Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Reduce Cr content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molybdenum-containing nickel-saving austenitic stainless steel with excellent corrosion resistance and manufacturing method thereof

ActiveCN102337481ALow costReduced corrosion resistancePitting resistance equivalent numberAustenitic stainless steel

Owner:BAOSTEEL DESHENG STAINLESS STEEL

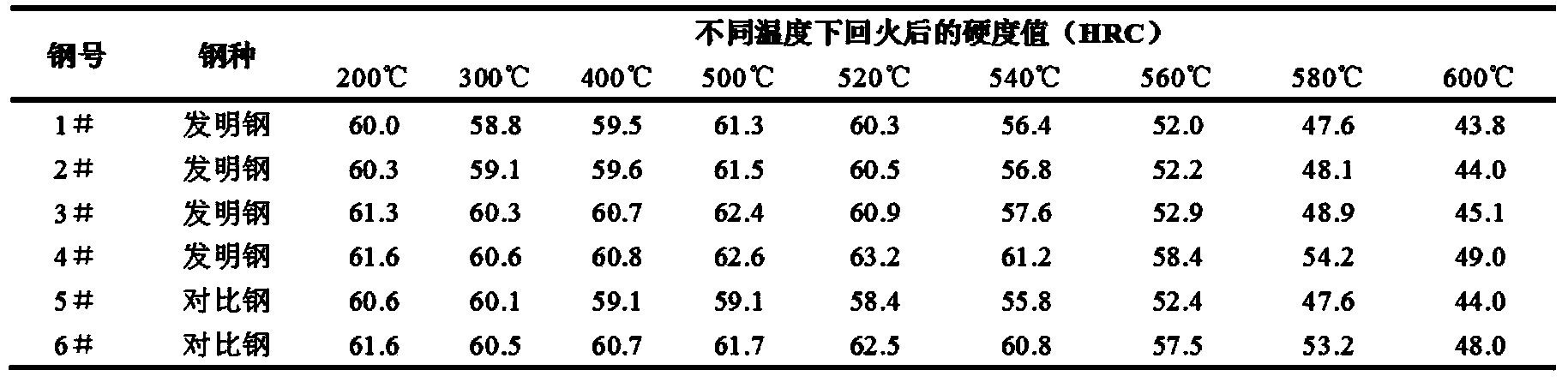

Hot-work die steel for extrusion wheel and manufacturing method thereof

InactiveCN102534391AImprove hardenabilityReduced temper softening resistanceMetal-working apparatusTemperingThermal fatigue

The invention relates to hot-work die steel for an extrusion wheel and a manufacturing method of the die steel. The invention adopts the technical scheme that the manufacturing method comprises the following steps: hot-forging after scrap steel or molten iron and scrap steel are smelted in an electric furnace and are subjected to electroslag remelting or vacuum induction melting and then carry out spheroidizing annealing at a temperature of 700-880 DEG C; quenching at a temperature of 1,020-1,120 DEG C and tempering at a temperature of 530-650 DEG C, wherein the hot-work die steel has a hardness of up to 40-52HRC and a tensile strength of up to 1,850-1,955MPa. The hot-work die steel comprises the following chemical components in percentage by weight: 0.30-0.50wt% of C, 0.80-1.20wt% of Si, 0.2-0.5wt% of Mn, 3.00-5.00wt% of Cr, 1.00-1.50wt% of Mo, 0.70-1.20wt% of V, 0.005-0.03wt% of N and less than 0.030wt% of P, less than 0.030wt% of S and the balances of Fe and inevitable impurities. The steel has the characteristics of low cost, good thermal fatigue property, high heat stability and excellent comprehensive property and can be used for manufacturing the extrusion wheel of a continuously-extrusion-molded coating machine and other hot-work dies.

Owner:WUHAN UNIV OF SCI & TECH

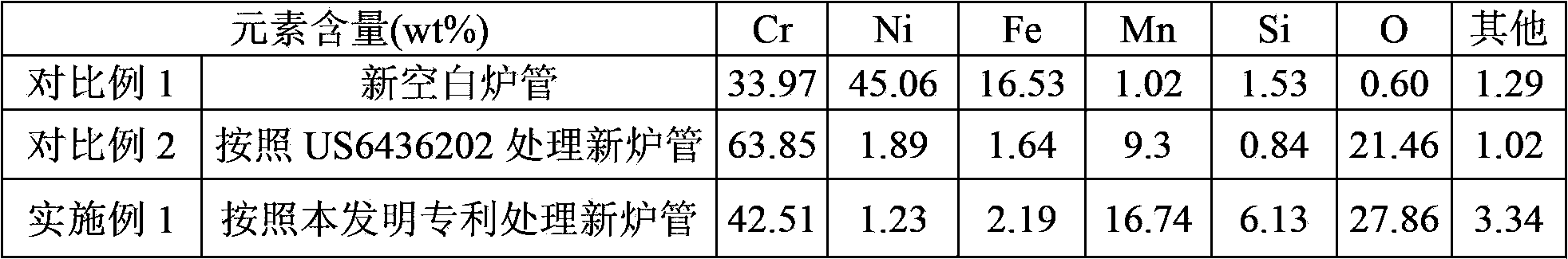

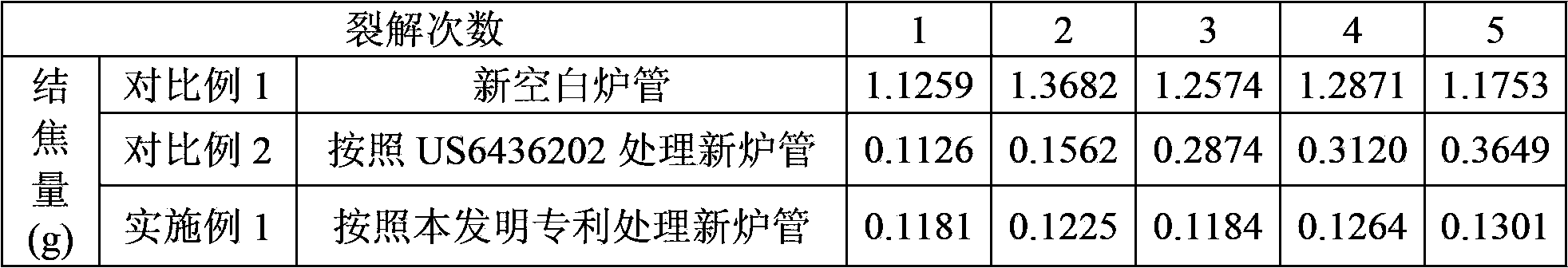

Coking-resistant hydrocarbon cracking furnace pipe and preparation method thereof

ActiveCN103788983AImprove stabilityEasy to maintain structureThermal non-catalytic crackingWater vaporStructural formula

The invention provides a coking-resistant hydrocarbon cracking furnace pipe and a preparation method thereof. A cracking furnace pipe is subjected to two-stage high-temperature heat treatment in a H2- and vapor-containing low-oxygen partial pressure gas atmosphere so that a manganese-chromium spinel coating is formed on the inner surface. In the first-stage high-temperature heat treatment, a mole ratio of H2 to vapor is in a range of 1792-107 and in the second-stage high-temperature heat treatment, a mole ratio of H2 to vapor is in a range of 1-1791. The manganese-chromium spinel has a structural formula of MnxCr3-xO4 and x is in a range of 0.5-1.5. The manganese-chromium spinel coating reduces deposition of coke on the inner wall of a radiation-section furnace pipe in hydrocarbon cracking and prolongs an operation period and a use life of the furnace pipe.

Owner:CHINA PETROLEUM & CHEM CORP +1

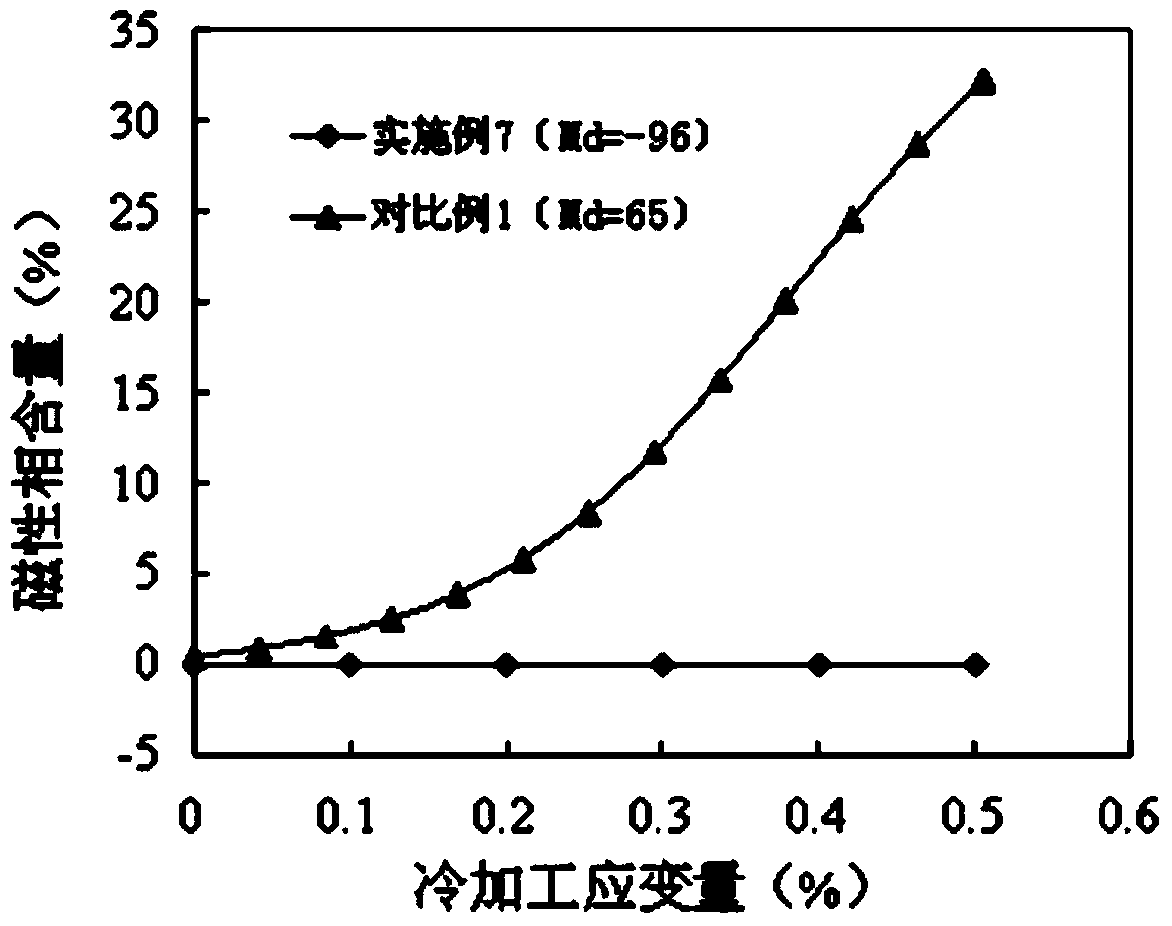

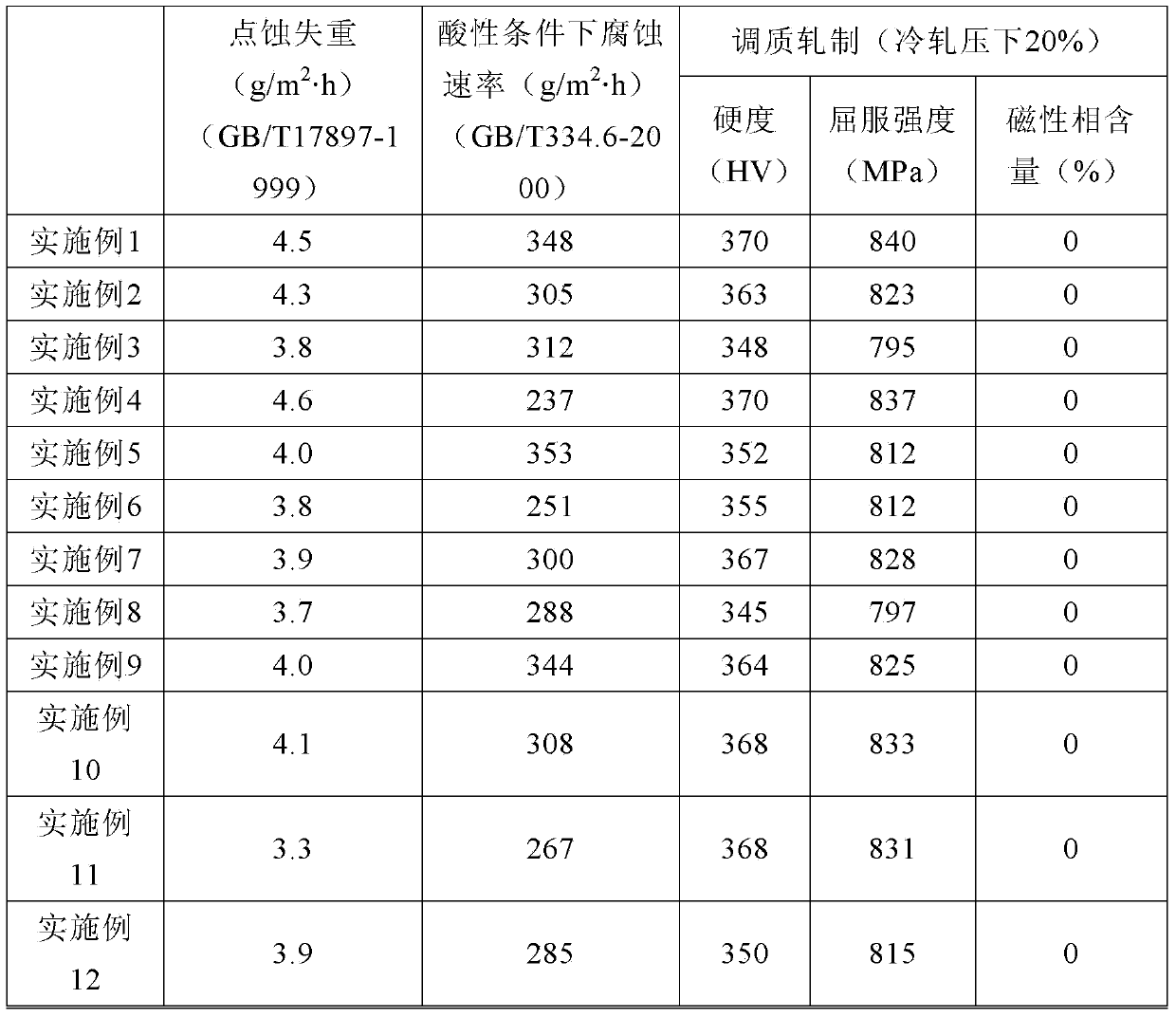

Non-magnetic hard austenitic stainless steel for precision electron and manufacturing method thereof

The invention relates to a non-magnetic hard austenitic stainless steel for precision electron and a manufacturing method thereof. The stainless steel comprises the following chemical components by weight percent: 0.06% to 0.10% of C, 0.51% to 0.8% of Si, 11.5% to 12.5% of Mn, 17.0% to 18.0% of Cr, 2.51% to 3.50% of Ni, 0.15% to 0.20% of N, 0.15% to 0.50% of Sn, 0.30% to 0.50% of Mo, 0.30% to 0.75% of Mo and W / 2, 2.0% to 2.5% of Cu and the balance of Fe and inevitable impurities, wherein at least one of the components as follows is selected: less than or equal to 0.1% of V and less than or equal to 0.1% of Nb; and 30Sn%+5Mo%+2.5W%+Ni%+Cu%+0.5Si%-0.25Mn% is greater than or equal to 9.0. Based on the Cu-Mo-Sn-Si alloying, the adverse effect to the corrosion resistance of the stainless steel in which the Ni is reduced and the Mn is added is eliminated, so that the stainless steel has the pitting corrosion resistance superior to 304 and can be prevented from being corroded by a reducing acid. Meanwhile, the temperature of Md30 / 50 is controlled to be lower than -75 DEG C and the austenitic stability is controlled to be superior to 304 and 305, so that the magnetic martensite phase transformation is avoided when the deformation of the stainless steel in cold machining is less than or equal to 50%. Thus, the non-magnetic performance of the hard austenitic stainless steel is also maintained.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

