Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110results about How to "Reduce the amount of coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

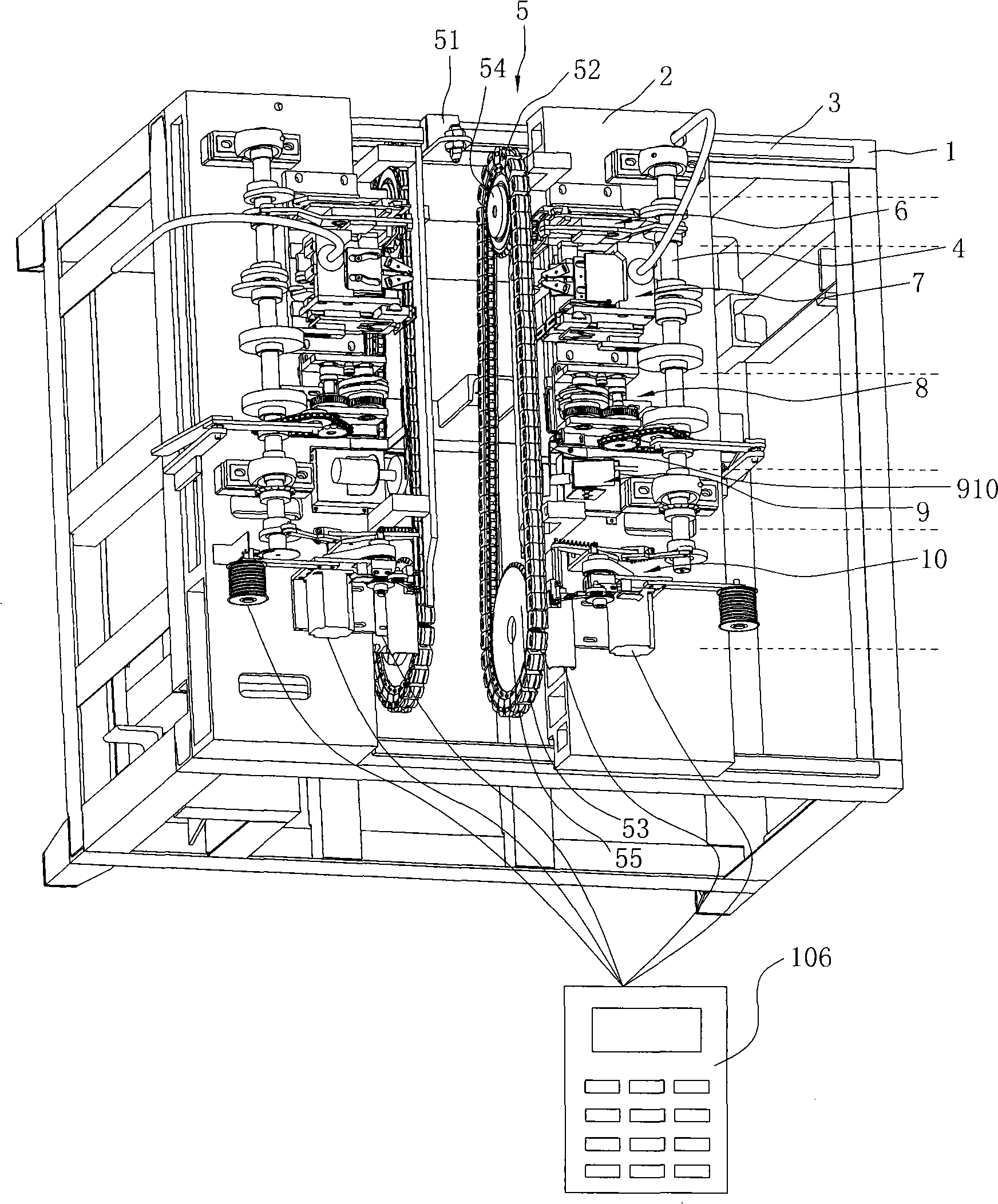

Automatic wire-stripping tin plating machine

An automatic wire stripping soldering machine belongs to the lead processing mechanical field. The prior art has unitary function and does not realize the mechanical lead soldering. The invention comprises a frame, a power transmission device mounted on the frame, a working table and a wire transmission device; the working table is parallely provided with a lead cutting device driven by the power transmission device and a wire separating device; the wire transmission device comprises a wire transmission machine and a lead transmission chain; the wire transmission machine is arranged on the frame on one side of the wire transmission gear and is connected with the power transmission device; the invention is characterize in the that: the working table on the other side of the wire separating device is orderly provided with a wire stripping device and a lead soldering device along the moving direction of the lead transmission chain; it has the advantages of realizing the lead mechanical soldering.

Owner:吴志浩

Coated particulate preparation method

The invention discloses a coated particulate preparation method, comprising the following steps: firstly, particulates in movement are coated with coating solution to cure the solution to form films; the coating rate and curing rate are controlled to ensure that the particulates reach the designed coating quantity while avoiding accumulation; then, the organic polymer films outside the coating films of particulates in movement are cured; inert organic substance is added to form continuous inert liquid membranes outside the organic polymer films before the particulates are likely to accumulate on the adopted coating film curing process conditions; then, the organic polymer films outside the particulates are continuously cured to lose autohension or so that the whole coating films are cured fully; and finally, the particulates coated films are cooled to the room temperature to obtain the coated particulates. The preparation method of the invention has high coating efficiency and good coating integrity and coating process.

Owner:NANJING UNIV OF SCI & TECH

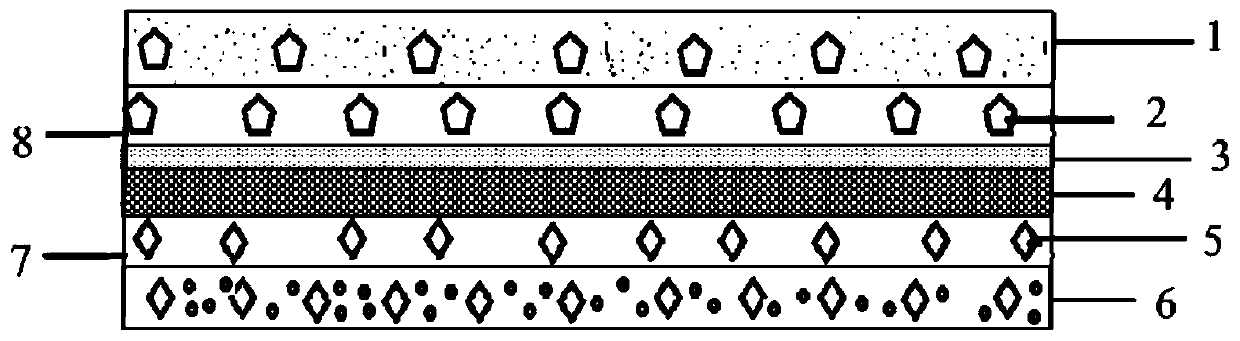

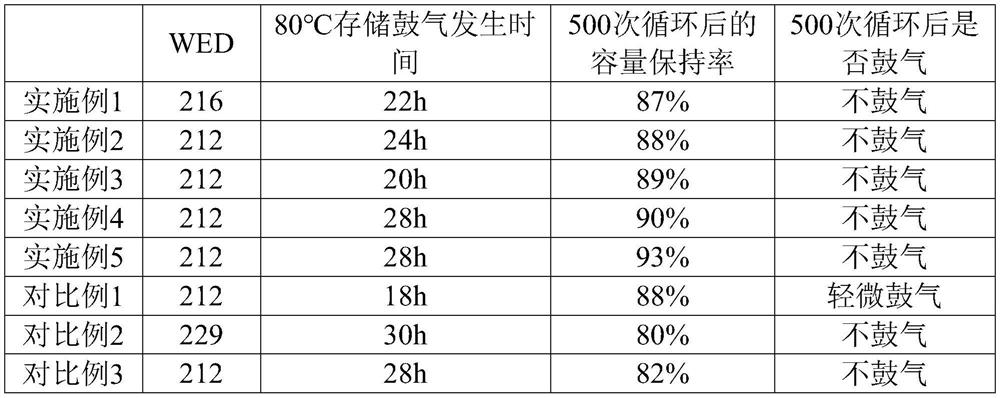

Water-based high-viscosity glued diaphragm, preparation method thereof, and application of diaphragm in battery

PendingCN111129406AImprove adhesionEasy to packCell component detailsPhysical chemistryPolymer chemistry

The invention relates to a water-based high-viscosity glued diaphragm, a preparation method thereof and an application of the diaphragm in a battery. The water-based high-viscosity glued diaphragm comprises a base membrane, and a positive polymer layer and a negative polymer layer which are respectively arranged at two sides of the base membrane, wherein a positive ceramic layer is arranged between the base membrane and the positive polymer layer, and / or a negative ceramic layer is arranged between the base membrane and the negative polymer layer; a binder in the positive polymer layer and a battery positive electrode piece is the same type of binder, and a binder in the negative polymer layer and a battery negative electrode piece is the same type of binder. The diaphragm disclosed by theinvention has the characteristics of small coating amount of coatings on two sides, light and thin coatings, high cohesiveness and the like, so the shaping effect of a battery cell is optimal, and module boxing is facilitated; meanwhile, a module limiting effect is achieved. Moreover, the risk of hole blockage of the diaphragm is low, so the internal resistance of the battery cell is stable and controllable, the lithium precipitation risk is reduced, and the cycle life and safety performance of the battery cell are ensured.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

