Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Good high current charge and discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite plumbago-carbon negative pole material and method of manufacturing the same

The invention discloses a method for preparing a composite graphite carbon cathode material, comprising the following steps that: 1. a step of adding and mixing materials, during which fine carbon powder and a caking agent with a weight ratio between 2:1 and 20:1 are added alternately in the stirring process, the mixture is stirred for 0.1 to 3 hours after adding the materials, the caking agent is selected from a thermoplasticity resin, asphalt and coal tar; 2. a step of increasing the temperature, during which the temperature is increased up to between 450 and 600 DEG C with a rate of 0.5 to3 DEG C per minute; 3. a step of keeping the temperature, during which the temperature of between 450 and 600 DEG C is kept constant for 1 to 10 hours; 4. a step of cooling to the room temperature; and 5. a step of graphitzation; wherein, the steps of 1 to 4 are performed without the protection of oxidation. The raw materials have high operating factor; the preparation method is environment-friendly and easy to implement; moreover, the composite graphite powder prepared has good isotropic properties and the characteristics of good high current performance, long cycle and low nonreversible capacity.

Owner:福建杉杉科技有限公司

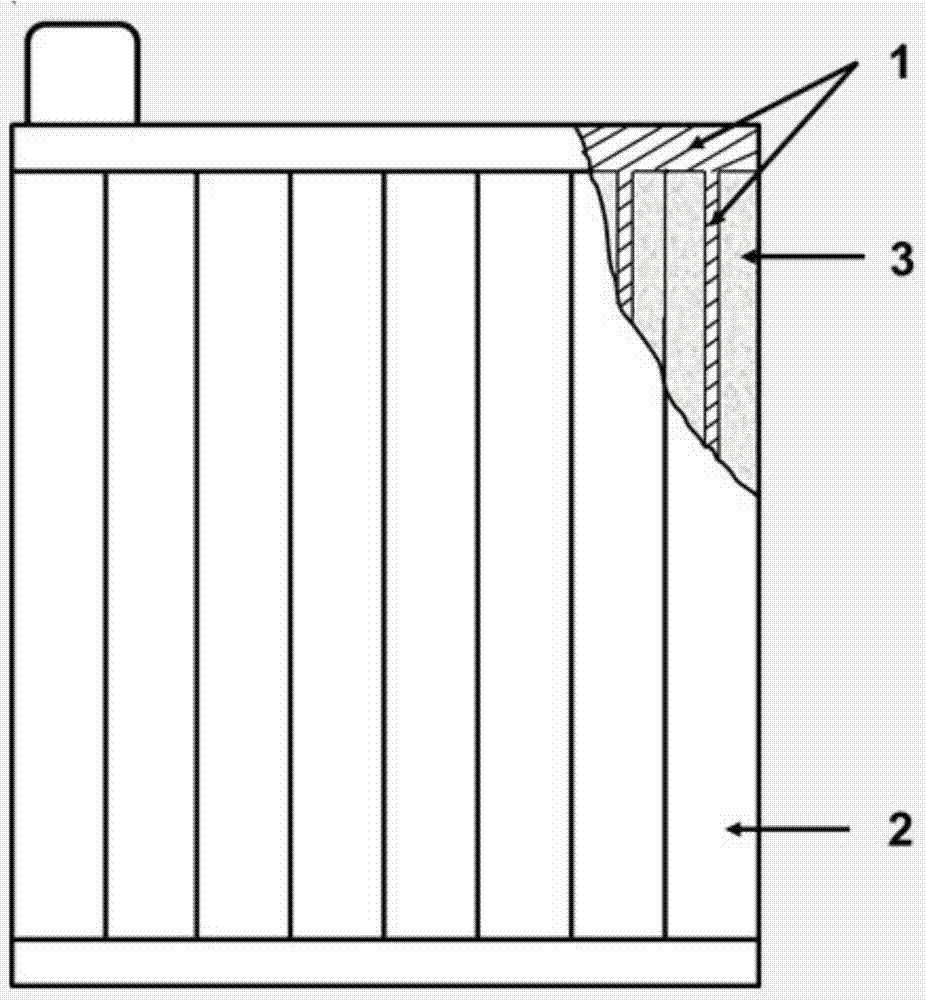

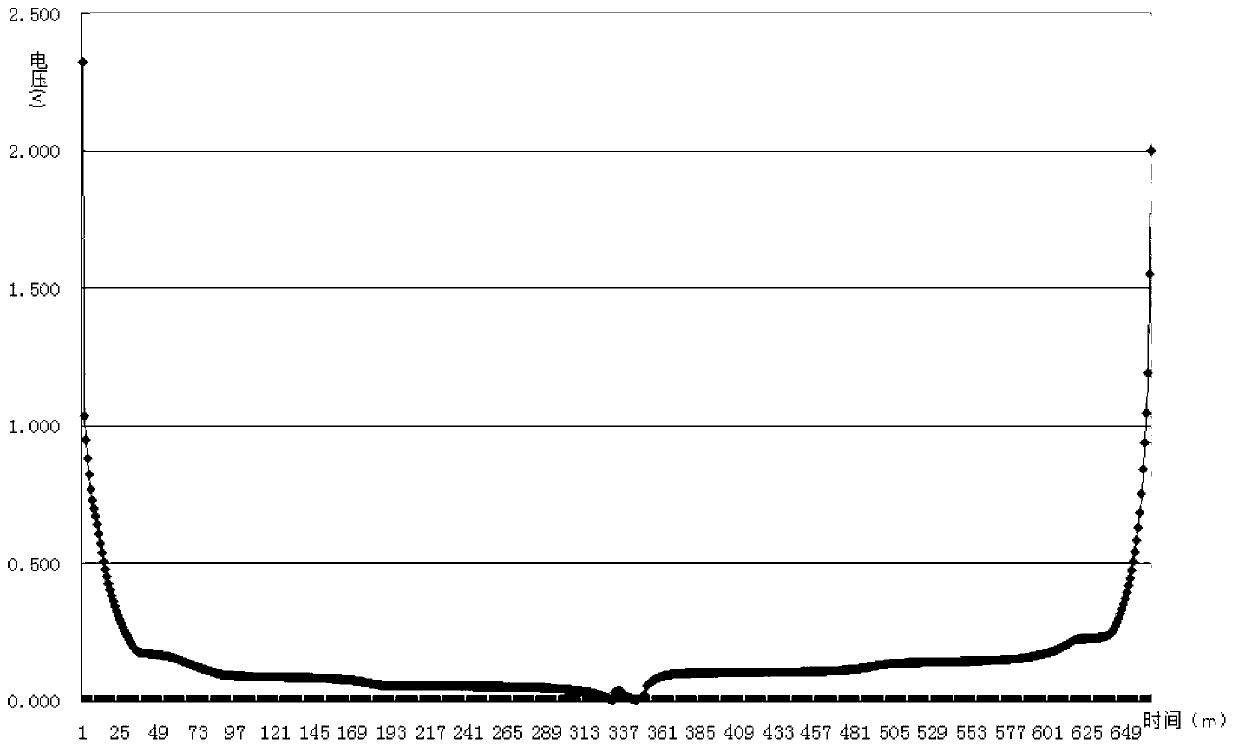

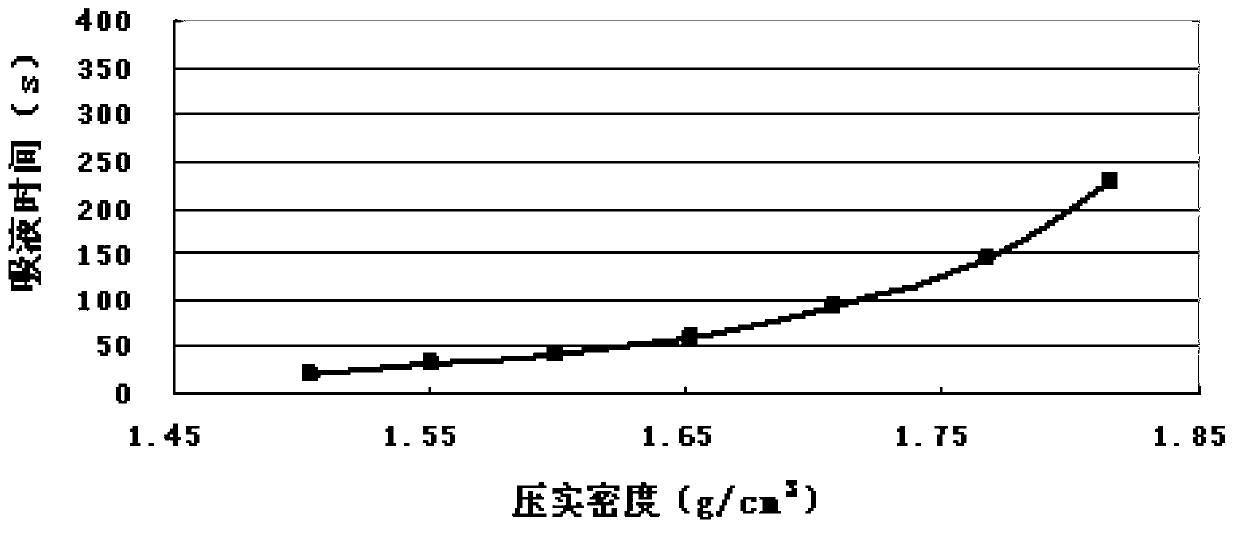

Negative plate of lead-carbon battery and preparation method

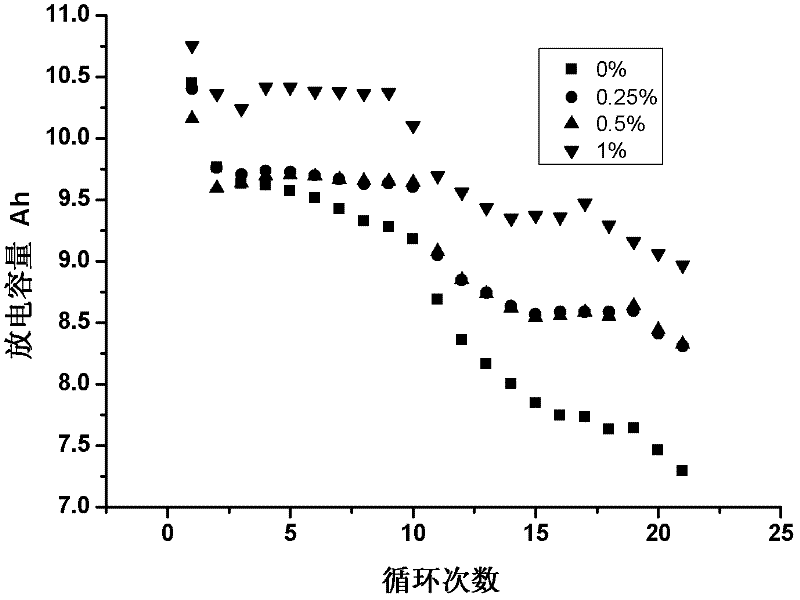

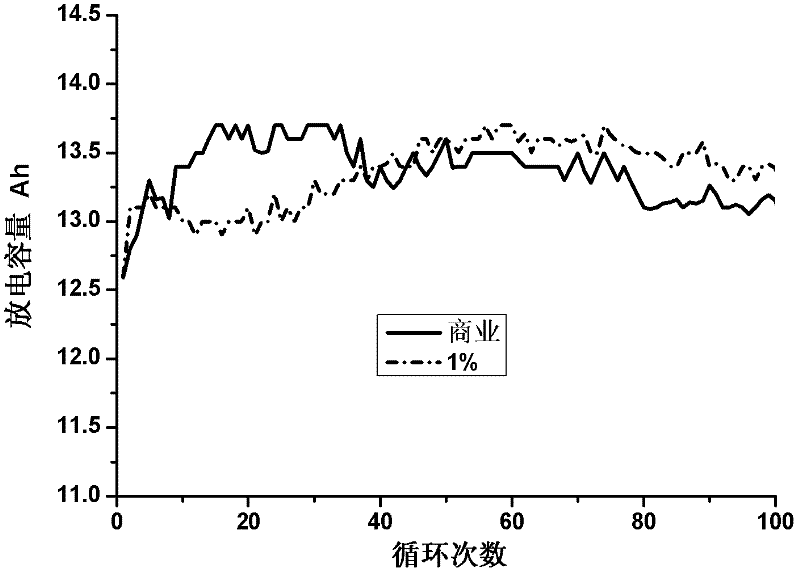

ActiveCN102339991AGood high current charge and discharge performanceImprove discharge capacityLead-acid accumulator electrodesCharge and dischargeCarbon nanotube

The invention relates to a negative plate of a lead-carbon battery and a preparation method. An anode material in the negative plate of the lead-carbon battery comprises lead powder, fibers which are 0.05 to 0.2 percent based on the mass of the lead powder, organic additives which are 0.2 to 0.5 percent based on the mass of the lead powder, barium sulfate which is 0. 5 to 1.2 percent based on the mass of the lead powder, carbon nano tubes which are 0.2 to 10 percent based on the mass of the lead powder and other nanoscale or micron-sized conductive carbon materials which are 0.2 to 1 percent based on the mass of the lead powder. The preparation method comprises the following steps of: dispersing the carbon nano tubes, mixing paste and coating lead plaster on a negative grid. The negative plate of the lead-carbon battery effectively improves the discharging capacity of the battery and prolongs the service life of the battery in an under-charging state, and remarkably improves the high-current charging and discharging performance of the battery in a full-charging state.

Owner:SHANDONG UNIV +1

Lithium ion battery negative electrode sheet containing electric-conduction coating, and preparation method thereof

ActiveCN108511685ASmall particle sizeGood adhesion and uniformityCell electrodesSecondary cellsSodium carboxymethylcelluloseCopper foil

The invention relates to the field of lithium batteries, and discloses a lithium ion battery negative electrode sheet containing an electric-conduction coating, and a preparation method thereof. The negative electrode sheet comprises a copper foil current collector, an electric-conduction coating and a negative electrode active material layer, wherein the negative electrode active material layer is formed by curing a negative electrode slurry, the negative electrode slurry comprises 93-95 parts of graphite, 1.5-2.5 parts of electric-conduction carbon black SP, 1-2 parts of sodium carboxymethylcellulose, 2-3 parts of styrene-butadiene rubber, and 130-150 parts of deionized water, the electric-conduction coating is formed by curing an electric-conduction slurry, and the electric-conductionslurry comprises 10-95 parts of a composite carbon source, 5-50 parts of a binder, 5-40 parts of a dispersing agent, and 450-550 parts of an organic solvent. According to the present invention, the current collector is coated with the special electric-conduction slurry layer, such that the specific surface area is large, the impedance is low, the bonding force of the electrode sheet can be substantially improved, the electric conductivity can be enhanced, the adding amounts of the binder and the electric-conduction agent can be reduced, and the energy density of the battery can be improved.

Owner:WANXIANG 123 CO LTD

Lithium ion battery positive electrode sheet containing electric-conduction coating, and preparation method thereof

ActiveCN108511689ASmall particle sizeImprove adhesionElectrode carriers/collectorsSecondary cellsFiberCarbon fibers

The invention relates to the field of lithium batteries, and discloses a lithium ion battery positive electrode sheet containing an electric-conduction coating, and a preparation method thereof. The positive electrode sheet comprises an aluminum foil current collector, an electric-conduction coating and a positive electrode active material layer, wherein the positive electrode active material layer is formed by curing a positive electrode slurry, the positive electrode slurry comprises 91-95 parts of lithium iron phosphate, 1-3 parts of electric-conduction carbon black SP, 0.5-1.5 parts of vapor grown carbon fiber, 3-5 parts of polyvinylidene fluoride, and 60-80 parts of N-N-dimethylpyrrolidone, the electric-conduction coating is formed by curing an electric-conduction slurry, and the electric-conduction slurry comprises 10-95 parts of a composite carbon source, 5-50 parts of a binder, 5-40 parts of a dispersing agent, and 450-550 parts of an organic solvent. According to the present invention, the current collector is coated with the special electric-conduction slurry layer, such that the specific surface area is large, the impedance is low, the bonding force of the electrode sheet can be substantially improved, the electric conductivity can be enhanced, the adding amounts of the binder and the electric-conduction agent can be reduced, and the energy density of the battery canbe improved.

Owner:WANXIANG 123 CO LTD

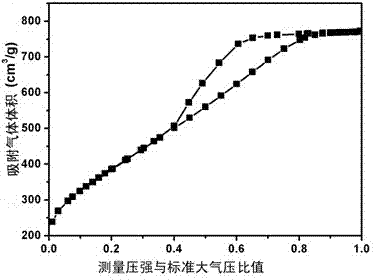

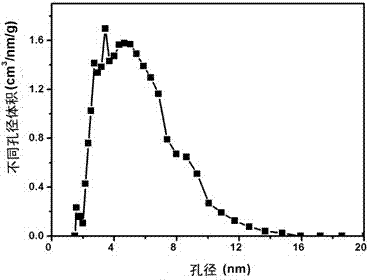

Method for preparing supercapacitor-dedicated active carbon by using mixed molten salts as activator

InactiveCN104709905ALarge specific surface areaEffective meso-micropore size distributionCarbonizationCharge discharge

The invention discloses a method for preparing supercapacitor-dedicated active carbon by using mixed molten salts as an activator. According to the method, asphalt or coal tar which is used as a raw material is uniformly mixed with mixed molten salts; under protection of argon or nitrogen, the mixture is placed in a carbonization furnace to be carbonized; and finally, the carbonized product is crushed, washed and dried to obtain active carbon. The active carbon has high specific surface area and effective mesopore-micropore pore size distribution, and has high electrochemical specific capacity and good high-current charge discharge capability and cycling stability.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

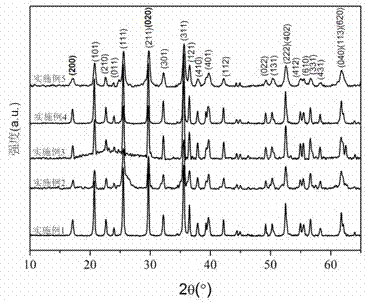

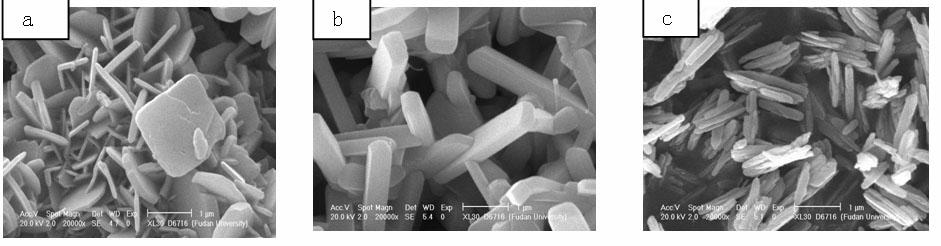

High-multiplying-power type lithium iron phosphate/carbon composite material and preparation method thereof

InactiveCN103904325AWell mixedPromote growthCell electrodesSecondary cellsCarbon coatingCarbon composites

The invention discloses a high-multiplying-power type lithium iron phosphate / carbon composite material and a preparation method thereof. The lithium iron phosphate / carbon composite material is in a structure of nanosheets which are irregular and are 25-35nm in thickness; the mass ratio of a carbon coating layer to lithium iron phosphate is (0.1-0.01):(0.9-0.99). The preparation method comprises the following steps: with lithium hydroxide, phosphoric acid and ferrous sulfate as materials, performing solvothermal reaction on the materials and a carbon source including an asphalt-based amphiphilic carbon material, and then performing coating treatment of the asphalt-based amphiphilic carbon material to obtain the lithium iron phosphate / carbon composite material with uniform carbon coating. The high-multiplying-power type lithium iron phosphate / carbon composite material disclosed by the invention has the following advantages that the process is simple, is easy to control and free from pollution; the prepared lithium iron phosphate / carbon composite material is good in orientation, fewer in defects and high in crystallinity, the discharging specific capacities under the temperatures of 10 DEG C and 30 DEG C reach 132.2 mAh.g<-1>and 113.3mAh.g<-1> respectively, the high-multiplying-power performance is good and the circulating stability is excellent.

Owner:TIANJIN UNIV

Composite graphite negative electrode material of lithium ion battery and preparation method thereof

ActiveCN103311520AImprove discharge capacityImprove adaptabilityCell electrodesElectrolytic agentPtru catalyst

The invention discloses a preparation method for a composite graphite negative electrode material of a lithium ion battery. The preparation method comprises the following steps: (1) uniformly mixing spherical natural graphite, mesophase graphite and a graphitized catalyst so as to obtain a mixture; (2) kneading the mixture and an adhesive so as to obtain a kneading product; (3) carrying out carbonizing treatment at first, then cooling and finally catalytic graphitization high temperature treatment; and (4) carrying out crushing and grading. The preparation method provided by the invention is simple and feasible and is applicable to industrial production. The prepared composite graphite negative electrode material has the advantages of good electrochemical properties, discharge capacity of more than 360 mAh / g, high charge and discharge efficiency, good heavy-current charge and discharge performance, excellent cycle performance, small expansion during charging, good security and good adaptability to electrolytes and other additives; and a lithium ion battery product prepared from the composite graphite negative electrode material has stable properties, and different batches of such product barely show difference.