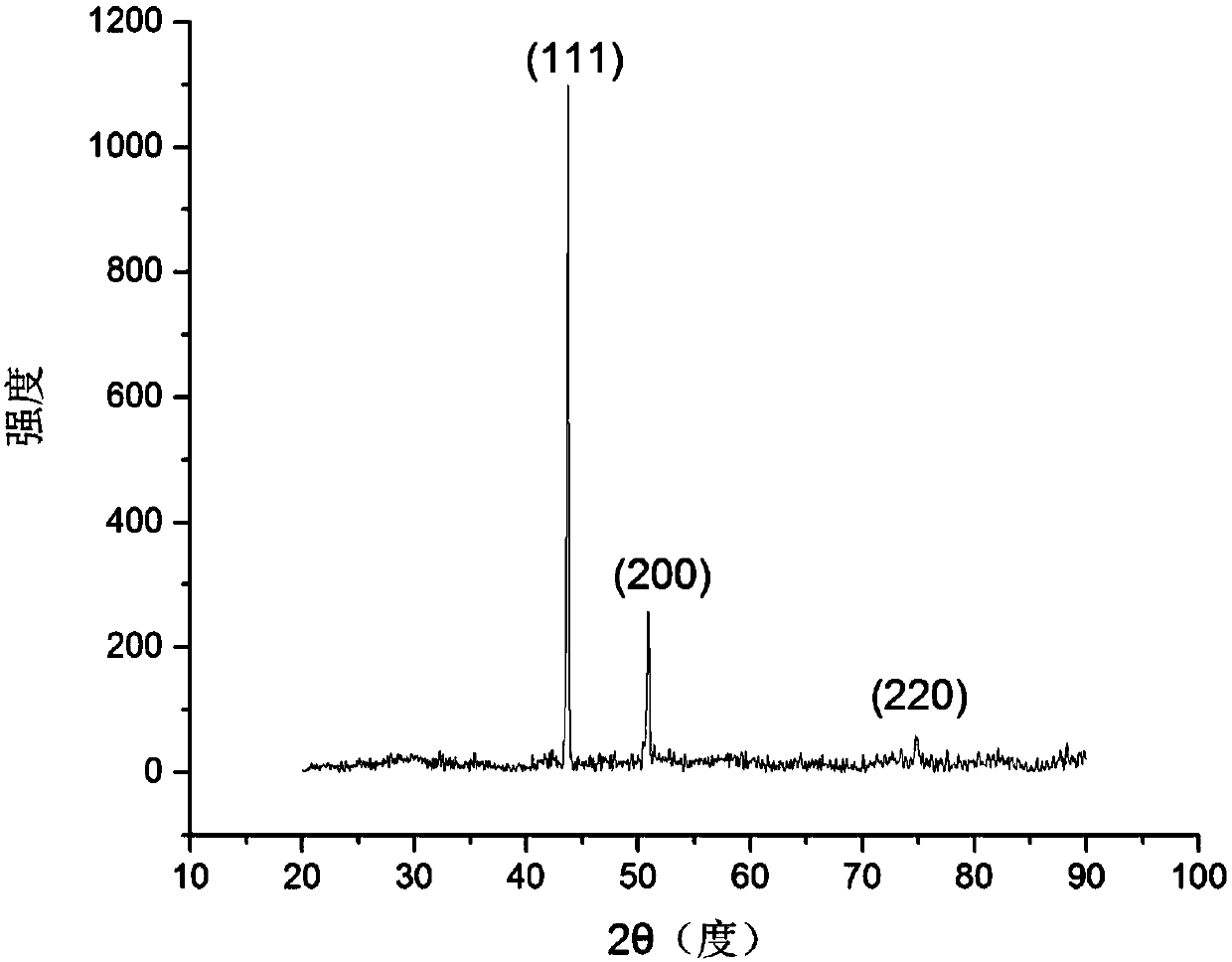

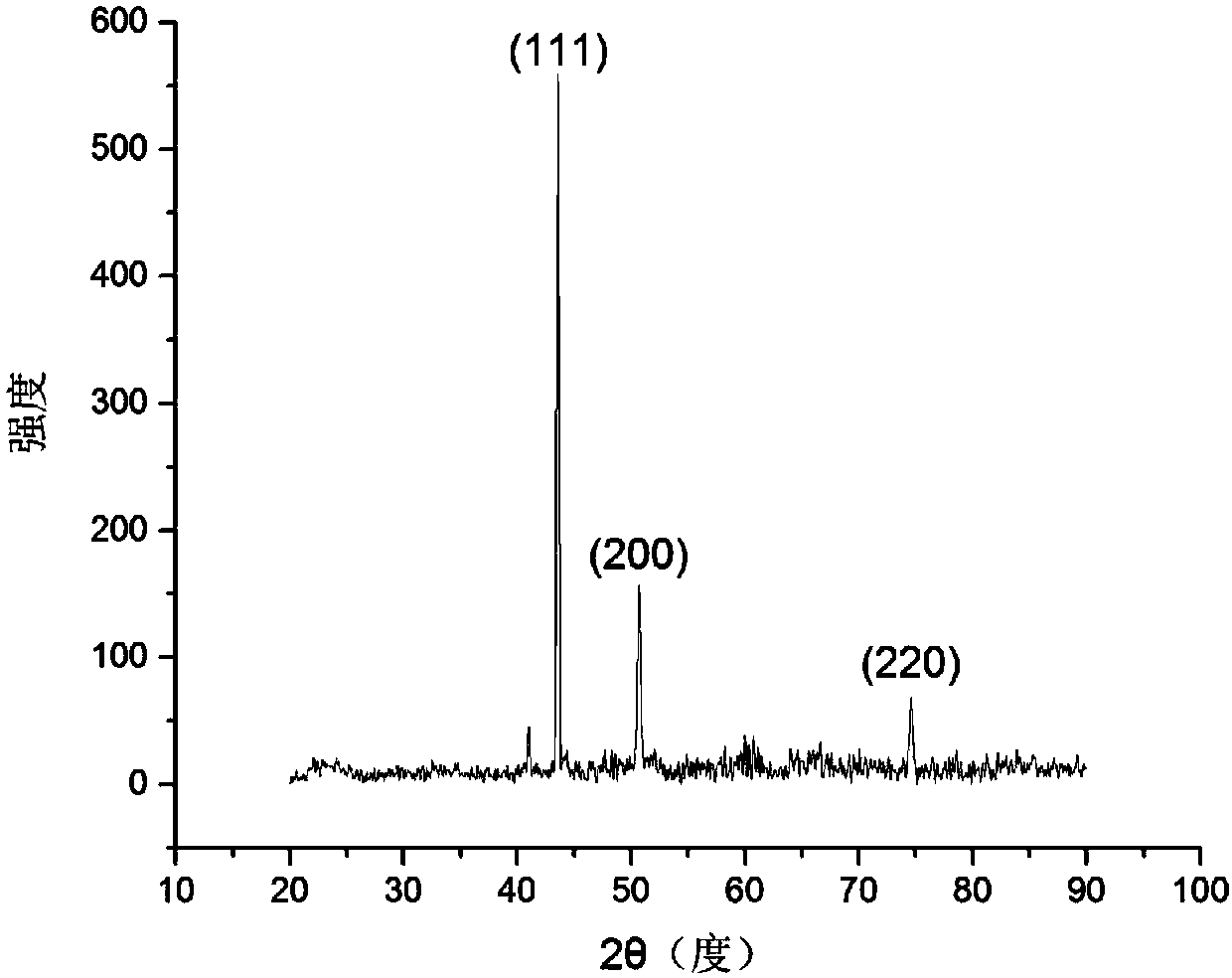

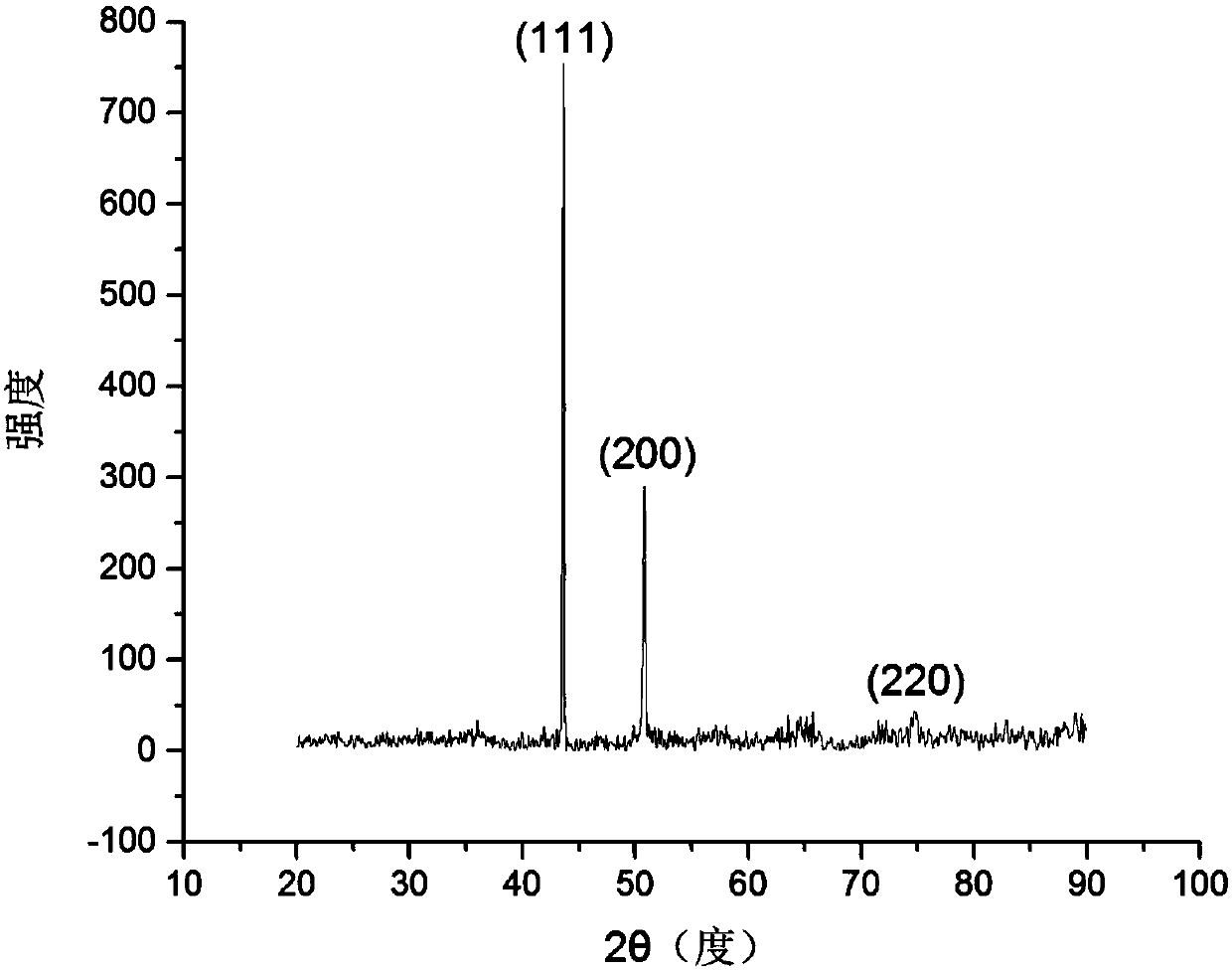

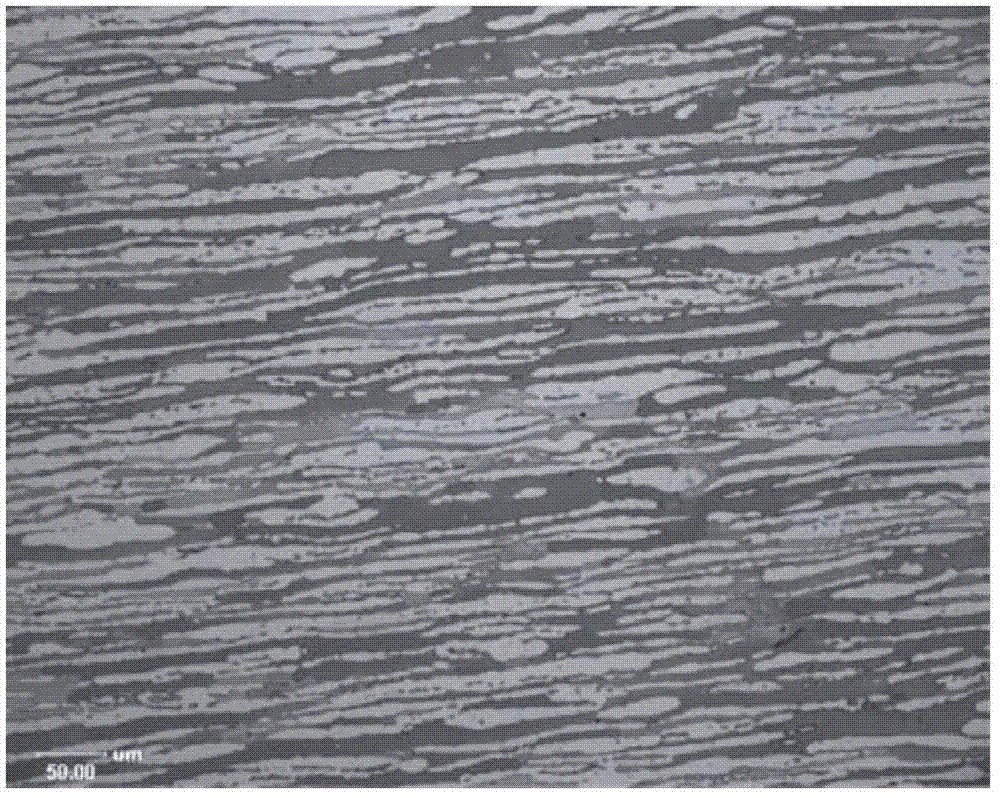

Nb microalloyed Ni-Co-Fe-Cr-Al high-entropy alloy

The invention relates to an Nb microalloyed Ni-Co-Fe-Cr-Al high-entropy alloy, and belongs to the technical field of metal materials. According to the Nb microalloyed Ni-Co-Fe-Cr-Al high-entropy alloy, through adjusting of proportioning of basic components of Al, Ni, Co, Cr and Fe and adding of microelement Nb, forming of an L12 phase is promoted, and occurrence of detrimental phases such as a B2phase, an Laves phase and a sigma phase is avoided; the high-entropy alloy is mainly composed of an FCC phase, the grain size is within 100 [mu]m-400 [mu]m, the yield strength is not lower than 300 MPa, the tensile strength is not lower than 740 MPa, the elongation rate is not lower than 18%, the good toughness and the high yield strength are both achieved, and the Nb microalloyed Ni-Co-Fe-Cr-Al high-entropy alloy meets the requirements of a modern industry for mechanical properties of materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Duplex stainless steel with excellent thermoplasticity and corrosion resistance and manufacturing method thereof

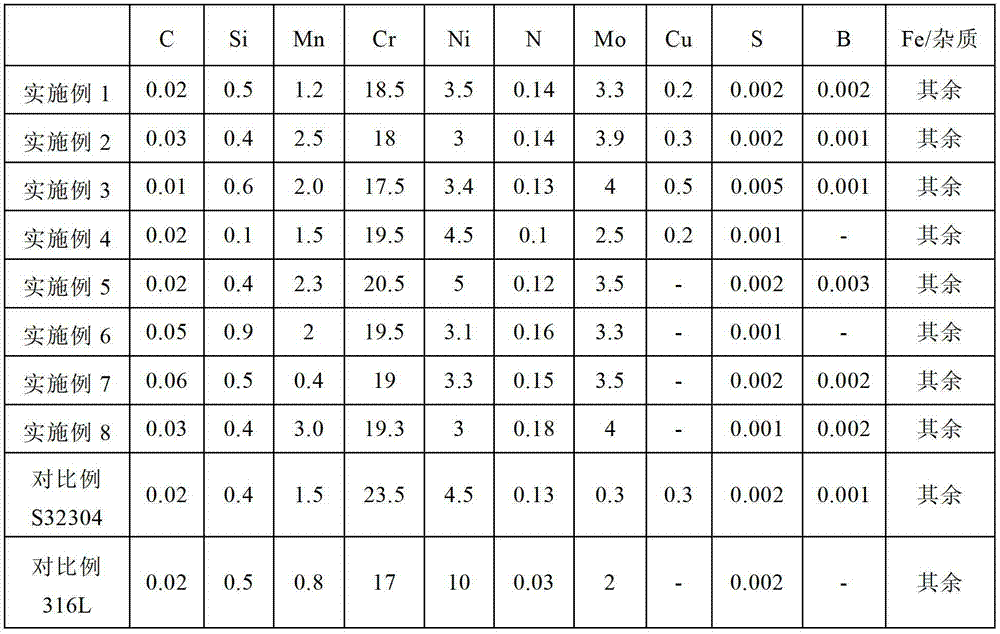

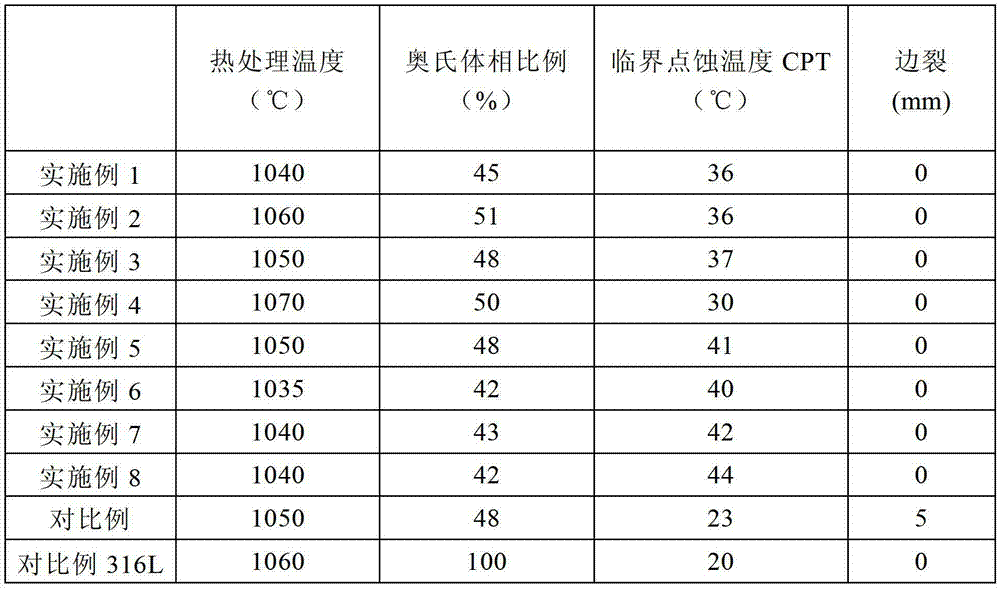

The present invention discloses a duplex stainless steel with excellent thermoplasticity and corrosion resistance and a manufacturing method thereof. The duplex stainless steel comprises chemical compositions of, by weight percentage, 0.01-0.06 % of C, 0.1-1.0 % of Si, 0.4-3.0 % of Mn, 17.5-20.5 % of Cr, 3.0-5.0 % of Ni, 0.1-0.18 % of N, 2.5-4.0 % of Mo,less than or equal to 0.005 % of S, less than or equal to 0.005 % B, less than or equal to 1.0 % of Cu, and the balance being Fe and inevitable impurities. According to the invention, a content of the Mo is increased to 2.5-4.0 %, a content of the Cr is reduced to 17.5-20.5 %, a content of the N is controlled at 0.1-0.18 %, and the trace elements S and B are also in control. The duplex stainless steel has excellent thermoplasticity and corrosion resistance, can be produced into hot-rolled and cold-rolled strip steels in mass and used in fields of construction, heat exchange, etc., and can partially replace costly 316 and 317 austenitic stainless steel.

Owner:BAOSTEEL STAINLESS STEEL

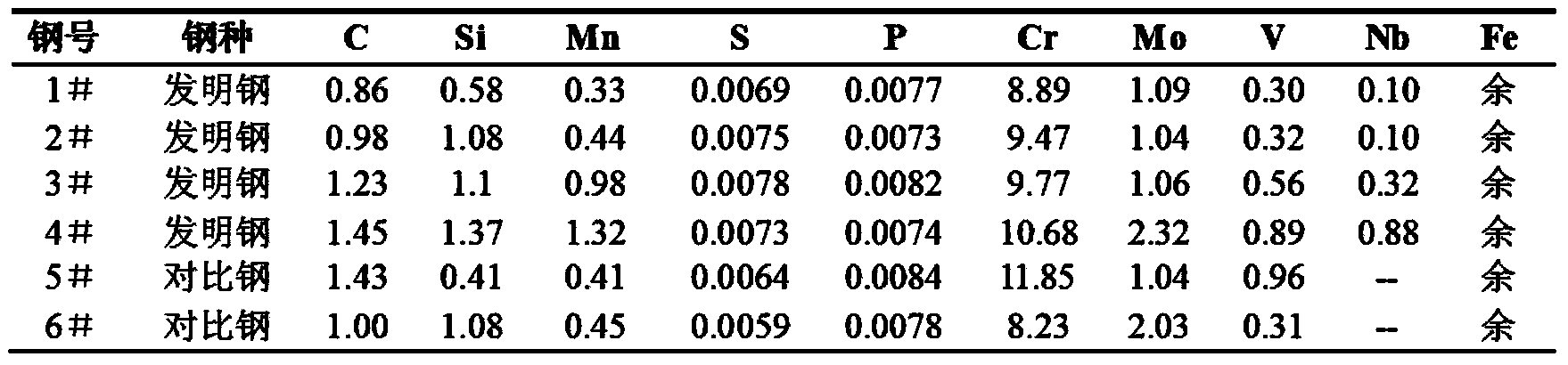

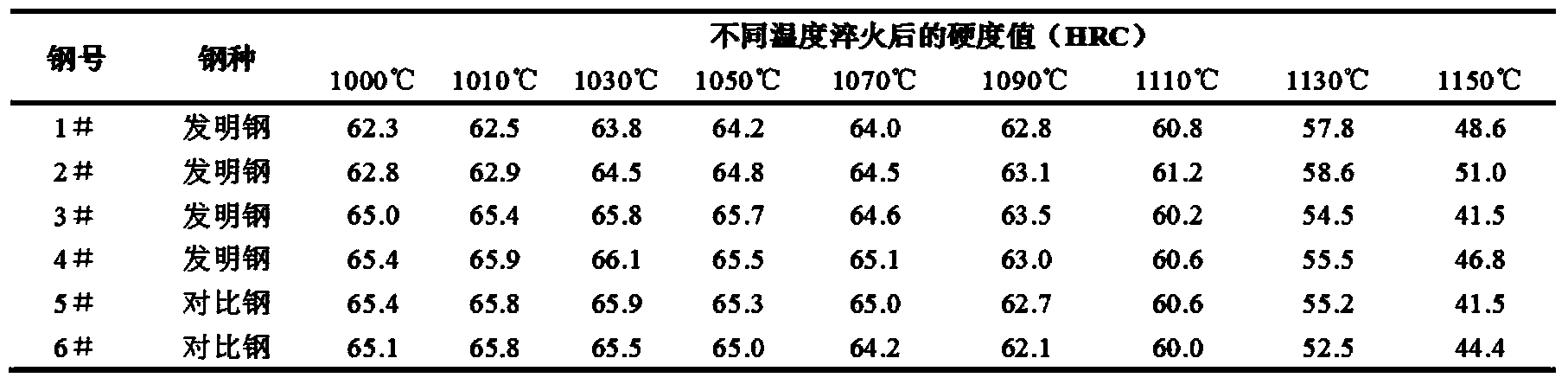

High-toughness and high-wear-resistant cold-work die steel

The invention discloses a high-toughness and high-wear-resistant cold-work die steel, belonging to the field of tool and die steels. The steel comprises the following chemical components in percentage by weight: 0.8-1.5% of C, 0.5-1.5% of Si, less than or equal to 0.030% of S, less than or equal to 0.030% of P, less than or equal to 1.5% of Mn, 0.8-2.5% of Mo, 8.0-11.0% of Cr, 0.1-1.0% of V, less than or equal to 1.0% of N, and the balance of Fe and inevitable impurities. Compared with the prior art, the high-toughness and high-wear-resistant cold-work die steel disclosed by the invention keeps high wear resistance, and has higher toughness and bending strength and good comprehensive performances at the same time. Compared with a Cr12 type cold-work die steel, the high-toughness and high-wear-resistant cold-work die steel reduces the Cr content, and ensures that a material has higher toughness. Compared with a Cr8 type cold-work die steel, the high-toughness and high-wear-resistant cold-work die steel increases the Cr content, increases the wear resistance, and reasonably controls the C / Cr ratio, thus achieving the purposes of obtaining a better carbide distribution state than the Cr8 type cold-work die steel, and ensuring that the material has better toughness. The content of elements Mn and Si is increased so as to improve the hardness and enhance the wear resistance. By adopting relatively high Nb<+>V composite alloying, the effects of V in the steel are increased, and the secondary hardening effect is improved.