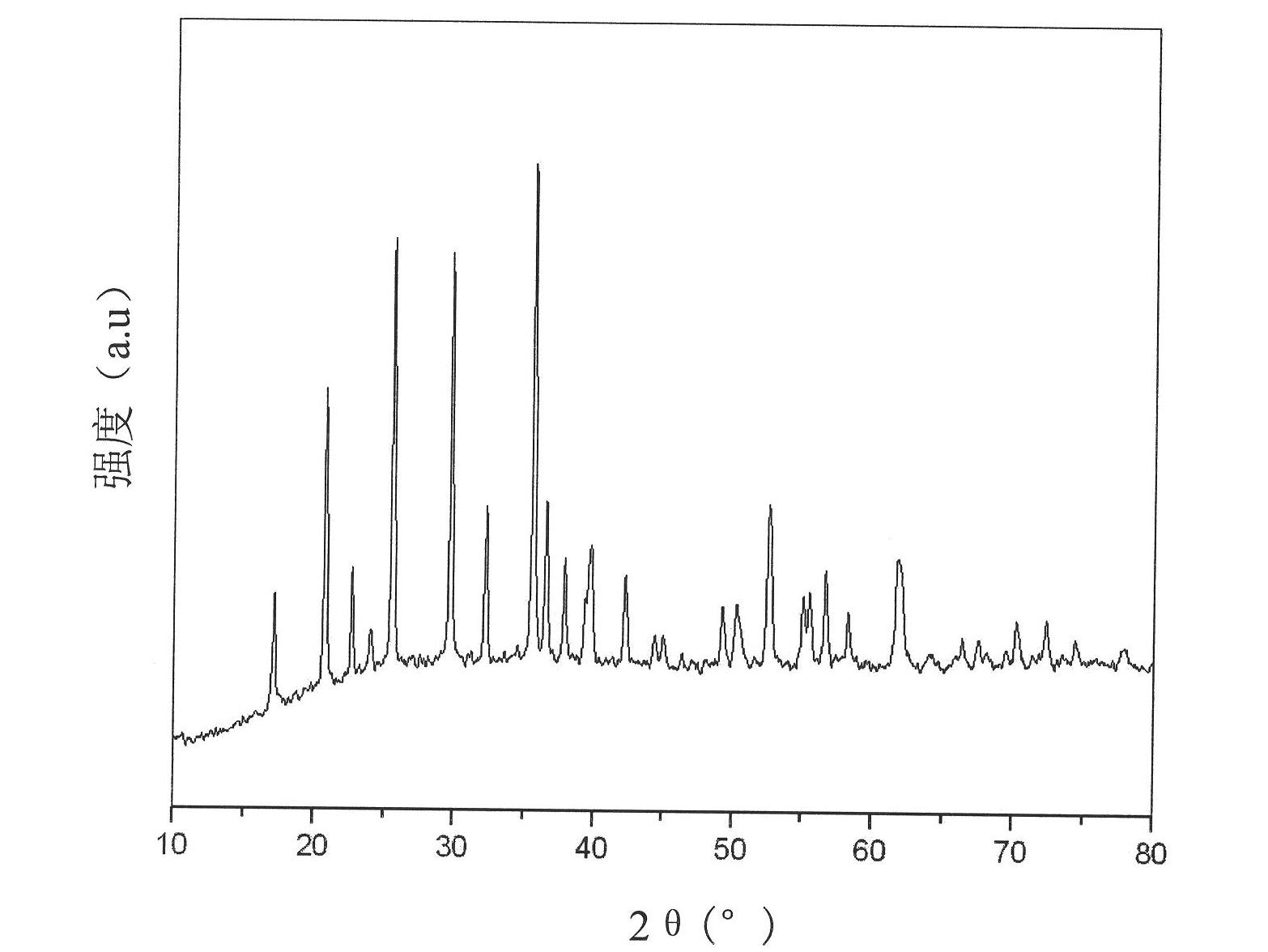

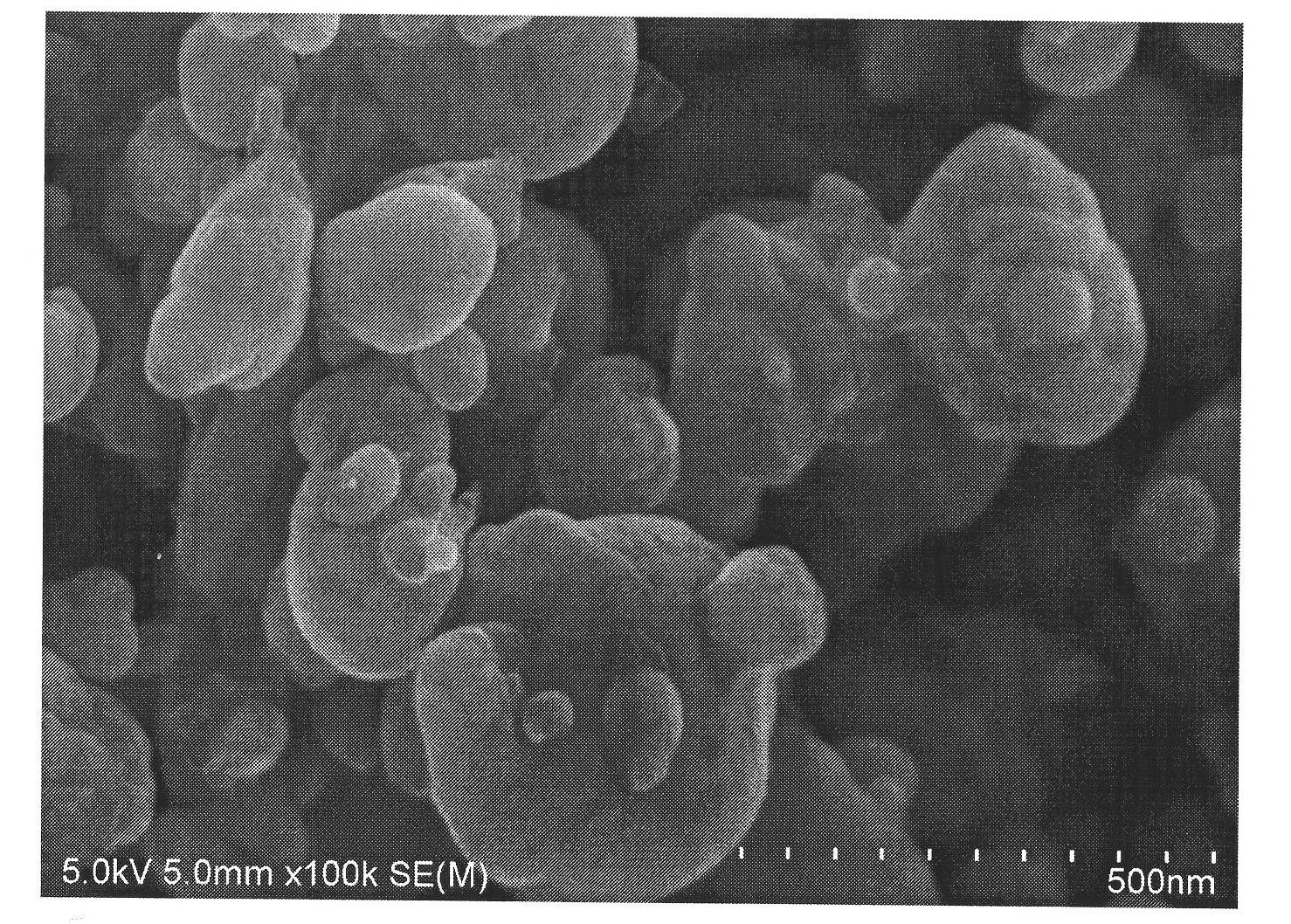

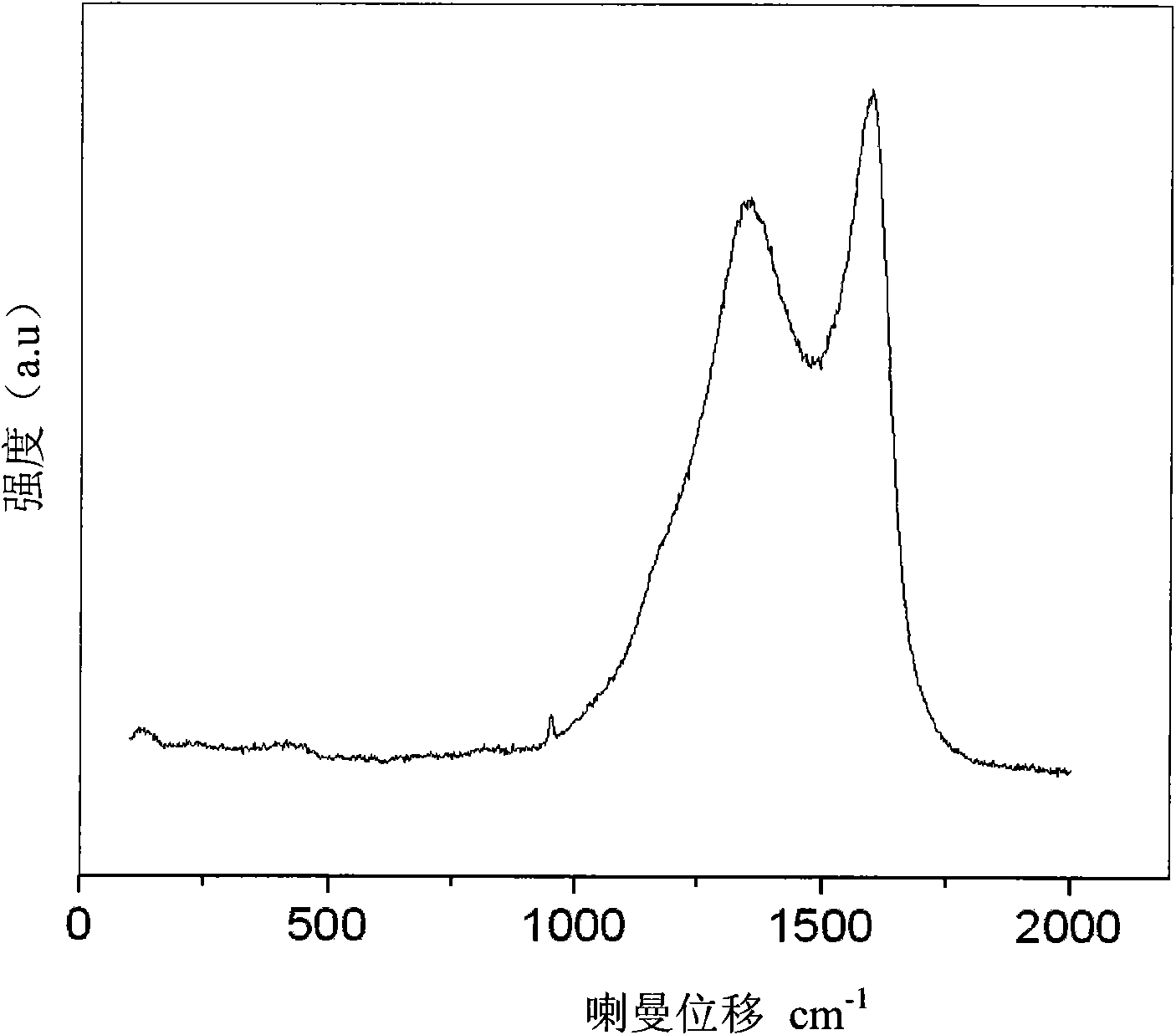

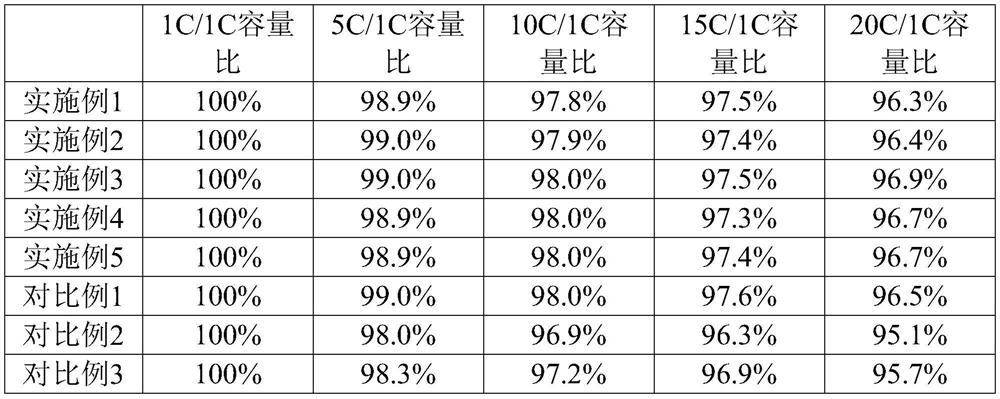

Preparation method of high-rate capacity lithium iron phosphate material

The invention discloses a preparation method of a high-rate capacity lithium iron phosphate material, which comprises the steps of: weighing FePO4.xH2O and a lithium source compound as raw materials according to the mol ratio of Li to Fe of (1-1.05) :1, adding a carbon source compound and a catalyst (nitrate or acetate of Fe, Co, Ni and the like), ball-grinding for 0.5-24h by using deionized water, absolute ethyl alcohol or acetone as a ball grinding medium to obtain slurry, spraying and drying the slurry and then thermally treating under the protection of an inert gas, and in the process, with the thermal cracking of the carbon source compound, promoting the carbon source compound to form a carbon cladding cover with higher graphitization crystallinity under a lower temperature through mutual action of the catalyst and the carbon source compound. The lithium iron phosphate cathode material prepared by adopting the preparation method has higher electronic conductivity and higher specific capacity under the condition of lower carbon content, greatly improved high-rate performance especially, and better application value in the field of power batteries.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

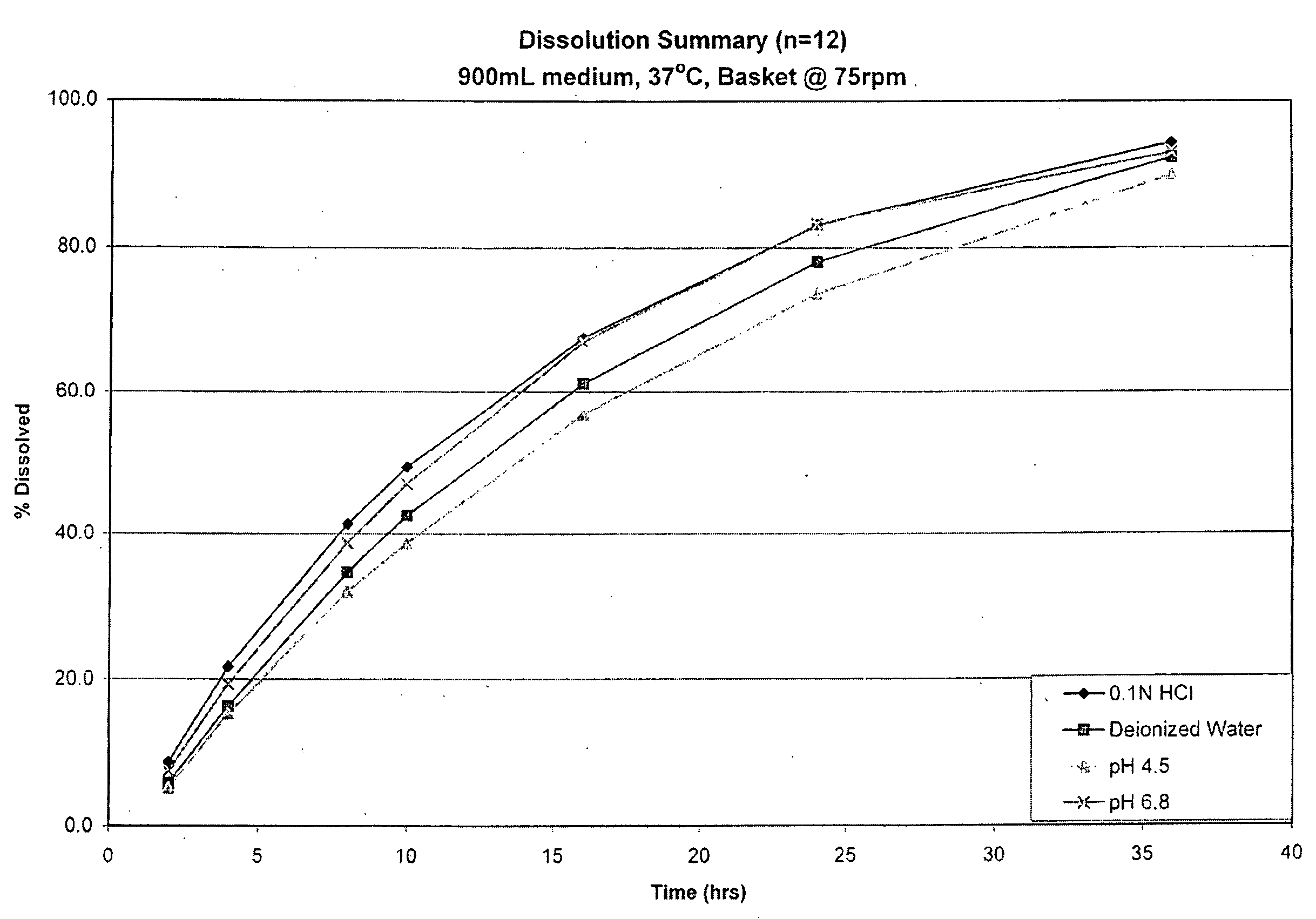

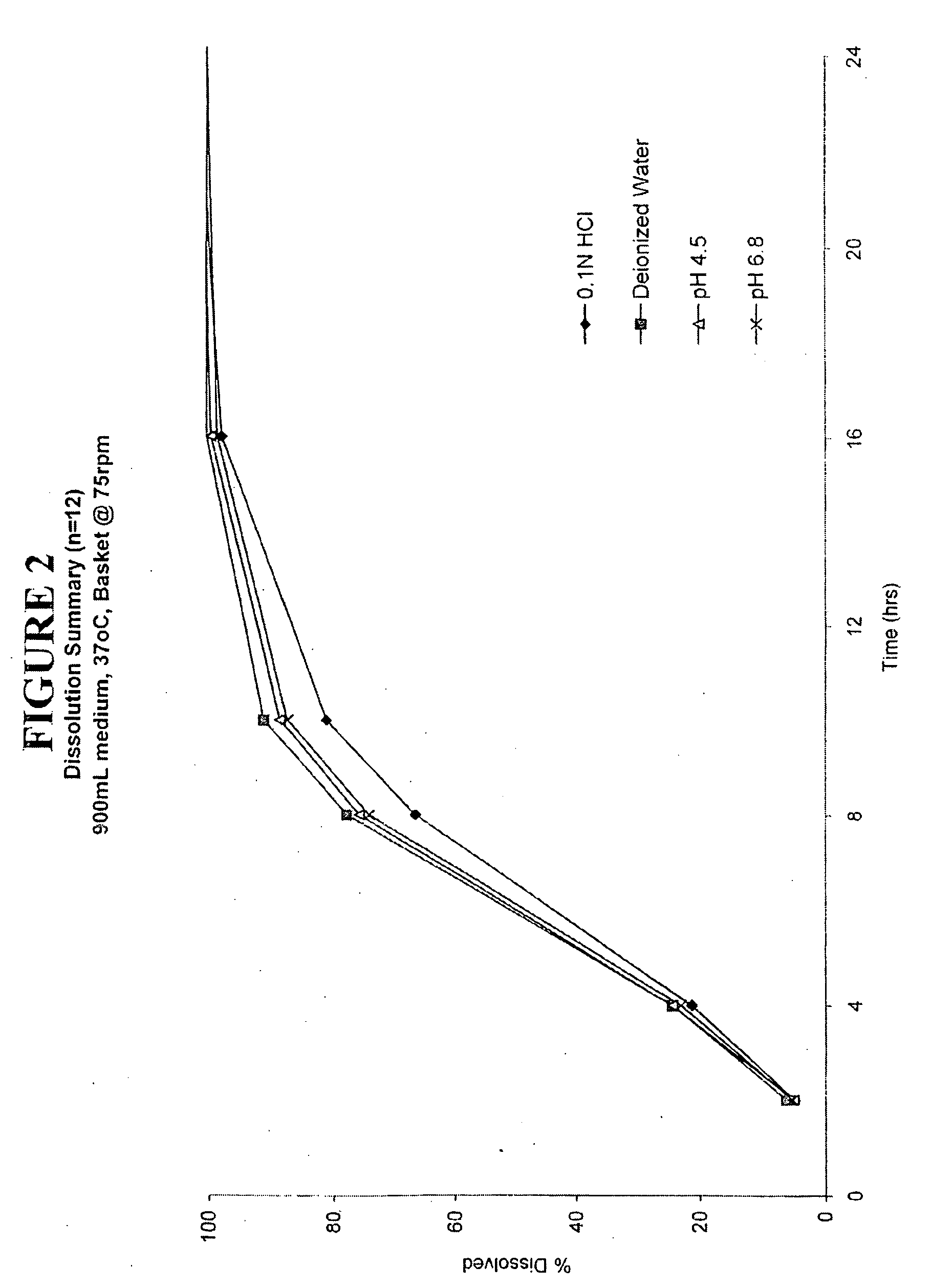

Enteric coated hydrophobic matrix formulation

InactiveUS20100003322A1Quicker TmaxReduce the amount of coatingBiocidePeptide/protein ingredientsHydrophobic matrixEnteric coated

Owner:IMPAX LAB INC

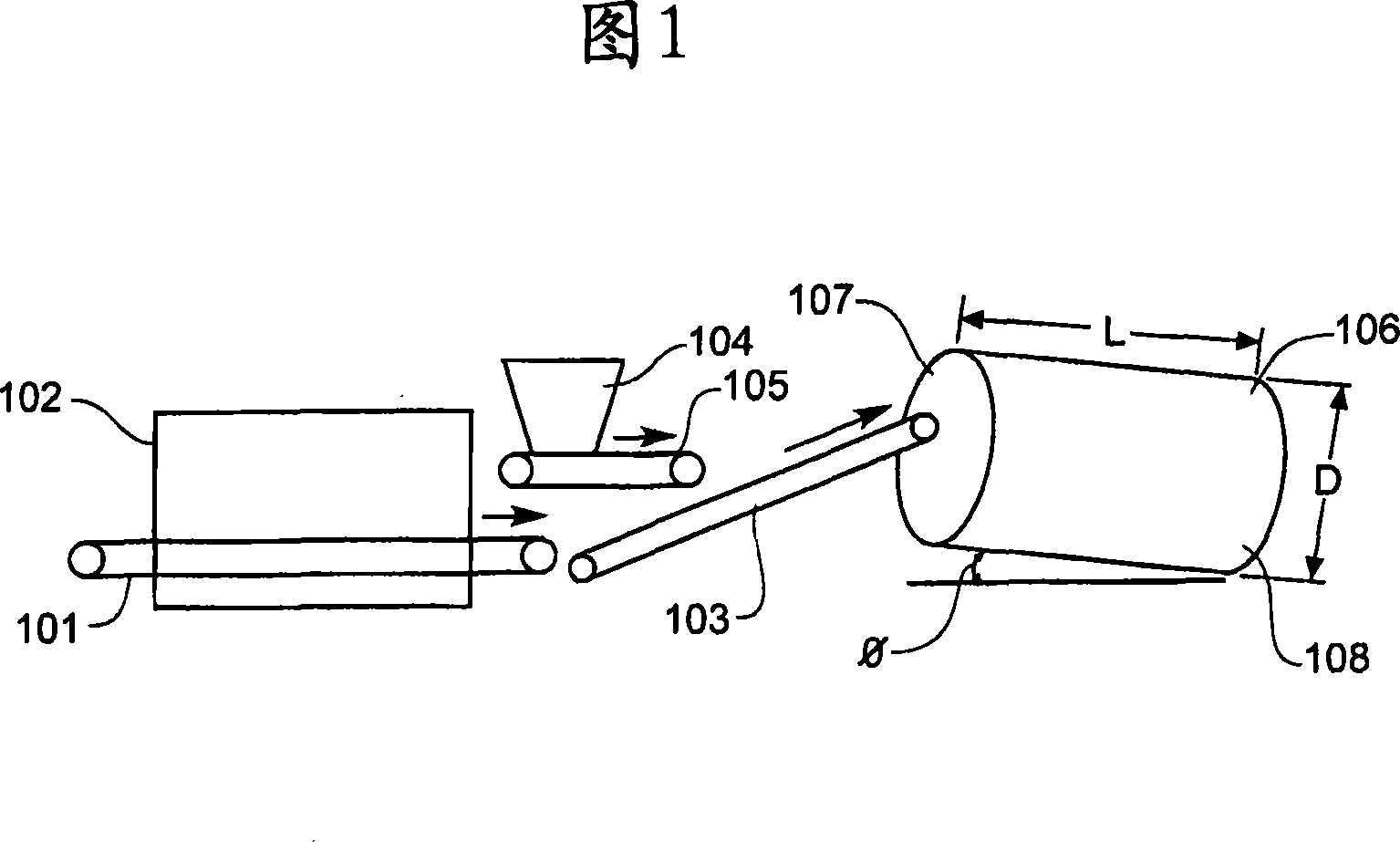

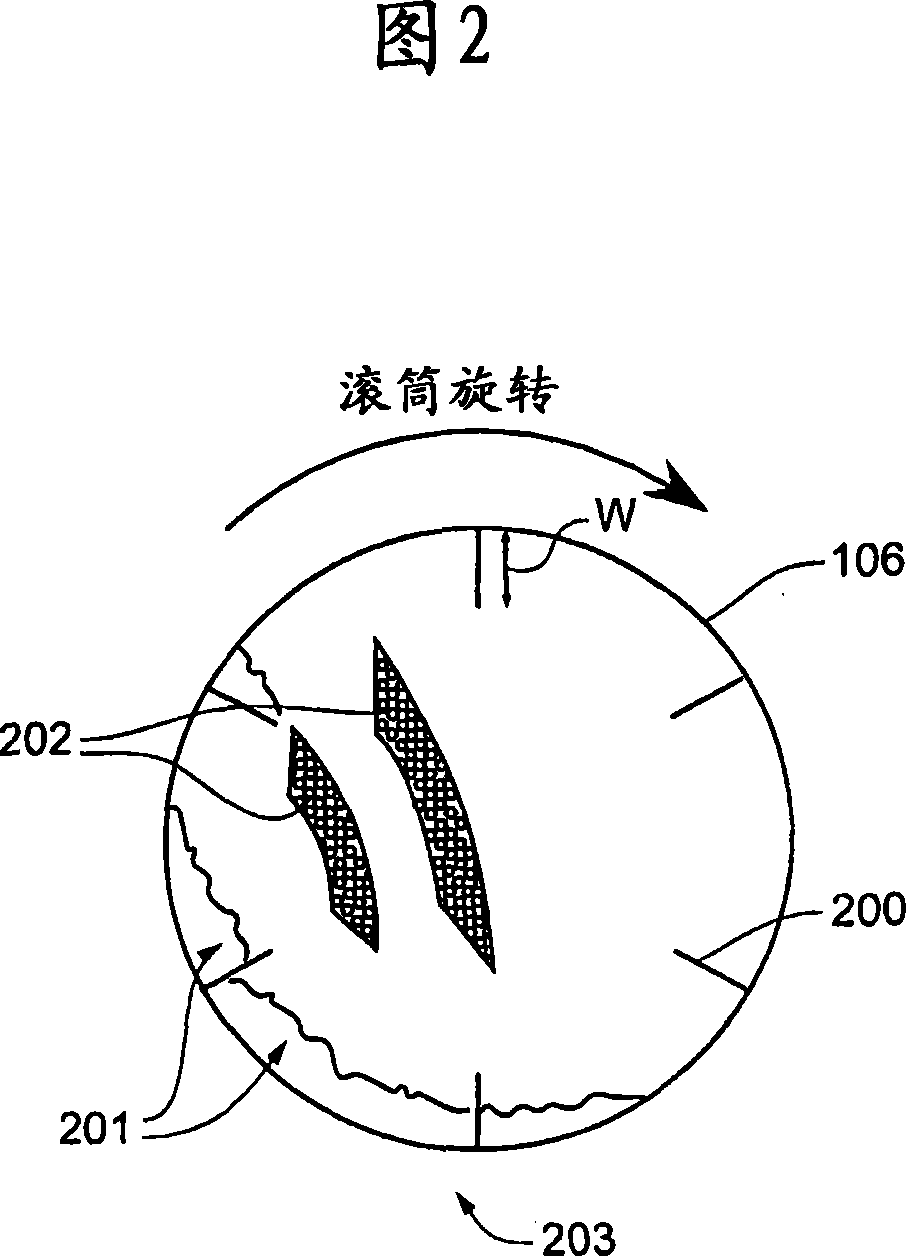

Improved tumbledrum design and method for coating objects

InactiveCN101057624ASimple designReduce the possibilityRotating receptacle mixersLiquid surface applicatorsParticulatesEngineering

A method of impregnating surfaces of objects with particulates comprising optionally, applying a liquid or semi-fluid binder to the objects to form pre-coated objects; adding the objects and particulates to a rotatable drum having at least an inlet, a length (L) and a diameter (D), the drum comprising at least 1 flight; and rotating the drum wherein each flight lifts and then drops the objects and particulates, wherein the impact of the falling objects and particulates drives the particulates into the objects or into the coating of the pre-coated objects.

