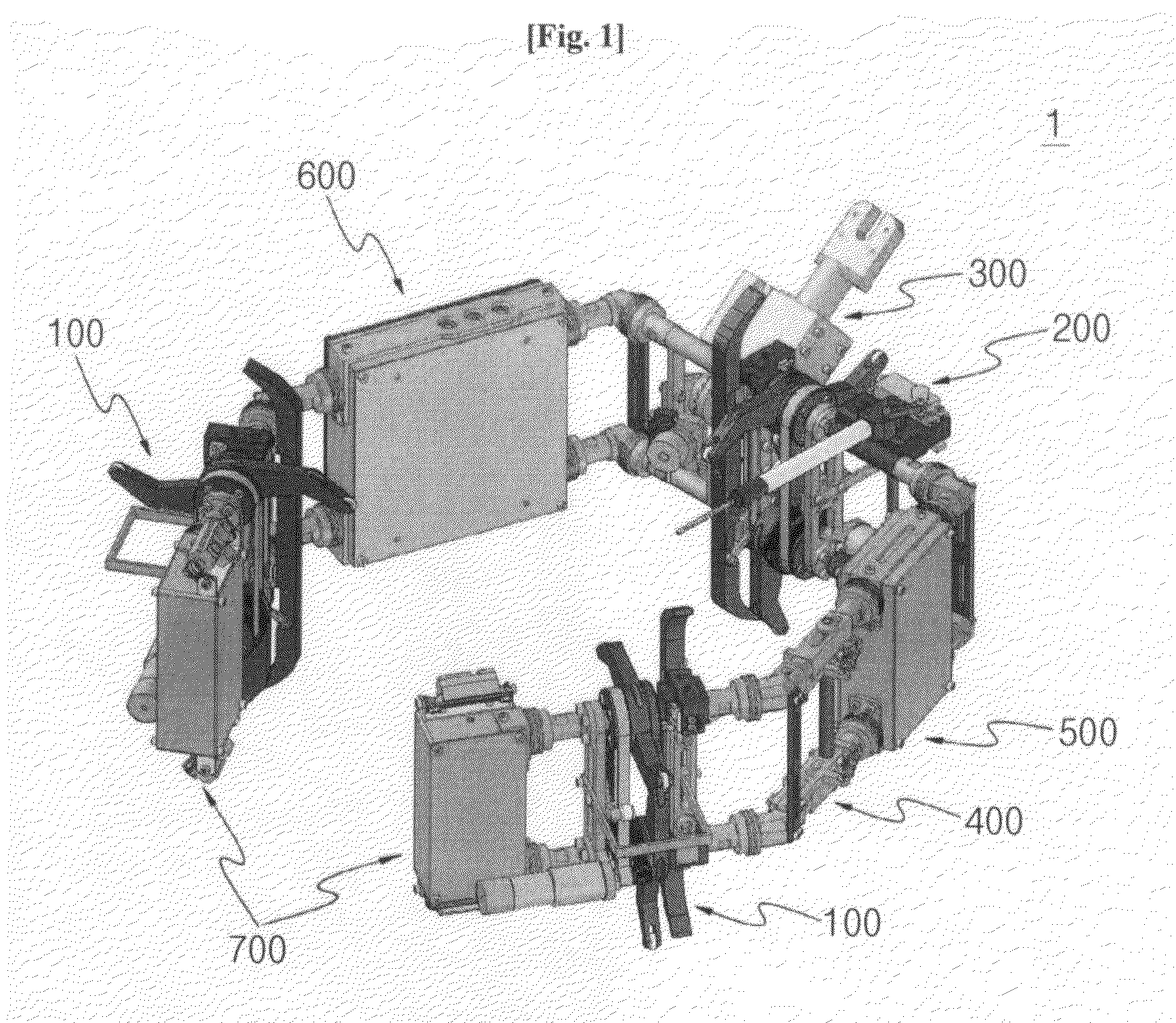

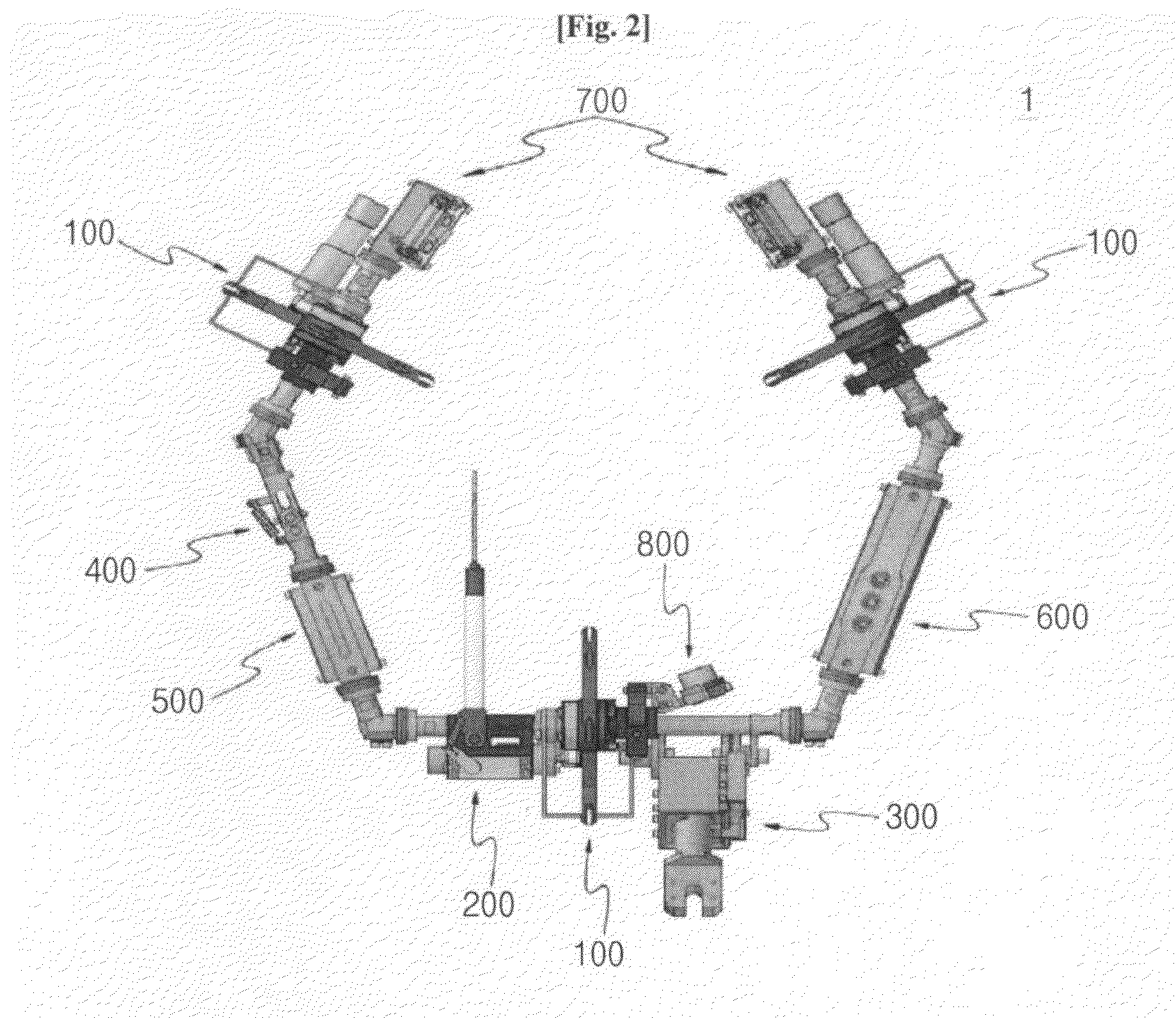

Robot mechanism for inspection of live-line suspension insulator string

ActiveUS20100100239A1Inspection is accurateProgramme controlVibration measurement in solidsControl theoryElectric wire

Disclosed herein is a robot mechanism for inspection of a live-line suspension insulator string. A robot body of the robot mechanism reciprocates along the live-line suspension insulator string and includes upper and lower robot frames configured to encircle the insulator string, a battery module provided to either end of the robot body, an actuation module for moving the robot body along the insulator string, an inspection module for electrically inspecting an insulator, a connection module for coupling the robot body to an installation / dismantlement mechanism, a wing opening / closing module for manually separating the robot body from the insulator string, a measurement module for measuring electrical properties of the insulator, a controller for controlling operation of the robot body, and a crack detection unit for detecting cracks formed in the insulator.

Owner:KOREA ELECTRIC POWER CORP

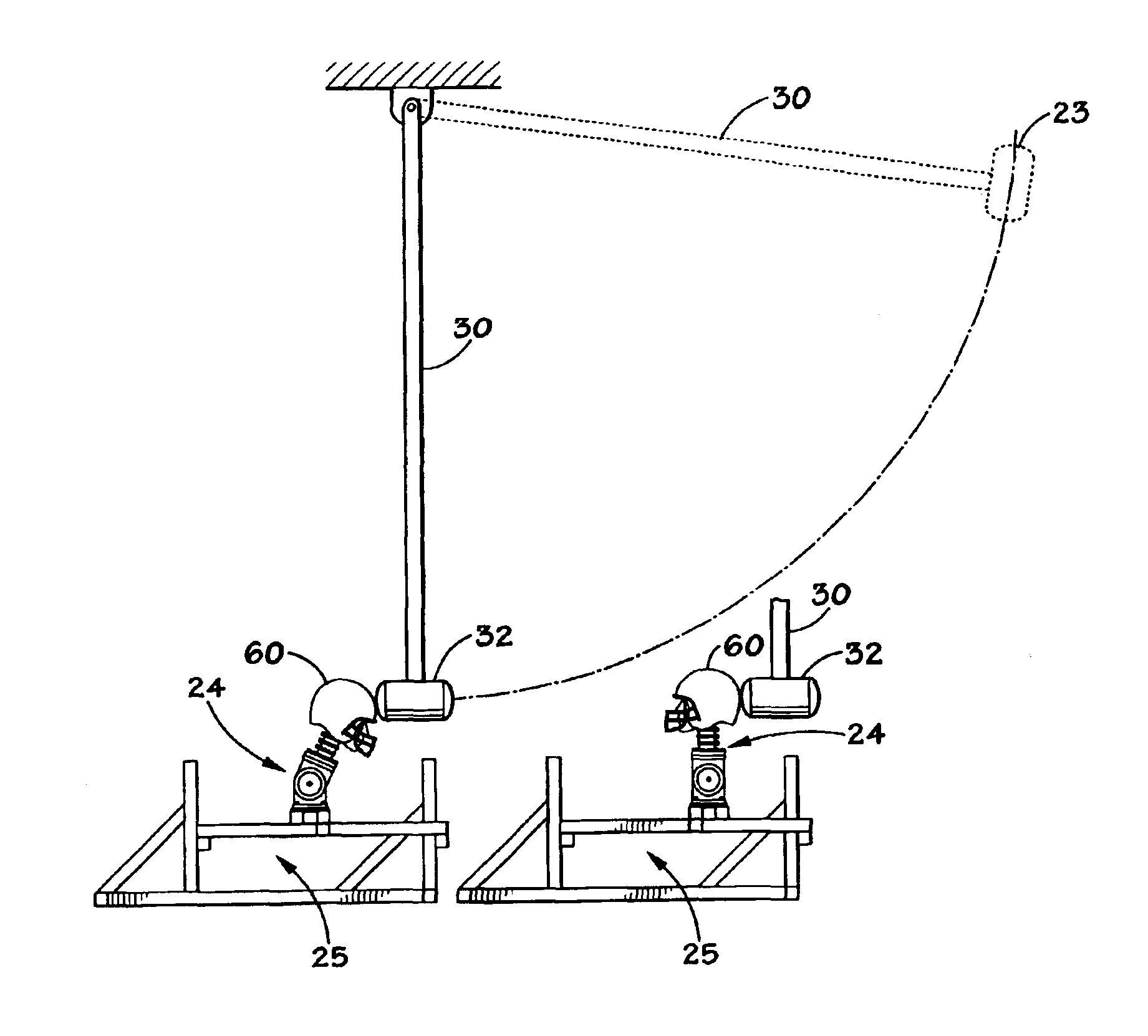

Method and apparatus for testing football helmets

ActiveUS6871525B2Permit deliveryAcceleration measurementMaterial strength using single impulsive forceEngineeringPreventing injury

A method and apparatus for testing a football helmet utilizes a weighted pendulum arm to impart an impact force upon the helmet. Linear head acceleration and rotational head acceleration caused by the impact force is measured and a Head Impact Power Index is computed and used as a standard to judge the ability and effectiveness of the football helmet in preventing injury to a football player.

