Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve UI" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

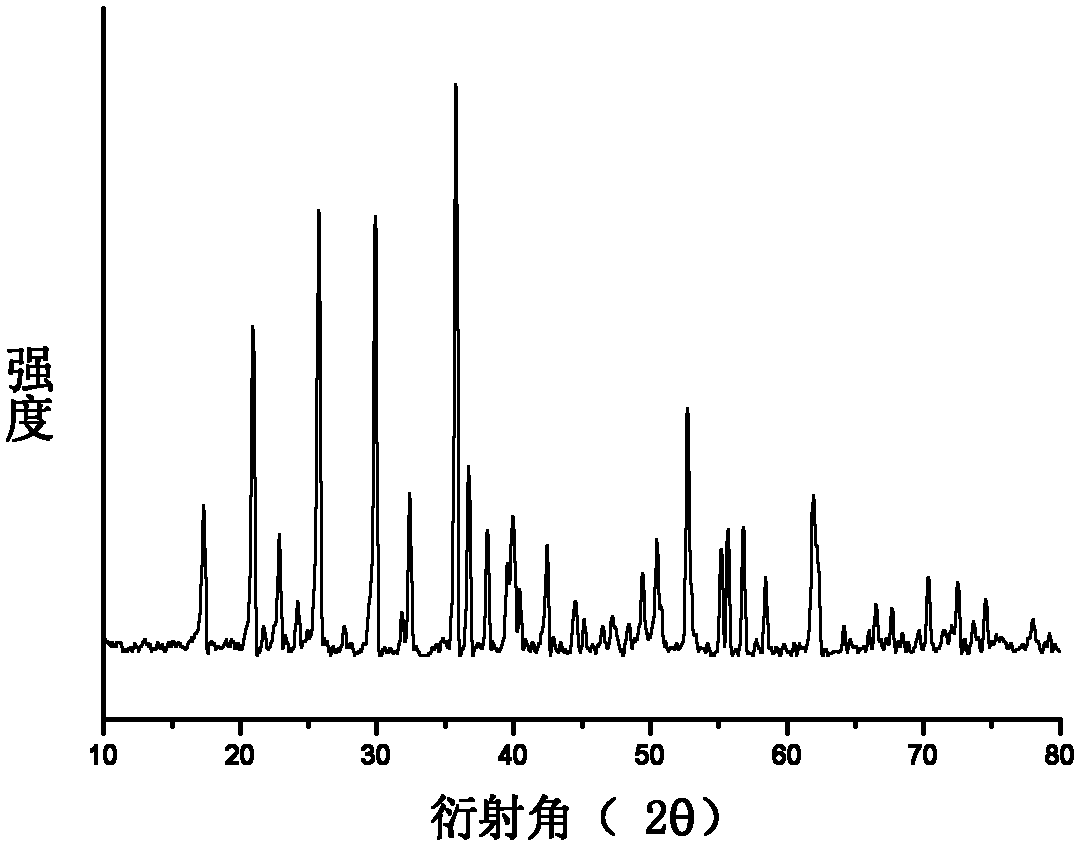

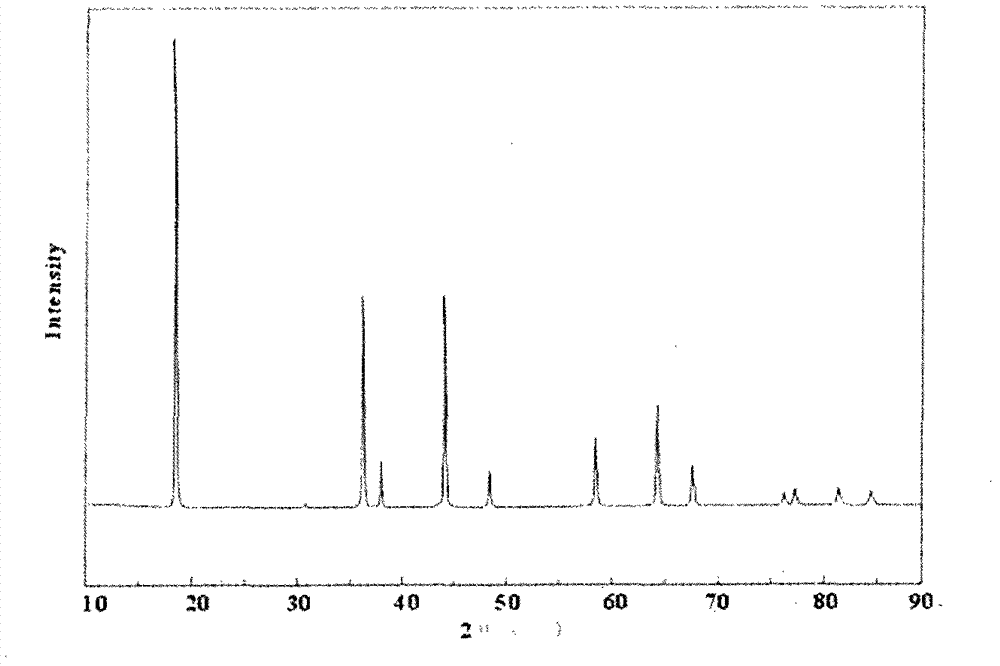

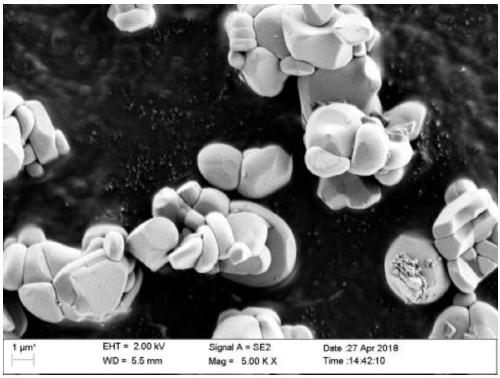

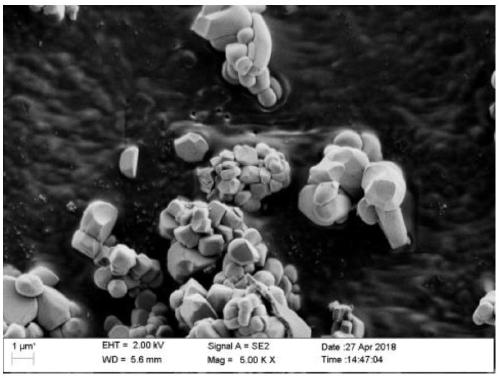

Lithium ion battery high-voltage anode material preparation and surface coating method