Owner:THE QUAKER OATS CO

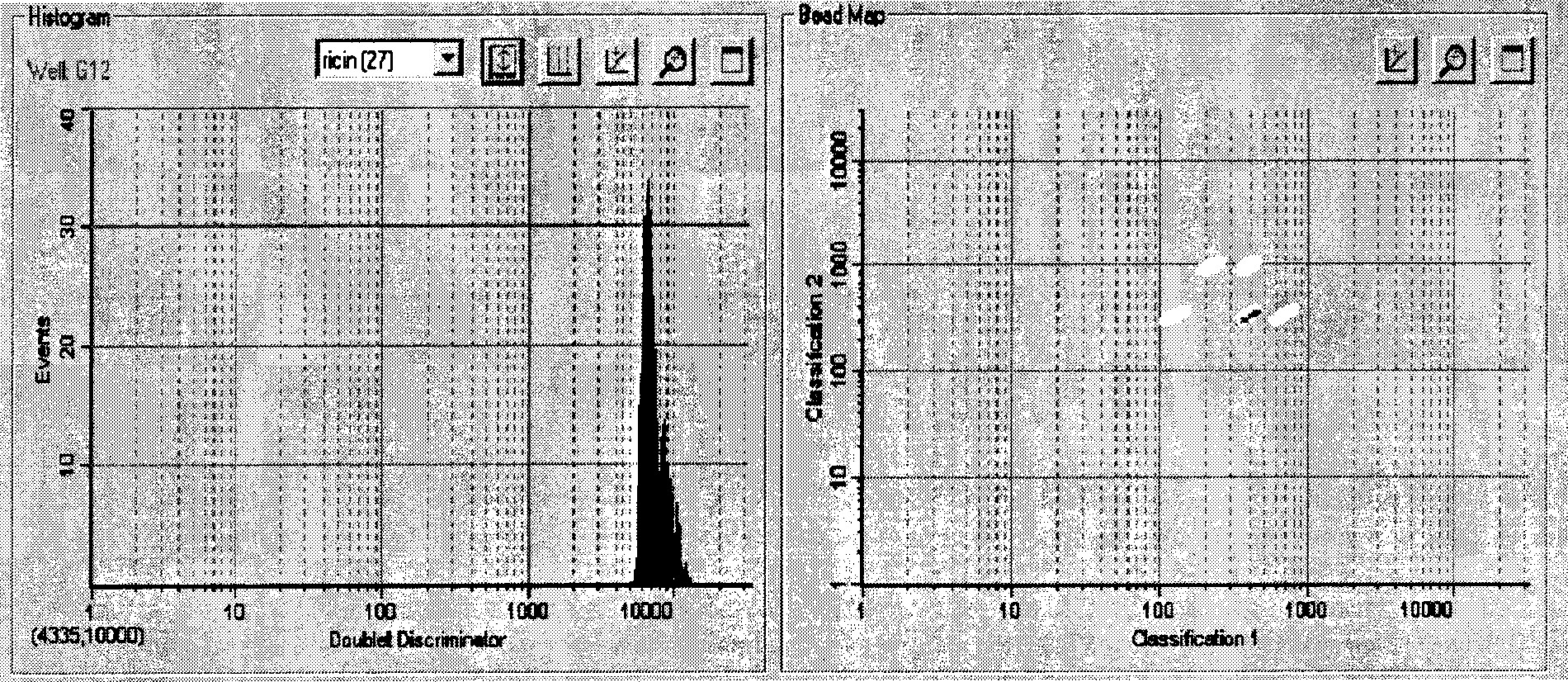

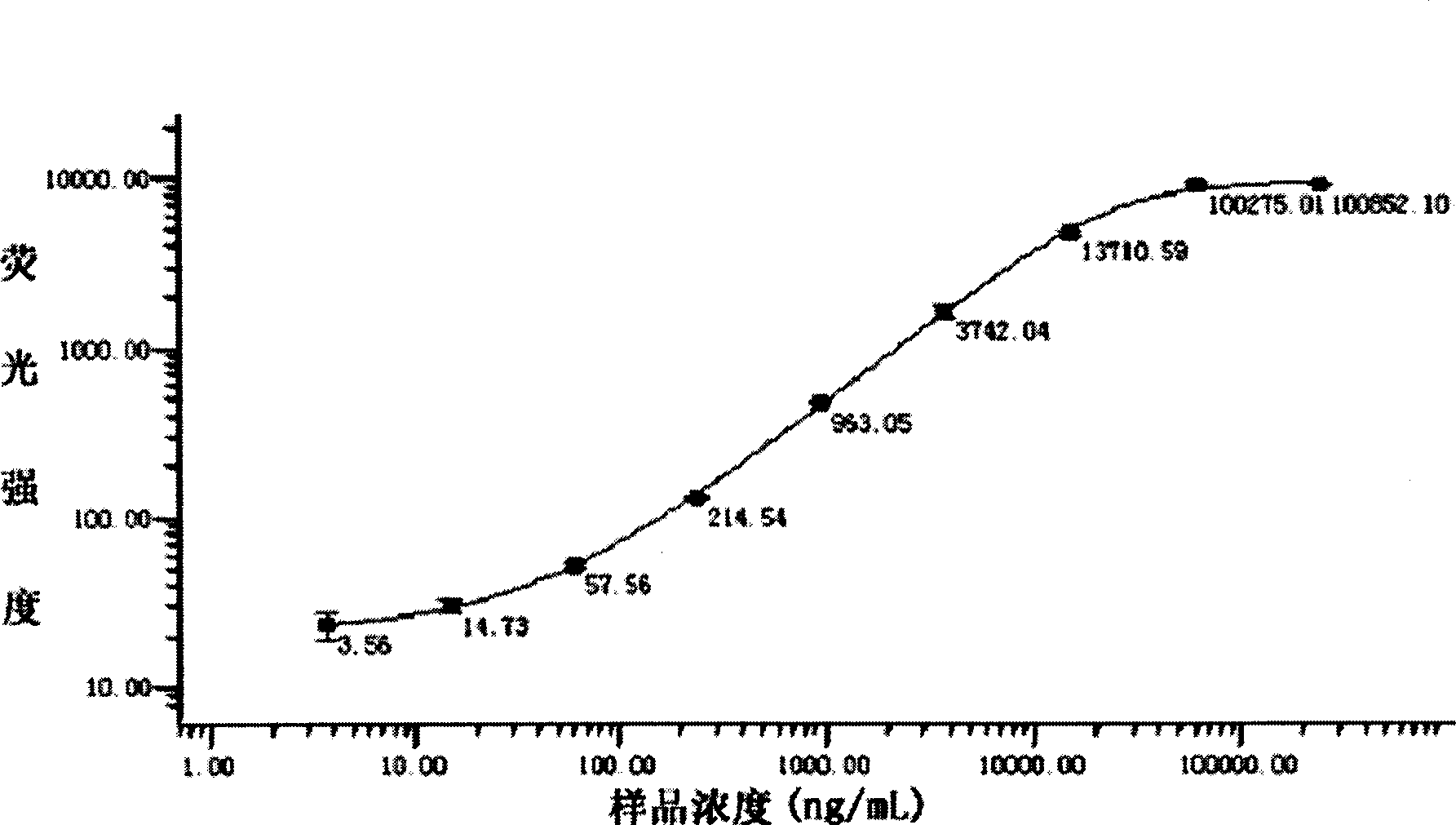

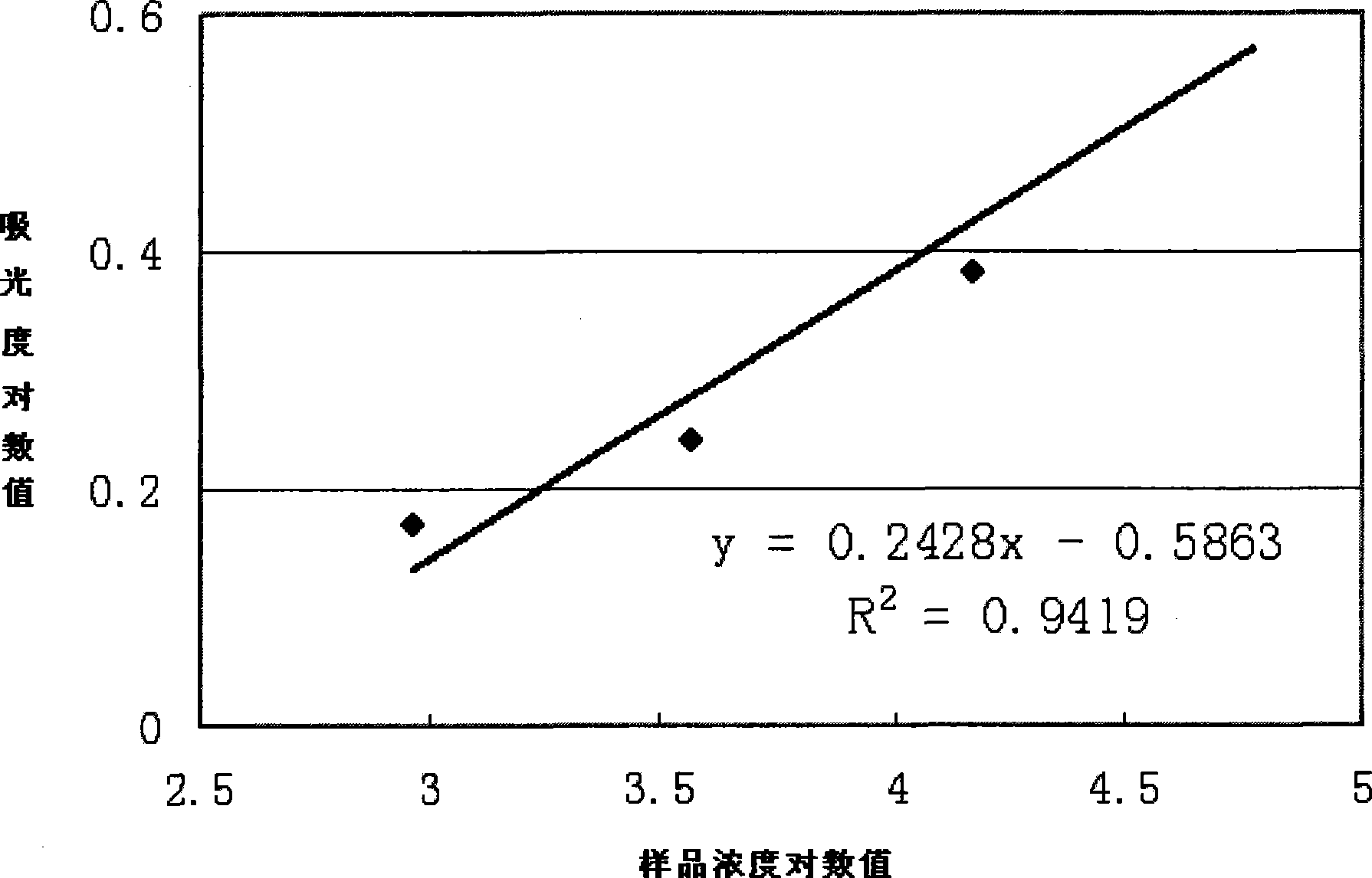

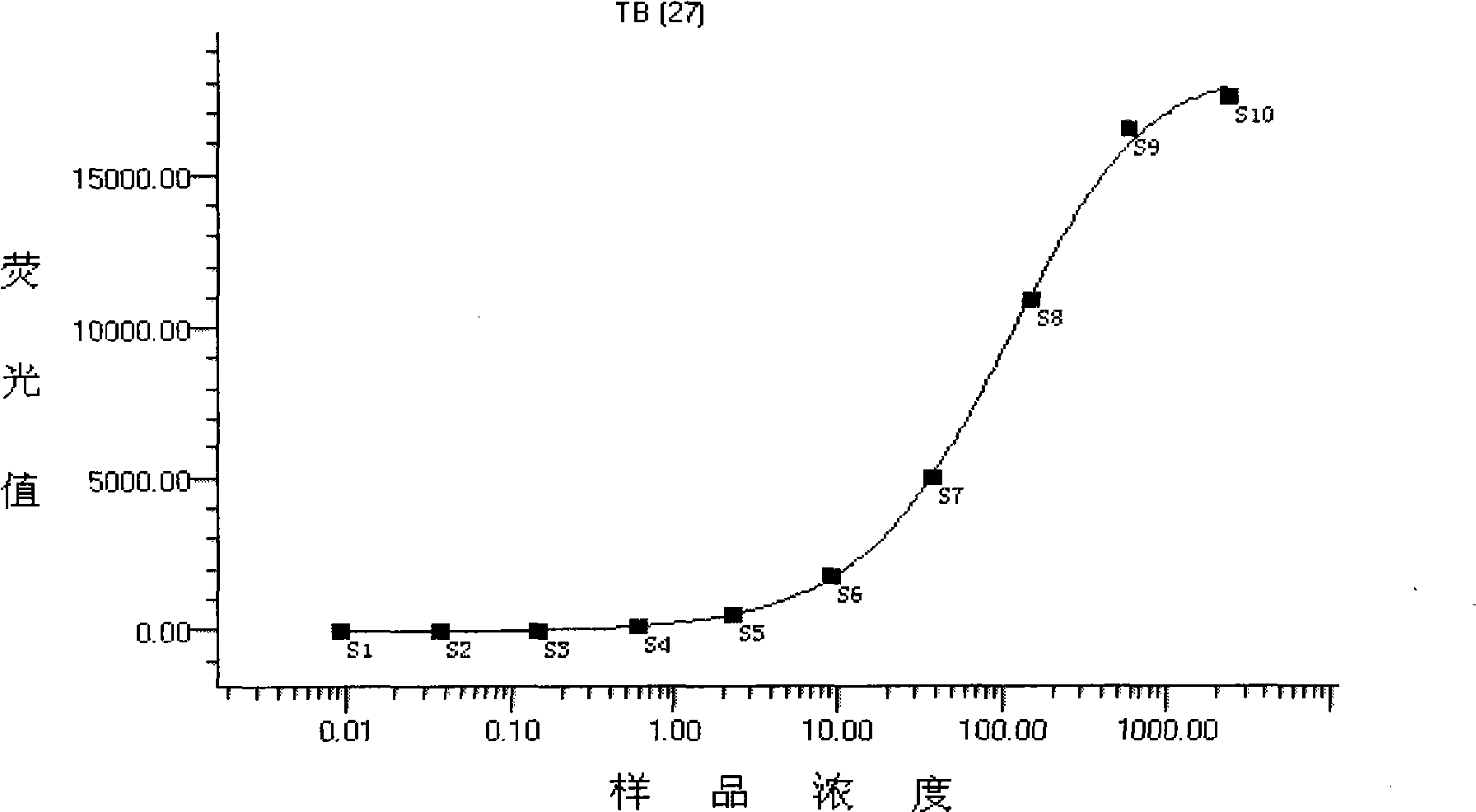

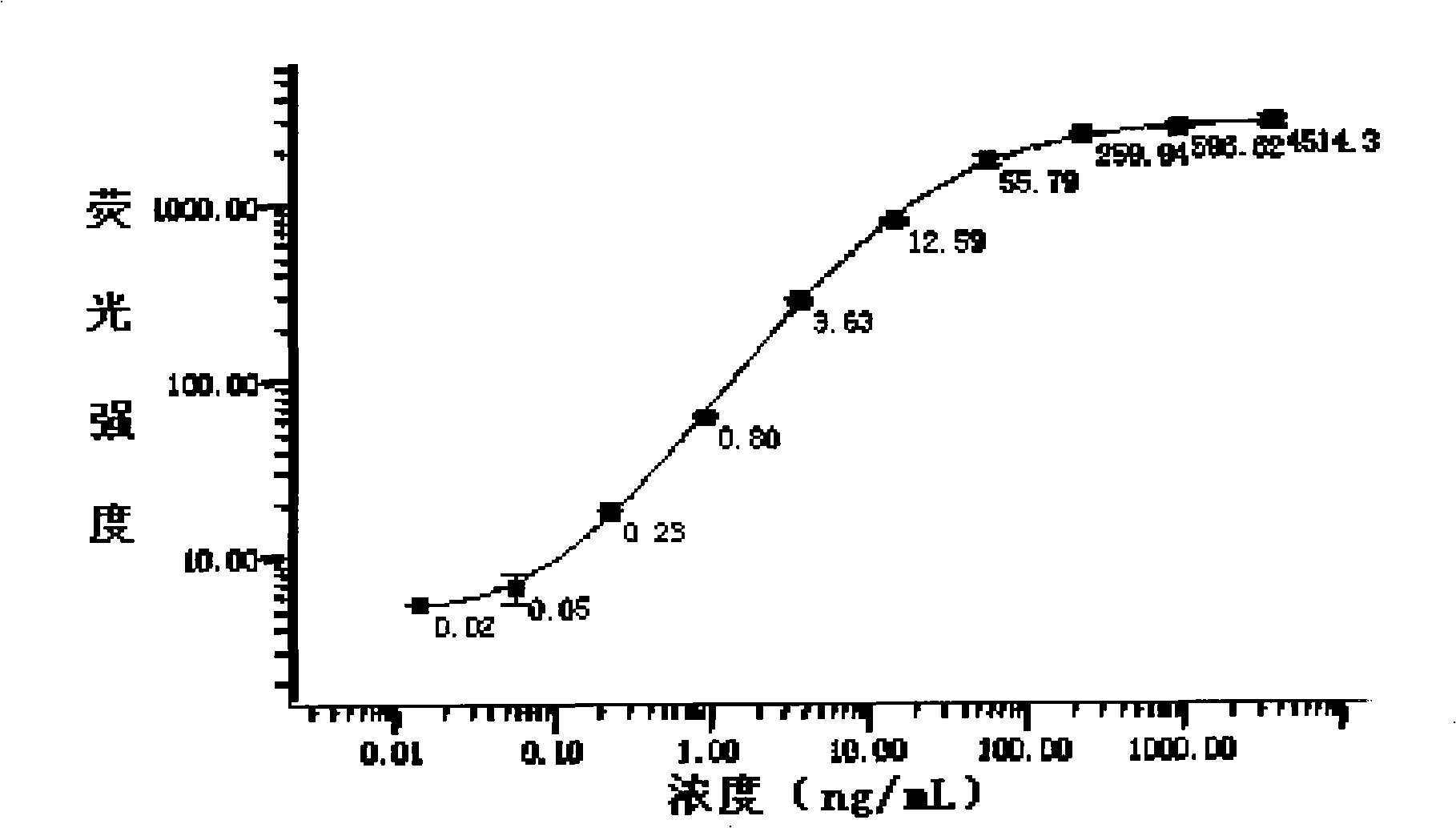

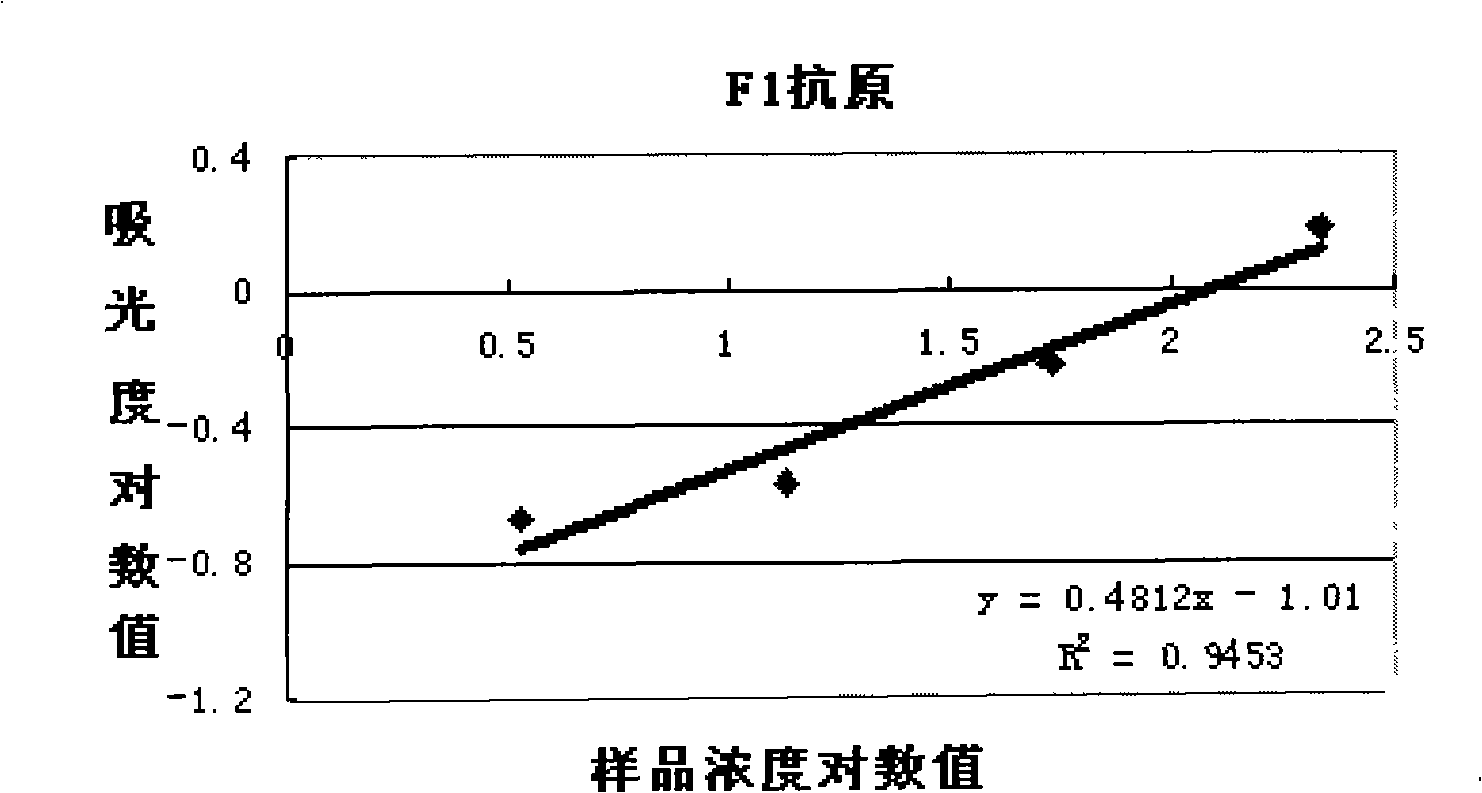

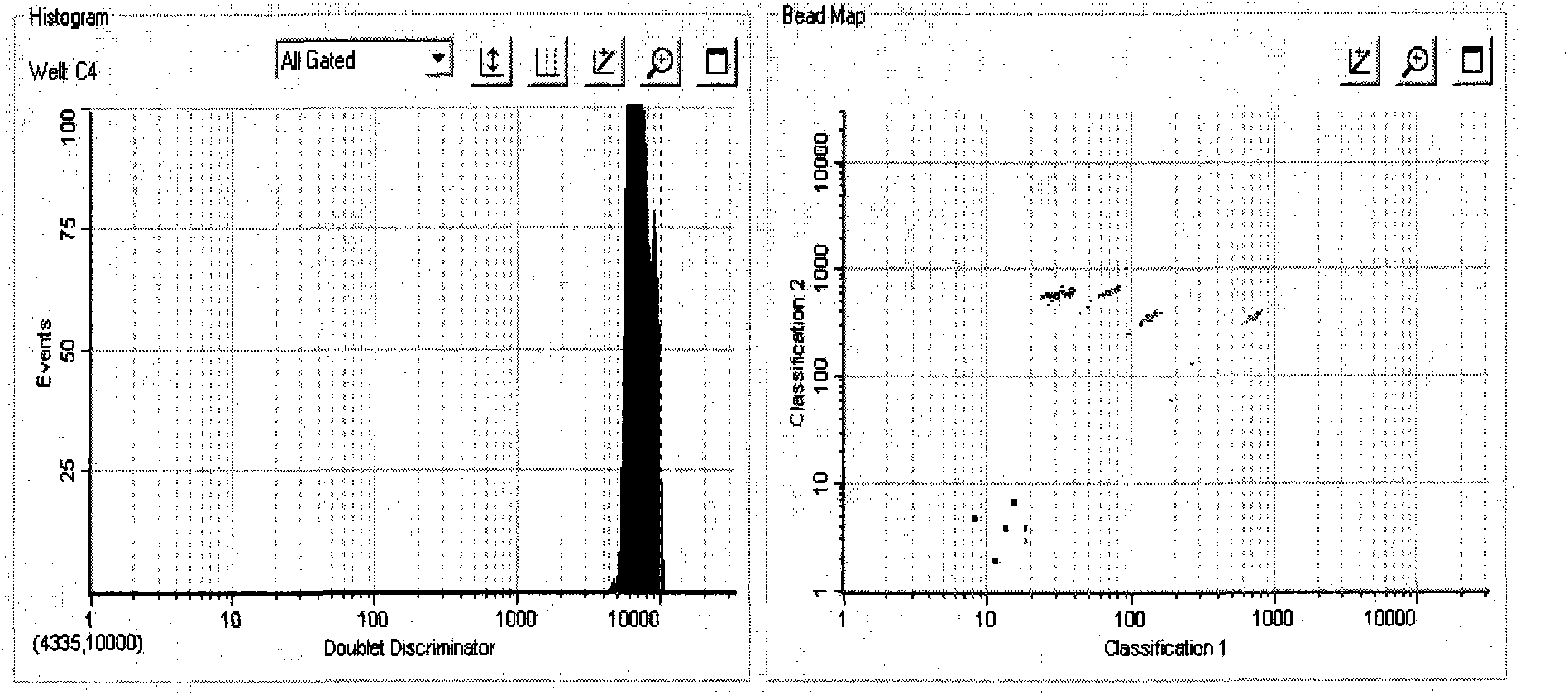

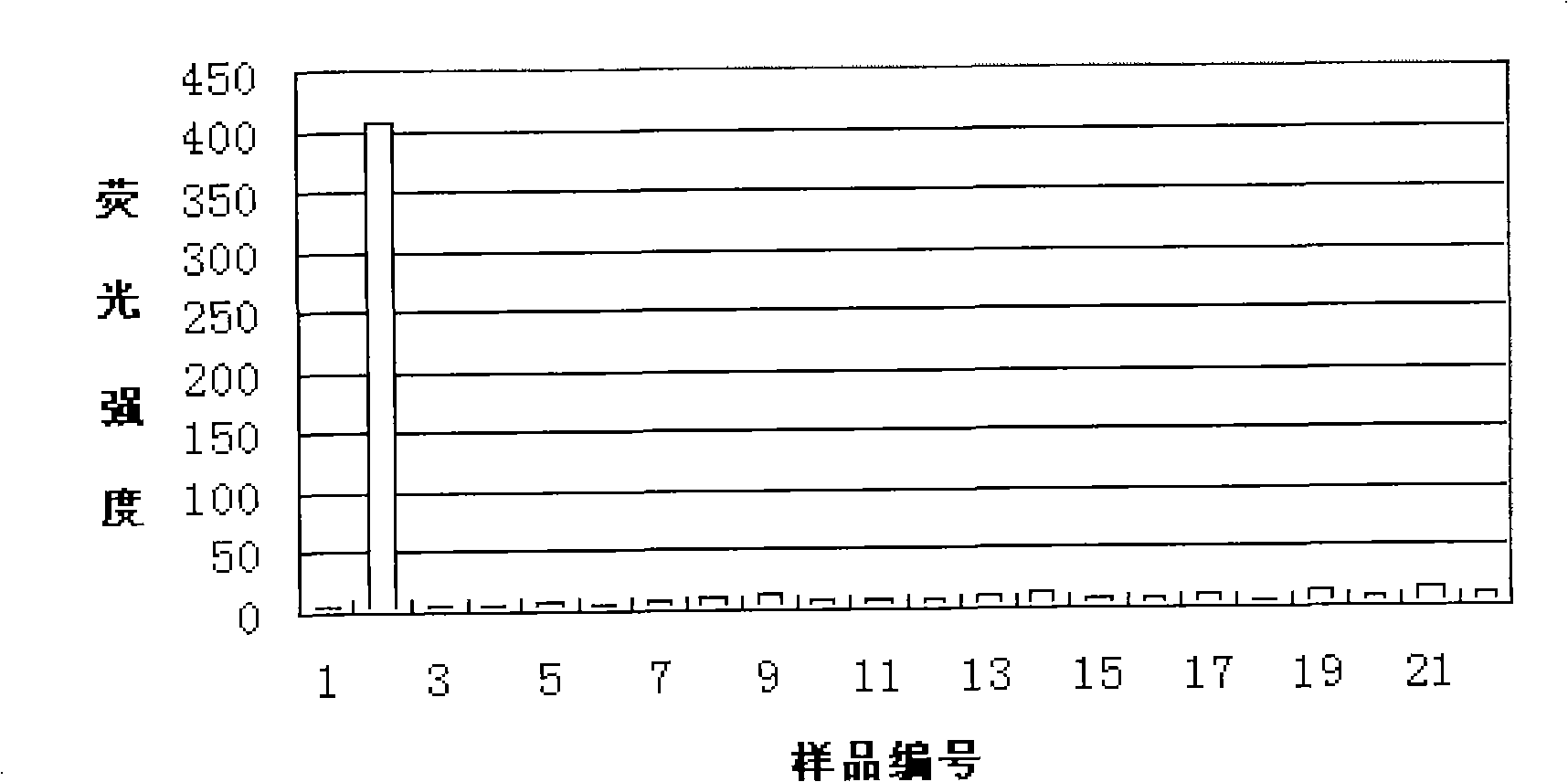

Methods for preparing, quantifying and detecting protein suspension chip of ricin

InactiveCN101545905ACoating volume improvementHigh sensitivityChemiluminescene/bioluminescenceBiotin-streptavidin complexAnalysis data

The invention relates to a protein suspension chip of ricin and methods for preparing, quantifying and detecting the same. The detecting method comprises the following steps: adding a working solution and a sample to be tested into a hole; adding a detection antibody; adding SA-PE; adding a detection buffer solution and mixing the mixture evenly; and reading numerical values, analyzing data and judging the detection result. The quantifying method comprises the following steps: adding a positive test sample or a standard product for dilution through gradient multiple proportions, detecting a series of diluted samples in a suspension chip system, and reading a corresponding fluorescence value (MFI); making a dosage-reaction curve; and fitting the dosage-reaction curve and an equation. The suspension chip comprises a coded microsphere, a ricin capturing antibody coated on the microsphere, a biotin-marked ricin detection antibody, a streptavidin-phycoerythrin and the buffer solution. The methods have the advantages of good detectability, high sensitivity, strong specificity and wide dynamic range.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Cement-based polymer waterproof mortar and preparation method thereof

The invention discloses cement-based polymer waterproof mortar which is characterized by being prepared from, by weight, 5-10 parts of 3-chloro-2-hydroxy propane sulfonic acid ionized modified hyperbranched polyamino acid, 2-5 parts of a fatty acid-based addition polymer, 0.5-2.5 parts of calcium borogluconate, 1-3 parts of nano alumina sol, 10-15 parts of pelelith powder, 100 parts of Portland cement, 3-7 parts of