Low-alloy-steel welding rod for welding of maritime work rack steel Q690

A technology of low-alloy steel and rack steel, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc. It can solve the problems of insufficient impact energy margin, unstable welding process arc, and high strength, and achieve slag removal Good performance, smooth electrode surface and excellent welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the embodiment of the present invention, a low-alloy steel electrode used for welding marine rack steel Q690 is composed of a welding core and a coating.

[0032] Take the powder of each component of the drug skin: 400g of marble, 190g of fluorite, 40g of silicon micropowder, 35g of rutile, 100g of iron powder, 5g of CMC, 5g of soda ash, 6.5g of alginate, 86g of a mixture of manganese alloy, chromium alloy and molybdenum alloy, nickel Powder 60g.

[0033] After mixing the above powders evenly, add 190g of potassium sodium water glass with a concentration of 42°, stir and mix evenly, send it into the bar press and wrap it on the high-quality solder core with low S and P content according to the conventional method, and then pass Baking at a low temperature of 95°C for 2 hours and a high temperature of 360°C for 1.5 hours, the low-alloy steel electrode is obtained.

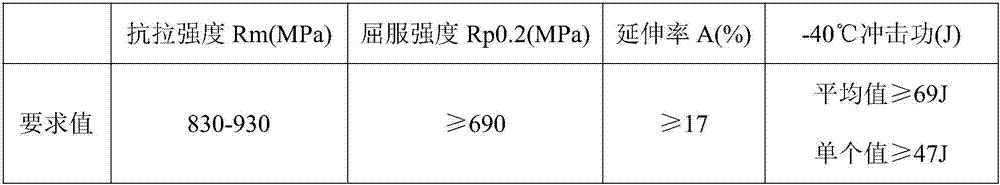

[0034] Adopt 155-165A current, adopt the test plate whose base material is Q345B with a plate thicknes...

Embodiment 2

[0042] In the embodiment of the present invention, a low-alloy steel electrode used for welding marine rack steel Q690 is composed of a welding core and a coating.

[0043] Get the powder of each component of the drug skin: 480g of marble, 160g of fluorite, 30g of silicon micropowder, 50g of rutile, 80g of iron powder, 6g of CMC, 6g of soda ash, 6g of alginate, 79g of manganese, chromium and molybdenum alloy mixture, and 64g of nickel powder.

[0044]After mixing the above powders evenly, add 210g of potassium sodium water glass with a concentration of 42°, stir and mix evenly, send it into the bar press and wrap it on the high-quality solder core with low S and P content according to the conventional method, and then pass Baking at a low temperature of 95°C for 2 hours and a high temperature of 360°C for 1.5 hours, the low-alloy steel electrode is obtained.

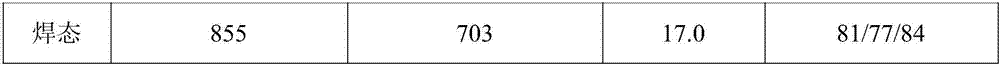

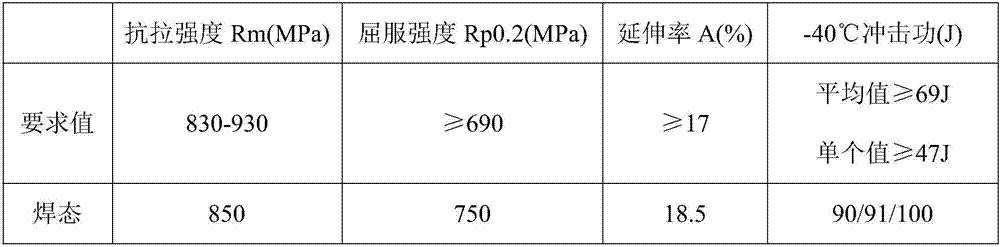

[0045] Adopt 155-165A current, adopt the test plate whose base material is Q345B with a plate thickness of 20mm, the g...

Embodiment 3

[0052] In the embodiment of the present invention, a low-alloy steel electrode used for welding marine rack steel Q690 is composed of a welding core and a coating.

[0053] Get each component powder of the drug skin: marble 450g, fluorite 220g, silicon micropowder 30g, rutile 40g, iron powder 60g, CMC 4g, soda ash 6g, alginate 6g, manganese, chromium, molybdenum alloy mixture 85g, nickel powder 66g.

[0054] After mixing the above powders evenly, add 230g of potassium sodium water glass with a concentration of 42°, stir and mix evenly, send it into the bar press and wrap it on the high-quality solder core with low S and P content according to the conventional method, and then pass Baking at a low temperature of 95°C for 2 hours and a high temperature of 360°C for 1.5 hours, the low-alloy steel electrode is obtained.

[0055] Adopt 155-165A current, adopt the test plate whose base material is Q345B with a plate thickness of 20mm, the groove of the test plate is 10°, and the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com