Double quenching technique for 9Cr2Mo leveler roll

A process method, double-liquid quenching technology, applied in the direction of manufacturing tools, heat treatment process control, furnace, etc., can solve problems such as difficult simultaneous guarantee, intense cooling, and difficulty in achieving the hardness of the roll body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

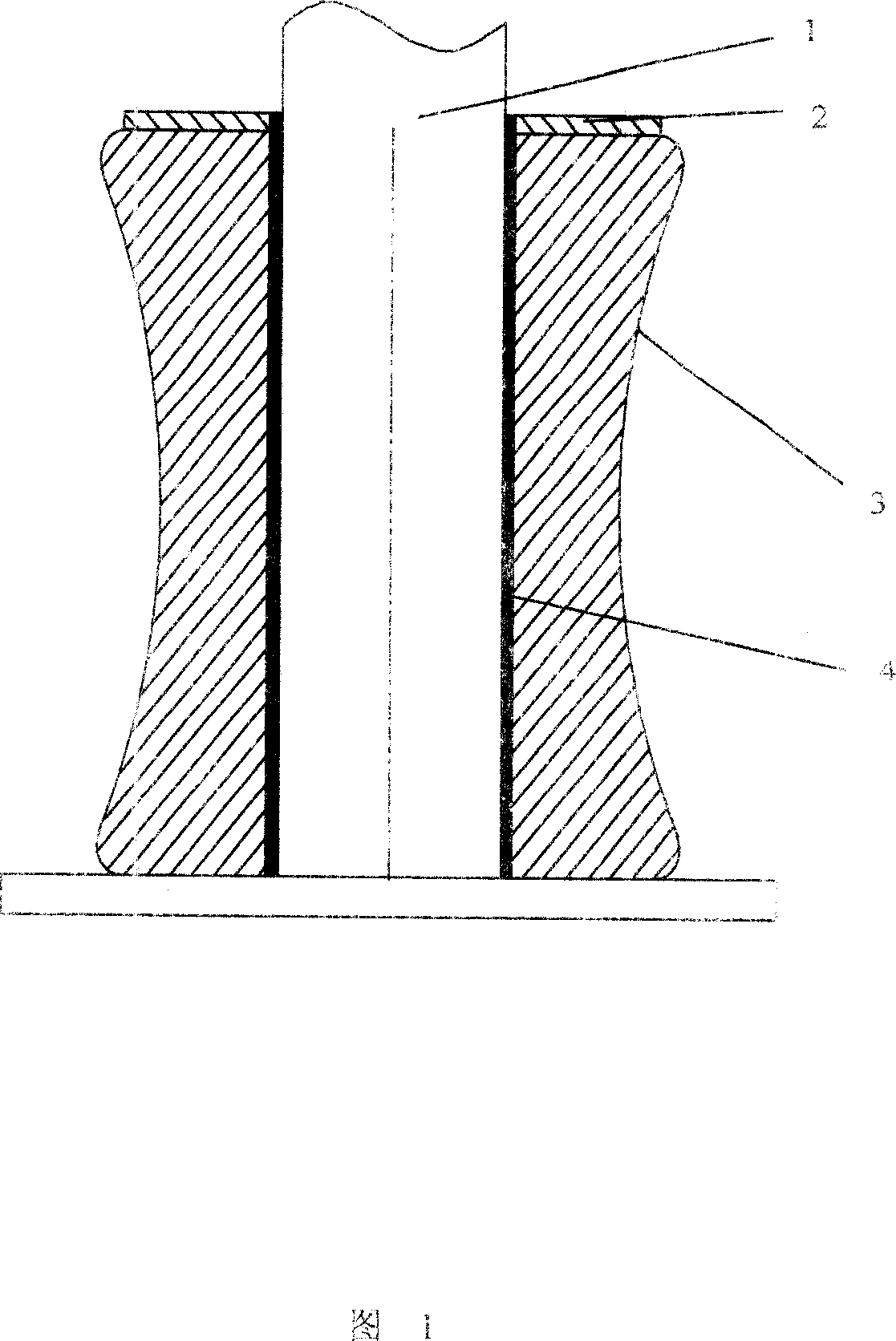

[0013] As shown in Figure 1, the two-liquid quenching process method of described a kind of 9Cr2Mo straightening roller, its concrete process is:

[0014] 1. Lift the roller body (3) of the straightening roller through the sling (1), the roller body (3) and the sling (1) are equipped with compacted loess (4), and the roller body (3) of the straightening roller ) The upper end is equipped with a cover plate (2), and then hoisted into the 105KW well-type electric furnace.

[0015] 2. Heat up to 840±10°C with the furnace and keep warm for 3.5 hours.

[0016] 3. After coming out of the oven, quickly lift the straightening roller to the sky above the water tank, pre-cool it in the air for 2 minutes, and then use a Φ24mm leather tube to pour water on the surface of the roller cover to make it fully pre-cooled. Stop watering after the top edge of the cover plate and rollers turn black, and water again after the temperature rises, repeat this 2-3 times, and at the same time, the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com