TiZrO2 carrier and precious metal/TIZrO2 catalyst and preparation and application thereof

A catalyst and precious metal technology, applied in the field of supported catalysts and their preparation, can solve the problems of difficult to achieve large-scale production, complex preparation process, long preparation period, etc., and achieve the effects of low production cost, large specific surface area and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] ① Dissolve 0.2xmol of titanium sulfate and 0.2(1-x)mol of zirconium oxychloride into 2.5L of ultrapure water, add 5ml of nitric acid to prevent hydrolysis, stir vigorously for 20min to prepare a titanium-zirconium composite salt solution. where x=0.1-0.5.

[0037] ②Titanium-zirconium compound salt solution was added dropwise to 1L of 12.5% ammonia water at a rate of 15ml / min to form a white jelly.

[0038] ③ The colloid was aged at room temperature for 12 hours, vacuum filtered and washed, and the obtained filter cake was fully kneaded and extruded.

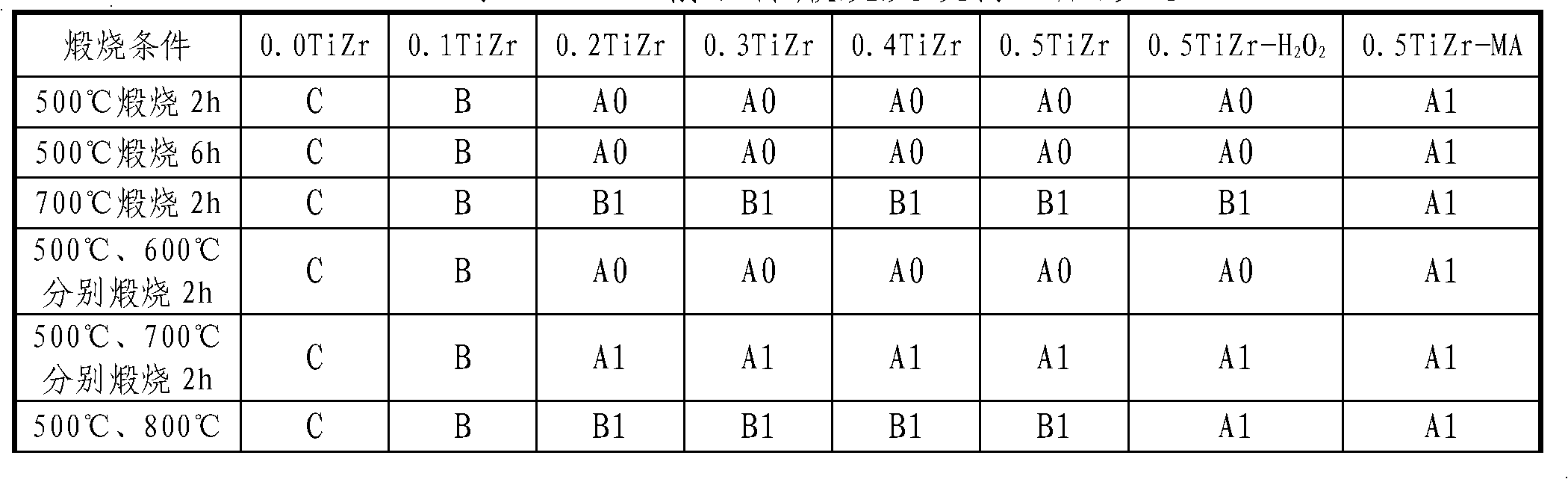

[0039] ④ After the extrudate is dried at room temperature, it is dried at 120°C for 2 hours, and then calcined at 500-900°C for one or two steps for 2-6 hours (see Table 1 for details).

[0040] ⑤ Equal volume impregnation of RuCl in vacuum 3 Solution, calcined at 350°C for 6h.