palygorskite powder, 3-5 parts of glass fiber powder, 3-8 parts of industrial solid waste powder, 20-30 parts of a styrene-acrylic emulsion, 1-3 parts of sodium laureth sulfate modified crosslinked super absorbent resin, 80-120 parts of fine sand and 80-100 parts of water. The invention also discloses a preparation method of the cement-based polymer waterproof mortar. The cement-based polymer waterproof mortar has the advantages of good impermeability, low water absorption rate, high bending strength and bonding strength, convenient construction, aging resistance and remarkable waterproof performance.

Owner:福建万施博建材有限公司

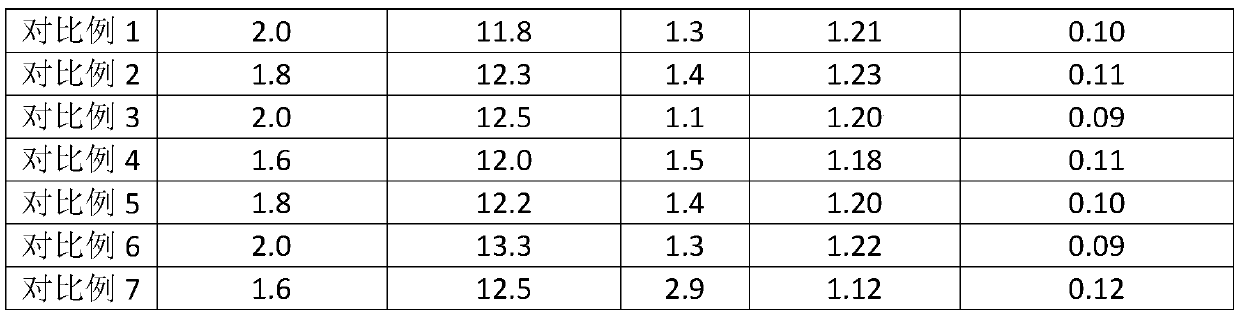

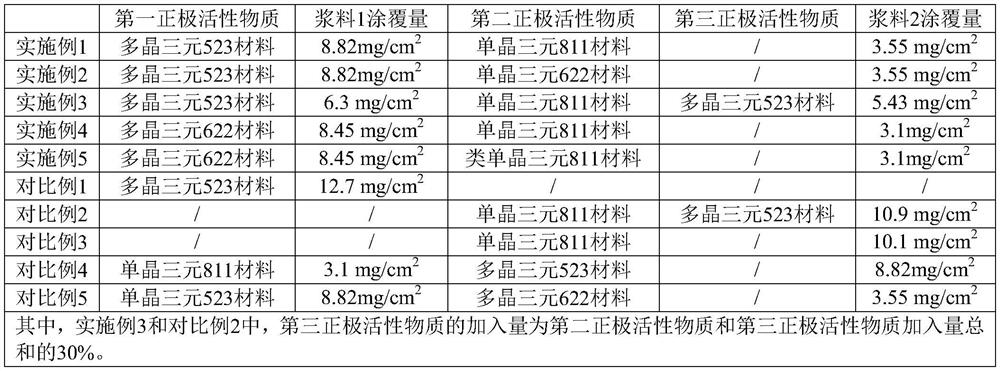

Positive electrode sheet capable of discharging at high rate, and lithium ion battery comprising positive electrode sheet

PendingCN112151793AImprove conductivityImprove securitySecondary cellsPositive electrodesElectrolytic agentElectrical battery

The invention provides a positive electrode sheet capable of realizing high-rate discharge, and a lithium ion battery comprising the positive electrode sheet. According to the invention, a first positive electrode active material layer is prepared from a first positive electrode active material comprising a polycrystalline nickel-containing ternary material, and a second positive electrode activematerial layer is prepared from a second positive electrode active material comprising a monocrystalline or monocrystalline-like nickel-containing ternary material; by arranging the first positive electrode active material layer and the second positive electrode active material layer, the coating amount can be reduced, and the rate capability of a lithium ion battery can be improved, or the energydensity of the lithium ion battery can be increased while the rate capability of the lithium ion battery is ensured; and by utilizing the characteristics of good stability of the second positive electrode active substance and relatively small contact area with an electrolytic solution, the side reaction in the high-rate discharge process can be reduced, the risk of gas production failure is reduced, and the quick discharge performance of the system can also be ensured.