Owner:CENT IRON & STEEL RES INST

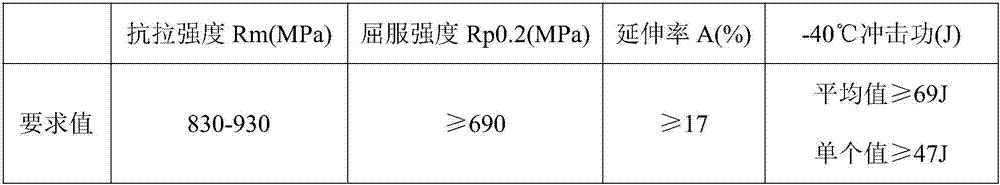

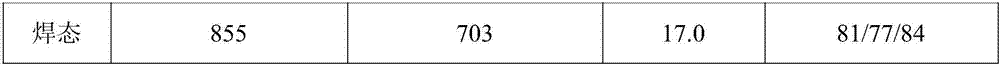

Low-alloy-steel welding rod for welding of maritime work rack steel Q690

ActiveCN107127480AImprove low temperature impact toughnessExcellent performanceWelding/cutting media/materialsSoldering mediaHigh intensityImpact toughness

The invention discloses a low-alloy-steel welding rod for welding of maritime work rack steel Q690. The low-alloy-steel welding rod comprises welding core and a coating. The coating comprises the following raw materials of, by mass, 15%-25% of fluorite, 2%-5% of silicon micro powder, 3%-6% of rutile, 6%-12% of iron powder, 0.3%-0.7% of CMC, 0.5%-0.8% of sodium carbonate, 0.5%-0.7% of alginate, 7%-10% of a mixture of manganese alloy, chromium alloy and molybdenum alloy, 6%-7% of nickel powder, and the balance marble. The welding core comprises the following components of, by mass, 0-0.10% of C, 0.35%-0.60% of Mn, 0-0.03% of Si, 0-0.20% of Cr, 0-0.30% of Ni, 0-010% of S, 0-0.015% of P, 0-0.20% of Cu, and the balance Fe and unavoidable impurities. The low-alloy-steel welding rod meets the chemical component requirements of matching of the maritime work rack steel Q690 and the low-alloy-steel welding rod, deposited metal keeps high strength, low-temperature impact toughness is improved, the surface of the welding rod is smooth, the yield is high, eccentricity is stable, and all-position welding performance of the welding rod is good.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

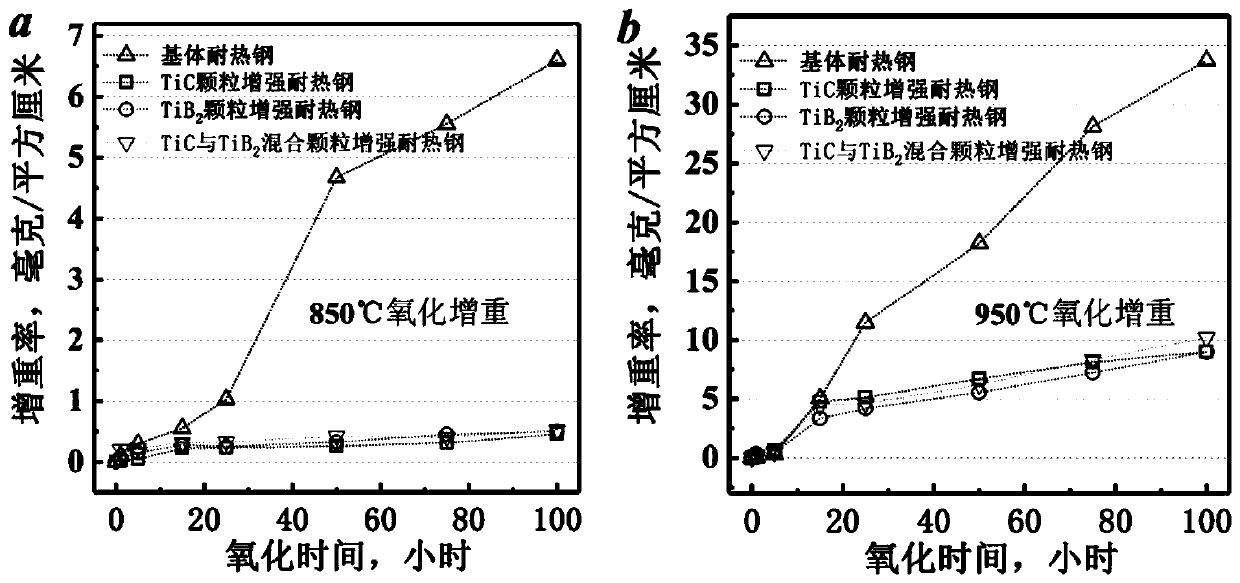

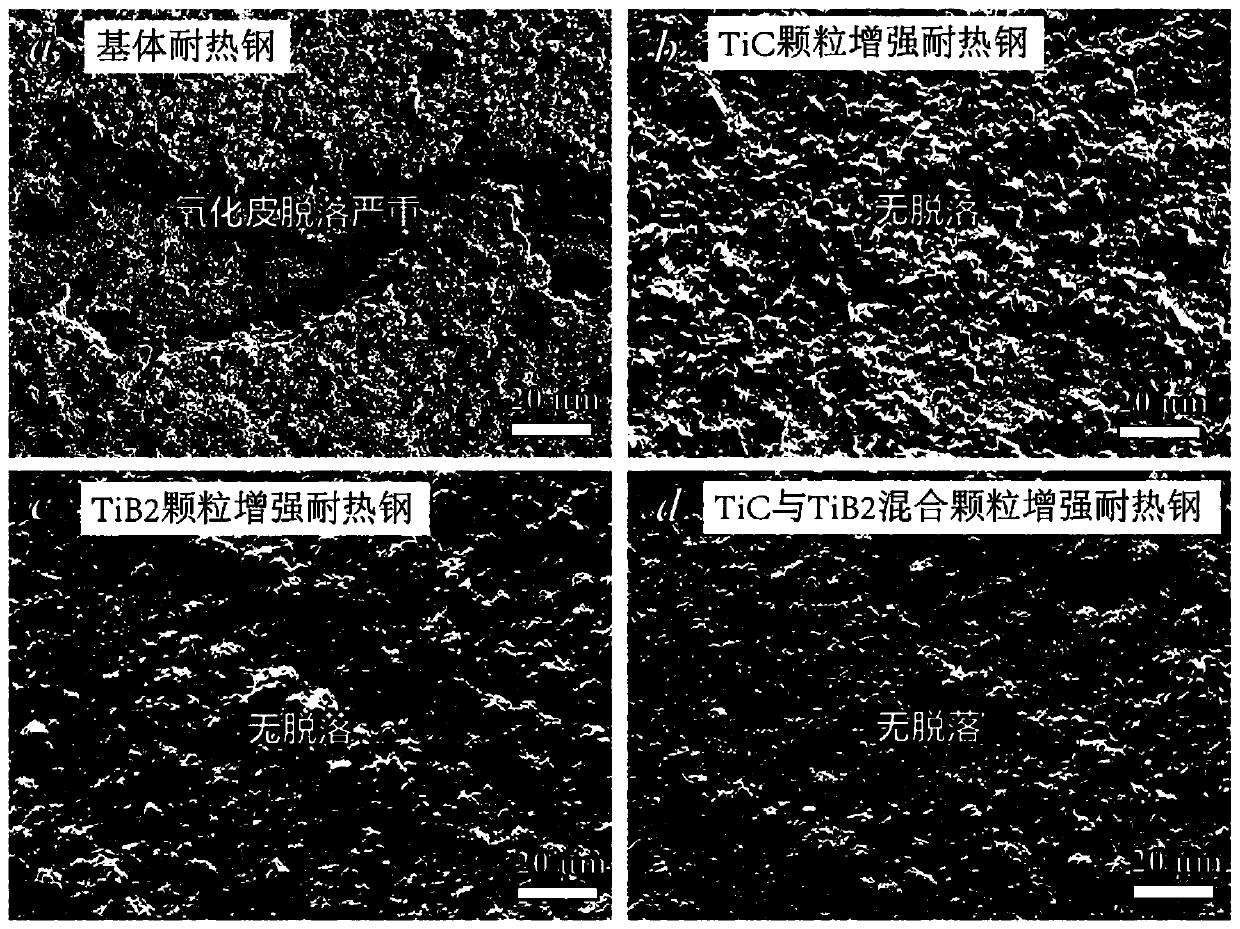

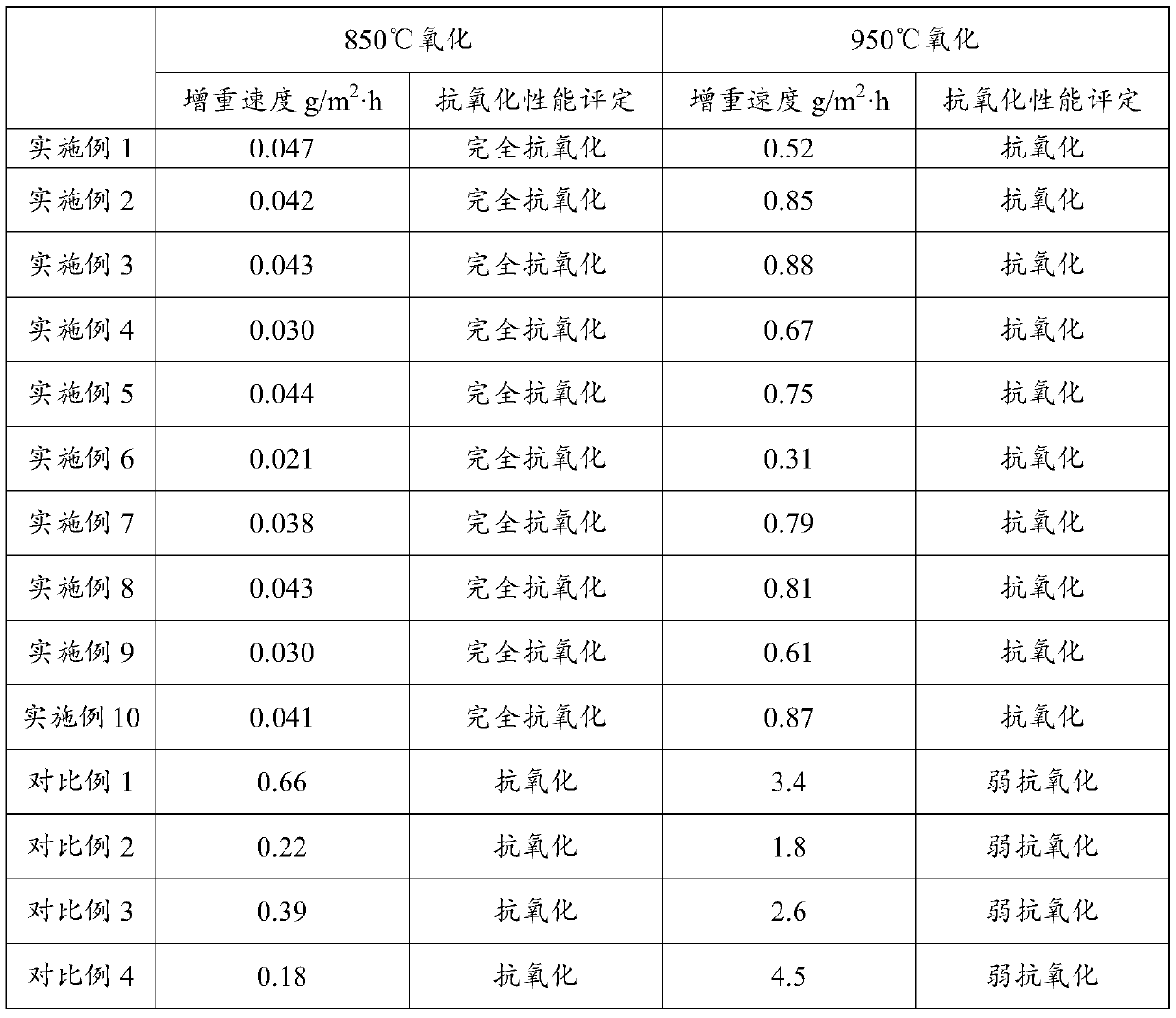

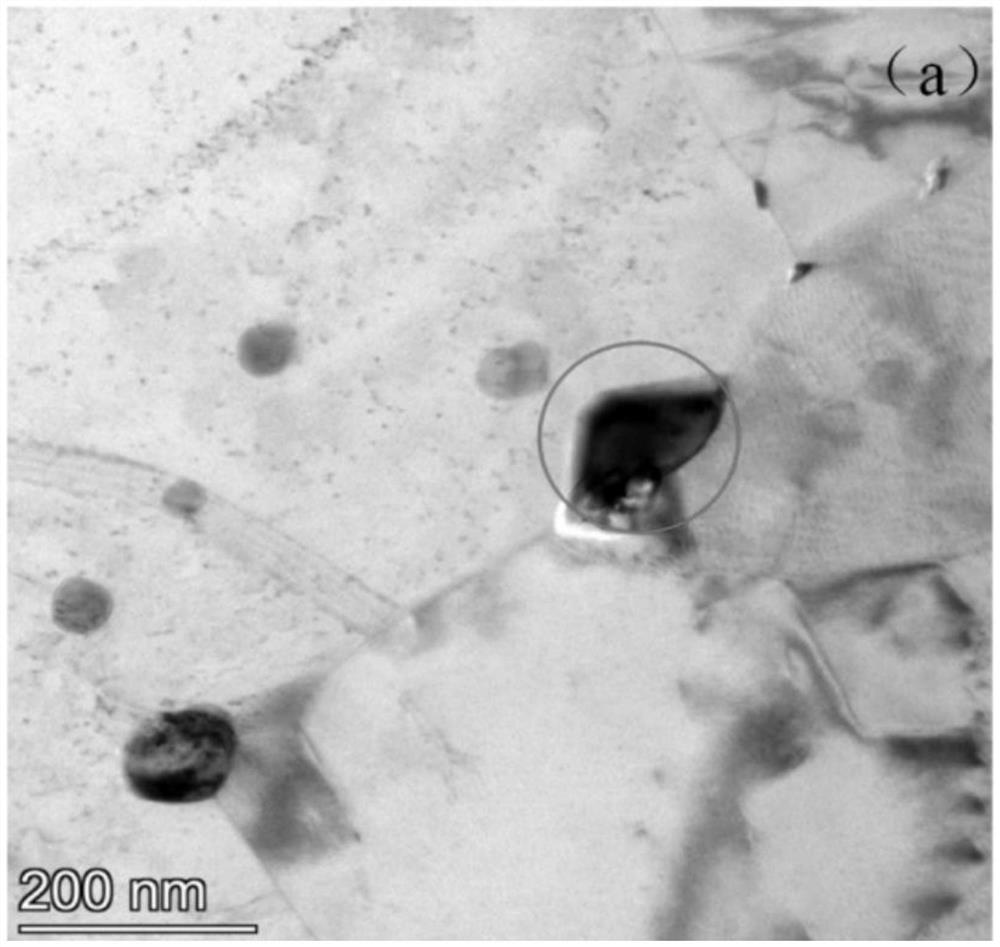

Cr-Ni austenitic heat-resistant steel with endogenous precipitated reinforcing phase and preparation method thereof

ActiveCN110952028AImprove antioxidant capacityImprove mechanical propertiesOxidation resistantAustenite

The invention relates to the technical field of metallurgy, in particular to Cr-Ni austenitic heat-resistant steel with an endogenous precipitated reinforced phase and a preparation method thereof. The Cr-Ni austenitic heat-resistant steel reinforced by TiC and / or TiB2 particles has a metal and ceramic two-phase structure, so that the mechanical property of the heat-resistant steel can be improved. Meanwhile, due to the reaction particle effect caused by TiC and / or TiB2, the high-temperature oxidation resistance of the heat-resistant steel is greatly improved. In the heat-resistant steel, thevolume fraction of the endogenous precipitated reinforcing phase is 1.2%-15.9%, uniform dispersion distribution of ceramic particles in a Cr-Ni austenitic heat-resistant steel matrix can be ensured, so that the high-temperature oxidation resistance of the Cr-Ni austenitic heat-resistant steel is greatly improved on the premise of lower Cr content.

Owner:GUANGDONG INST OF NEW MATERIALS

Ferrite martensite steel ladle shell material and preparation method thereof

InactiveCN112695256AImprove high temperature performanceImprove neutron radiation resistance performanceNuclear energy generationFurnace typesLead bismuthMachining deformation

The invention belongs to the technical field of fourth-generation lead bismuth cooling fast reactor structural materials, and particularly relates to a ferrite martensite steel ladle shell material and a preparation method thereof. The ferrite martensite steel ladle shell material comprises the components of 0.08wt%-0.16wt% of C, 0.30wt%- 0.8wt% of Mn, 0.50wt%-1.20wt% of Si, 8.5wt%-10.5wt% of Cr, 1.0wt%-2.5wt% of W, 0.10wt%-0.40wt% of V, 0.10wt%-0.40wt% of Ta, 0.005wt%-0.08wt% of Zr, 0.005wt%-0.05wt% of La, 0.008wt%-0.04wt% of N, and the balance Fe and impurities. The preparation method of the ferrite martensite steel ladle shell material comprises the following process steps of (1) smelting; (2) casting; (3) forging; (4) extruding; (5) pipe blank machining and heat treatment; (6) multi-pass cold rolling and intermediate heat treatment of the alloy; and (7) final heat treatment of the pipe. According to the ferrite martensite steel ladle shell material and the preparation method thereof, through the innovative component design, the optimized pipe machining deformation process and the heat treatment technology, the microstructure of the material is improved, grains are refined, and therefore the comprehensive performance of the alloy is improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Gear steel and heat treatment method thereof

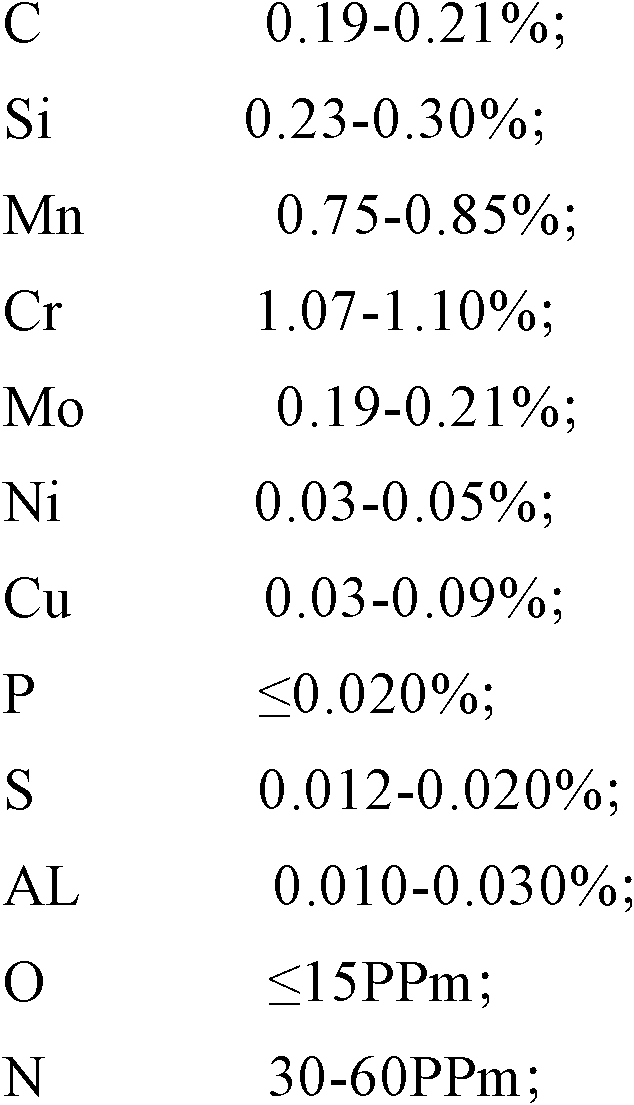

The invention provides gear steel and a heat treatment method thereof. The gear steel comprises the following constituents: 0.19 to 0.21 percent of C; 0.23 to 0.30 percent of Si; 0.75 to 0.85 percent of Mn; 1.07 to 1.10 Cr; 0.19 to 0.21 percent of Mo; 0.03 to 0.05 percent of Ni; 0.03 to 0.09 percent of Cu; 0.020 or less percent of P; 0.012 to 0.020 percent of S; 0.010 to 0.030 percent of Al; 15 or less PPm of O; 30 to 60 PPm of N; and Fe and other inevitable elements in balancing amount. The constituents of the gear steel are scientific and reasonable, the technical problems in the prior art are solved, the advantages of narrow hardenability band and high austenite grain size grade are achieved.