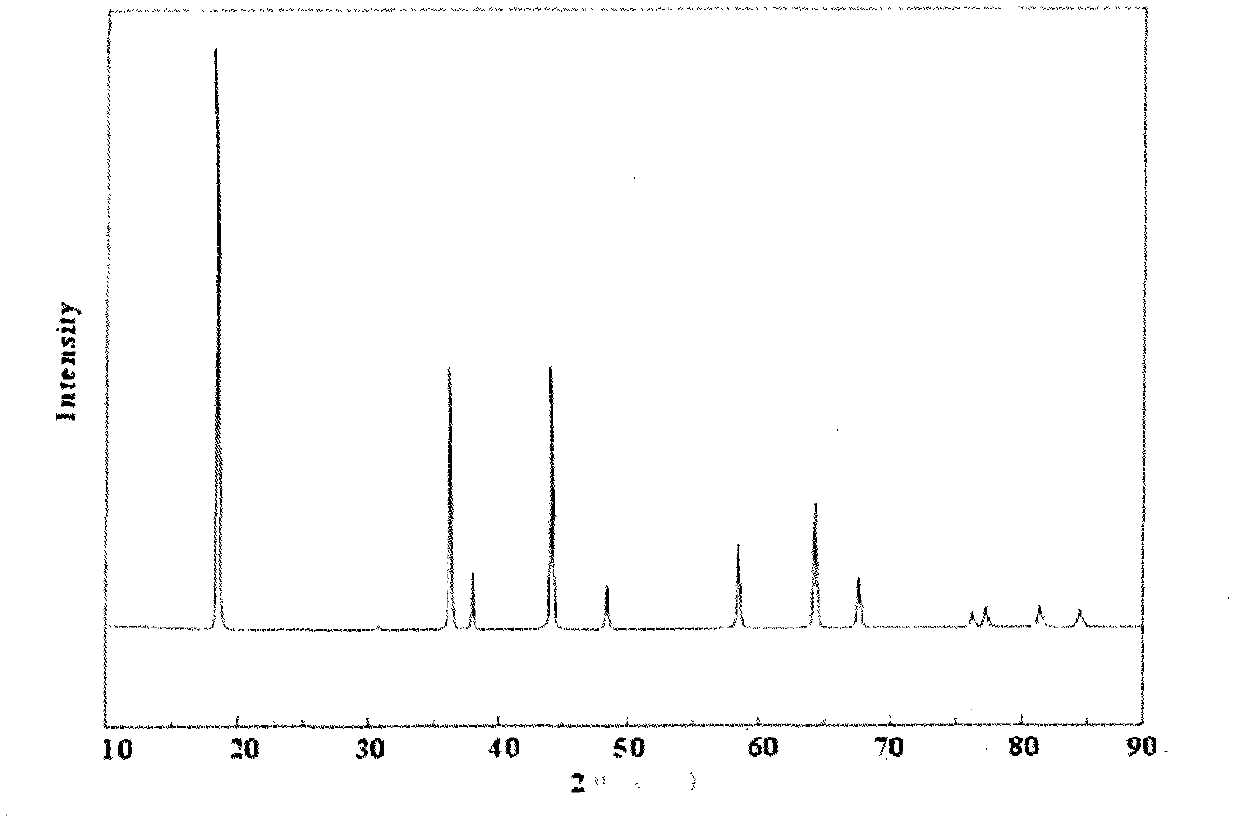

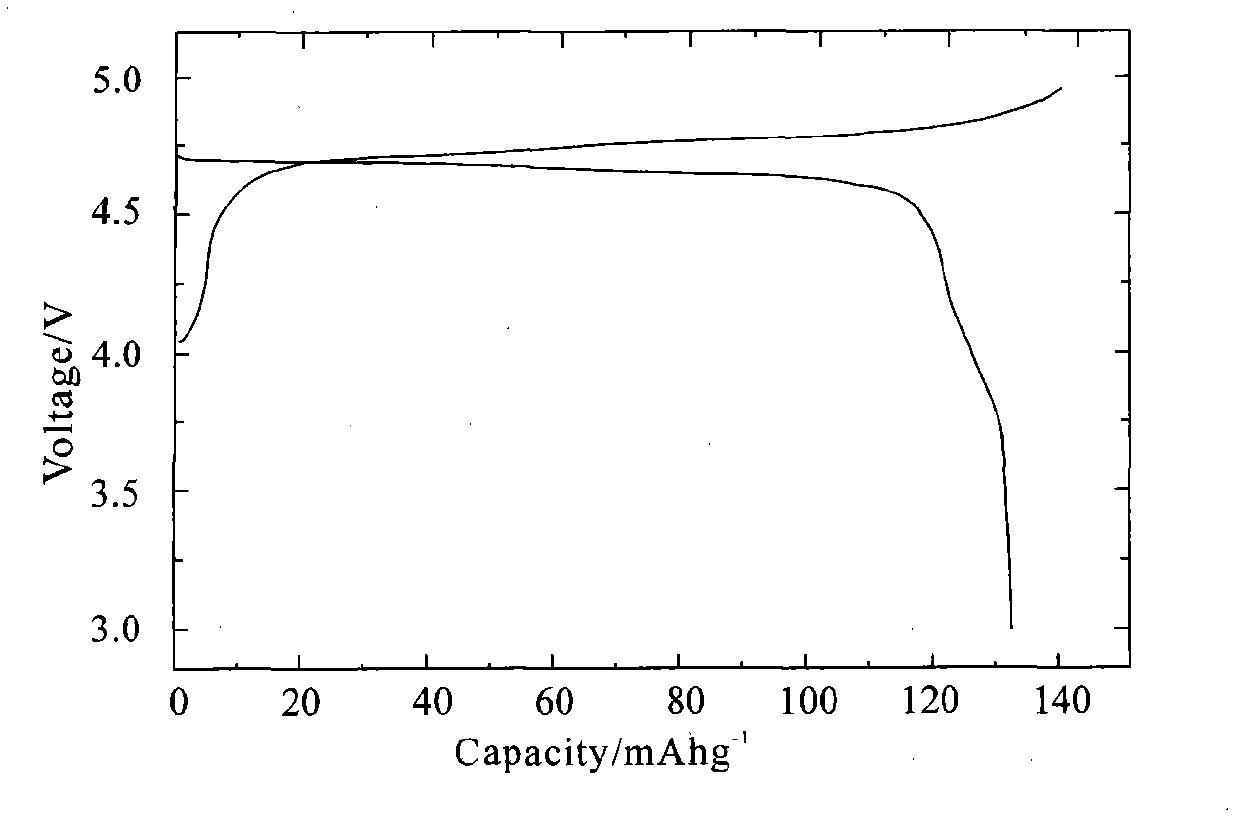

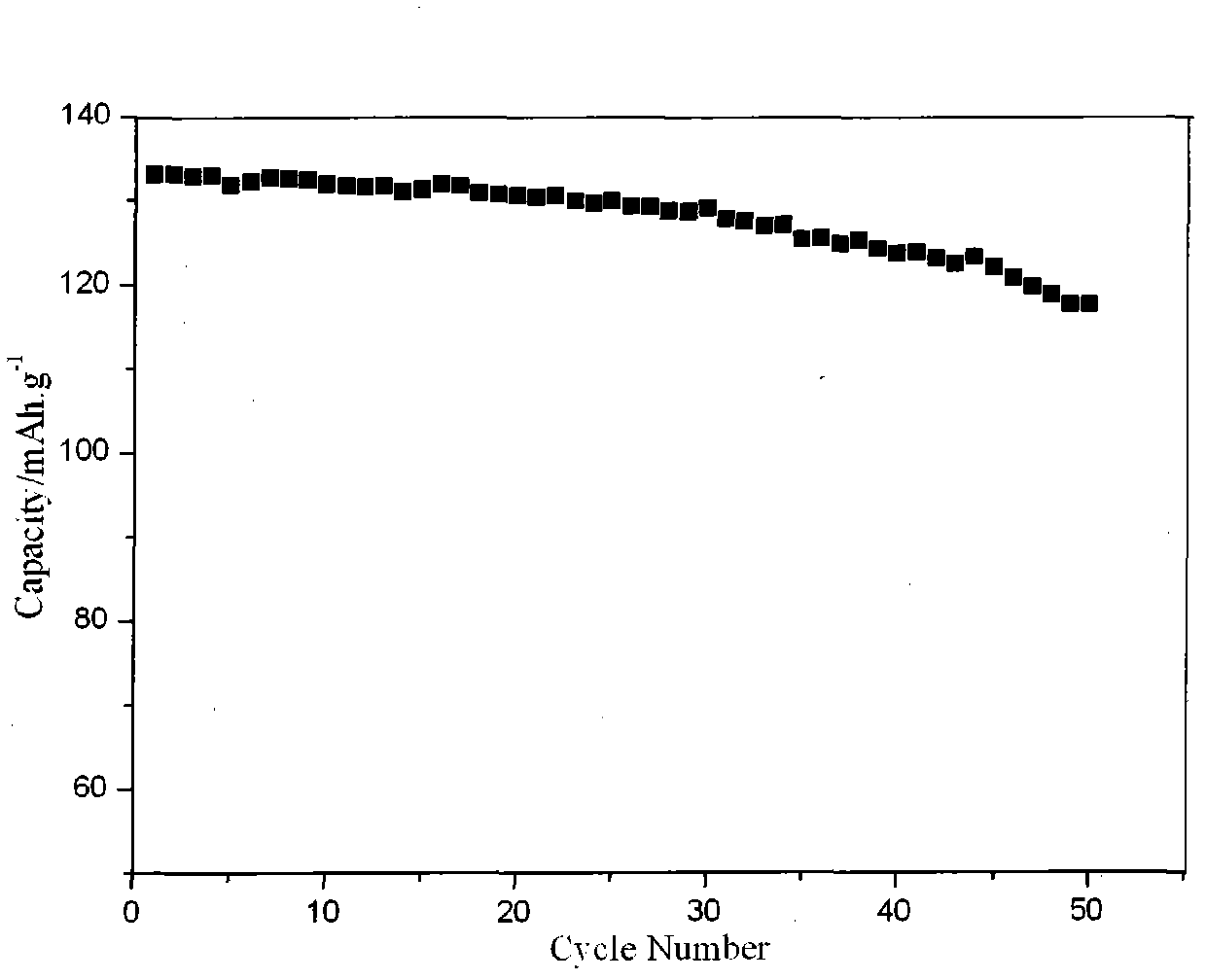

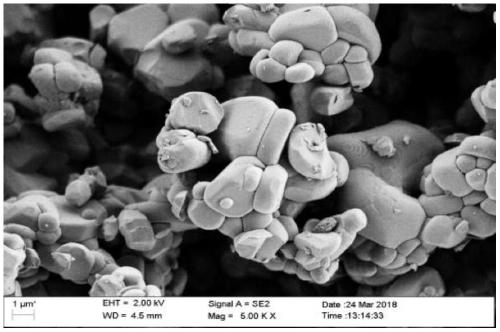

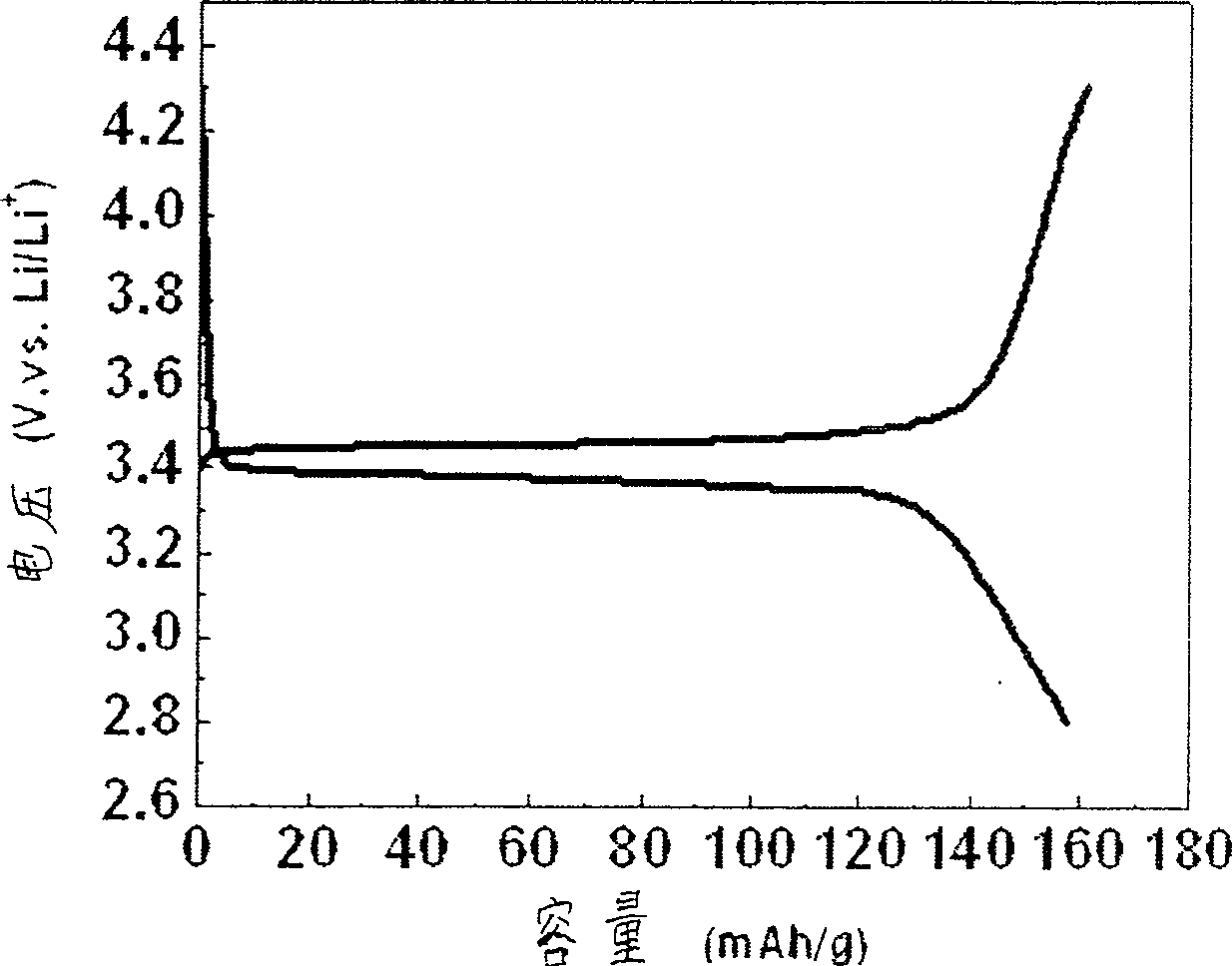

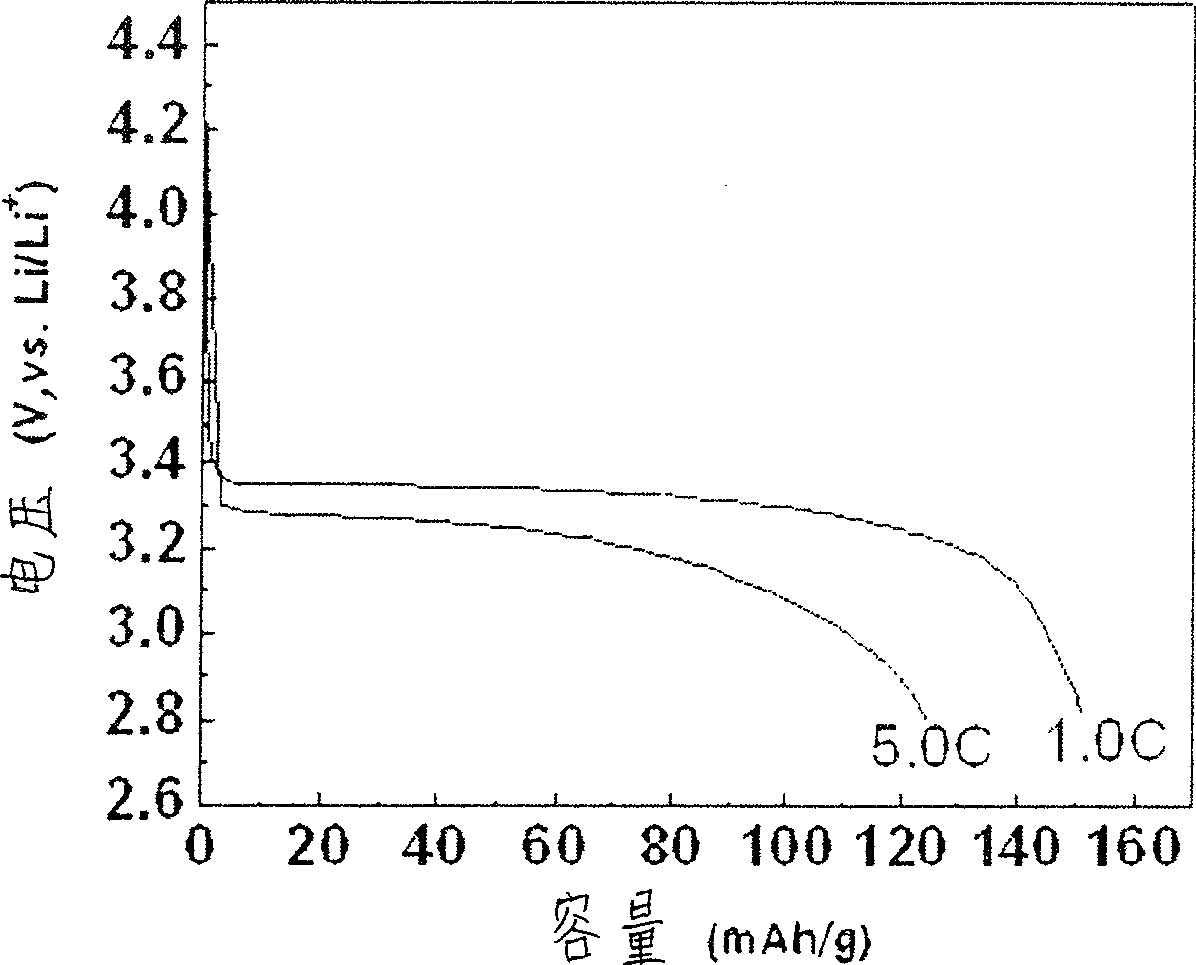

The invention provides lithium ion battery high-voltage anode material preparation and surface coating method. The method adopts high-voltage anode material spinel-type LiNi0.5Mn1.5O4 prepared by a two-step method and comprises the following steps of: firstly, evenly mixing nickel source and manganese source solutions with a surface active agent solution, then drying and roasting in the air of 350-450 DEG C to obtain a precursor of a nickel and manganese oxide; mixing the precursor with a lithium source through liquid phase ball milling, drying and finally roasting in the air of 400-900 DEG Cto obtain an anode active material; and adding the anode active material to a soluble aluminum solution containing a lithium source, sufficiently and evenly mixing under controlling the lithium source, the soluble aluminum source and the anode active material to be at the proper mol, drying and carrying out high-temperature roasting treatment to obtain a final product which is the lithium ion battery high-voltage anode material which is coated with a layer of lithium-contained transition metal oxide on the surface. The high-voltage anode material prepared by the method has the characteristicsof high initial capacity, good cycle performance and the like.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

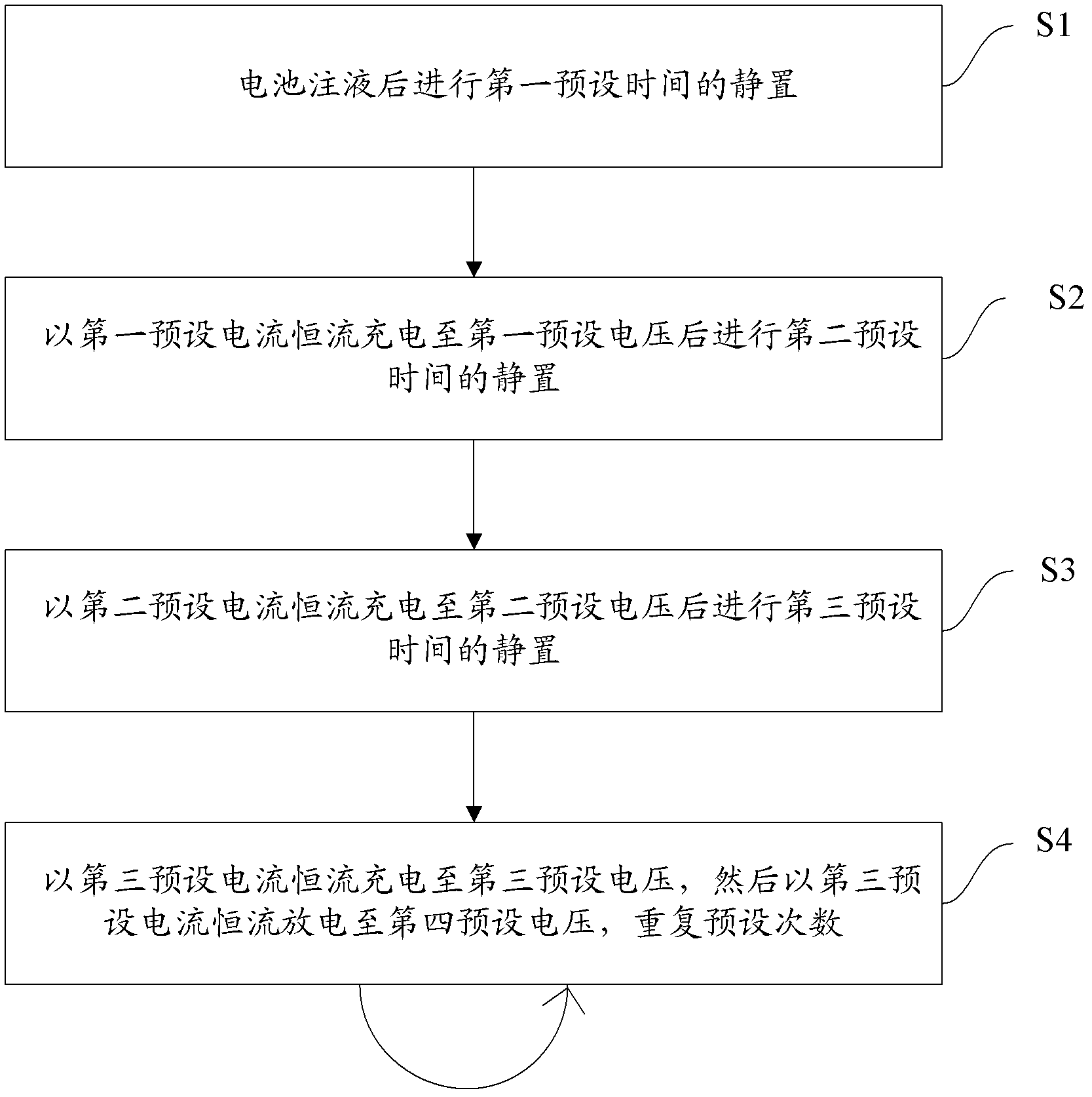

Method for forming lithium manganese power cells

ActiveCN103326069AImprove usable capacityImprove cycle performanceFinal product manufactureSecondary cells charging/dischargingLithiumElectric vehicle

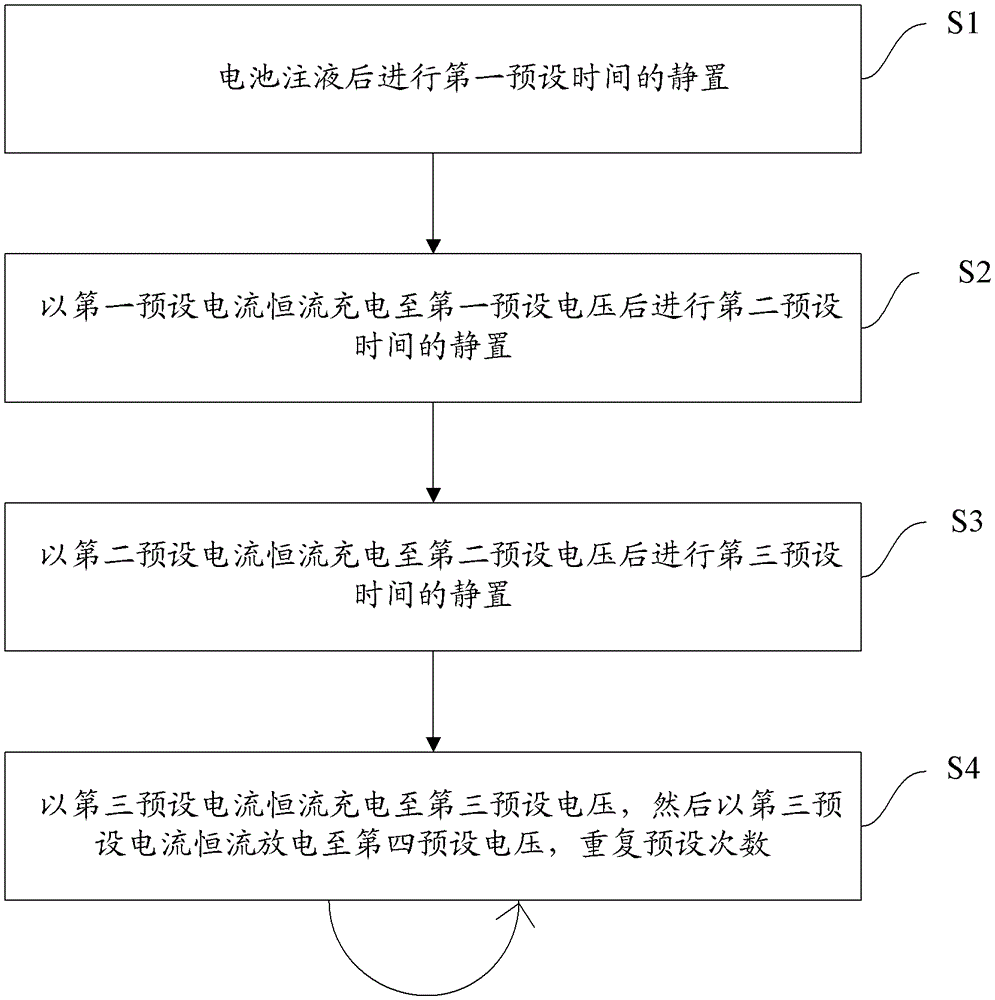

The invention discloses a method for forming lithium manganese power cells. The method comprises the following steps: injecting liquid to a power cell and allowing for standing for a first preset time thereafter; allowing for standing for a second preset time after constant-current charge to a first preset voltage with a first preset current; allowing for standing for a third preset time after constant-current charge to a second preset voltage with a second preset current; and performing constant-current charge to a third preset voltage with a third preset current, then performing constant-current discharge to a fourth preset voltage with a third preset current, and repeating the step for a preset number of times. The method provided by an embodiment of the invention can form a compact and stable SEI film and completely eliminate gases generated in formation. The method effectively improves the available capacity of cells, the cycling performance, the consistency and the safety. Besides, the method is easy and reliable, is particularly suitable for lithium manganese power cells for electric vehicles, and can be promoted for wide applications.

Owner:BEIQI FOTON MOTOR CO LTD

Reinforcing filler used for rubber latex product, preparation method thereof and application thereof

ActiveCN101696282APrevent each other from approachingClose to each other to preventPigment treatment with macromolecular organic compoundsPigment physical treatmentParaffin waxCellulose

The invention relates to reinforcing filler used for a rubber latex product, a preparation method thereof and application thereof. The reinforcing filler consists of the following components in part by weight: 50 to 80 parts of base material, 0.01 to 0.4 part of dispersant, 0.001 to 0.5 part of surface treating agent, 0.01 to 1 part of emulsion and 20 to 50 parts of water, wherein the base material is any one of heavy calcium carbonate powder, kaolin powder and argil powder; the dispersant is any one of casein, methylene dinaphthalene sodium sulfonate, sodium polyacrylate, potassium hydroxide and ammonia water; the surface treating agent is any one of bentonite, cellulose, swelling soil and attapulgite; and the emulsion is any one of mineral oil, vaseline, liquid paraffin and polyoxychloroethylene wax. The reinforcing filler has economic formulation and good reinforcing effect. The preparation method is a conventional stirring and grinding method. The process is simple, and little equipment is used. The application comprises the following steps: adding the reinforcing filler into rubber latex, blending the mixture evenly, forming a layer of film on a die by adopting a soaking and casting method, and then drying the film for 15 to 30 minutes at a temperature of between 110 and 130 DEG C to obtain the reinforced filled rubber latex product. The reinforcing filler is favorable for improving the tensile strength of the rubber latex product and reducing the usage amount of the latex.

Owner:BENGBU RUIJIE TECH

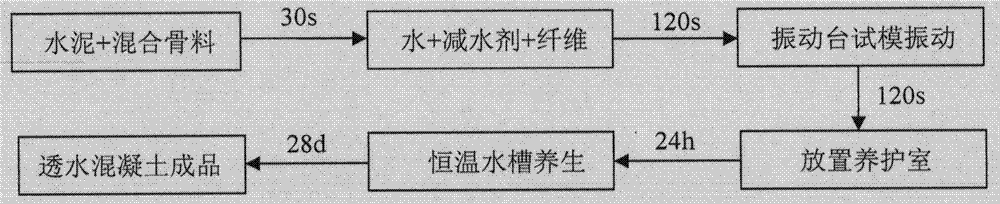

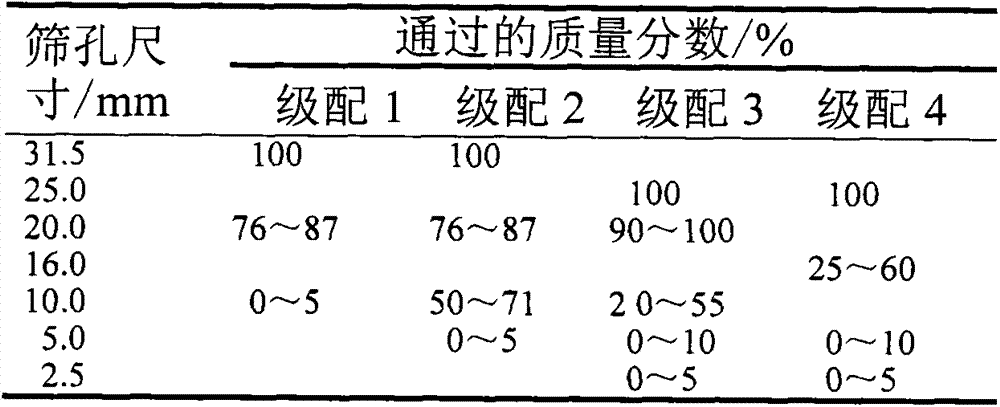

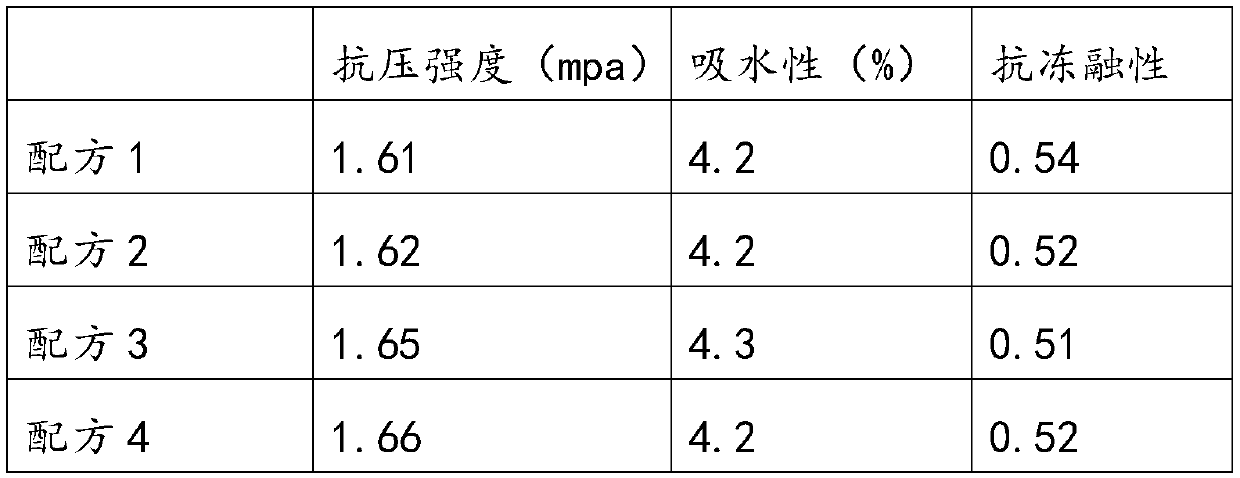

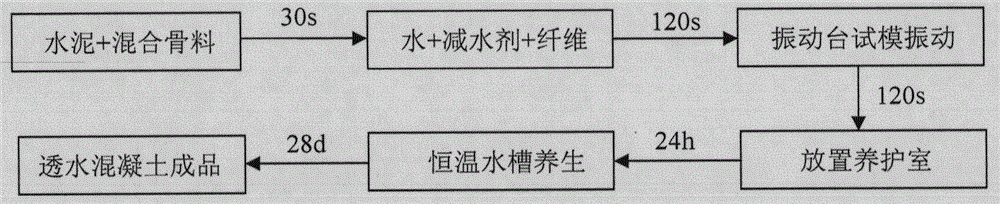

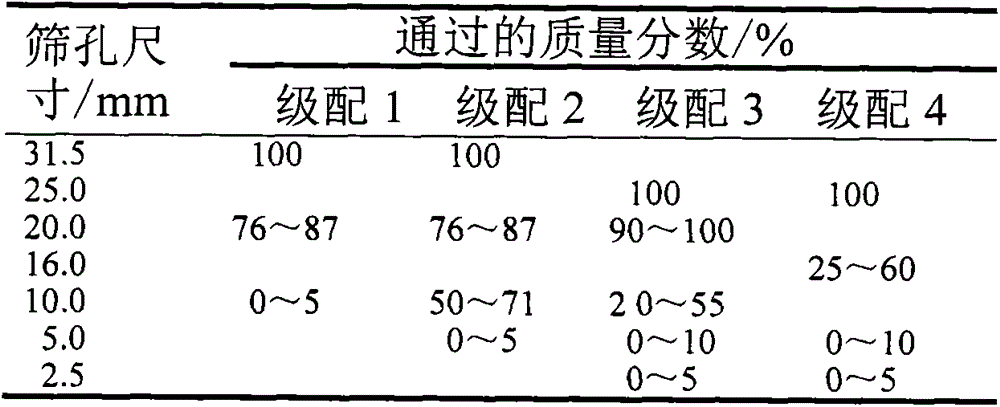

Preparation method for water permeable concrete

The invention discloses a method for preparing water permeable concrete by using high-quality recycled coarse aggregates. The concrete is composed of cement, mixed coarse aggregates, PVA, water and a high performance water-reducing agent. By doping PVA, the high-quality recycled coarse aggregates enhance binding force between a cementing material and the aggregates and compaction strength indexes of the cement while guaranteeing water permeability. The preparation method for the water permeable concrete has practical significance for recycling waste concrete and improving performances of environment-friendly water permeable and breathable concrete.