Owner:ZHUHAI COSMX BATTERY CO LTD

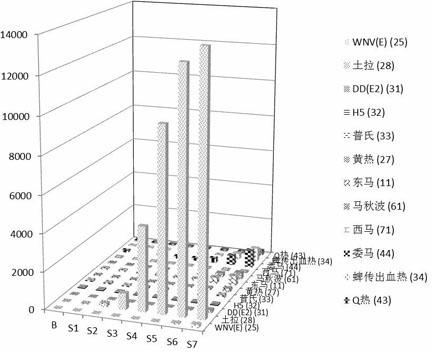

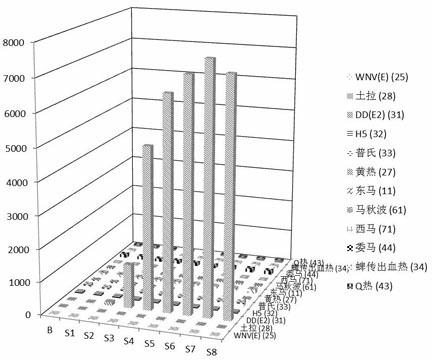

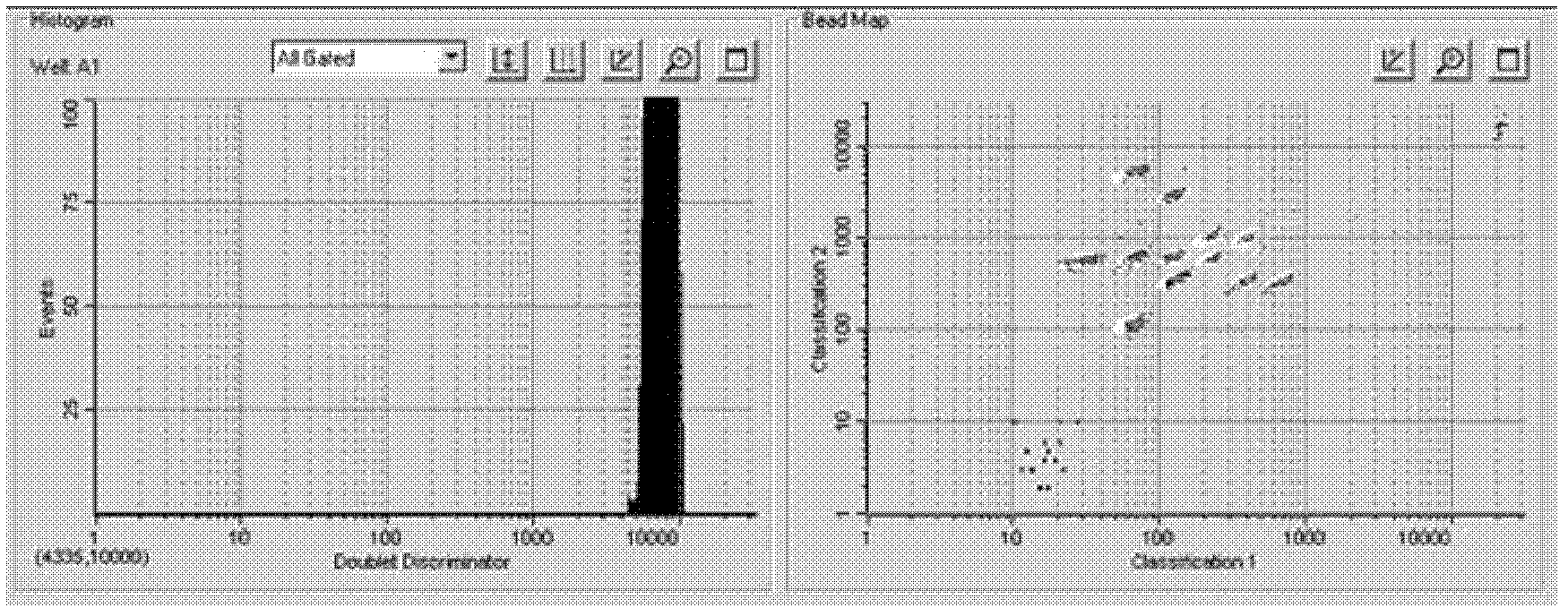

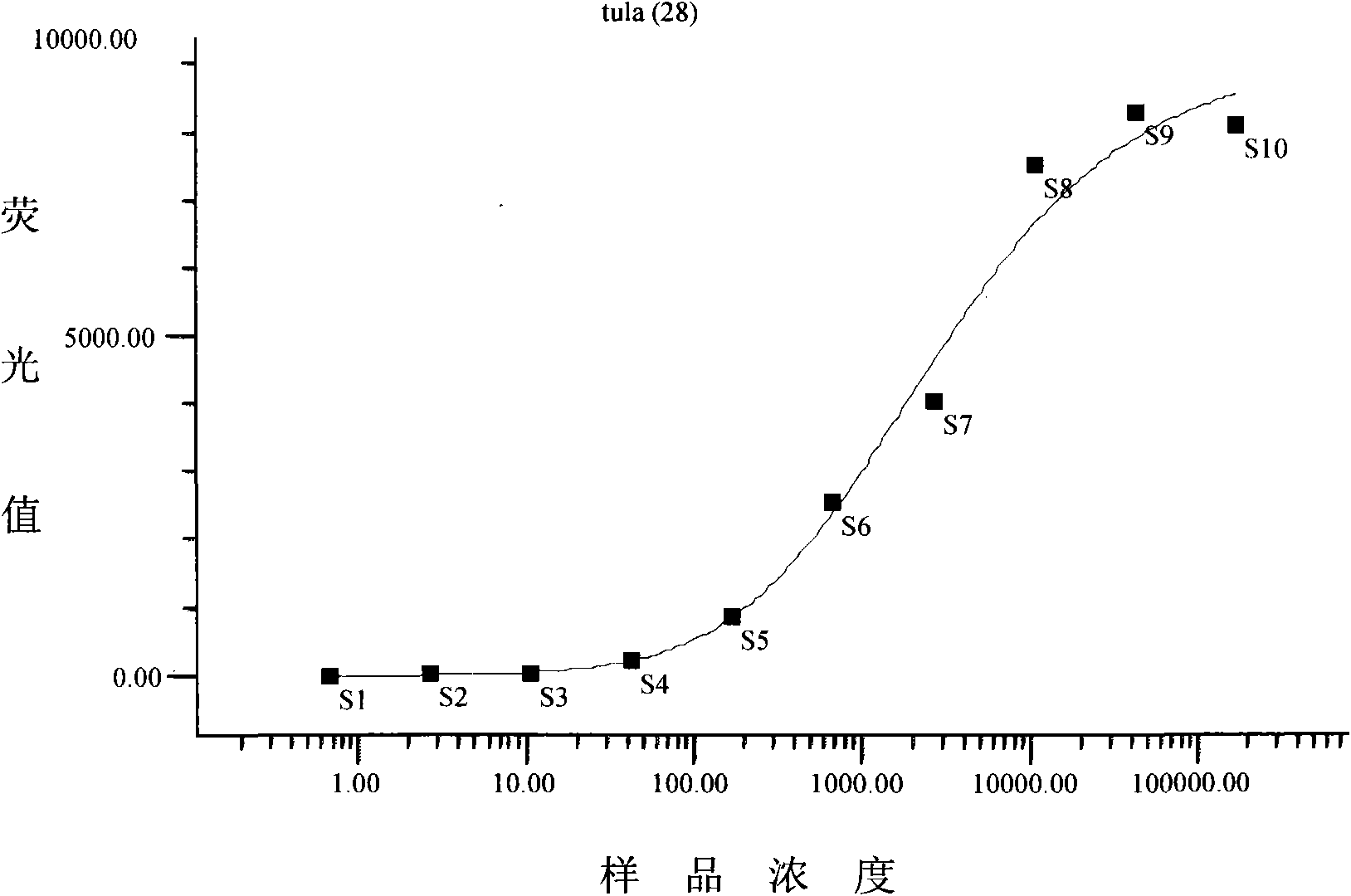

Liquid phase chip for detecting twelve pathogen antibodies in blood serum sample in high flux, and preparation method and using method thereof

InactiveCN102183666AFlexible detectionEasy to detectBiological testingFluorescence/phosphorescenceMicroorganismSerum samples

The invention discloses a liquid phase chip for detecting twelve pathogen antibodies in a blood serum sample in high flux, and a preparation method and a using method thereof. The method is high in detection capability, sensitivity and specificity and wide in dynamic range; during sample detection at one time, the twelve pathogen antibodies can be detected at the same time; detection items can be organized flexibly, so only the requested pathogen antibodies are detected; moreover, an open detection modeling platform which is represented by a Tula antibody and a Dengue antibody and used for detecting the liquid phase chip for quantitatively detecting microorganism antibodies is built.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Positive electrode sheet capable of discharging at high rate, and lithium ion battery comprising positive electrode sheet

InactiveCN112151794AImprove conductivityImprove securitySecondary cellsPositive electrodesElectrolytic agentElectrical battery

The invention provides a positive electrode sheet capable of realizing high-rate discharge, and a lithium ion battery comprising the positive electrode sheet. According to the invention, a positive active material layer is prepared by mixing a first positive active material (polycrystalline nickel-containing ternary material) and a second positive active material (monocrystalline or monocrystalline-like nickel-containing ternary material), and can reduce the coating amount and improve the rate capability of a lithium ion battery at the same time, or increase the energy density of the lithium ion battery while ensure the rate capability of the lithium ion battery; and by utilizing the characteristics that a second positive electrode active substance has good stability and the contact area with an electrolytic solution is small, the side reaction in the high-rate discharge process can be reduced, the risk of gas production failure is reduced, and the quick release performance of the system can be ensured.

Owner:ZHUHAI COSMX BATTERY CO LTD

Coated titanium anode and spraying pyrolysis preparation method thereof

ActiveCN107779847AOvercome the technical flaw of short lifespanLow costLiquid/solution decomposition chemical coatingSlurryMaterials science

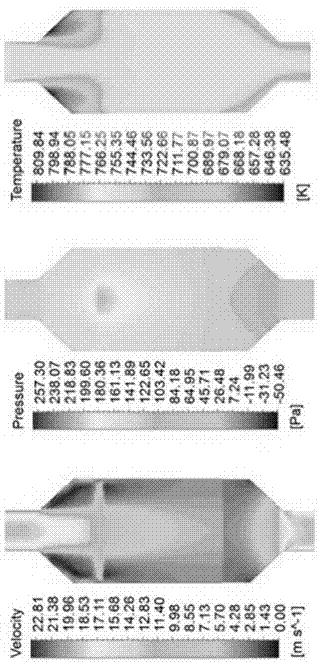

The invention belongs to the field of preparing electrodes for electrochemical engineering, and more specifically, relates to a coated titanium anode and a spraying pyrolysis preparation method thereof. The method includes following steps: (1), coating the surface of a titanium plate after being pretreated with an antioxidation layer; (2), controlling temperature of the titanium plate to 250-300 DEG C, and atomizing and spraying electrode preparation raw material slurry onto the surface of the antioxidation layer of the titanium plate; (3), sintering the titanium plate at high temperature to obtain the coated titanium anode. The coated titanium anode is prepared by combining spraying technology with step-by-step thermal treatment, so that the technical defect of short service life of electrodes caused by the fact that coatings are prone to dry-cracking when being baked at high temperature in a brush-coating method in the prior art is overcome ingeniously; quick and accurate preparationof the coated titanium anode is realized, preparation cost is low, and product quality is controllable. On the premise that performance is ensured, coating amount of precious metal is lowered greatly, cost of the coated titanium plate is lowered remarkably, and expansion and parity of applying the coated titanium anode are facilitated.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION +1