Owner:建龙北满特殊钢有限责任公司

Low-activation bainitic steel applicable to neutron-irradiated environment and preparation method thereof

The invention discloses low-activation bainitic steel applicable to a neutron-irradiated environment and a preparation method thereof. A structural steel material has a matrix element of an element Fe, contains 2.5 to 3.5 percent (by weight) of Cr, 2.2 to 2.8 percent (by weight) of W, 0.2 to 0.25 percent (by weight) of V, 0.12 to 0.18 percent (by weight) of Ta, 0.40 to 0.80 percent (by weight) of Mn, 0.40 to 0.45 percent (by weight) of Si, 0.08 to 0.12 percent (by weight) of C and 0.01 to 0.05 percent (by weight) of N, and is suitably used in a fusion-reactor environment. Radioactive nuclides Mo, Ni, Cu, Nb and the like, which can be enabled to have long service life after being subjected to neutron irradiation, are strictly controlled in the componential formula of the steel, so as to guarantee that the low-activation bainitic steel applicable to the neutron-irradiated environment has a low-activation characteristic. A bainitic structural steel material has a favorable high-temperature property, particularly has a high-temperature croop property, can need no heat treatment after being welded, and is suitable for making large-sized components of a fusion-reactor vacuum container and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

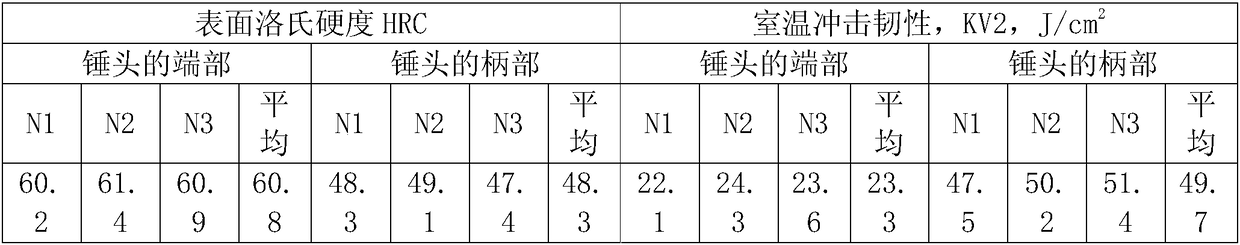

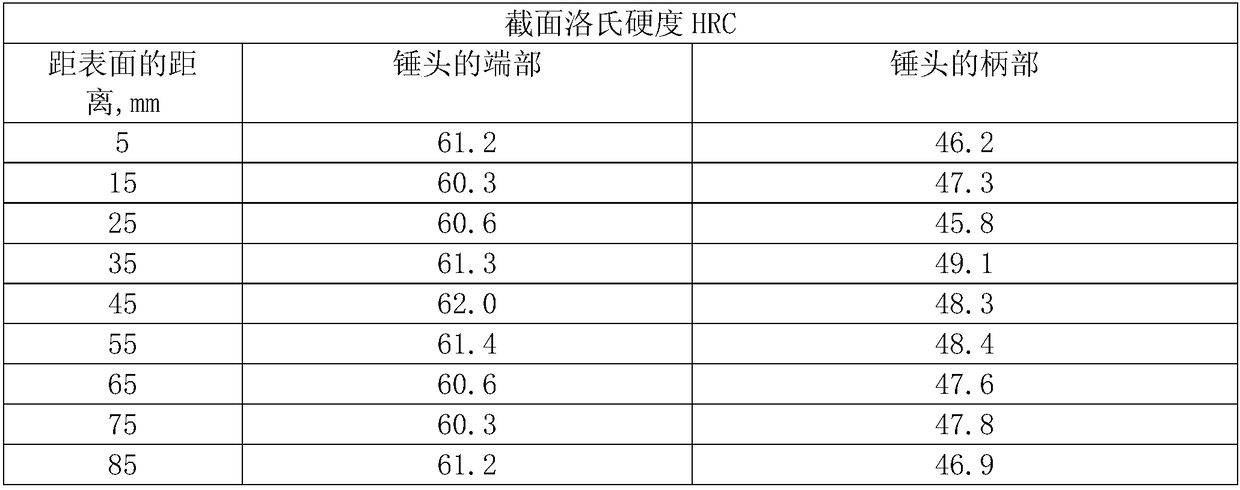

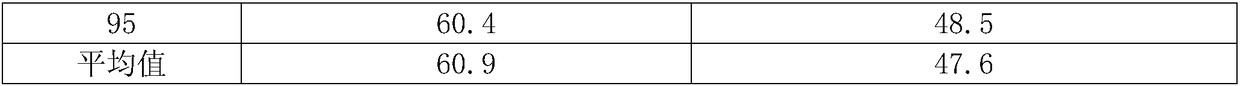

Low-cost and high-toughness heterogeneous alloy abrasion-resisting hammerhead and manufacturing method thereof

ActiveCN108546883AHigh hardnessImprove wear resistanceFurnace typesHeat treatment furnacesChemical compositionCompound (substance)

The invention relates to a low-cost and high-toughness heterogeneous alloy abrasion-resisting hammerhead and a manufacturing method thereof. The end part of the hammerhead comprises the chemical compositions of 1.50-1.70% of C, 0.30-0.45% of Si, 0.30-0.45% of Mn, no more than 0.020% of P, no more than 0.010% of S, 10.0-12.0% of Cr, 0.40-0.60% of Mo, 0.15-0.30% of V, and 0.01-0.03% of RE; and the handle part of the hammerhead comprises the chemical compositions of 0.26-0.32% of C, 0.30-0.40% of Si, 0.80-1.00% of Mn, no more than 0.020% of P, no more than 0.010% of S, 1.80-2.30% of Cr, 0.60-0.80% of Ni, and 0.40-0.50% of Mo. Compared with a high-chromium cast iron hammerhead, the life of the low-cost and high-toughness heterogeneous alloy abrasion-resisting hammerhead is prolonged by 1-3 times.

Owner:TANGSHAN DONGFANG HUASHENG GOOD WEAR RESISTING HIGH TECH

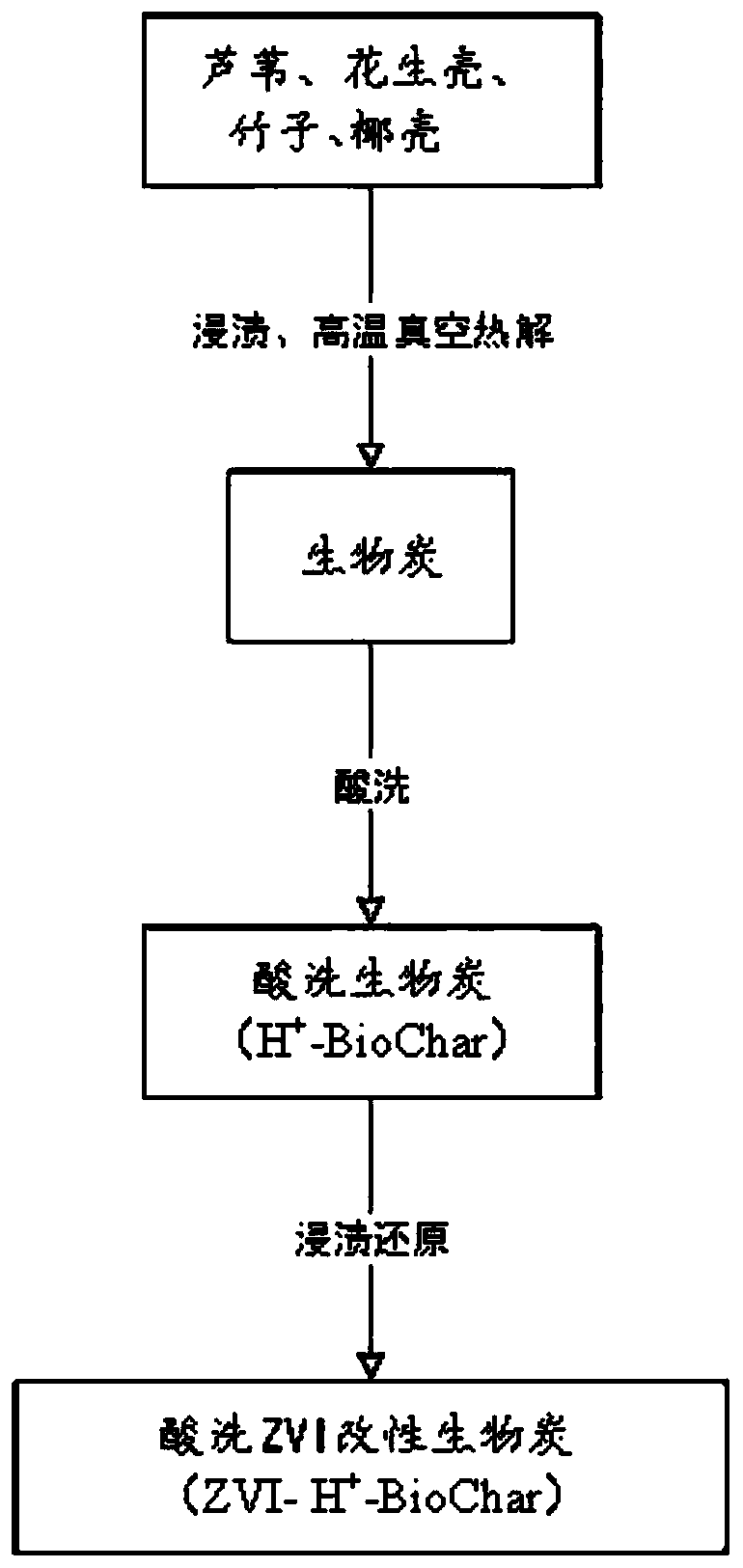

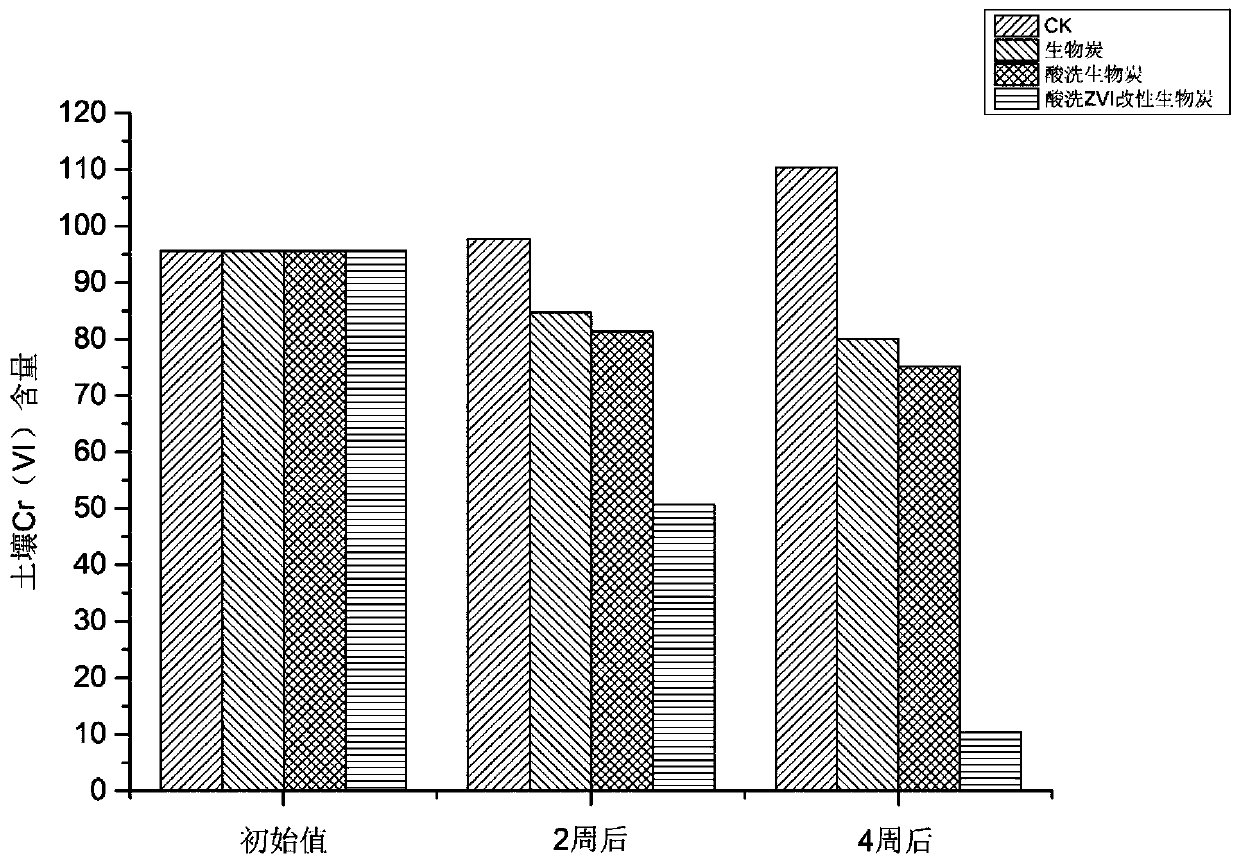

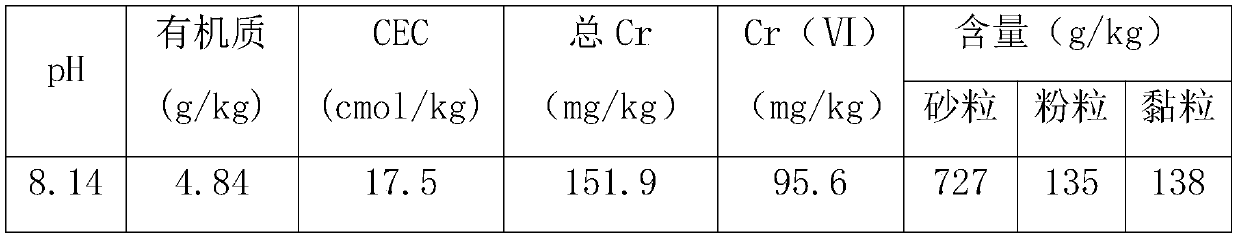

Preparation method and application of acid pickled ZVI (zero-valent iron) modified charcoal

ActiveCN110217775AReduced bioavailability and mobilityLarge specific surface areaCarbon preparation/purificationSoil-working methodsBiomassHeavy metals

The invention provides a preparation method and application of acid pickled ZVI (zero-valent iron) modified charcoal. The preparation method comprises the following steps: 1) crushing, grinding and drying a biomass raw material; 2) carrying out soaking treatment on the dried biomass into a blended soaking solution, and carrying out centrifugal dehydration drying; 3) putting charcoal into an acid solution, carrying out stirring at a uniform speed at the room temperature, and carrying out centrifugal dehydration drying so as to obtain acid pickled charcoal; 5) under protection of an argon environment, putting the acid pickled charcoal into an iron solution, carrying out stirring for 1 hour at the room temperature, and dropping a NaBH4 solution to carry out a reaction; and 6) after the reaction is completed, carrying out centrifugal dehydration drying, so as to obtain the acid pickled ZVI modified charcoal. The acid pickled ZVI modified charcoal prepared by using the preparation method has a remarkable repairing effect on heavy metal Cr (VI) polluted soil, is capable of effectively reducing the content of Cr (VI) in the soil, and in addition is capable of effectively degrading bio-availability and migration of chromium in the soil.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

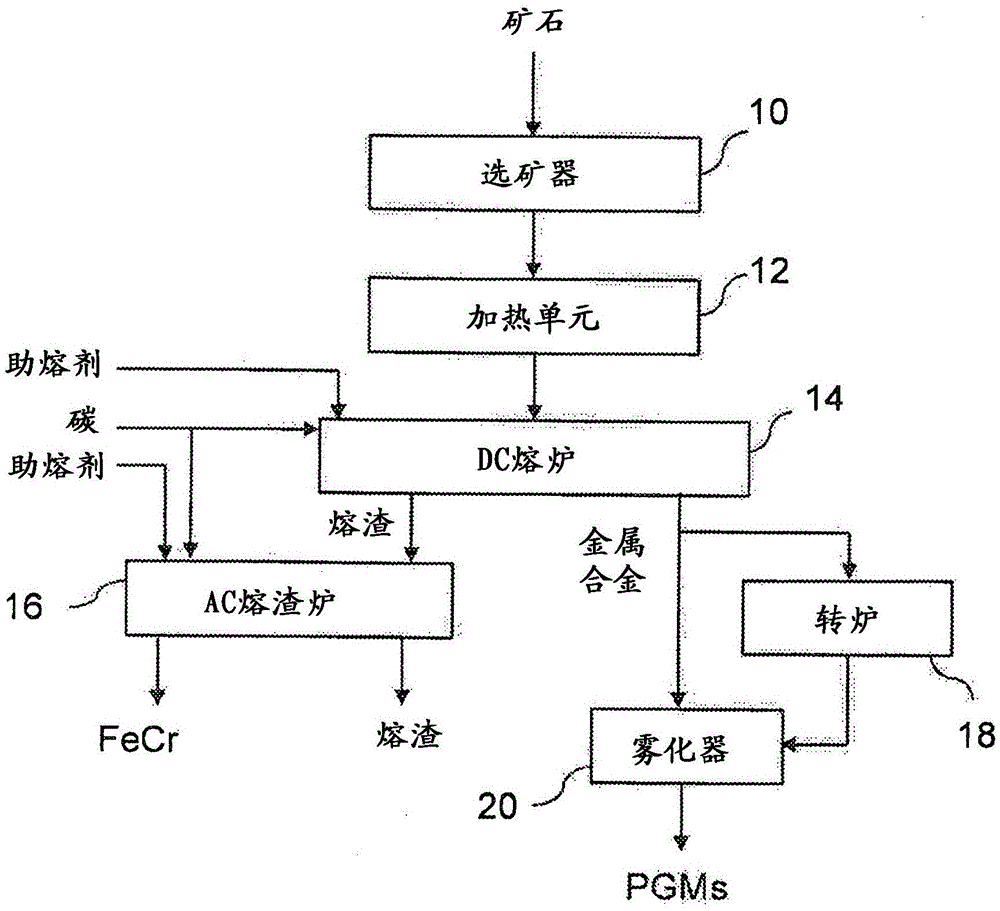

Method and apparatus for recovering PGM and ferro-chrome from PGM bearing chromite ore

InactiveCN105164285AMineral processing is easySave energyFurnace typesProcess efficiency improvementHydrometallurgyFerrochrome

In a method for recovering PGMs and ferrochrome from platinum group metals bearing chromite ore, a concentrate is prepared that contains most of PGMs and chromite of the ore and the concentrate is subjected to a heating step to dry and / or preheat the concentrate, after which the preheated concentrate is smelted under reducing conditions in a DC smelting furnace (14) to produce molten metal alloy containing the PGMs of the feed and molten slag containing the chromium of the feed. The molten slag is tapped from the smelting furnace (14) into an AC slag furnace (16), where iron and chromium are reduced to produce a ferrochrome alloy. PGMs are recovered from the metal alloy tapped from the smelting furnace (14) utilizing hydro-metallurgical processes.