Owner:INNER MONGOLIA UNIVERSITY

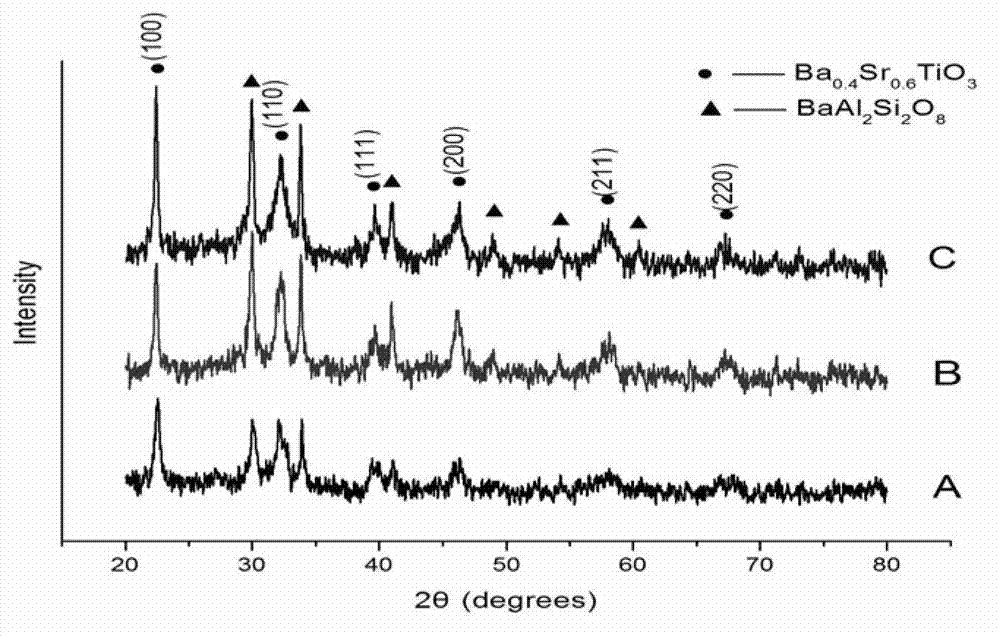

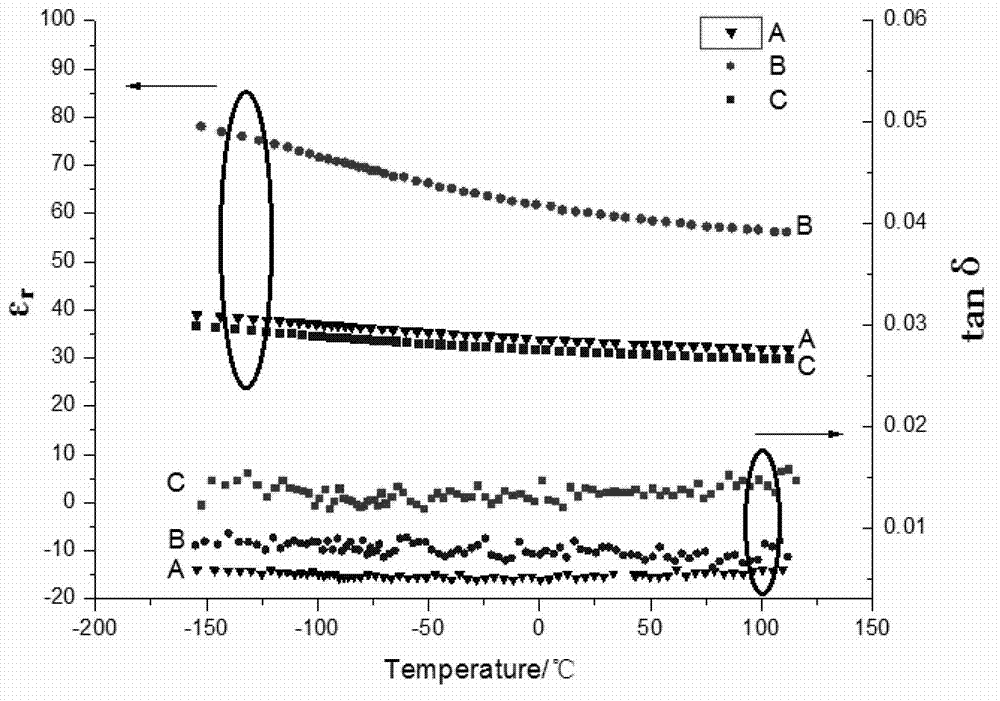

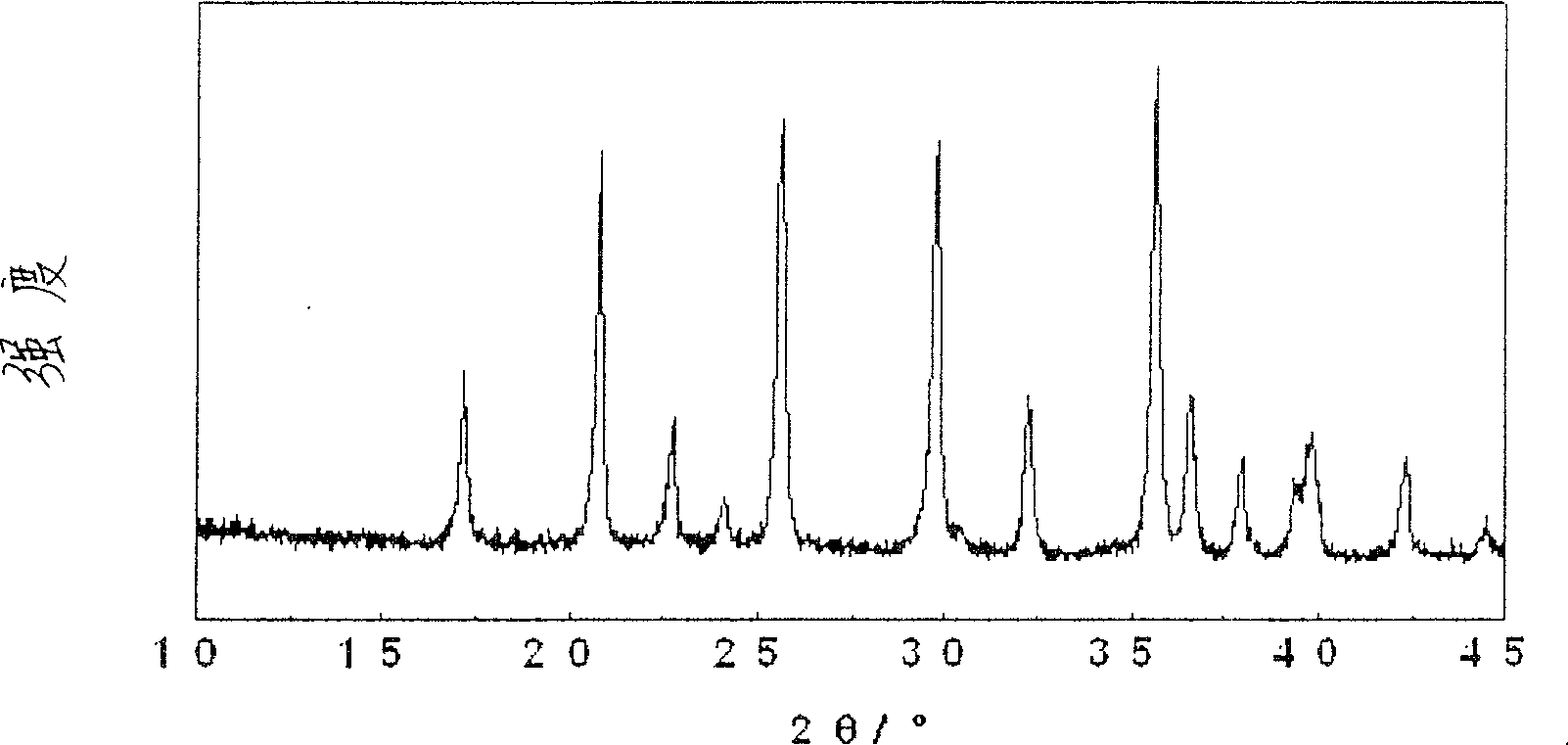

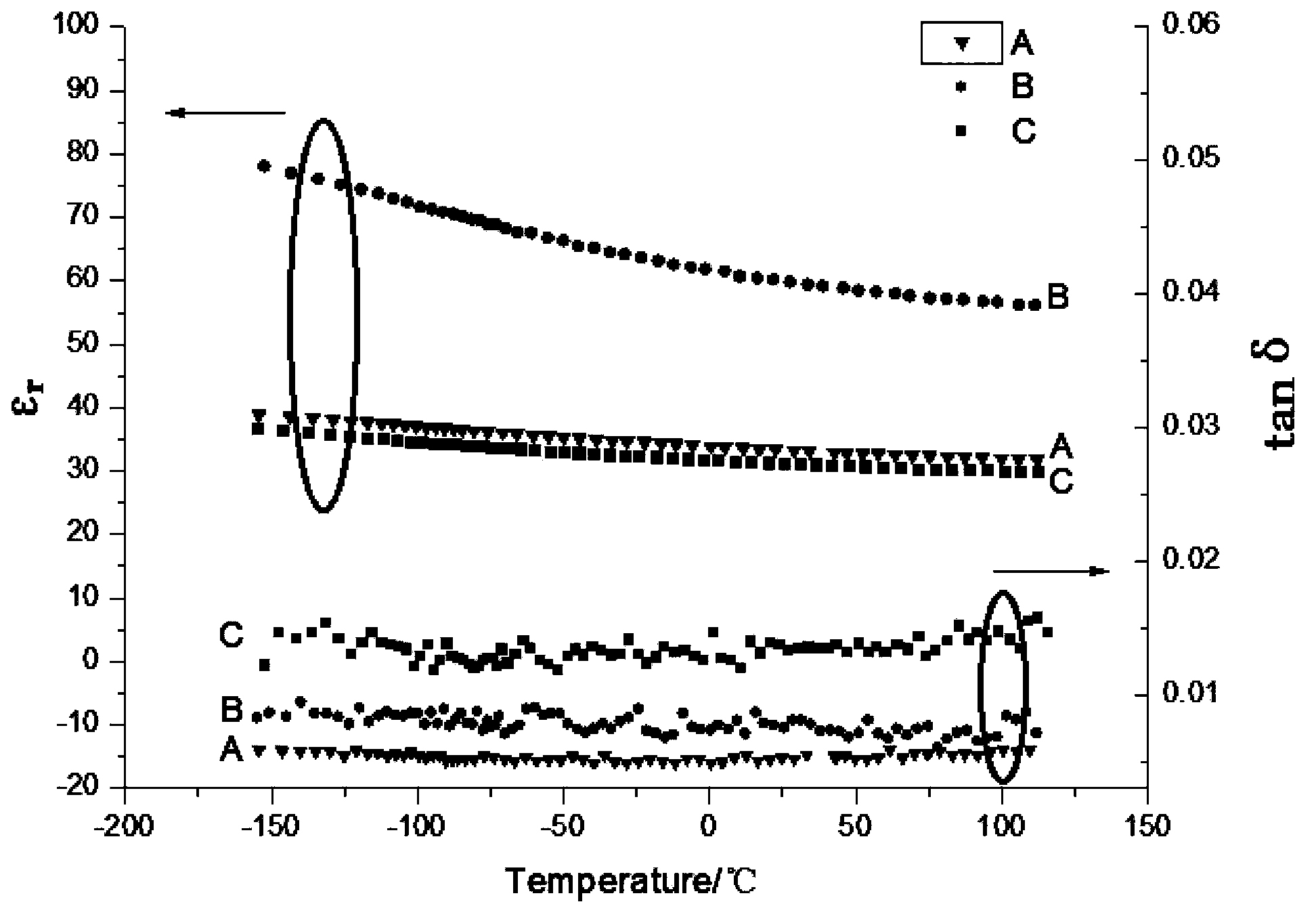

Preparation method of barium strontium titanate based glass ceramic energy storage material

InactiveCN102775069AImprove energy storage performanceHigh compressive strengthFixed capacitor dielectricGlass productionDielectricBarium strontium titanate

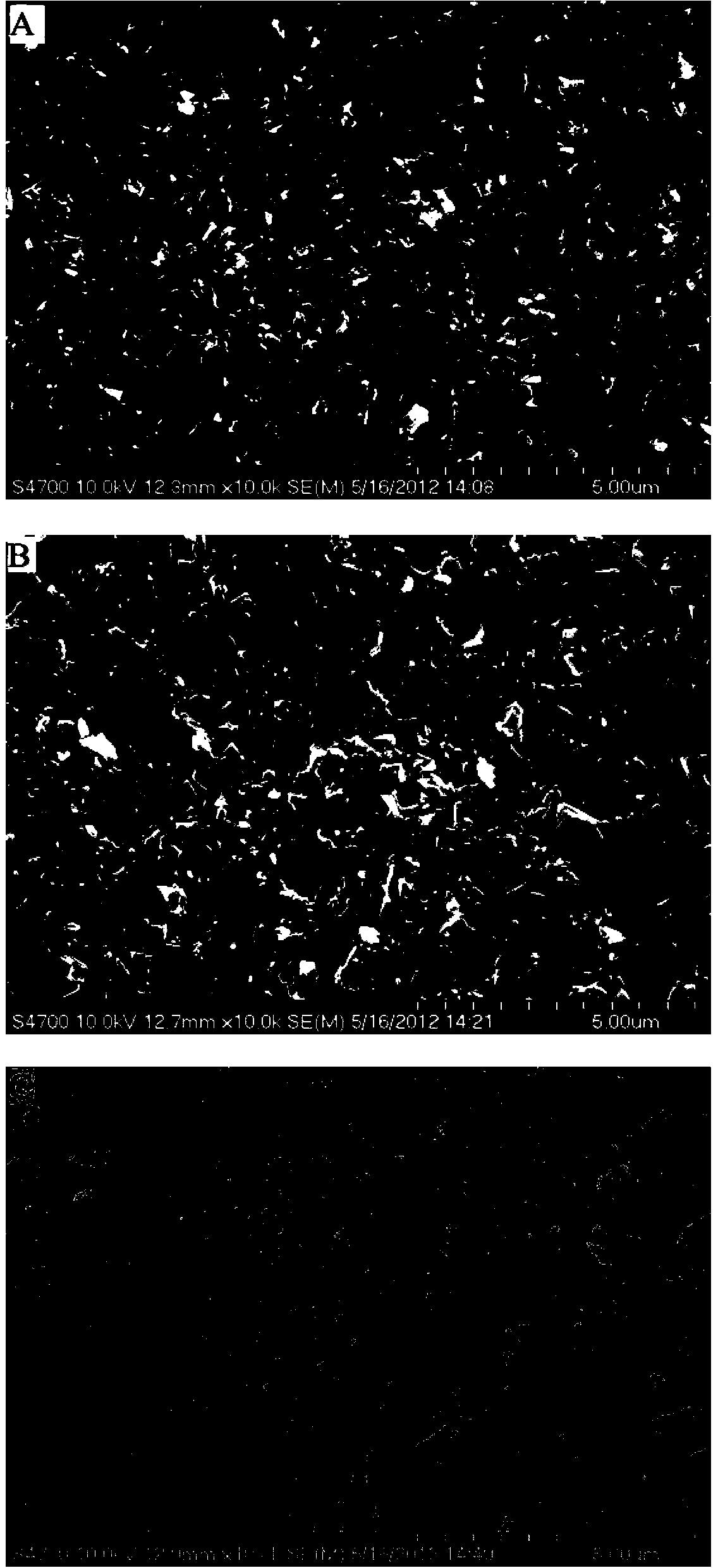

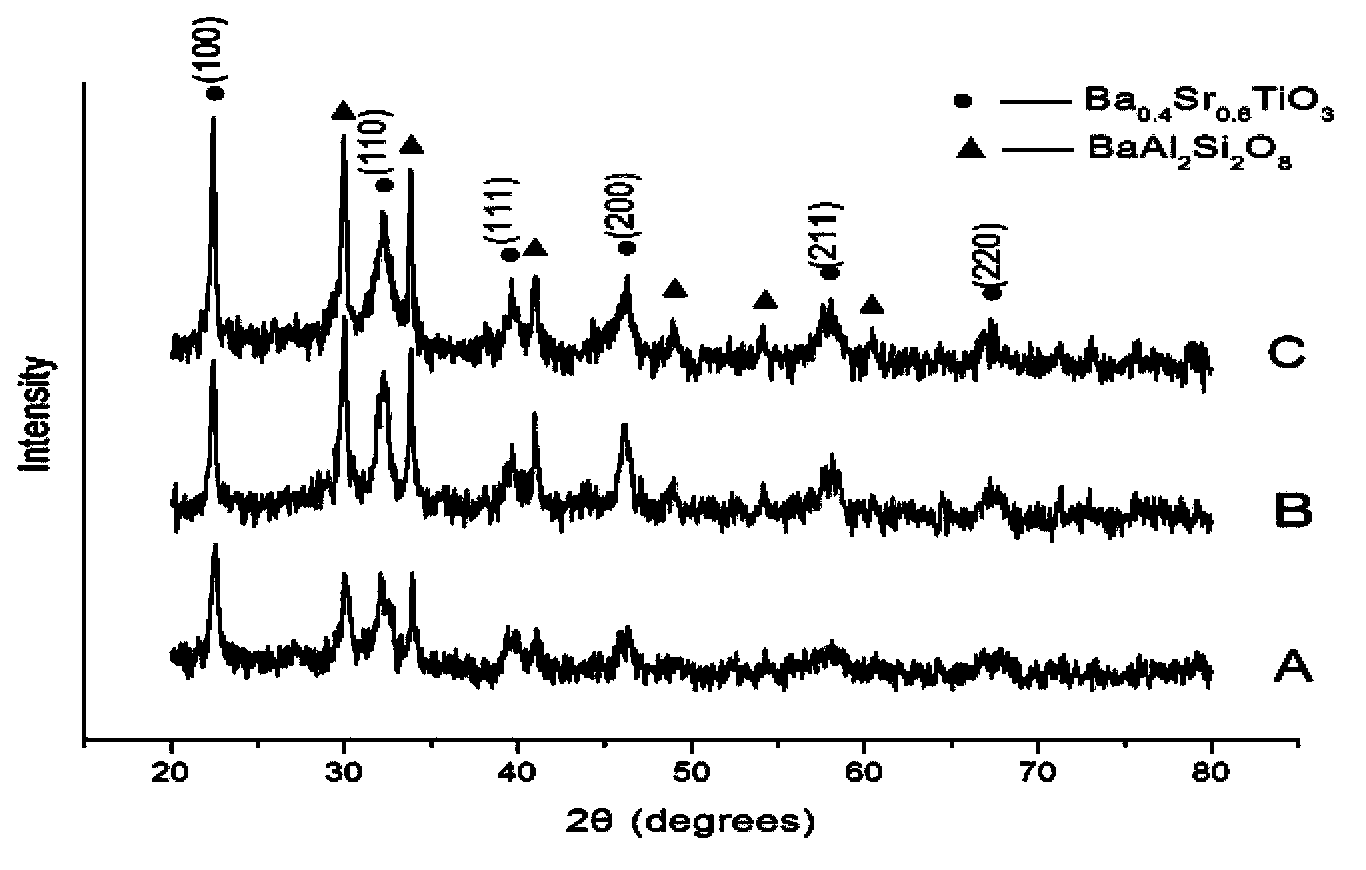

The invention belongs to the field of dielectric energy storage material, and specifically relates to a preparation method of barium strontium titanate based glass ceramic material with high energy storage density. The invention provides the preparation method of barium strontium titanate based glass ceramic energy storage material, which comprises the following steps: burdening according to (BaxSr1-x) TiO3-aAl2O3-bSiO2, wherein x=0.4-0.6, (a+b) / (2+a+b)=0.3-0.35 and a / b=0.5-1.0, drying after ball-milling and mixing materials, and melting at high temperature; casting high-temperature melt into a metal mold, performing stress relief annealing, and then cutting to obtain glass thin sheet with thickness of 0.5-1.0mm; performing controlled devitrification to the glass thin sheet to obtain glass ceramic; performing microwave heat treatment to the glass ceramic in a microwave oven to obtain the glass ceramic dielectric with high energy storage density. The method provided by the invention is simple and the energy storage property of the prepared glass ceramic material is improved greatly.