Owner:RIDDELL

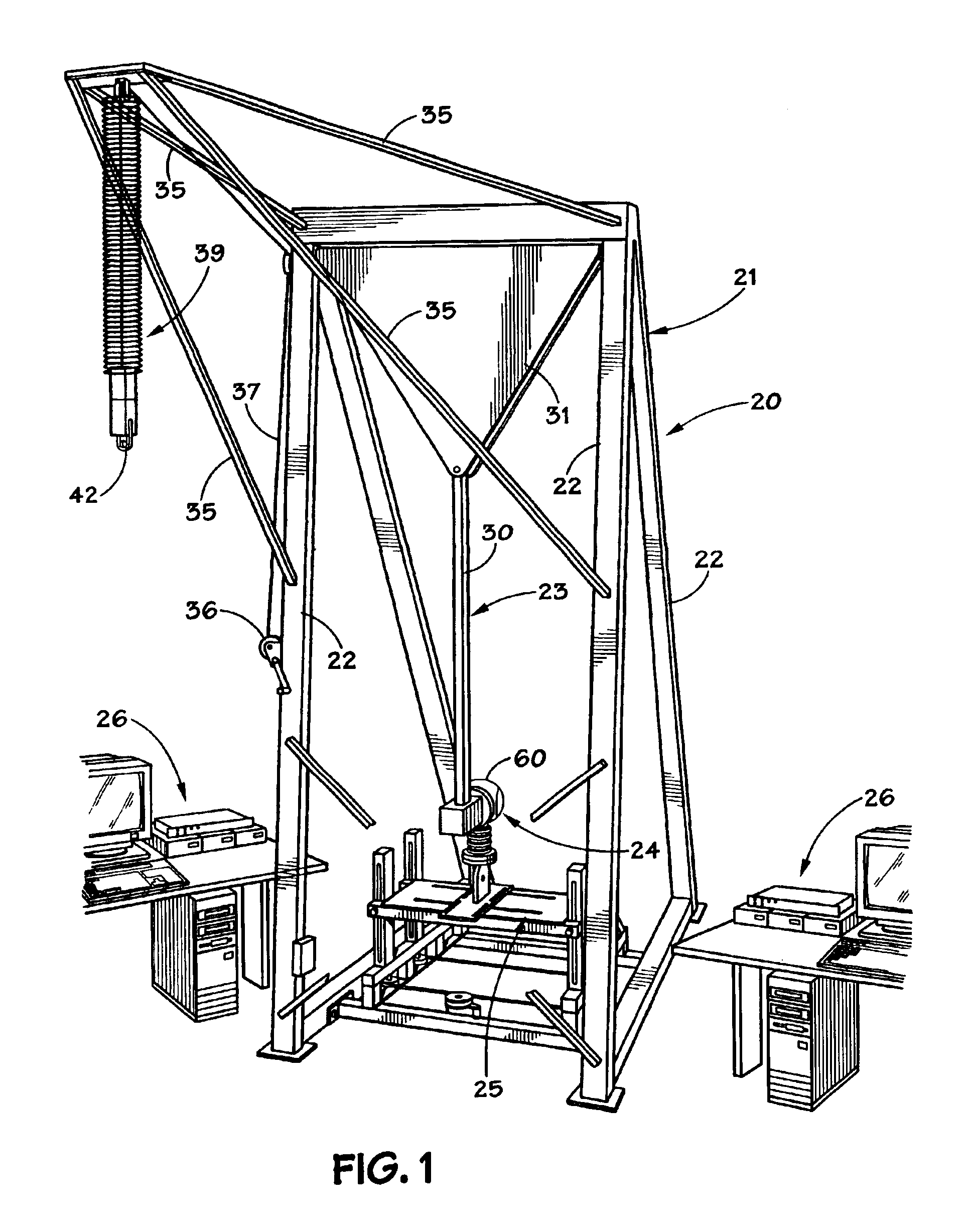

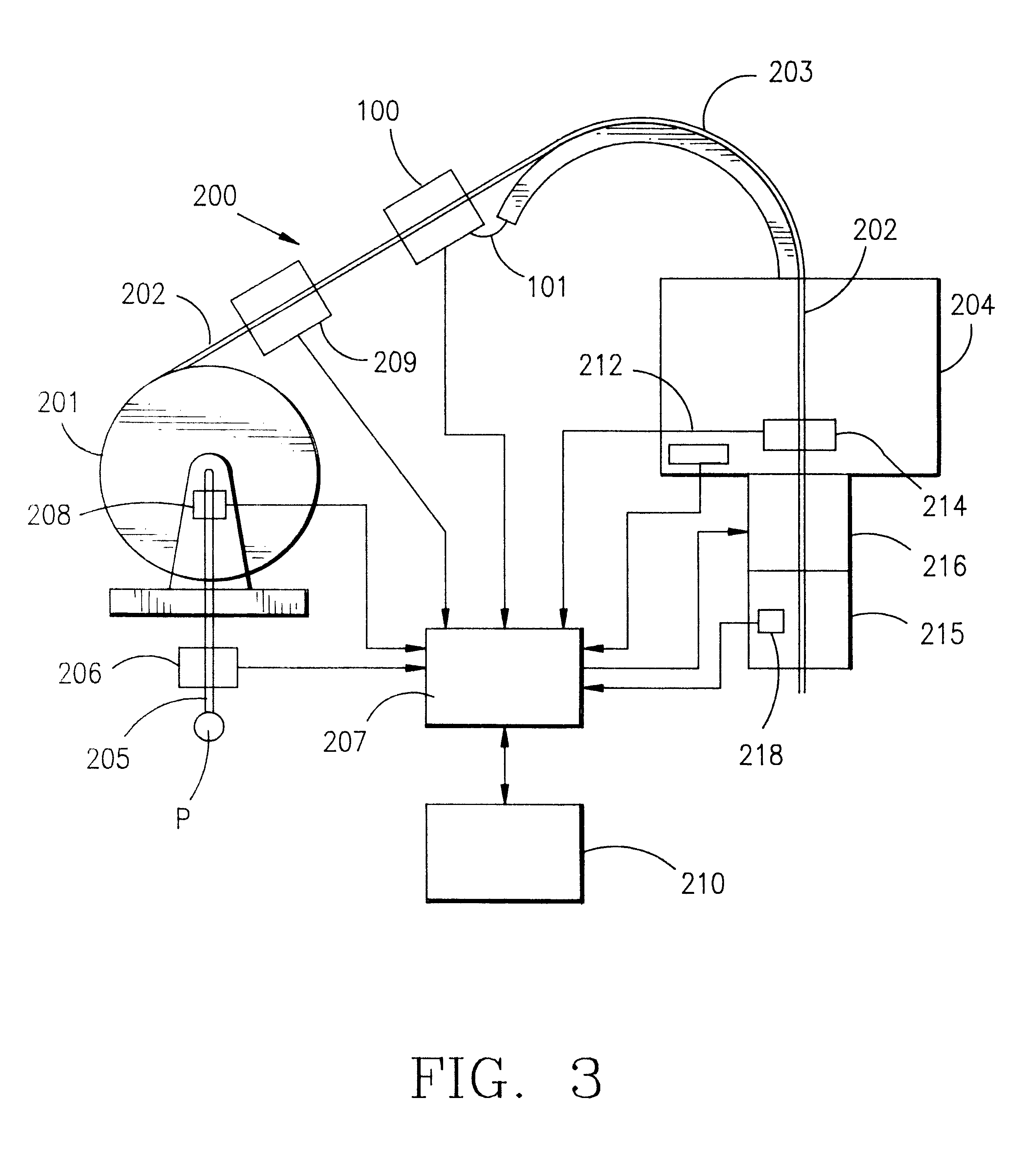

System, apparatus and method for testing under applied and reduced loads

InactiveUS7353715B2Easy maintenanceApply evenlyMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesEngineeringLoad regulation

A system which cyclically applies and reduces a load on a test specimen and which can use an apparatus comprising: (a) a frame; (b) a load adjusting section having a fluidic mechanical muscle that contracts and extends in length to cyclically apply and reduce a load; (c) a load train section frame for subjecting a test specimen to the load; and (d) a lever arm configured to apply and reduce the load from the loading adjusting section to the load train section. The system and apparatus can be used in a method for cyclically applying and reducing a load on a test specimen to thereby subject the test specimen to tensile testing and can also comprise a mechanism for decoupling at least a portion of the load from the test specimen when the load is reduced.

Owner:GENERAL ELECTRIC CO

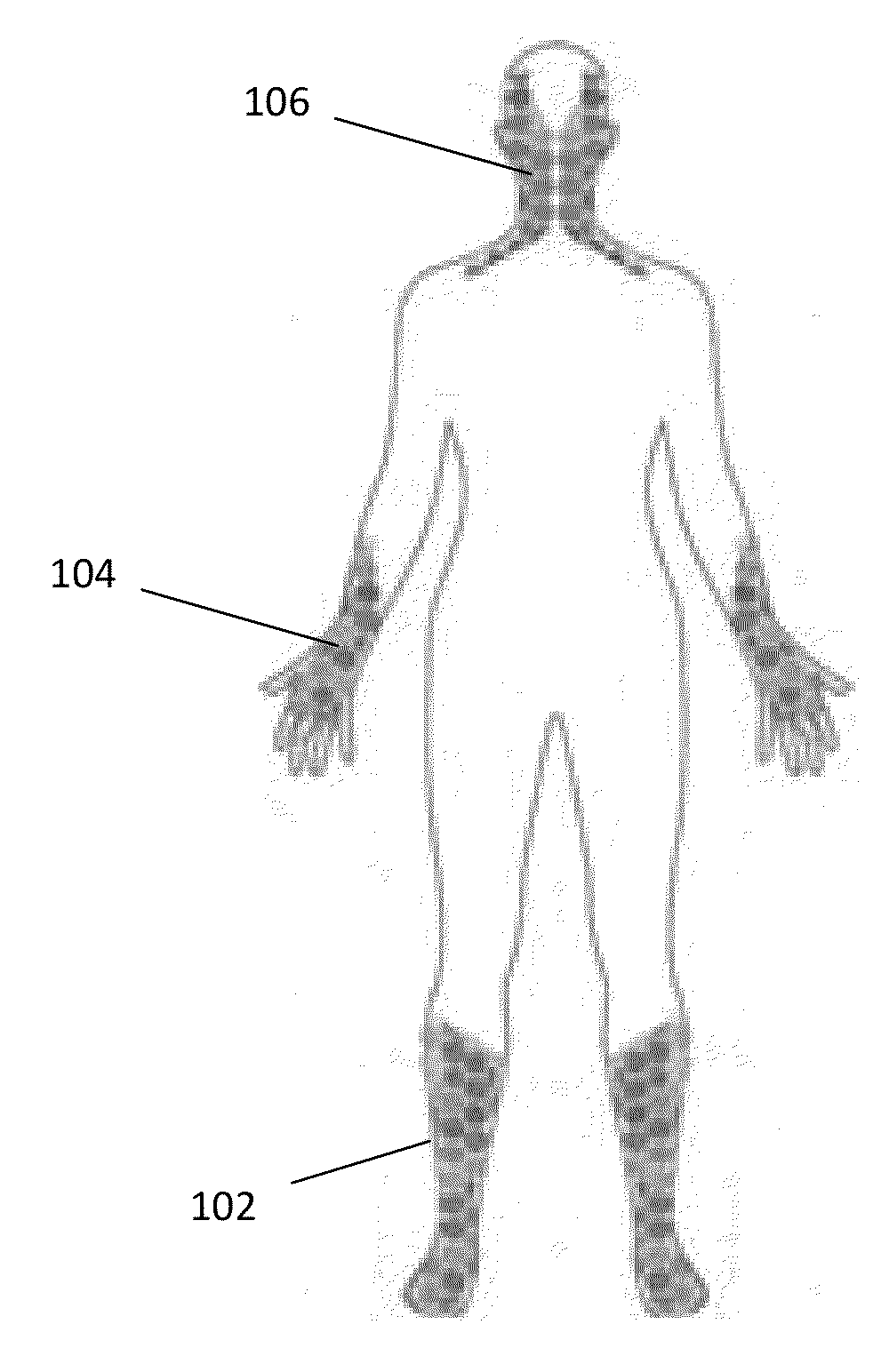

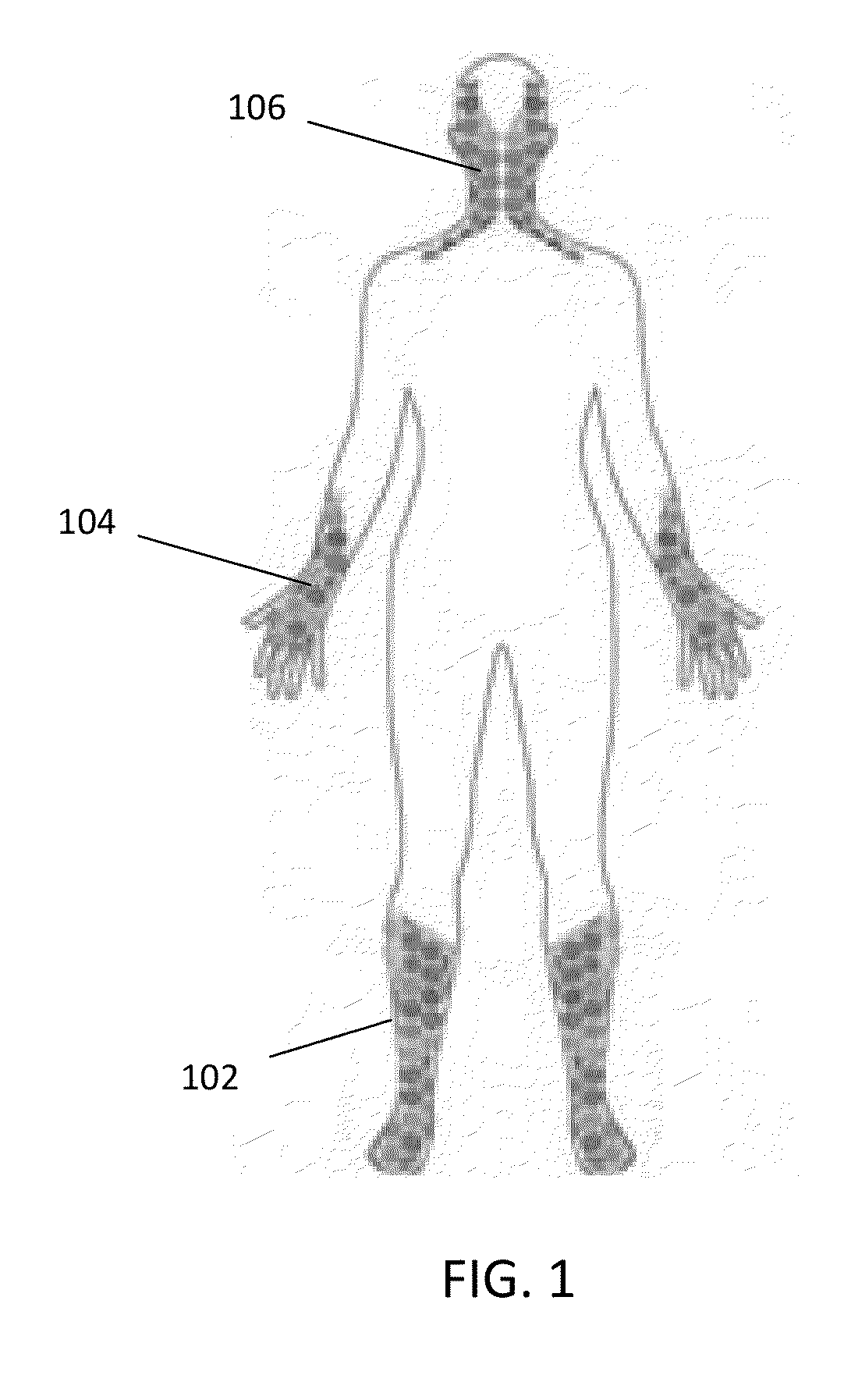

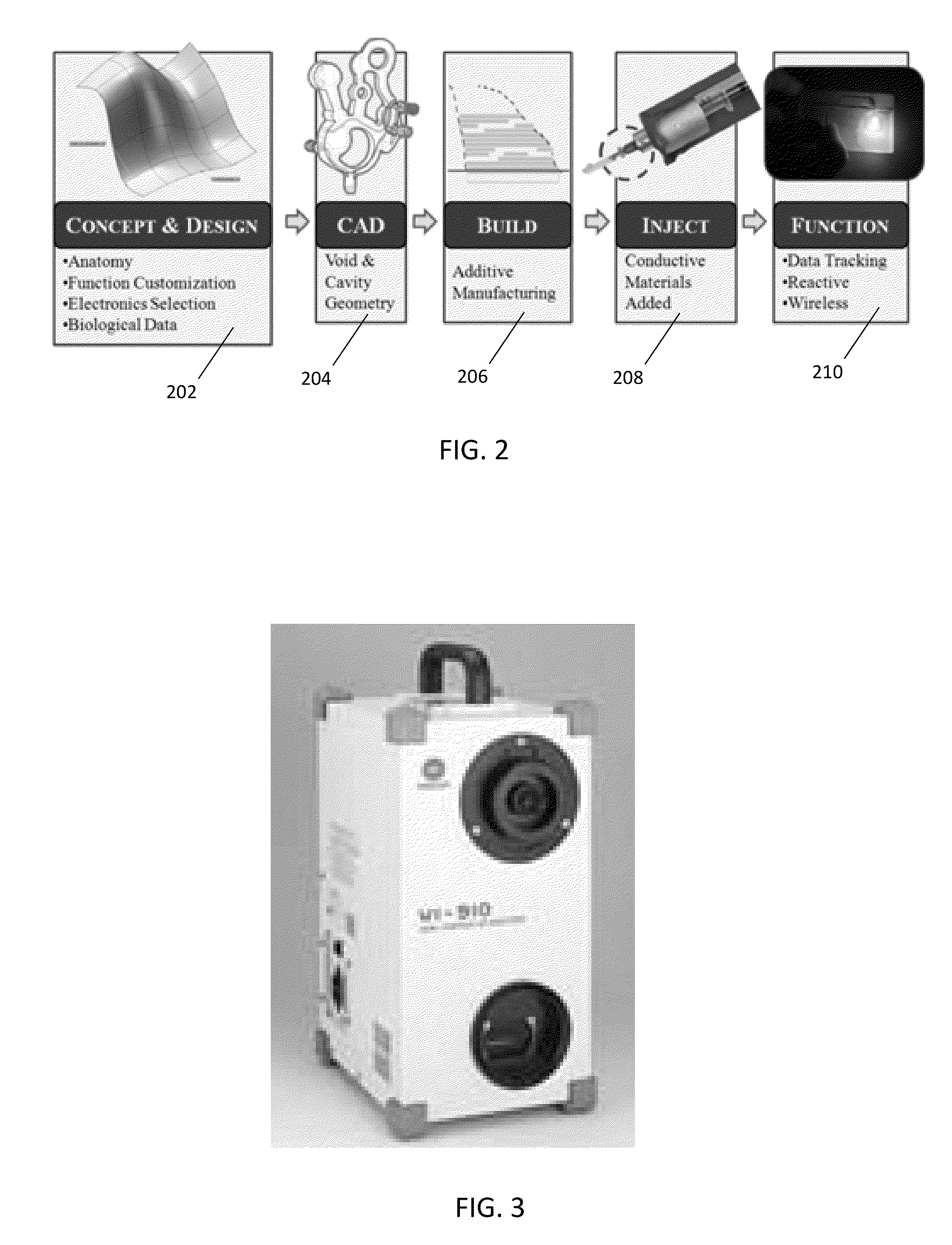

Customizable Embedded Sensors

InactiveUS20130079693A1Force measurement by permanent gauge deformationMeasurement apparatus componentsEngineeringEngineering physics

