Low-cost and high-toughness heterogeneous alloy abrasion-resisting hammerhead and manufacturing method thereof

A heterogeneous alloy and high toughness technology, applied in the field of metal materials, can solve the problems of insufficient toughness of the hammer handle, weak market competitiveness, high production cost, etc., and achieve the effects of uniform cross-sectional hardness distribution, high wear resistance and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

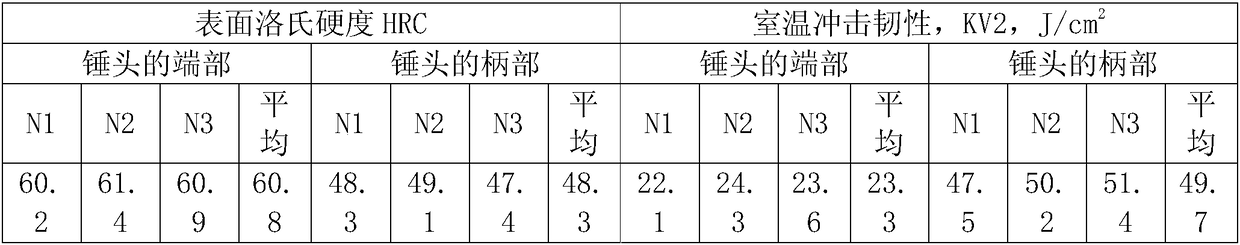

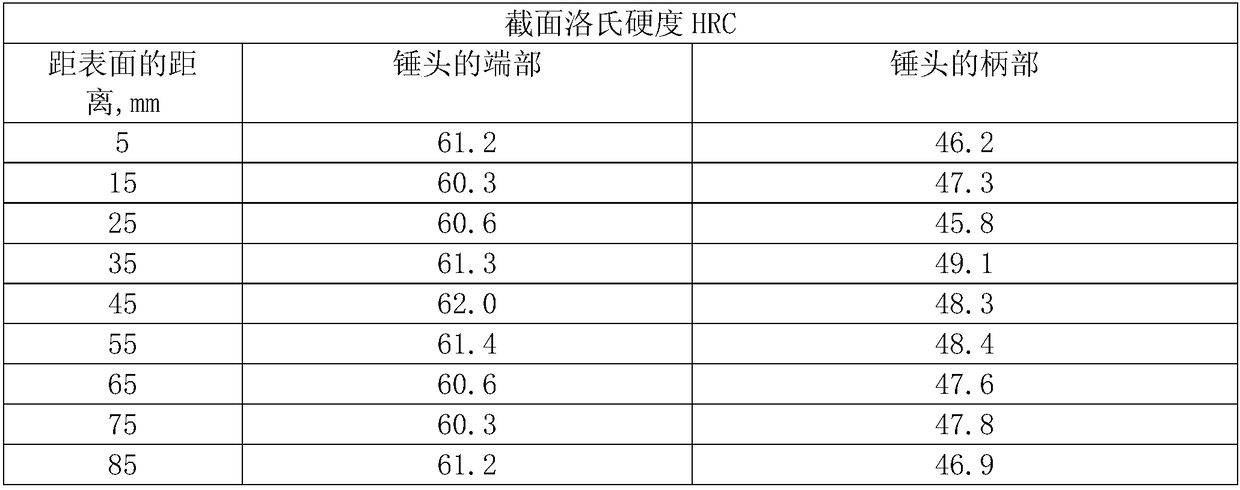

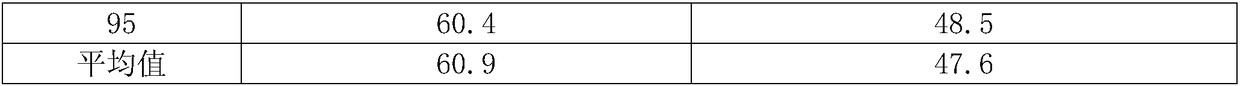

Embodiment 1

[0027] Production of 50kg hammer heads.

[0028] (1) Smelting: The chemical composition weight percentage of the end of the hammer head is: C: 1.58%, Si: 0.42%, Mn: 0.34%, P: 0.018%, S: 0.007%, Cr: 10.5%, Mo: 0.48% , V: 0.18%, RE: 0.025%; the weight percentage of the chemical composition of the shank of the hammer is C: 0.26%, Si: 0.34%, Mn: 0.82%, P: 0.016%, S: 0.010%, Cr: 1.83% , Ni: 0.68%, Mo: 0.42%. According to the chemical composition requirements of the end of the hammer head and the handle of the hammer head, two furnaces of molten steel are smelted using an intermediate frequency induction furnace. When the temperature is 1580°C, the molten steel at the end of the hammer head is first poured into the mold, and then the molten steel at the handle of the hammer head is poured into the mold.

[0029] (2) Pretreatment

[0030] The castings after slow cooling are pretreated according to the following process sequence: ①The castings are heated to 550°C with the furnace, ...

Embodiment 2

[0042] Production of 70kg hammer heads.

[0043] (1) Smelting: The chemical composition weight percentage of the end of the hammer head is: C: 1.63%, Si: 0.31%, Mn: 0.44%, P: 0.018%, S: 0.008%, Cr: 11.5%, Mo: 0.58% , V: 0.22%, RE: 0.015%; the chemical composition weight percentage of the shank of the hammer head is C: 0.30%, Si: 0.36%, Mn: 0.91%, P: 0.016%, S: 0.005%, Cr: 2.14% , Ni: 0.72%, Mo: 0.44%. According to the chemical composition requirements of the end of the hammer head and the handle of the hammer head, two furnaces of molten steel are smelted using an intermediate frequency induction furnace. When the temperature is 1580°C, the molten steel at the end of the hammer head is first poured into the mold, and then the molten steel at the handle of the hammer head is poured into the mold.

[0044] (2) Pretreatment

[0045] The castings after slow cooling are pretreated according to the following process sequence: ①The castings are heated to 560°C with the furnace, an...

Embodiment 3

[0056] Production of 90kg hammer heads.

[0057] (1) Smelting: The chemical composition weight percentage of the end of the hammer head is: C: 1.70%, Si: 0.45%, Mn: 0.43%, P: 0.020%, S: 0.008%, Cr: 12%, Mo: 0.52% , V: 0.28%, RE: 0.023%; the weight percentage of the chemical composition of the shank of the hammer is C: 0.31%, Si: 0.38%, Mn: 0.98%, P: 0.016%, S: 0.009%, Cr: 2.28% , Ni: 0.80%, Mo: 0.50%. According to the chemical composition requirements of the end of the hammer head and the handle of the hammer head, two furnaces of molten steel are smelted using an intermediate frequency induction furnace. When the temperature is 1590℃, the molten steel at the end of the hammer head is first poured into the mold, and then the molten steel at the handle of the hammer head is poured into the mold.

[0058] (2) Pretreatment

[0059] The castings after slow cooling are pretreated according to the following process sequence: ①The castings are heated to 580°C with the furnace for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com