Owner:OUTOTEC FINDLAND OY

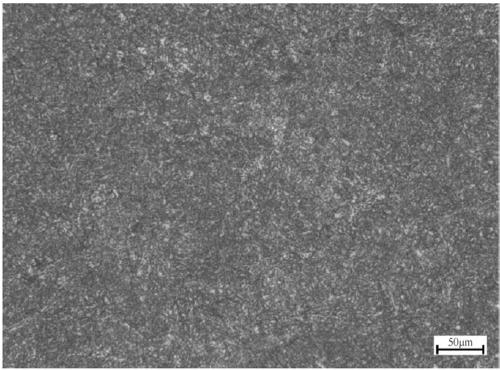

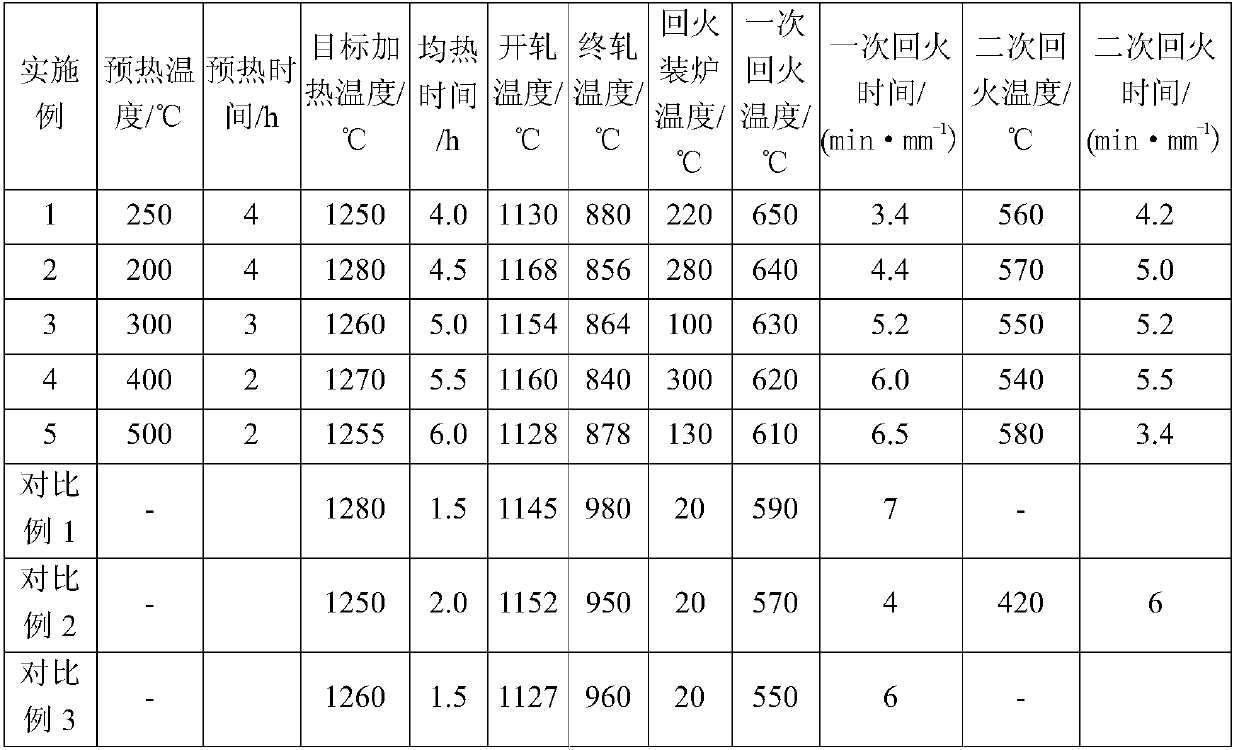

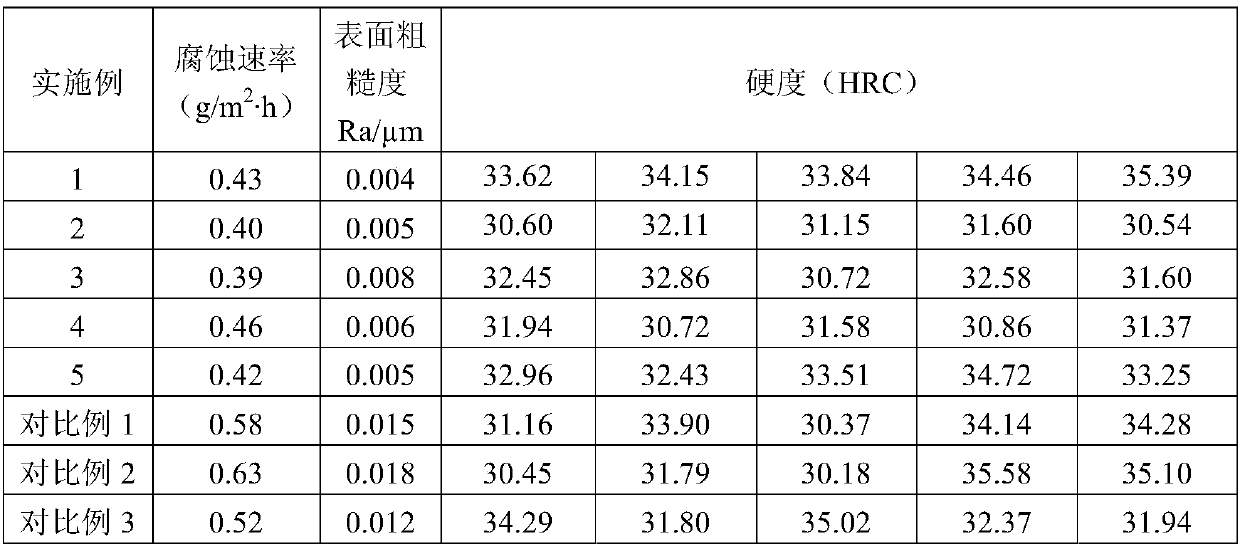

High mirror corrosion resistant plastic die steel and manufacturing method thereof

The invention discloses high mirror corrosion resistant plastic mold steel and a manufacturing method. The steel contains 0.32-0.46% of C, 0.4-1.2% of Si, 0.4-0.8% of Mn, P which is less than or equalto 0.020%, S which is less than or equal to 0.040%, 10.8-12.8% of Cr, 0.3-1.2% of Cu, 0.5-1.0% of Ni, 0.15-0.25% of Nb, and 0.01-0.03% of N, with the balance being Fe and inevitable impurities. A steel billet can be heated after being charged and preheated at 200-500 DEG C, the preheating time is greater than or equal to 2h, a heating temperature is 1,250-1,280 DEG C, the soaking time is 4-6 h, an initial rolling temperature is greater than or equal to 1,100 DEG C, and a finish rolling temperature is 840-880 DEG C; air cooling can be performed to 100-300 DEG C after rolling; the temperature of primary tempering is 610-650 DEG C, and the heat preservation time is 3.4-6.5 min / mm; the temperature of secondary tempering is 540-580 DEG C, and the heat preservation time is 3.4-5.5 min / mm. The produced die steel has excellent corrosion resistance and surface properties.

Owner:ANGANG STEEL CO LTD

Low-chromium low-carbon hardfacing flux-cored wire

InactiveCN106514060AHigh hardnessImprove wear resistanceWelding/cutting media/materialsSoldering mediaIron powderWollastonite

The invention discloses a low-chromium low-carbon hardfacing flux-cored wire which comprises a low-carbon steel skin and a flux core with which the low-carbon steel skin is filled. The flux core is prepared from, by weight, 15-20% of rutile, 3-7% of wollastonite, 2-4% of cryolite, 5-10% of low-carbon ferrochromium, 1-3% of sodium alga acid, 2-5% of white mica, 15-35% of alloying agent and the balance iron powder. The alloying agent is prepared from, by weight, 35-60% of Mn, 15-35% of Fe, 5-20% of Ca, 3-10% of Mg, 1-2.5% of Mo, 1-3% of W and 2-5% of Nb. According to the alloying agent prepared from the various kinds of alloy, the component ratio is reasonably set, the chromium content is lowered, meanwhile, high wear resistance and welding performance are ensured, the wear capacity is greatly lowered, the production cost is reduced, and practical production and using requirements are met.

Owner:天长市通联焊业有限公司

High-alloy wear-resisting casting iron and thermal treatment process thereof

InactiveCN101775534AIncrease the amount of controlControl the amount addedChemical compositionRoom temperature

The invention discloses high-alloy wear-resisting casting iron containing the following chemical compositions by weight percent: 2.4-2.8 percent of C, 10-18 percent of Cr, 3.0-4.0 percent of Mn, 0.3-0.4 percent of Al, 0.5-1.0 percent of Si, not more than 0.05 percent of P, not more than 0.03 percent of S and the balance of Fe. A thermal treatment process provided by the invention comprises the following steps of: filling workpieces required to be processed in a thermal treatment furnace at the room temperature and slowly heating; respectively preserving heat for 2h at the temperatures of 200 DEG C, 360 DEG C, 520 DEG C, 640 DEG C and 900 DEG; preserving the heat for 5-15 min until the quenching temperature is 1040-1060 DEG C when heating; and air cooling to the room temperature. The high-alloy wear-resisting casting iron greatly saves the production cost while ensuring the product performance and can be widely applied to manufacturing various wear-resisting products in mining industry, steel mill industry, power plant industry, steel tubing plant industry, ship building industry and the like.

Owner:HUNAN XINGLIANG WEAR RESISTANT NEW MATERIAL

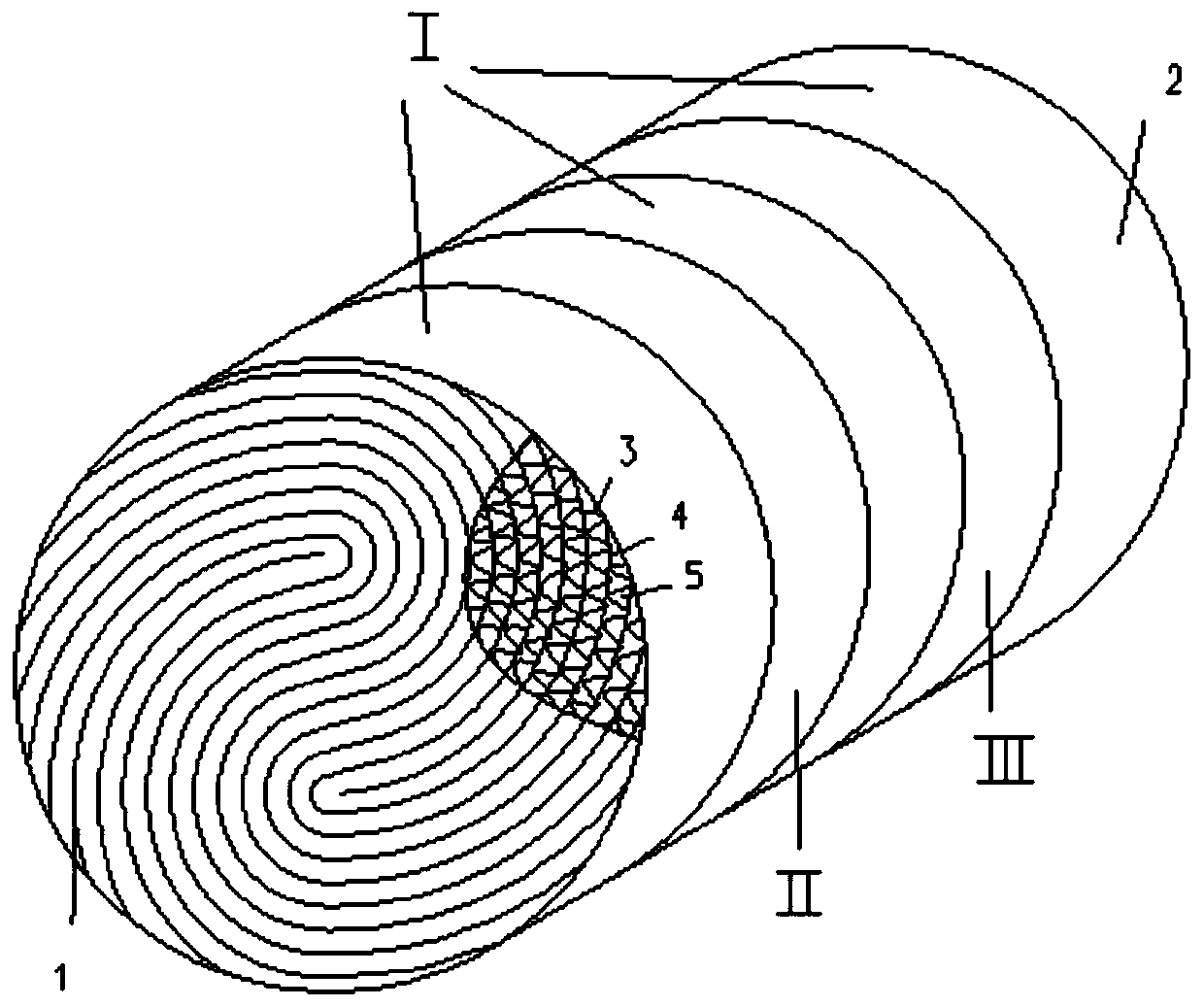

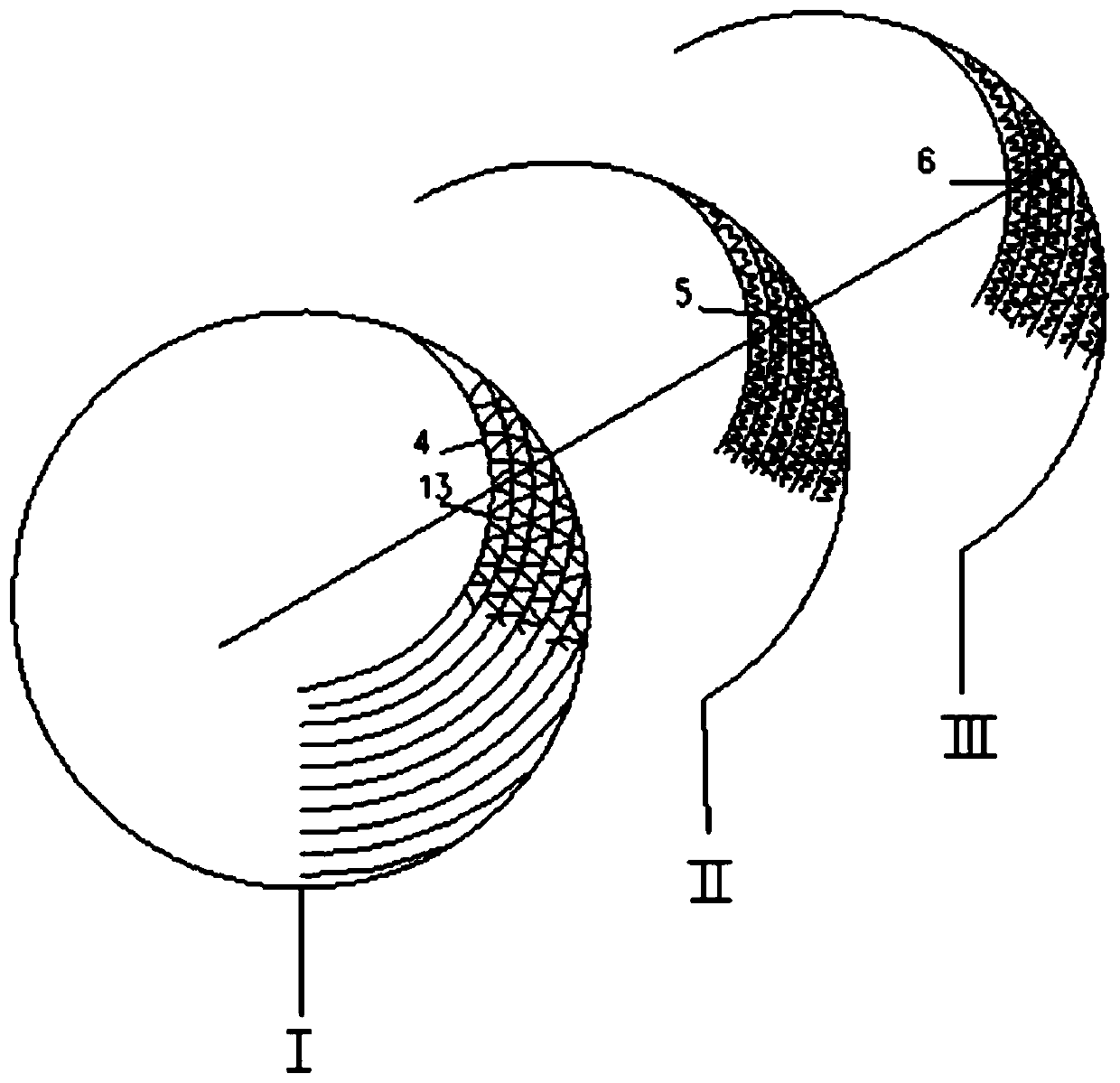

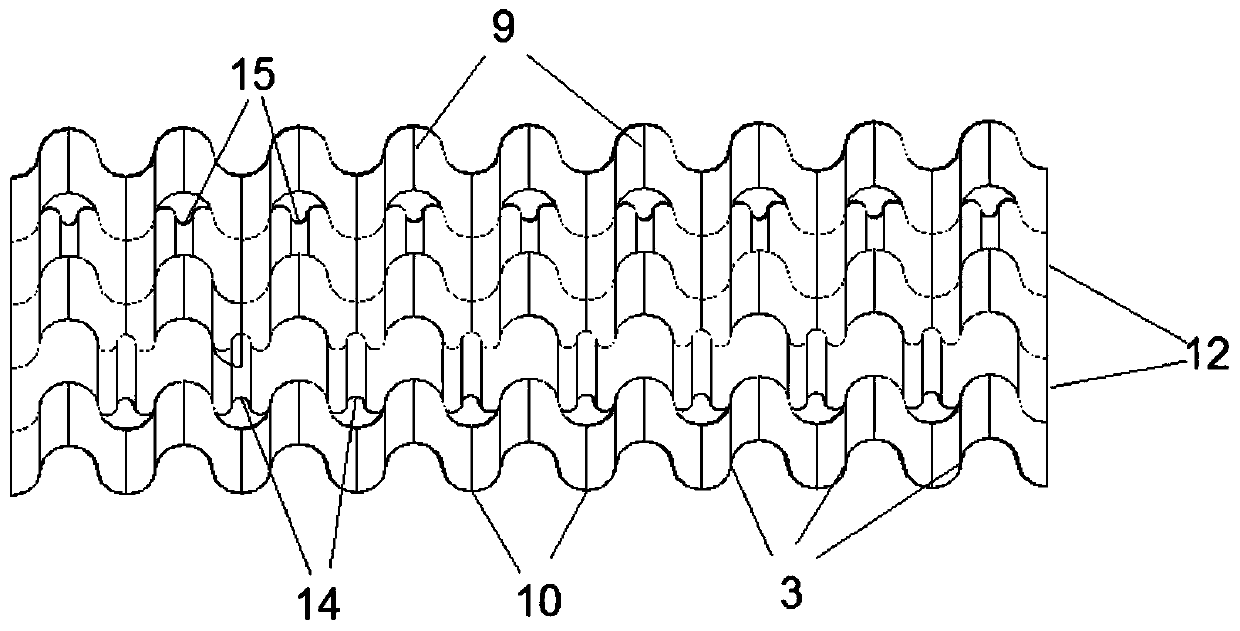

Integrated honeycomb carrier with multi-channel structure

PendingCN110318851ALow costImprove conversion efficiencyCatalyst carriersSilencing apparatusHoneycombLocal structure

The invention provides an integrated honeycomb carrier with a multi-channel structure. The integrated honeycomb carrier has an inflow side end face (1) and an outflow side end face (2) and having a plurality of channels flowing in one direction, is provides with a core body formed by at least one thin flat plate (4) arranged in a layered manner and at least one partially structured corrugated sheet (5), the structure of the corrugated sheet forms a hole wall in the flowing direction of the channel, the integral honeycomb carrier has a plurality of different sections (I, II and III) in the flowing direction, and corrugated sheets (3) with sinusoidal waveforms are arranged between the adjacent structured corrugated sheet at intervals. According to the integrated honeycomb carrier, the prepared catalyst device is more uniform in gas flow distribution in the tail gas purification process, and the utilization rate of the catalyst can be improved.