Owner:上海杉杉新材料有限公司

Composite graphite cathode material and preparation method thereof

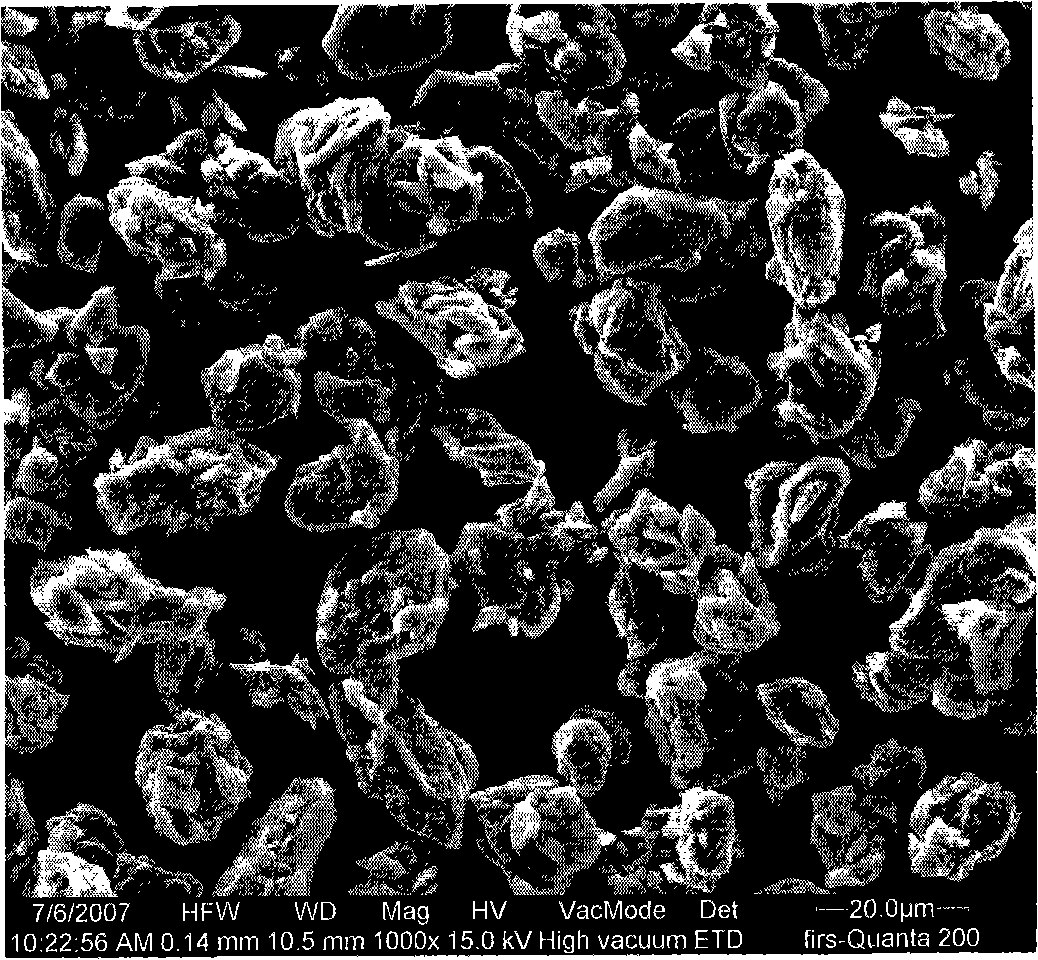

ActiveCN104609400AImprove cycle performanceGood high current charge and discharge performanceCell electrodesCarbonizationGraphite particle

The invention discloses a composite graphite cathode material and a preparation method thereof. The composite graphite cathode material comprises graphite particles a and b, wherein the graphite particles a are secondary artificial graphite particles formed by granulating, coating and bonding oil-based petroleum coke; the graphite particles b are secondary composite graphite particles, adopting core-shell structures, formed by removing impurities from small-particle diameter natural graphite balls, and spherodizing, coating and bonding the small-particle diameter natural graphite balls; the composite graphite material is prepared by mixing the graphite particles a and b, adding a binding agent, coating, bonding and performing high temperature carbonization. By compounding the two secondary graphite particles with different characteristics to prepare the composite graphite material, the capacity of graphite is improved and the problems that the graphite is poor in rate capability, poor in high-current charge and discharge performance, poor in compacting performance are solved.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

High-capacity graphite composite material of lithium-ion battery and preparation method of composite material

The invention discloses a high-capacity graphite composite material of a lithium-ion battery and a preparation method of the composite material. The high-capacity graphite composite material comprises two materials a and b, wherein a is highly graphitized particles, while b is secondary composite particles with core-shell structures; the secondary composite particles with the core-shell structures are prepared from natural graphite by virtue of impurity removal, spheroidization, coating and gluing; the weight ratio of a to b is 90:10 to 5:95. The high-capacity graphite composite material is produced by virtue of a high-temperature integrated coating, gluing and carbonizing process, and cooling; as a result, the graphite capacity is improved, the cost is reduced, and the problems of poor high-current charging / discharging performance and poor compaction performance of the graphite are solved.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Preparation method of low-expansion long-circulating natural graphite

The invention belongs to the technical field of graphite preparation, and more specifically relates to a preparation method of a low-expansion long-circulating natural graphite. The preparation method comprises following steps: 1, smashing shaping is carried out; 2, mixing is carried out; 3, low temperature heat treatment is carried out; 4, graphitization high temperature treatment is carried out; and 5, material mixing sieving is carried out. An adhesive convenient for graphitization is an ingredient or a mixture of ingredients selected from petroleum asphalt, coal pitch, phenolic resin, epoxy resin, furane resin, or furfural resin; and the using amount of the adhesive accounts for 10 to 30% of the weight amount of a microcrystalline graphite raw material. Compared with the prior art, the preparation method possesses following advantages: the preparation method is simple and feasible, and is suitable for industrialized production; prepared graphite is low in expansion performance, large in discharge capacity, and long in cycle life; and the comprehensive properties of button cells prepared from the low-expansion long-circulating natural graphite are excellent.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

Mesophase negative electrode material and preparation method thereof

ActiveCN104143641AImprove discharge capacityImprove adaptabilityCell electrodesSecondary cellsAdhesiveMicrosphere

The invention discloses a mesophase negative electrode material and a preparation method thereof. The method comprises the following steps: 1, uniformly mixing spherical natural graphite with raw mesophase carbon microspheres and a graphitization catalyst to obtain a mixture; 2, carrying out heating kneading on the mixture and a graphitization adhesive for 1-2h to obtain a kneaded material; 3, pressing to form a block in order to obtain a formed body of the kneaded material; 4, charring the formed body at 800-1500DEG C under the protection of an inert gas, and cooling to room temperature; and 5, carrying out catalytic graphitization high temperature treatment at 2800-3200DEG C. The preparation method can further improve the charge and discharge capacity and the charge and discharge efficiency of the mesophase negative electrode material and improve the cycle performance of the material.

Owner:福建杉杉科技有限公司

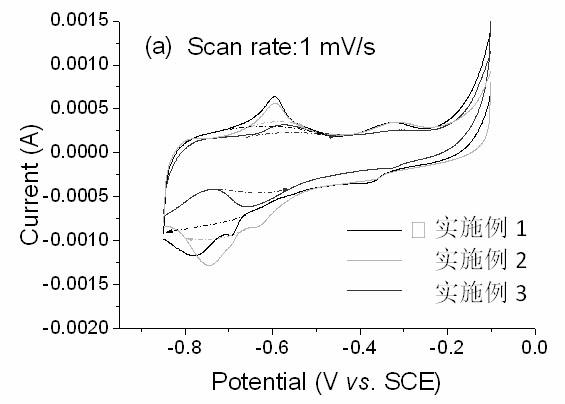

Super capacitor

InactiveCN102157271AIncrease specific energyGood high current charge and discharge performanceElectrolytic capacitorsHigh energyPhysical chemistry

The invention belongs to the technical field of chemical power sources, in particular to a super conductor. Negative electrode active substances of the super capacitor are oxide which has metal elements with two oxidation states except vanadium, and modified compounds of the oxide. The electrolyte of the super capacitor is aqueous solution containing alkaline metal ion. The negative active substance is the known active material. Compared with the conventional aqueous solution system super capacitor, the super capacitor has higher energy density and better safety performance. In addition, the capacitor also has excellent rate performance and better cycle performance. The super conductor has strong operability and good repeatability; and products produced by the super capacitor have stable product quality and good performance.

Owner:FUDAN UNIV

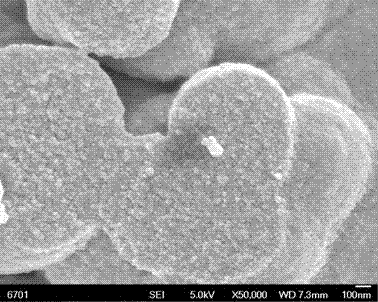

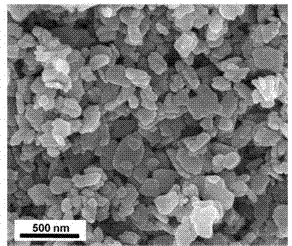

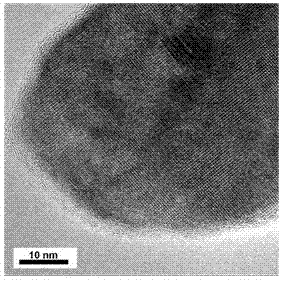

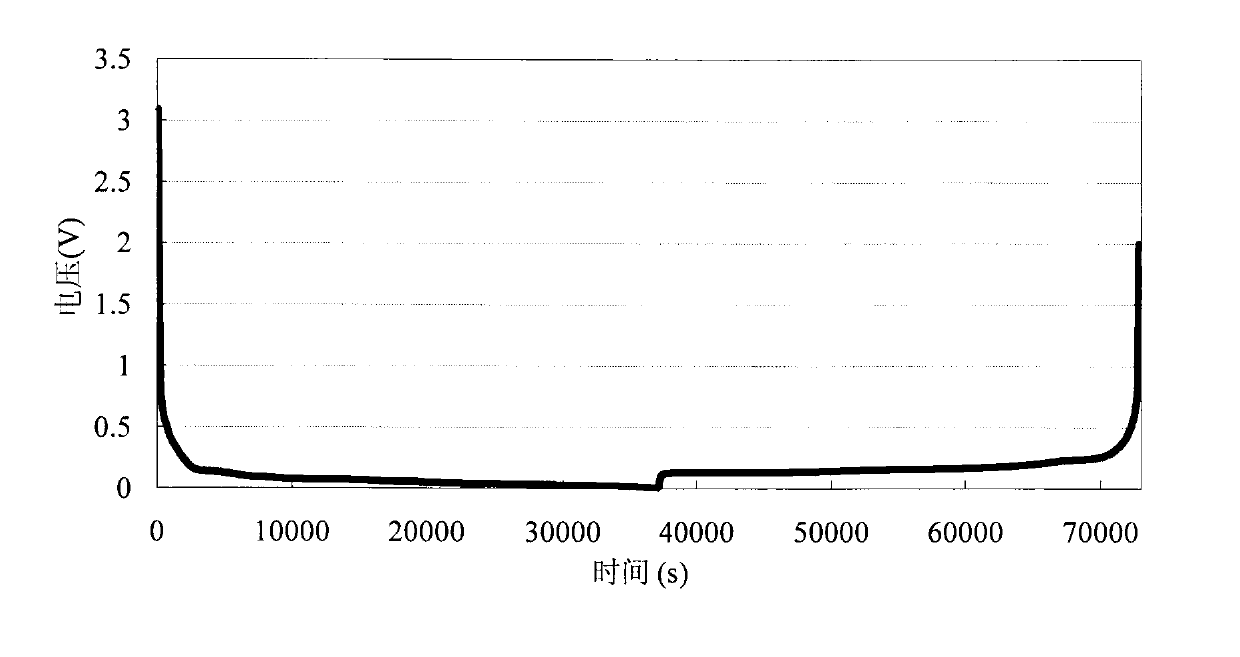

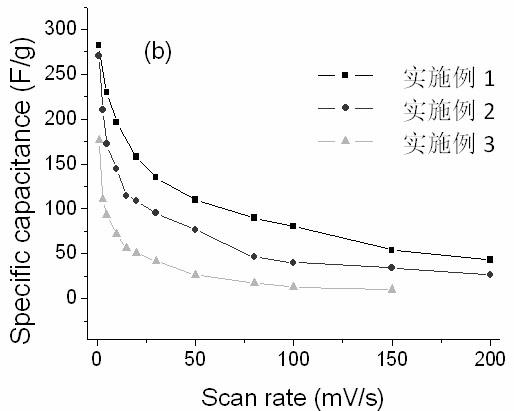

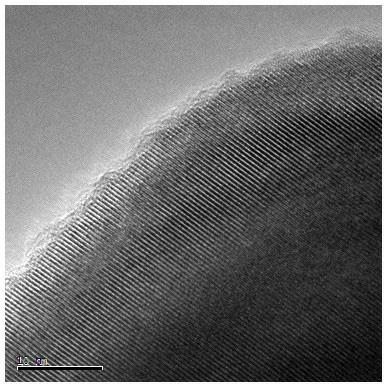

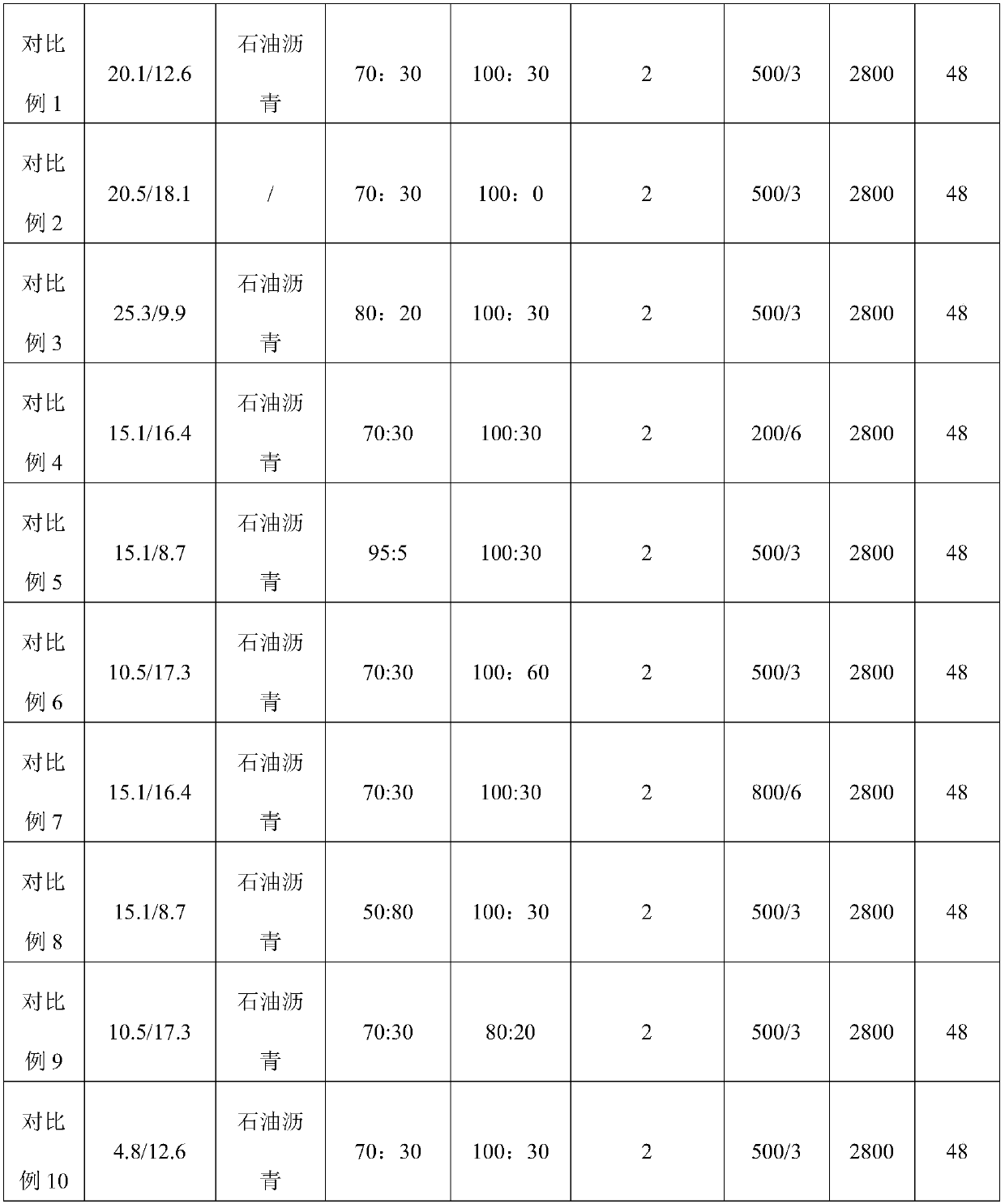

Preparation method of carbon-coated lithium titanate composite material for lithium ion power battery

InactiveCN102610807AImprove electronic conductivityImprove rate charge and discharge performanceCell electrodesPower batteryRoom temperature

The invention discloses a preparation method of a carbon-coated lithium titanate composite material for a lithium ion power battery. The method comprises the following steps of: dissolving an amphiphilic carbon material into water at room temperature to prepare suspension, adding lithium titanate and mixing uniformly; heating to 80-90 DEG C, evaporating to dryness, and drying; performing constant-temperature thermal treatment for 0.5-10 hours at 500-1,000 DEG C to obtain the lithium titanate with a particle size of 100-400nm serving as a kernel; and coating the kernel with an amphiphilic carbon material with thickness of 3nm. The preparation method disclosed by the invention is environment-friendly, has a simple preparation process and is easy to realize large-scale production. The prepared material has large charge / discharge capacity, excellent heavy-current charge / discharge performance and stable cycle performance when used as a lithium ion battery cathode material, wherein the 10C discharge / charge capacity is 160mAh / g, the 20C discharge / charge capacity reaches 143mAh / g, and the capacity retention rate reaches 91% after 100 times of heavy-current 20C discharge and charge.