Owner:NORTHEASTERN UNIV

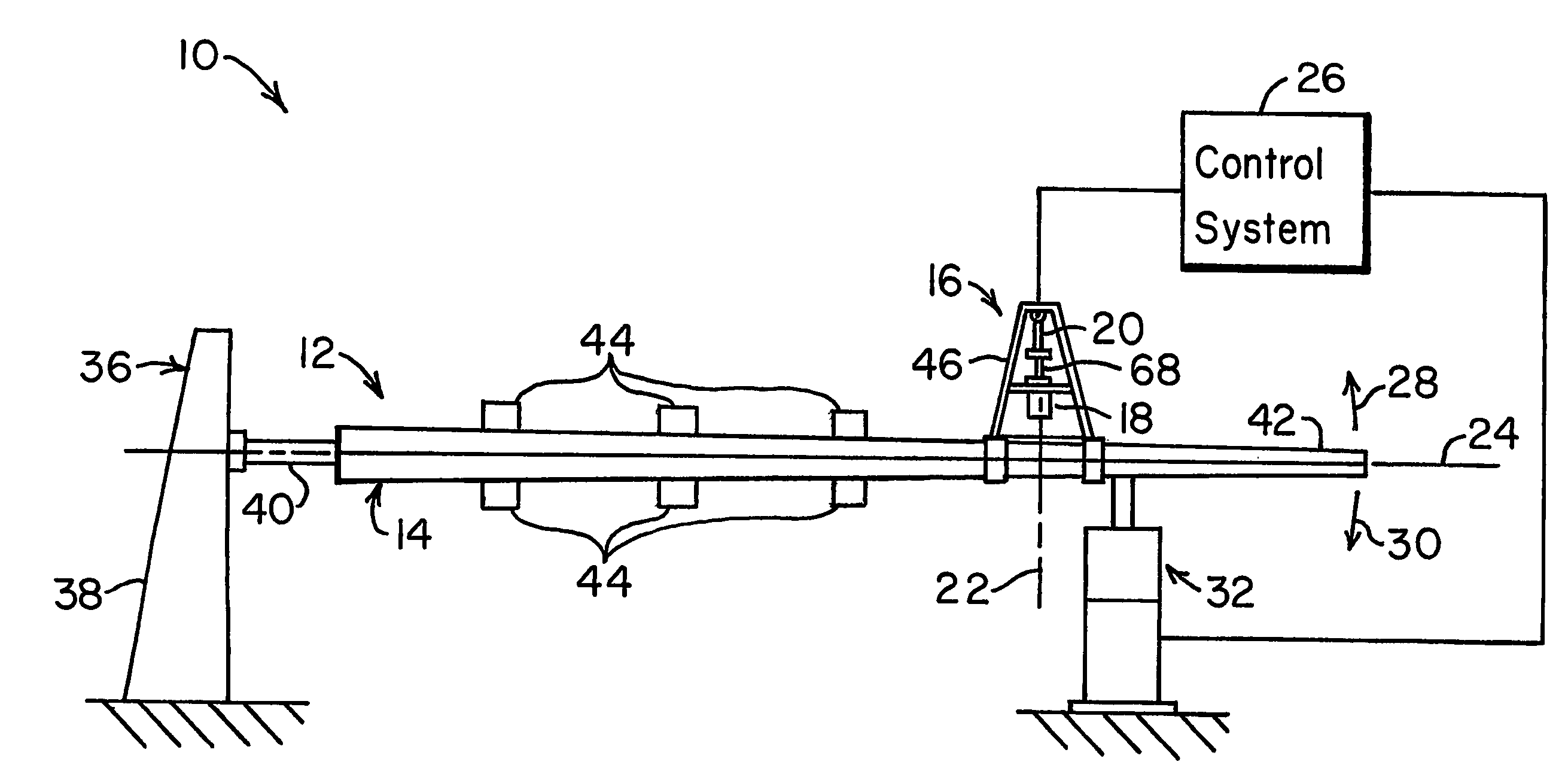

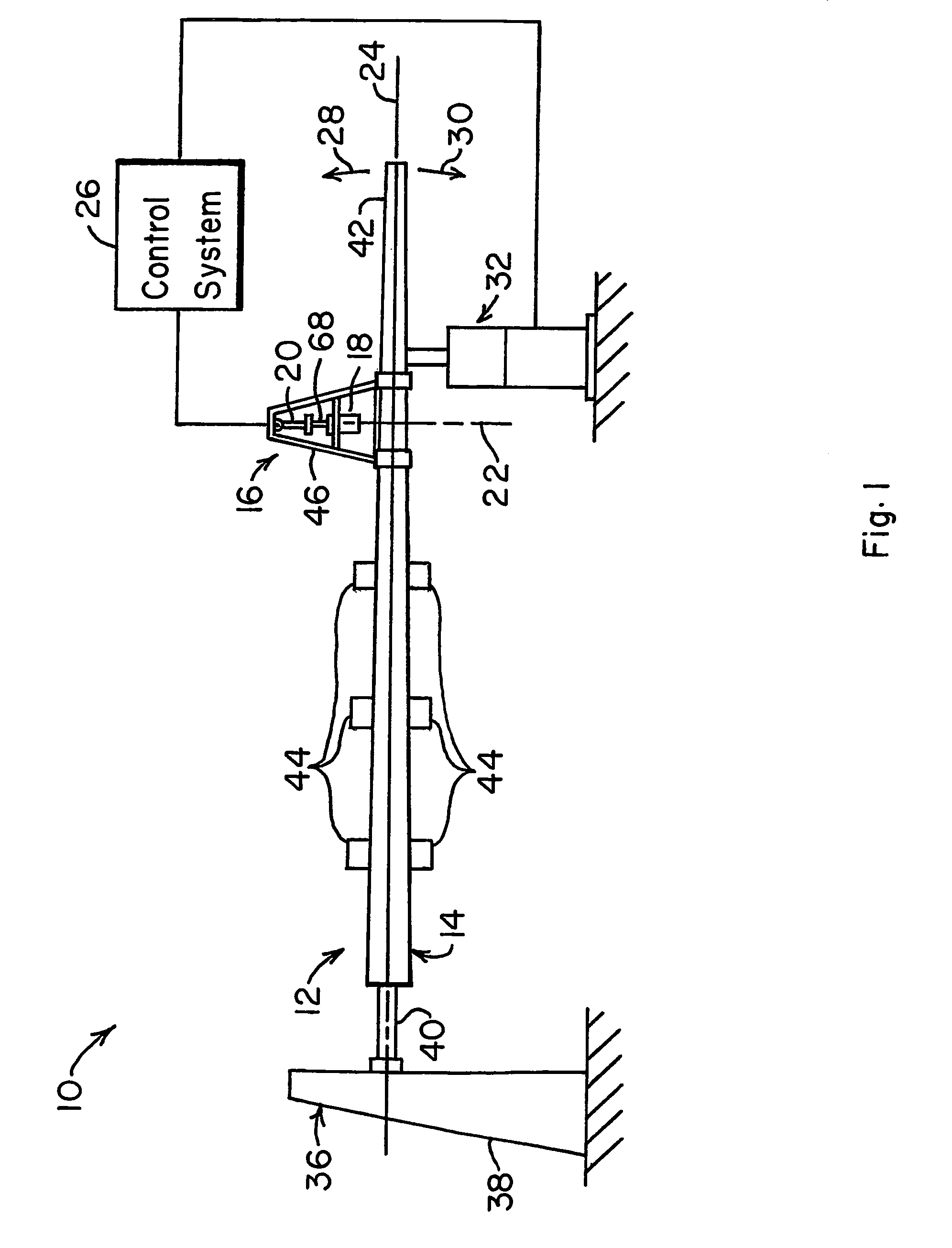

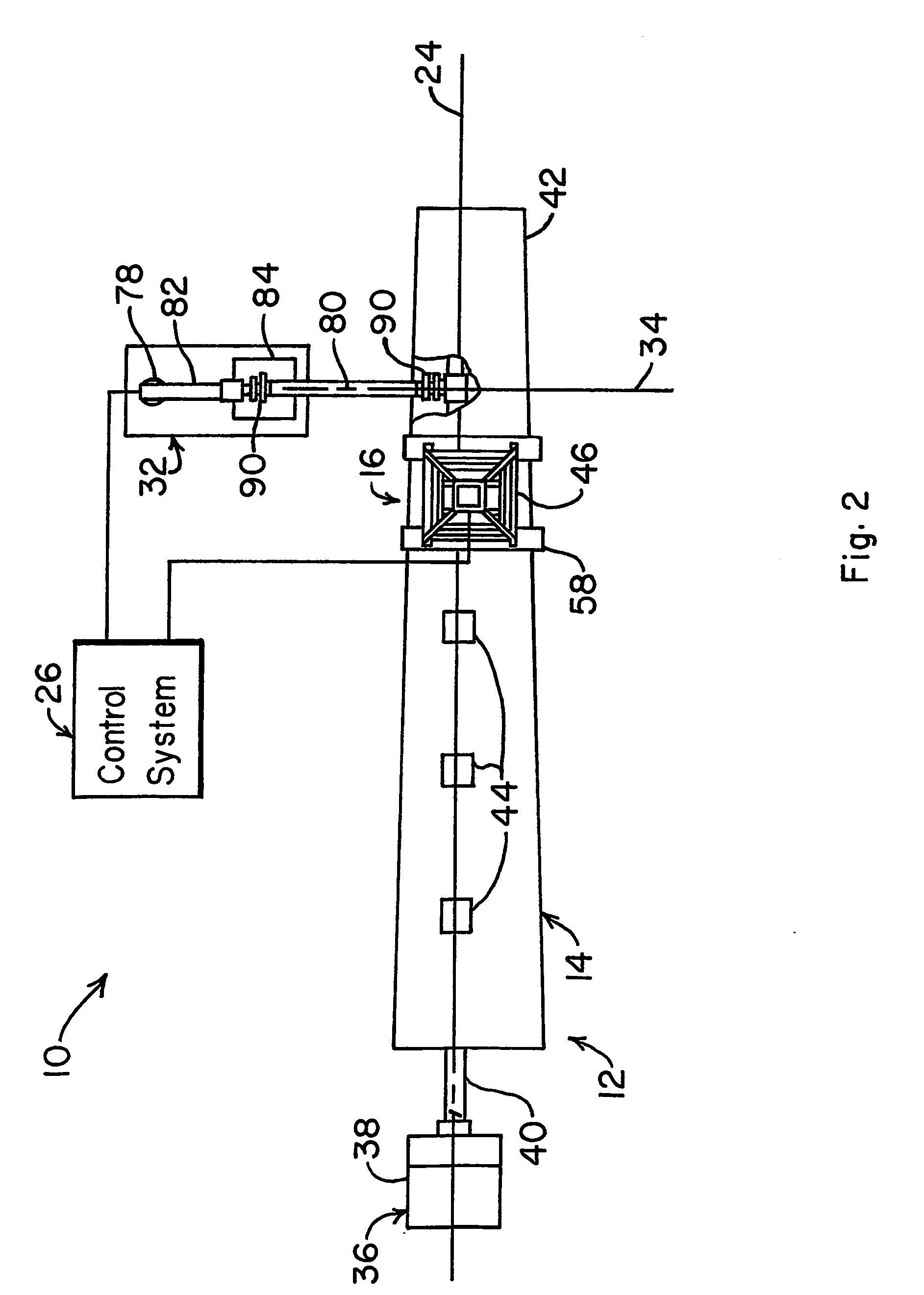

Resonance test system

ActiveUS20060037402A1Material analysis using sonic/ultrasonic/infrasonic wavesFlow propertiesResonanceControl system