Owner:亿达天地环保技术股份有限公司

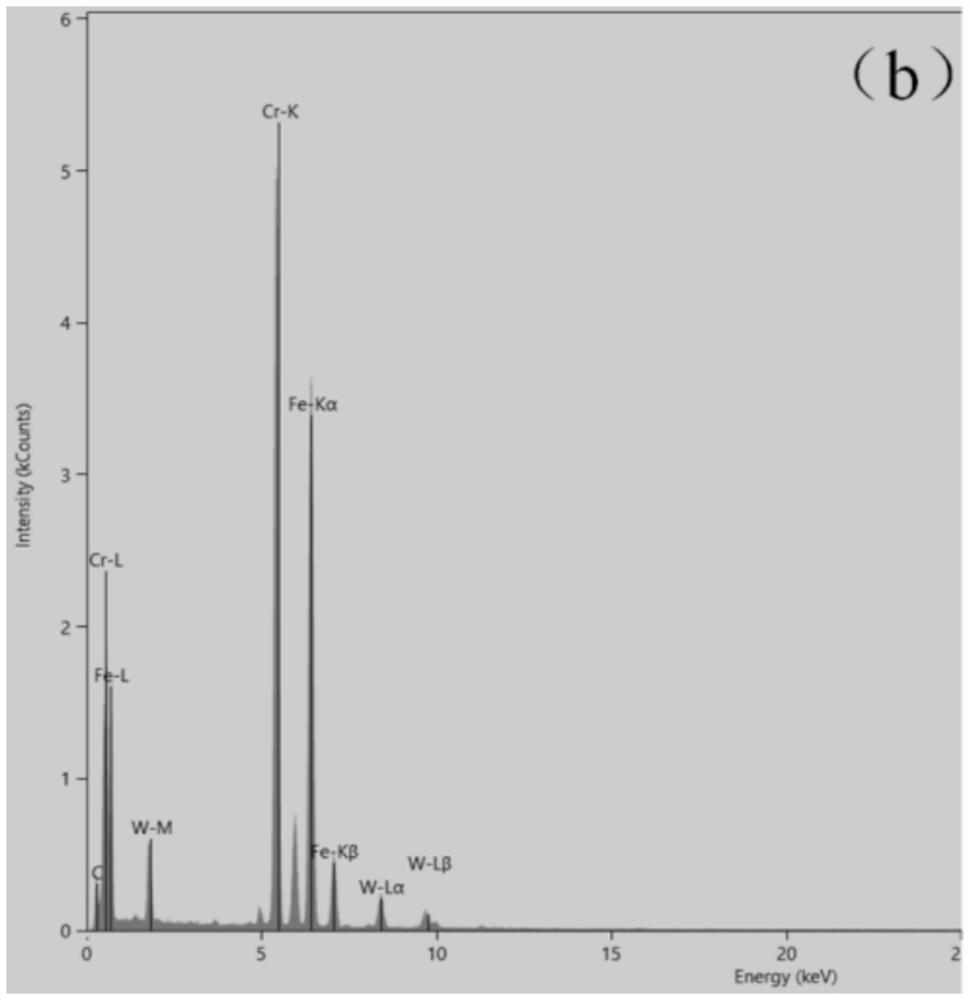

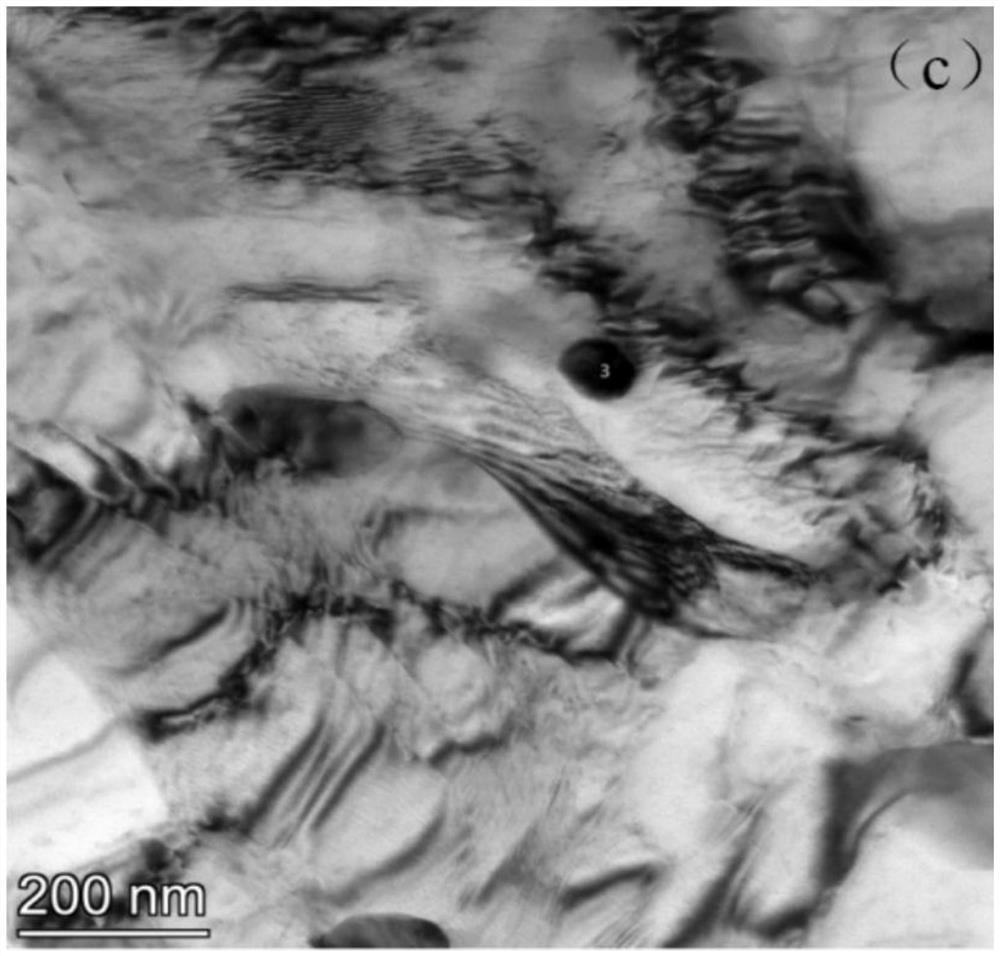

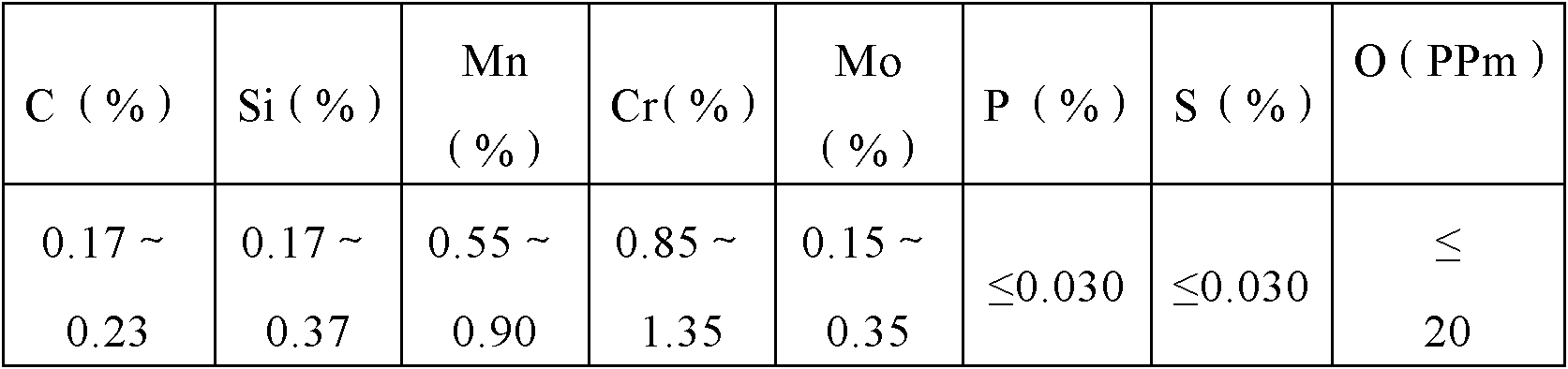

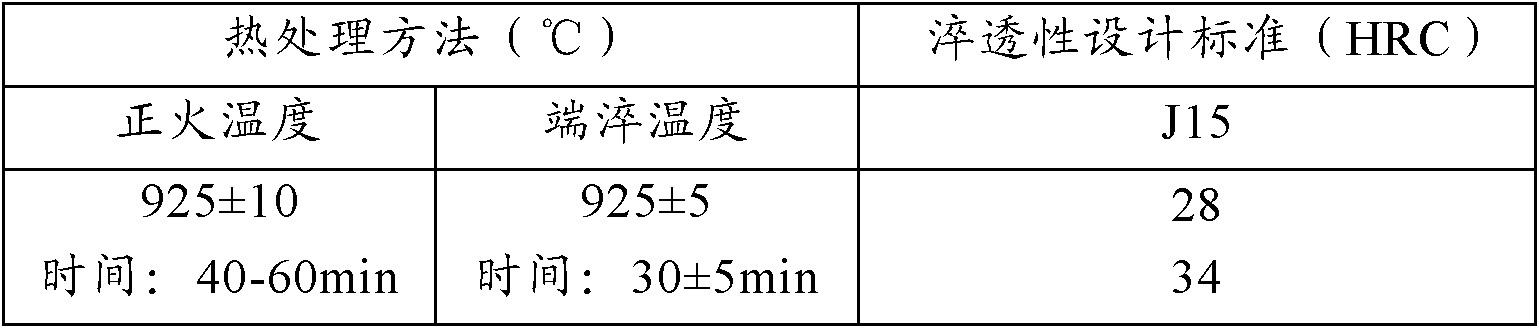

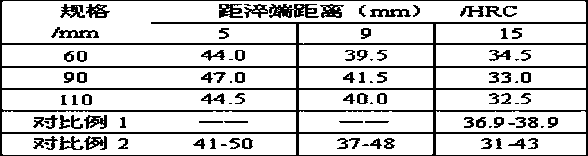

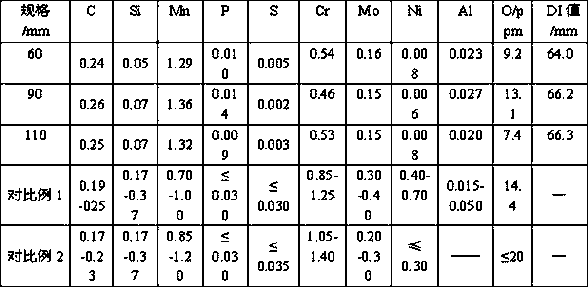

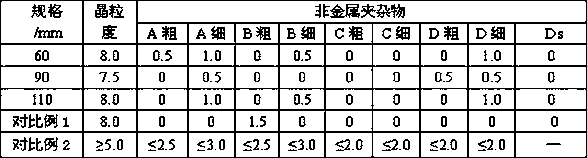

A crmo series gear round steel

The invention relates to a manufacturing method of CrMo gear round steel. The CrMo gear round steel is characterized by comprising the following components in percentage by weight: 0.22-0.27% of C, 0.03-0.12% of Si, 1.20-1.45% of Mn, S not more than 0.020%, P not more than 0.020%, 0.30-0.60% of Cr, Mo not more than 0.20%, 0.015-0.040% of Al, Ni not more than 0.10%, O not more than 15*10-6%, and the balance of Fe and inevitable impurities. A type and D type inclusions in the manufactured round steel are not higher than 1.5 grade; B type and C type inclusions are not higher than 1.0 grade; and the round steel has the following hardenability values: J5mm is 42-50 HRC; J9mm is 38-46 HRC; and J15mm is 32-40 HRC. The traditional technical thought of improving the steel hardenability by adding a lot of alloy elements as Cr, Ni and Mo is changed; the C and Mn contents are properly increased to largely reduce the content of Mo and the content of Cr; a Ni alloy is replaced; and under the precondition of not reducing the hardenability of gear steel, the product production cost is largely reduced, and the product competitiveness is improved.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

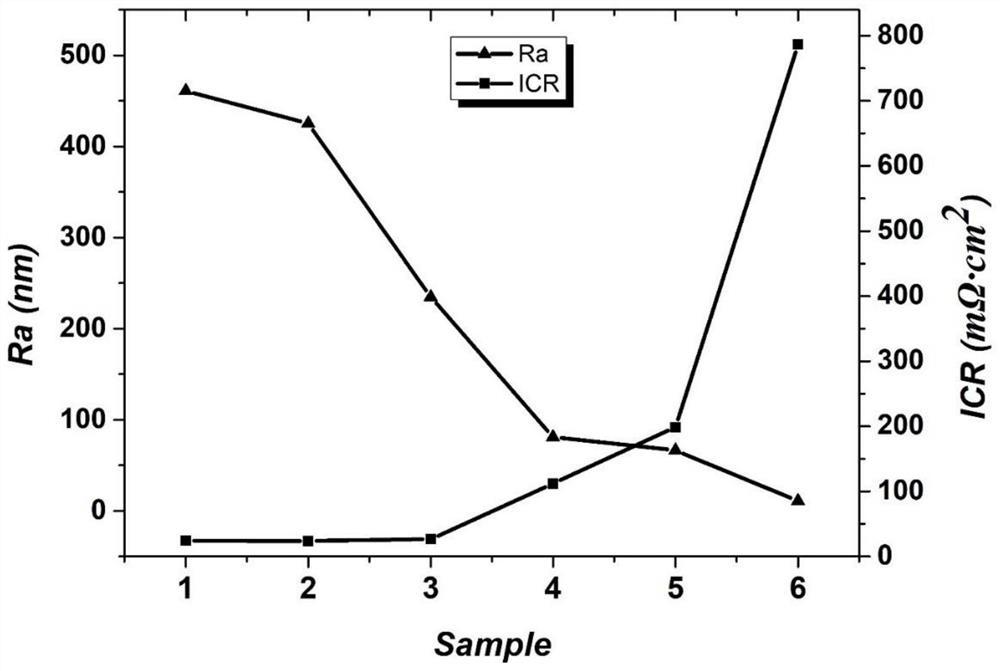

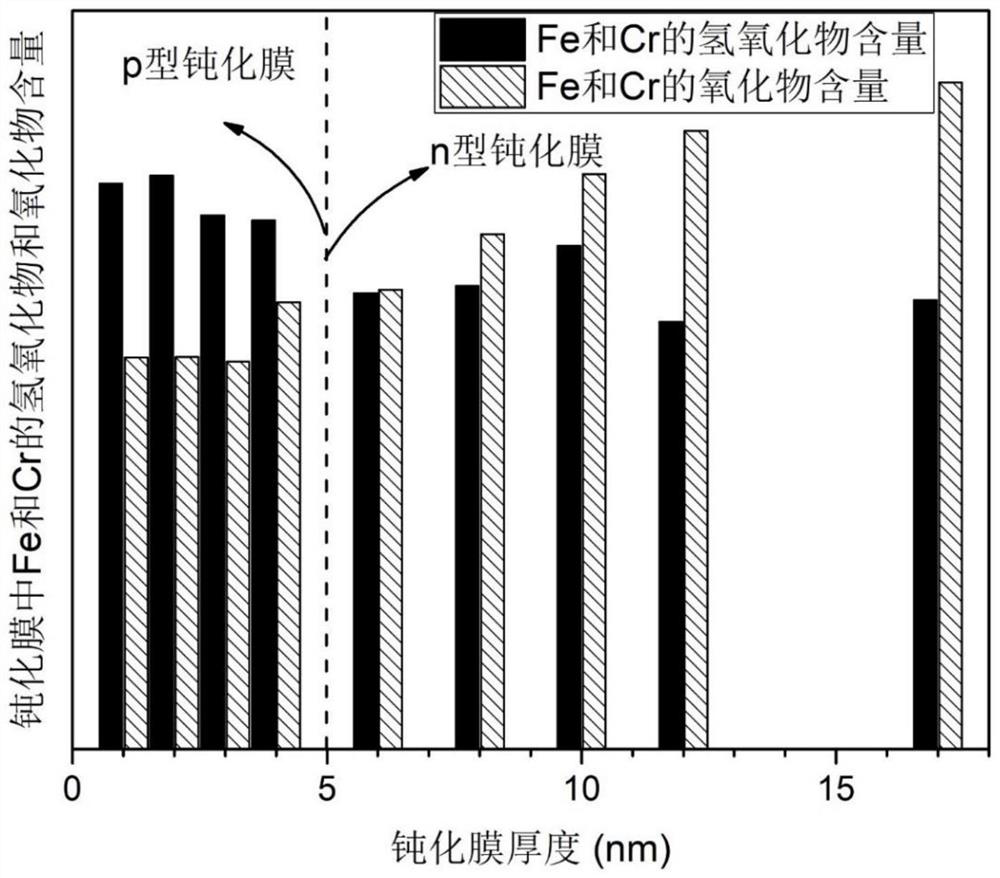

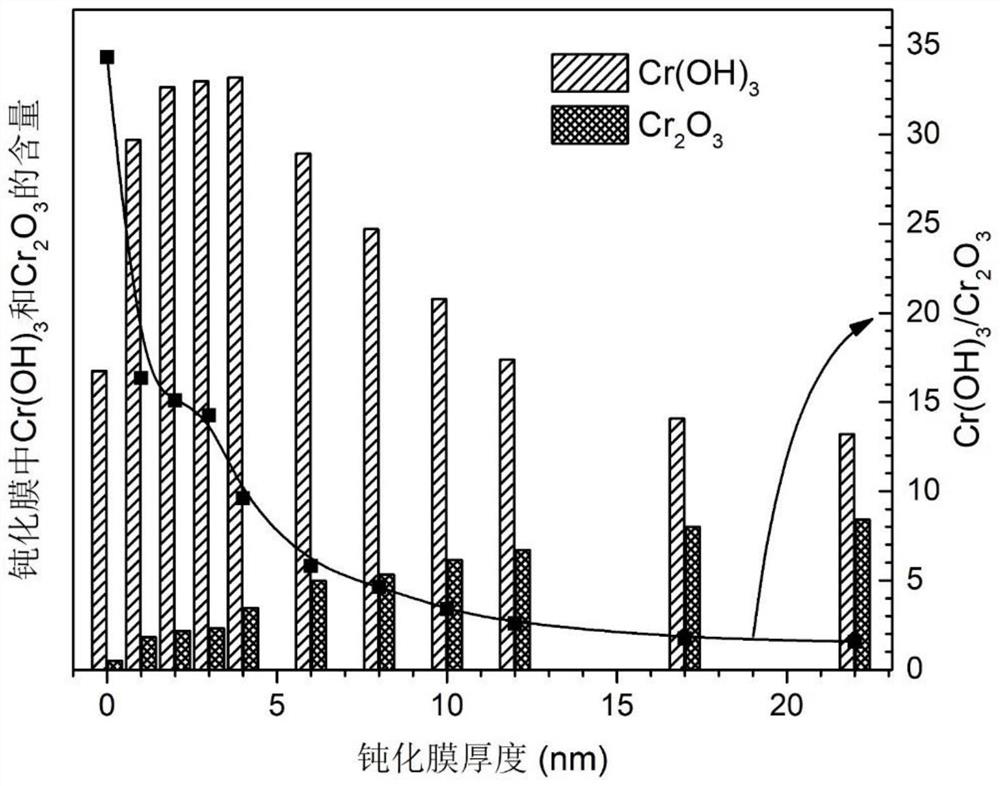

Ferritic stainless steel for fuel cell bipolar plate, method for regulating and controlling surface roughness, method for forming passive film and application

ActiveCN114574759AReduce Cr contentImprove conductivityAnodisationCollectors/separatorsFuel cellsSurface roughness

The invention discloses ferritic stainless steel for a bipolar plate of a fuel cell, a surface roughness regulation and control method, a method for forming a passive film and application of the ferritic stainless steel. The ferritic stainless steel comprises 0.03 wt% or less of C, 0.02 wt% or less of N, 0.4 wt% or less of Si, 0.5 wt% or less of Mn, 16-23 wt% of Cr, 0-2.0 wt% of Cu, 1.8-2.5 wt% of Mo, 0.2-2.0 wt% of Ni, 0.1-0.5 wt% of Ti, 0.005-0.5 wt% of Nb, 0.02 wt% or less of P, 0.02 wt% or less of S and the balance Fe and other unavoidable elements, and the grain size of the ferritic stainless steel is grade 4-9. The aluminum alloy has good corrosion resistance, conductivity, ductility and deformability, and has the advantages of economical efficiency and cost at the same time.