Owner:TIANJIN UNIV

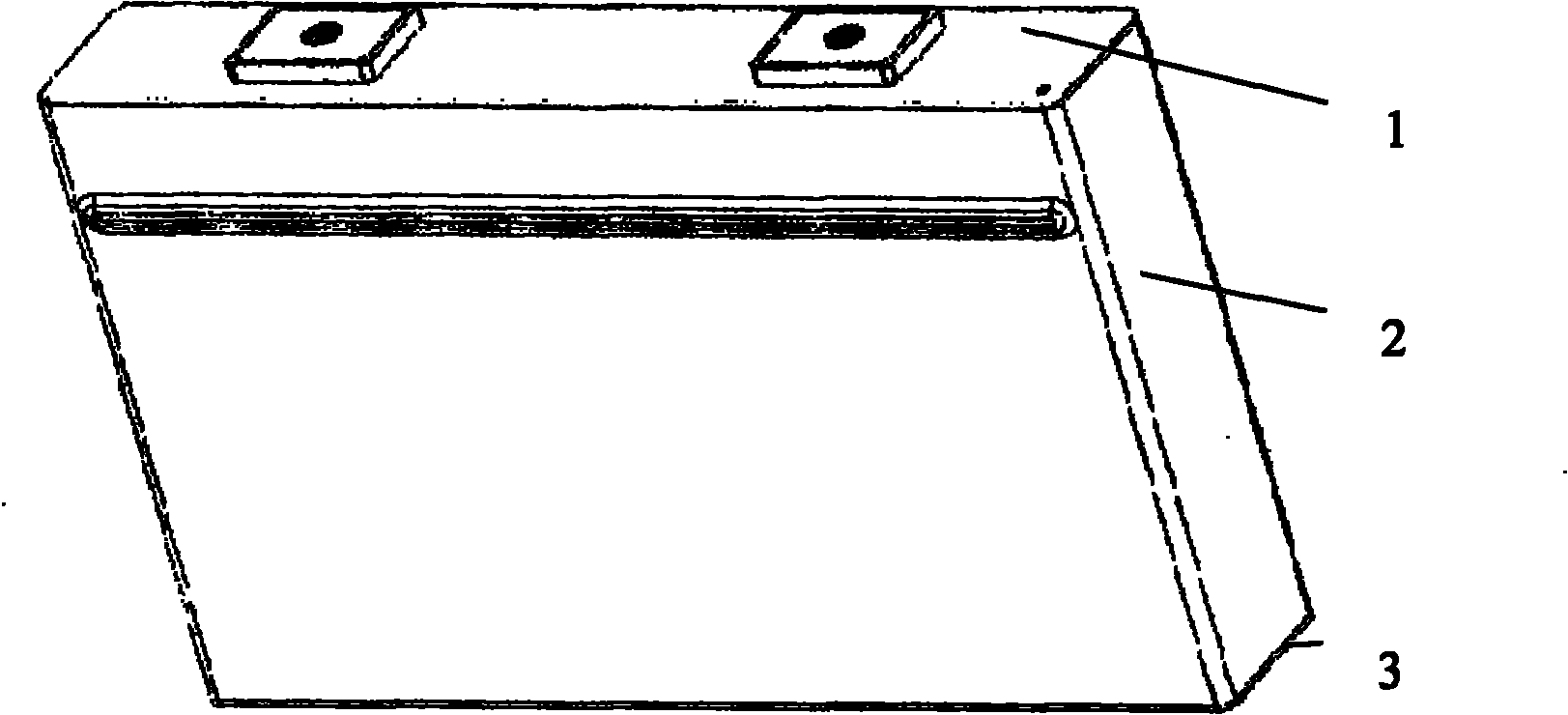

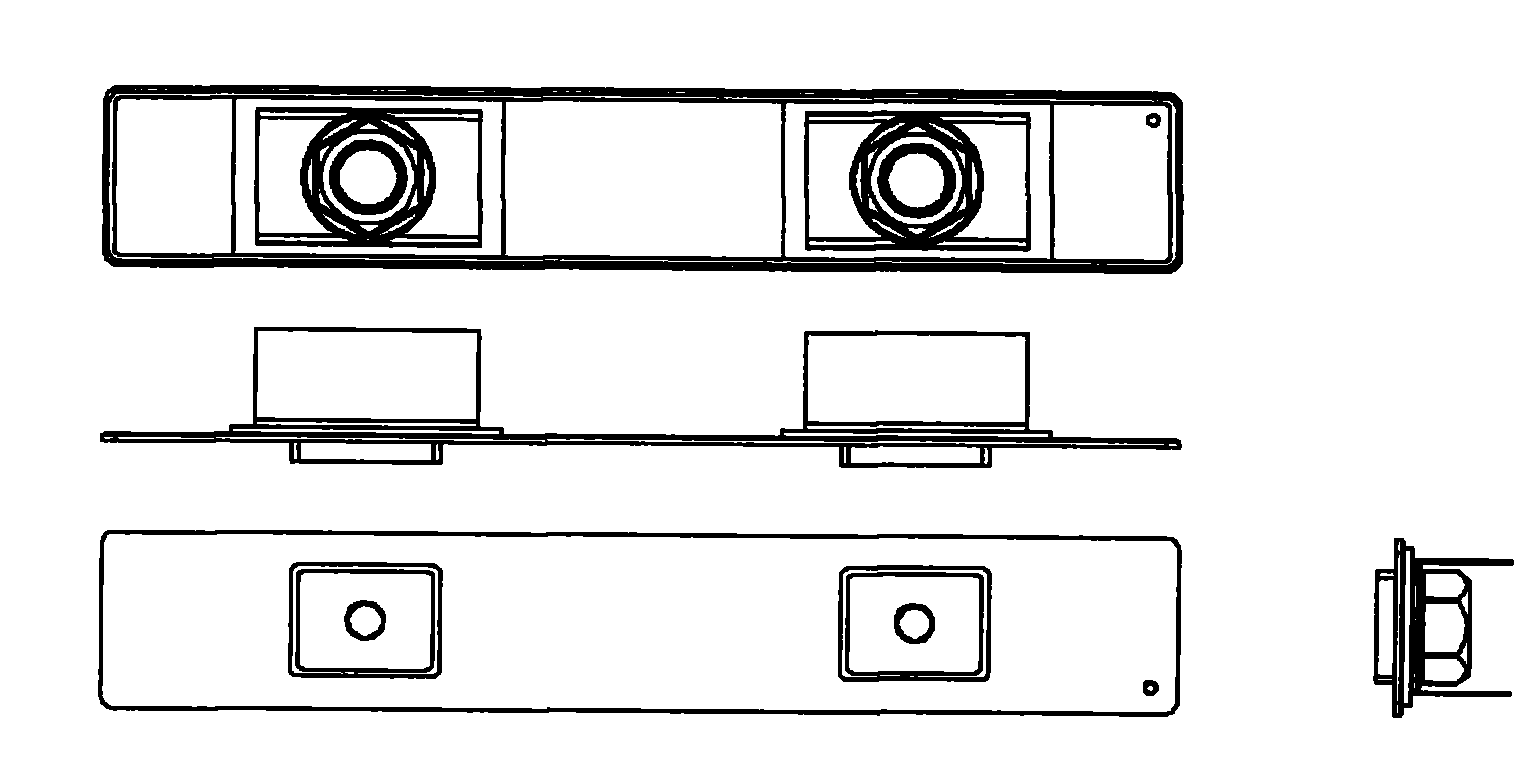

Square lithium ion battery shell and square lithium ion power battery using same

InactiveCN102315395AGood high current charge and discharge performanceImprove securityCell electrodesSecondary cellsPower batteryElectrical battery

The invention relates to the technical field of lithium ion batteries, and particularly discloses a square lithium ion battery shell. The square lithium ion battery shell comprises a shell cover, a shell body and a bottom plate; the shell body is provided with a predetermined space for accommodating the shell cover; the shell cover and the bottom plate are respectively and fixedly connected with the shell body to form a whole; the shell cover is provided with a pole post; and an internal thread and an external thread are arranged in the pole post. The invention also discloses a square lithium ion powder battery using the battery shell. The square lithium ion battery shell and the square lithium ion powder battery using the same are particularly suitable for occasions, on which massive connection in series or parallel and long-term vibration occur, such as an energy storage powder supply, a vehicle powder battery, an electric bicycle, a motorcycle and the like.

Owner:SHANGHAI AEROSPACE POWER TECH

Composite doping modification lithium-ion battery anode material and its manufacture method

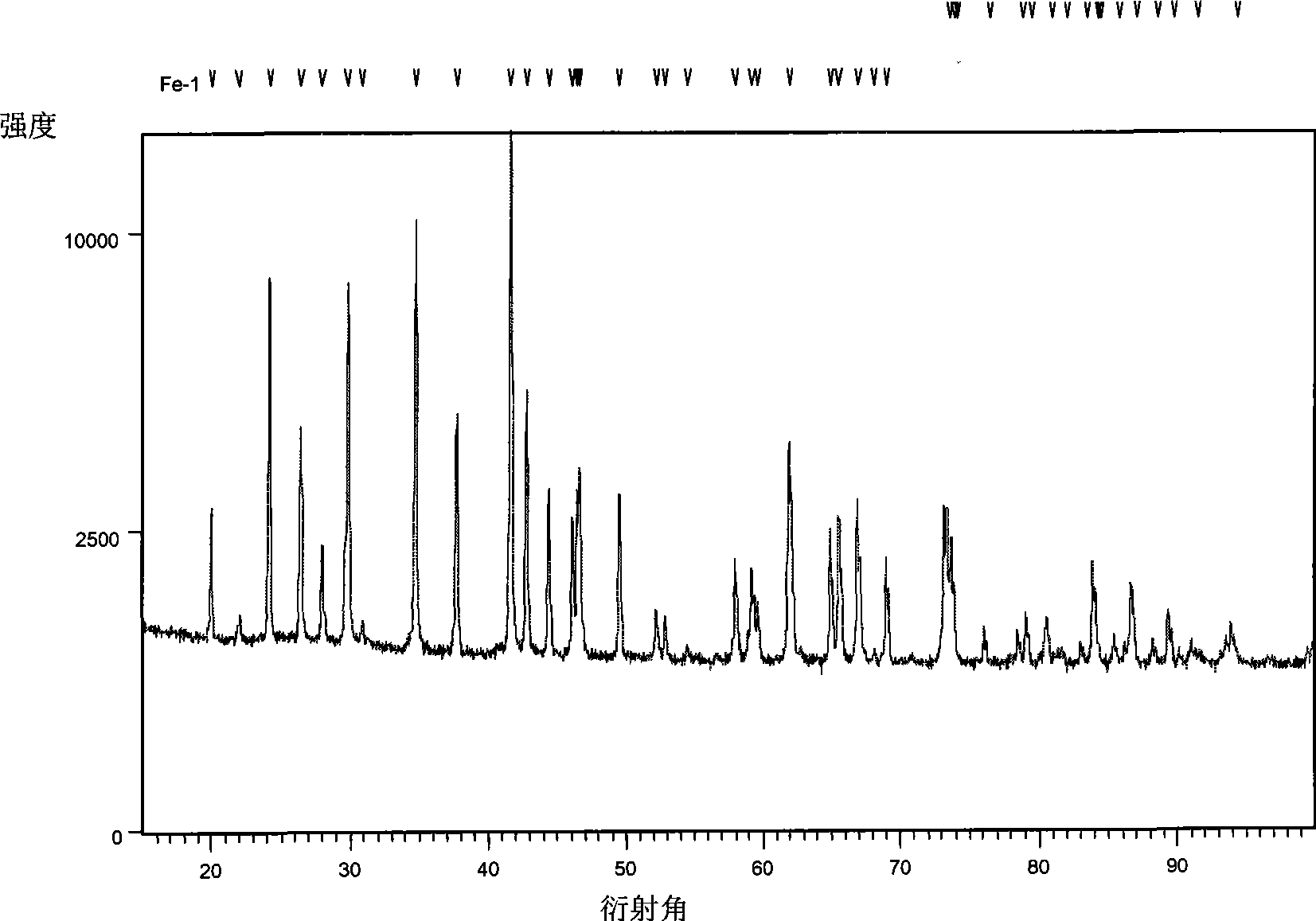

InactiveCN1964105AImprove UIEnhanced ionic conductivity and electronic conductivityElectrode manufacturing processesChemical/physical/physico-chemical processesIonRare-earth element

The disclosed preparation method for anode material of composite doped modified Li-ion cell comprises: mixing the Li-source compound, P-source compound, Fe-source compound, crystal phase doped M (rare earth element) compound and non-crystal phase doped element C to heat for 5-20h at 250-400Deg; cooling, and grinding to obtain the reaction predecessor contained PO43-, Li+, Mn+, Fe2+ and carbon black; calcining for 10-40h at 500-800Deg to cool and obtain the final product. This invention improves material electrochemical property and fit to industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Tubular negative plate of lead-carbon battery

InactiveCN103618067ASimple preparation processEasy to implementLead-acid accumulator electrodesSulfonateFiber

The invention discloses a tubular negative plate of a lead-carbon battery. The negative plate comprises a negative plate grid and filled active substance powder, wherein the negative plate grid is of a fence structure consisting of transverse beams and conductive cores perpendicular to the transverse beams; a sleeve layer is arranged outside the negative plate grid; the gaps among the sleeve layer and the conductive cores is filled with the active substance; the active substances consist of the following substances in percentage by weight: 57-95% of lead powder, 1-40% of a capacitive carbon material, 0.1-0.5% of carbon black, 0.3-2% of barium sulfate, 0-1.2% of sodium lignin sulfonate, 0.5-2% of humic acid, 0.05-0.1% of short fiber. The tubular negative plate of the lead-carbon battery is simple in manufacturing process and easy to realize, a diachylon structure is stabilized and prevented from dropping off, and the service life of the battery is prolonged.

Owner:STATE GRID CORP OF CHINA +3

Sodium ion battery anode, preparation method thereof and sodium ion battery

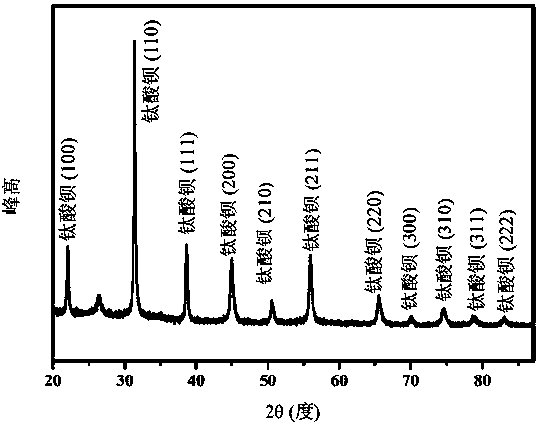

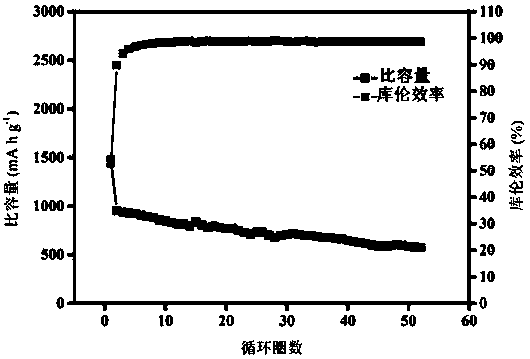

ActiveCN108550789ALow costImprove performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesHigh energyBarium titanate

The invention discloses a sodium ion battery anode, a preparation method thereof and a sodium ion battery, wherein the method comprises the steps of: using a ball milling method to mill the block redphosphorus ball to nano red phosphorus; using the ball milling method to composite the nano red phosphorus and graphene to obtain a composite material of the nano red phosphorus and graphene; using the ball milling method to composite the composite material of the nano red phosphorus and grapheme and the barium titanate to obtain an active material; and mixing the active material with the bondingmaterial and the conductive agent, thereby obtaining the sodium ion battery anode after being coated, dried, and sliced. The sodium ion battery anode material provided by the invention has good high current charge and discharge performance, high tap density, large mass specific capacity and high energy density.

Owner:SHENZHEN UNIV

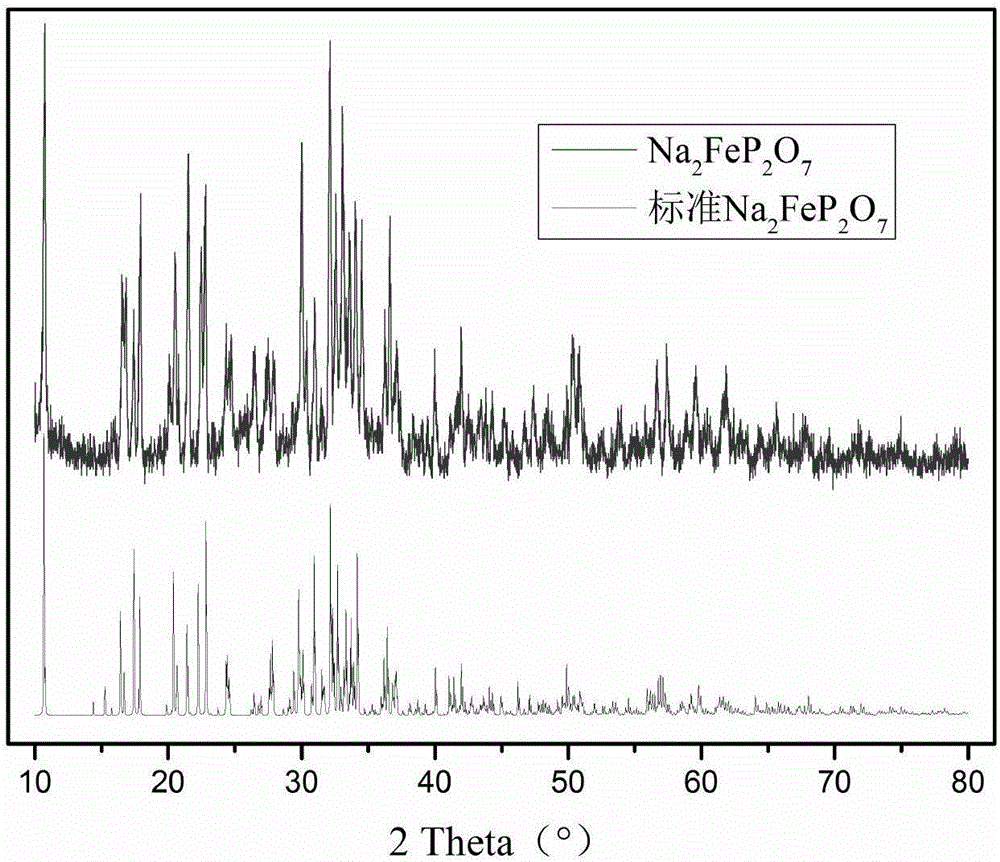

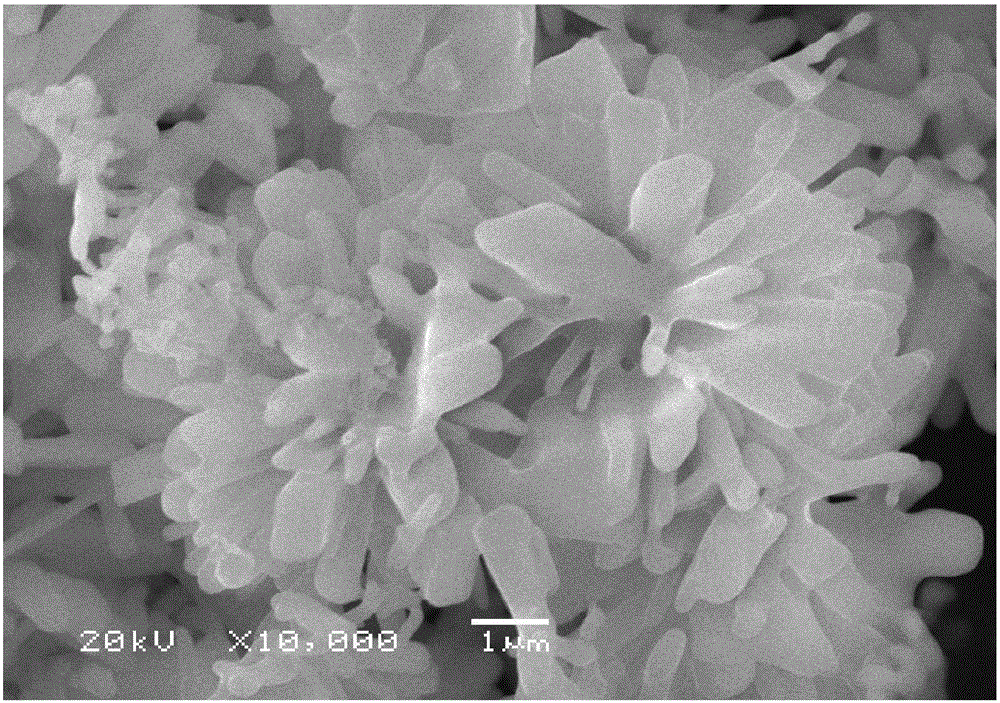

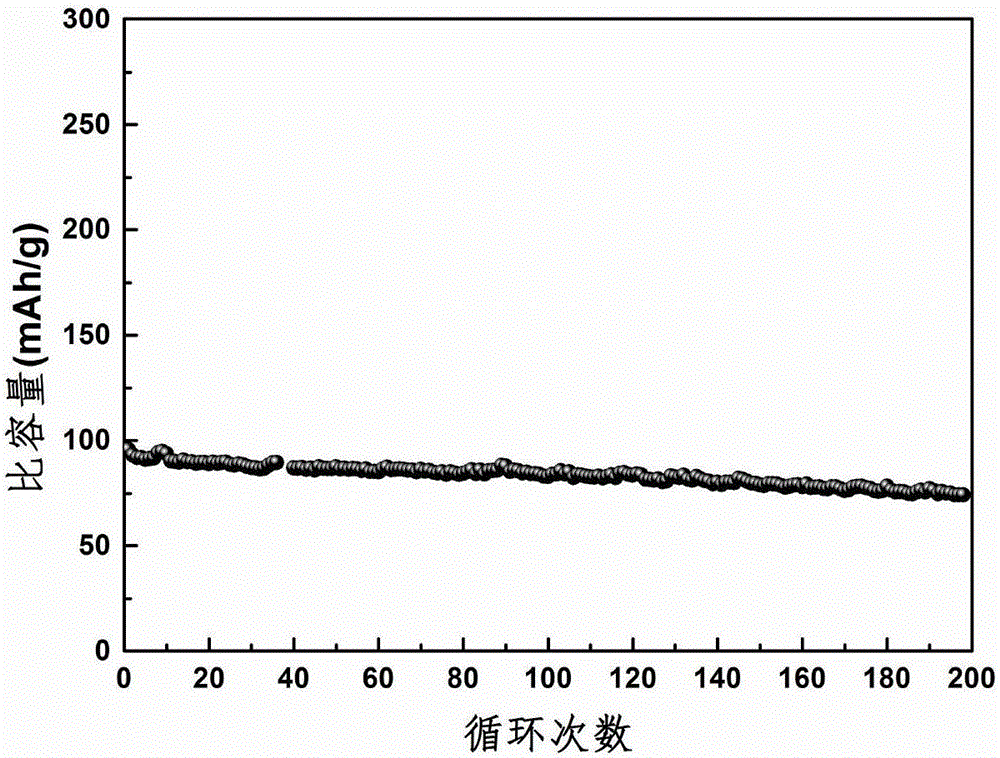

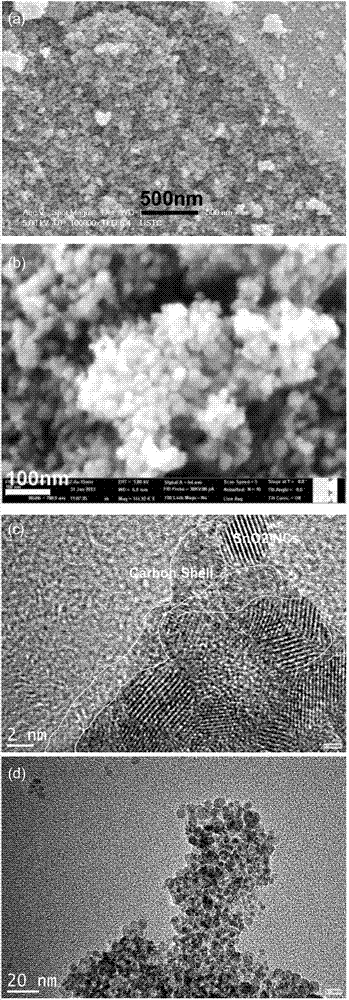

Na2Fe2P2O7 material with flower-like structure and preparation method and application thereof

ActiveCN106450300ALarge specific surface areaImprove electrochemical activityCell electrodesSecondary cellsFlower likeHigh activity

The invention discloses an Na2Fe2P2O7 material with a flower-like structure and a preparation method and application of the Na2Fe2P2O7 material with the flower-like structure. The material is formed by assembling Na2Fe2P2O7 with the flower-like structure, and the preparation method of the Na2Fe2P2O7 material comprises the following steps that a precursor is synthesized by using a hydrothermal method, and then calcined to obtain the Na2Fe2P2O7 material with the flower-like structure; the Na2Fe2P2O7 material with the flower-like structure can expose high-activity crystal faces, and has higher electrochemical activity, thereby having high specific capacity and working voltage while being used as a sodium ion anode material, and still having excellent rate capability and good cycle stability without using a carbon substrate.