Owner:TONGJI UNIV

High-durability damping concrete and preparation method thereof

The invention discloses a high-durability damping concrete and a preparation method thereof, and relates to several concretes and a preparation method thereof. The invention solves the problems of low damping capability and poor durability of the conventional concrete structure material per se. The high-durability damping concrete is prepared by stirring and mixing cements, rubber powder, water, medium sand, stones, and adding fibers and silicon powder. In the invention, c the loss factors of the high-durability damping concrete are improved by about 80-200 percent compared with that of pain concrete under the condition of different frequencies. After maintenance for 28 days, the concrete prepared by using the method has chloridion-resistant permeability and carbonizing-resistant capability both superior to that of blank concretes.

Owner:刘铁军

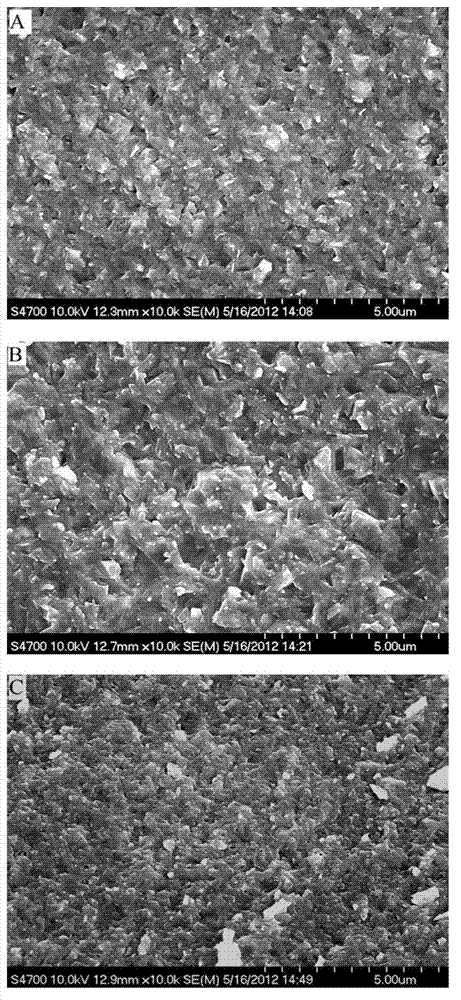

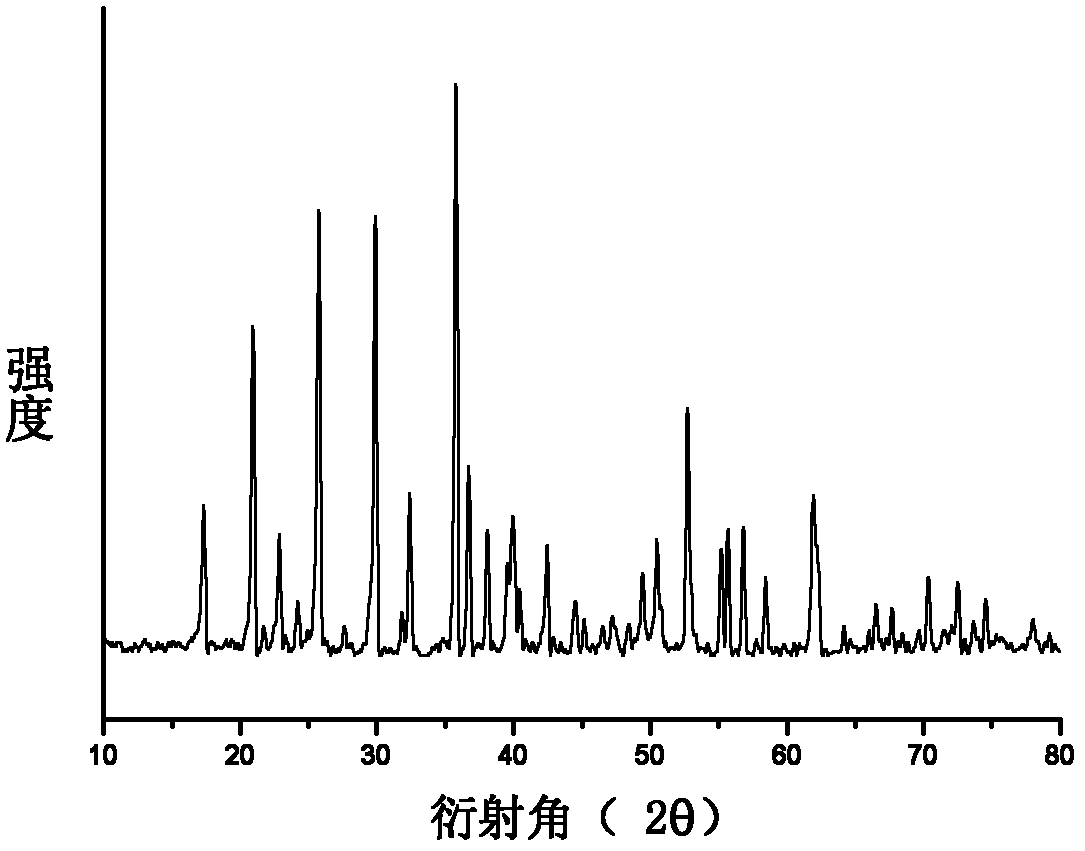

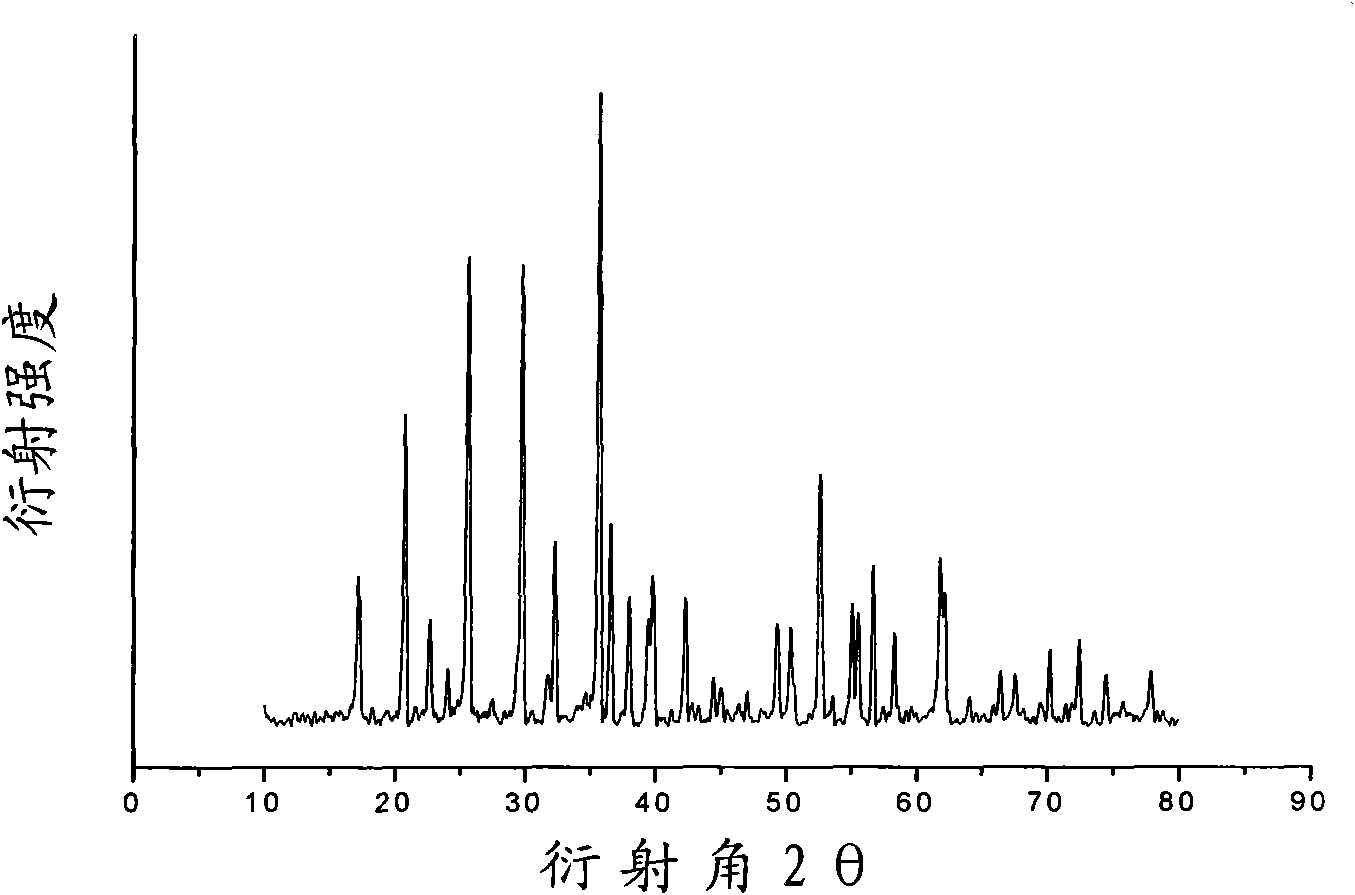

Composite doping modification lithium-ion battery anode material and its manufacture method

InactiveCN1964105AImprove UIEnhanced ionic conductivity and electronic conductivityElectrode manufacturing processesChemical/physical/physico-chemical processesIonRare-earth element

The disclosed preparation method for anode material of composite doped modified Li-ion cell comprises: mixing the Li-source compound, P-source compound, Fe-source compound, crystal phase doped M (rare earth element) compound and non-crystal phase doped element C to heat for 5-20h at 250-400Deg; cooling, and grinding to obtain the reaction predecessor contained PO43-, Li+, Mn+, Fe2+ and carbon black; calcining for 10-40h at 500-800Deg to cool and obtain the final product. This invention improves material electrochemical property and fit to industrial production.