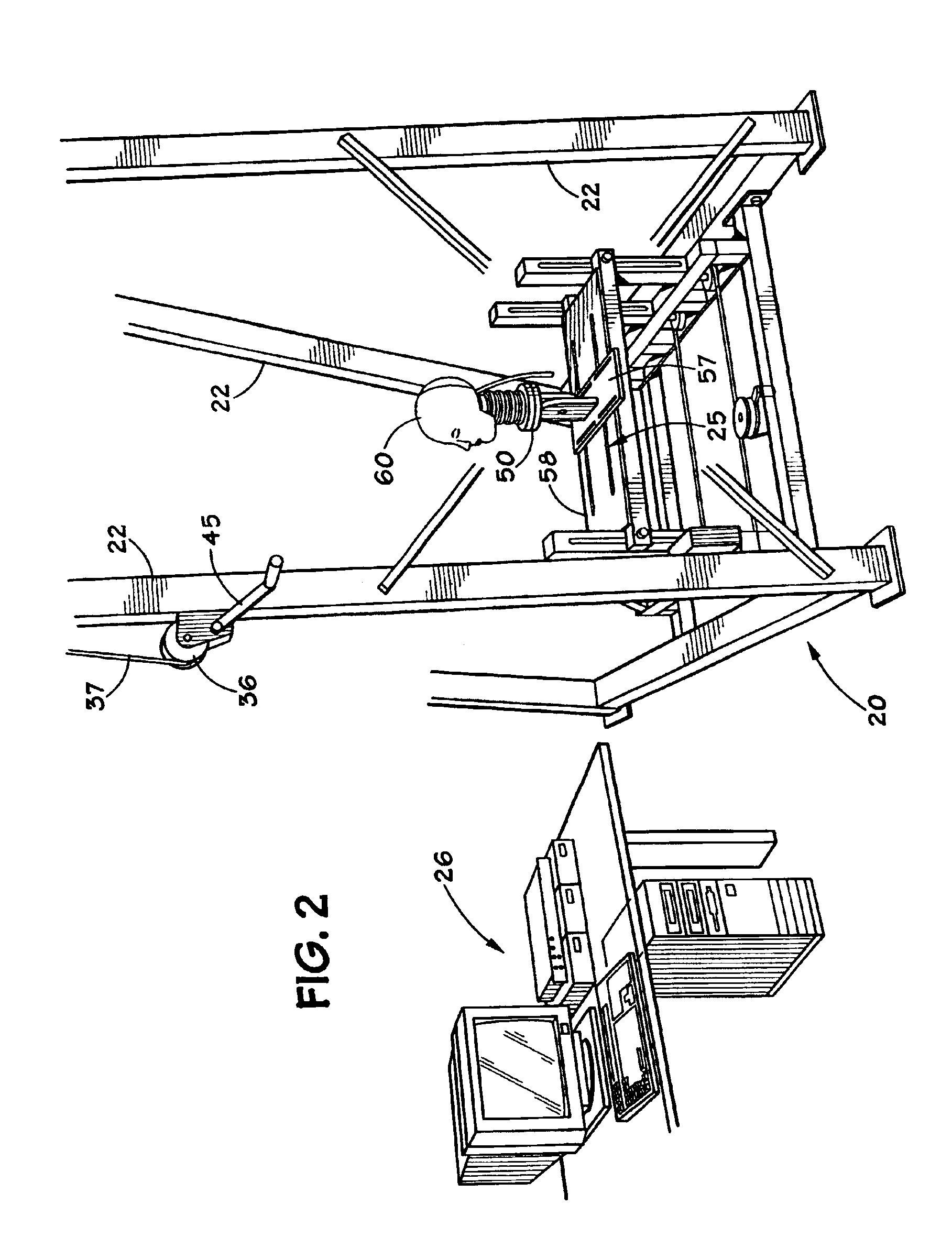

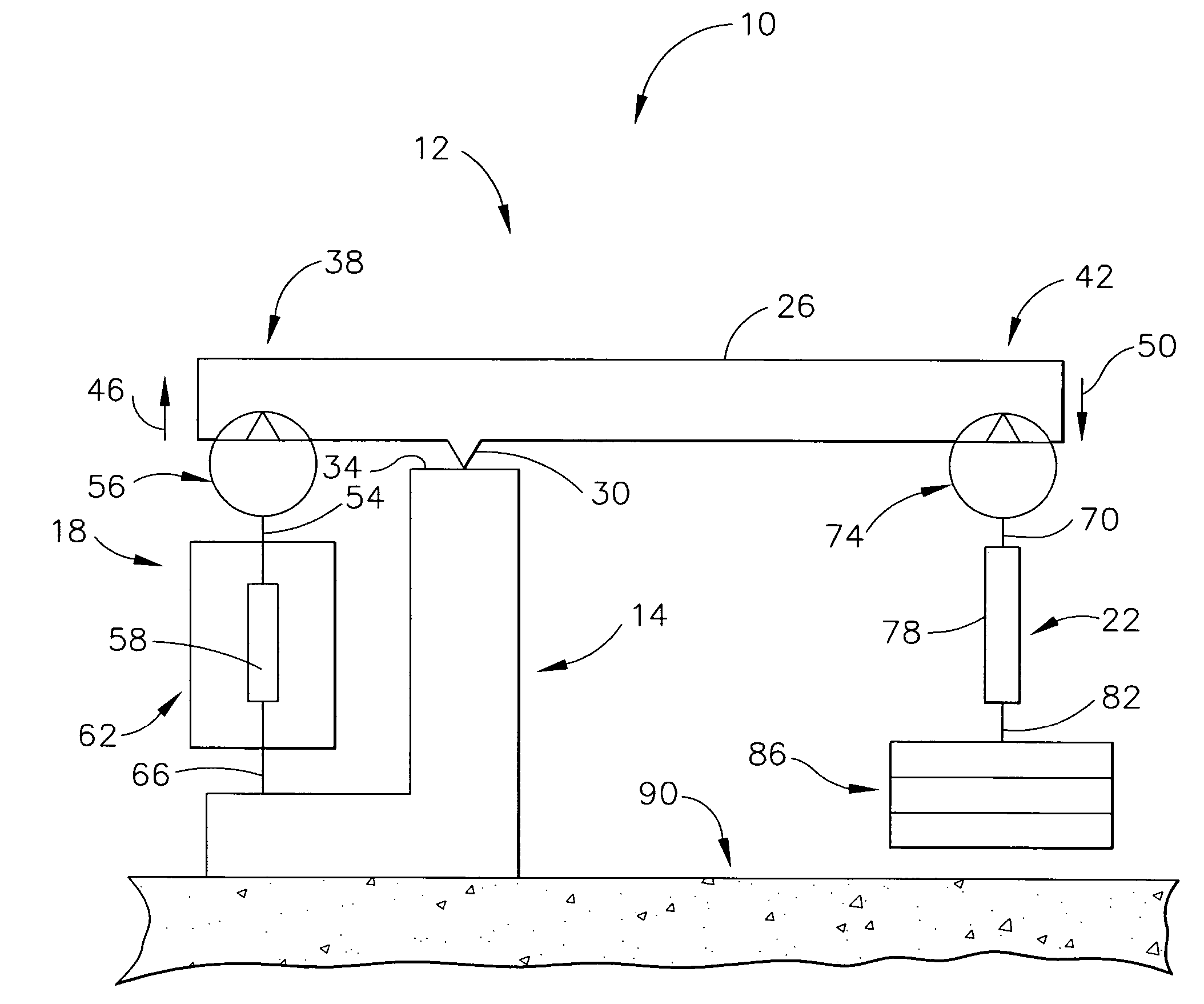

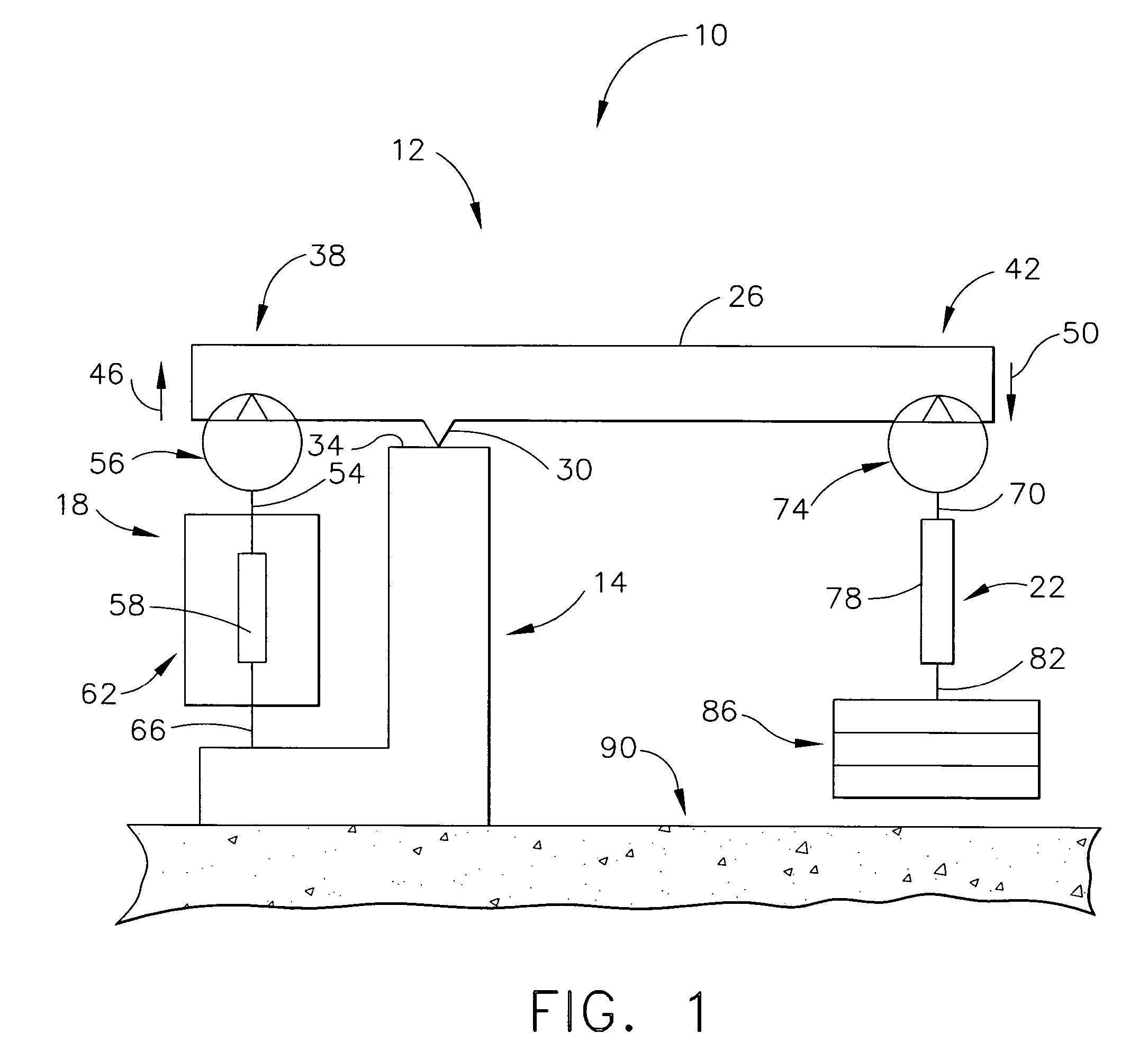

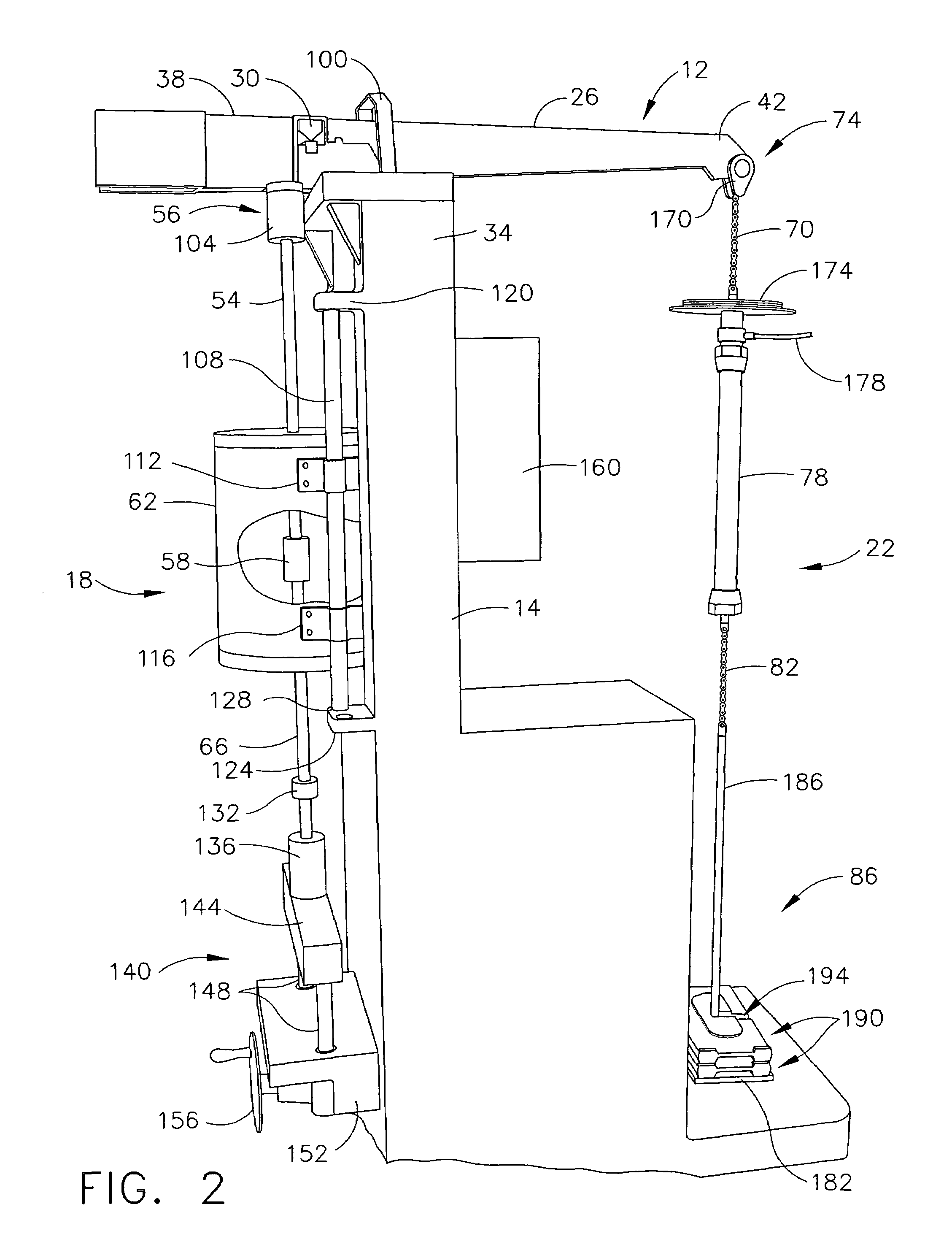

An apparatus (10) for applying at least one load to a specimen (12) according to one embodiment of the invention may comprise a mass (18). An actuator (20) mounted to the specimen (12) and operatively associated with the mass (18) moves the mass (18) along a linear displacement path (22) that is perpendicular to a longitudinal axis of the specimen (12). A control system (26) operatively associated with the actuator (20) operates the actuator (20) to reciprocate the mass (18) along the linear displacement path (22) at a reciprocating frequency, the reciprocating frequency being about equal to a resonance frequency of the specimen (12) in a test configuration.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