Owner:CENT SOUTH UNIV

Graphite cathode material of lithium ion battery and preparation method thereof

The invention discloses a graphite cathode material of a lithium ion battery and a preparation method there, comprising the following steps of: (1) heating natural spherical graphite under 350-450 DEG C for pretreatment; (2) uniformly mixing the pretreated natural spherical graphite and a graphitization catalyst to obtain a mixture; (3) kneading the mixture and an adhesive to obtain a kneaded object, wherein the a mass ratio of the mixture to the adhesive is 2:1:6:1; (4) carbonizing the kneaded object, and then high temperature treating the kneaded object by catalysis and graphitization after cooling; and (5) crushing and grading to obtain the graphite cathode material of the lithium ion battery. The preparation method is simple and feasible, and is suitable for industrialization production. The graphite cathode material of the lithium ion battery has advantages of good electrochemistrical performances, high charging and discharging capacity and efficiency, good heavy-current charging and discharging performances, good cycle performance, tiny expansion when charged, good security, good adaptability on an electrolyte and other additives, property stabilization of the lithium ion battery prepared by the graphite cathode material of the lithium ion battery.

Owner:CHENZHOU SHANSHAN NEW MATERIAL

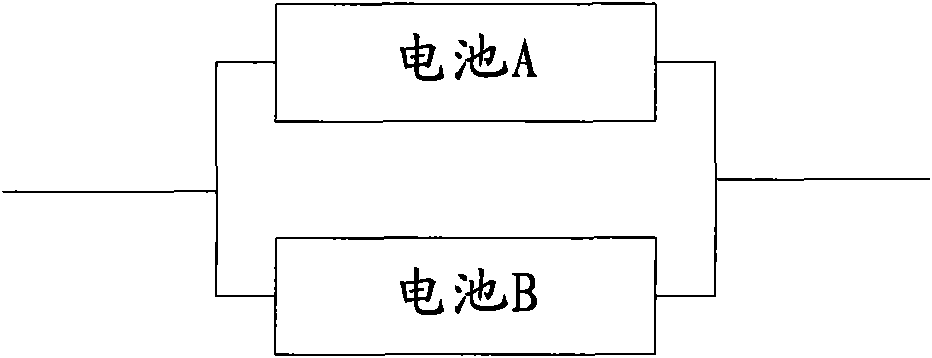

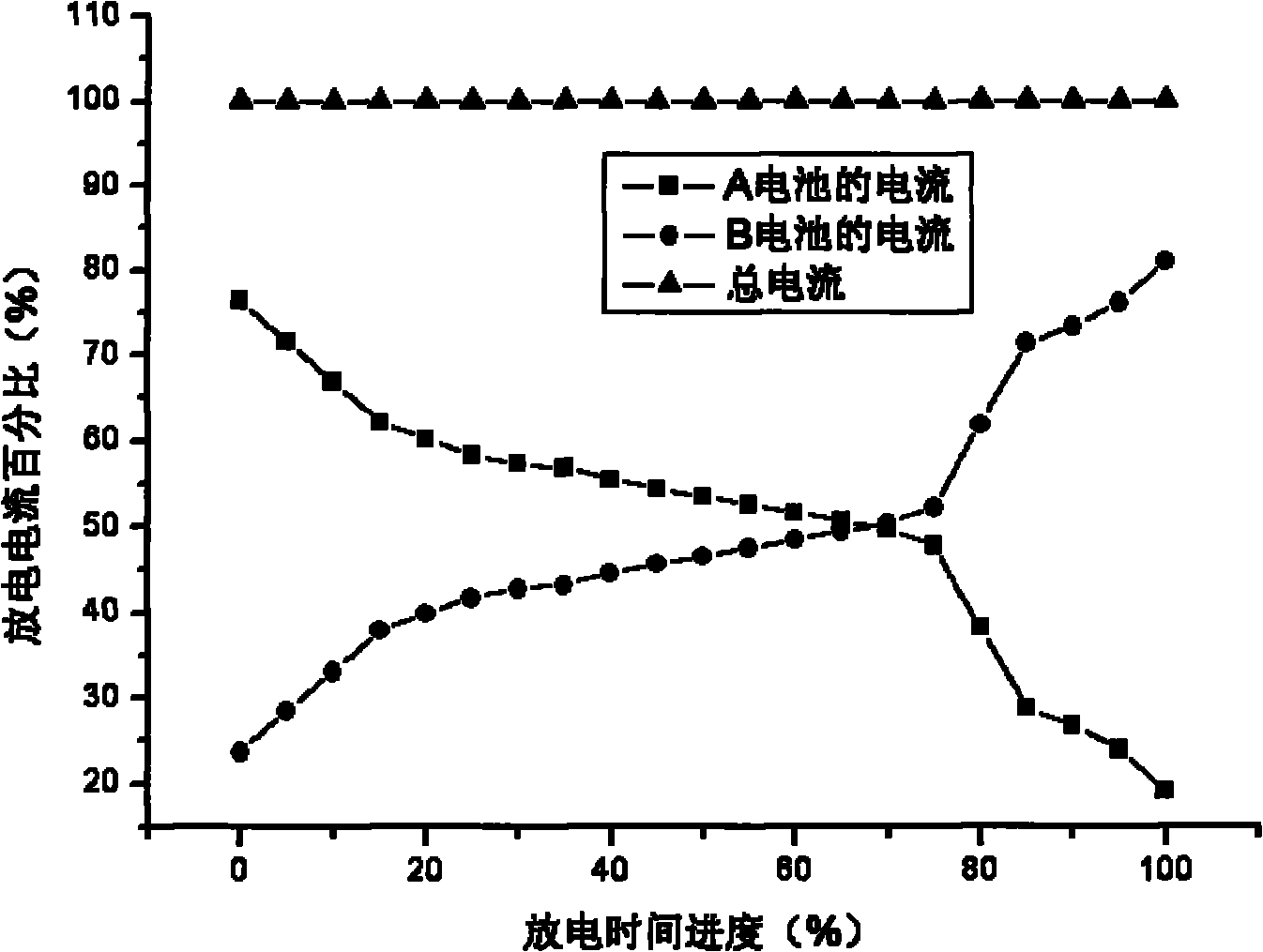

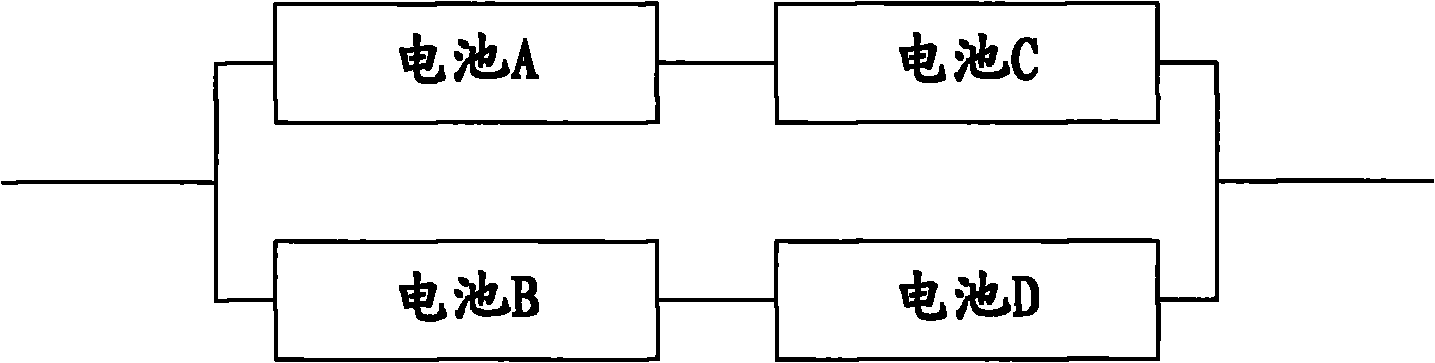

Secondary battery pack

InactiveCN101834325AImprove feverImprove poor battery cycle performanceSecondary cells servicing/maintenanceHybrid cellsEngineeringCurrent density distribution

The invention relates to a secondary batter pack which comprises a plurality of battery pack units connected in parallel mutually, wherein each battery pack unit is formed by at least two secondary batteries connected in series. The invention ensures that the consistency of current density distribution of the batteries is improved, thereby solving the problems of battery heating, poor battery circulating performance and the like and enhancing the battery pack performance.

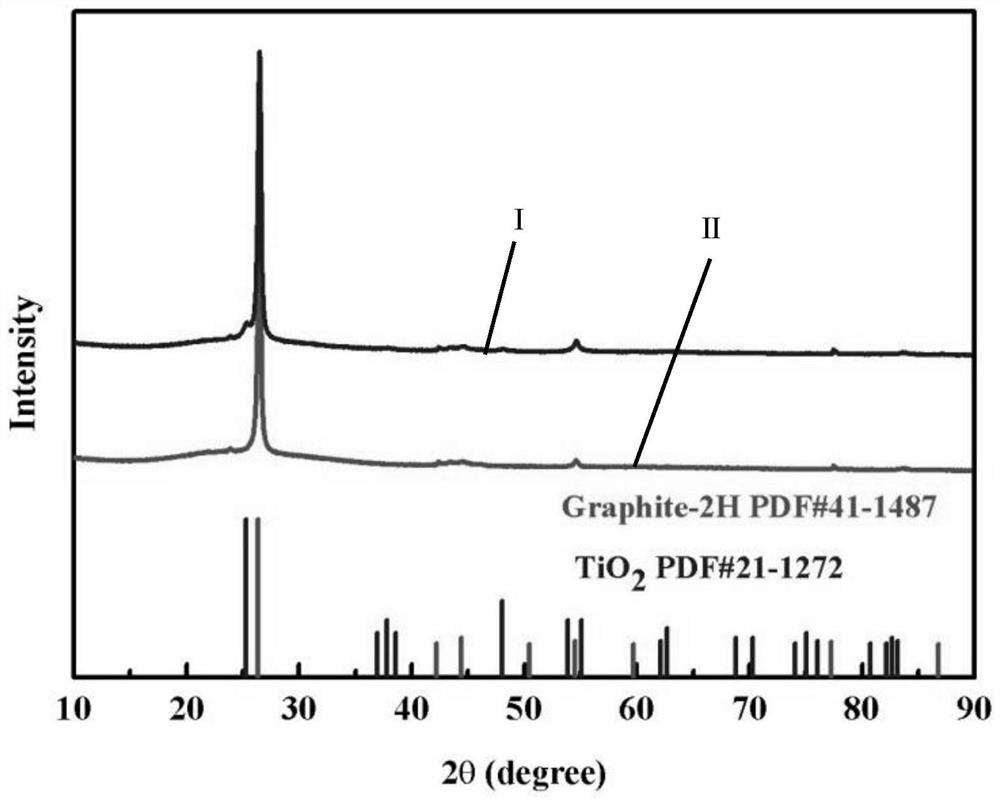

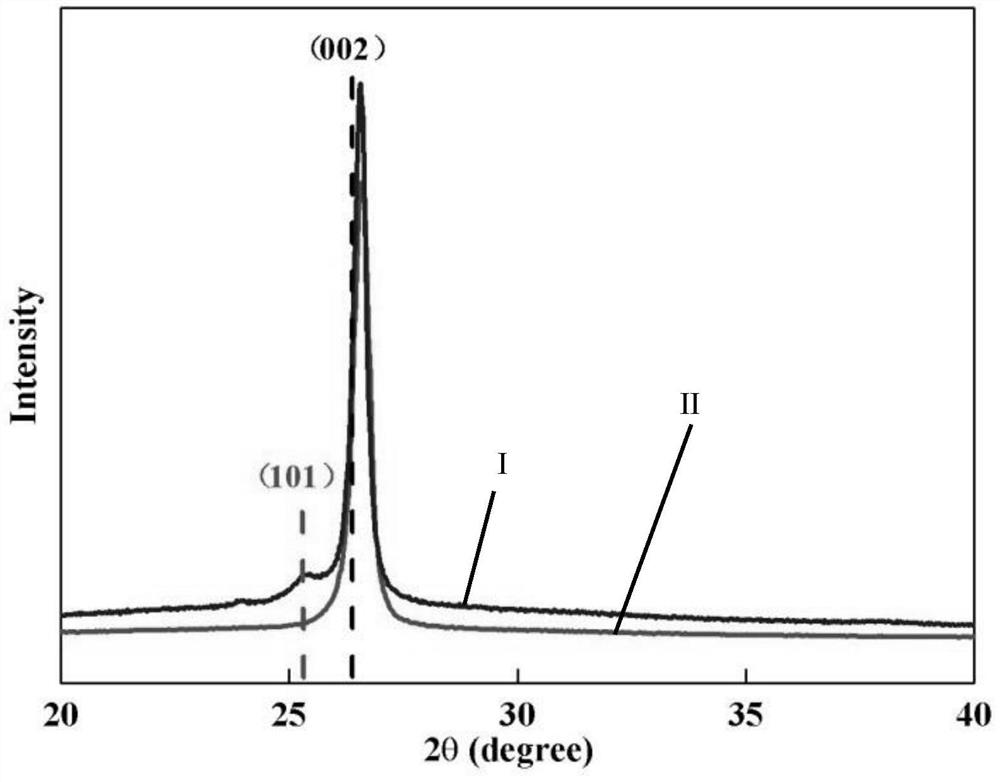

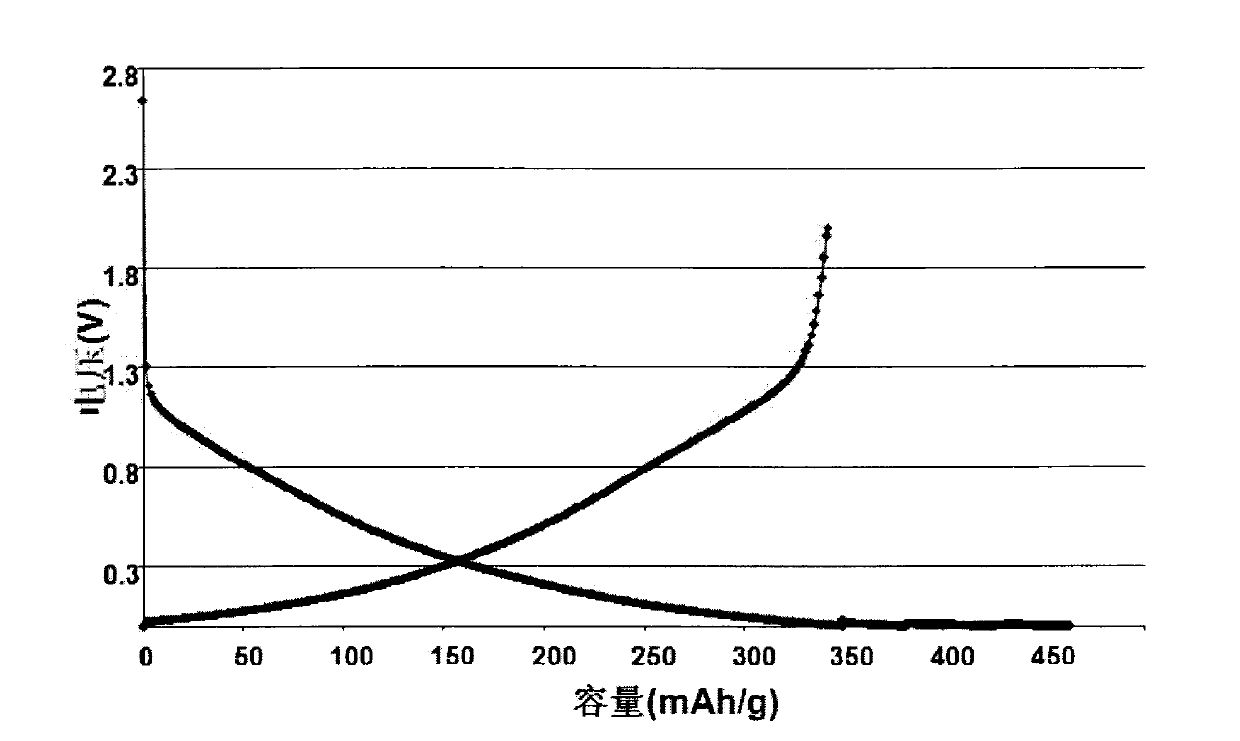

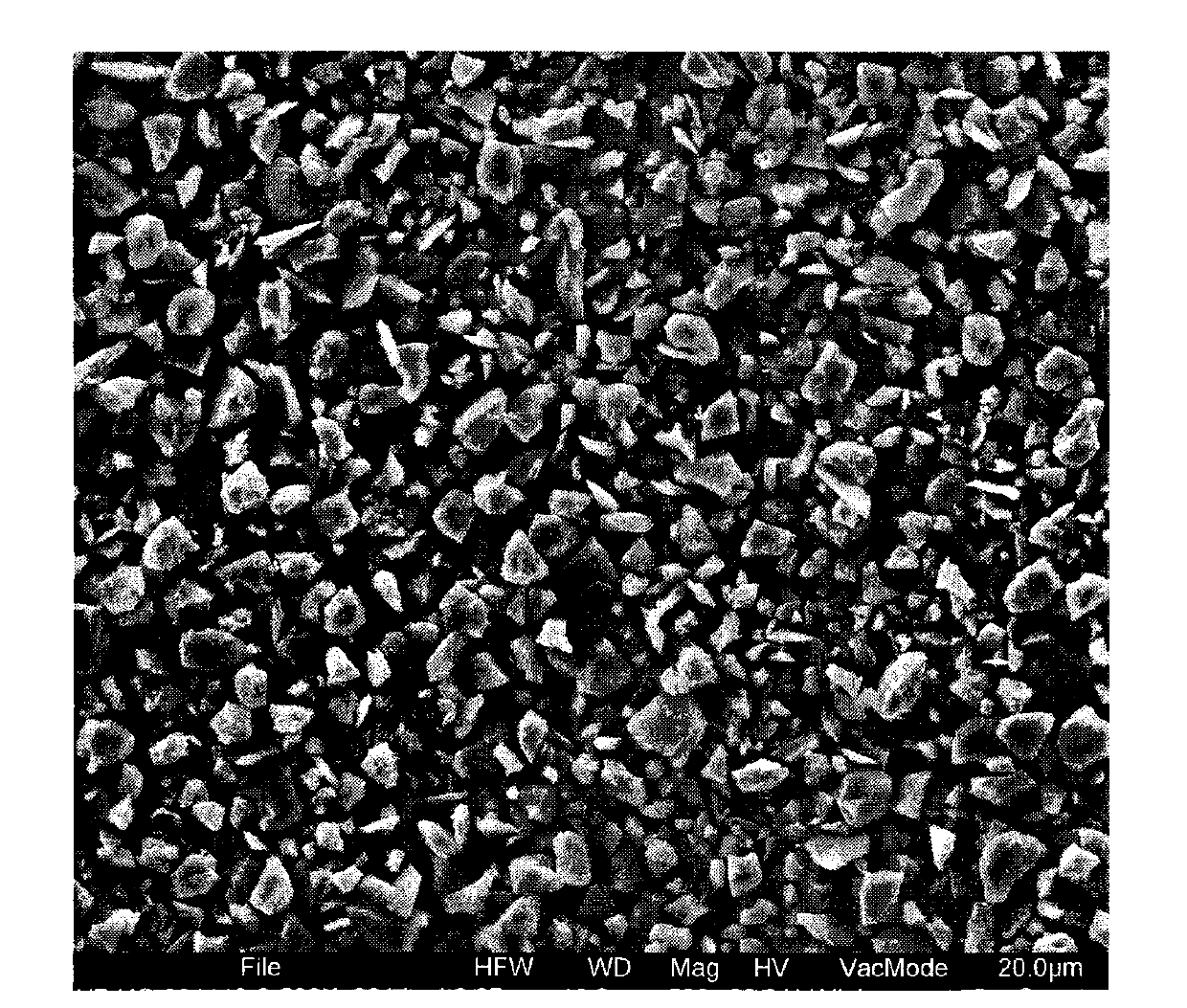

TiO2-coated graphite double-ion battery composite positive electrode material and preparation method thereof

ActiveCN111969185AImprove cycle stabilitySuppression of mechanical stressGraphiteCell electrodesGraphiteMagnetic stirrer

The invention provides a preparation method of a TiO2-coated graphite double-ion battery composite positive electrode material. The method comprises the following steps: S1, by taking tetrabutyl titanate as a TiO2 source, uniformly mixing the tetrabutyl titanate with graphite powder, and putting the mixture into absolute ethyl alcohol to obtain a solid-liquid mixture; S2, continuously stirring thesolid-liquid mixture in a magnetic stirrer of a water bath kettle until absolute ethyl alcohol is completely evaporated to obtain a sample; and S3, heating the sample in an inert protective atmosphere, and carrying out heat preservation to obtain the TiO2-coated graphite double-ion battery composite positive electrode material. The TiO2-coated graphite double-ion battery composite positive electrode material provided by the invention is relatively good in cycle performance.