Owner:SOUTH CHINA UNIV OF TECH

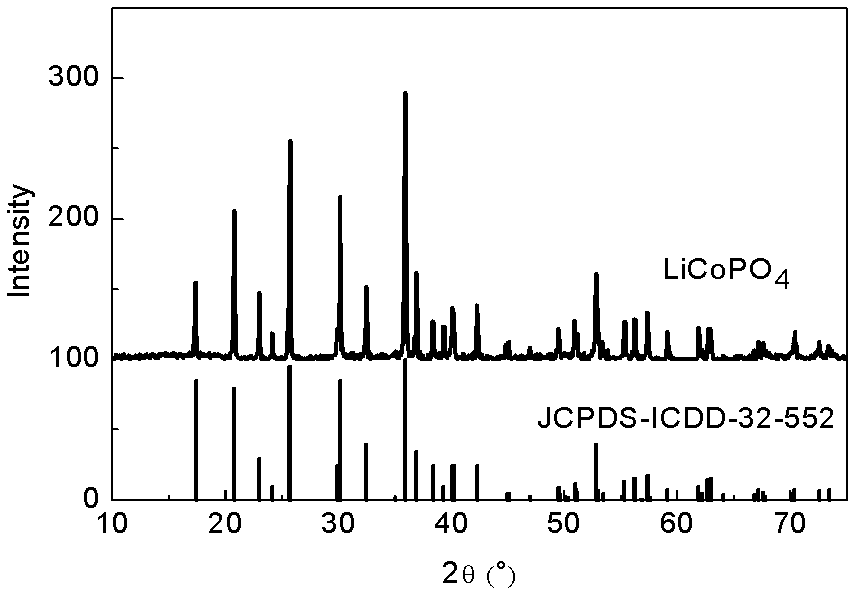

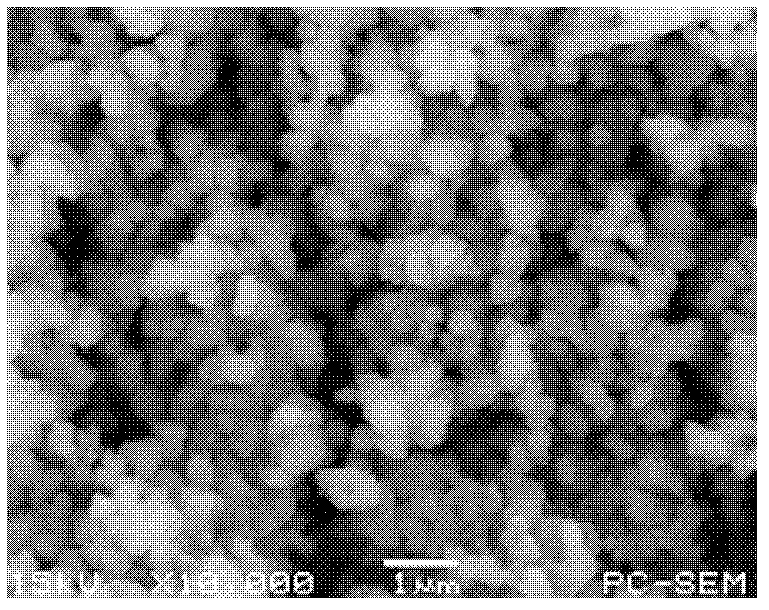

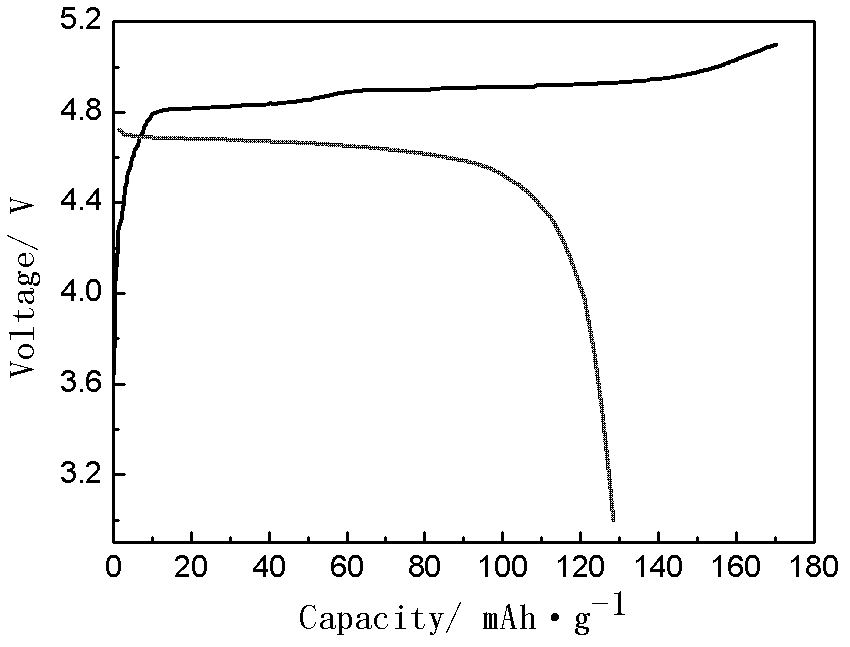

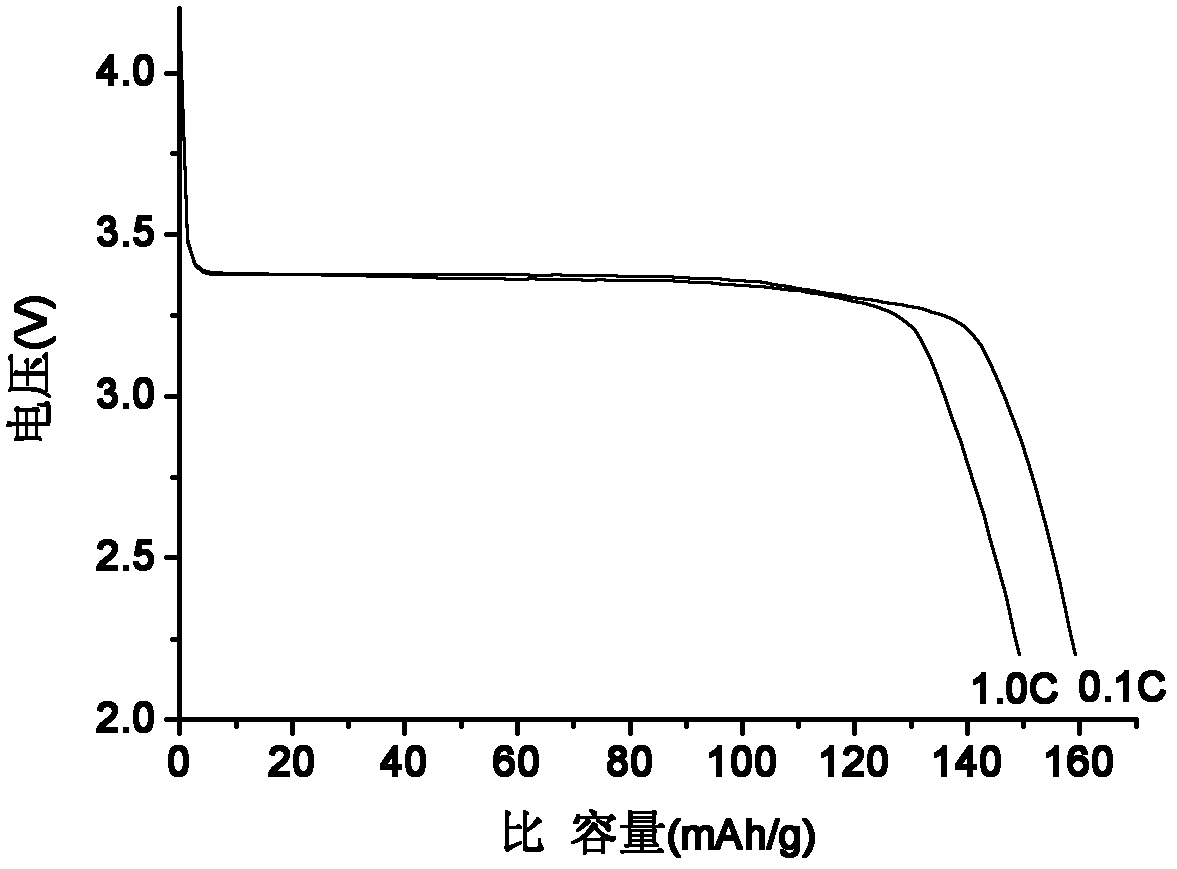

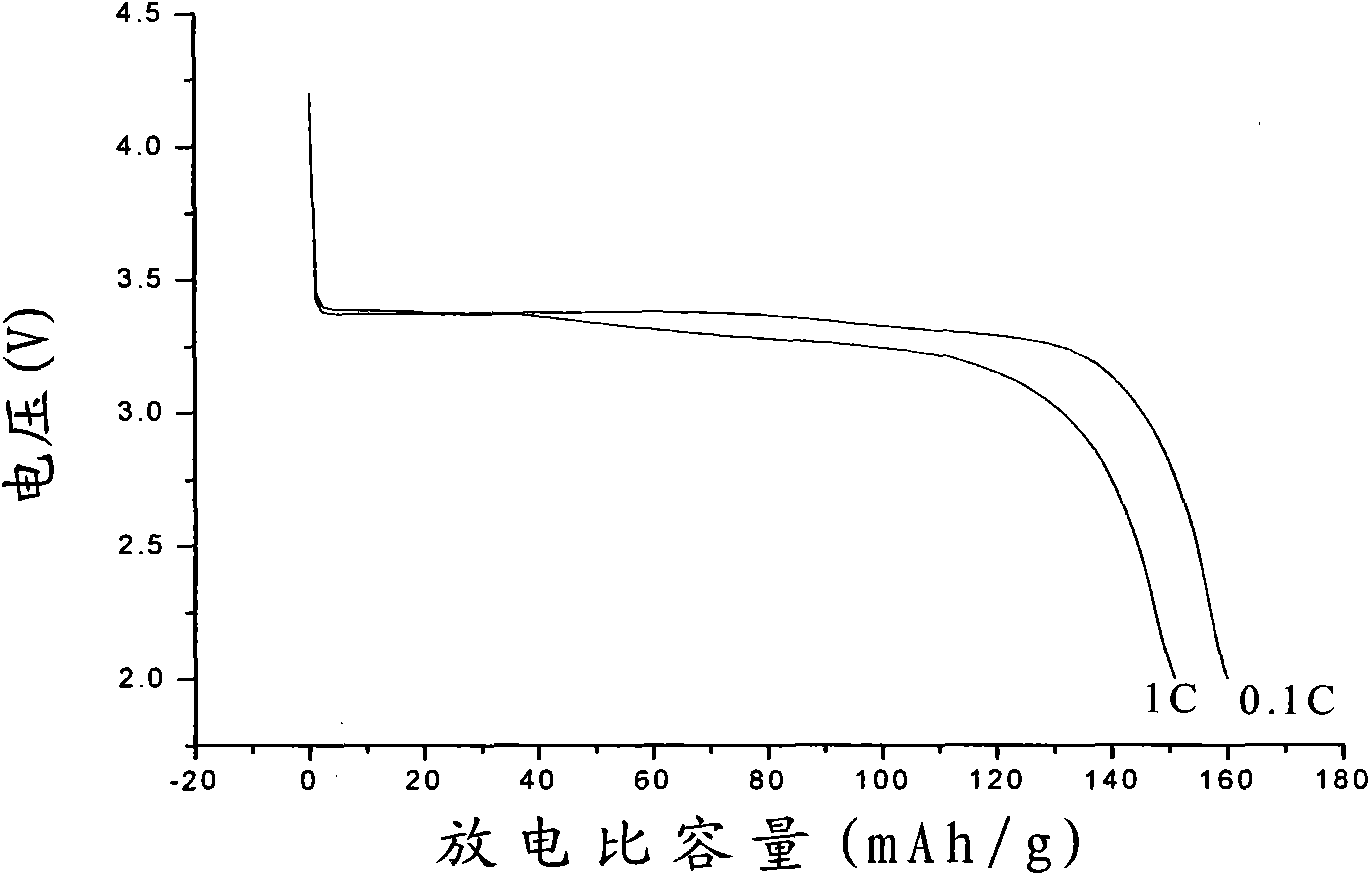

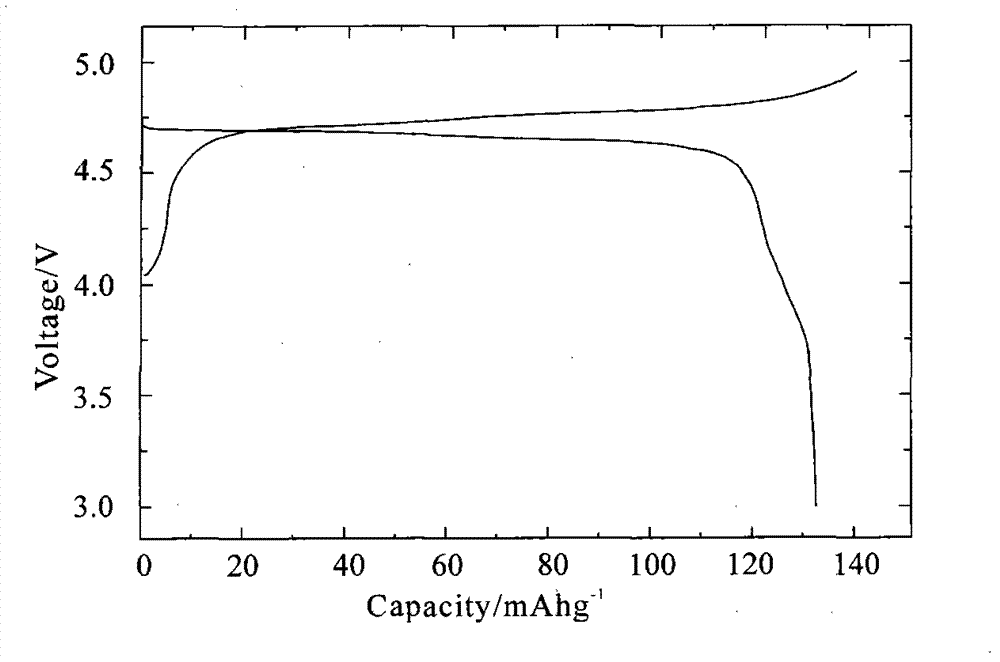

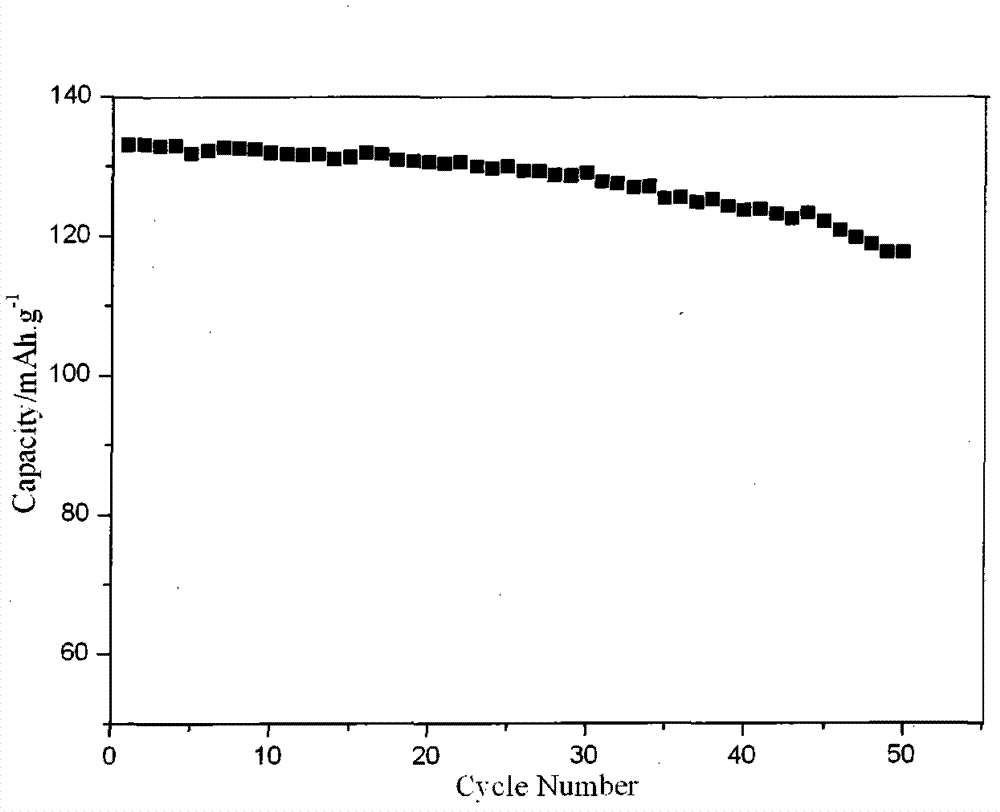

Lithium ion battery anode material LiCoPO4/Al2O3 and preparation method thereof

The invention relates to the technical field of battery materials, in particular to a lithium ion battery anode material LiCoPO4 / Al2O3 and a preparation method thereof. The material consists of an olivine LiCoPO4 material and aluminum salt, and the preparation method comprises the following step of adopting a surface coating technology to coat a layer of metal oxide film on surface of lithium ion battery anode active substance so as to prepare the lithium ion battery anode compound material with high voltage and high cyclical stability. As the special method is adopted in the invention to prepare the LiCoPO4 material, the reduction for particle size and uniformity of a product can be favored; interface situation of electrolyte and the anode active substance can be improved, adverse reaction between the electrolyte and the anode active substance can be inhibited, so that the purpose of improving cyclical stability of the active substance can be achieved; according to the material and the method provided by the invention, the technique is simple the industrialization is easy to realize, and moreover, the electrochemical property of the high voltage lithium ion battery is improved through the modification of the anode material, thus, the material has a wide application prospect in the field of power type lithium ion battery.

Owner:MCNAIR TECH +2

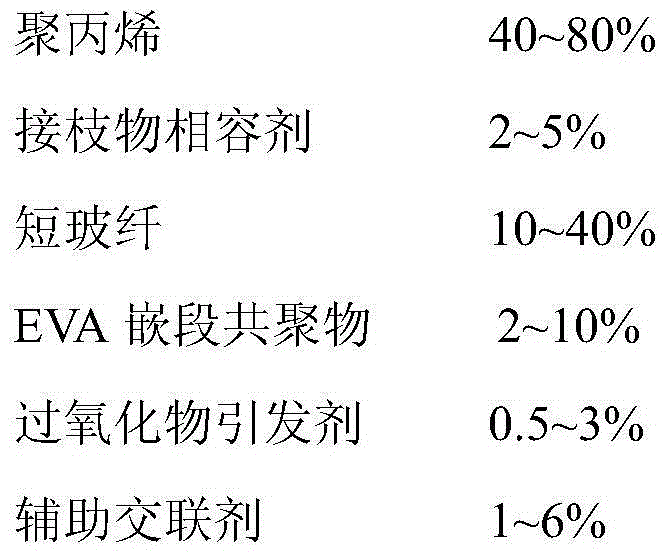

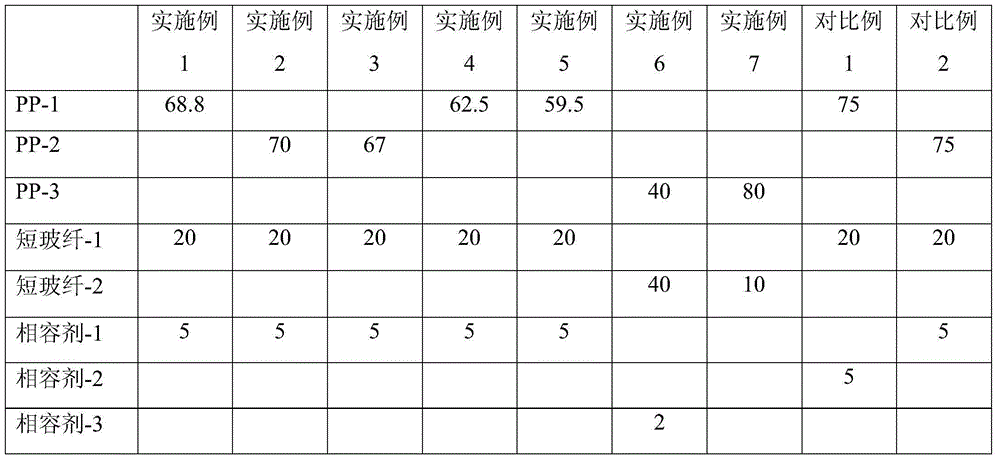

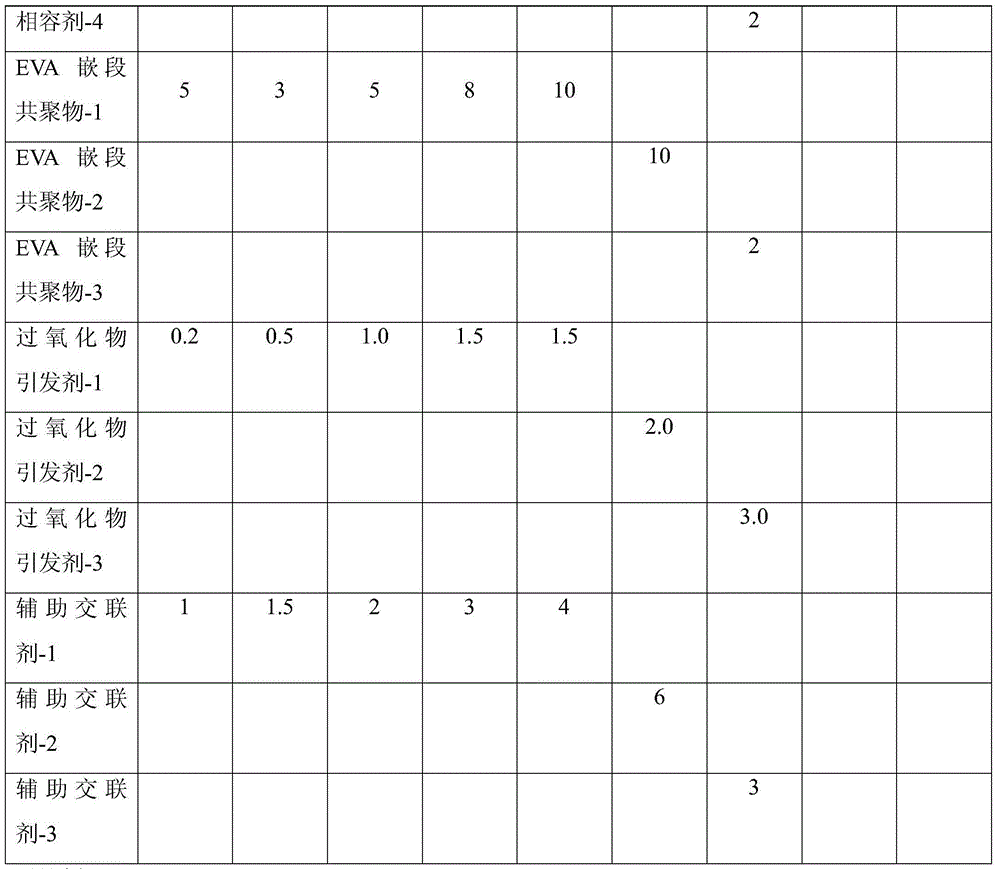

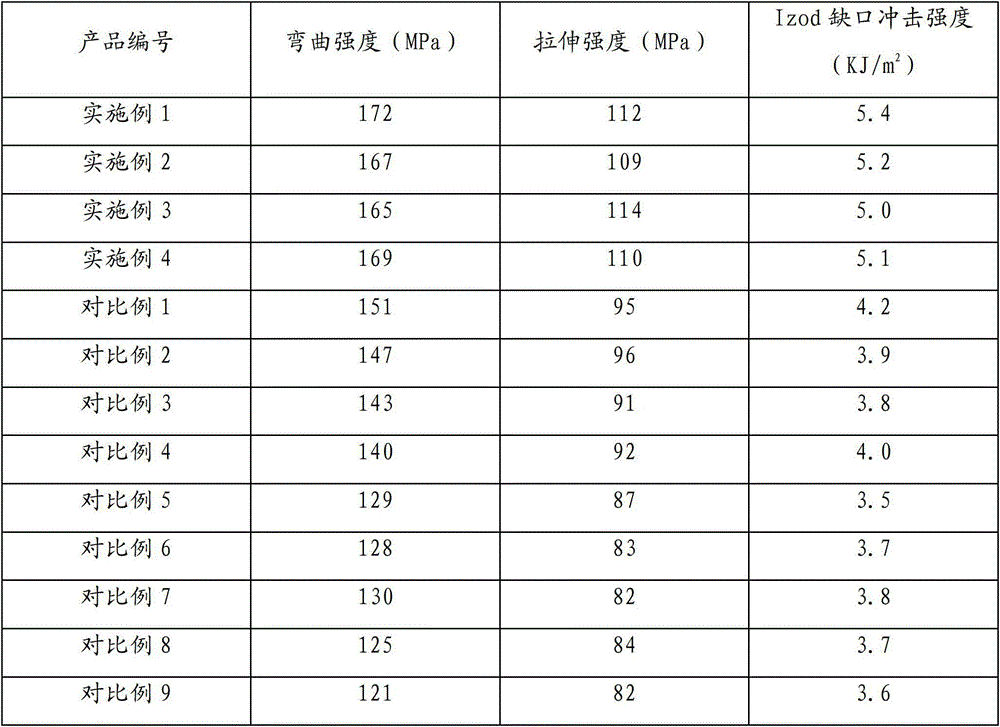

EVA (ethylene-vinyl acetate)-post-crosslinking-modified high-performance glass-fiber reinforced polypropylene composite material and preparation method thereof

The invention relates to an EVA (ethylene-vinyl acetate)-post-crosslinking-modified high-performance glass-fiber reinforced polypropylene composite material and a preparation method thereof. The composite material is prepared from the following raw materials in percentage by weight: 40-80% of polypropylene, 10-40% of chopped glass fiber, 2-5% of graft compatilizer, 2-10% of EVA block copolymer, 0.5-3% of peroxide crosslinking agent and 1-6% of auxiliary crosslinking agent. The tensile strength and impact strength of the composite material have the most obvious improvement amplitude, and are enhanced by 30-50% as compared with the conventional formula material; and the tensile modulus and bending modulus are correspondingly enhanced to 6000 MPa above. In the 150-DEG C 100-hour long-term hot-oxidative-aging test, the tensile strength, impact strength and other indexes of the composite material can be further enhanced in the early test stage, and the property retention rate is 85% above in the final test stage (>=2000 hours); and thus, the composite material has excellent long-term hot oxidative aging resistance.

Owner:SHANGHAI JUNER NEW MATERIALS

Method for preparing lithium ion battery positive electrode composite material

InactiveCN1945876AImprove UIHigh capacity retentionElectrode manufacturing processesFiltrationFree cooling

This invention discloses a preparation method for the positive complex material of Li ionic cells, which applies a surface covering technology to cover an Al2O film of amorphous structure on a positive active substance surface of the Li ionic cells, confects the Al salt and a solvent to a soluble Al salt solution then mixes it with the positive active substance in proportion and mix them uniformly then to get a positive complex material of Li ionic cell with an amorphous structure Al2O film covered on the surface after filtration, sinter and cool naturally, which improves the interface state of the electrolyte and positive active substance and suppresses the badness reaction between the two.

