Steel plate ingot casting device and method for producing ultra-thick steel plate cast ingot with same

A technology for casting ingots and steel plates, which is applied in the field of steel plate ingot casting devices, can solve the problems of shrinkage cavities, segregation of microstructure and components, coarse crystal grains, and high mold cost, and achieves large performance margin, high microstructure and grain size, and solidification time. the effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

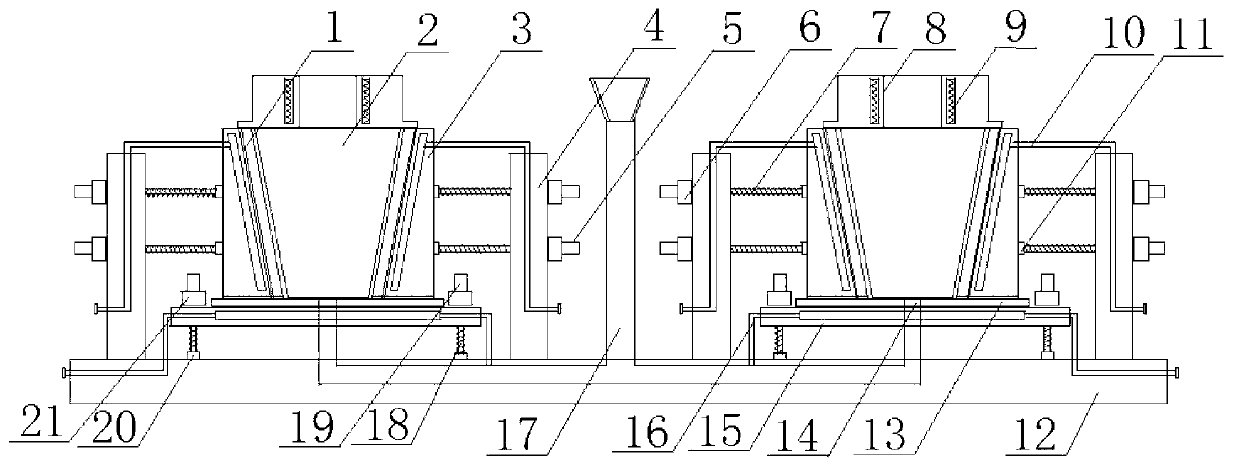

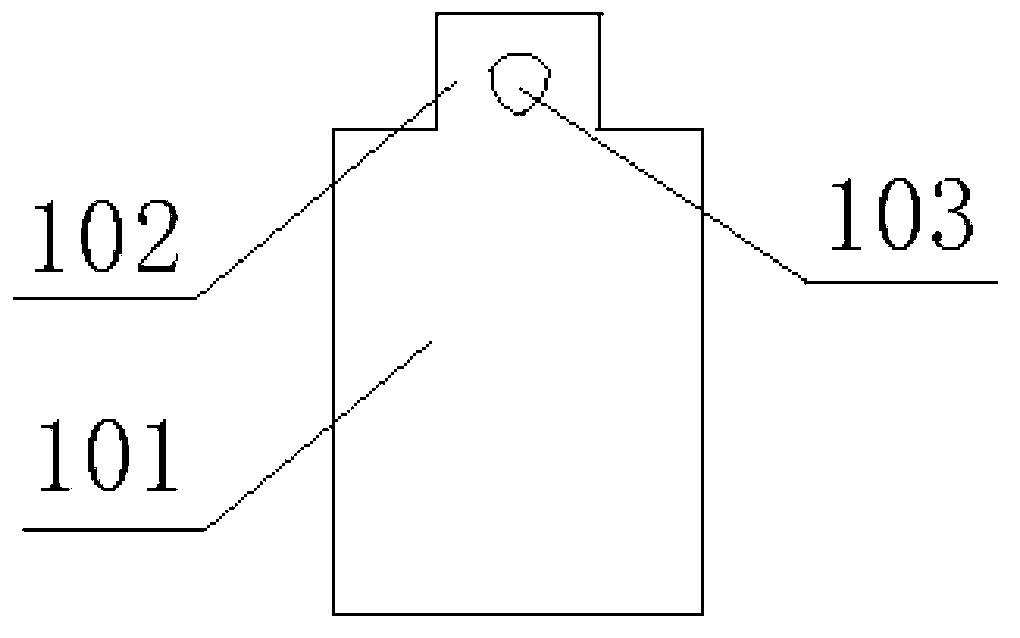

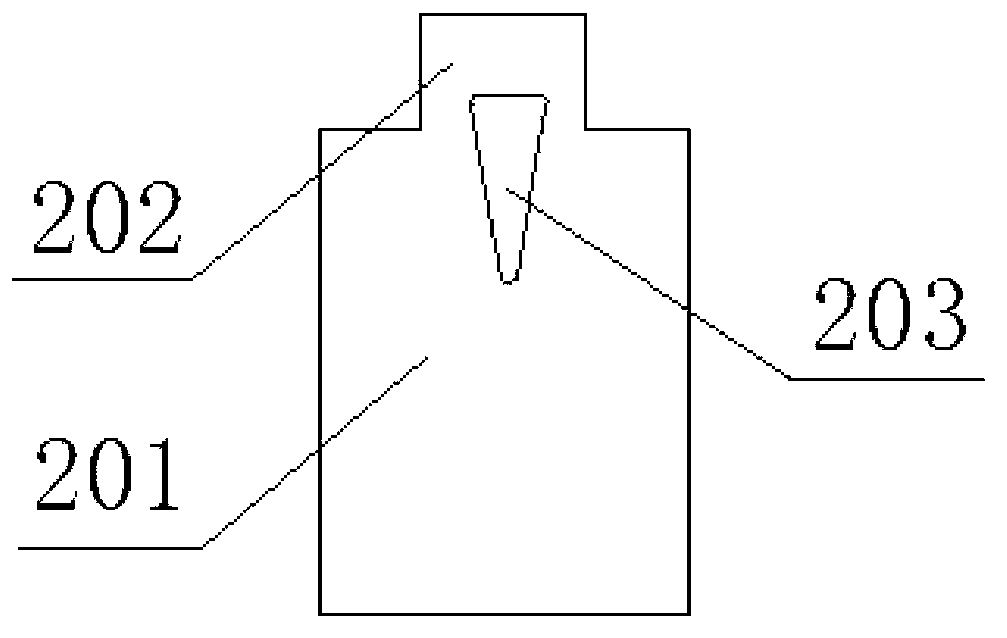

[0025] Such as figure 1Shown: the steel plate ingot casting device of the present invention comprises a base 12, a fixed frame 4 and an ingot mold, wherein the fixed frame 4 is fixedly connected with the base 12, and the ingot mold is located in the fixed frame 4, and the ingot mold is formed from the front , rear, left and right two pairs of side templates 1,2 and bottom template 13 constitute. Both the side templates 1, 2 and the bottom template 13 are made of copper plate with high thermal conductivity, which is beneficial to speed up the condensation rate of the steel ingot and prevent the segregation of the internal structure of the steel ingot. Among the two pairs of side templates 1 and 2, one pair of side templates 2 is located in the opening of the other pair of side templates 1 and can be moved and adjusted. Through adjustment, a set of side templates 1 and 2 can produce ingots of various specifications. Cooling water tanks 3, 15 are provided outside the side templa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com