Owner:HUNAN UNIV

Hard-carbon negative electrode material for lithium ion secondary battery and preparation method thereof

ActiveCN103311518ASolve problems in the preparation processWide variety of sourcesCell electrodesCross-linkPolycyclic aromatic hydrocarbon

The invention discloses a hard-carbon negative electrode material for a lithium ion secondary battery and a preparation method thereof. The preparation method comprises the following steps: (1) subjecting an aromatic compound and a cross-linking agent to cross-linking and polymerization so as to obtain a cross-linked polymer; (2) successively subjecting the cross-linked polymer to curing treatment, crushing and grading so as to obtain a particle with a particle size of less than 250 mu m and carrying out pre-carbonization treatment; (3) carrying out crushing and grading until the particle has a particle size of less than 250 mu m and then carrying out carbonization treatment; and (4) carrying out crushing and grading until the particle has a volume mean particle size D50 of 2 to 30 mu m; wherein the aromatic compound is C12-C16 aromatic hydrocarbon and / or heterocyclic aromatic hydrocarbon. The preparation method provided by the invention has the advantages of easiness, feasibility, wide sources of raw materials and low cost. The hard-carbon negative electrode material prepared by using the method has good heavy-current charge and discharge performance, good cycle performance, good security, good stability and good adaptability to an electrolyte and other additives; and a lithium ion battery product prepared from the hard-carbon negative electrode material has stable properties, and different batches of the product barely show a difference.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH +1

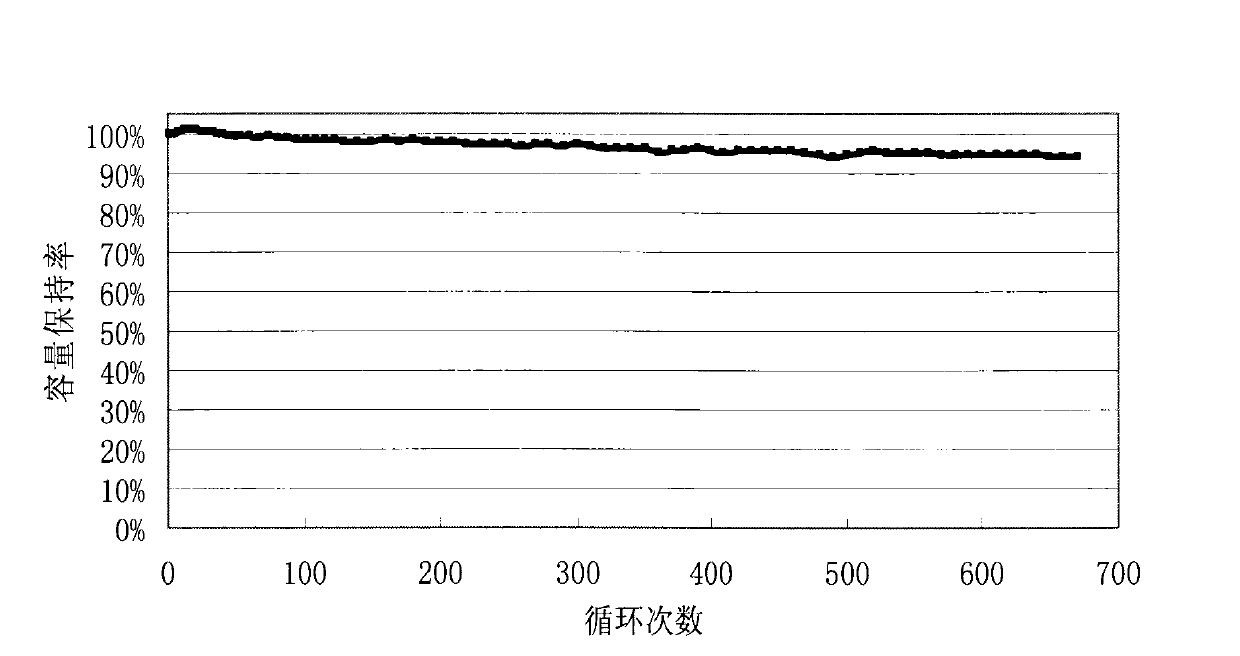

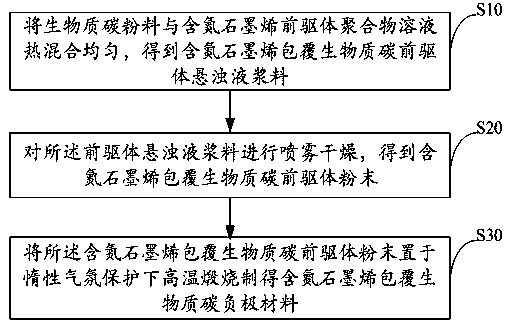

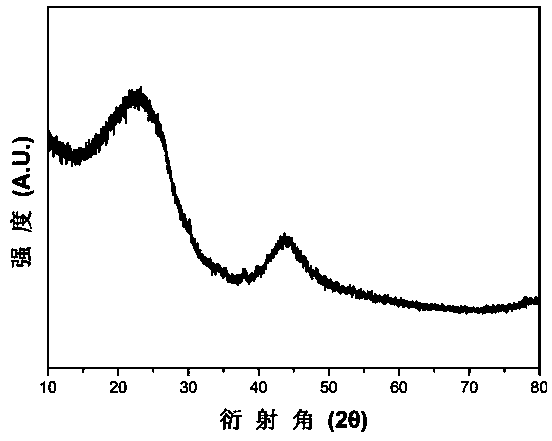

Nitrogen-containing graphene coated biomass carbon negative material and preparation method thereof

ActiveCN109950520AGood high current charge and discharge performanceImprove cycle stabilityCell electrodesBiomass carbonNitrogen

The invention discloses a nitrogen-containing graphene coated biomass carbon negative material and a preparation method thereof. According to the method, a plant raw material is dehydrated at low temperature, the raw material is carbonized at high temperature to obtain a primary biomass powdered carbon material, a final biomass powdered carbon material is obtained after removing impurities, the biomass powdered carbon material is mixed uniformly with a nitrogen-containing graphene precursor polymer solution according to certain mass proportion, the mixed solution is heated and stirred to obtain a micro-solidified crosslinking slurry, a solvent is removed by spray drying, particle shaping is carried out by means of air-flow grinding and the like, and high-temperature calcining is implemented to obtain the nitrogen-containing graphene coated biomass carbon negative material. The preparation method is green, technology is simple, source of raw materials is wide, the cost is low, and the prepared nitrogen-containing graphene coated biomass carbon negative material has extremely high heavy current charging / discharging performance, high circulation stability, high first coulombic efficiency, and high charging / discharging specific capacity.