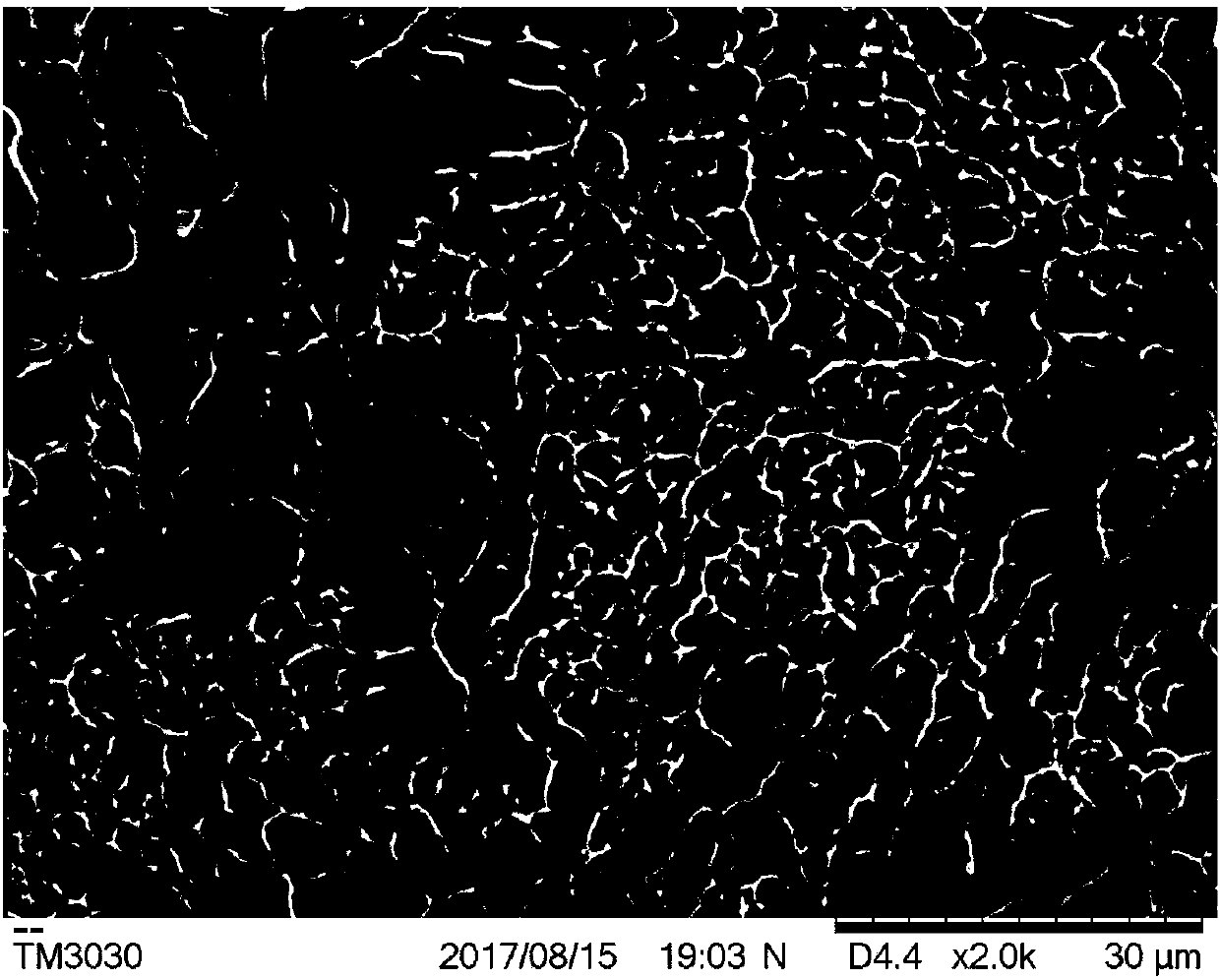

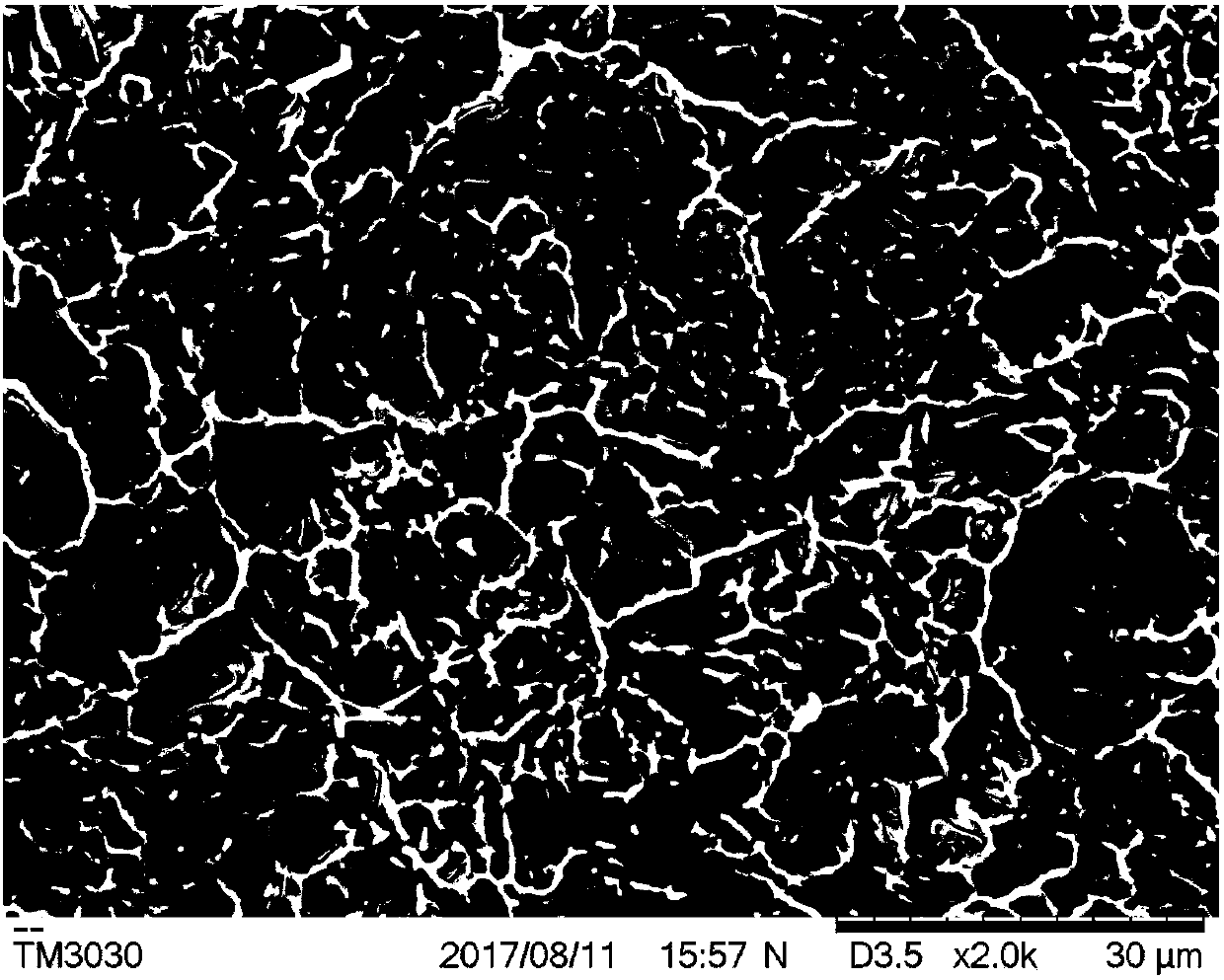

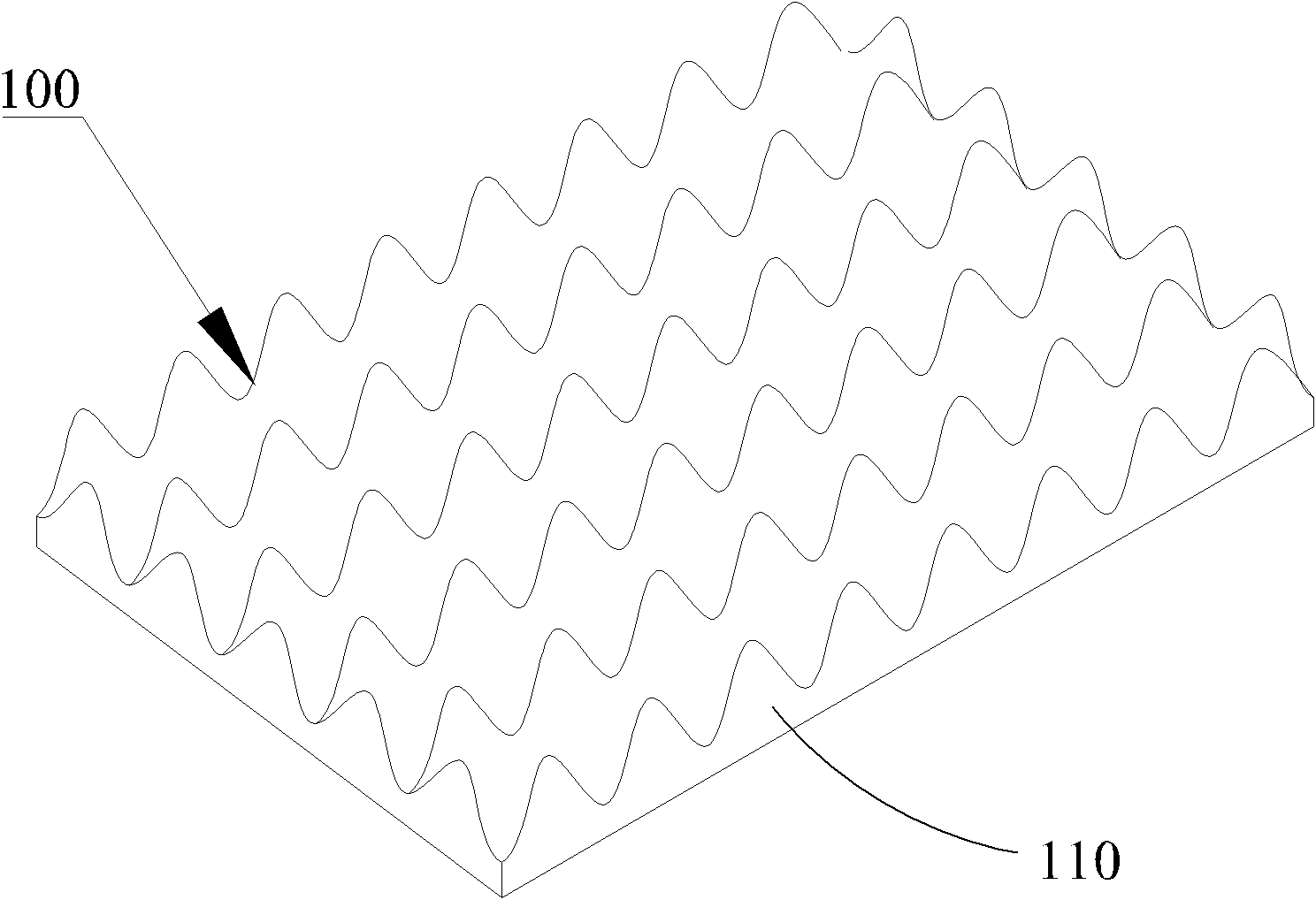

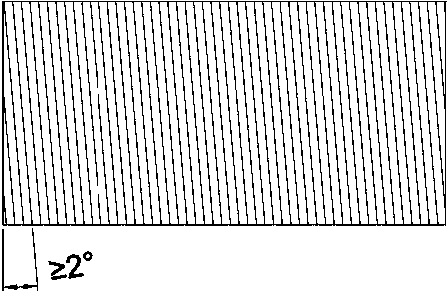

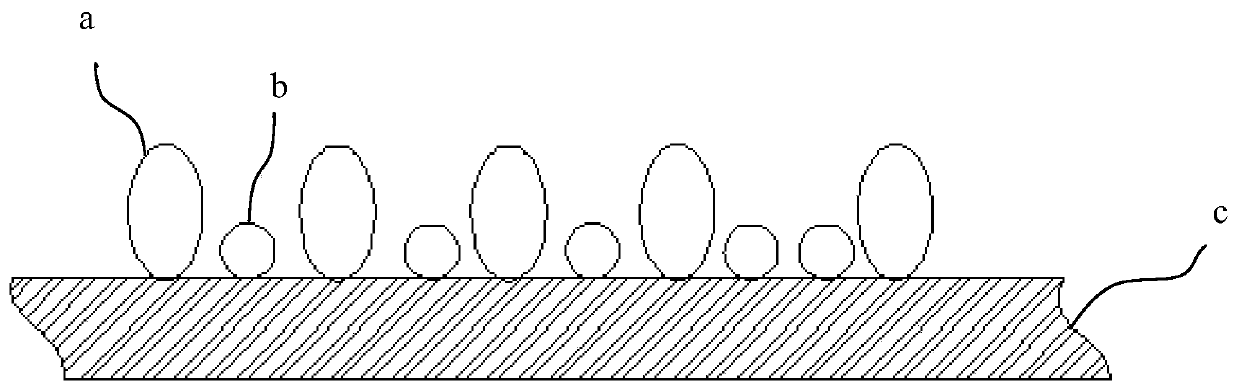

Electrode and method for manufacturing same

InactiveCN103151491ALarge specific surface areaHigh capacity densityNon-aqueous electrolyte accumulator electrodesHigh rateTrade offs

The invention relates to an electrode and a method for manufacturing the same. The electrode is manufactured by mixing slurry, coating, drying, rolling and cutting to shape, and includes a current collector and an electrode material layer coated on the surface of the current collector. The surface of the electrode material layer is arranged in a peak-valley shape after roughening treatment, and the roughening treatment step of electrode material layer is arranged after any step of drying, rolling or cutting to shape. According to the invention, the specific surface area of the electrode surface is increased by changing the surface morphology of the electrode, so that the electrode has a high specific surface area, the coating amount of an electrode active material can not be reduced, and the absorption rate and absorption amount of electrolyte by the electrode, thereby breaking the rule of a trade-off between rate and capacity and enabling the lithium battery to have both a high capacity density and improved rate performance, so that the lithium battery has high-rate charge and discharge characteristics; and a high coating amount of the electrode active material can better control stability of the prepared lithium battery, without foil leakage risks, thereby greatly reducing the security risks of lithium batteries.

Owner:SHENZHEN BAK BATTERY CO LTD +1

Preparation method of waterborne bass with pressure change resistance and high resilience property

The invention relates to a preparation method of a waterborne bass with pressure change resistance and high resilience property. The method comprises steps as follows: (1) preparation of slurry: 1) preparation of waterborne bass foaming slurry: 10-30 parts of tap water, 2-5 parts of a waterborne dispersant, 1-3 parts of a waterborne crosslinking agent, 3-6 parts of a waterborne stabilizer, 3-6 parts of a waterborne foaming agent, 2-5 parts of a medium-temperature microsphere foaming agent, 20-40 parts of filling powder and 1-2 parts of a thickener are sequentially added to 200-300 parts of waterborne polyurethane resin, the mixture is stirred and mechanically foamed, and the waterborne bass foaming slurry with uniform pores is prepared; 2) preparation of a curing liquid: 85-95 parts of tap water are added to 6-14 parts of a demulsifying curing agent and stirred uniformly, and the curing liquid is obtained; (2) preparation of the waterborne bass: the waterborne bass foaming slurry is uniformly applied to knitted or woven fabric and sequentially subjected to water washing and press drying after being solidified through the curing liquid and finally enters a five-zone stepped heating oven to be foamed and dried, and the waterborne bass is obtained. The waterborne bass is low in cost, safe, environment-friendly and high in pressure change resistance and air permeability.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD

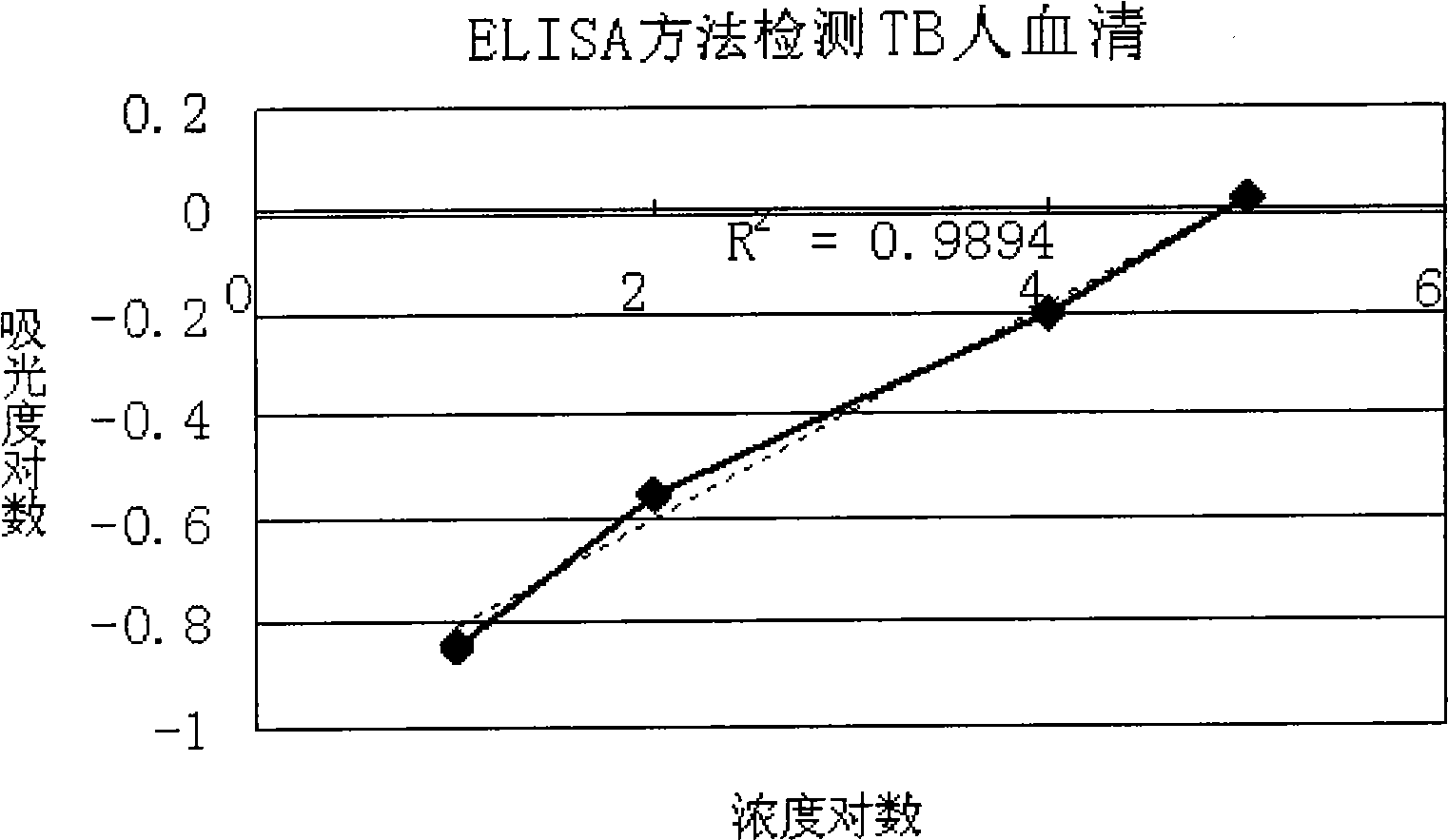

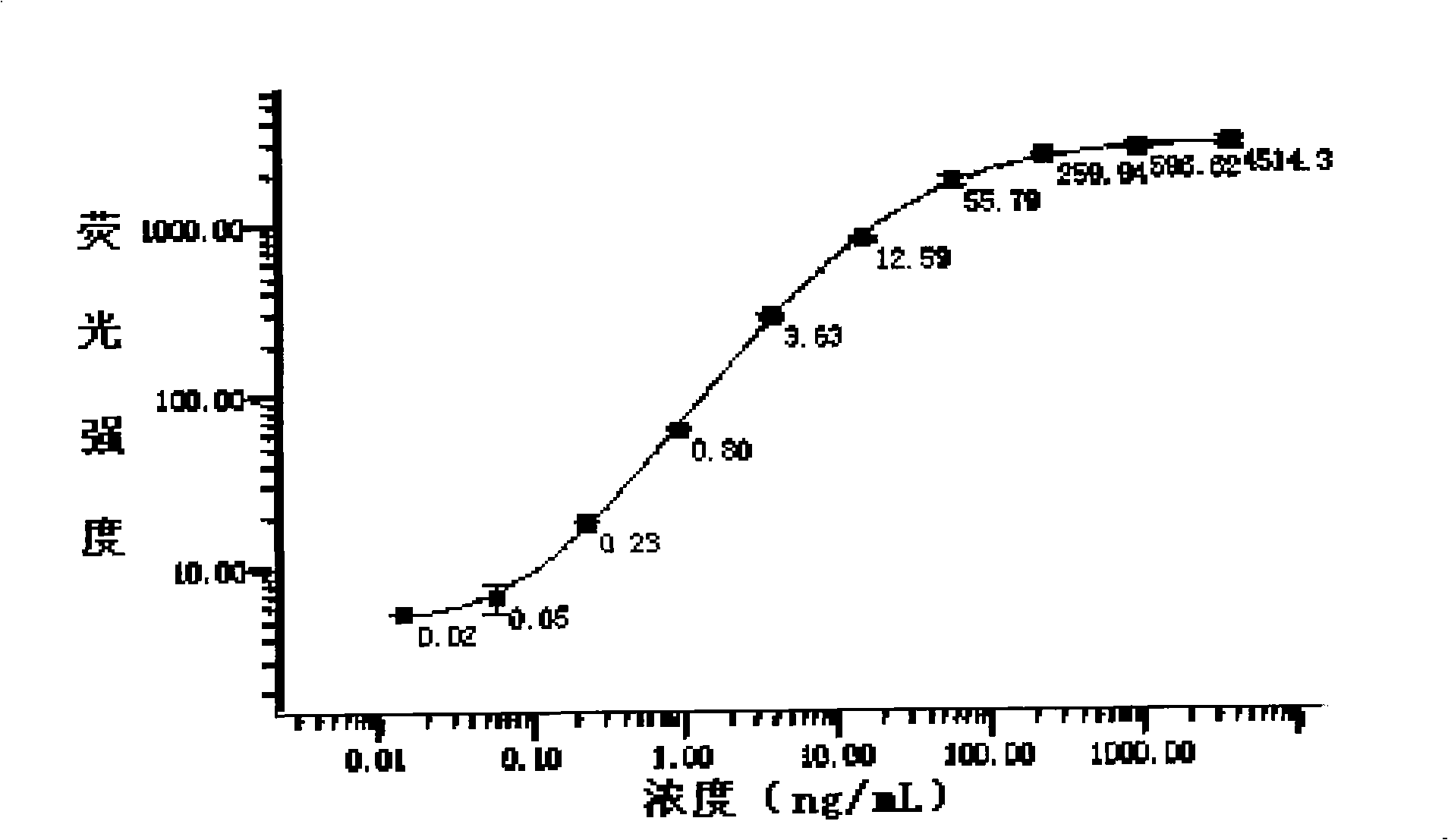

New method and product for detecting tuberculosis antibody in serum sample

The invention relates to a new quantitative detection method and a product for detecting tuberculosis antibody in a serum sample. The method of the invention has good detection capability, high sensitivity, strong specificity and wide dynamic range. The invention establishes an open detection modularised platform of pathogenic bacteria antibody protein suspension chip detection with the tuberculosis antibody as a representative.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

