Integrated honeycomb carrier with multi-channel structure

A technology of honeycomb carrier and pore structure, applied in the direction of catalyst carrier, catalyst carrier, engine components, etc., can solve the problems of insufficient utilization of catalyst and uneven distribution of air flow of metal honeycomb carrier, so as to improve the catalytic effect, reduce the coating amount, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

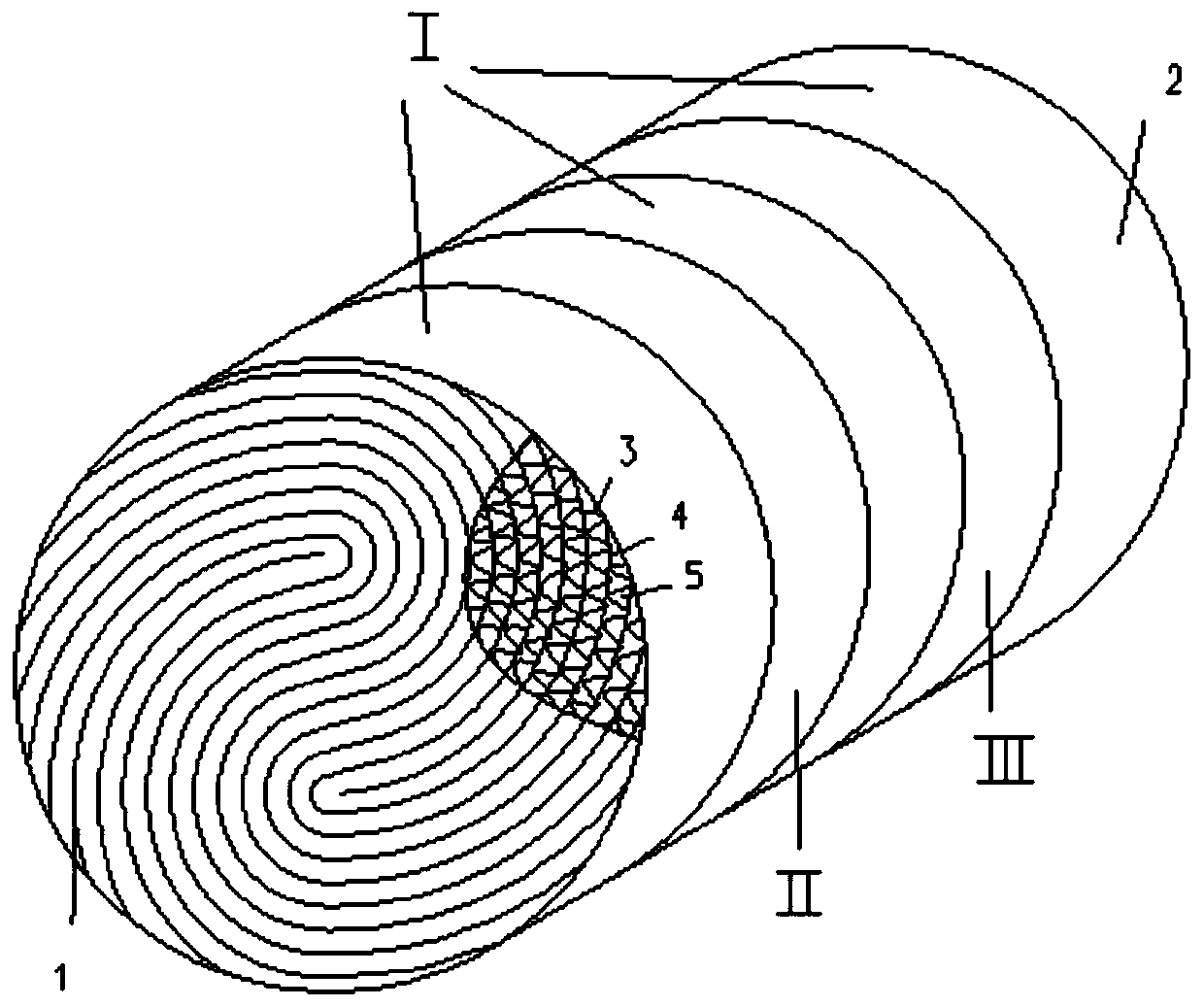

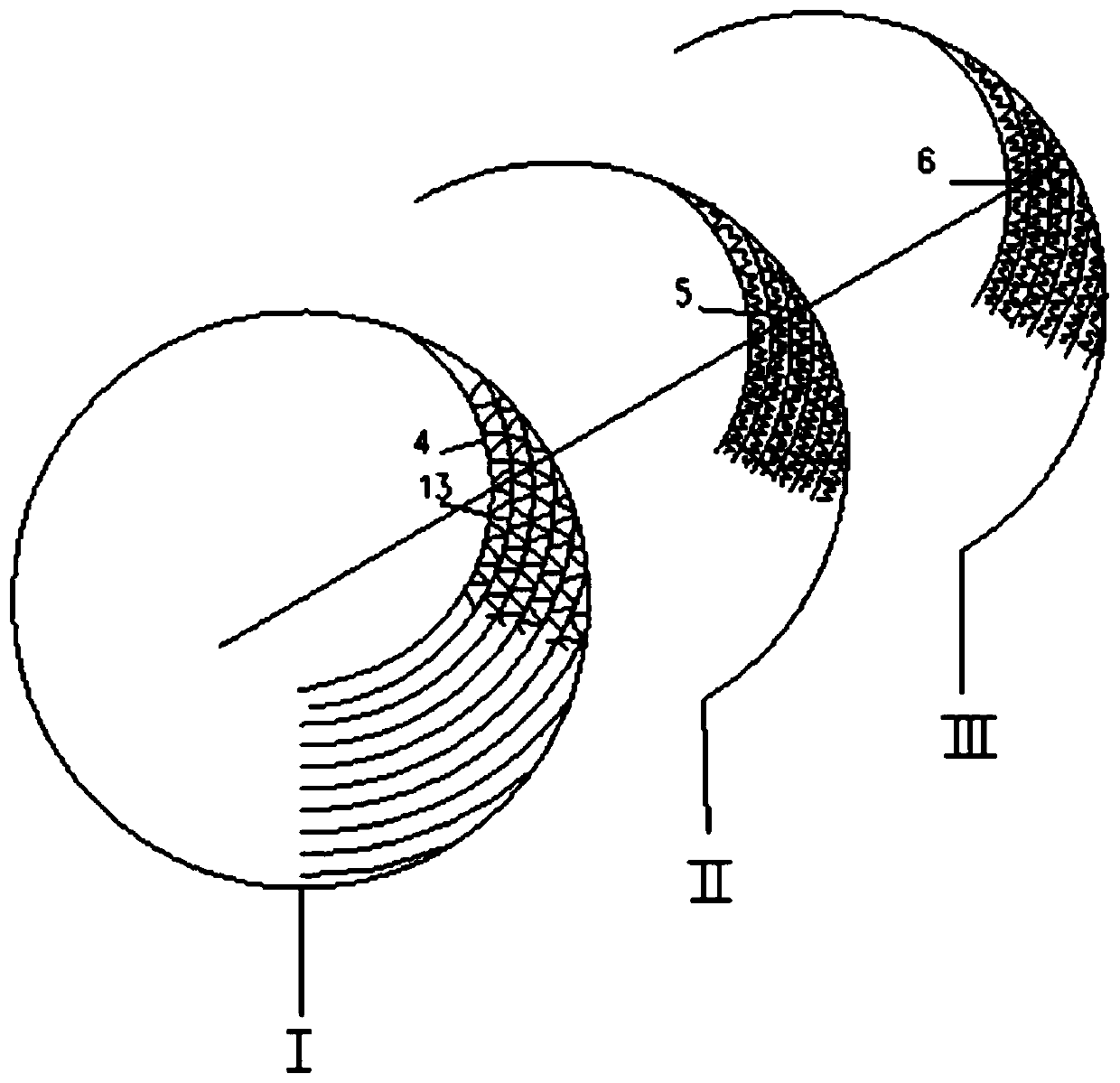