Owner:SHENZHEN EIGEN EQUATION GRAPHENE TECH CO LTD

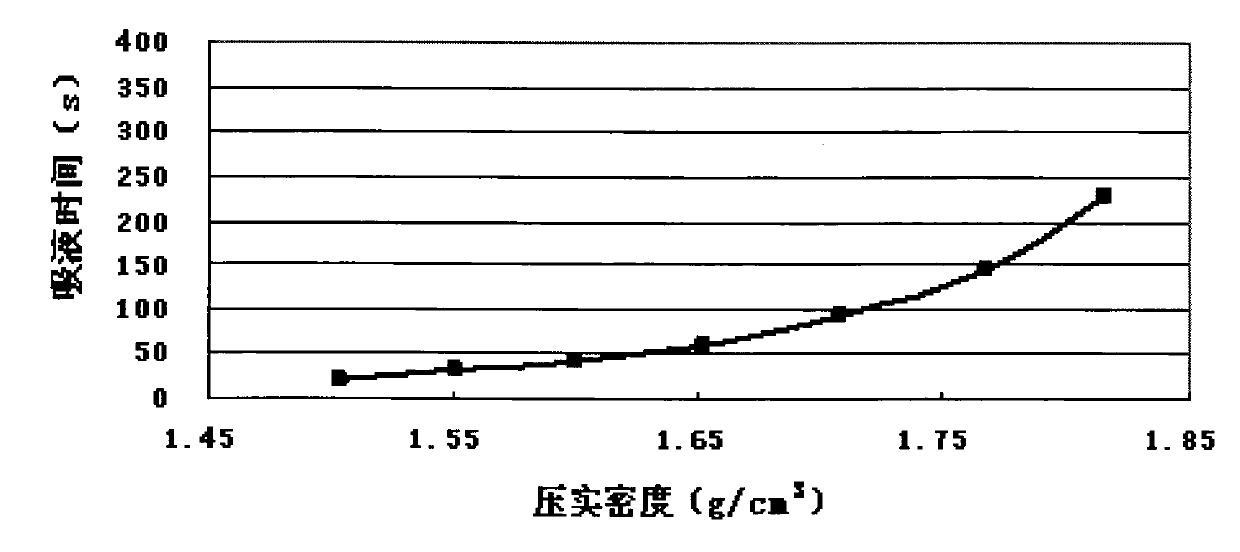

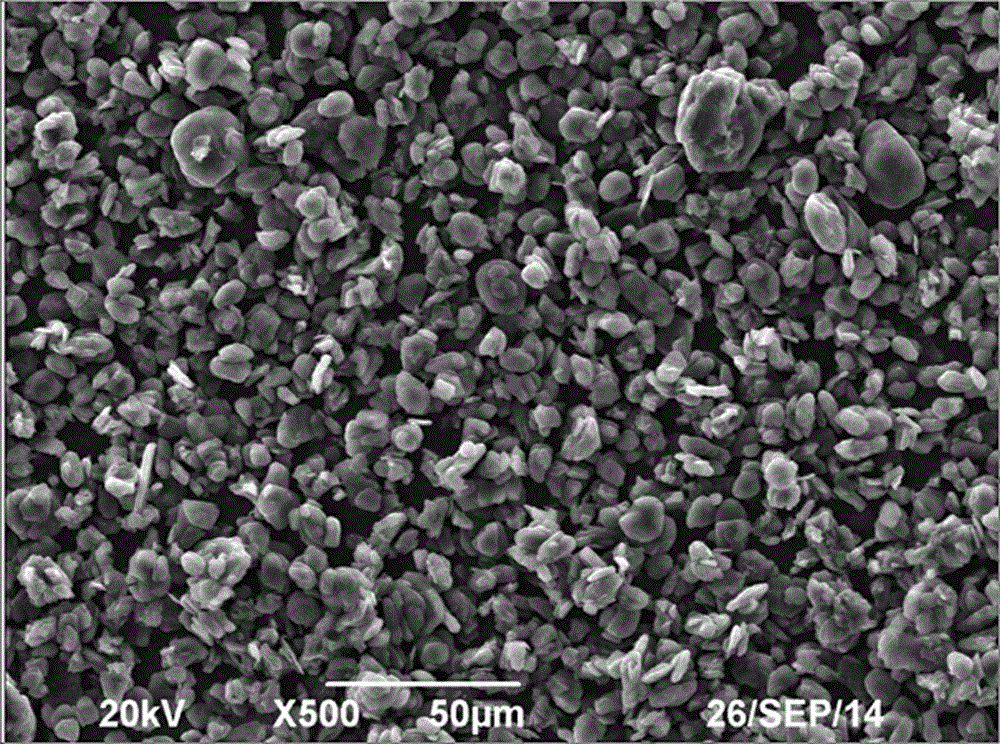

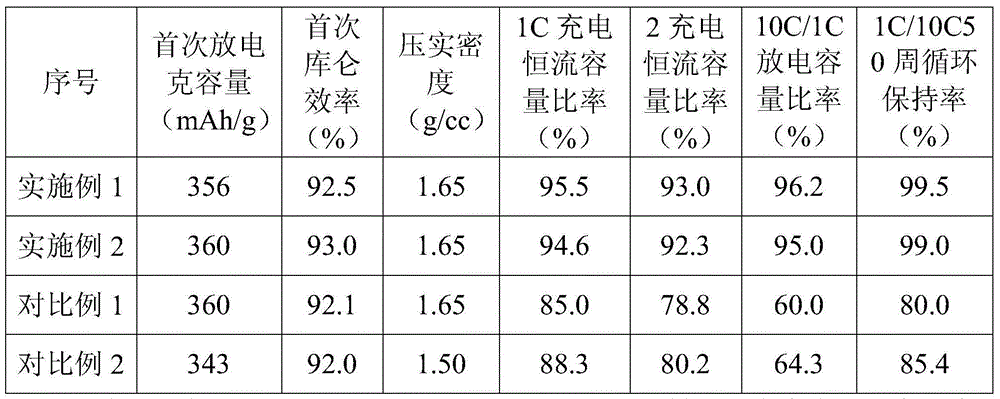

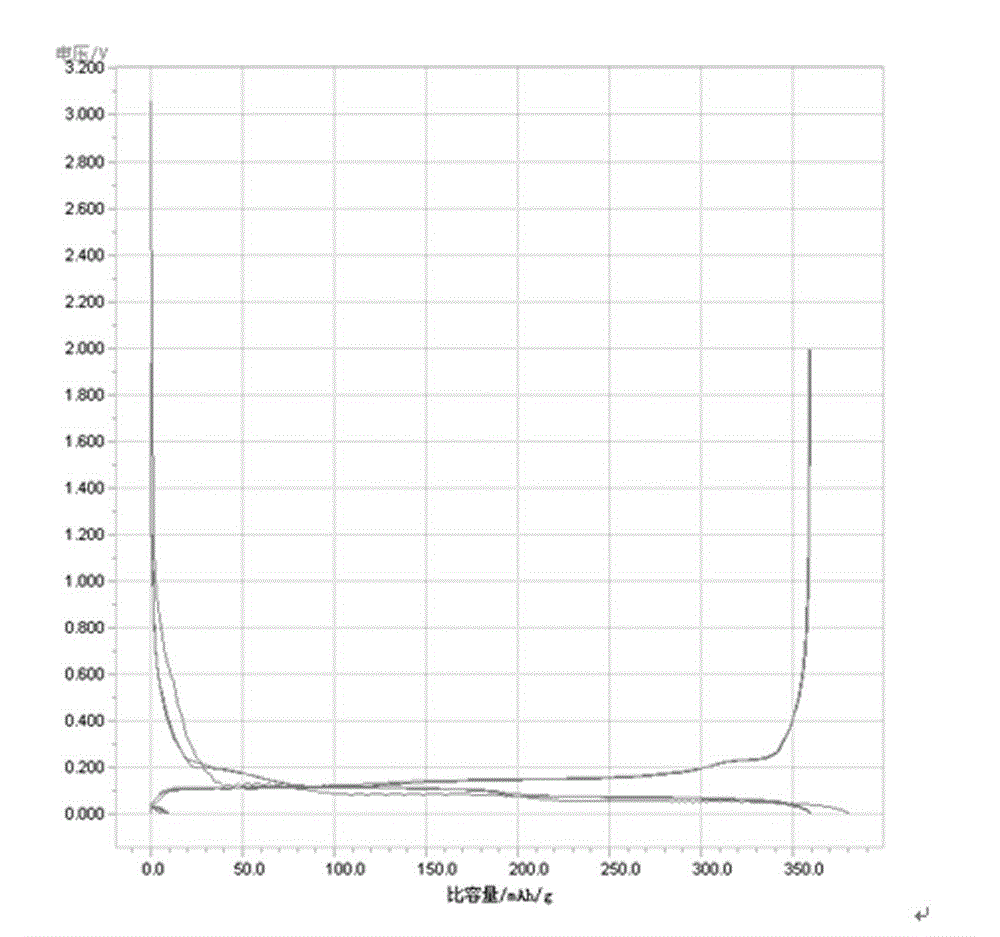

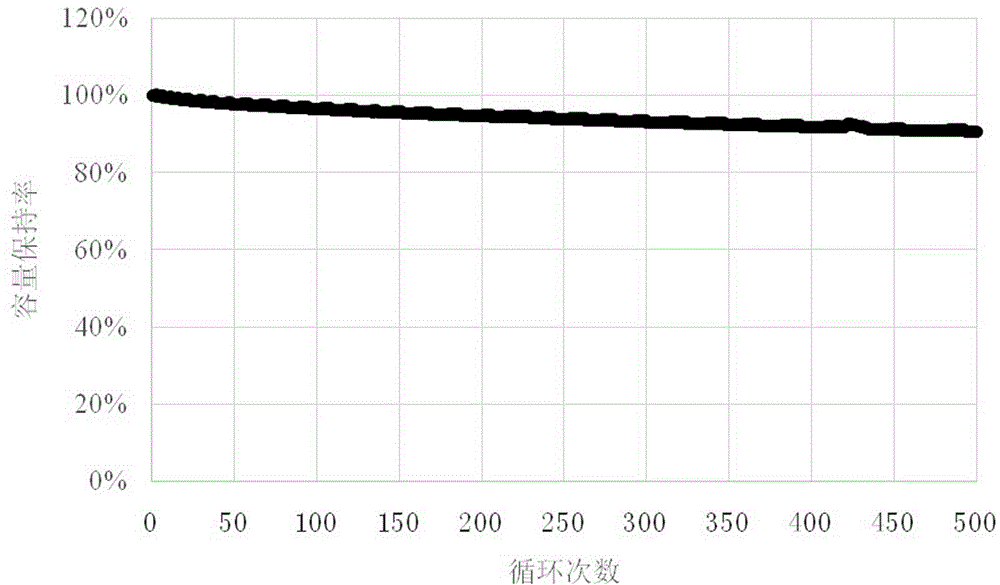

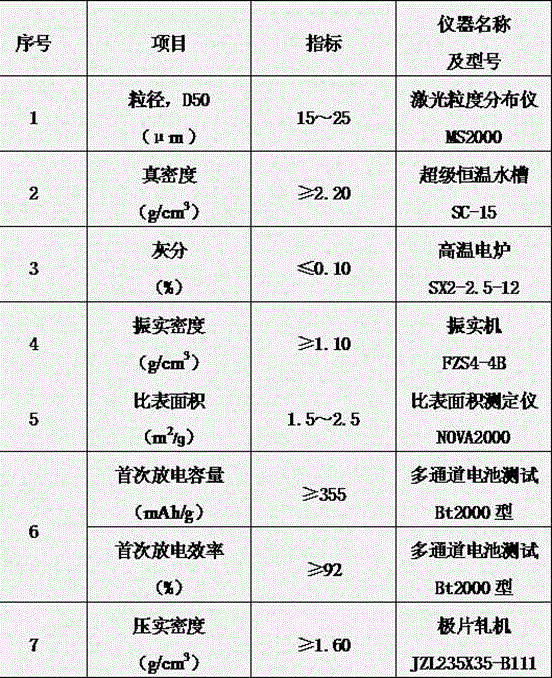

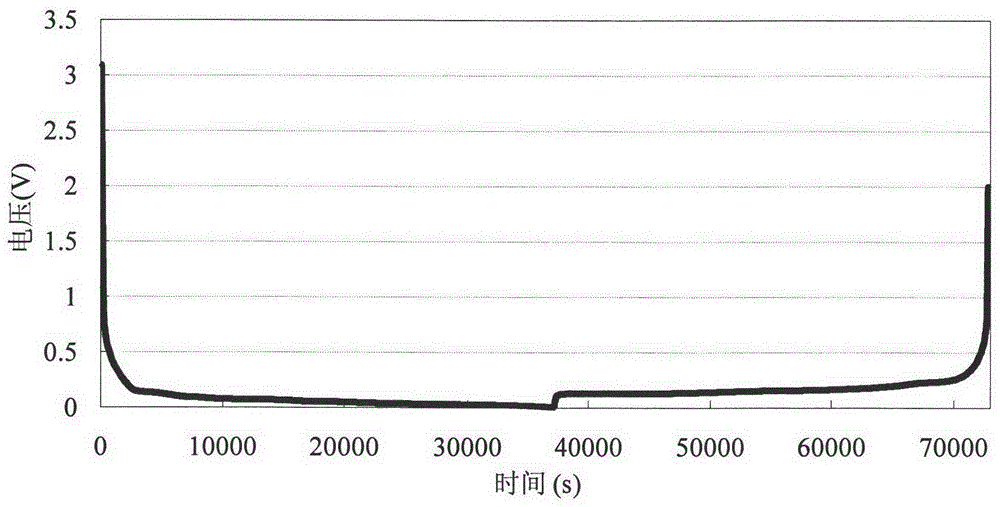

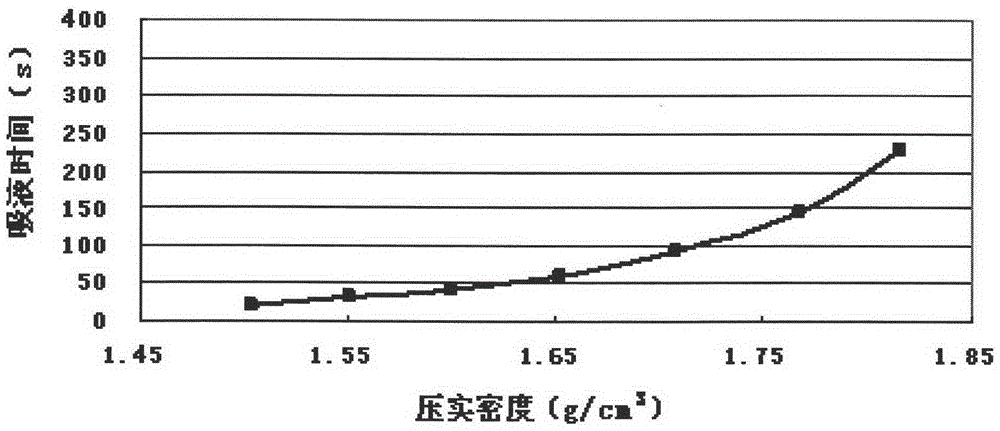

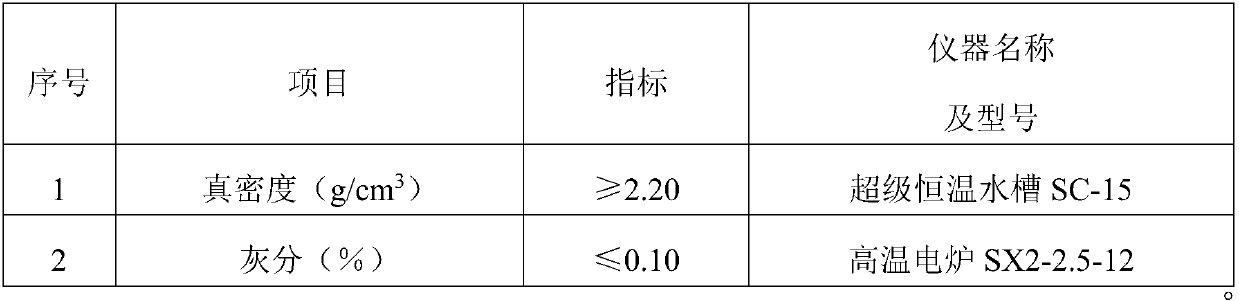

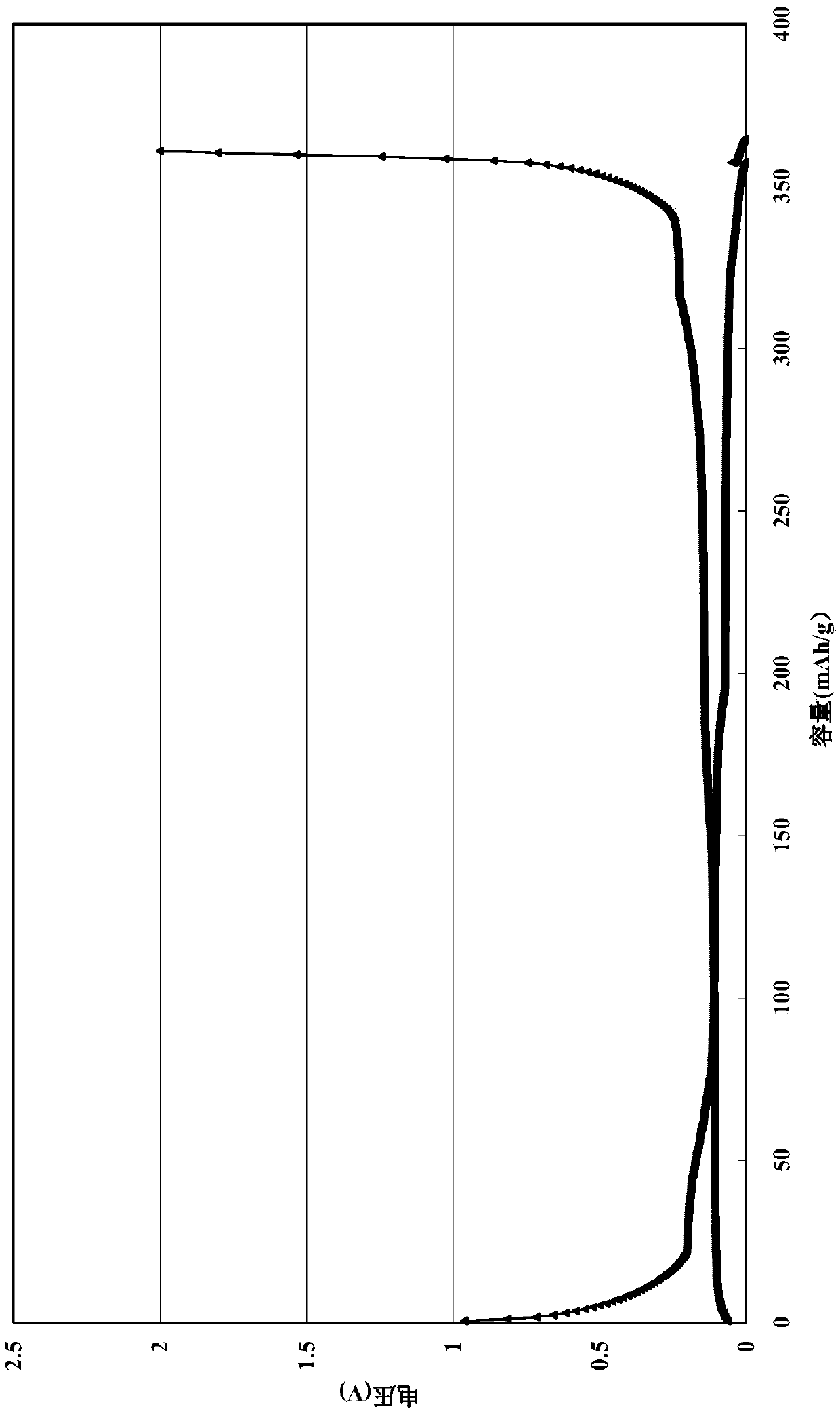

Hot-isostatic-press intermediate-phase graphite anode material used in lithium battery and preparation method thereof

InactiveCN105047859AImprove discharge capacityImprove cycle efficiencyCell electrodesState of artMicrosphere

The invention discloses a preparation method of a hot-isostatic-press intermediate-phase graphite anode material used in lithium batteries, wherein the preparation method includes the following steps: 1) performing pre-moulding with self-roasting mesocarbon microbeads as a raw material; 2) performing hot isostatic pressing; 3) performing graphitization; and 4) crushing and classifying a product. Compared with a reparation method in the prior art, in the preparation method in the invention, the self-roasting mesocarbon microbeads are subjected to mould-pressing pre-moulding, hot isostatic pressing and graphitization high-temperature treatment and then are crushed and classified. The material is high in compact density, is high in discharge capacity, is less in cyclic expansion and is long in cyclic life. The prepared lithium battery anode material is higher than 1.60 g / cm<3> in compact density, is higher than 355 mAh / g in initial discharge capacity, is higher than 92% in initial charging-discharging efficiency, is less than 6% in cyclic expansion (at 45 DEG C by 400 cycles), and is higher than 90% in cyclic life (by 500 cycles). The invention also relates to the graphite anode material prepared through the preparation method and a battery comprising the graphite anode material.

Owner:SHANGHAI SHANSHAN TECH CO LTD

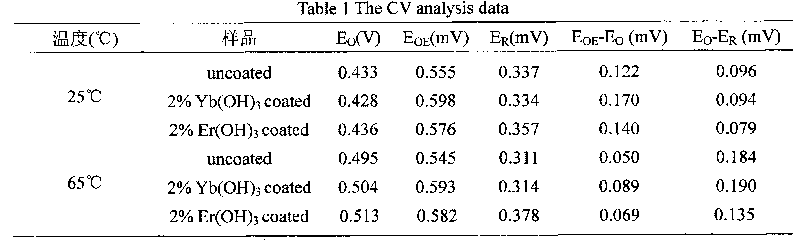

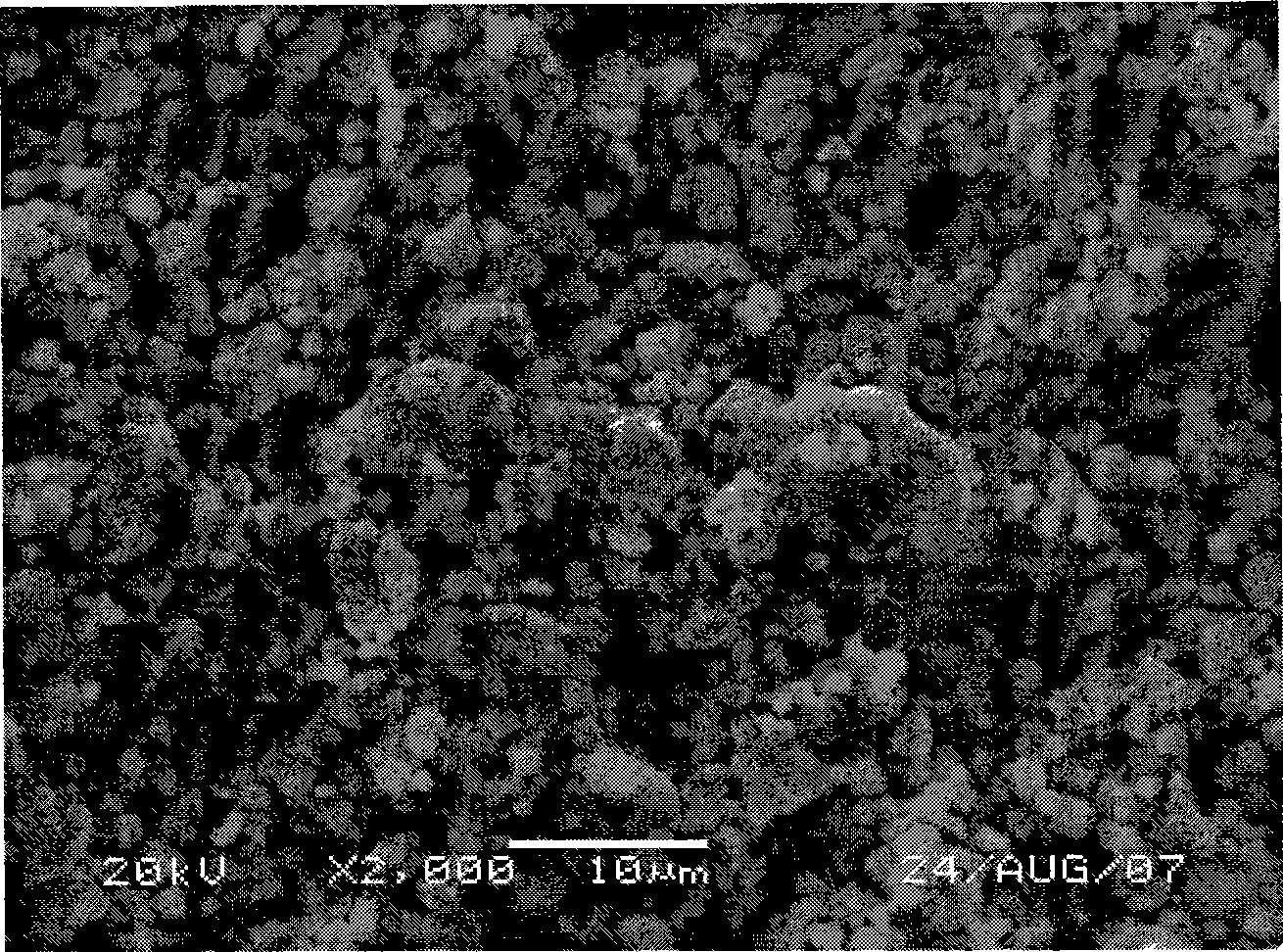

Preparation method of Co-covered nickel hydroxide anode material with surface covered by rare earth compound

InactiveCN101728521AGood high current charge and discharge performanceExcellent high temperature characteristicsAlkaline accumulator electrodesNickel oxide hydroxideCharge and discharge

The invention relates to a preparation method of a Co-covered nickel hydroxide anode material with the surface covered by a rare earth compound, belonging to the field of materials. The preparation method is characterized by covering a certain amount of Yb(OH)3 or Er(OH)3 on the upper surface of the nickel hydroxide material covered by 2.0 percent Co(OH)2. The discharge capacity of nickel hydroxide covered by 2 percent Yb(OH)3 is enhanced by 45 mAh / g compared with uncovered nickel hydroxide during 0.2 C charge and discharge at the high-temperature performance of 65 DEG C; the utility ratio of active materials of the nickel hydroxide covered by the 2 percent Yb(OH)3 is still 85 percent; the high-temperature charging and discharging performance of the nickel hydroxide covered by the certain amount of Er(OH)3 is also obviously improved; the discharge capacities of 1 C and 3 C at 65 DEG C are respectively 295.7 mAh / g and 290.3 mAh / g; the utility ratios of the active materials respectively reach 83 percent and 81 percent; and the optimal covering amount of Fr is 1.0-2.0 percent.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

A kind of lithium-ion battery composite graphite negative electrode material and preparation method thereof

ActiveCN103311520BImprove discharge capacityImprove adaptabilityCell electrodesAdhesiveSodium-ion battery

The invention discloses a preparation method for a composite graphite negative electrode material of a lithium ion battery. The preparation method comprises the following steps: (1) uniformly mixing spherical natural graphite, mesophase graphite and a graphitized catalyst so as to obtain a mixture; (2) kneading the mixture and an adhesive so as to obtain a kneading product; (3) carrying out carbonizing treatment at first, then cooling and finally catalytic graphitization high temperature treatment; and (4) carrying out crushing and grading. The preparation method provided by the invention is simple and feasible and is applicable to industrial production. The prepared composite graphite negative electrode material has the advantages of good electrochemical properties, discharge capacity of more than 360 mAh / g, high charge and discharge efficiency, good heavy-current charge and discharge performance, excellent cycle performance, small expansion during charging, good security and good adaptability to electrolytes and other additives; and a lithium ion battery product prepared from the composite graphite negative electrode material has stable properties, and different batches of such product barely show difference.

Owner:上海杉杉新材料有限公司

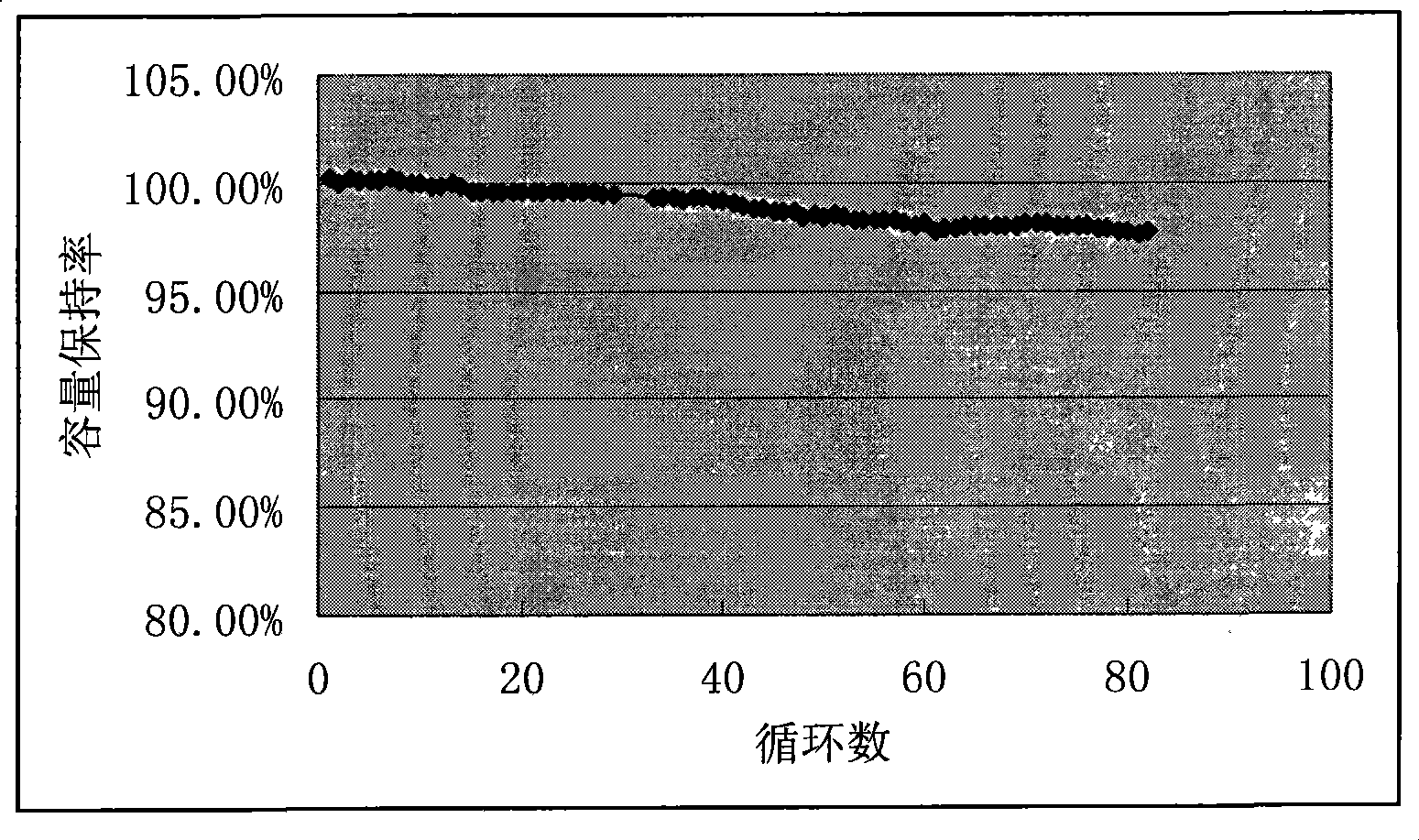

Lithium iron phosphate positive pole material

InactiveCN101399342AGood high current charge and discharge performanceCell electrodesPhosphorus compoundsLithium iron phosphatePhysical chemistry

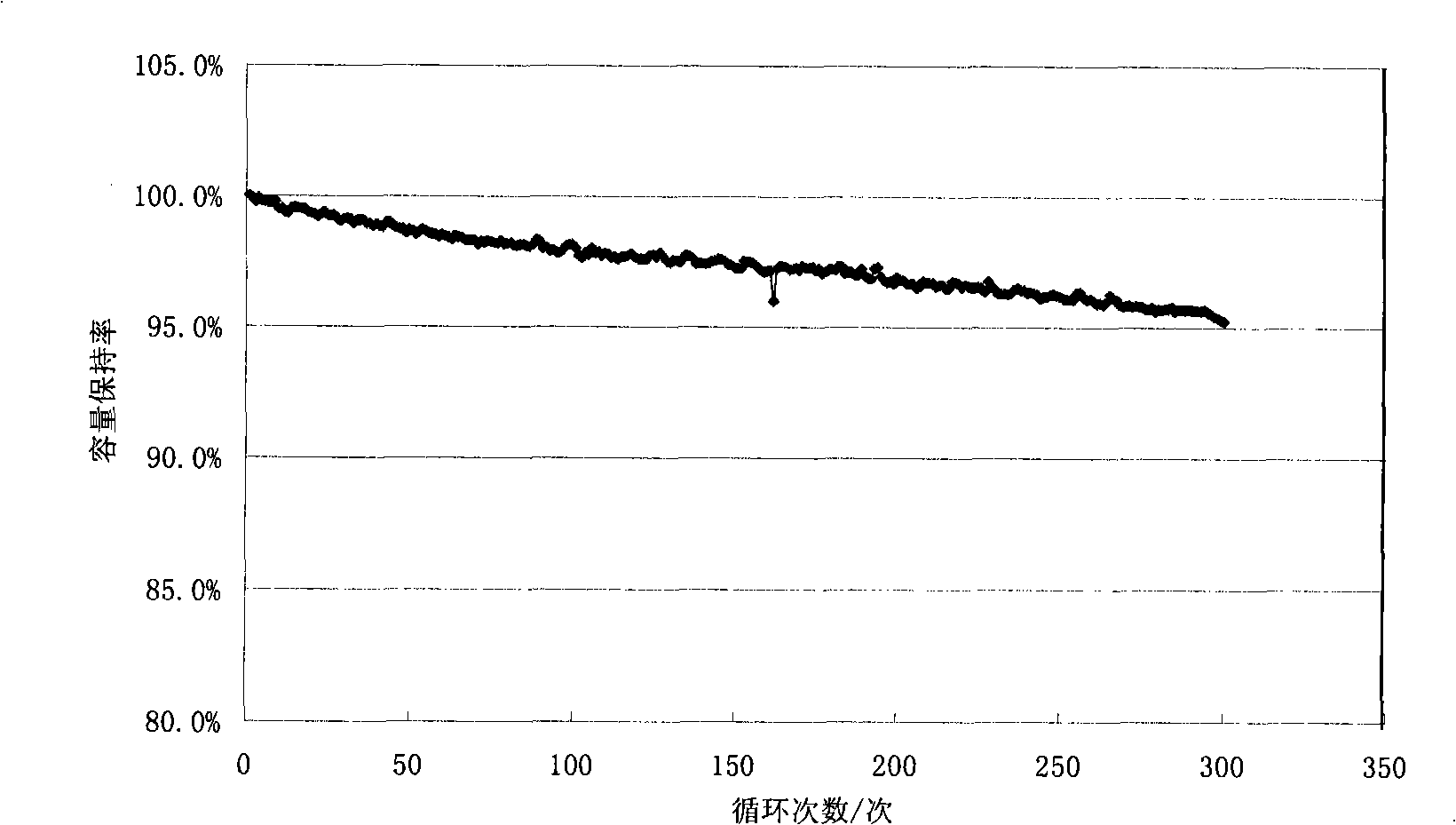

The invention provides a lithium iron phosphate positive electrode material, the chemical formula thereof is Li1-xMgx / 2FePO4 / C, wherein, x is not less than or equal to 0.01 and not more than or equal to 0.04. The positive electrode material Li1-xMgx / 2FePO4 / C still has an olivine structure of the lithium iron phosphate, the high-current cycle test of 5A under the charge / 15A under the discharge is carried out on a lithium-ion battery which adopts the positive electrode material Li1-xMgx / 2FePO4 / C at the normal temperature, the first discharge capacity is more than 138mAh / g, and the capacity retention rate after 80 cycles is more than 97 percent, thereby having good high-current charge-discharge performance.