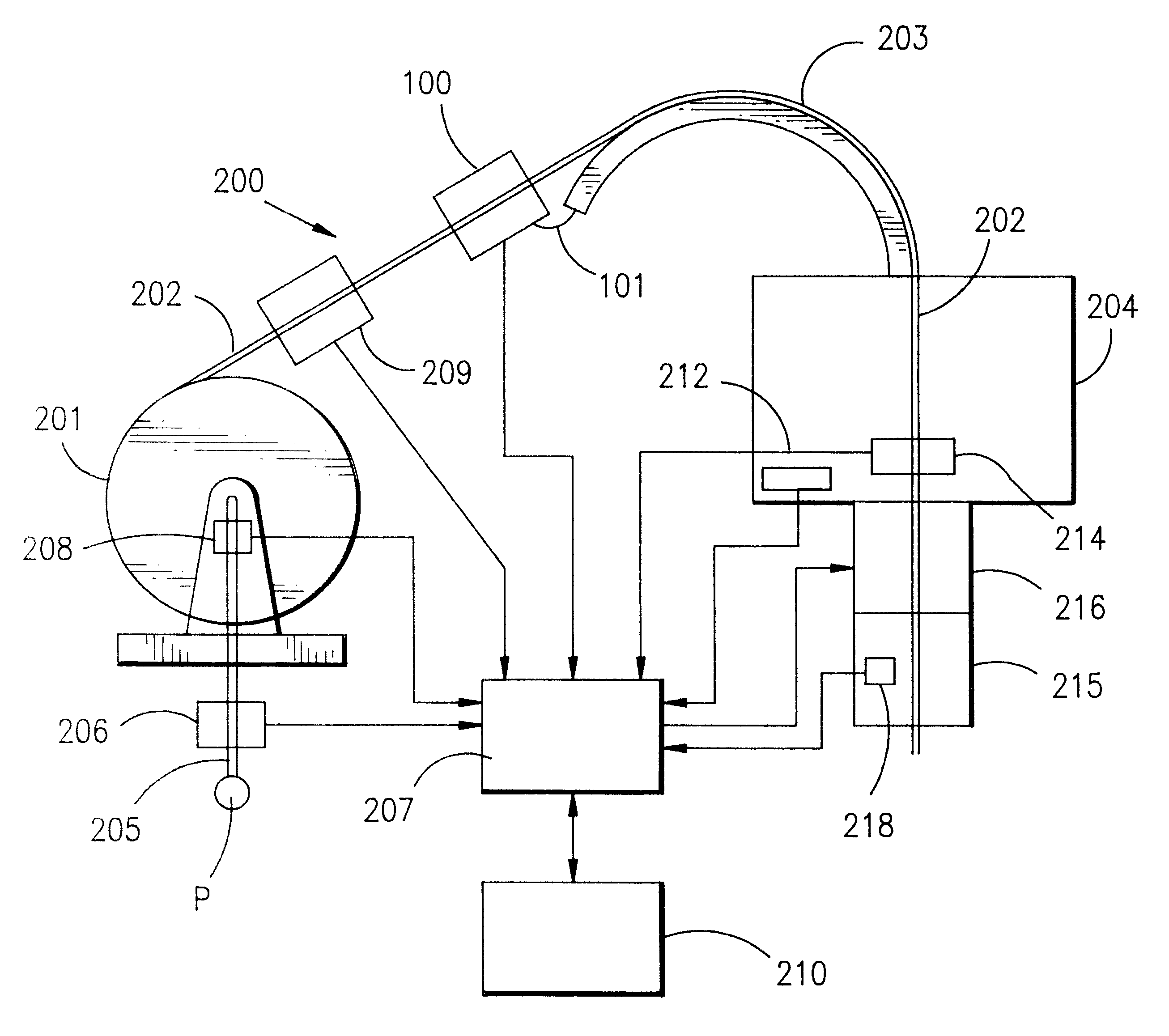

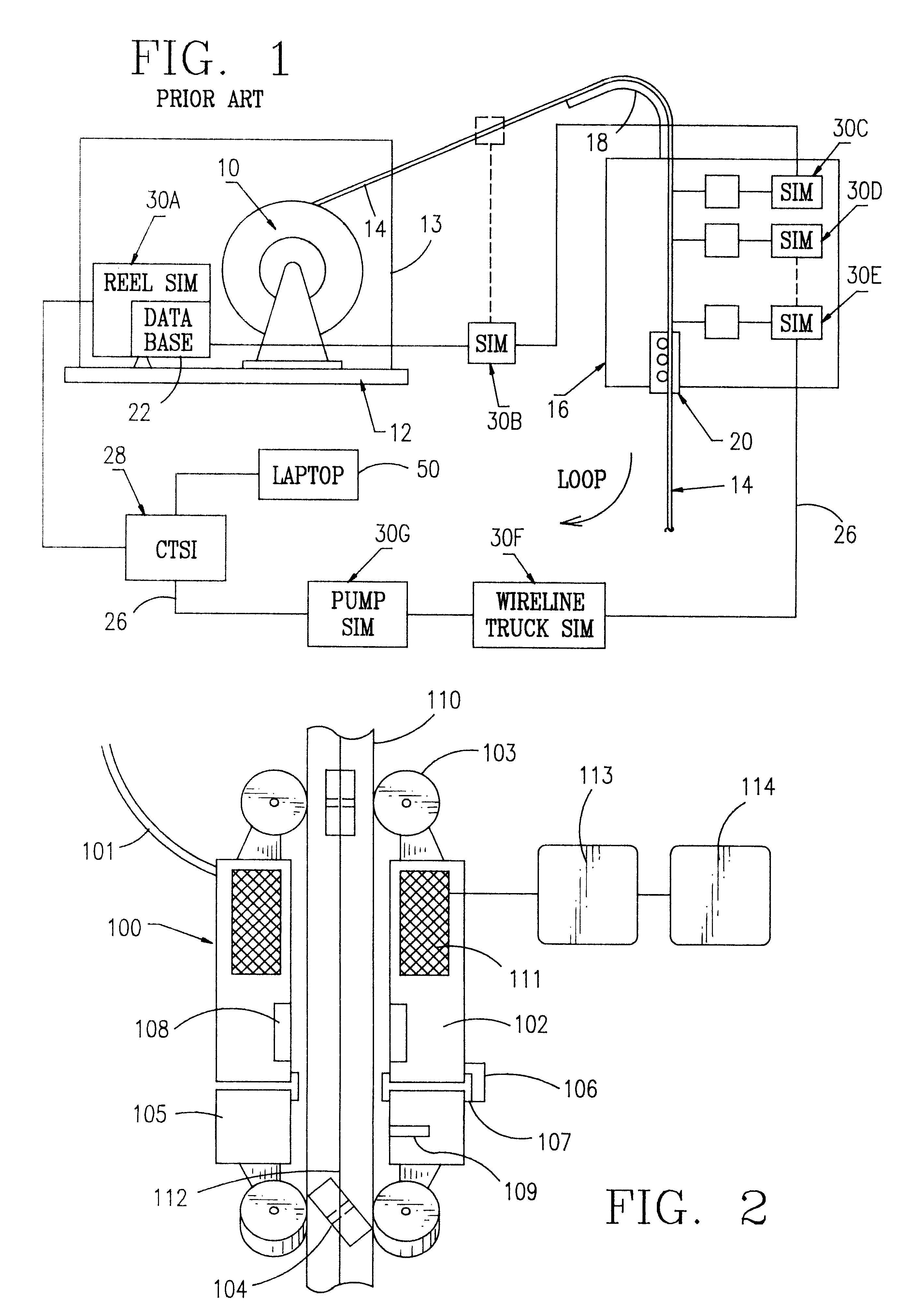

System and method for measuring and controlling rotation of coiled tubing

InactiveUS6321596B1Accurately determineAccurately determinedDrilling rodsMaterial strength using repeated/pulsating forcesCoiled tubingEngineering

The present invention, in certain embodiments, discloses an apparatus for determining characteristics of coiled tubing that is run in and out of a bore, e.g. a wellbore, for calculating fatigue life of the coiled tubing, the apparatus having a reel structure for said coiled tubing including a reel on which said coiled tubing is wound and a frame supporting the reel for rotation, an injector structure for running the coiled tubing from the reel structure into said bore and for withdrawing said coiled tubing from the bore, sensor apparatus for continuously monitoring sensing and recording rotation of said coiled tubing and for measuring amount of said rotation, said sensor apparatus including apparatus for receiving and transmitting data relating to said characteristics of the coiled tubing, and a computer apparatus for receiving data from said sensor apparatus and processing said data to determine fatigue life of said coiled tubing.

Owner:COILED TUBING ENG SERVICES

Systems and methods to determine elastic properties of materials

InactiveUS7107159B2Elastic propertyInherent ambiguityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesTime domainHarmonic

The present invention provides systems and methods to used a measured driving-point response of a nonlinear material to determined one or more elastic properties of the material. The present invention takes advantage of the full information represented by the transient component, the steady-state component, the anharmonic components, and the nonlinear response components of a measured driving-point response of a real nonlinear material, without limitation in the use of large-amplitude forces. The elastic properties are determined by forming and solving a time-domain system of linear equations representing a differential equation model of the driving-point motions of the material. Based on a single, short duration, large-amplitude driving point measurement, both linear and nonlinear properties can be determined; both large-amplitude and near-zero amplitude properties can be determined; and elastic-wave speed and elastic moduli and their variation with depth can be determined.

Owner:GERMAN PETER THOMAS

Process diagnostics

ActiveUS7290450B2Improve abilitiesEasy to useVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTransducerEngineering

A diagnostic device for use in a industrial process includes monitoring electronics or diagnostic circuitry configured to diagnose or identify a condition or other occurrence in the industrial process. The system can be implemented in a process device such as a flowmeter, and in one example an acoustic flowmeter. A transducer can also be used and a frequency response, such as resonant frequency, can be observed.

Owner:ROSEMOUNT INC

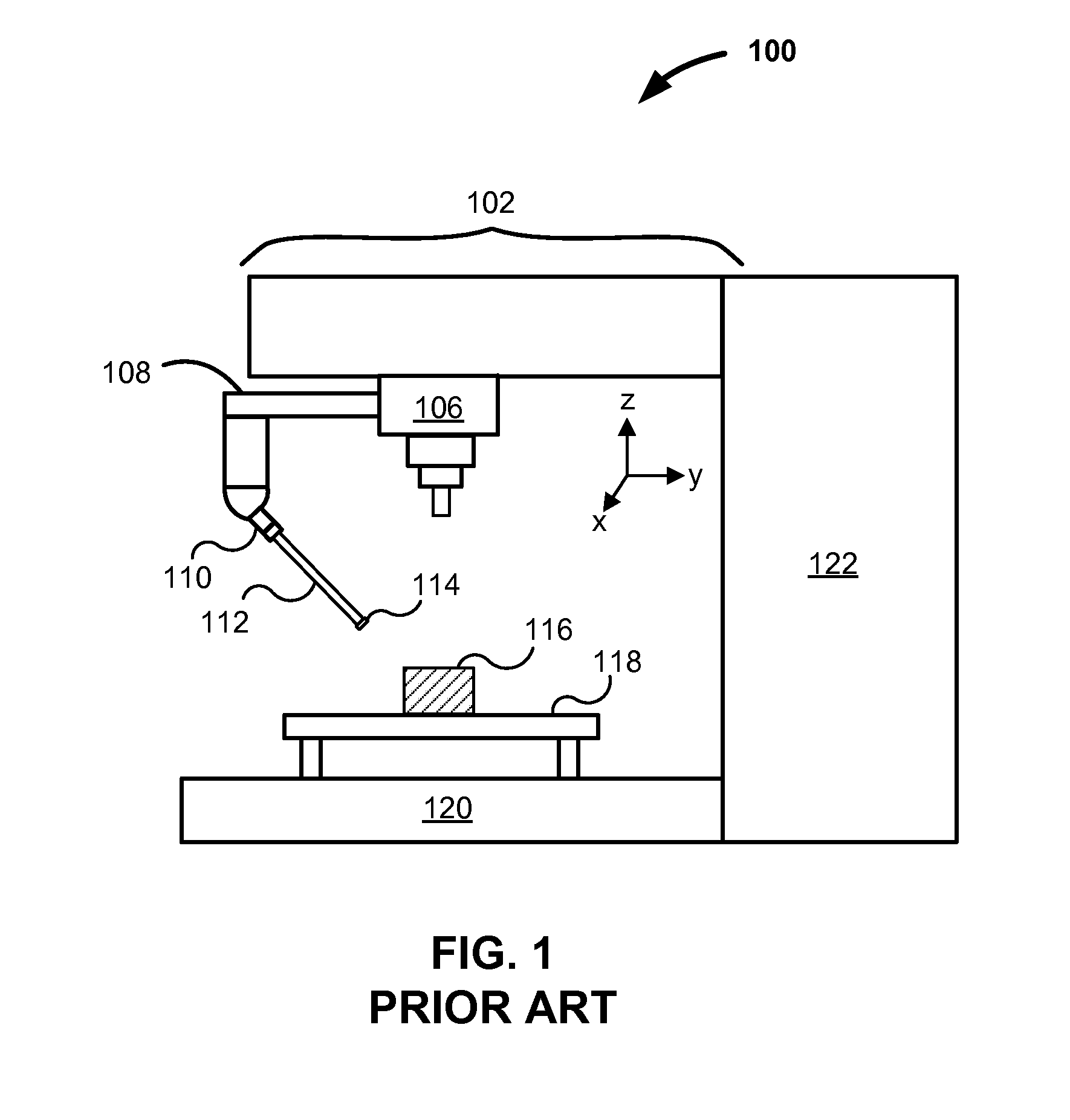

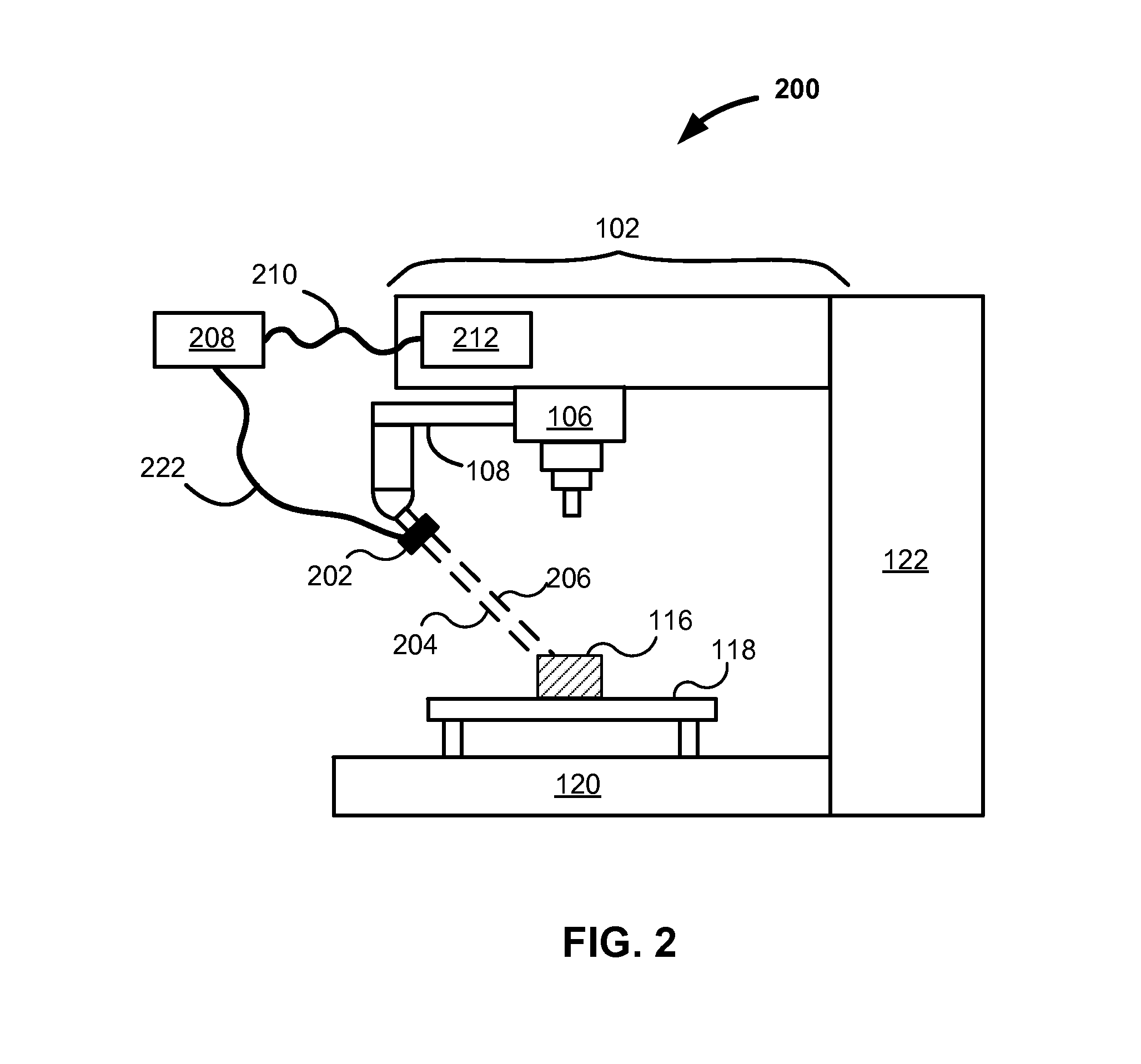

High Speed Metrology with Numerically Controlled Machines

ActiveUS20140157610A1Accurate verificationTight stack-up toleranceVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesNumerical controlMetrology

Systems, apparatuses and methods are described for integrating an electronic metrology sensor with precision production equipment such as computer numerically controlled (CNC) machines. For example, a laser distance measuring sensor is used. Measurements are taken at a relatively high sample rate and converted into a format compatible with other data generated or accepted by the CNC machine. Measurements from the sensor are synchronized with the position of the arm of the machine such as through the use of offsets. Processing yields a detailed and highly accurate three-dimensional map of a workpiece in the machine. Applicable metrology instruments include other near continuously reading non-destructive characterization instruments such as contact and non-contact dimensional, eddy current, ultra-sound, and X-Ray Fluorescence (XRF) sensors. Various uses of measurements include: multiple component matching, correction of machine drift, closed loop control of machines, and verification of product tolerances via substantially complete serialized dimensional quality control.