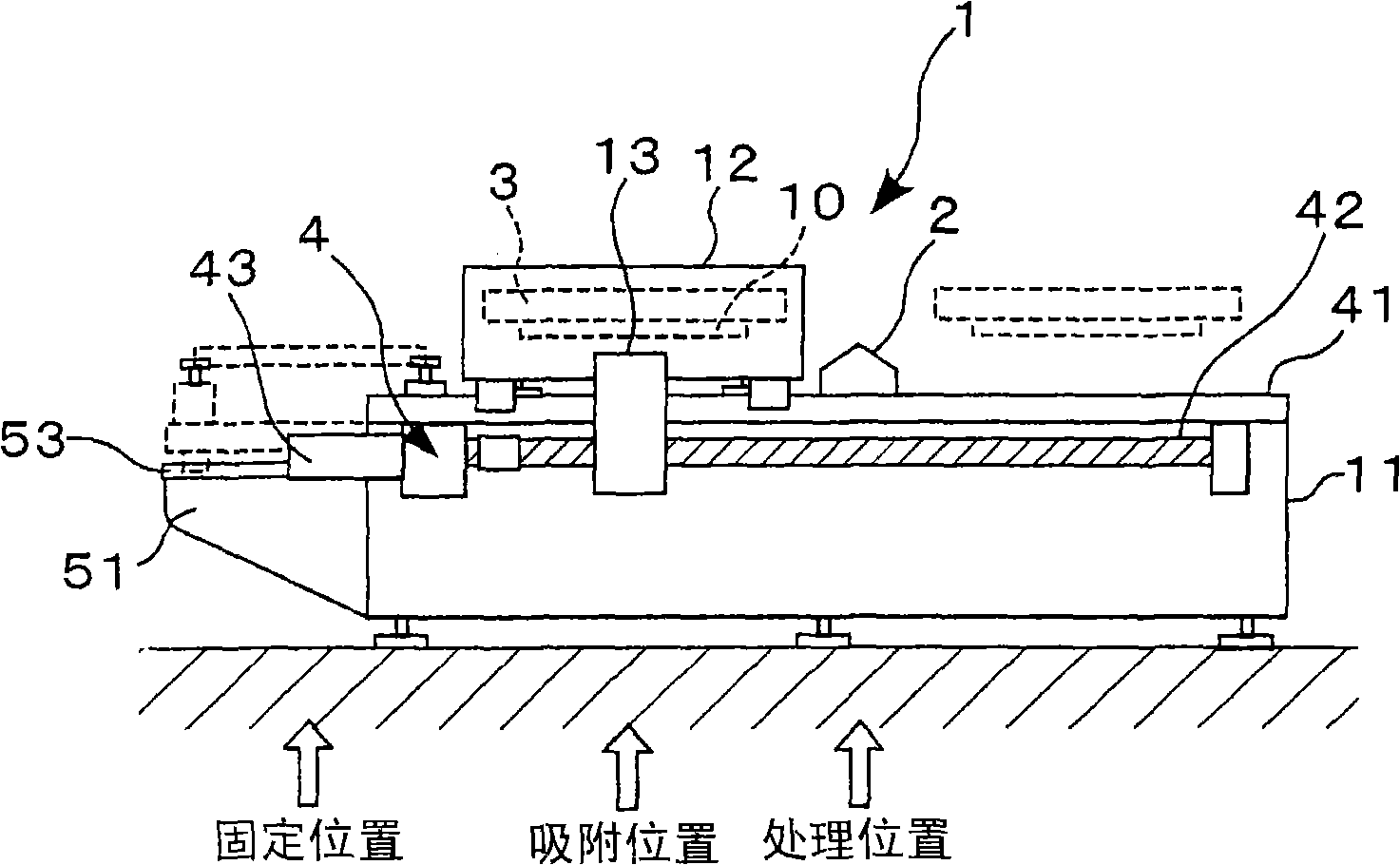

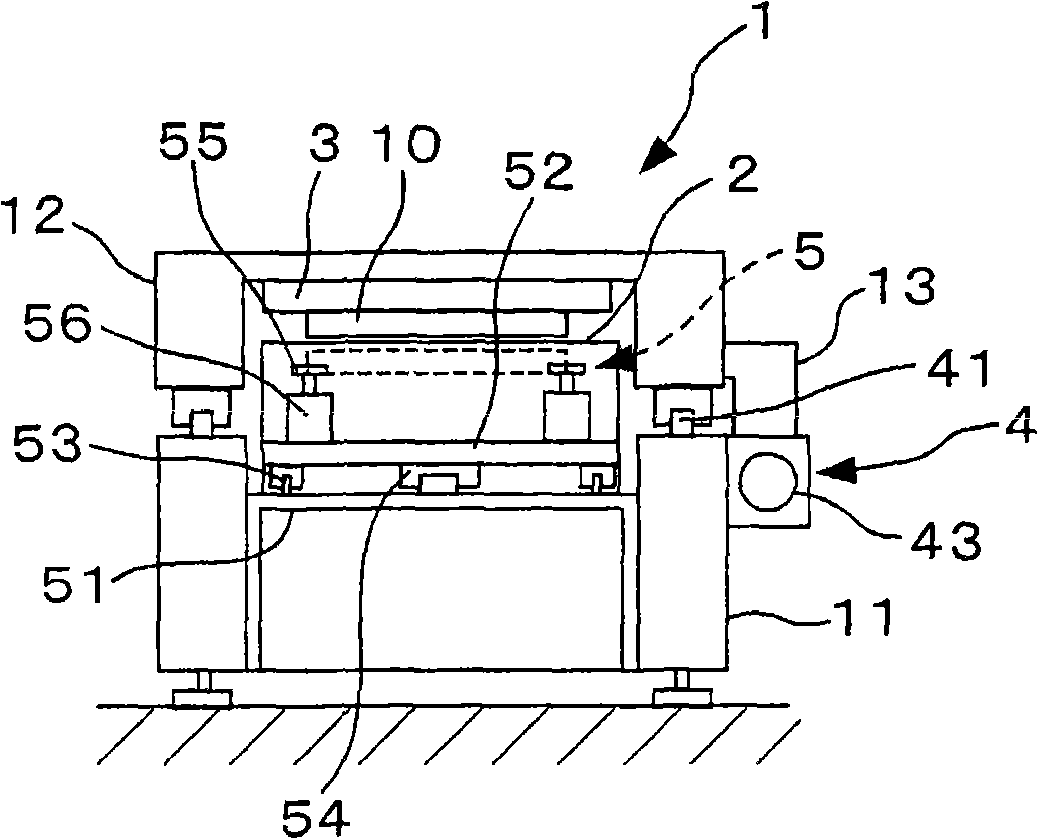

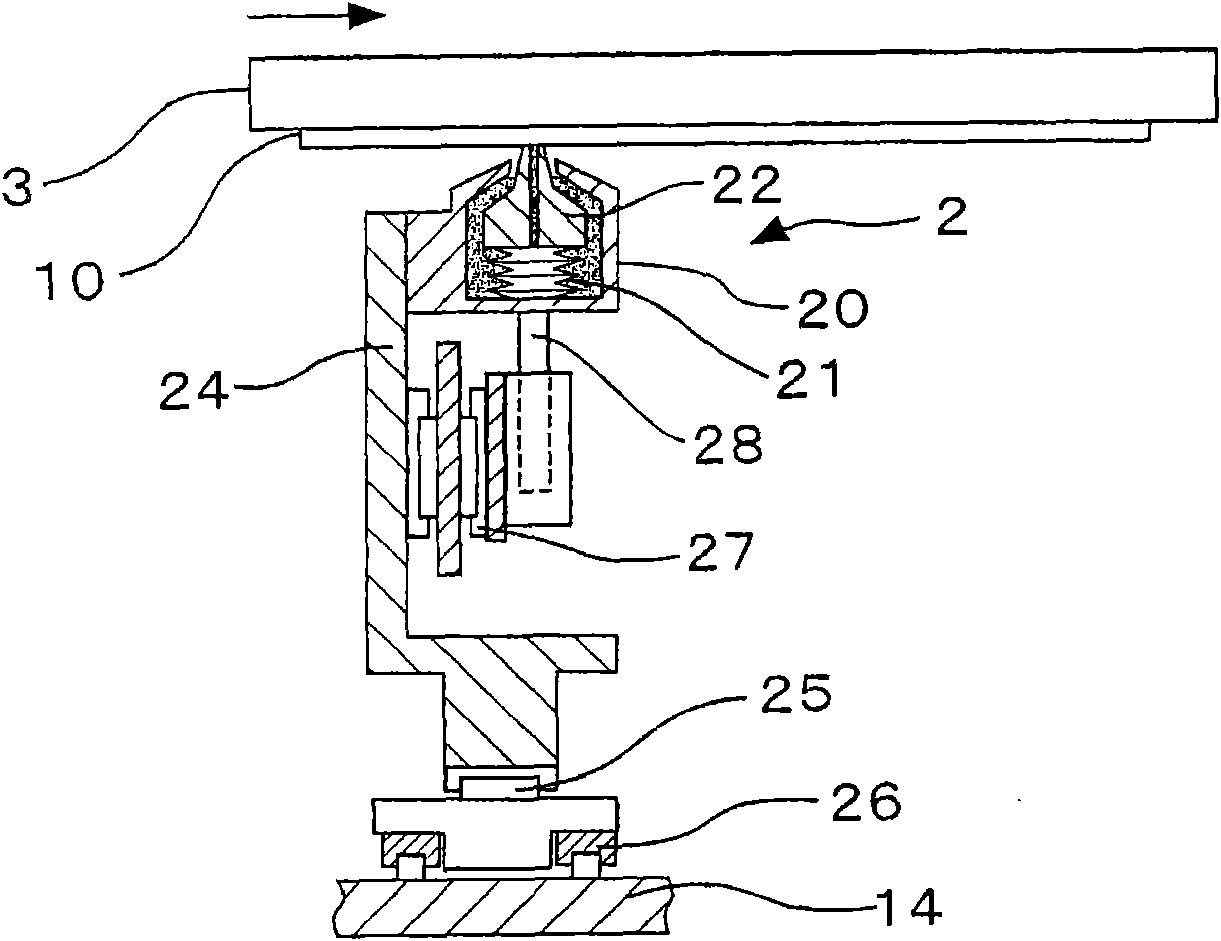

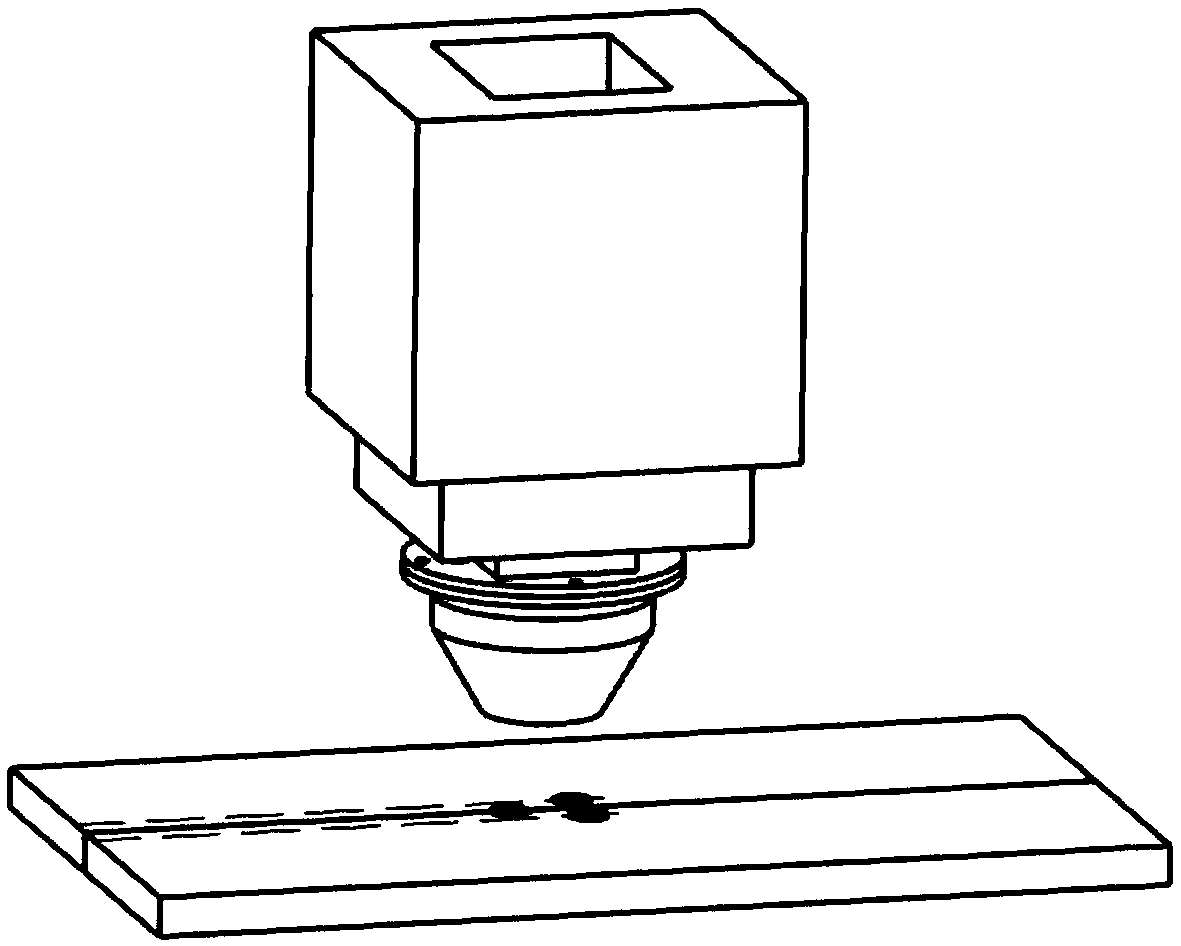

Method for manufacturing mask blank and photomask

InactiveCN101556435AImprove uniformityReduce the amount of coatingLiquid surface applicatorsSemiconductor/solid-state device manufacturingCoated surfaceResist

The present invention provides a method for manufacturing mask blank and photomask, comprising the following processes: causing the resists flowing from a liquid tank holding liquid resist to the front opening of a nozzle through a coating nozzle under the action of capillary phenomena to contact with the coated surface of a substrate having films for forming copy patterns, synchronously moving the substrate and the coating nozzle correspondingly, and then coating resists on the coated surface to form a resist film. In the process of forming the resist film, when the coating nozzle reaches nearby the coating ending position of the substrate through the corresponding movement, the coating condition is changed to reduce the coating amount of the coated surface.

Owner:HOYA CORP +1

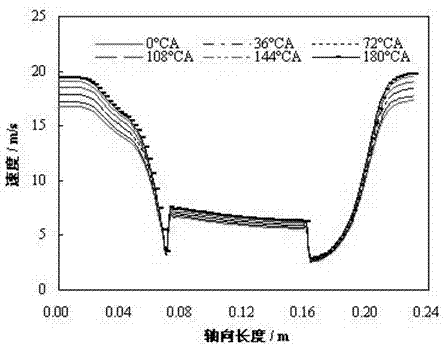

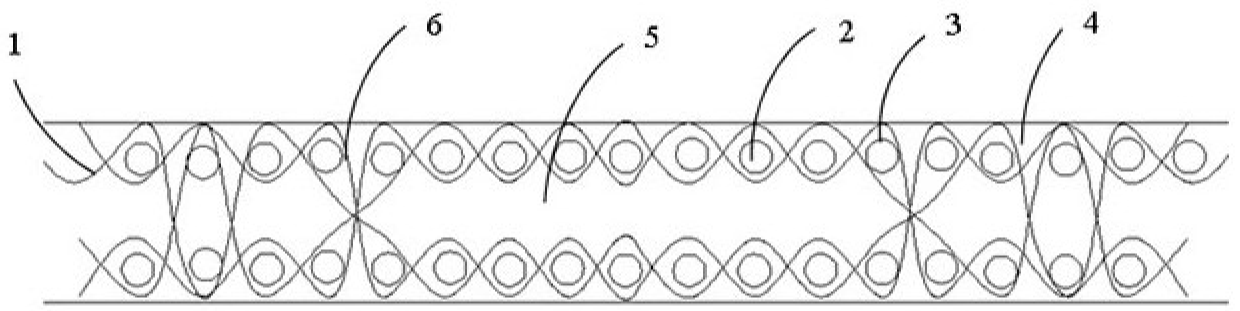

Hole-channel-staggering-type high-performance metal honeycomb carrier

InactiveCN103628957ALow costImprove conversion efficiency and utilizationCatalyst carriersExhaust apparatusExhaust gasMetal foil

The invention discloses a hole-channel-staggering-type high-performance metal honeycomb carrier which is characterized in that the metal honeycomb carrier is made only by corrugated plates in a coiling mode, a traditional structure of flat plates and corrugated plates is broken through, holes and channels are communicated in a staggering mode, a single straight-through hole-channel structure which is not communicated is avoided, design is ingenious, so that the flat plates are avoided, only the corrugated plates are used for making an inner core, and the using number of metal foil belt materials is saved by more than 35%. The metal honeycomb carrier of the novel structure is low in air resistance and even in air flow distribution, the problems that traditional flat plate and corrugated plate metal honeycomb carrier inner core air flow distribution is not even, and the catalyst using rate is not sufficient are solved, and the metal honeycomb carrier is suitable for tail gas purifying catalyst coating of engines for various purposes.

Owner:黄小春

Coating fabric for air bags and production method thereof

The invention discloses a kind of coating fabric for air bags and a production method thereof. The fabric is composed of weft yarns and warp yarns, which are polyester flat yarns with a flatness rate of 1.6 to 2.5, the coating amount of the fabric is 10 to 15 g / m2, and the capacity of the fabric is 1300 to 1500 cm3. The coating fabric for air bags has the characteristics of high tensile strength, good capacity, low air permeability, and low production cost.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

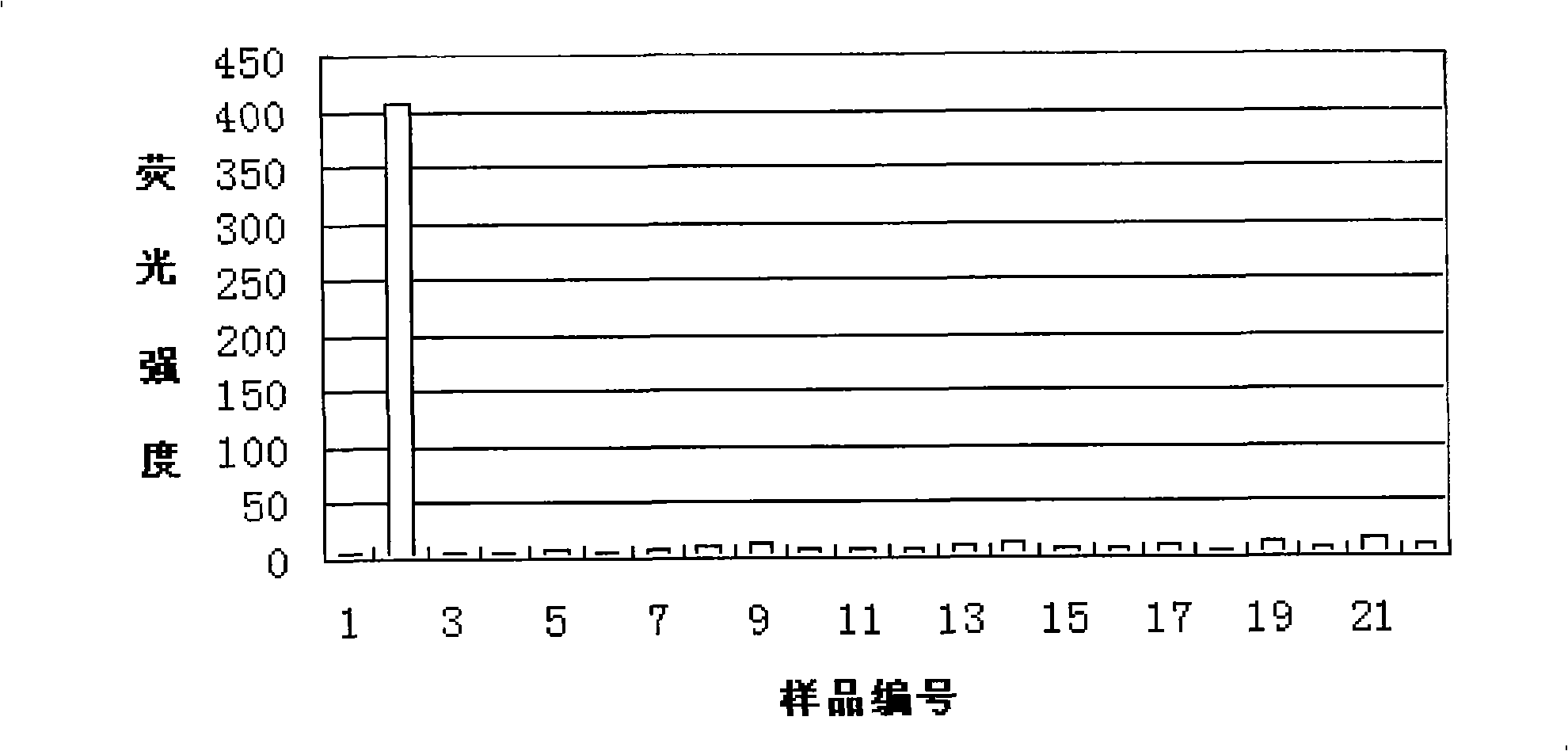

Protein suspension chip method capable of quantitatively determining yersinia pestis

InactiveCN101493468ACoating volume improvementReduce the amount of coatingBiological testingYersinia pestisBiology

The invention aims at providing a protein suspension chip which can quantitatively detect the bacteria and a detection method thereof, particulary relates to a method for detecting the protein suspension chip which is suitable for quantitative detection and analysis of Yersinia pestis (Y.pestis). The method has high sensitivity, strong specificity, good detection capacity and wide dynamic range, and establishes a new detection mode platform.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

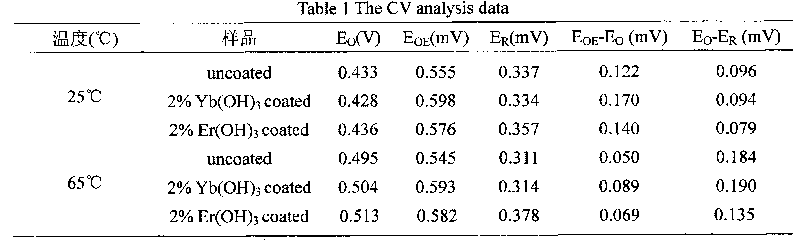

Preparation method of Co-covered nickel hydroxide anode material with surface covered by rare earth compound

InactiveCN101728521AGood high current charge and discharge performanceExcellent high temperature characteristicsAlkaline accumulator electrodesNickel oxide hydroxideCharge and discharge

The invention relates to a preparation method of a Co-covered nickel hydroxide anode material with the surface covered by a rare earth compound, belonging to the field of materials. The preparation method is characterized by covering a certain amount of Yb(OH)3 or Er(OH)3 on the upper surface of the nickel hydroxide material covered by 2.0 percent Co(OH)2. The discharge capacity of nickel hydroxide covered by 2 percent Yb(OH)3 is enhanced by 45 mAh / g compared with uncovered nickel hydroxide during 0.2 C charge and discharge at the high-temperature performance of 65 DEG C; the utility ratio of active materials of the nickel hydroxide covered by the 2 percent Yb(OH)3 is still 85 percent; the high-temperature charging and discharging performance of the nickel hydroxide covered by the certain amount of Er(OH)3 is also obviously improved; the discharge capacities of 1 C and 3 C at 65 DEG C are respectively 295.7 mAh / g and 290.3 mAh / g; the utility ratios of the active materials respectively reach 83 percent and 81 percent; and the optimal covering amount of Fr is 1.0-2.0 percent.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

