EVA (ethylene-vinyl acetate)-post-crosslinking-modified high-performance glass-fiber reinforced polypropylene composite material and preparation method thereof

A technology of cross-linking modification and composite materials, applied in the field of polymer materials, can solve the problems of reducing the high cost performance of polypropylene composite materials, the improvement of material performance retention rate is not obvious, and the price of additives is expensive, so as to improve the interface condition and weather resistance. Improved performance and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

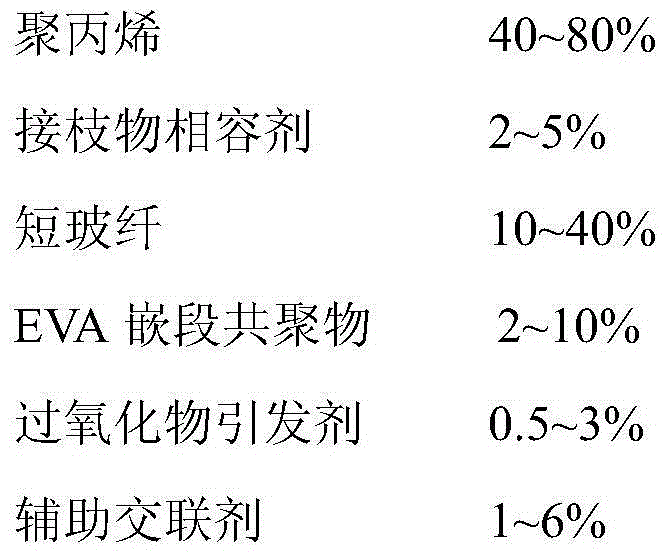

Method used

Image

Examples

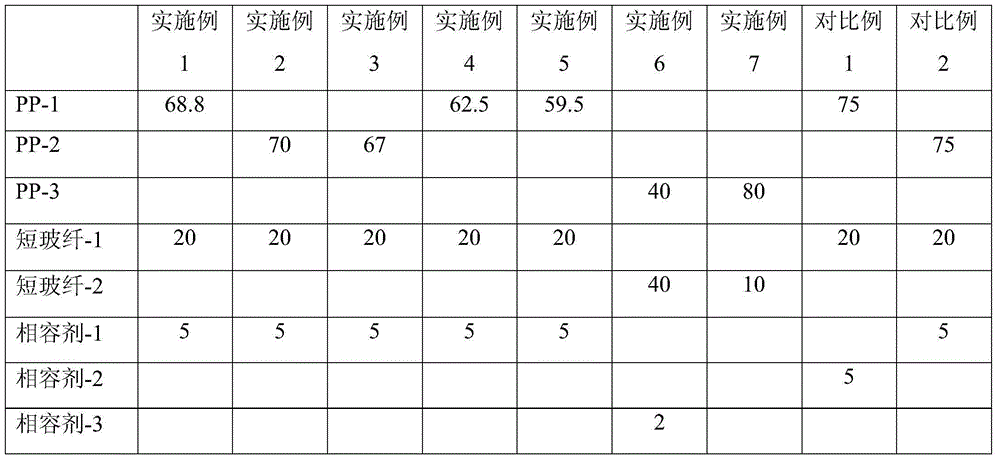

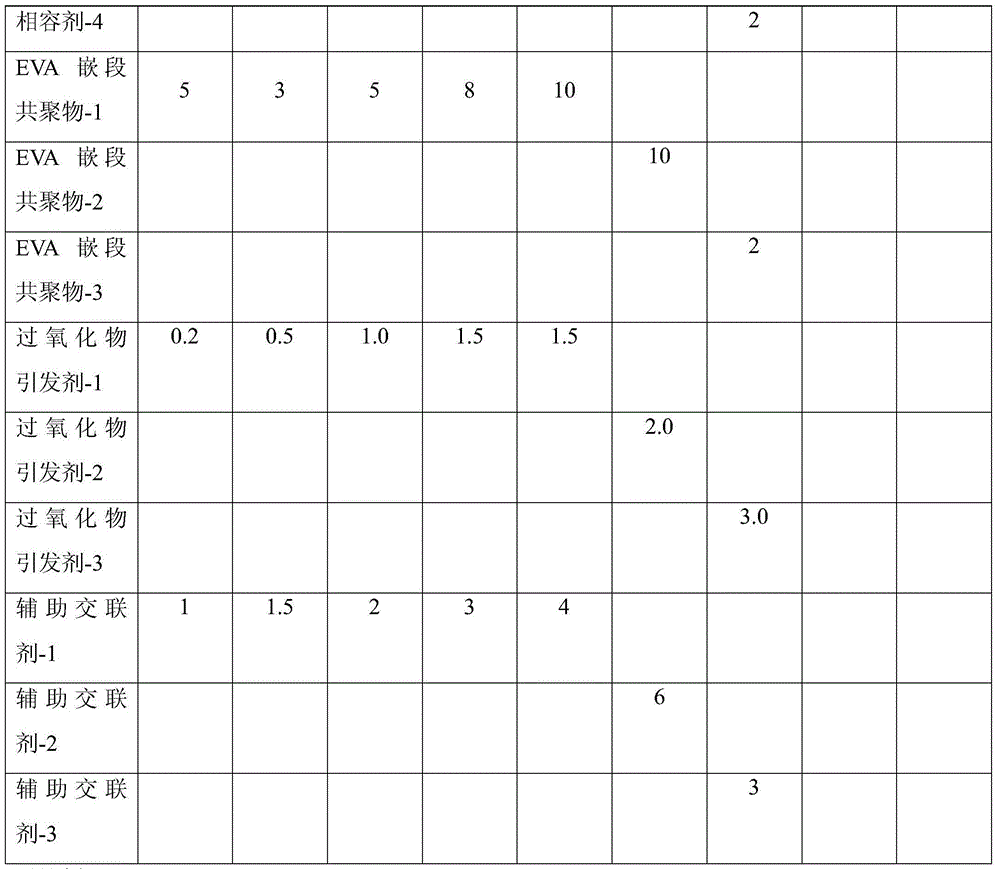

Embodiment 1

[0046] Each component is weighed according to the data of Example 1 shown in Table 1, and the mixed raw material A composed of polypropylene, graft compatibilizer, and EVA block copolymer is placed in the main feeding bin, and the short glass fiber , peroxide cross-linking agent, auxiliary cross-linking agent, the mixed raw material B after mixing is placed in the side feeding bin, and is added into the main barrel of the twin-screw extruder through the respective feeding screws, and the extruder The diameter of the screw is 35mm, the length-to-diameter ratio L / D is 40, the speed of the main engine is set at 200 rpm, and the temperature of each zone of the main barrel (from the feeding port to the outlet of the machine head) is set as: 60 ° C, 160 ° C, 170 ° C °C, 180 °C, 190 °C, 200 °C, 200 °C, after melt extrusion, cooling, granulation, drying and other processes to obtain particles, and then injection molded into standard mechanical Performance test splines.

Embodiment 2