Owner:GRALE TECH

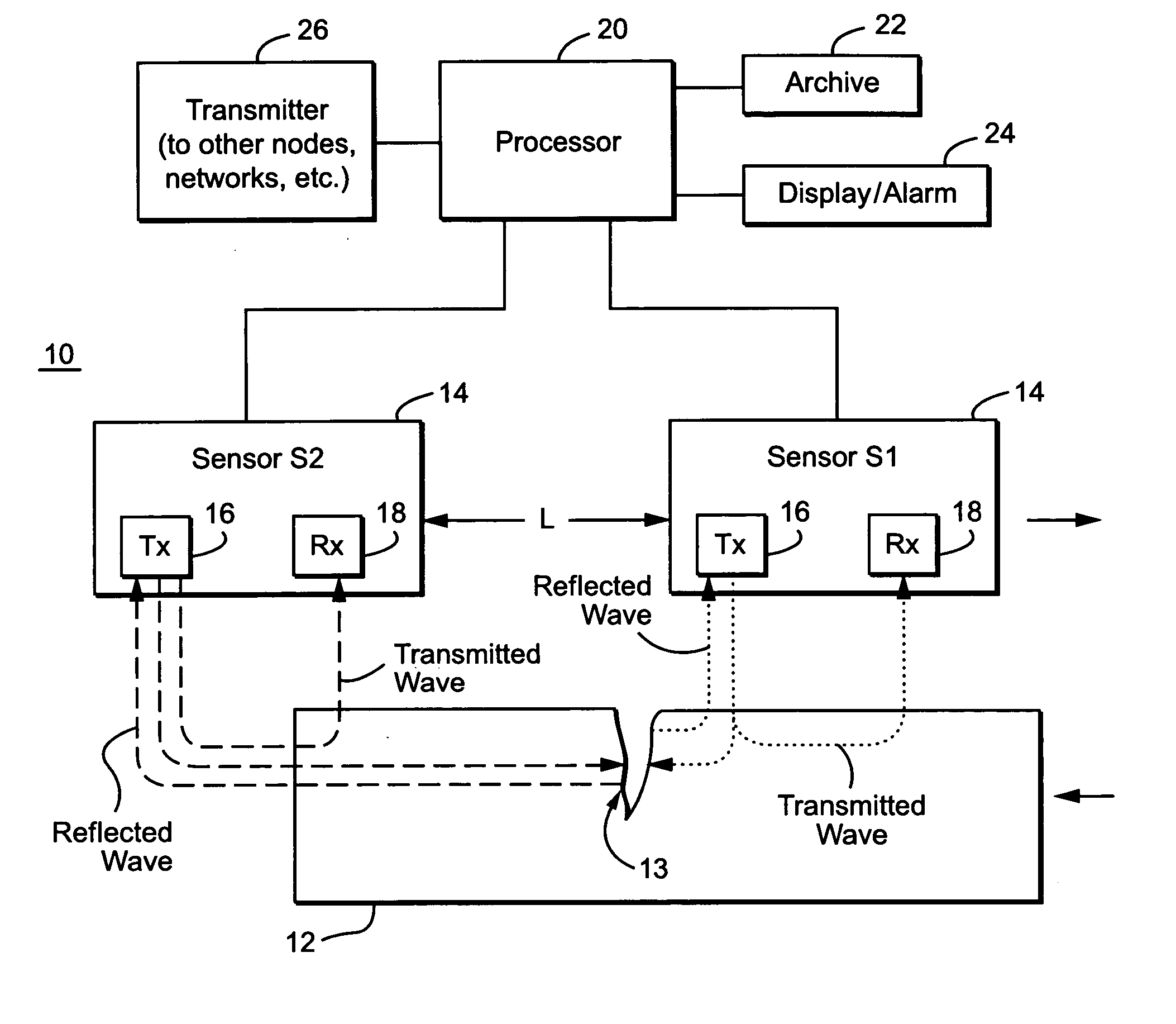

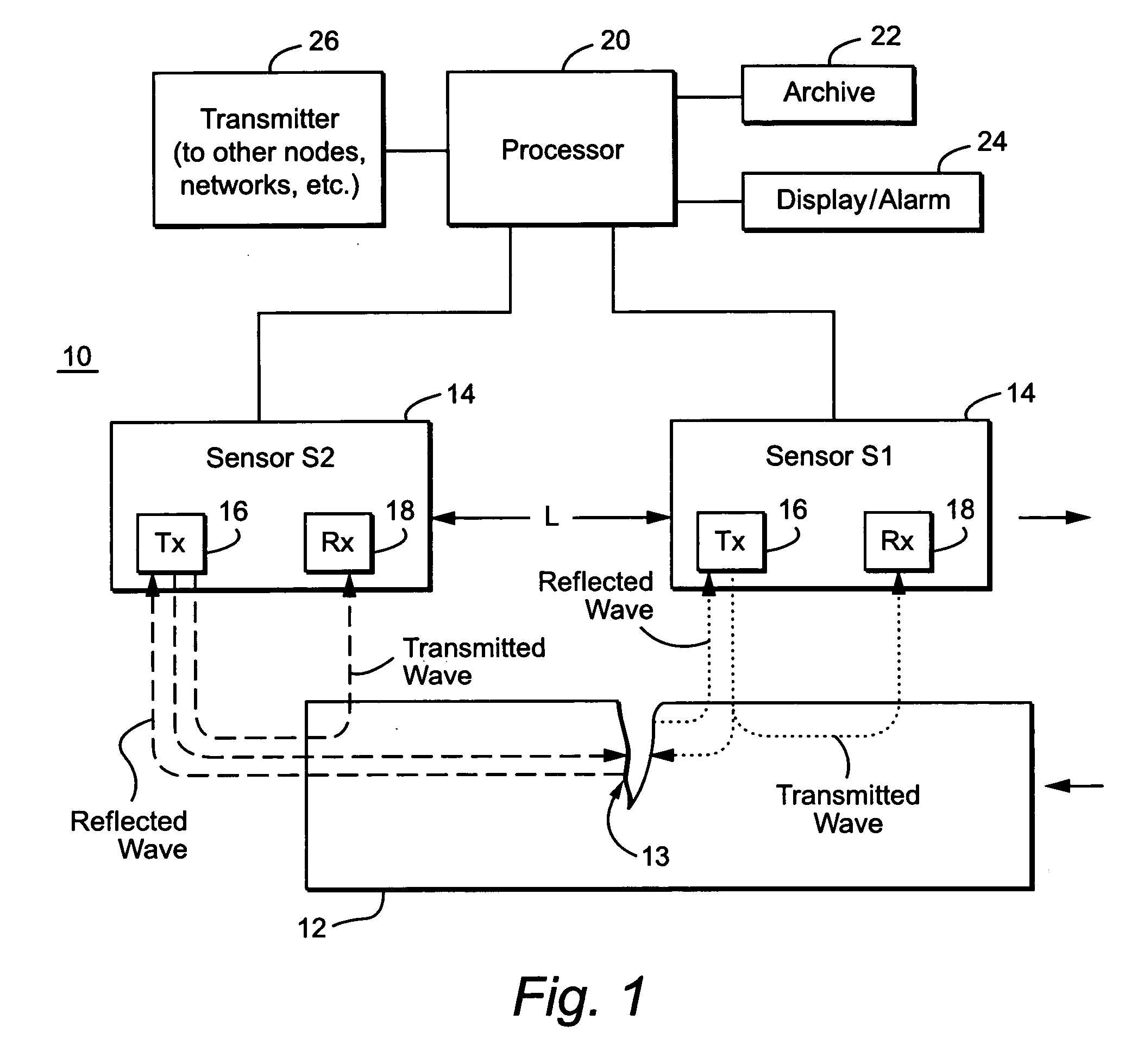

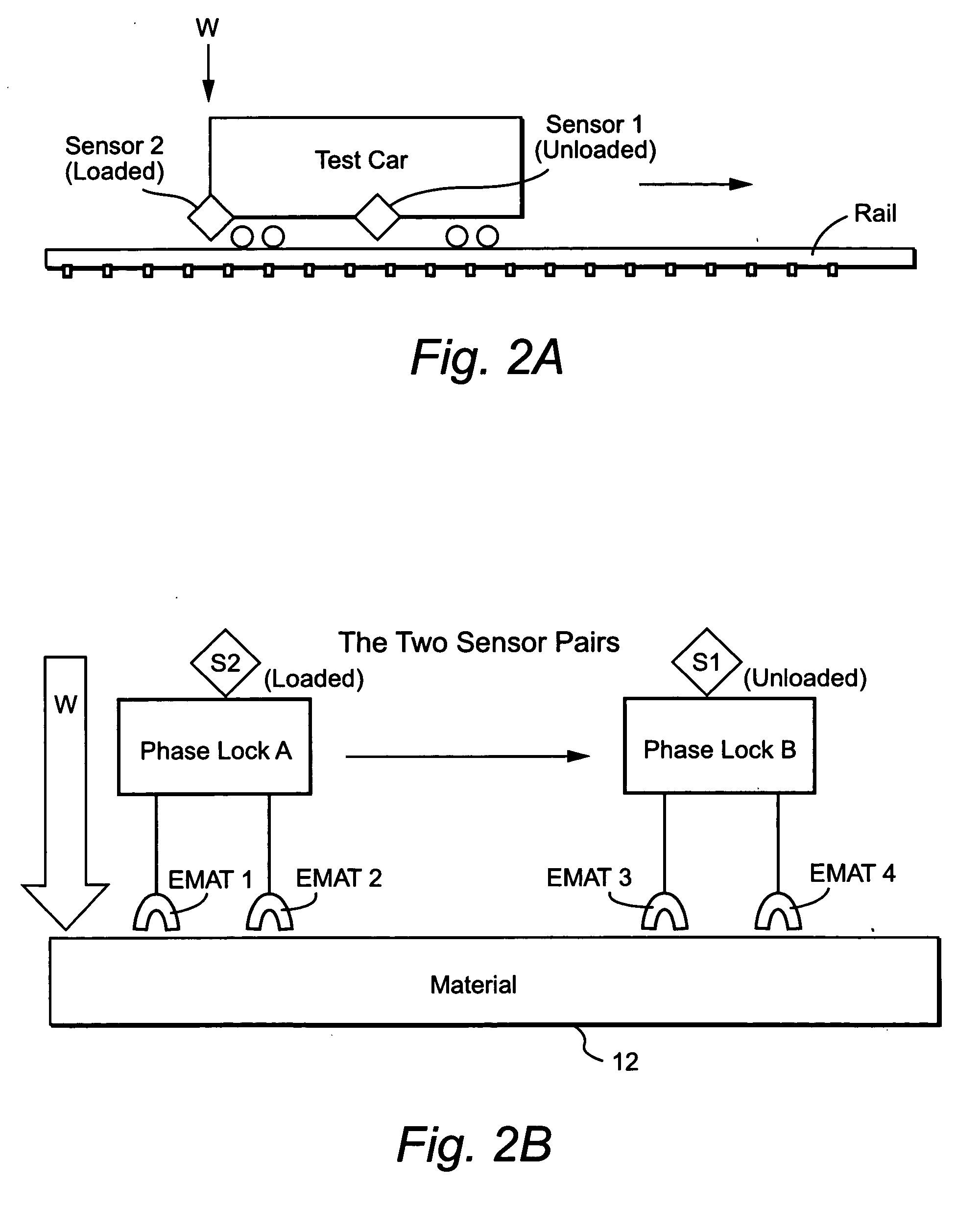

Method and apparatus for determining and assessing a characteristic of a material

InactiveUS20050072236A1Low costImprove accuracyAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesDifferential measurementCrazing

An acoustic energy-based, non-contact or contact testing approach provides low cost, highly accurate, and reliable information to (a) identify flaws and anomalies and (b) assess the integrity of a particular material. This approach is not hindered by surface conditions or impediments, and indeed, looks beneath the surface of the material by propagating an acoustic wave through the material using two differential transducers. A dynamic differential measurement is made of the material under a load condition and an unloaded condition that allows identification and assessment of various characteristics of the material. Multiple “windows” of information may be generated that permit (a) direct detection of flaws, defects, and anomalies using a scattering technique, (b) detection of crack closure and opening used to assess the stability of the material, (c) determination of strain on the material which relates to its performance, and (d) determination of defect dynamics linked to the defect size and stability.

Owner:LUNA INNOVATIONS

Impact monitoring apparatus

InactiveUS20110219852A1Easy to disassembleWell formedInertial sensorsAcceleration measurementEngineeringImpact monitoring

An impact monitoring apparatus that includes a support member made of an elastic material capable of being attached to or worn by a user and at least one force measuring element attached to the support member. The force measuring elements may be easily removed from the support member. The force measuring element may include an indicator capable of indicating the amount of force or impact sustained by the user. If the force measuring element does not include an indicator, then the apparatus may further include an indicator that is associated with the force measuring element.

Owner:KASTEN STEPHEN P

Helmet with shock detector, helmet attachment device with shock detector & methods

InactiveUS20070089480A1Easy to installLow costAcceleration measurement using interia forcesMaterial strength using single impulsive forceEngineeringShock detector

A helmet includes a head enclosure with an open cavity for the head of a user and a shock detector attached to the head enclosure that provides a signal when the head enclosure is subjected an impact exceeding a predetermined level.

Owner:BECK GREGORY S

Helmet blastometer

InactiveUS20100005571A1Easy to buildMore robustAcceleration measurementHatsContact pressurePositive pressure

A helmet blastometer for characterizing the direction, speed, magnitude, and duration of a blast event to determine the likelihood of blast-induced traumatic brain injury (biTBI). A set of external sensors, each having one or more time of arrival (TOA) gages, is mounted at various positions on a rigid outer shell of the helmet. Each external sensor includes a first TOA gage that produces a TOA signal in response to a fast rising blast induced positive pressure change above a predetermined threshold. These positive pressure change TOA signals are received by a receiver and analyzed to determine direction, speed, and magnitude of a blast. At least one of the external sensors may also include a second TOA gauge that produces a TOA signal in response to a negative pressure change below a predetermined threshold. The positive and negative pressure change TOA signals from the same external sensor are used by the receiver processor to determine blast duration. In another embodiment, a second set of internal contact pressure sensors is connected to an inner liner of the helmet to detect contact pressure on a user's head. Preferably, the receiver processor determines that a biTBI has likely been sustained by when one or more of the blast direction, speed, magnitude and contact pressure has satisfied a predetermined biTBI threshold, upon which a biTBI warning indicator may be triggered.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

