Vanadium micro-alloyed 1300 Mpa-grade high-strength hot-rolled steel plate and production method of cold-rolled dual-phase steel plate

The technology of a hot-rolled steel sheet and a production method is applied in the field of preparation of a dual-phase steel sheet, which can solve the problems of insufficient strength of the dual-phase steel sheet, and achieve the effects of improving strength, good elongation, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

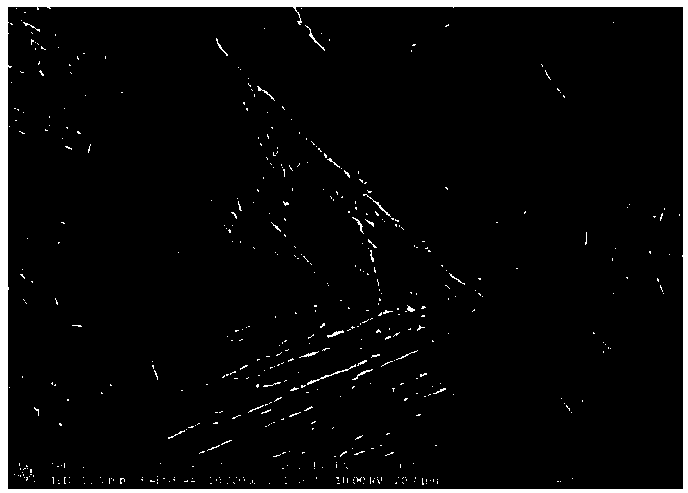

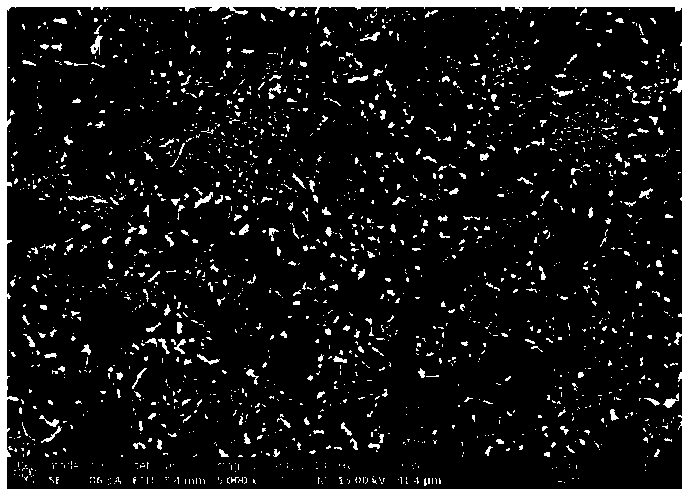

Image

Examples

Embodiment 1

[0035] Chemical composition (wt%) of table 1 invention steel

[0036] Element

C

mn

Al

V

Si

P

S

A

0.10

1.84

0.080

0.08

0.20

<0.005

<0.005

B

0.16

2.62

0.053

0.15

0.33

<0.005

<0.005

C

0.25

4.13

0.120

0.35

0.80

<0.005

[0037] The test in this example adopts the chemical composition shown in Table 1. After smelting, it is cast into an ingot, hot-forged into a slab with a thickness of 50 mm, heated to 1200 ° C for 3 hours, and then hot-rolled to about 4.7 mm by a pilot single-stand rolling mill to obtain a hot Rolled products, the final rolling temperature is about 850°C, and then divided into 1 and 2 coiling methods according to the cooling process and coiling temperature, which are marked as 1 group and 2 groups respectively. , in which group 1 is rapidly cooled to about 530°C at a cooling rate of about 5°C / s after final rolling, and then cooled to 150°C at a rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com