Owner:山东产研先进材料研究院有限公司 +1

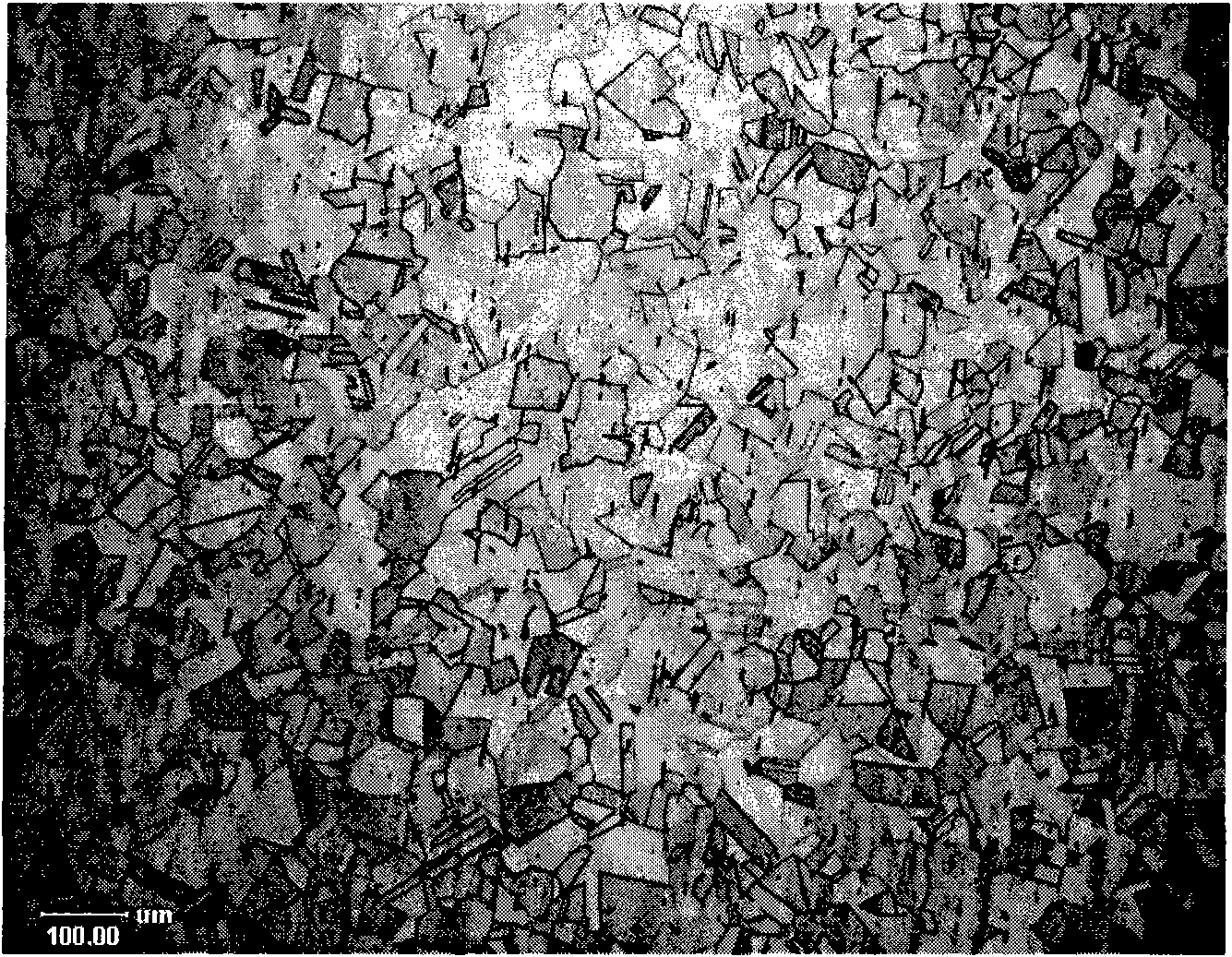

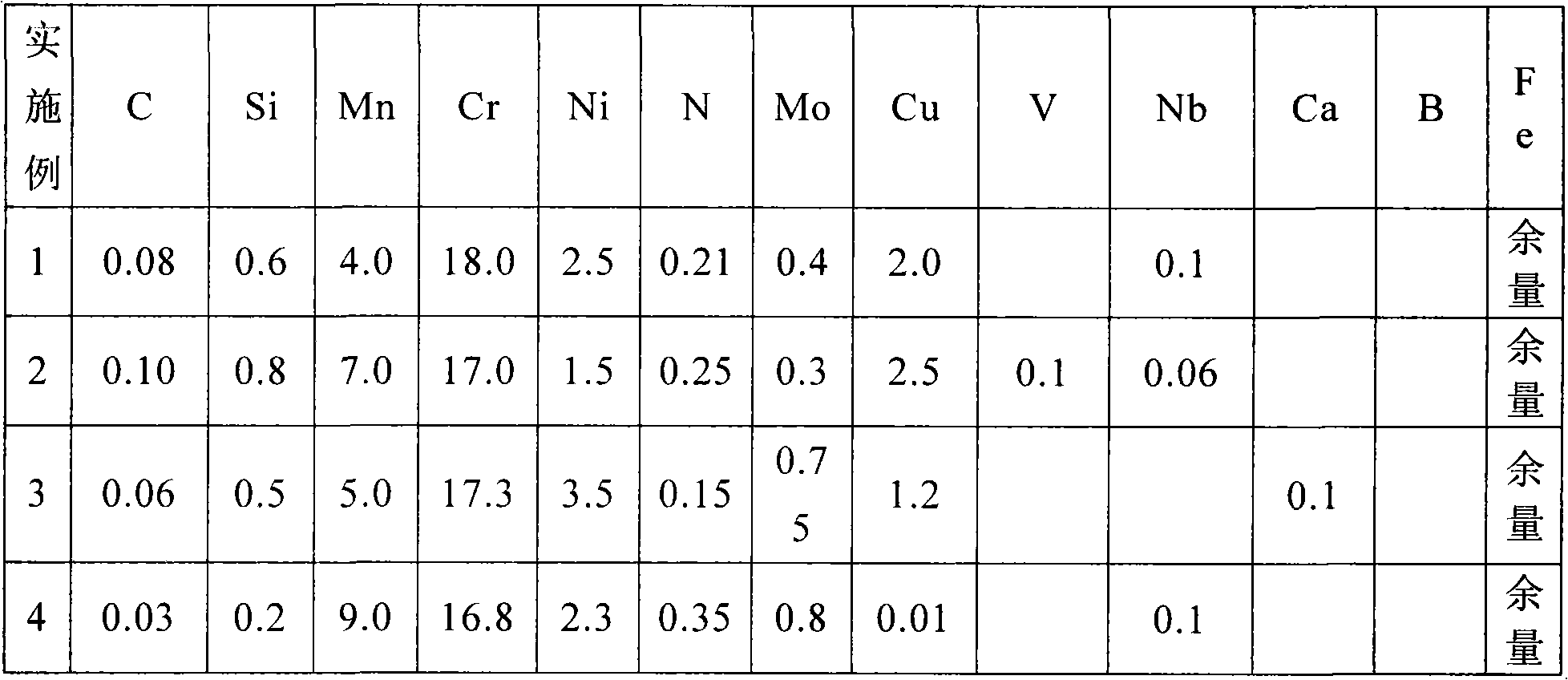

Molybdenum-containing nickel-saving austenitic stainless steel with excellent corrosion resistance and manufacturing method thereof

ActiveCN102337481BLow costReduced corrosion resistancePitting resistance equivalent numberChemical composition

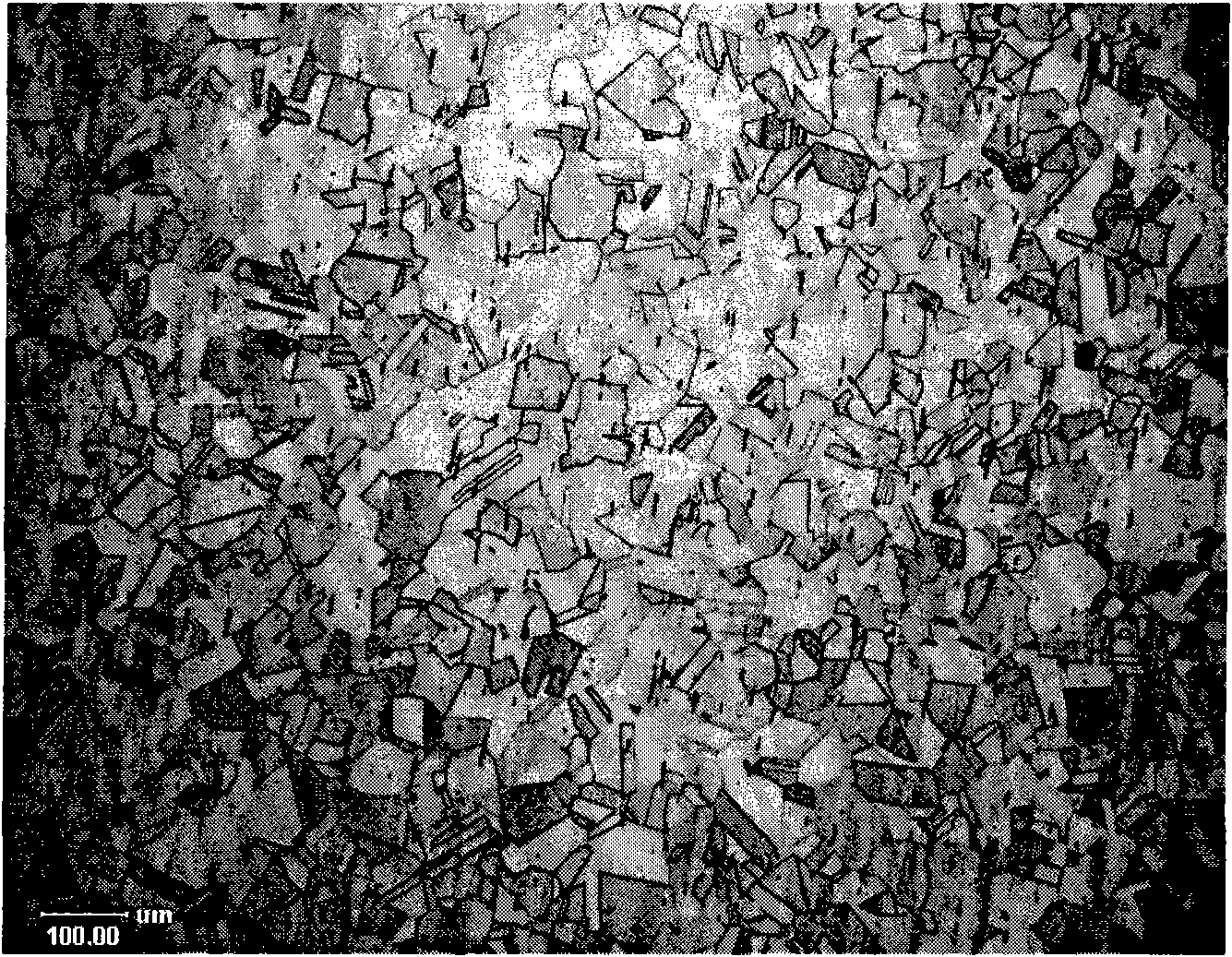

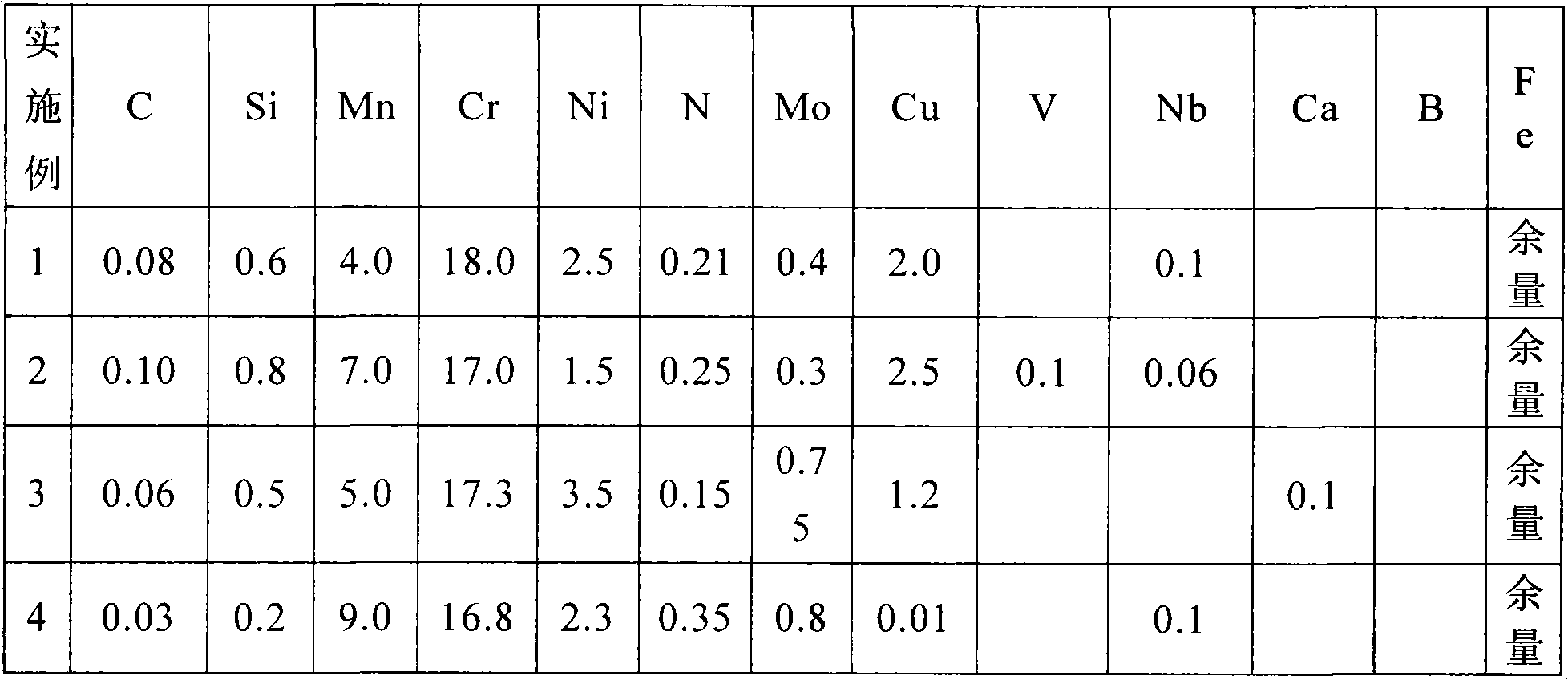

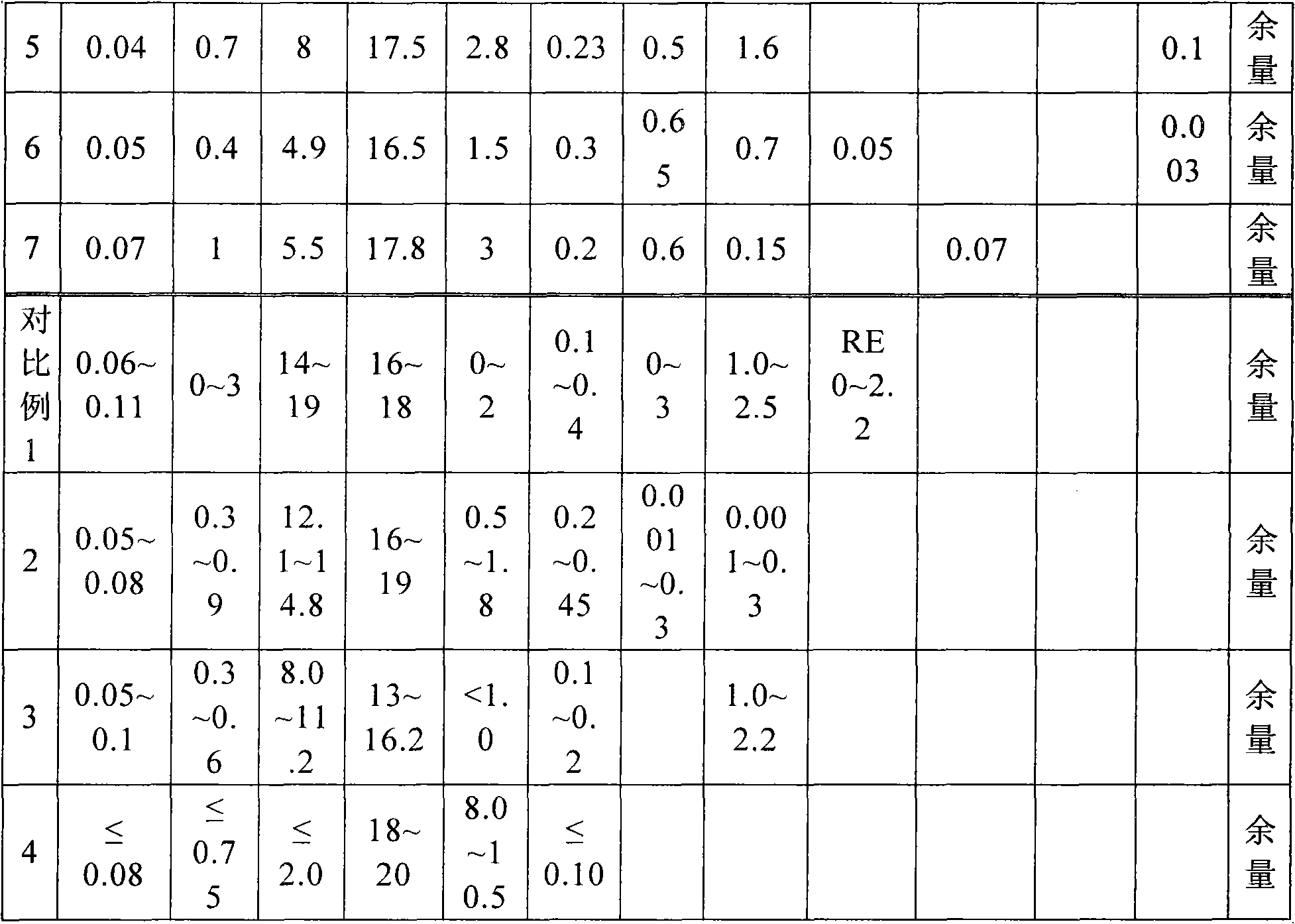

The invention discloses molybdenum-containing nickel-saving austenitic stainless steel with excellent corrosion resistance and a manufacturing method thereof. The molybdenum-containing nickel-saving austenitic stainless steel with excellent corrosion resistance contains: by weight, 0.03 to 0.10% of C, 0.2 to 1.0% of Si, 4.0 to 9.0% of Mn, 16.5 to 18.0% of Cr, 1.5 to 3.5% of Ni, 0.15 to 0.35% of N, 0.2 to 0.8% of Mo, 0.01 to 2.5% of Cu, less than or equal to 0.1% of one or more of V, Nb, Ca and B, and the balance Fe and unavoidable impurities. Through the manufacturing method, Ni content is controlled in a rang of 1.5 to 3.5%, and Mn and N elements are added to replace precious metal Ni to be utilized for austenitizing, so that a microstructure of room-temperature austenite is obtained. The manufacturing method adopts 0.2 to 0.8% of Mo and utilizes a synergistic effect of Cr, Mo and N to improve corrosion resistance. Through the manufacturing method, the pitting-resistance equivalent number of the molybdenum-containing nickel-saving austenitic stainless steel with excellent corrosion resistance is great than or equal to 18 and the pitting potential is great than or equal to 330mV, wherein the properties of the molybdenum-containing nickel-saving austenitic stainless steel with excellent corrosion resistance are equivalent to or superior to corresponding properties of 304 austenitic stainless steel.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

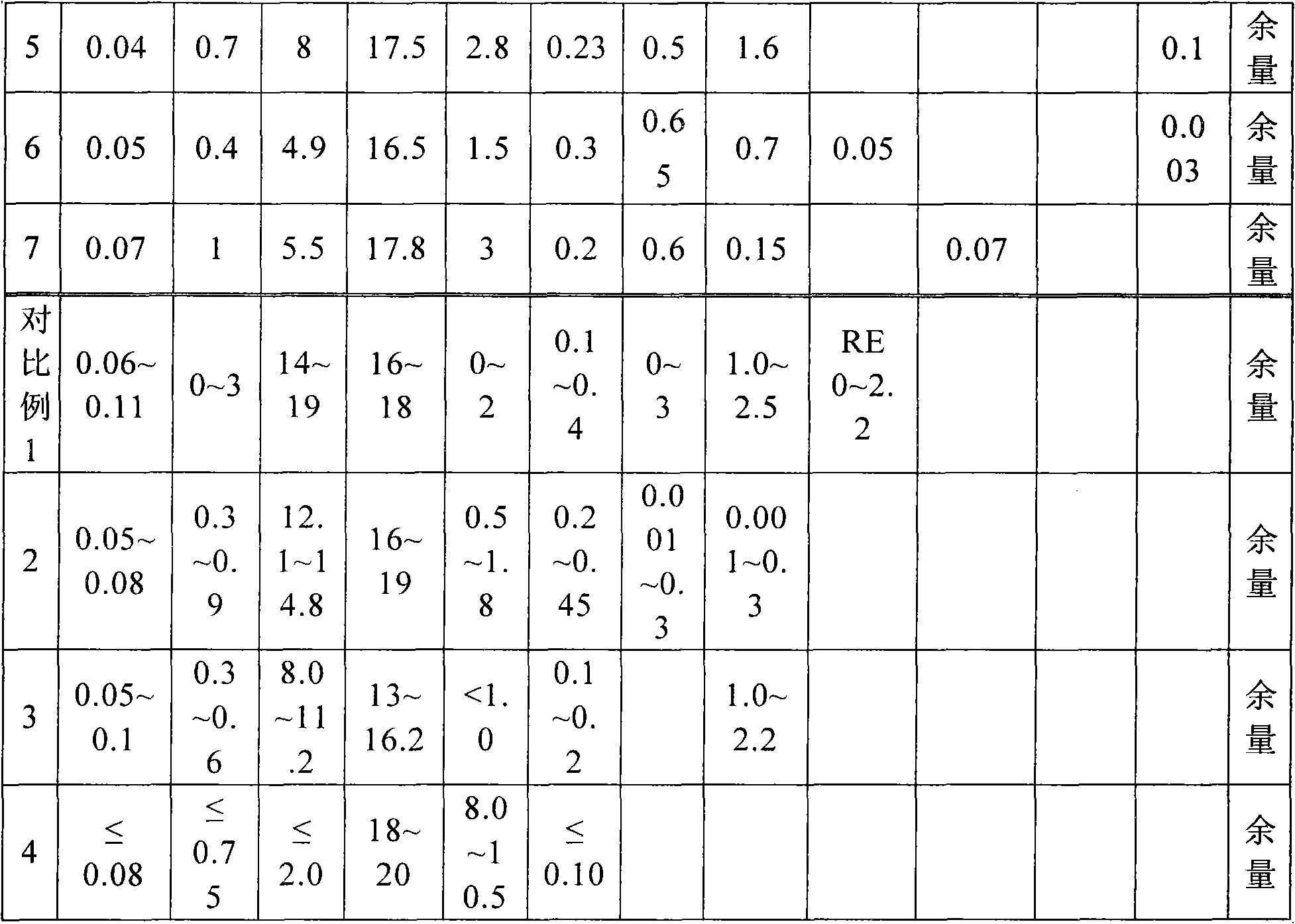

Low-carbon alkane dehydrogenation process

ActiveCN107488093AReduce Cr contentLong one-way operation cycleCatalystsHydrocarbon preparation catalystsAlkaneMethanation

The present invention discloses a low-carbon alkane dehydrogenation process, which is performed under a hydrogen present condition, and uses a bifunctional catalyst capable of catalyzing a dehydrogenation reaction and a methanation reaction between deposited carbon and H2, wherein the bifunctional catalyst contains Cr2O3, K2O, one or a plurality of elemental M selected from Fe, Co, Ni and Cu, and Al2O3. According to the present invention, with the method, the dynamic balance between the carbon generation and the carbon digestion in the low-carbon alkane dehydrogenation process can be achieved so as to substantially improve the single-pass life of the catalyst.