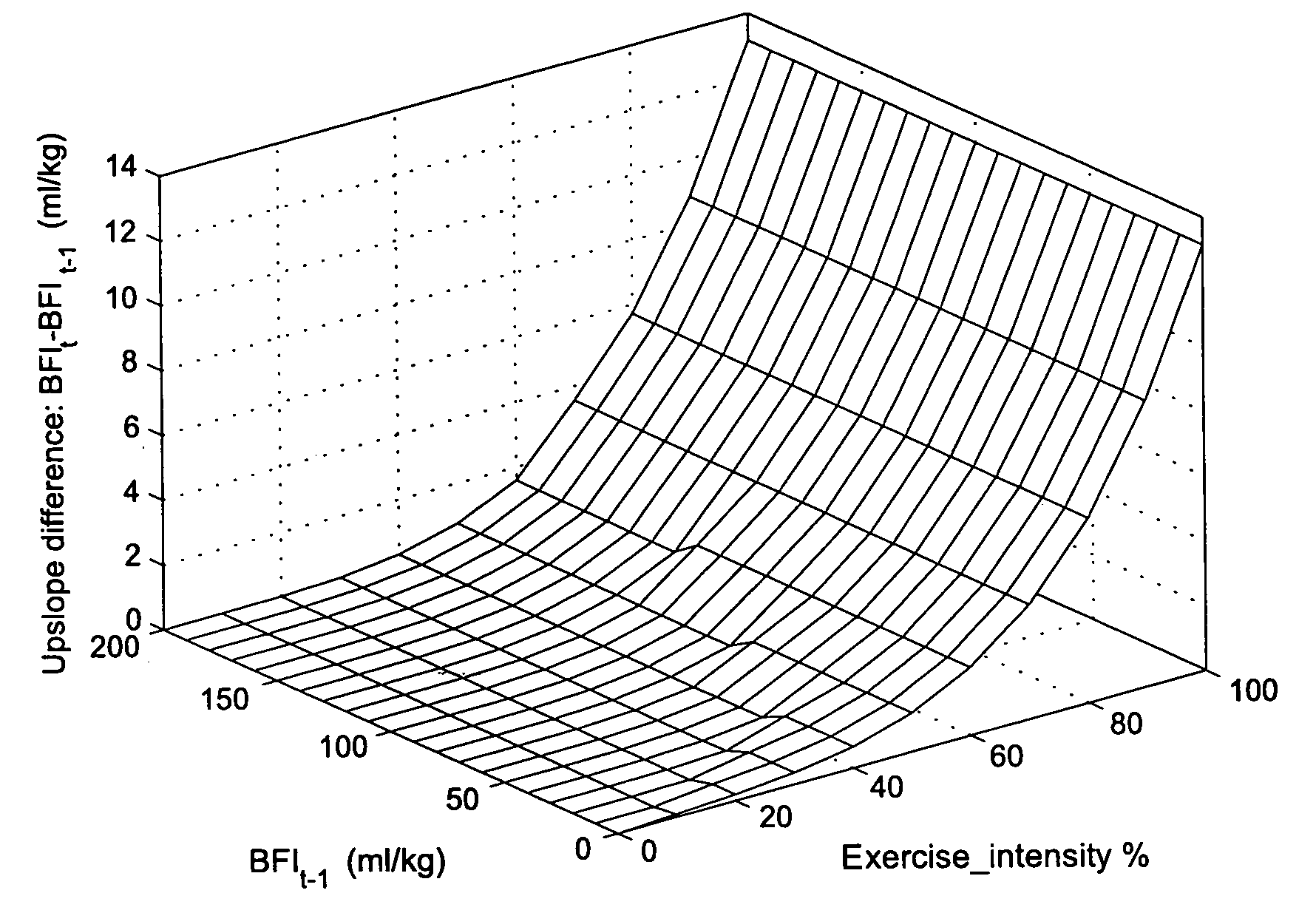

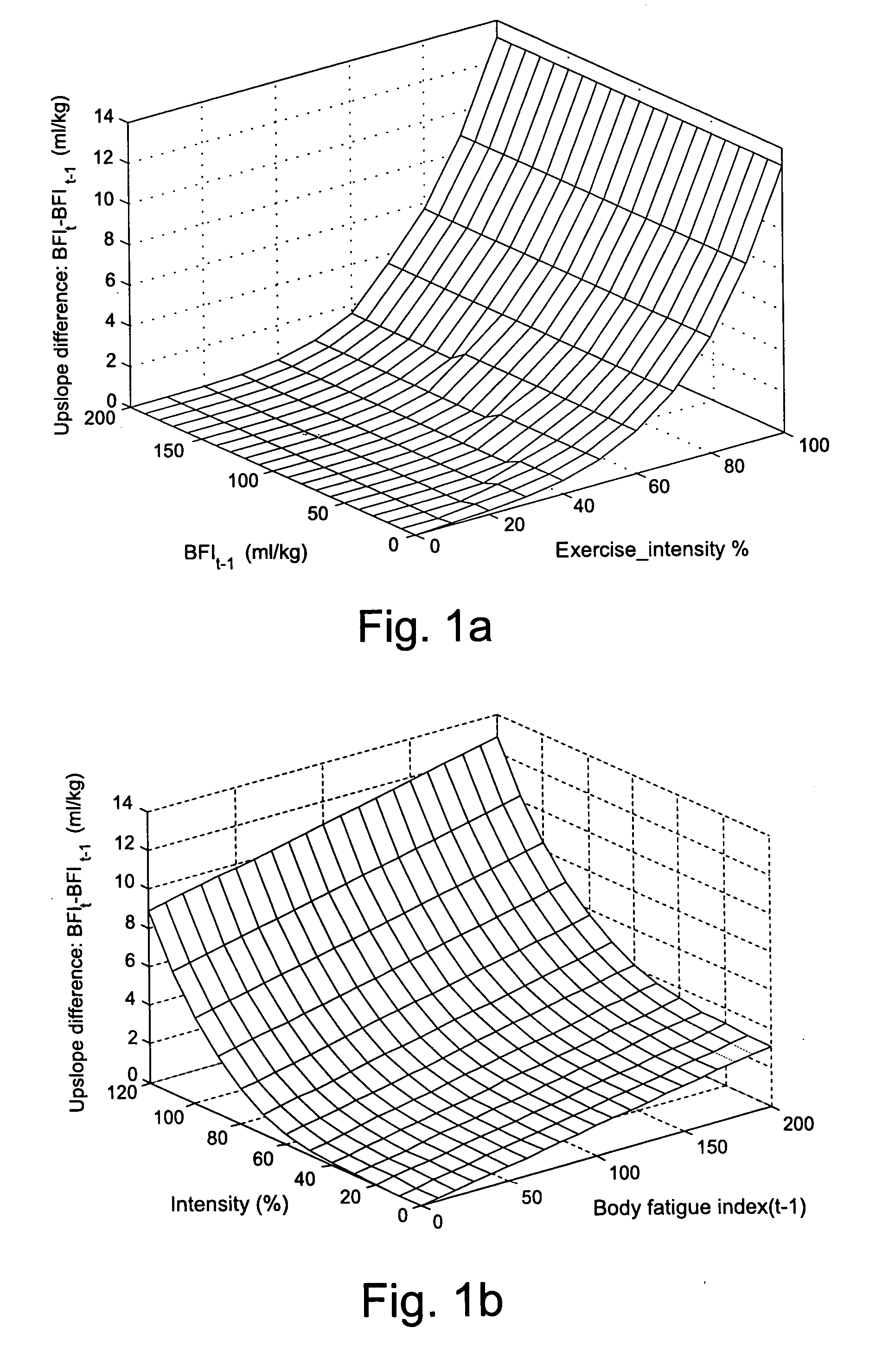

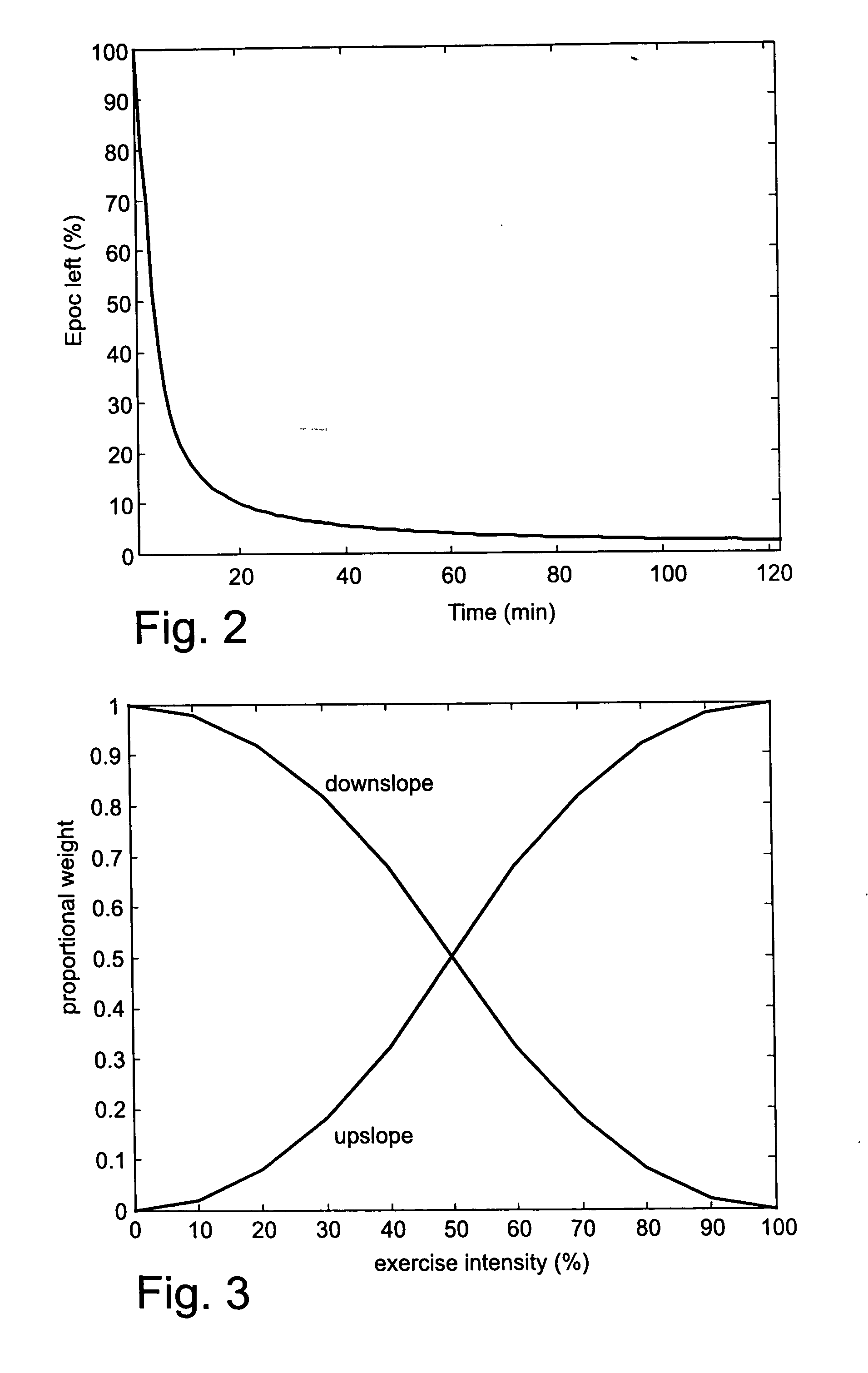

Method for monitoring accumulated body fatigue for determining recovery during exercise or activity

The invention relates to a method for determining accumulated body fatigue index (BFI), wherein one or more parameters from the measurement of one or more signals are obtained sequentially as input and these parameters are information on the intensity of physical activity. BFI has a predetermined initial value, and next BFI value is always a sum of BFI-value and a difference. The difference is combination of upslope and optional downslope components of BFI determined with the said parameters and the upslope component and the optional downslope component are each determined with a function, which is scaled by a preset physiological character.

Owner:FIRSTBEAT ANALYTICS OY

Ultrasound vibrometry

ActiveUS7753847B2Vibration measurement in solidsUltrasonic/sonic/infrasonic diagnosticsSonificationHarmonic

A method for measuring a mechanical property of a subject includes using an ultrasonic transducer to apply ultrasonic vibration pulses to a vibration origin in the subject in an on-off time sequence in order to impart a harmonic motion at a prescribed frequency to the subject, and when the vibration pulses are off, using the same transducer to apply ultrasonic detection pulses to a motion detection point and to receive echo signals therefrom in order to sense the harmonic motion on the subject at the motion detection point. From the harmonic signal information, a harmonic signal is detected and a characteristic such as amplitude or phase of the detected harmonic signal is measured. The mechanical property is calculated using the measured characteristic using for example a wave speed dispersion method.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