Owner:TSINGHUA UNIV

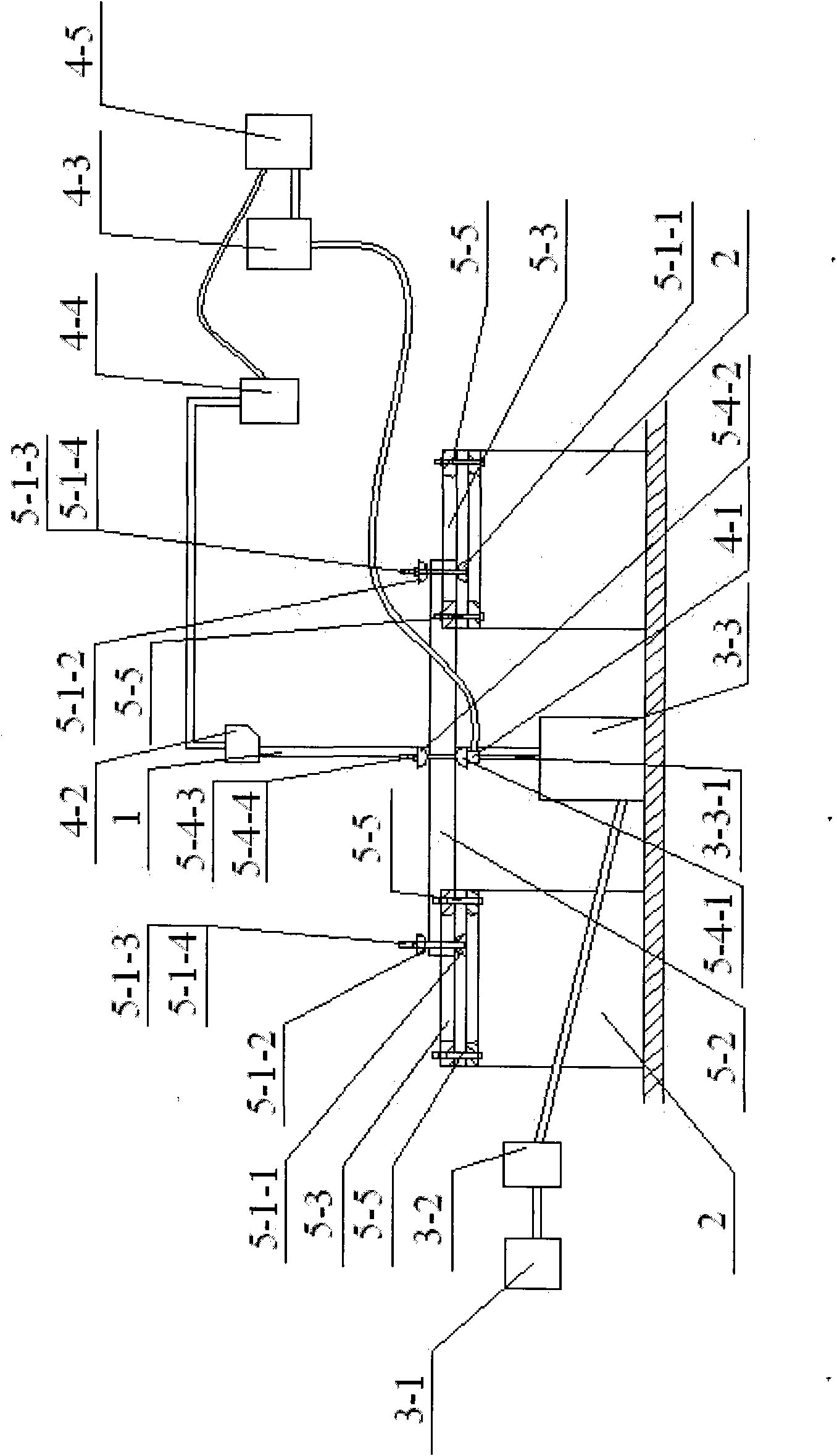

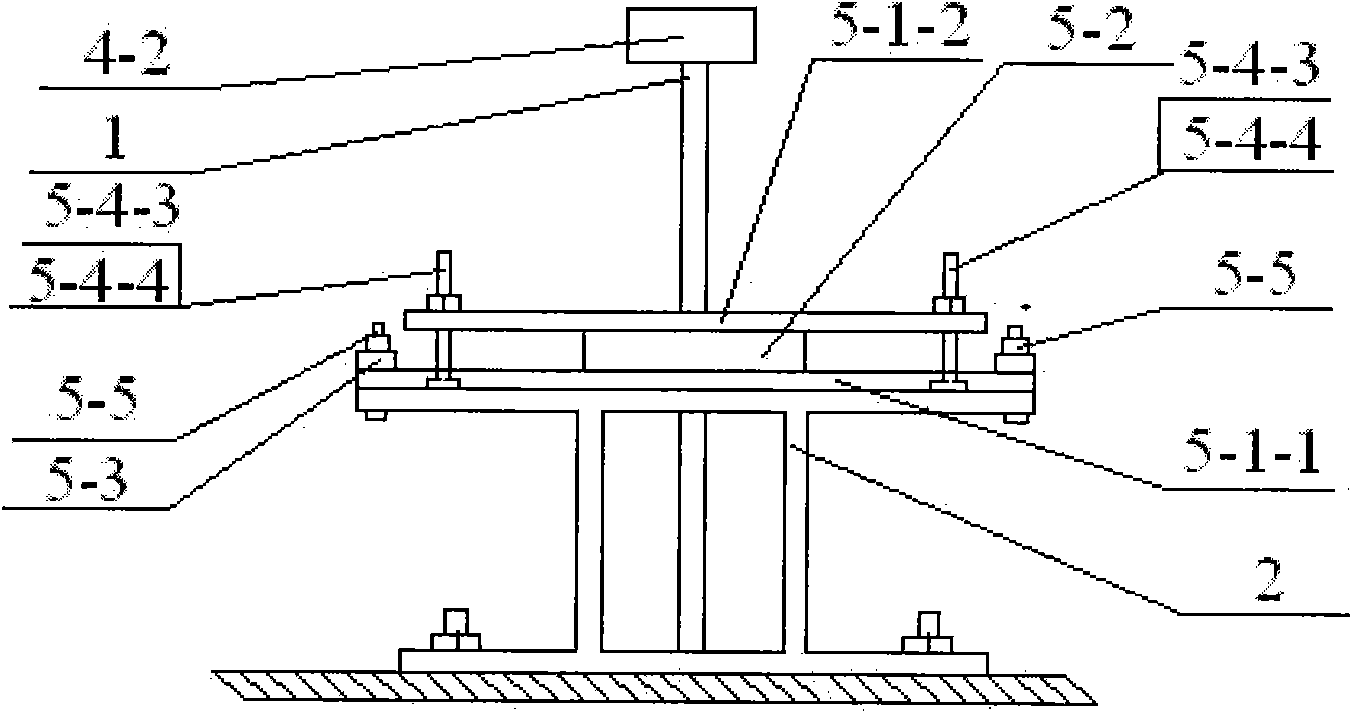

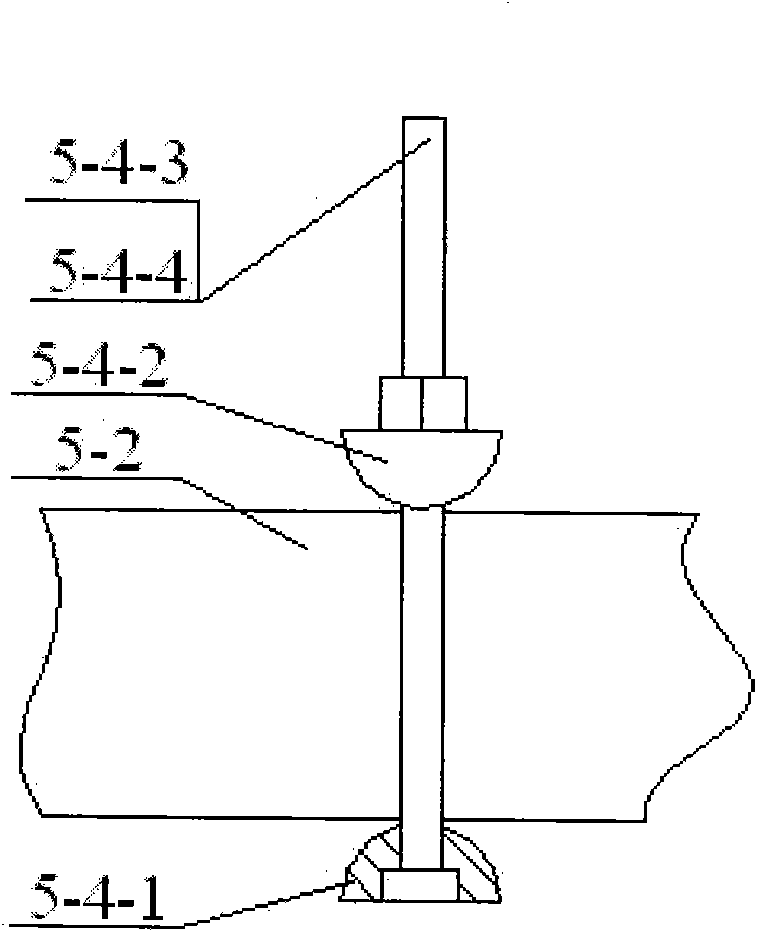

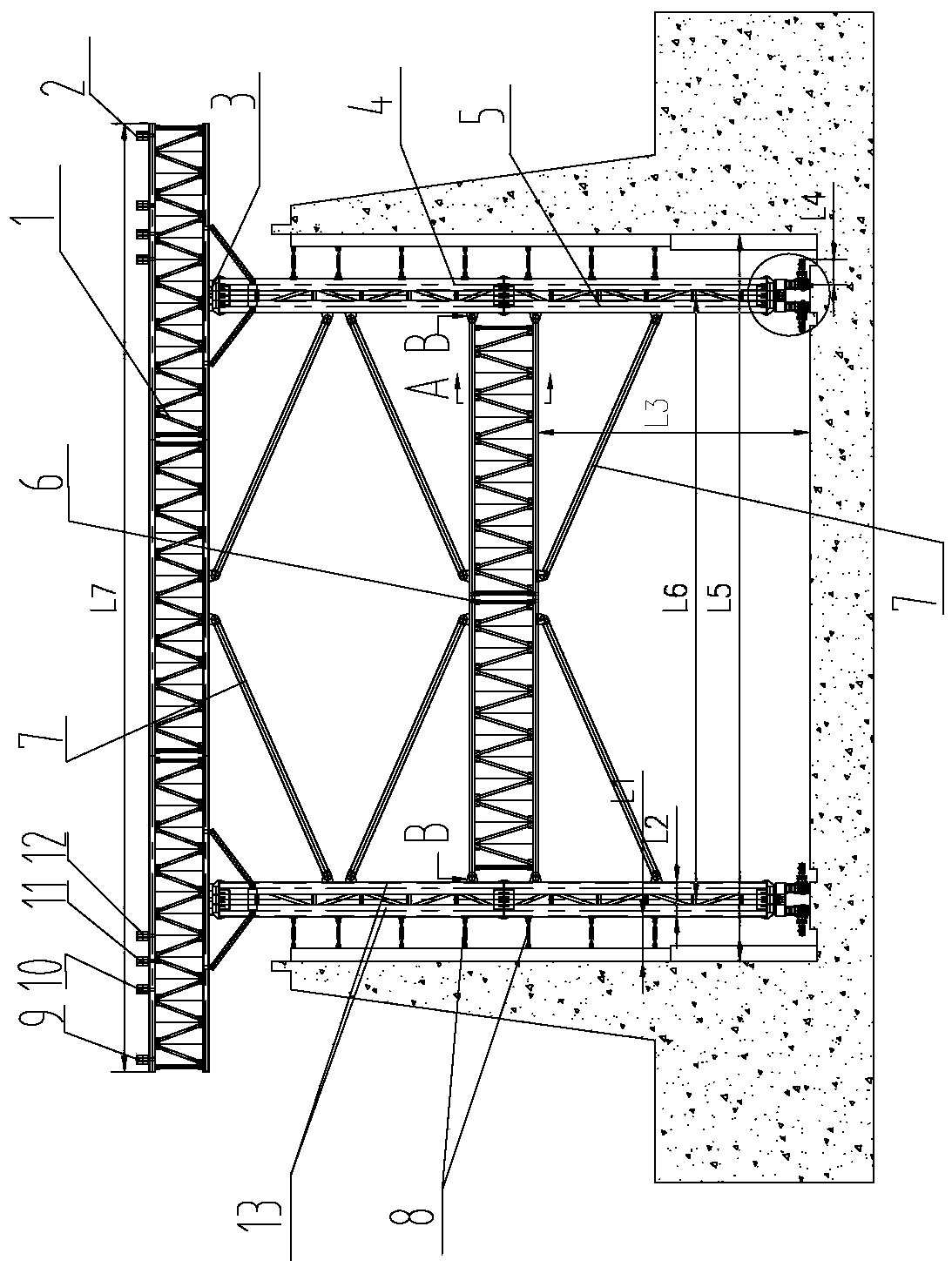

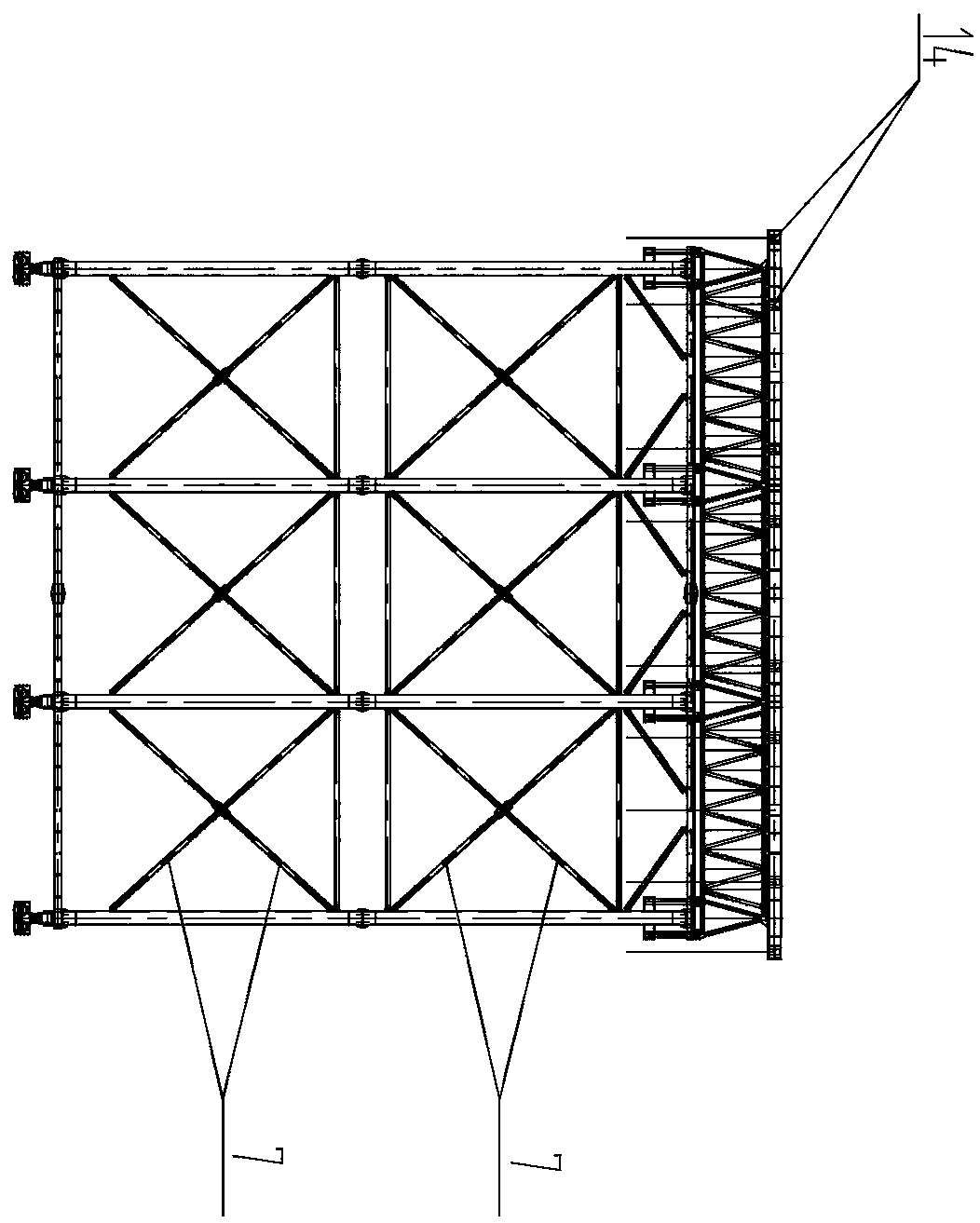

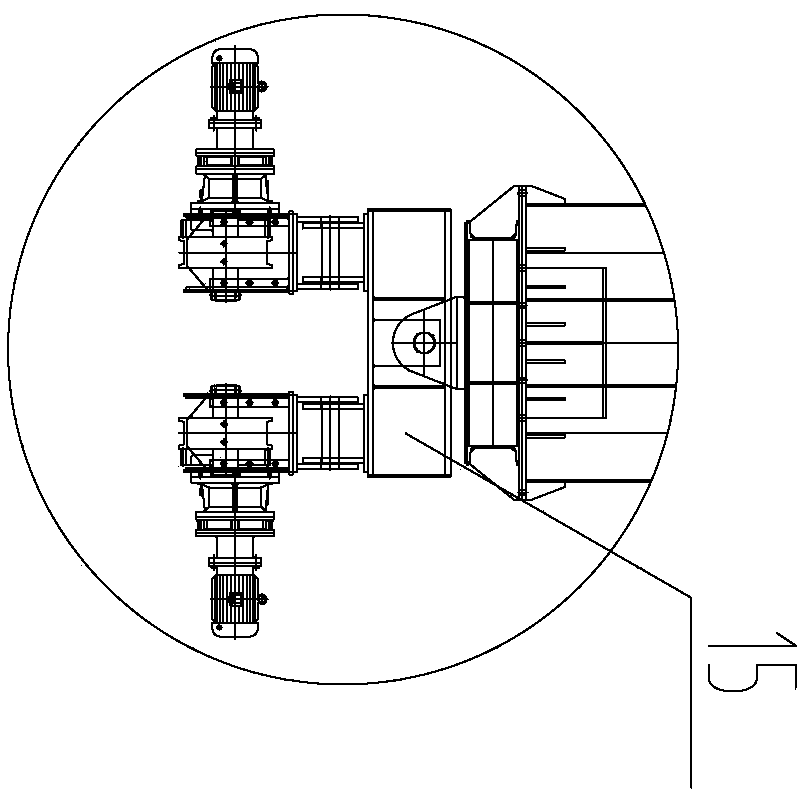

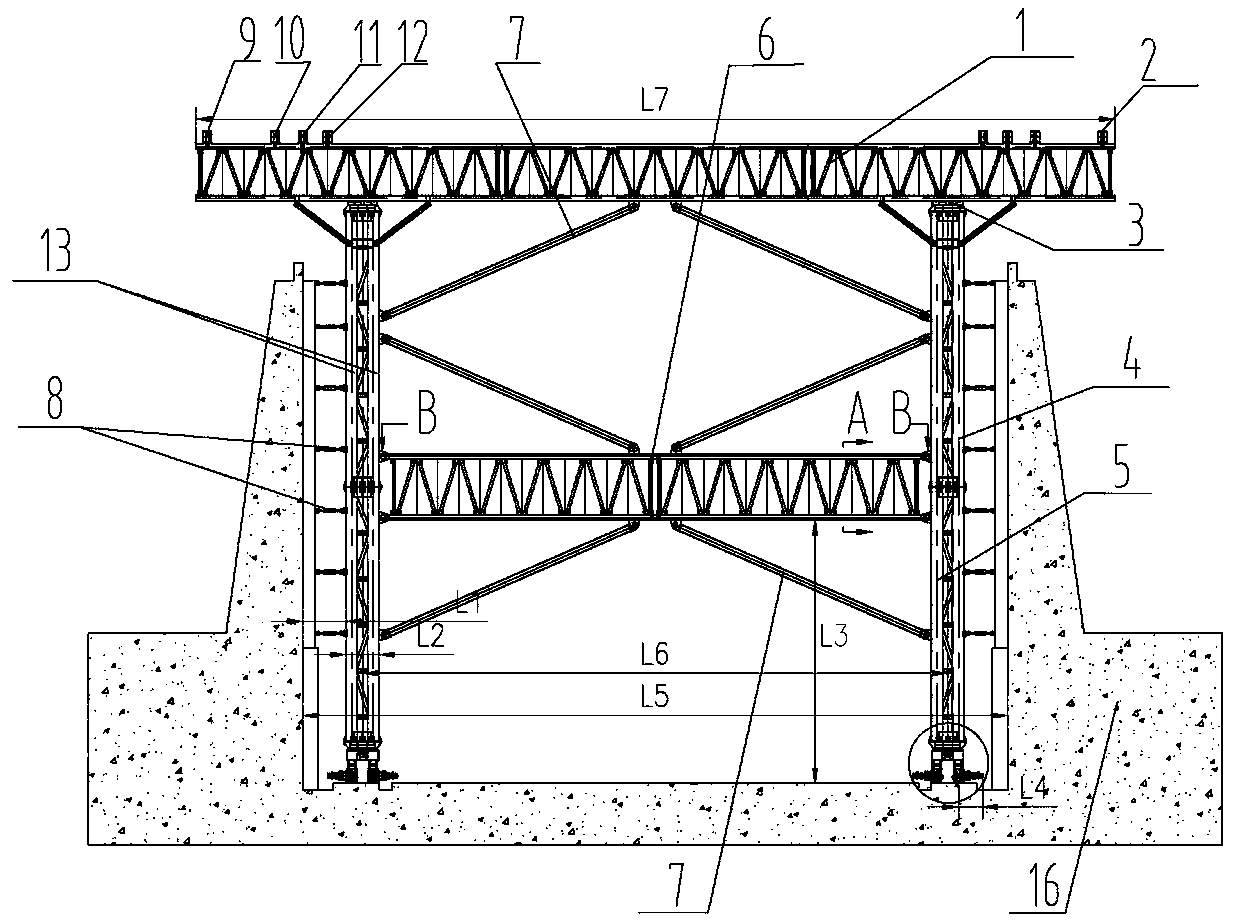

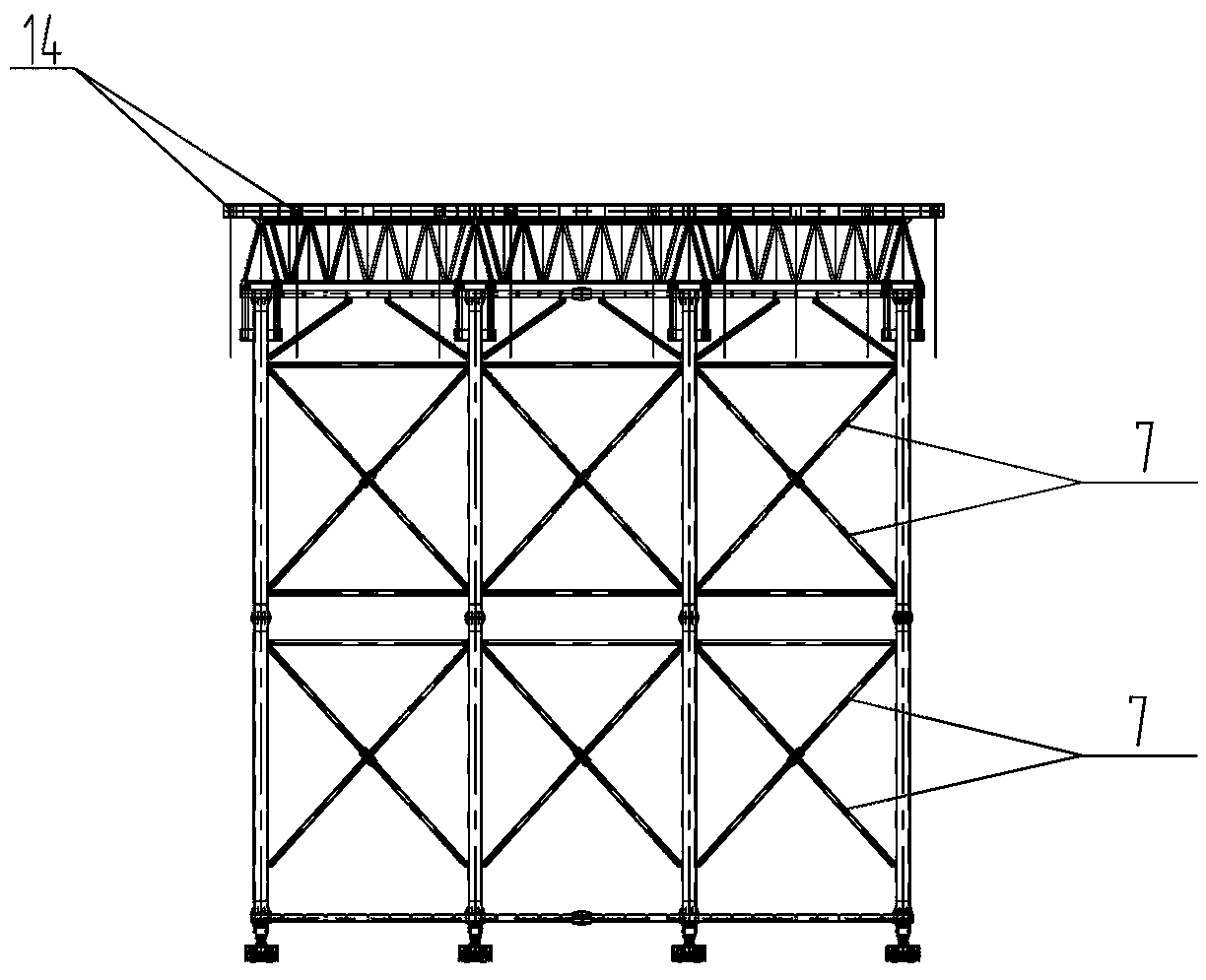

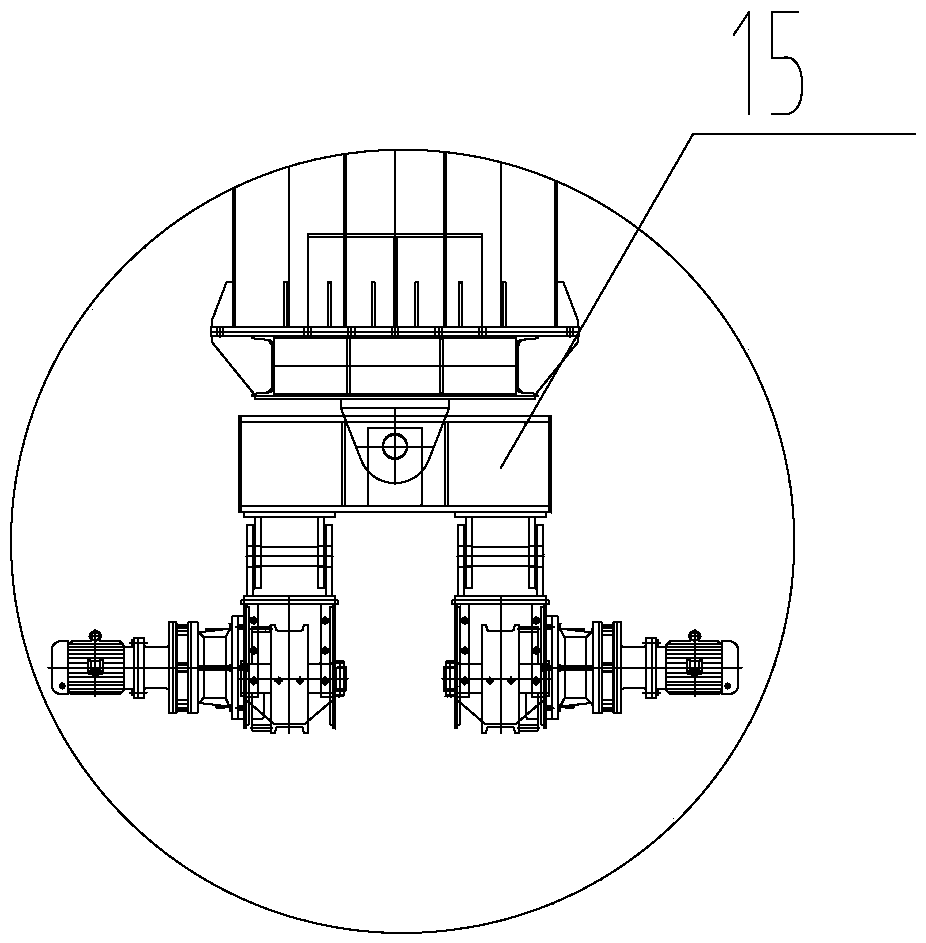

Construction method for movable mold frame for lock chamber wall of ship lock

InactiveCN107386246AReduce equipmentReduce labor intensityDry-docksClimate change adaptationSingle sectionBuilding construction

Owner:周学顺

Method for treating red mud by using soil stabilizer

The invention relates to a method for treating red mud by using a soil stabilizer. The soil stabilizer, a cementing material and red mud are mixed to obtain a mixture, and then forming is carried out.A series of performance tests on unconfined compressive strength, freeze thawing resistance, water stability and the like are carried out, and results show that a pavement base course is good in performance, has better performance than a conventional process in the aspects of compressive strength, deflection value and the like, and has the advantages of improving quality, reducing manufacturing cost, saving energy, protecting the environment and the like. The method can be widely applied to the field of civil engineering, and the added value of red mud is greatly improved.

Owner:光大国信环保科技(北京)有限公司

Lithium iron phosphate composite modified lithium ion battery cathode material and preparation method thereof

InactiveCN102610815ASame crystal structureHigh ion conductivityCell electrodesLithium iron phosphateRare earth

The invention discloses a lithium iron phosphate composite modified lithium ion battery cathode material and a preparation method thereof. The chemical formula of the cathode material is LiFe1-xRExPO4-REPO4 / (C+Fe2P), and a multi-phase structure with LiFe1-xRExPO4, REPO4 and Fe2P exists; REPO4, C and Fe2P are coated on the surface of the LiFe1-xRExPO4; and x ranges from 0.01 to 0.04. The method comprises the following steps of: uniformly mixing a lithium source compound, a phosphorus source compound, inorganic and organic mixed iron source compound and rare earth oxide RE2O3 so as to prepare a reaction precursor; and forging the reaction precursor so as to obtain the lithium iron phosphate composite modified lithium ion battery cathode material. The preparation method is simple and feasible and low in production cost; the prepared material has relatively high electrochemical performance and tap density; and the method is favorable for industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Rare-earth element samarium-doped modified lithium ion battery anode material and preparation method thereof

The invention discloses a rare-earth element samarium-doped modified lithium ion battery anode material and a preparation method thereof. The method comprises the following steps of: mixing a lithium source compound, a phosphor source compound, an iron source compound, a crystalline-phase element samarium-doped compound and a carbon source compound, heating at 250-400 DEG C for 5-20h, cooling and grinding to obtain a reaction precursor; and calcining the reaction precursor at 500-800 DEG C for 10-40h, cooling to obtain an LiFe1-xSmxPO4-SmPO4 / C (x=0.01-0.04) composite rare-earth element samarium-doped modified lithium ion battery anode material. The invention can effectively control the structure and the grain diameter of the composite doped modified cathode material, improve the electronic conductivity of the material and the dispersion rate of lithium ions as well as the electrochemical performance of the material, also simplify the synthesis process of the material and be convenient for industrial mass production.