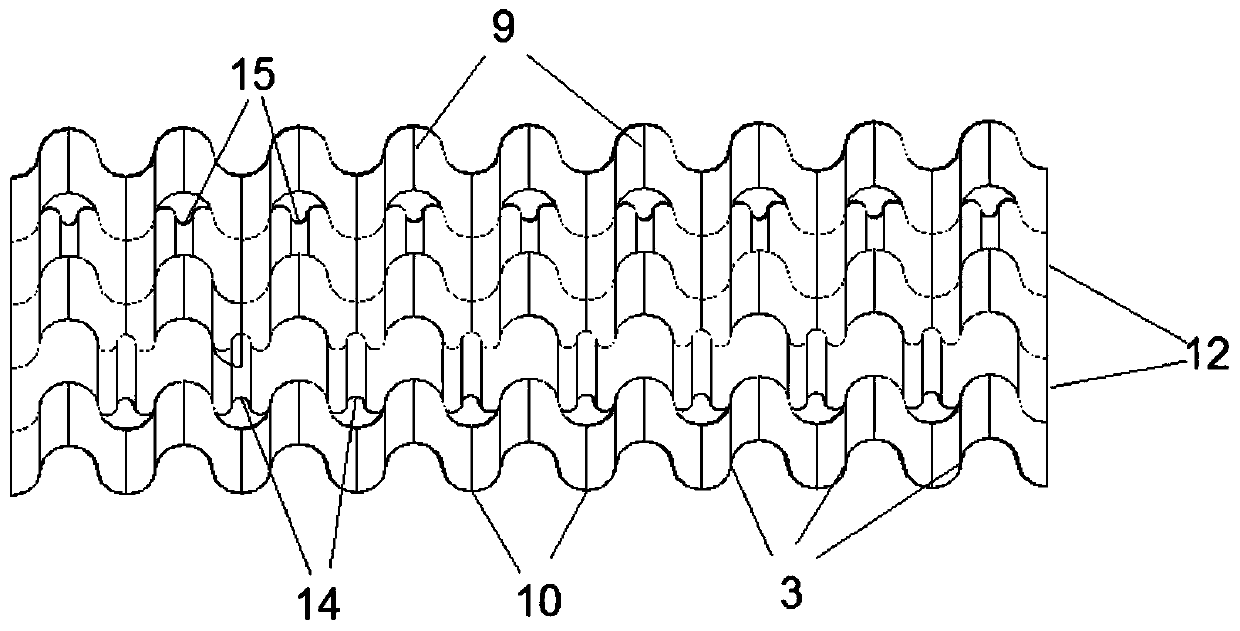

[0060] With reference to accompanying drawing, prepare a kind of metal honeycomb carrier that changes traditional sinusoidal wave pattern and make it into multi-channel, described metal is conventional commercially available Fe-Cr-Al alloy, utilizes such as Figure 5 The rolling gear set shown in the figure rolls the metal material which is initially a thin flat plate 4 into a structured corrugated plate 12, cuts the thin flat plate and the corrugated plate to the same length according to the required carrier size, and stacks and uses at least one Layers of locally structured corrugated plates and thin flat plates are stacked and rolled in sequence to form an S-shaped structural carrier core, such as figure 1 As shown; the metal honeycomb core body is placed in the metal shell 21 and fixed; the whole is formed as a multi-channel metal honeycomb carrier by arranging solder brazing. Such as figure 1 and 3 As shown, the monolithic honeycomb carrier has three different segments ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com