Owner:PETROCHINA CO LTD

High-hardness high-carbon medium-chromium wear-resistant cast iron and preparation method thereof

The invention relates to high-hardness high-carbon medium-chromium wear-resistant cast iron and a preparation method thereof. According to the technical solution, the high-hardness high-carbon medium-chromium wear-resistant cast iron comprises the following chemical components of, in percentage by weight, 3.61wt%-3.99wt% of C, 12.11wt%-14.99wt% of Cr, 0.51wt%-0.79wt% of Si, 0.61wt%-0.89wt% of Mn,1.71wt%-1.99wt% of Mo, 0.31wt%-0.39wt% of B, 0.51wt%- 0.89wt% of Zr, less than or equal to 0.049wt% of P, less than or equal to 0.049wt% of S, the balance Fe and the inevitable impurities, wherein Cr / C is greater than or equal to 3.35 and less than or equal to 3.99, and B / Mo is greater than or equal to 0.15 and less than or equal to 0.23, burdening is conducted according to the chemical componentsand the contents thereof, smelting, pouring, air-cooling to room temperature, and polishing are conducted; and heating is conducted to 850-1050 DEG C, the temperature is kept for 1-3 hours, quenchinginto oil is conducted, and cooling is conducted to the room temperature to obtain the high-hardness high-carbon medium-chromium wear-resistant cast iron. The high-hardness high-carbon medium-chromiumwear-resistant cast iron and the preparation method thereof have the characteristics of low production cost, simple preparation method and short production period, and a prepared product has good toughness and hardness is significantly improved.

Owner:WUHAN UNIV OF SCI & TECH +1

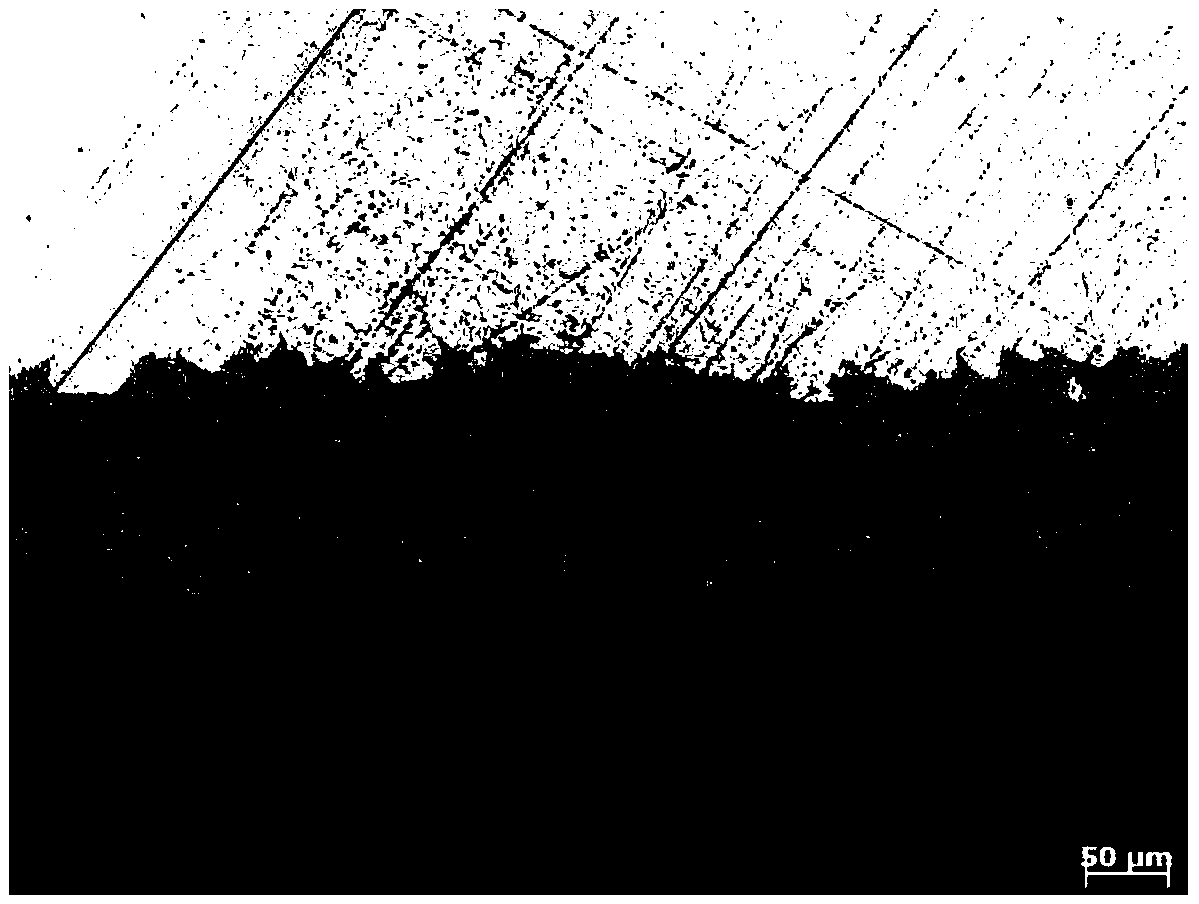

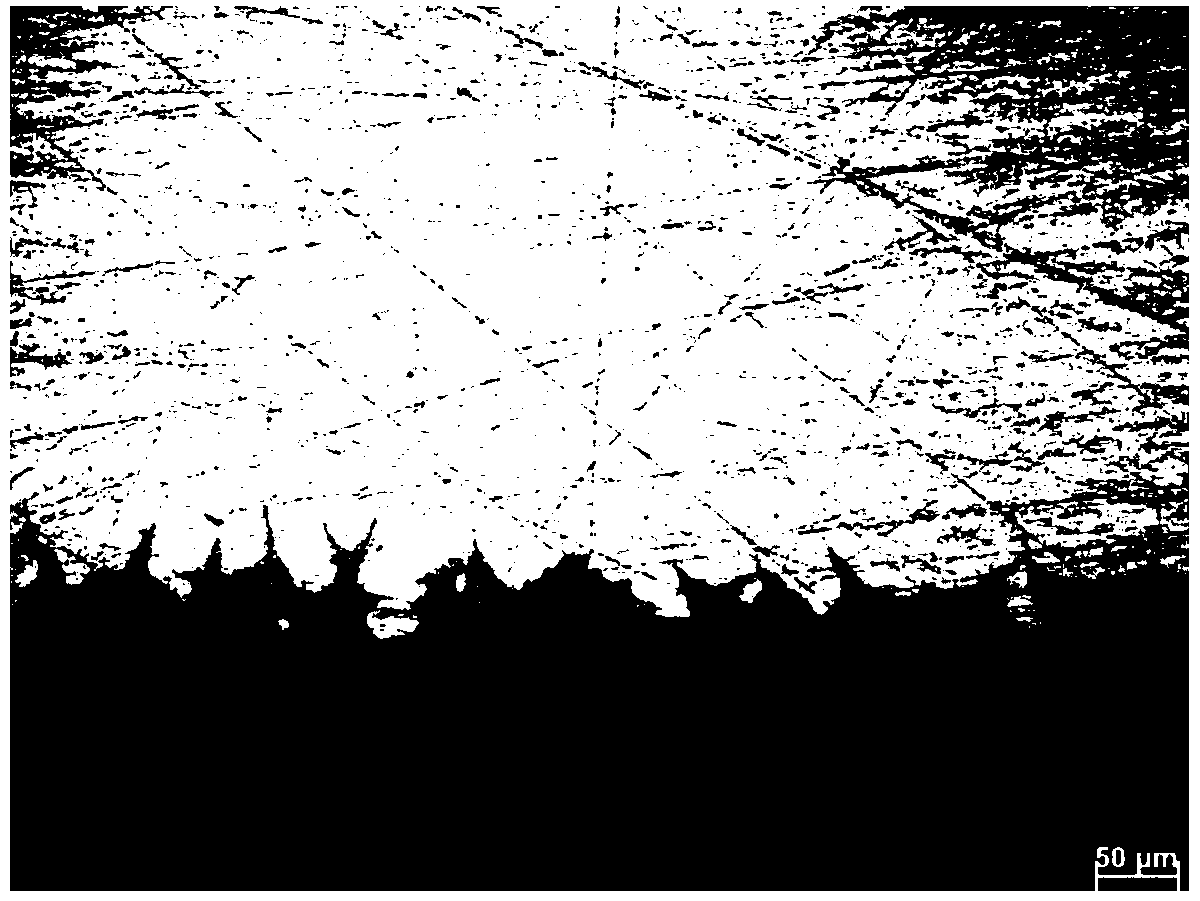

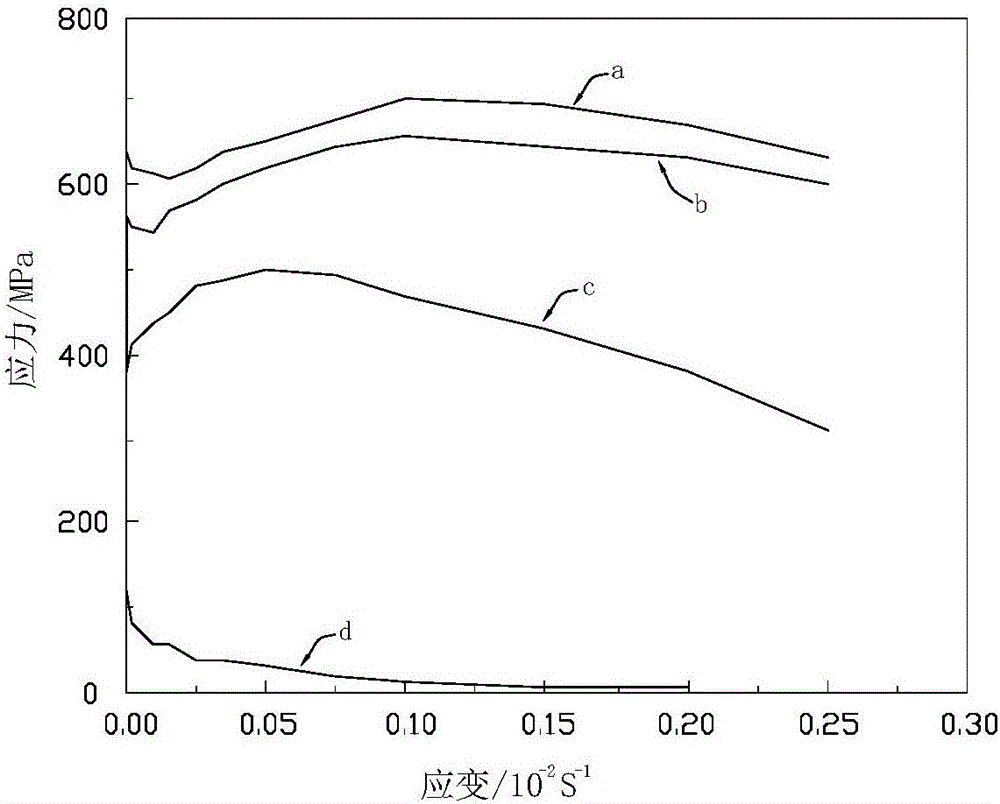

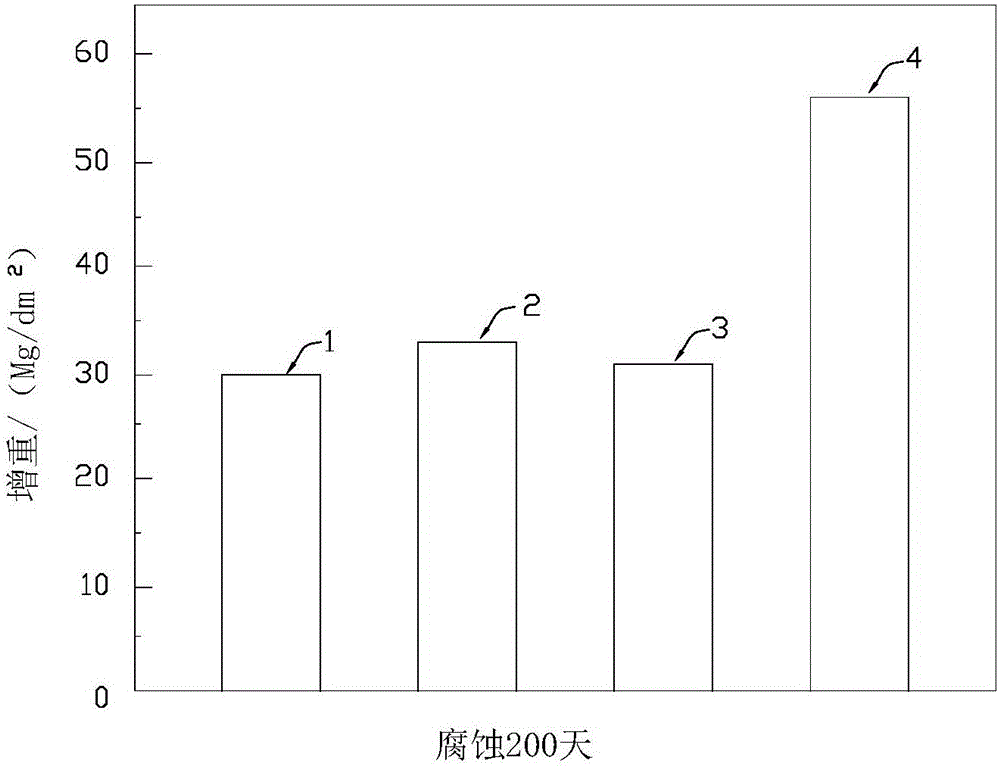

Economical long-perforation-service-life top for seamless steel pipe and manufacturing method of top

ActiveCN110616364ALow costImprove bindingMandrelsSolid state diffusion coatingChemical compositionMetallurgy

The invention relates to an economical long-perforation-service-life top for a seamless steel pipe and a manufacturing method of the top. The chemical components of the top are prepared from, by mass,0.15-0.25% of C, 0.20-0.50% of Si, 0.60-1.60% of Mn, 0.50-1.00% of Cr, 2.80-3.20% of Ni, 0.20-0.40% of Mo and the balance Fe and other unavoidable impurities. The surface of the top is generated witha layer of oxidation film, the thickness of the oxidation film is 80-200 microns, and metal particles with rich Ni are dispersed in the oxidation film. The oxidation film and a substrate are bound ina canine tooth staggering mode, the canine tooth density of the top is higher than that of a traditional top, it is sufficiently explained that the binding force of the oxidation film and the substrate is high, and therefore the oxidation film does not easily fall off in the top perforation process. The perforation service life of the top is greatly prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD

Stainless steel elastomer material for weighing sensor

The invention discloses a stainless steel elastomer material for a weighing sensor. The tainless steel elastomer material comprises the following components in percentage by mass: 0.09 percent of C, 1.35 percent of Si, 0.035 percent of P, 0.030 percent of S, 1.00 percent of Mn, 15.0-17.0 percent of Cr, 4.50-8.00 percent of Ni, 3.50-5.50 percent of Cu, 0.15-0.45 percent of Nb and the balance of Fe. Stainless steel is high in mechanical performance after heat treatment, the hardness can reach HRC 42-47, the ultimate strength can reach 135 kg / mm<2>, the coefficient of linear expansion is 11.1x10<-6>m / DEG C; therefore, the stainless steel elastomer material is equivalent to the commonly-used alloy steel 40CrNiMoA.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Stainless steel alloy, preparation method thereof and stainless steel cladding of fuel assembly

The invention discloses stainless steel alloy, a preparation method of the stainless steel alloy and a stainless steel cladding of a fuel assembly. The stainless steel alloy comprises, by mass, 8%-18% of chromium, 4%-8% of aluminum, 0.1%-1% of niobium, 0.1%-4% of molybdenum, 0.1%-2% of titanium, 0.01%-2% of silicon, 0.1%-2% of zirconium, 0.05%-2% of tungsten, 0.005%-1% of yttrium and the balance Fe. According to the stainless steel alloy, under the synergistic effect of the microelements like Cr, Nb and Mo, the Cr content is lowered, the brittle phase is restrained, the machining property of the stainless steel alloy is improved, and the corrosion resistance, high-temperature mechanical property and ductility of the stainless steel alloy are also improved. By limiting the carbon and nitrogen contents of impurities in the stainless steel alloy, the effective Cr content in a solid solution is increased; and moreover, formed carbide and nitride are beneficial to grain refinement, and the strength and plasticity of manufactured tubes are improved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

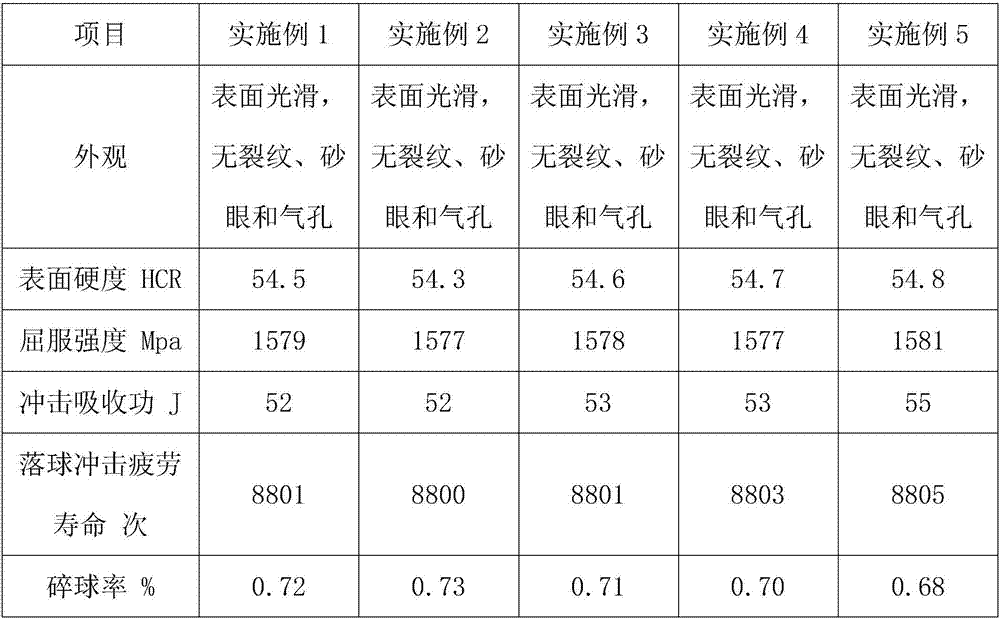

High-hardness low-carbon bearing steel ball

InactiveCN107012405APromote precipitationImprove stabilitySolid state diffusion coatingFurnace typesSteel ballUltimate tensile strength

The invention discloses a high-hardness low-carbon bearing steel ball. The high-hardness low-carbon bearing steel ball comprises the following components by weight percent: 0.1% to 0.2% of C, 13% to 14% of Cr, 1% to 1.5% of W, 3% to 4% of Co, 0.22% to 0.28% of V, 0.3% to 0.4% of Si, 0.1% to 0.3% of Mn, 0.2% to 0.3% of Ni, 0.006% to 0.008% of B, 0.015% or less of S, 0.015% or less of P, and Mo, and the balance being Fe, wherein Mo weight percent equals to Ni weight percent * (Co weight percent-W weight percent)* 100. The high-hardness low-carbon bearing steel ball is high in hardness, high in strength, good in toughness and good in fatigue resistance.

Owner:芜湖市永帆精密模具科技有限公司

Stainless steel strip for electronic device shells

Owner:WUXI FANGZHENG METAL LIGATURE

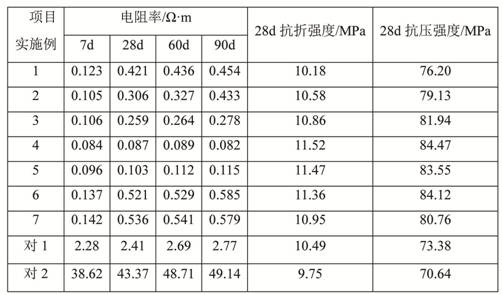

High-conductivity composite grounding material and preparation method thereof

The invention belongs to the technical field of power transmission, and particularly relates to a high-conductivity composite grounding material and a preparation method thereof. The high-conductivity composite grounding material is prepared from the following raw materials in parts by weight: 100 parts of a gel material, 90-110 parts of aggregate fine sand, 30-50 parts of water, 0.3-0.8 part of a water reducing agent, 0.5-1.0 part of a defoaming agent, 0.5-1.0 part of a dispersing agent, 1-2 parts of stainless steel fibers and 0.1-0.5 part of carbon fibers. According to the high-conductivity composite grounding material, stainless steel fibers and carbon fibers are adopted as composite conductive phase materials, the two conductive phase materials are complementary in performance, hydroxypropyl methyl cellulose is adopted as a dispersing agent, and the grounding effect of a grounding grid is remarkably improved.

Owner:国网河南省电力公司直流中心 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com