Owner:SHENZHEN BAK BATTERY CO LTD

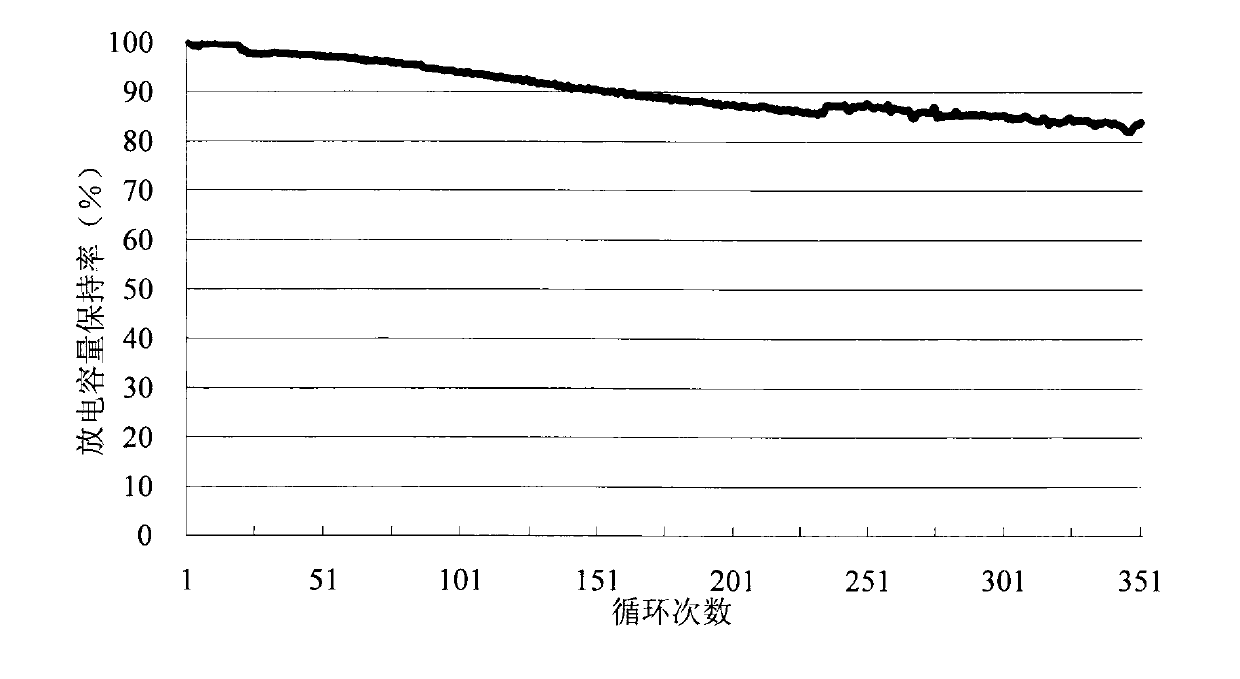

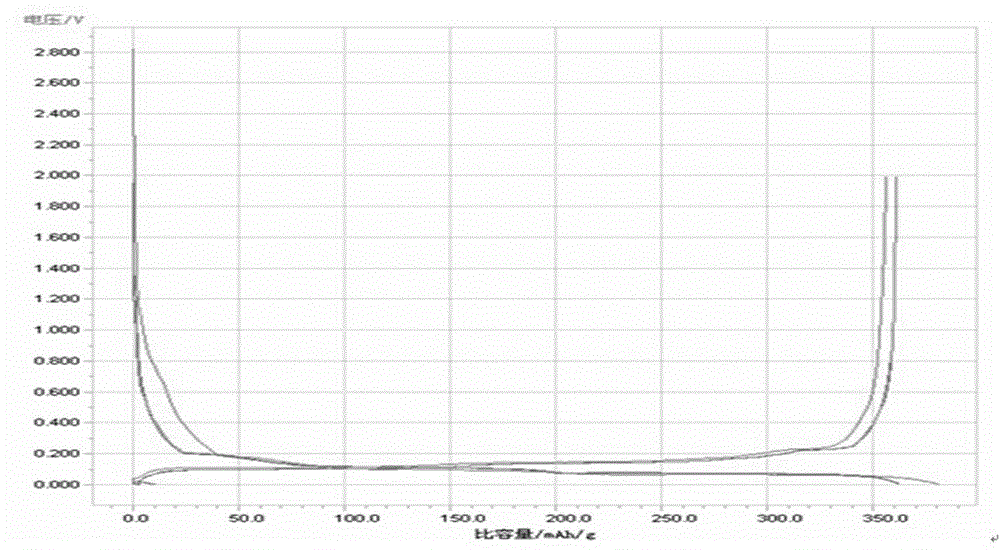

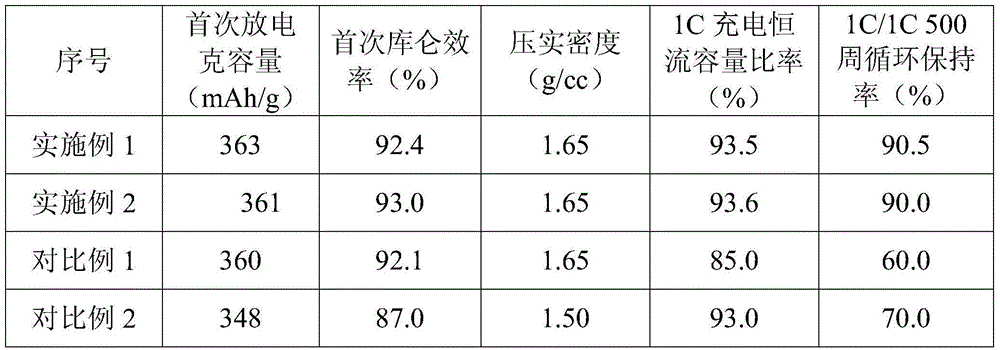

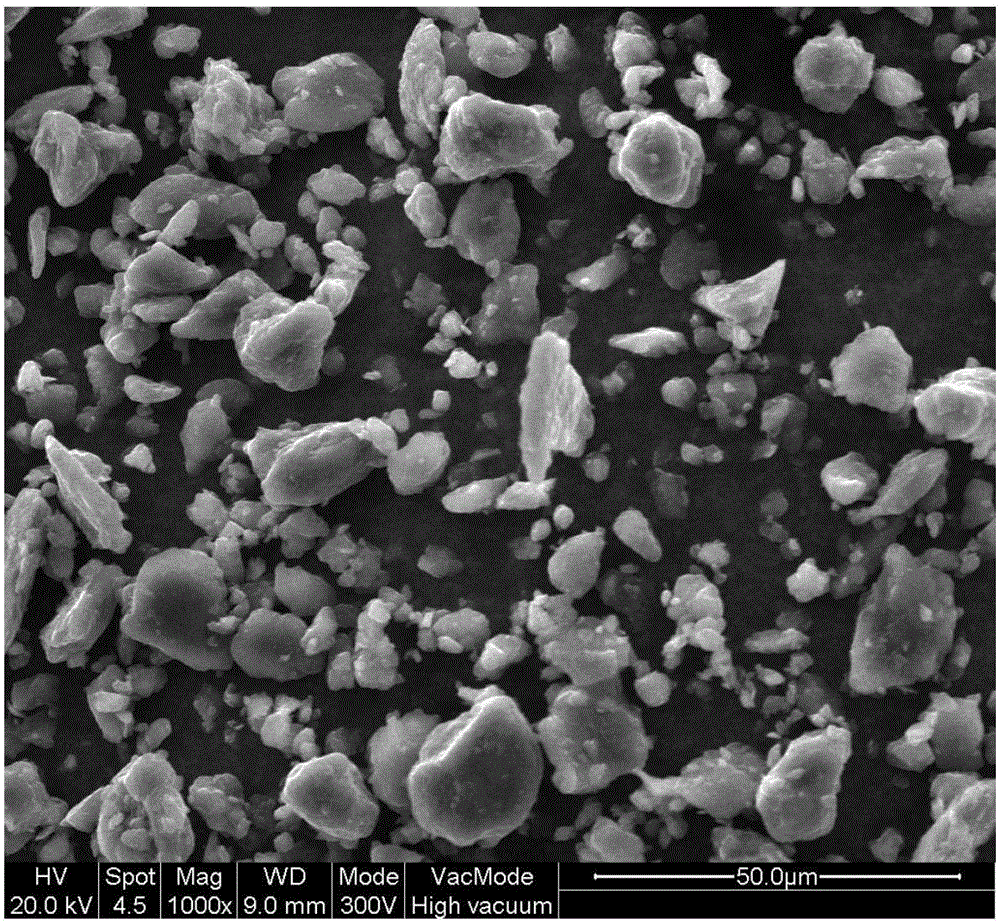

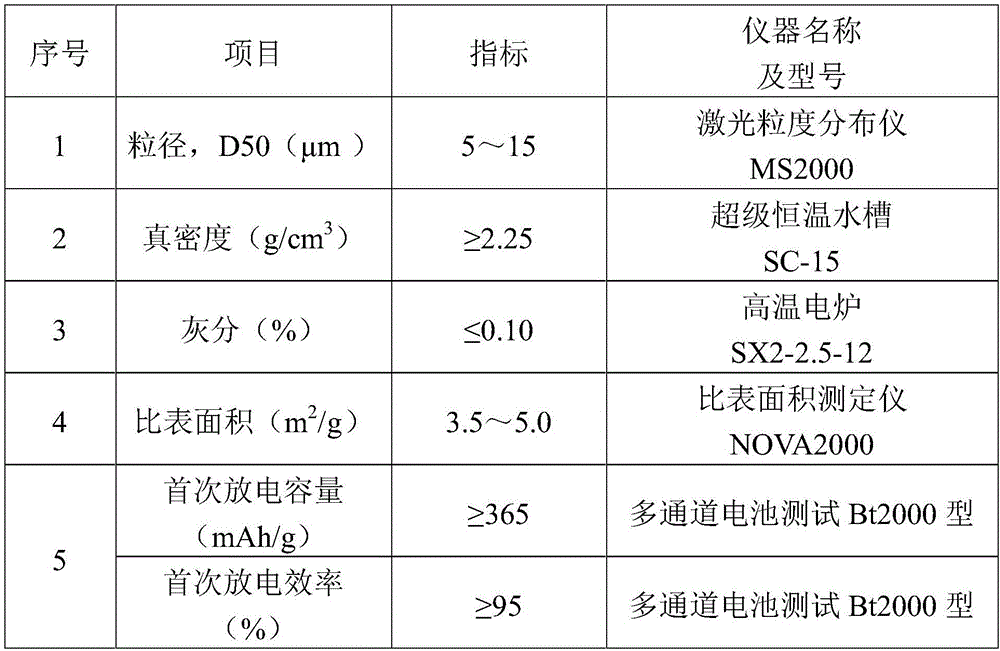

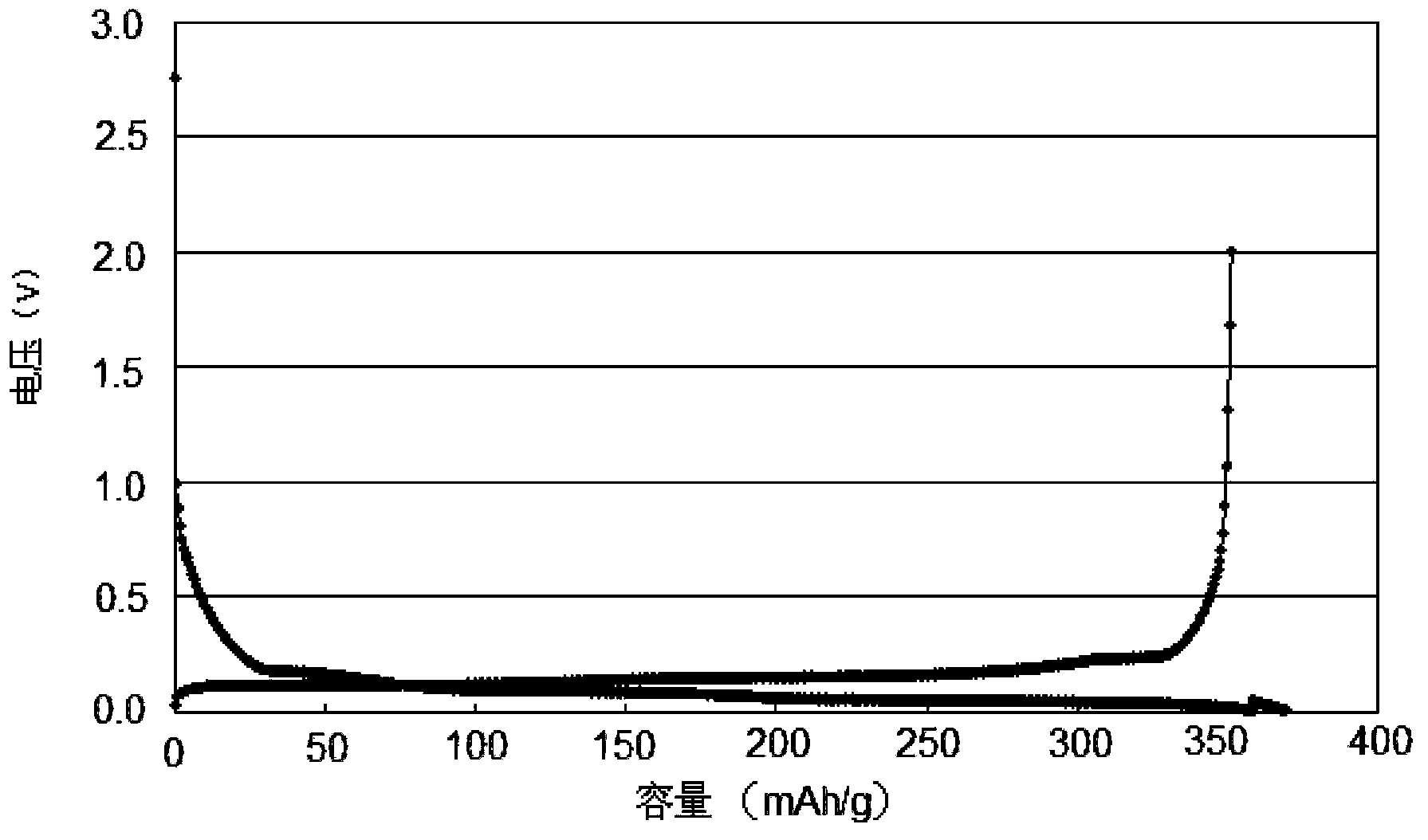

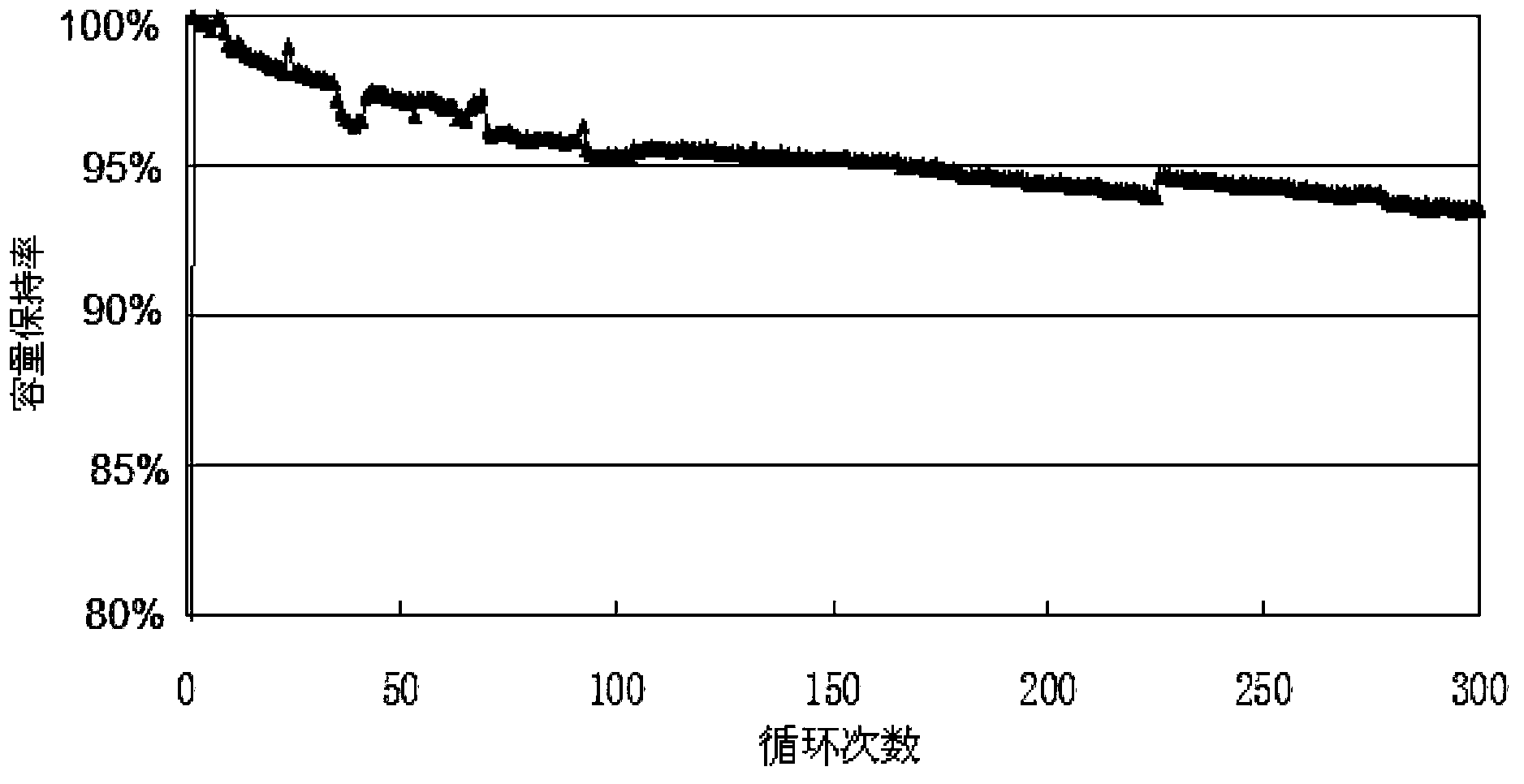

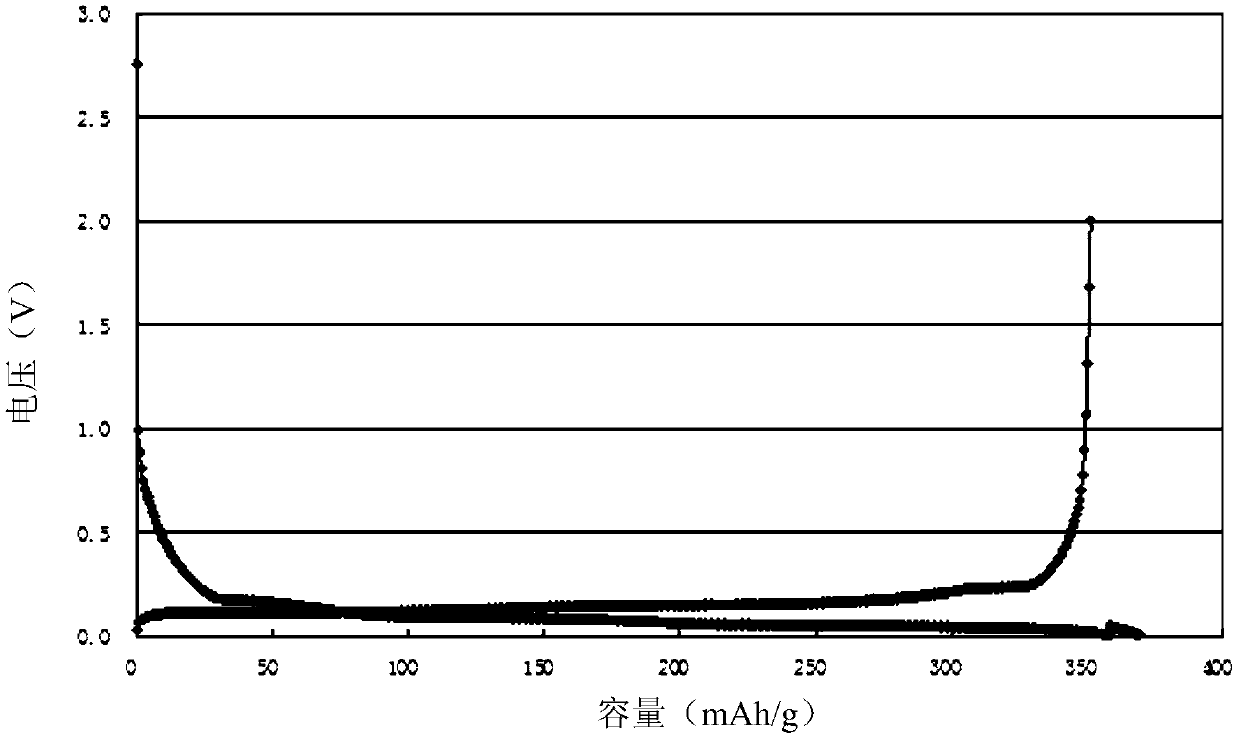

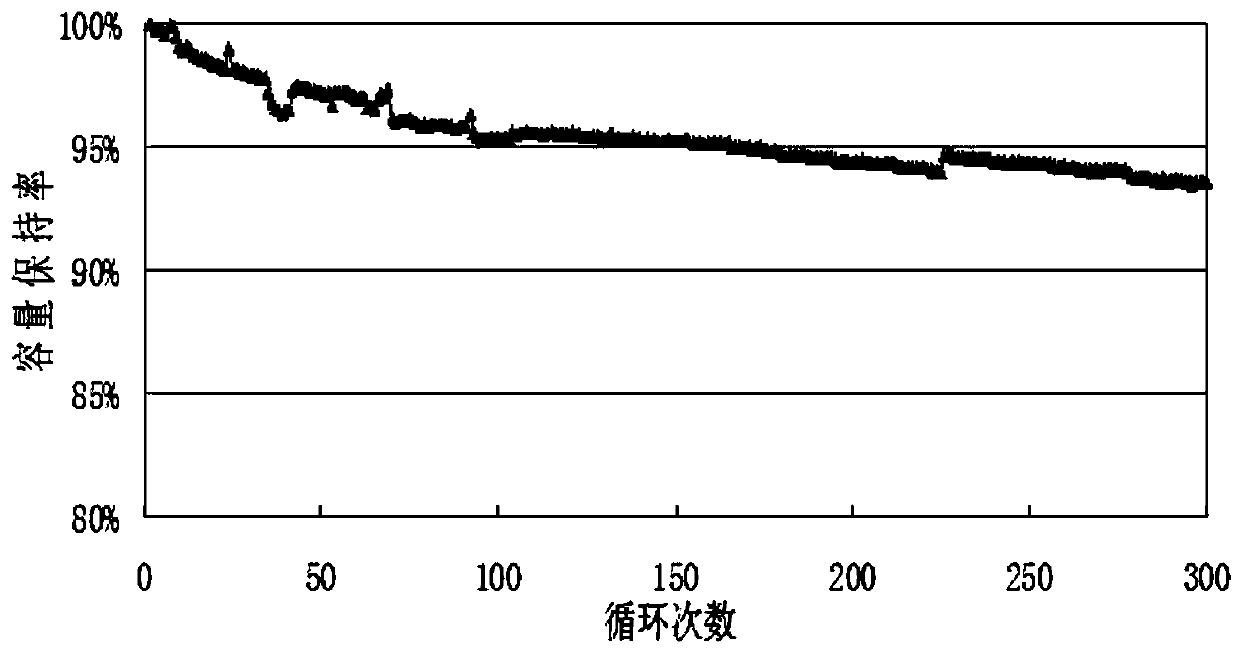

Composite mesophase negative electrode material, lithium ion secondary battery, preparation method and application