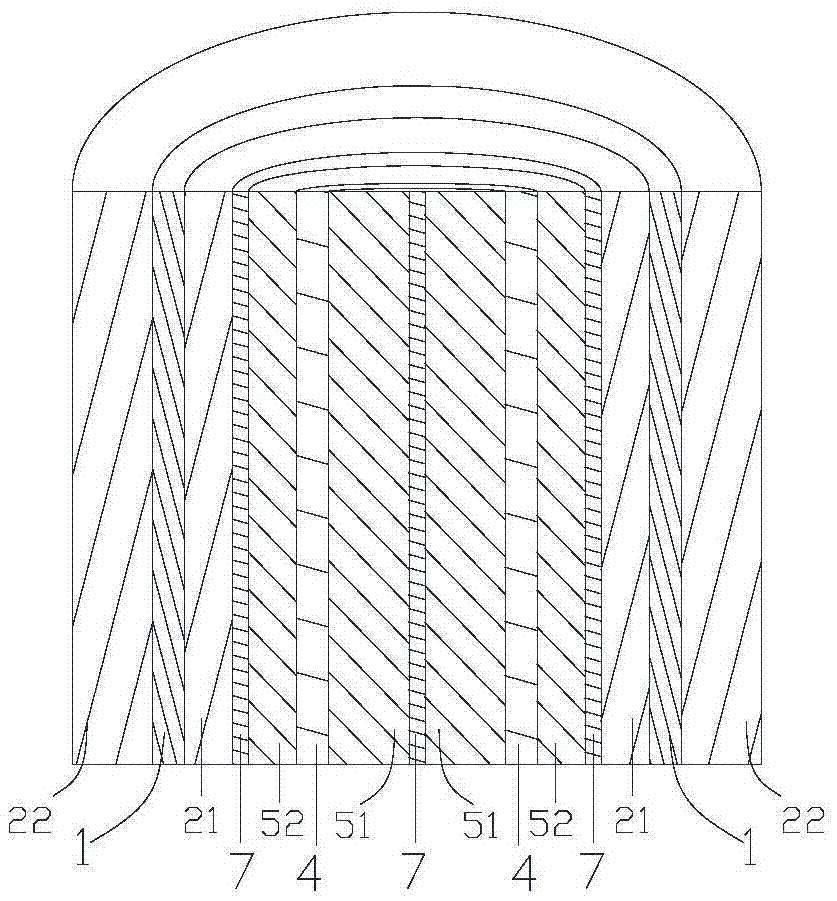

Lithium ion battery positive electrode plate and lithium ion battery negative electrode plate, making methods thereof, roll core, and lithium ion battery

PendingCN106941150AFit closelyIncrease compaction densityFinal product manufactureSecondary cellsEngineeringLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and concretely discloses a lithium ion battery positive electrode plate and a lithium ion battery negative electrode plate, making methods thereof, a roll core, and a lithium ion battery. In the lithium ion battery positive electrode plate and the lithium ion battery negative electrode plate, the positive / negative electrode plate comprises a positive / negative electrode current collector layer, a positive / negative electrode light surface material layer and a positive / negative electrode shadow surface material layer; the positive electrode light surface material layer and the positive electrode shadow surface material layer are respectively arranged on two external surfaces of the positive electrode current collector layer; the negative electrode light surface material layer and the negative electrode shadow surface material layer are respectively arranged on two external surfaces of the negative electrode current collector layer; the surface density of the electrode material in the shadow material layer is 30-48% of the surface density of the total electrode material of the corresponding electrode plate; and the surface density of the electrode material in the light material layer is 52-70% of the surface density of the total electrode material of the corresponding electrode plate. The above positive and negative plate structure makes the positive electrode plate closely cooperate with the negative electrode plate in order to effectively increase the compacted density of the positive electrode plate and the negative electrode plate, so the energy density of the finally obtained lithium ion battery is improved by at least 8.5%.

Owner:ZHENGZHOU BAK BATTERY CO LTD +1

Solvent type polyurethane resin and preparation method thereof, and fluoride-free clothes with lotus leaf effect

ActiveCN110818880AExcellent resistance to hydrolysisLower surface energyTextiles and paperFluorine freeIsocyanate

The invention relates to solvent type polyurethane resin and a preparation method thereof, and fluoride-free clothes with a lotus leaf effect. The polyurethane resin is prepared from the following rawmaterials according to a formula: polycarbonate polyol, polyether polyol, polyethylene glycol, micromolecular polyol, isocyanate, a solvent, a catalyst, reactive organic silicon oil, fumed silica, aterminating agent and an auxiliary agent. According to the invention: the polycarbonate polyol, the polyether polyol and the polyethylene glycol are combined according to a specific ratio to constitute a macromolecular polyol mixture, while the micromolecular polyol in a specific proportion is matched, and specifically the reactive organic silicon oil and the fumed silica in a certain proportion are matched, so the coating formed by the polyurethane resin prepared by using the preparation method provided by the invention has the advantages of good hydrolysis resistance, aging resistance, moisture penetrability and low surface energy, wherein the surface energy of the coating is 15 to 20N / m, while the surface energy of water is 60 N / m.

Owner:JIANGSU HUADA NEW MATERIAL CO LTD

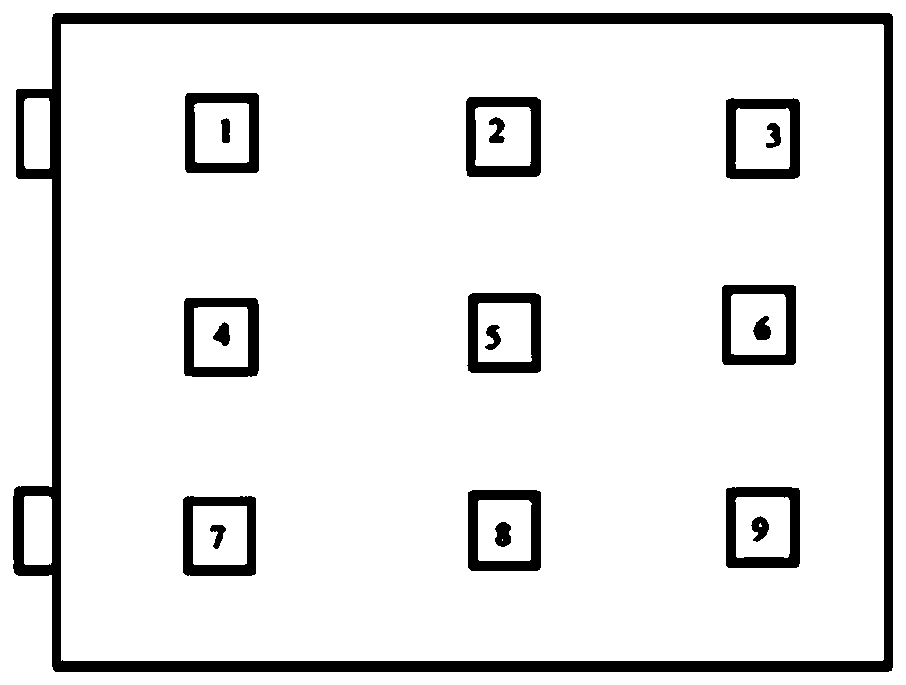

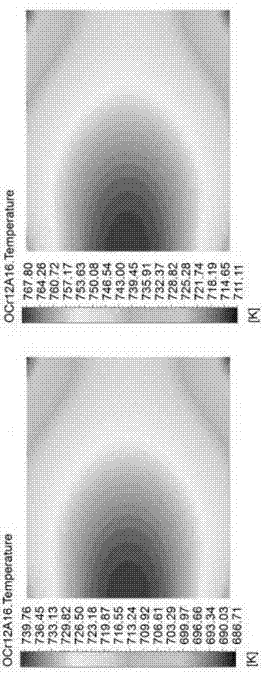

Preparation method of composite oxide catalyst used for purifying diesel engine

ActiveCN104759281AReduce the amount of coatingPerformance is not affectedExhaust apparatusDispersed particle separationPtru catalystPhysical chemistry

The invention relates to a preparation method of a composite oxide catalyst used for purifying a diesel engine and belongs to the technical field of catalysis. The catalyst is prepared with cordierite honeycomb-like ceramic as a carrier, with [gamma]-Al2O3 as a coating and with Pt as an active component with addition of components such as Ce, Ba and the like. In the composite oxide catalyst, one or two coated catalysts can be employed, when one coated catalyst is employed, the coated catalyst is one of an oxidizing catalyst or a reducing catalyst and the catalyst can be used for coating an A zone and a B zone of the carrier at different coating amounts; and when two coated catalysts are employed, one is the oxidizing catalyst and the other is the reducing catalyst. The one or two catalysts coat the same carrier with different loading capacities in the A zone and the B zone of the carrier. The composite oxide catalyst can effectively reduce discharge of PM and NOx in tail gas of the diesel engine, can effectively increase the conversion rates of the PM and the NOx, and is better in economy.

Owner:JIANGSU UNIV

Protein suspension chip for synchronously detecting various antibodies in serum sample and preparation method and using method thereof

InactiveCN101936989AEasy to detectReduce the amount of coatingFluorescence/phosphorescenceAgainst vector-borne diseasesSerum igeSerum samples

The invention discloses a protein suspension chip for synchronously detecting various antibodies in serum sample and a preparation method and a using method thereof. The method has the advantages of good detection capacity, high sensitivity, strong specificity and wide dynamic range, and an open detection modular platform of the protein suspension chip for detecting microbial antibodies represented by West Nile antibody, Francisella tularensis antibody, dengue fever antibody and influenza antibody is established.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Thermal insulating polymer composite glass fiber flame-retardant facing material for wall body

ActiveCN102535774AReduce appearance weightGood polyester leakage prevention and flame retardant effectCovering/liningsClimate change adaptationHalogenThermal insulation

The invention relates to a thermal insulating polymer composite glass fiber flame-retardant facing material for a wall body. According to the facing material, a reinforced glass fiber mat is adopted as a substrate, and a polymer flame-retardant cement mortar coating is coated through an advanced coating process. The polymer flame-retardant cement mortar coating is prepared by the following steps:(1) uniformly mixing and stirring a silane coupling agent KH-560, a dispersant K-1900 and water; (2) adding an acrylic polymer (45-50%), cement and sand into the uniformly stirred mixture, and fully and uniformly stirring at a speed of 800-1,200r / min; and (3) after uniformly stirring, adding a cellulosic thickener such as hydroxyethylcellulose, finally adding a flame retardant (non halogen class,99%) and uniformly stirring for later use. The thermal insulating polymer composite glass fiber flame-retardant facing material provided by the invention has the advantages of good flame retardance, high flatness, good thermal insulation system and light weight of appearance.

Owner:JIANGSU CHANGHAI COMPOSITE MATERIALS CO LTD

Fiber surface PE protective film pressure sensitive adhesive and preparation method thereof

InactiveCN101575485AGood viscosityReduce the amount of coatingEster polymer adhesivesSolventPressure sensitive

The invention discloses a fiber surface PE protective film pressure sensitive adhesive, which is prepared from the following raw materials by mass portion: 30 to 38 portions of acrylic acid 2-ethylhexyl acrylate, 0 to 4 portions of vinyl acetate, 0.4 to 2 portions of hydroxy-ethyl acrylate, 1.6 to 4 portions of acrylic acid and 55 to 60 portions of solvent. The PE protective film pressure sensitive adhesive prepared by the process is good in viscosity, can achieve a pressure sensitive effect by coating in a small amount during use, avoids PE thin film protruding and winding during drying due to small coated amount and prevents residual adhesive on a protected surface when the protective film is stripped, thereby being widely used for the manufacturing of PE protective films.

Owner:广东华丽宝实业有限公司

Protein suspension chip method capable of quantitatively determining yersinia pestis and method for making same

InactiveCN101493469ACoating volume improvementReduce the amount of coatingBiological testingYersinia pestisWide dynamic range

The invention aims at providing a protein suspension chip which can quantitatively detect the bacteria and a preparation method thereof, particulary relates to a protein suspension chip which is suitable for quantitative detection and analysis of Yersinia pestis (Y.pestis). The method has high sensitivity, strong specificity, good detection capacity and wide dynamic range, and establishes a new detection mode platform.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

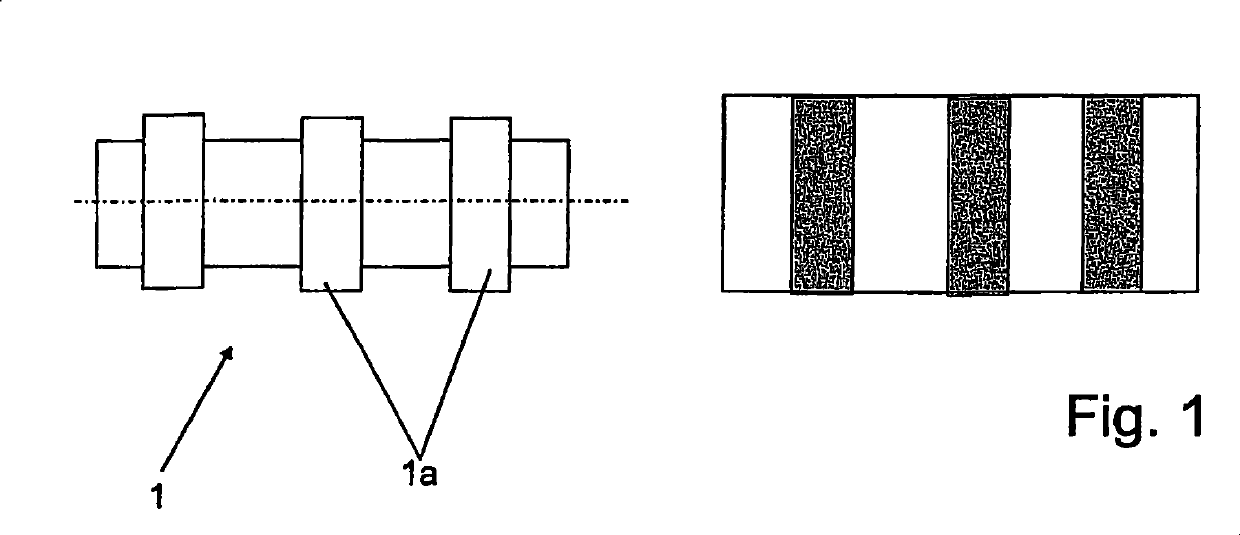

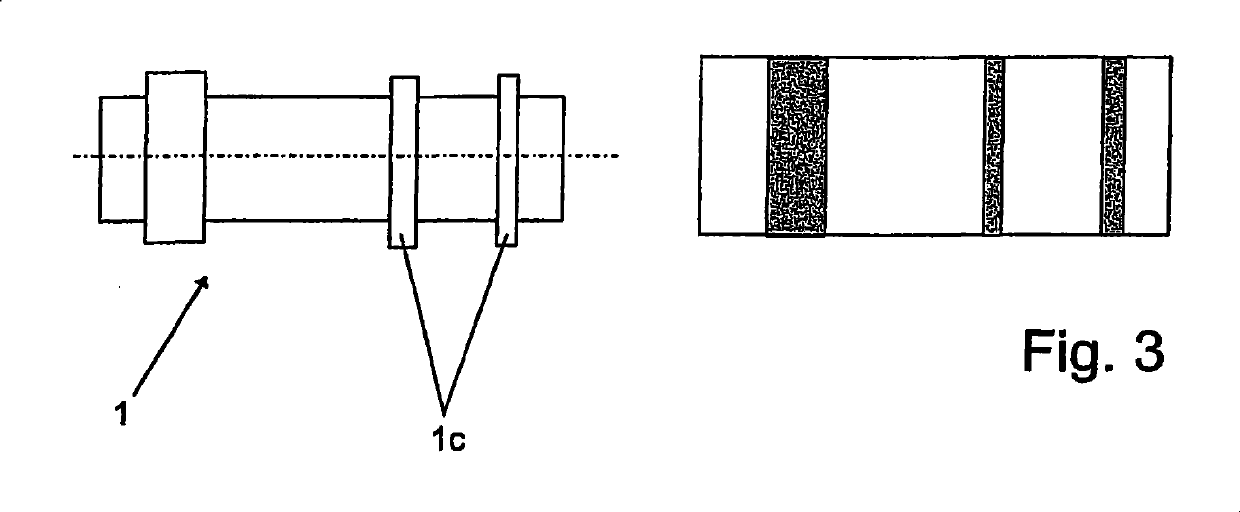

Method for producing a metal part

InactiveCN101374623AAvoid leavingCoating automaticHeat exchange apparatusMetal working apparatusMaterials scienceMetal

The invention relates to a method for producing a metal part. Said method comprises the steps of supplying a strand of metal material and applying a coating from a fluxing agent composition to a surface of the strand of material by means of an application device (1), said fluxing agent composition being applied to only a defined portion of the surface of the strand of material by means of the application device (1).

Owner:BEHR GMBH & CO KG

Laser welding method for plate composed of steel base body and pre-plating layer

ActiveCN111360406AHigh strengthReduce the amount of coatingWelding/soldering/cutting articlesLaser beam welding apparatusHeat-affected zoneButt joint

The invention discloses a laser welding method for a plate composed of a steel base body and a pre-plating layer. According to the laser welding method, firstly, a preheating heat source is adopted for preheating areas on the two sides of the butt joint position of adjacent plates, the pre-plating layer on the surface of a heat affected zone of the heated plate is melted and flows to the positionnearby a hot melting area formed after preheating, then the plate is subjected to laser welding, accordingly, the plating layer amount of the surface of a weld joint formed after plate welding is reduced, the plate is away from the weld joint, especially the heat affected zone, intermetallic compounds of the plate in the weld joint area are reduced, and the strength of the weld joint is improved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Low-air-permeability one-time forming safety air bag and production technology thereof

ActiveCN110549985AReduce usageReduce the amount of coatingPedestrian/occupant safety arrangementFibre typesFiberEthylene oxide

The invention discloses a low-air-permeability one-time forming safety air bag which comprises double cloth. The edge of the double cloth is continuously bonded together, and a cavity can be formed inthe double cloth. A moistening layer evenly covers the fiber surface of the double cloth, and the moistening layer is manufactured through a moistening layer treatment agent. The moistening layer treatment agent comprises the following components including, by weight, 0.5-10 parts of fatty alcohol and ethylene oxide condensation compounds, 0.5-10 parts of fatty alcohol polyoxyethylene ether, 0.5-10 parts of fatty alcohol glycol ether and 70-97.5 parts of water. Each of the front surface and the back surface of the moistening layer is evenly coated with a coating. The invention further discloses a production technology of the above low-air-permeability one-time forming safety air bag. The low-air-permeability one-time forming safety air bag and the production technology of the above low-air-permeability one-time forming safety air bag have the beneficial effects that on the premise that the same pressure maintaining performance is reached, 23%-31% of the coating amount can be reduced,the use amount of the chemical raw material of organic silica gel is reduced, the cost is saved, and the production process is more environment-friendly.

Owner:HMT XIAMEN NEW TECHN MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com