High-hardness low-carbon bearing steel ball

A bearing steel ball, high hardness technology, applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of easy cracking, low impact toughness, reducing the hardness of steel balls and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

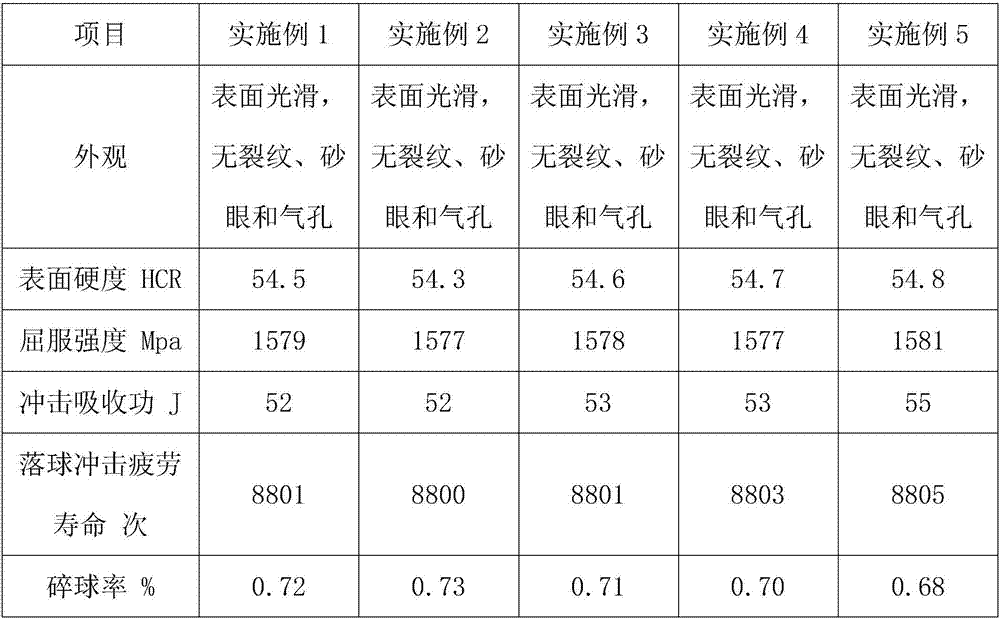

Examples

Embodiment 1

[0017] A high-hardness low-carbon bearing steel ball, the weight percentage of each component is as follows: C: 0.15%, Cr: 13.5%, W: 1.2%, Co: 3.5%, V: 0.25%, Si: 0.35%, Mn : 0.2%, Ni: 0.25%, B: 0.007%, S≤0.015%, P≤0.015%, Mo: 0.575%, and the remainder is Fe.

Embodiment 2

[0019] A high-hardness low-carbon bearing steel ball, the weight percentage of each component is as follows: C: 0.1%, Cr: 14%, W: 1%, Co: 4%, V: 0.22%, Si: 0.4%, Mn : 0.1%, Ni: 0.3%, B: 0.006%, S≤0.015%, P≤0.015%, Mo: 0.9%, the remainder is Fe;

[0020] Among them, in the preparation process of high-hardness low-carbon bearing steel balls, scrap steel is smelted, carbon, chromium, molybdenum, tungsten, cobalt, vanadium, silicon, manganese, nickel, boron are added, rough refining, refining, casting out of the furnace, cleaning and polishing A smooth spherical ingot satisfying the above-mentioned components was obtained, wherein the casting temperature was 1500°C; the spherical ingot was taken, heated to 940°C in a propane atmosphere, and the carbon potential was adjusted to 1.4%. 0.95%, heat preservation for 6 hours, then adjust the temperature to 500°C, heat preservation and tempering for 4 hours, then raise the temperature to 990°C, heat preservation for 40 minutes, water que...

Embodiment 3

[0022] A high-hardness low-carbon bearing steel ball, the weight percentage of each component is as follows: C: 0.2%, Cr: 13%, W: 1.5%, Co: 3%, V: 0.28%, Si: 0.3%, Mn : 0.3%, Ni: 0.2%, B: 0.008%, S≤0.015%, P≤0.015%, Mo: 0.3%, the remainder is Fe;

[0023] Among them, in the preparation process of high-hardness low-carbon bearing steel balls, scrap steel is smelted, carbon, chromium, molybdenum, tungsten, cobalt, vanadium, silicon, manganese, nickel, boron are added, rough refining, refining, casting out of the furnace, cleaning and polishing A smooth spherical ingot satisfying the above composition was obtained, wherein the casting temperature was 1460°C; the spherical ingot was taken, heated to 950°C in a propane atmosphere, and the carbon potential was adjusted to 1.3%. 0.91%, heat preservation for 6.5 hours, then adjust the temperature to 480°C, heat preservation and tempering for 6 hours, then raise the temperature to 970°C, heat preservation for 60 minutes, water quench t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com