Owner:SOUTH CHINA UNIV OF TECH

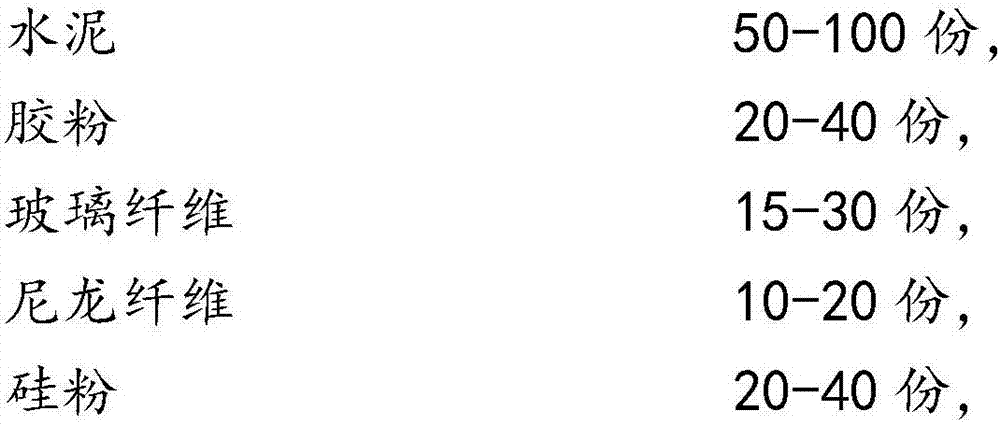

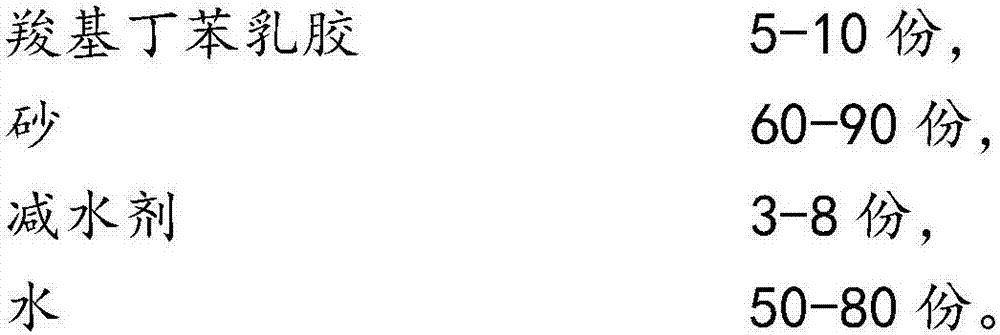

Novel bendable concrete

The invention discloses novel bendable concrete. The novel bendable concrete is prepared from the following raw materials in parts by mass: 50 to 100 parts of cement, 20 to 40 parts of gelatin powder, 15 to 30 parts of glass fibers, 10 to 20 parts of nylon fibers, 20 to 40 parts of silicon powder, 5 to 10 parts of carboxylated styrene-butadiene latex, 60 to 90 parts of sand, 3 to 8 parts of a water reducing agent and 50 to 80 parts of water. The novel bendable concrete disclosed by the invention has the characteristics of good strength, low elastic modulus, good flexibility and ductility, good heat-preservation and heat-insulation effect, good crack resistance and anti-impact strength and the like.

Owner:SUZHOU TANGSHI JIANHUA CONCRETE PILE

Lithium ion battery high-voltage anode material preparation and surface coating method

The invention provides lithium ion battery high-voltage anode material preparation and surface coating method. The method adopts high-voltage anode material spinel-type LiNi0.5Mn1.5O4 prepared by a two-step method and comprises the following steps of: firstly, evenly mixing nickel source and manganese source solutions with a surface active agent solution, then drying and roasting in the air of 350-450 DEG C to obtain a precursor of a nickel and manganese oxide; mixing the precursor with a lithium source through liquid phase ball milling, drying and finally roasting in the air of 400-900 DEG C to obtain an anode active material; and adding the anode active material to a soluble aluminum solution containing a lithium source, sufficiently and evenly mixing under controlling the lithium source, the soluble aluminum source and the anode active material to be at the proper mol, drying and carrying out high-temperature roasting treatment to obtain a final product which is the lithium ion battery high-voltage anode material which is coated with a layer of lithium-contained transition metal oxide on the surface. The high-voltage anode material prepared by the method has the characteristics of high initial capacity, good cycle performance and the like.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

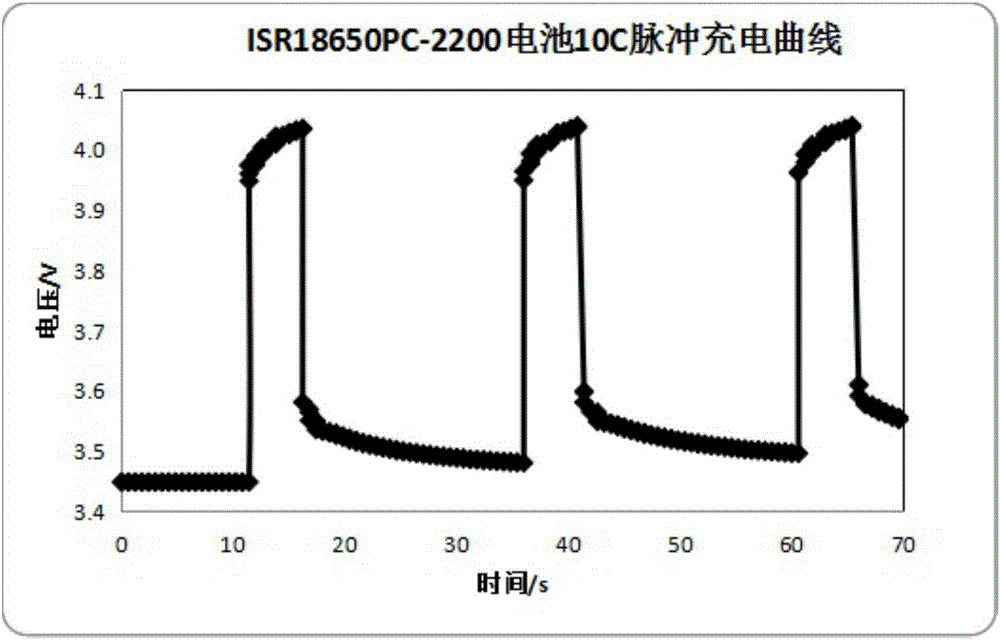

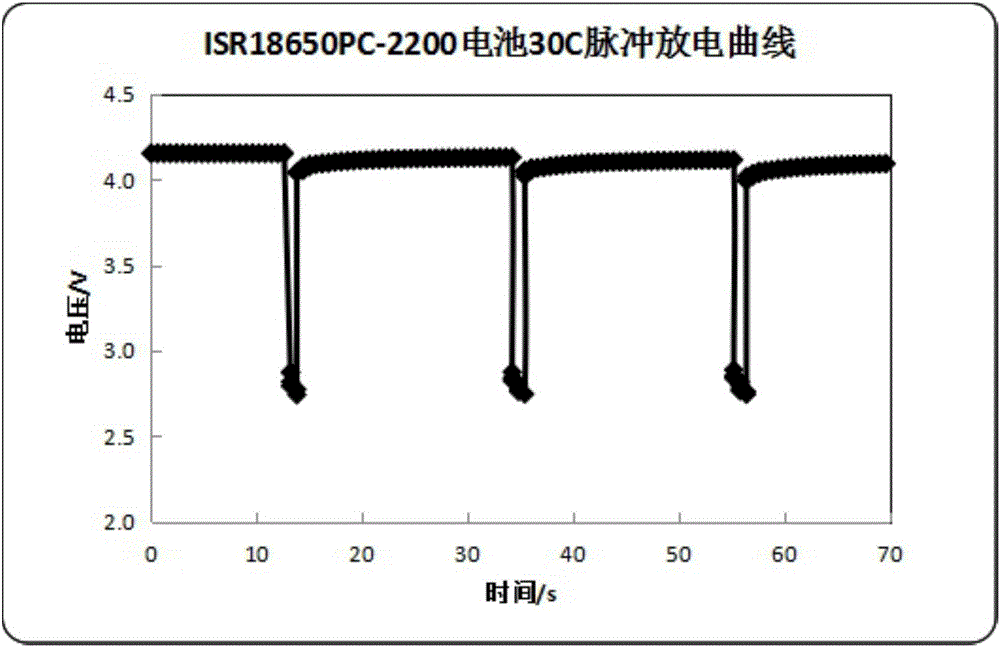

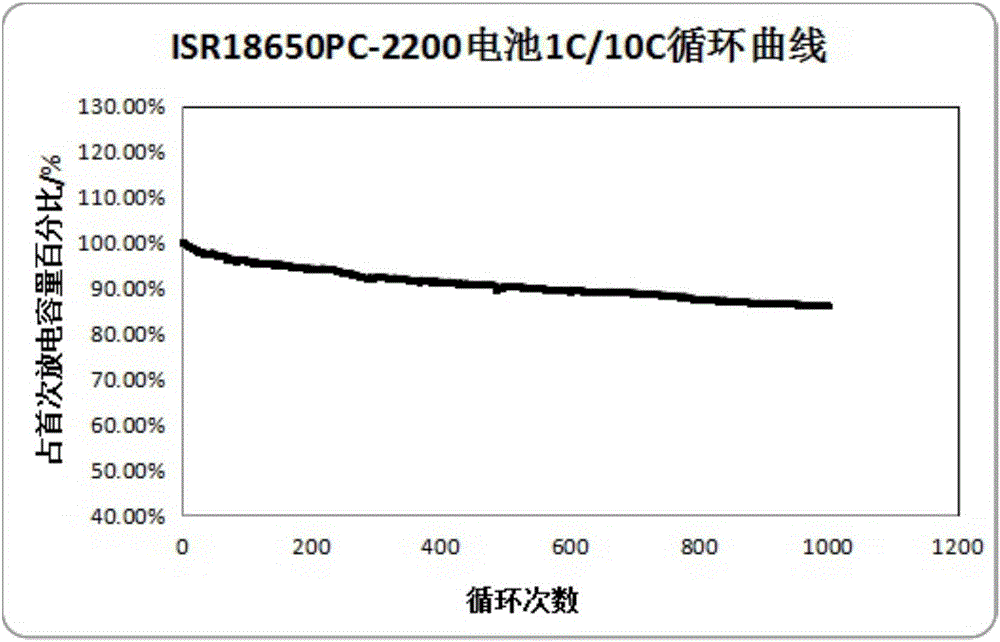

Cylindrical lithium ion battery used for high-capacity electric tool and preparation method thereof

InactiveCN106252718AReduce polarizationExtended service lifeCell electrodesFinal product manufacturePower toolCopper foil

The invention discloses a cylindrical lithium ion battery used for a high-capacity electric tool and a preparation method thereof. The preparation method comprises the following steps: (1) stirring a conductive agent Super P, KS-6, a positive active material, a binder PVDF and NMP at a high speed, smearing the mixture on the front and back surfaces of an aluminum foil, drying, grinding, stripping, and flaking to obtain a positive plate; (2) stirring the conductive agent Super P, a negative active material, a binder and deionized water at a high speed, and finally, smearing the mixture on the front and back surfaces of the aluminum foil, drying, grinding, stripping and flaking to obtain a negative plate; (3) roasting the positive plate and the negative plate, winding, injecting electrolyte and sealing to obtain an assembly battery; and (4) forming. The cylindrical lithium ion battery for the high-capacity electric tool prepared by the method has the characteristics of excellent inner resistance, rate capability, rapid charging performance, high-current cycling performance and safety.