[0048] Each component is weighed according to the data of Example 2 shown in Table 1, and the mixed raw material A composed of polypropylene, graft compatibilizer, and EVA block copolymer is placed in the main feeding bin, and the short glass fiber , peroxide cross-linking agent, auxiliary cross-linking agent, the mixed raw material B after mixing is placed in the side feeding bin, and is added into the main barrel of the twin-screw extruder through the respective feeding screws, and the extruder The diameter of the screw is 35mm, the length-to-diameter ratio L / D is 40, the speed of the main engine is set at 200 rpm, and the temperature of each zone of the main barrel (from the feeding port to the outlet of the machine head) is set as: 60 ° C, 160 ° C, 170 ° C °C, 180 °C, 190 °C, 200 °C, 200 °C, after melt extrusion, cooling, granulation, drying and other processes to obtain particles, and then injection molded into standard mechanical Performance test splines.

Embodiment 3

[0050] Each component is weighed according to the data of Example 3 shown in Table 1, and the mixed raw material A composed of polypropylene, graft compatibilizer, and EVA block copolymer is placed in the main feeding bin, and the short glass fiber , peroxide cross-linking agent, auxiliary cross-linking agent, the mixed raw material B after mixing is placed in the side feeding bin, and is added into the main barrel of the twin-screw extruder through the respective feeding screws, and the extruder The diameter of the screw is 35mm, the length-to-diameter ratio L / D is 40, the speed of the main engine is set at 200 rpm, and the temperature of each zone of the main barrel (from the feeding port to the outlet of the machine head) is set as: 60 ° C, 160 ° C, 170 ° C °C, 180 °C, 190 °C, 200 °C, 200 °C, after melt extrusion, cooling, granulation, drying and other processes to obtain particles, and then injection molded into standard mechanical Performance test splines.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com