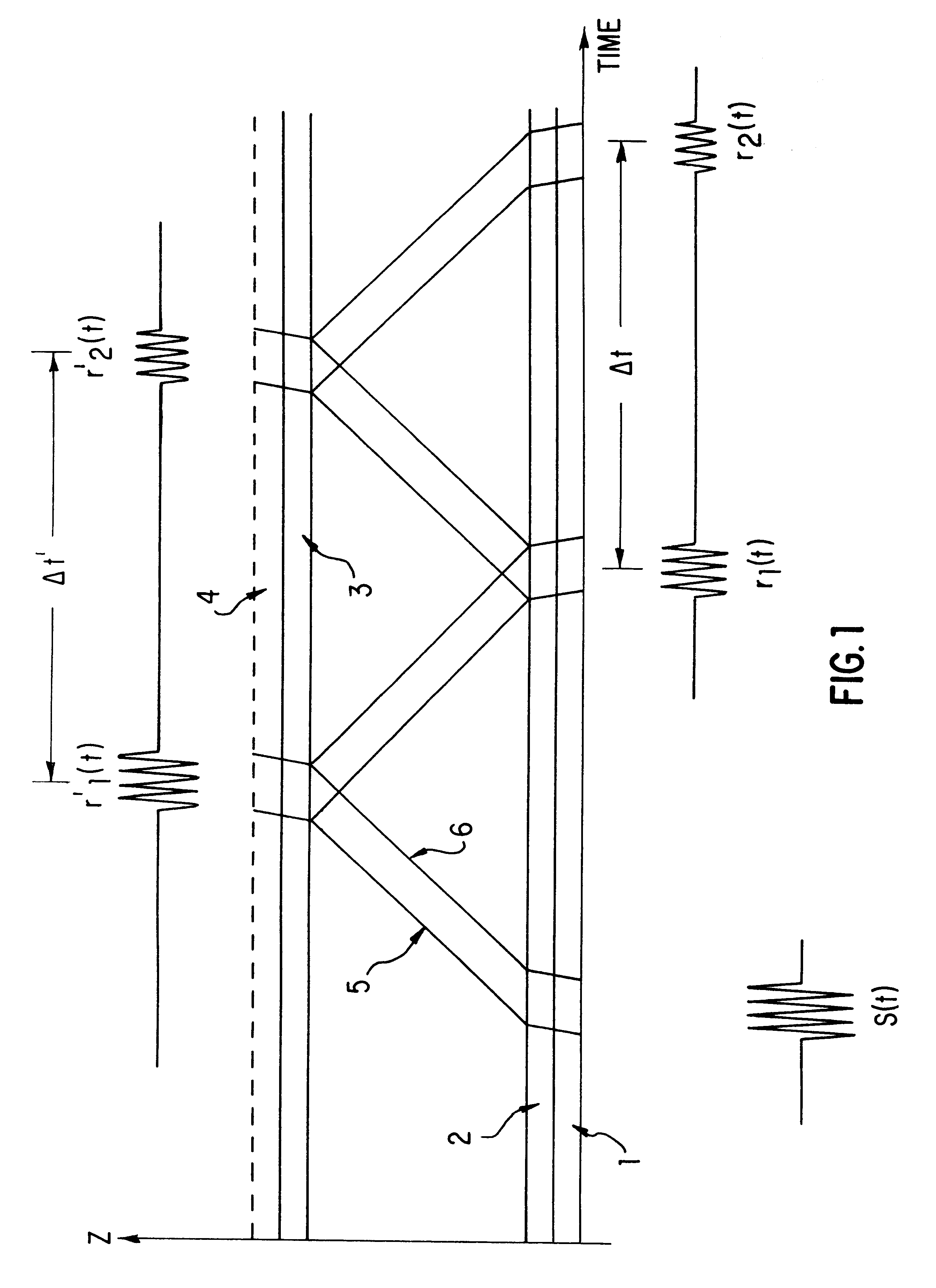

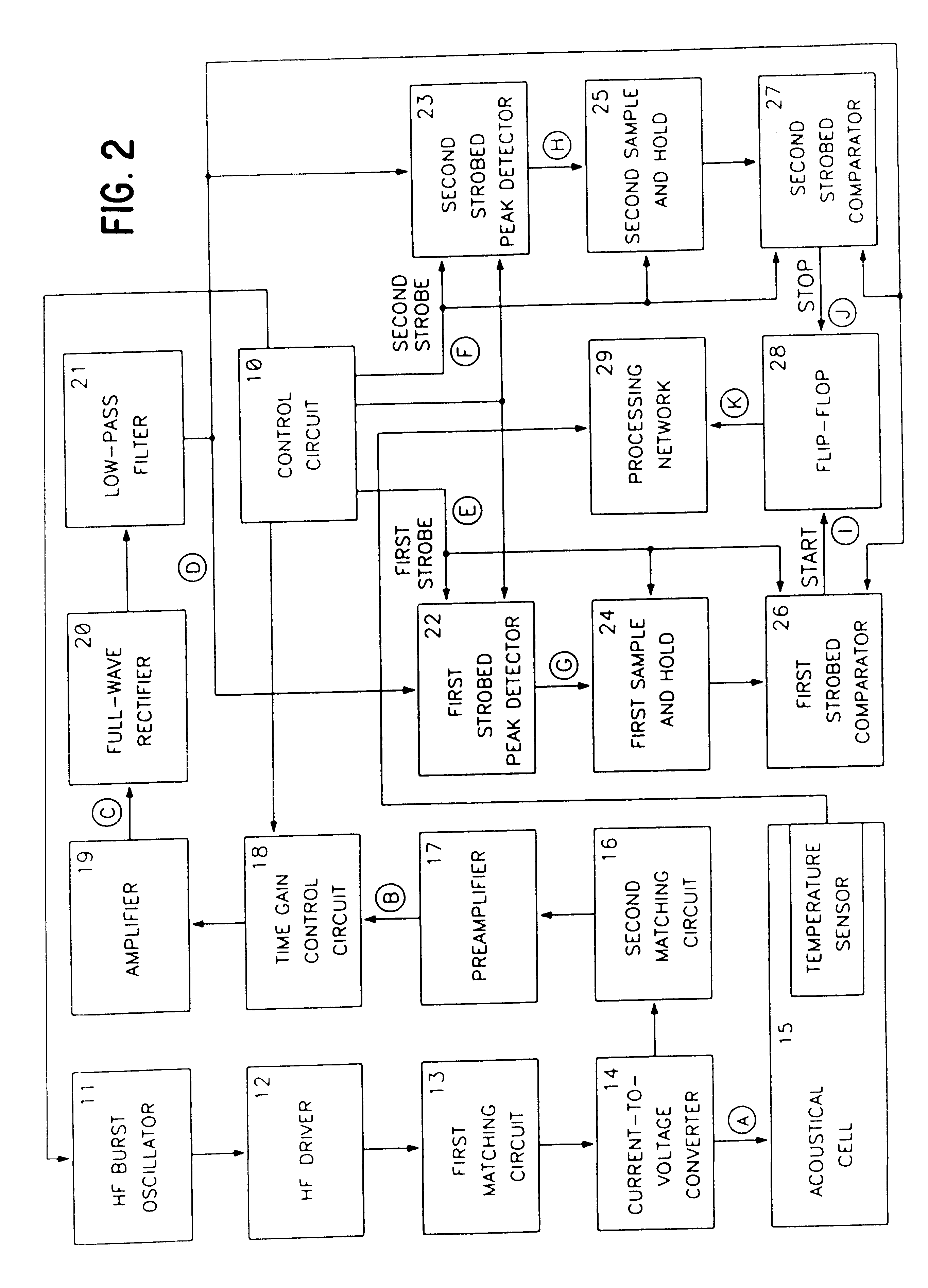

Apparatus and methods for performing acoustical measurements

InactiveUS6279379B1Good repeatabilityAbsenceVibration measurement in solidsSpectral/fourier analysisFast Fourier transformCorrelation function

Apparatus (15, 30) and methods for performing acoustical measurements are provided having some and preferably all of the following features: (A) the system (15, 30) is operated under near-field conditions; (B) the piezoelement (40) or piezoelements (40, 48) used in the system are (i) mechanically (41, 49) and electrically (13, 16) damped and (ii) efficiently electrically coupled to the signal processing components of the system; (C) each piezoelement (40, 48) used in the system includes an acoustical transformer (42, 50) for coupling the element to a gaseous test medium (9); (D) speed of sound is determined from the time difference between two detections of an acoustical pulse (81, 82) at a receiver (40, FIG. 3; 48, FIG. 7); (E) cross-correlation techniques are employed to detect the acoustical pulse at the receiver; (F) forward and inverse Fourier transforms employing fast Fourier transform techniques are used to implement the cross-correlation techniques; in such a mathematical manner that the peak of the cross-correlation function corresponds to the detection of a pulse at the receiver and (G) stray path signals through the body (31) of the acoustic sensor (15, 30) are removed from detected signals prior to signal analysis. Techniques are also provided for performing acoustical measurements on gases whose thermodynamic properties have not been measured and on mixtures of compressible gases. Methods and apparatus (29) for performing feedback control of a gas of interest in a mixture of that gas and a carrier gas are provided in which the controlled variable is the flow of the carrier gas.

Owner:VEECO INSTR

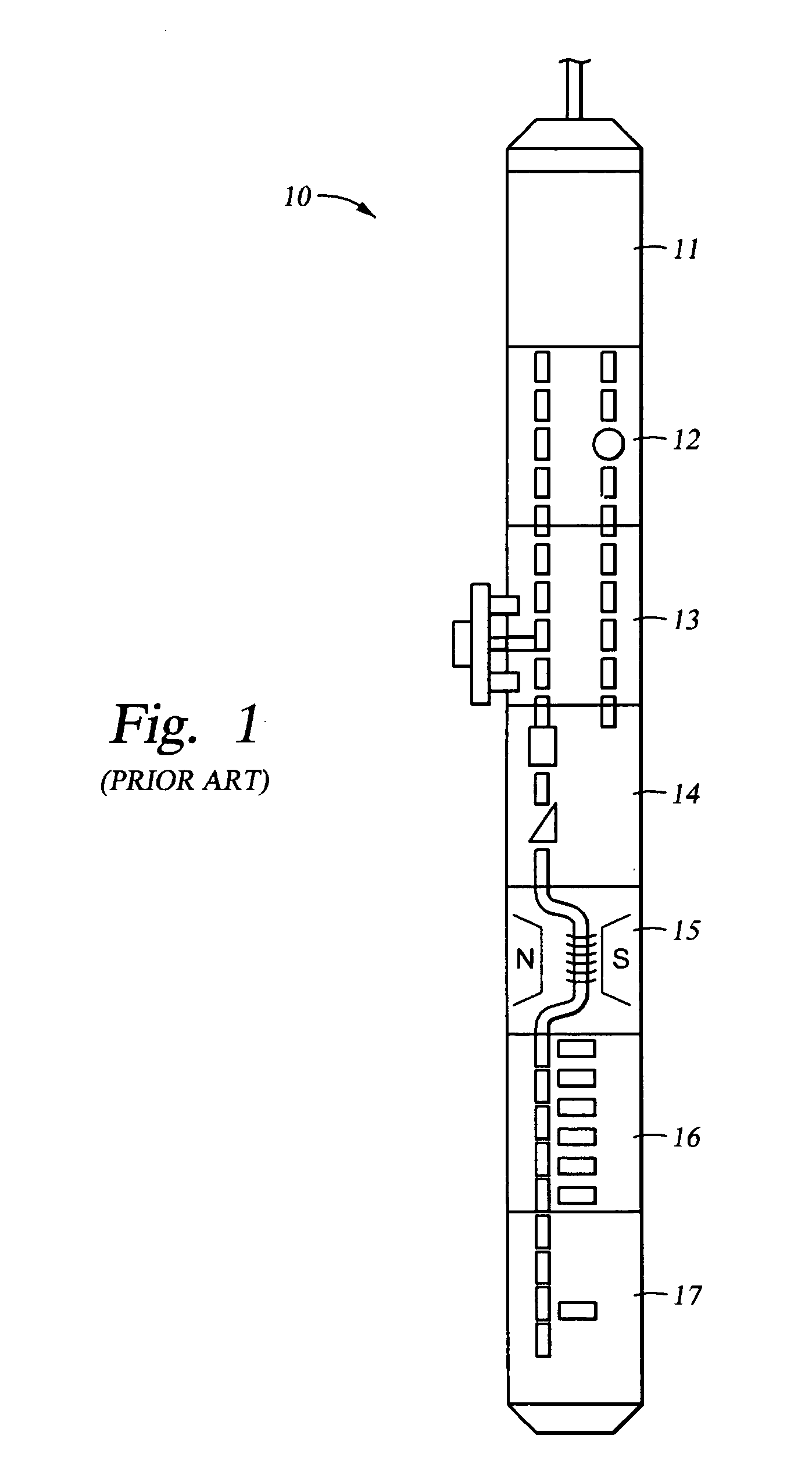

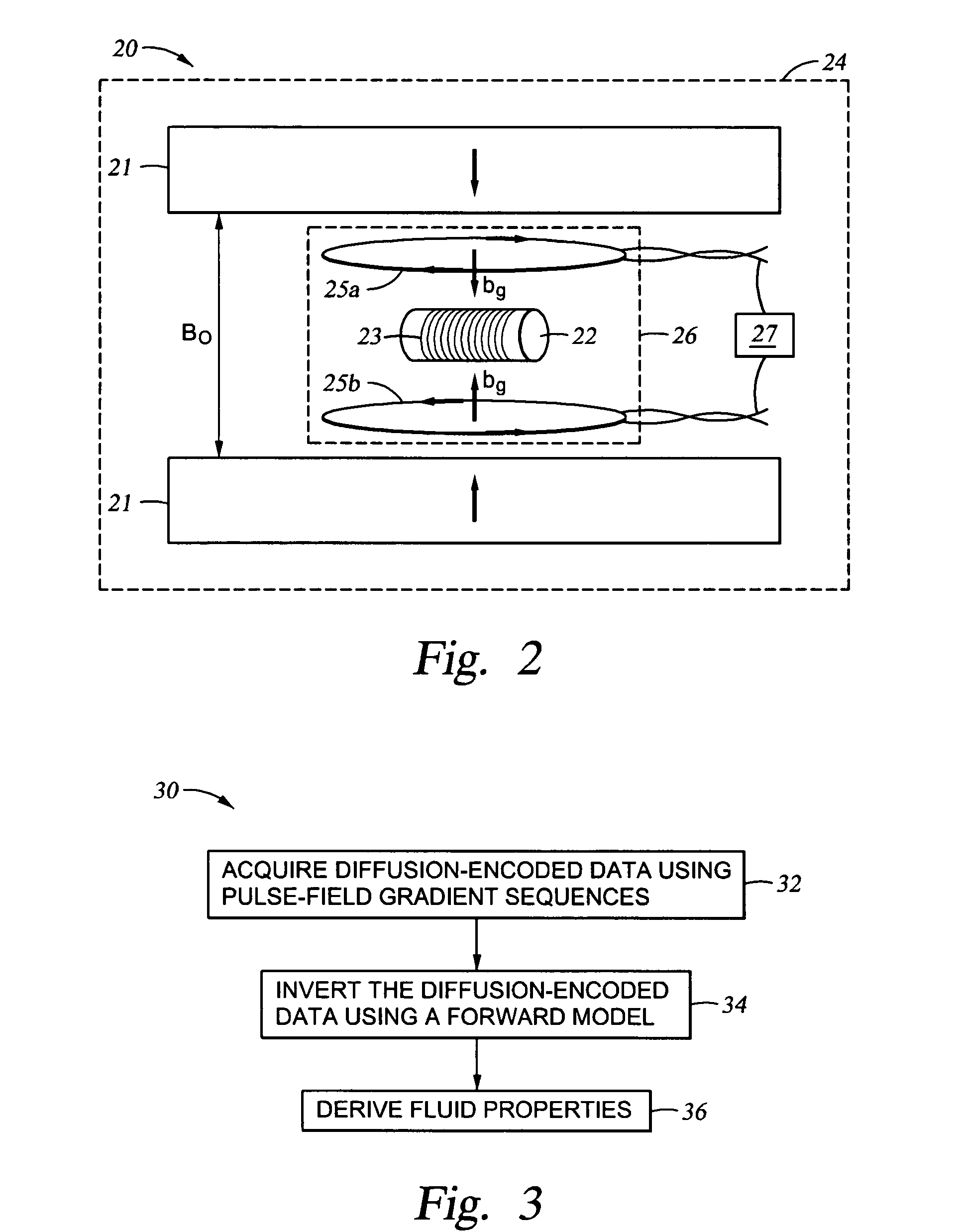

Method and apparatus for using pulsed field gradient NMR measurements to determine fluid properties in a fluid sampling well logging tool

InactiveUS20050270023A1Easy to detectRaise the ratioElectric/magnetic detection for well-loggingSurveyDiffusionNMR - Nuclear magnetic resonance

A method for determining a formation fluid property includes acquiring a suite of nuclear magnetic resonance (NMR) measurements of a fluid sample using a pulse sequence that includes pulsed field gradient pulses for encoding diffusion information, wherein each NMR measurement in the suite is acquired with a different value in a parameter in the pulsed field gradient pulses for producing a different diffusion effect, wherein the acquiring is performed in a formation fluid sampling tool in a borehole; inverting the suite of NMR measurements to produce a distribution function that relates diffusion properties of the fluid sample with an NMR property of the fluid sample; and determining the formation fluid property from the distribution function.

Owner:SCHLUMBERGER TECH CORP

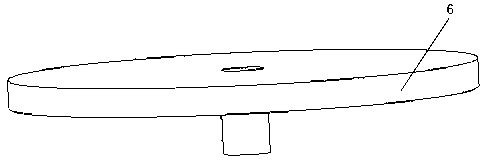

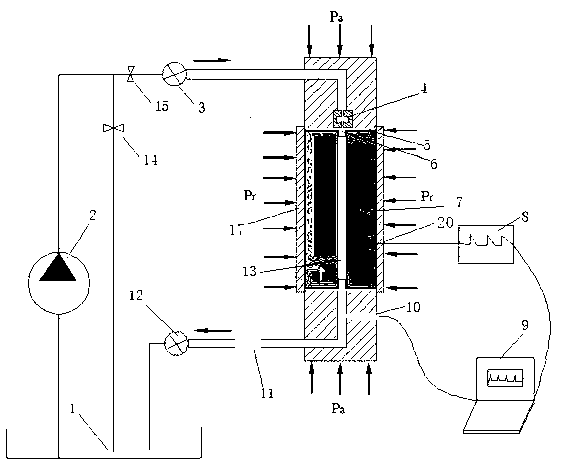

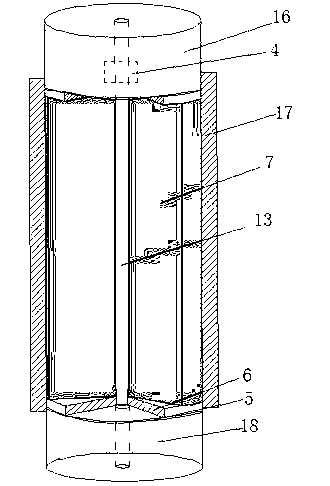

Experimental device and method for pulse hydrofracture transforming of shale gas storing layer

ActiveCN103196762AMonitor developments in real timeGenerating type of real-time monitoringSurface/boundary effectMaterial strength using repeated/pulsating forcesImpulse frequencyFracturing fluid

The invention relates to an experimental device and method for pulse hydrofracture transforming of a shale gas storing layer. The experimental device comprises a high pressure water pump, a fracturing fluid pond, a filtering device, a waterpower pulse generating device, a triaxial stress loading device, a pressure sensor, a sound emission device, a throttle valve, an overflow valve, a data collection recording system and a core test specimen. The device provided by the invention can simulate the operating environment of a shale sample under main operating parameter such as different pulse pressures and impulse frequencies on a certain confining pressure condition; moreover, the device can monitor a space-time developing rule of cracks and can test permeability change before and after fracture in real time; therefore, an experimental platform is provided for researching pulse hydrofracture of a shale gas storing layer. The experimental device provided by the invention has strong practicality, is easy to assemble, convenient to operate, is compact in structure, and can better imitate fracture damage and permeability change mechanism of a shale sample of the shale gas storing layer under the actions of static pressure and pulse hydrofracture.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com