Owner:江苏海四达电源有限公司 +1

Construction method of mobile formwork for ship lock chamber wall

InactiveCN107386246BStrong symmetryAvoid installationDry-docksClimate change adaptationSingle sectionBuilding construction

Owner:周学顺

Lithium ion battery cathode material and preparation method thereof and lithium ion battery

ActiveCN111224094AGood particle consistencyImprove crystal structureSecondary cellsPositive electrodesHigh energyLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a lithium ion battery cathode material and a preparation method thereof and a lithium ion battery. The preparation method of the lithium ion battery cathode material comprises the following steps: (1) uniformly mixing a ternary precursor, a lithium source and an auxiliary agent, and keeping the temperature at 600-980 DEG C for 5-15 hours to obtain an intermediate product, wherein the chemical formula of the ternary precursor is NixCoyD(1-x-y)(OH)2, x is greater than 0 and less than or equal to 1,y is greater than 0 and less than or equal to 1, x+y is greater than 0 and less than 1, and D is one of Mn and Al elements, the auxiliary agent is one or more of AlF3, KF, LiF, NaCl, KCl, H3BO3 and B2O3; and (2) uniformly mixing the intermediate product with a lithium source, and keeping the temperature at 650-980 DEG C for 5-15 hours to obtain the lithium ion battery cathode material. The cathode material prepared according to the preparation method disclosed by the invention is relatively good in crystal structure and relatively high in particle consistency; when the material is used as a cathode active material for a lithium ion battery, the lithium ion battery has relatively high energy density.

Owner:DO FLUORIDE CHEM CO LTD

A kind of chemical synthesis method of lithium manganate power battery

ActiveCN103326069BImprove securityFully absorbedFinal product manufactureSecondary cells charging/dischargingPower batteryPower flow

The invention discloses a method for forming a lithium manganese oxide power battery, comprising the following steps: injecting liquid into the power battery, and standing still for a first preset time after the liquid injection; charging with a first preset current and a constant current After reaching the first preset voltage, rest for the second preset time; charge with the second preset current constant current to the second preset voltage and then carry out the third preset time for rest; use the third preset current constant current charging to a third preset voltage, and then discharging to a fourth preset voltage with a constant current at a third preset current, and repeating this step for a preset number of times. The formation method of the lithium manganese oxide power battery provided by the embodiment of the present invention can form a dense and stable SEI film, completely eliminate the gas generated by the formation, and effectively improve the usable capacity, cycle performance, consistency and safety of the battery, and the The formation method has simple operation and high reliability, is especially suitable for lithium manganese oxide batteries for electric vehicles, and can be popularized and applied.

Owner:BEIQI FOTON MOTOR CO LTD

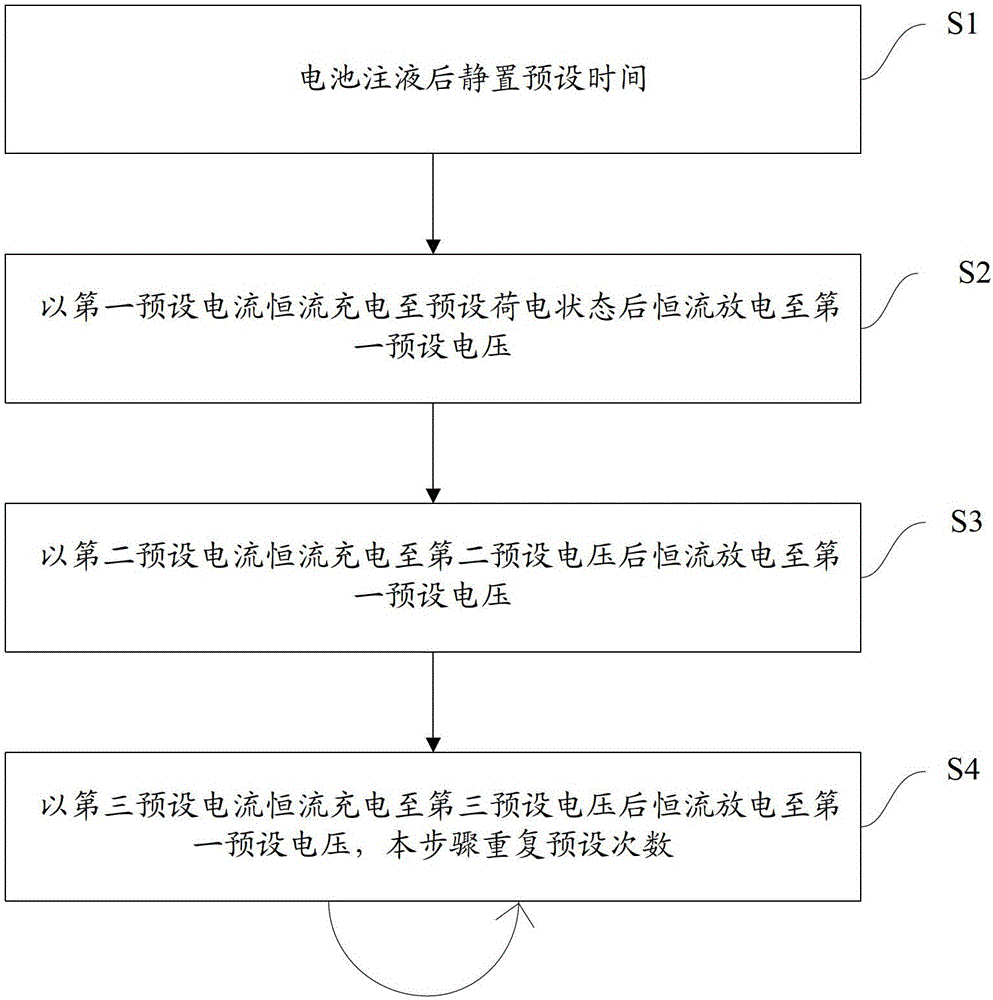

Formation method of lithium iron phosphate power battery

ActiveCN103579679BIncrease usable capacityImprove cycle performanceFinal product manufactureElectrolyte/reactants regenerationEngineeringChemical conversion

The invention discloses a method for forming a lithium iron phosphate power battery, comprising the following steps: S1, injecting electrolyte solution into the power battery and standing it for a preset time; S2, charging the battery cell of the power battery with a first preset current constant current to the preset state of charge, and then constant current discharge to the first preset voltage; S3, charge the cell of the power battery to the second preset current constant current to the second preset voltage, and then constant current discharge to the first preset voltage. Set the voltage, the second preset current is greater than the first preset current and the second preset voltage is greater than the first preset voltage; S4, charge the cell of the power battery with a third preset current to a third preset voltage at a constant current , and then constant current discharge to the first preset voltage, the third preset current is greater than the first preset current and the third preset voltage is greater than the first preset voltage; and S5, repeat step S4 for a preset number of times. According to the chemical formation method provided by the invention, the SEI film is stable, the thermal stability is better, and the safety performance is good.

Owner:BEIQI FOTON MOTOR CO LTD

Nylon modified material and preparation method thereof

Owner:KINGFA SCI & TECH CO LTD

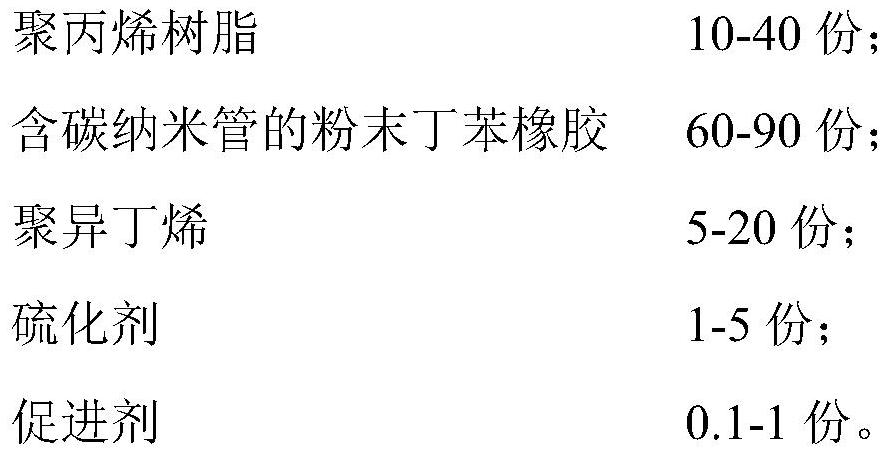

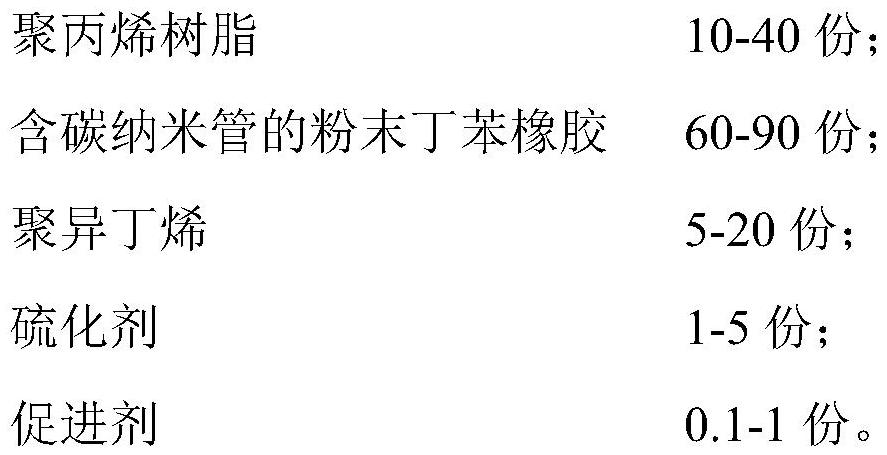

Low-temperature-resistant low-hardness thermoplastic elastomer and preparation method thereof

The invention relates to a low-temperature-resistant low-hardness thermoplastic elastomer and a preparation method thereof, and belongs to the field of high-molecular elastomers. The low-temperature-resistant low-hardness thermoplastic elastomer is prepared from the following raw materials in parts by mass: 10-40 parts of polypropylene resin, 60-90 parts of powdered styrene-butadiene rubber containing carbon nanotubes, 5-20 parts of polyisobutene, 1-5 parts of a vulcanizing agent, and 0.1-1 part of an accelerant. According to the invention, styrene-butadiene rubber and polypropylene resin are taken as basic raw materials, a dynamic vulcanization technology is adopted, the powdered styrene-butadiene rubber containing carbon nanotubes is prepared by a co-flocculation process of a carbon nanotube emulsion and a styrene-butadiene rubber emulsion, the powdered styrene-butadiene rubber is blended with polypropylene resin, and low-molecular-weight polyisobutene is used for oil-filled softening to prepare the low-temperature-resistant low-hardness thermoplastic elastomer. The problem of large permanent deformation caused by poor dispersibility of the filler is solved by using the co-flocculation process of the carbon nanotube emulsion and the styrene-butadiene rubber emulsion, the hardness of the TPV product is reduced by filling the low-molecular-weight polyisobutene, and the TPV has excellent low-temperature resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

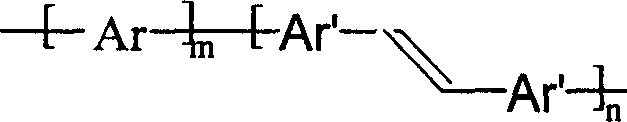

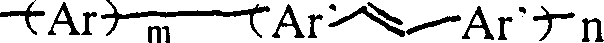

Copolymer type conjugated polymer whose main chain contains double bond, its preparation method and application

InactiveCN1151187CSimple preparation stepsLow costLuminescent compositionsPolymer sciencePhotoluminescence

The present invention discloses a kind of copolymer conjugated polymers with main chain containing double bond and its preparation method and application. This kind of polymer can be obtained by using aromatic heterocyclic and fused ring compound or its derivative and diaryl ethylenes compound through the process of direct oxidation coupling reaction. Its preparation method is simple, cost is low, can batch-prepare several conjugated polymers with various structures and more complete function. These polymers can be used as luminescent material, and can be used for manufacturing light-emitting diode, electroluminescent device, photoluminescent device and other photoelectric conersion device and product.

Owner:WUHAN UNIV

Method for preparing lithium ion battery positive electrode composite material

InactiveCN100521299CImprove UIHigh capacity retentionElectrode manufacturing processesFiltrationFree cooling

Owner:TSINGHUA UNIV

A kind of permeable cement concrete and its construction method

InactiveCN107352868BReduce usageImprove adhesionRoads maintainenceCeramicwareFiberUltimate tensile strength

Belonging to the technical field of concrete, the invention provides a water permeable cement concrete and a construction method thereof. The water permeable cement concrete consists of the following raw materials by weight: cement, recycled concrete coarse aggregate, stone, water, fly ash, a water reducer, isocyanate modified phenolic resin, short fiber and sodium bentonite. The water permeable cement concrete provided by the invention uses waste concrete and stone cooperatively to replace natural coarse aggregate, and takes the isocyanate modified phenolic resin as the binder, the added short fiber ensures the water permeability of concrete and simultaneously improves the coarse aggregate interface state of the cementitious material, and improves the concrete strength. The used composite water reducer effectively reduces the use of water under the premise of guaranteeing the concrete flowability and workability, and improves the project quality. The sodium bentonite is used as a thickener, can increase the coagulating force between all the materials, also can be used in combination with other components, and plays a role of strengthening, thickening, tackifying and water retention.

Owner:光合新兴产业控股集团股份有限公司

A kind of production method of permeable concrete

The invention discloses a method for preparing water permeable concrete by using high-quality recycled coarse aggregates. The concrete is composed of cement, mixed coarse aggregates, PVA, water and a high performance water-reducing agent. By doping PVA, the high-quality recycled coarse aggregates enhance binding force between a cementing material and the aggregates and compaction strength indexes of the cement while guaranteeing water permeability. The preparation method for the water permeable concrete has practical significance for recycling waste concrete and improving performances of environment-friendly water permeable and breathable concrete.

Owner:INNER MONGOLIA UNIVERSITY

Composite doped modified lithium-ion battery anode material and its manufacture method

InactiveCN100490221CSame crystal structureImprove ionic conductivityElectrode manufacturing processesChemical/physical/physico-chemical processesRare-earth elementChemical composition

The disclosed preparation method for anode material of composite doped modified Li-ion cell comprises: mixing the Li-source compound, P-source compound, Fe-source compound, crystal phase doped M (rare earth element) compound and non-crystal phase doped element C to heat for 5-20h at 250-400Deg; cooling, and grinding to obtain the reaction predecessor contained PO43-, Li+, Mn+, Fe2+ and carbon black; calcining for 10-40h at 500-800Deg to cool and obtain the final product. This invention improves material electrochemical property and fit to industrial production.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of barium strontium titanate based glass ceramic energy storage material

InactiveCN102775069BImprove energy storage performanceHigh compressive strengthFixed capacitor dielectricGlass productionStrontium titanateBarium strontium titanate

The invention belongs to the field of dielectric energy storage material, and specifically relates to a preparation method of barium strontium titanate based glass ceramic material with high energy storage density. The invention provides the preparation method of barium strontium titanate based glass ceramic energy storage material, which comprises the following steps: burdening according to (BaxSr1-x) TiO3-aAl2O3-bSiO2, wherein x=0.4-0.6, (a+b) / (2+a+b)=0.3-0.35 and a / b=0.5-1.0, drying after ball-milling and mixing materials, and melting at high temperature; casting high-temperature melt into a metal mold, performing stress relief annealing, and then cutting to obtain glass thin sheet with thickness of 0.5-1.0mm; performing controlled devitrification to the glass thin sheet to obtain glass ceramic; performing microwave heat treatment to the glass ceramic in a microwave oven to obtain the glass ceramic dielectric with high energy storage density. The method provided by the invention is simple and the energy storage property of the prepared glass ceramic material is improved greatly.

Owner:TONGJI UNIV

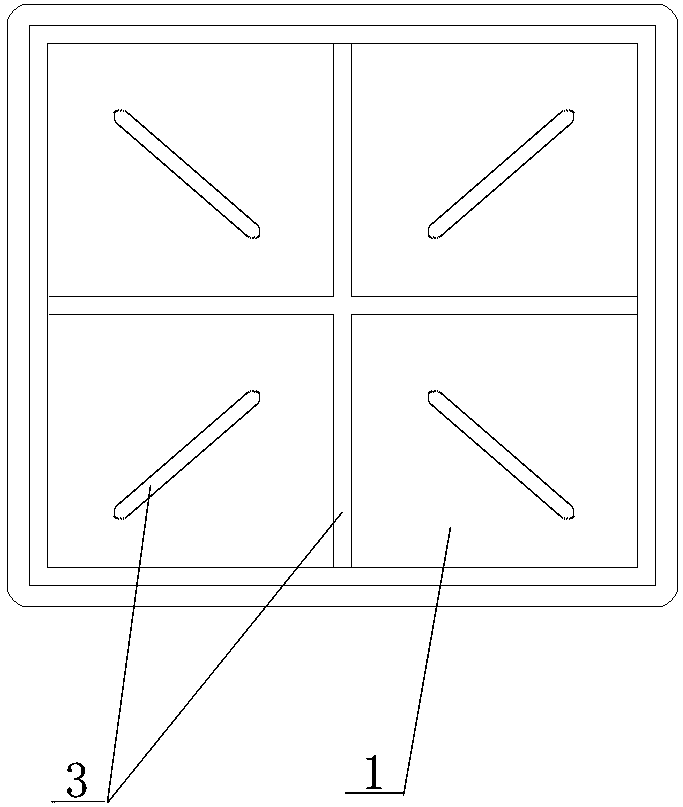

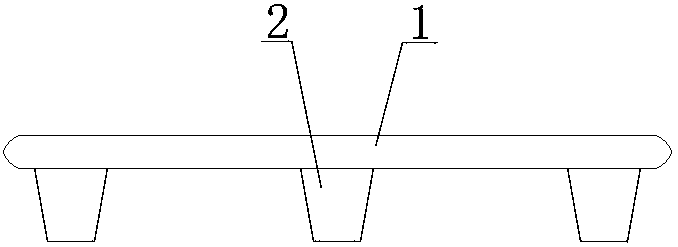

Novel die-cast type tray

The invention belongs to the technical field of cargo transportation trays, and discloses a novel die-cast type tray. The tray comprises a supporting plate, a plurality of supporting legs are uniformly arranged on the bottom surface of the supporting plate, and a plurality of reinforcing ribs are uniformly arranged on the supporting plate; and the supporting plate, the supporting legs and the reinforcing ribs are of an integral die-cast structure. The die-cast type tray adopts the scraps of an automobile interior trim as raw materials, and civil carpet leftover materials can further be utilized, so that the waste recycling is realized, the cost is low, the mass is relatively light, mechanical property is excellent, and high-temperature-resistant, low-temperature-resistant and corrosion-resistant are achieved.

Owner:张玉云

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com