ActiveCN111232969AImprove adaptabilityImprove performanceCarbon compoundsSecondary cellsElectrolytic agentPtru catalyst

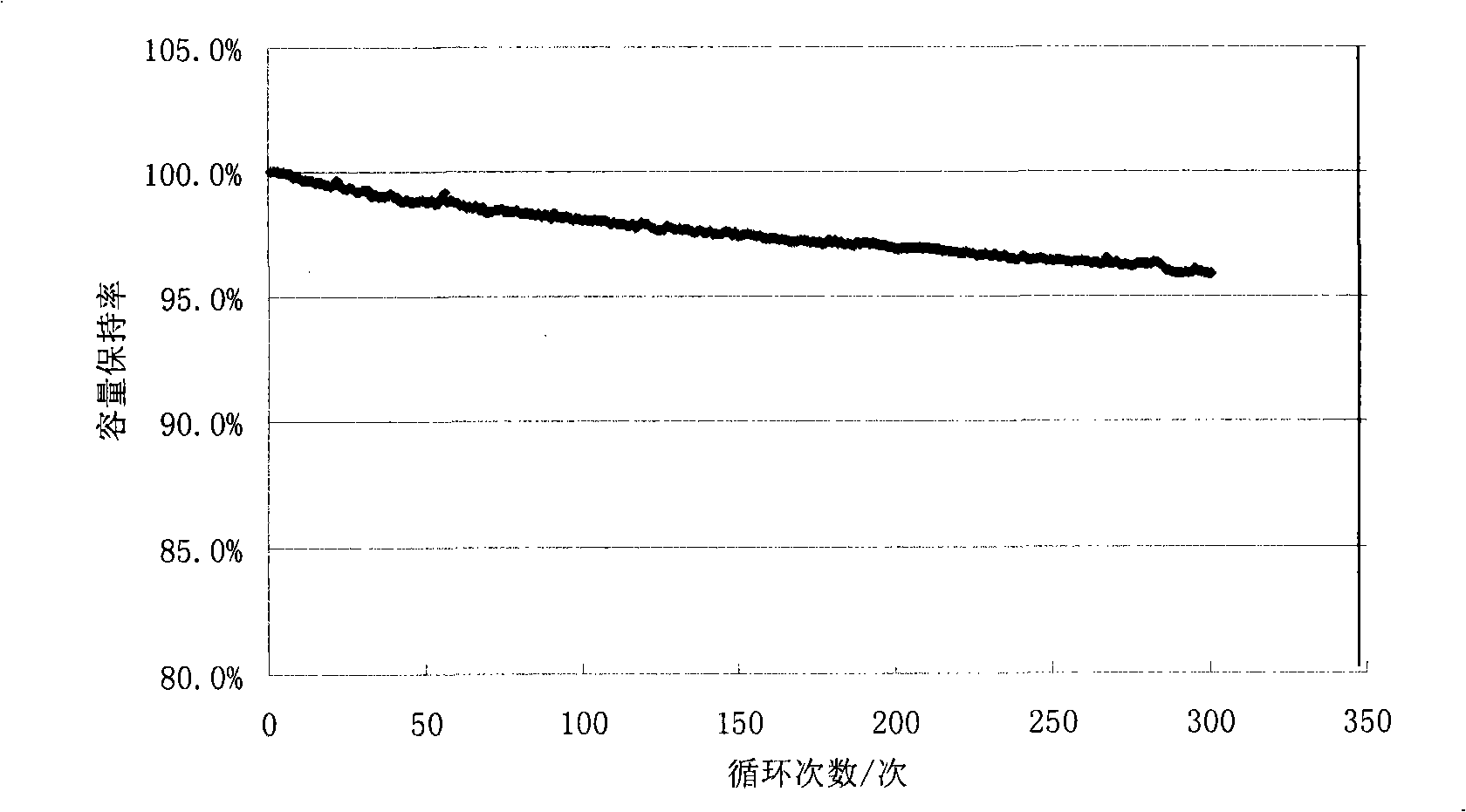

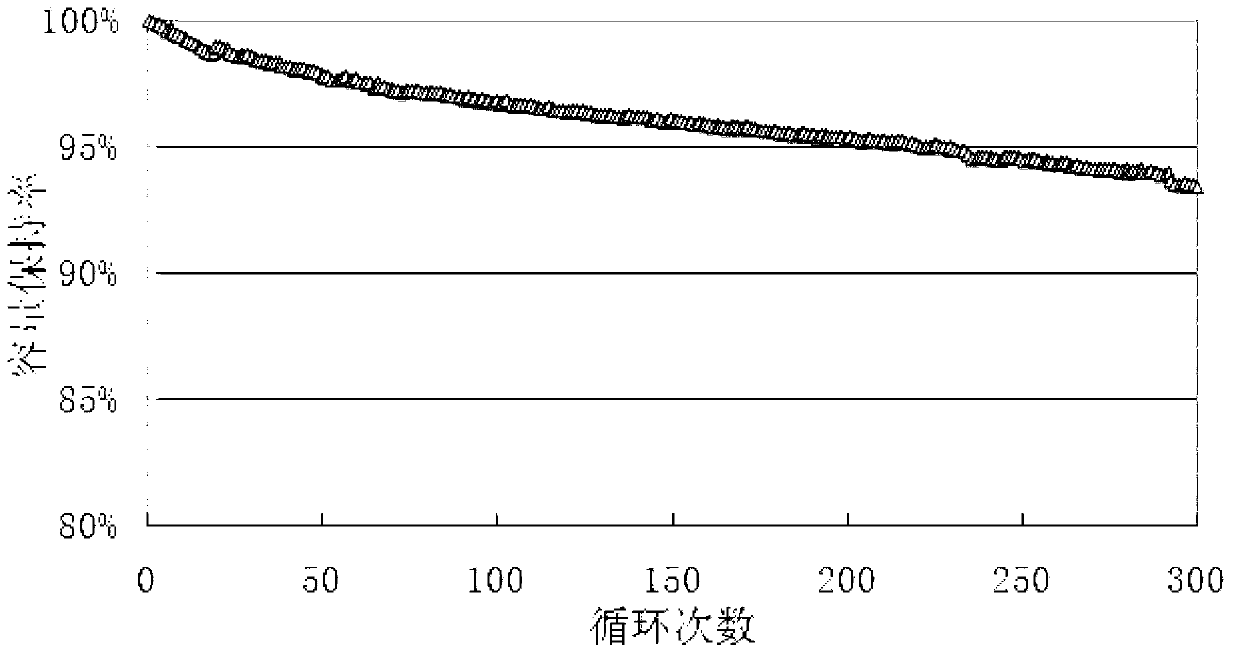

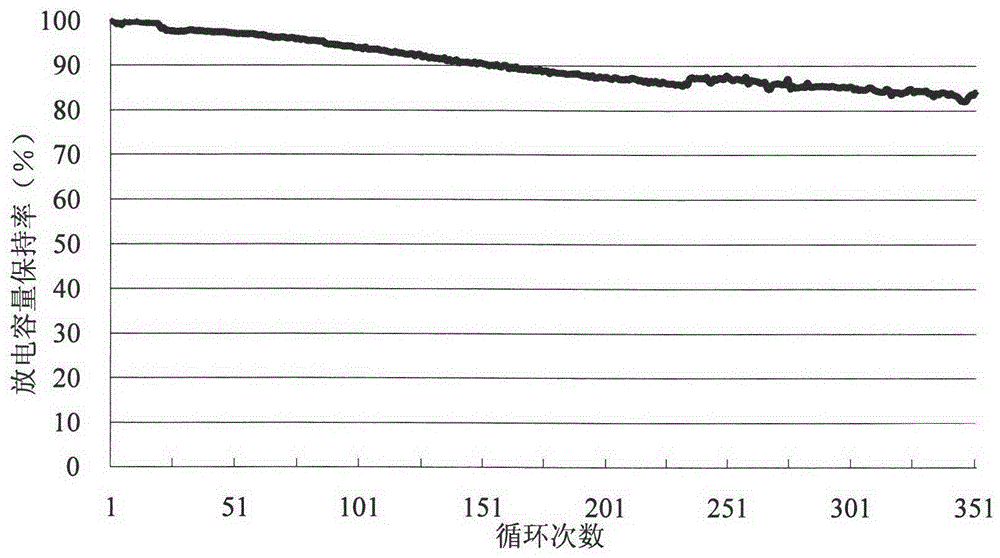

The invention discloses a composite intermediate phase negative electrode material, a lithium ion secondary battery, a preparation method and application. The preparation method comprises the following step: carrying out catalytic graphitization treatment on a blocky mixture containing uncalcined green coke powder, mesocarbon microbead green pellets, a graphitization catalyst and an adhesive capable of being graphitized, wherein the particle size D50 of the uncalcined green coke powder is 1-50 [mu] m, and the mass ratio of the uncalcined green coke powder to the mesocarbon microbead green pellets is (0.25-1): 1. The composite intermediate-phase negative electrode material prepared by the method is large in discharge capacity and good in cycle performance; a prepared button cell has excellent comprehensive performance, the discharge capacity is 365 mAh / g or above, the cycle performance is good (300 cycles, the capacity is maintained to be greater than or equal to 90%), the safety is better (130 DEG C / 60 minutes, explosion and expansion are avoided), the adaptability to electrolytes and other additives is better, the preparation method is simple and feasible, and the preparation method is suitable for industrial production.

Owner:SHANGHAI SHANSHAN TECH CO LTD

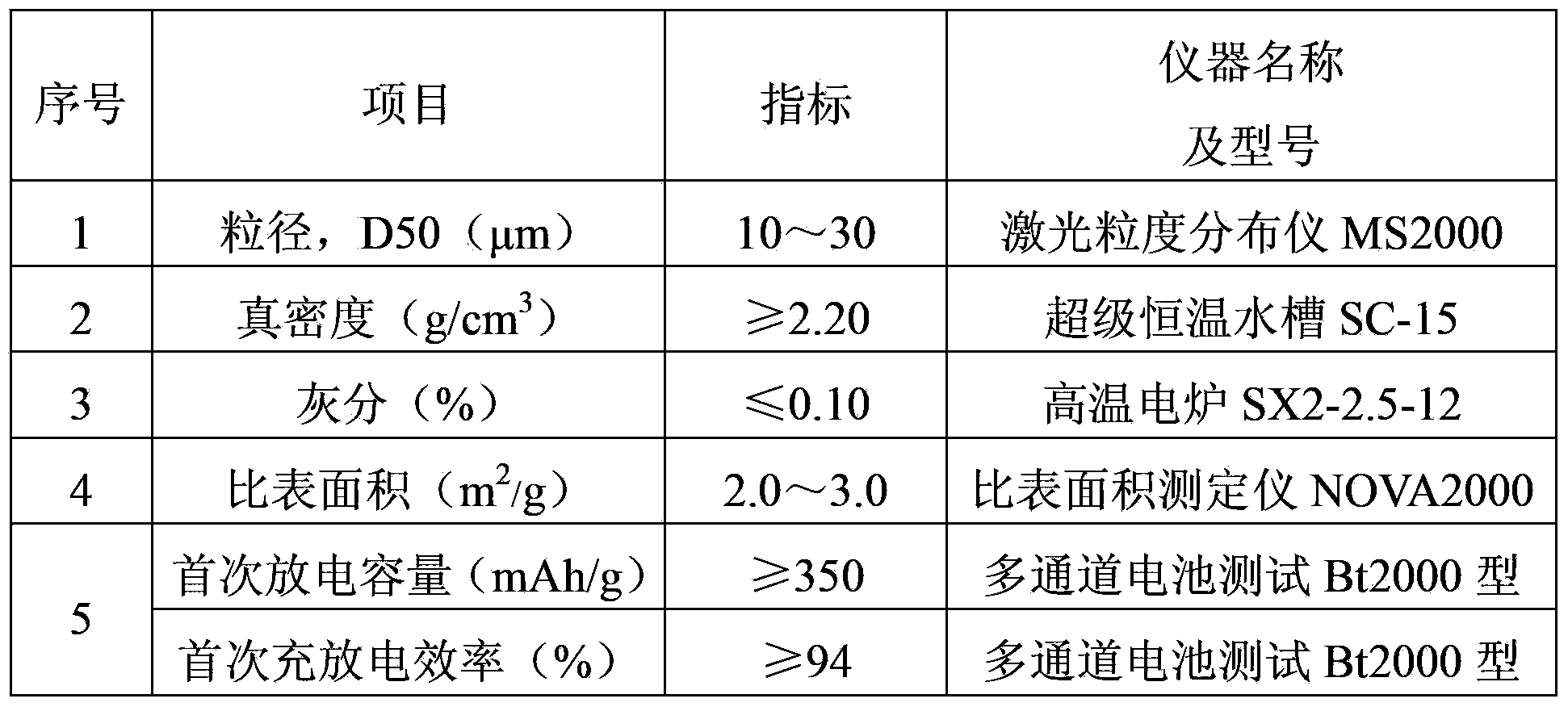

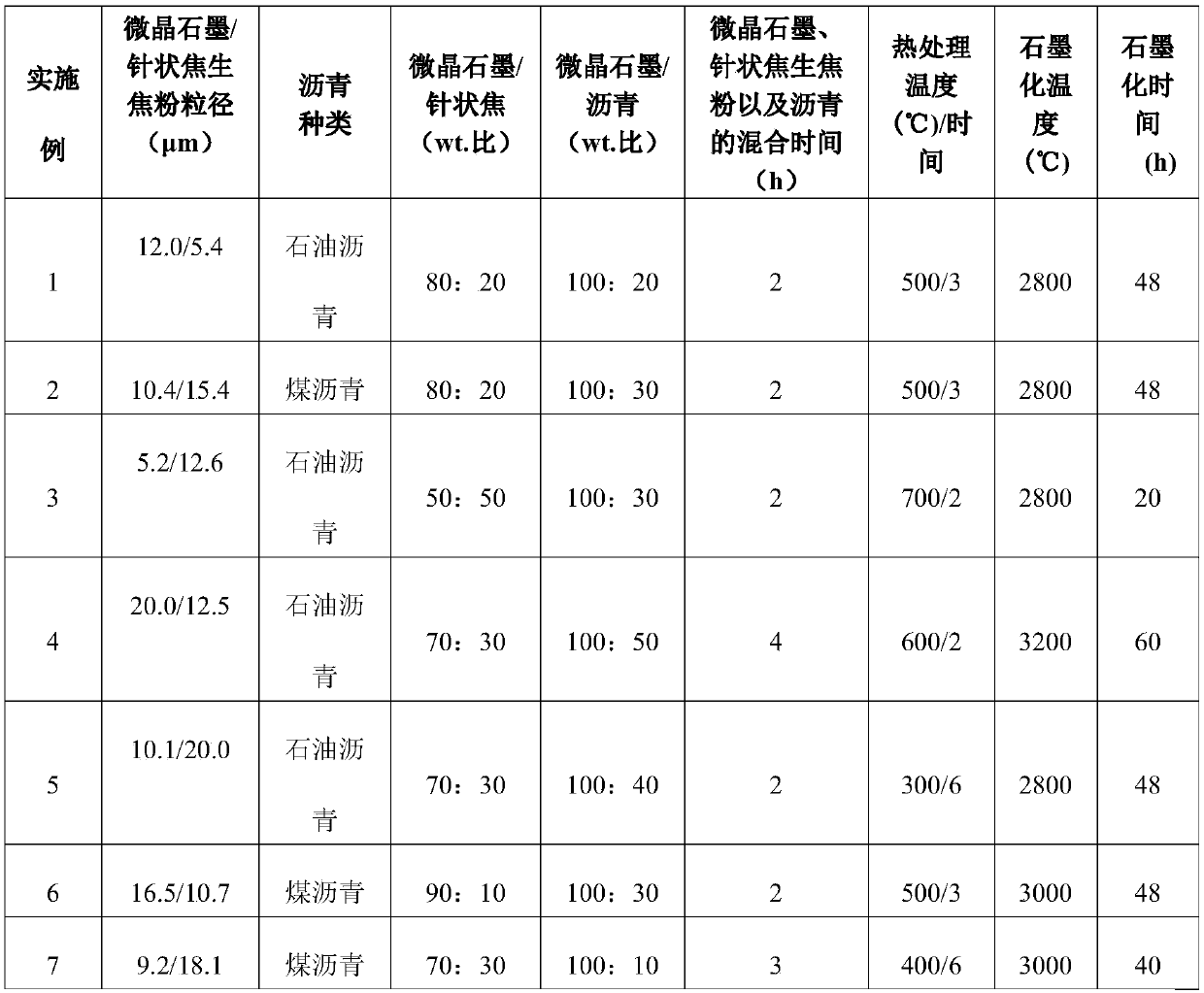

Composite graphite negative electrode material, lithium ion secondary battery, preparation method and application

PendingCN111232968AIncrease gram capacityImprove discharge efficiencyCarbon compoundsCell electrodesDischarge efficiencyGraphite

The invention discloses a composite graphite negative electrode material, a lithium ion secondary battery, a preparation method and application. The preparation method of the composite graphite negative electrode material comprises the following steps: carrying out heat treatment on a mixture of microcrystalline graphite, needle coke powder and asphalt at 300-700 DEG C, cooling to room temperature, and carrying out graphitization high-temperature treatment, wherein the mass ratio of the microcrystalline graphite to the needle coke powder is (1-9): 1, wherein the mass ratio of the microcrystalline graphite to the asphalt is 5: (1-2), wherein the average particle size D50 of the microcrystalline graphite is 5-20 [mu] m. The lithium ion secondary battery is high in first discharge efficiencyand discharge capacity.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Preparation method of carbon-coated tin dioxide superfine powder lithium ion battery negative electrode material

InactiveCN103531747BLarge specific surface areaNot easy to collapseCell electrodesTin dioxideCarbon film

The invention discloses a preparation method of a carbon-coated tin dioxide superfine powder lithium ion battery negative electrode material. The preparation method comprises the following steps of: dissolving the precursor of tin and long-chain fatty acid in a high boiling point solvent under certain condition; continuously blowing in air at 200 DEG C-280 DEG C to prepare a tin dioxide nanocrystal which is high in degree of crystallinity and monodisperse; and recycling, purifying, roasting in a nitrogen gas atmosphere to obtain carbon-coated tin dioxide superfine powder. According to the preparation method disclosed by the invention, dimension of the carbon-coated tin dioxide superfine powder can be adjusted by controlling factors of reaction temperature, time, and the like. The carbon-coated tin dioxide superfine powder prepared by the preparation method disclosed by the invention has characteristics of high capacity (as high as 1000 mAh.g<-1>), stable capacity (battery capacity of 480 mAh.g<-1> during 8C discharging) under high-rate discharge condition, and the like.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com