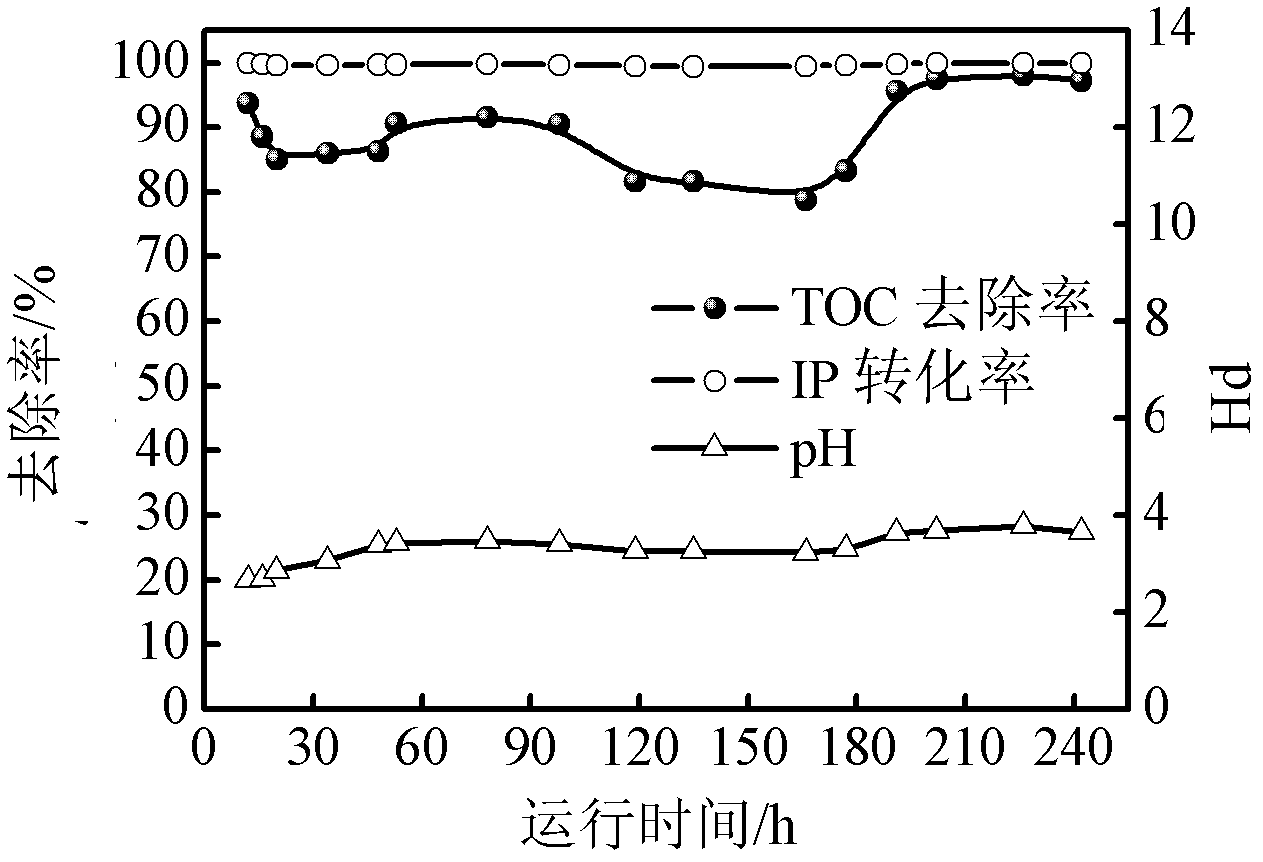

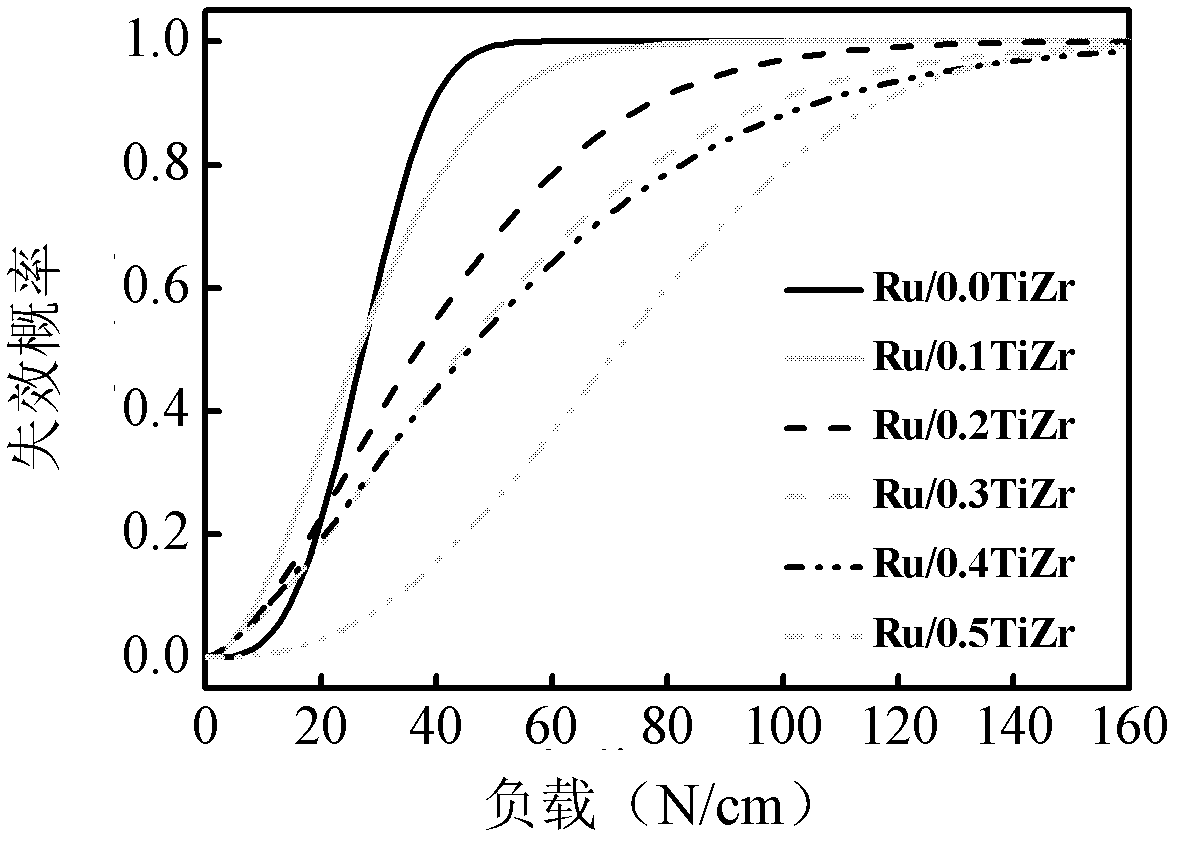

[0041] From figure 1 It can be seen that the statistical analysis of the strength data of Ru / xTiZr catalysts shows that they all obey the W...

Embodiment 2

[0043] ①Dissolve 0.1mol of titanium sulfate and 0.1mol of zirconium oxychloride into 2.5L of ultrapure water, add 5ml of nitric acid to prevent hydrolysis, add 200ml of hydrogen peroxide to homogenize the precipitation of titanium-zirconium salt solution, stir vigorously for 20 minutes to prepare titanium-zirconium Compound salt solution.

[0044] ②Titanium-zirconium compound salt solution was added dropwise to 1L of 25% ammonia water at a rate of 15ml / min to form a white jelly.

[0045] ③ The colloid was aged at room temperature for 12 hours, vacuum filtered and washed, and the obtained filter cake was fully kneaded and extruded.

[0046] ④The extrudate is dried at room temperature and then dried at 120°C for 2 hours, then calcined in one or two steps at 500-900°C for 2-6 hours.

[0047] ⑤ Vacuum equal volume impregnation of RuCl 3 Solution, calcined at 350°C for 6h. The molding and acetic acid corrosion results are shown in Table 1.

Embodiment 3

[0049] ① Dissolve 0.1mol of titanium sulfate and 0.1mol of zirconium oxychloride into 2.5L of ultrapure water, add 5ml of nitric acid to prevent hydrolysis, stir vigorously for 20min to prepare a titanium-zirconium composite salt solution.

[0050] ②Titanium-zirconium compound salt solution was added dropwise to 1L of 25% ammonia water at a rate of 15ml / min to form a white jelly.

[0051] ③ The colloid was aged at room temperature for 12 hours, vacuum filtered and washed, and the obtained filter cake was fully kneaded with 2% metatitanic acid and extruded.

[0052] ④The extrudate is dried at room temperature and then dried at 120°C for 2 hours, then calcined in one or two steps at 500-900°C for 2-6 hours.

[0053] ⑤ Equal volume impregnation of RuCl in vacuum 3 Solution, calcined at 350°C for 6h. The molding and acetic acid corrosion results are shown in Table 1. It can be seen from Table 1 that two-step calcination is better than one-step calcination. If the carrier wants ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com