High-durability damping concrete and preparation method thereof

A concrete and durable technology, which is applied in the field of concrete and its preparation, can solve the problems of low damping capacity and poor durability, and achieve the effects of improving utilization rate, improving interface conditions, and improving chloride ion penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

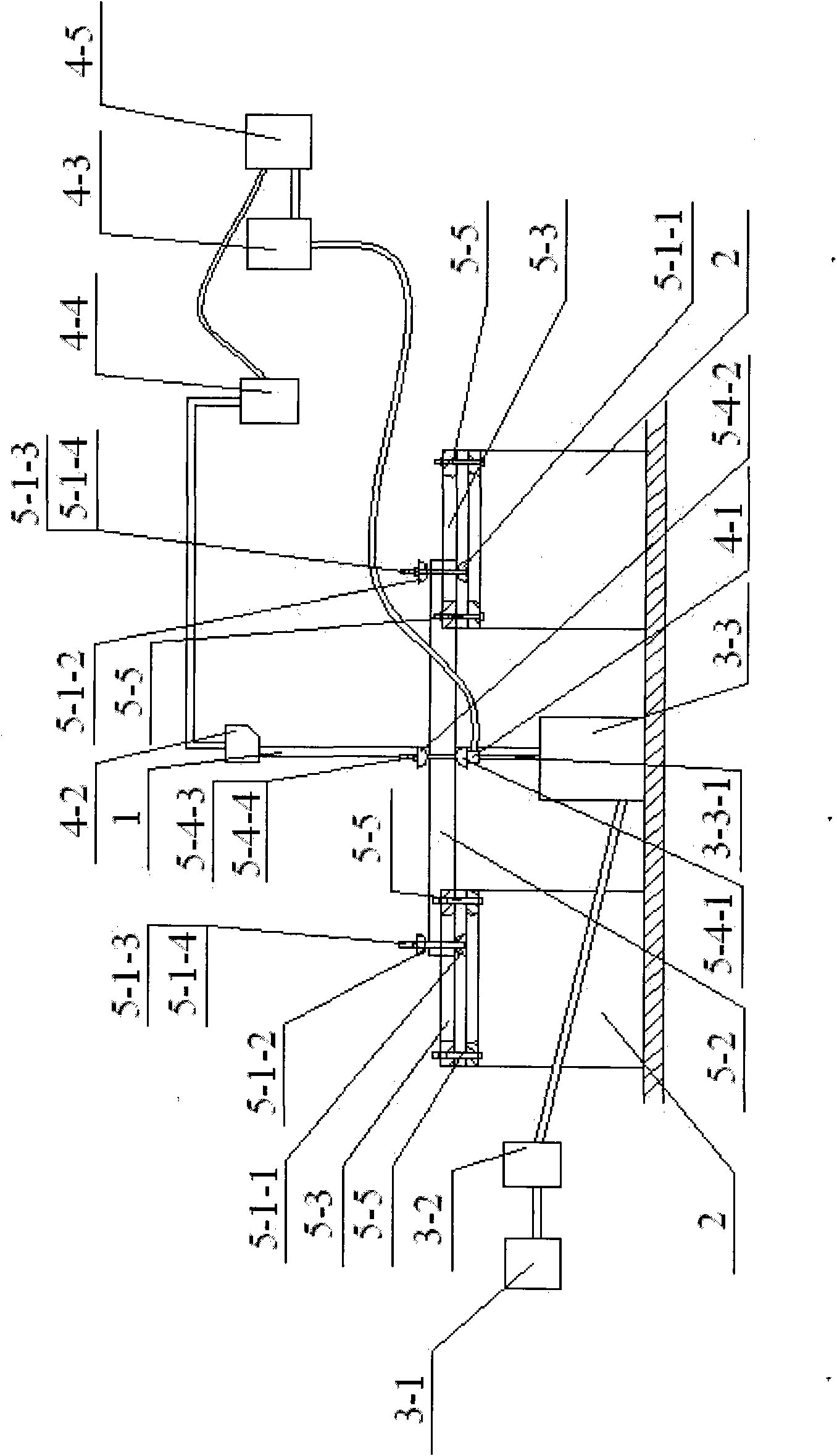

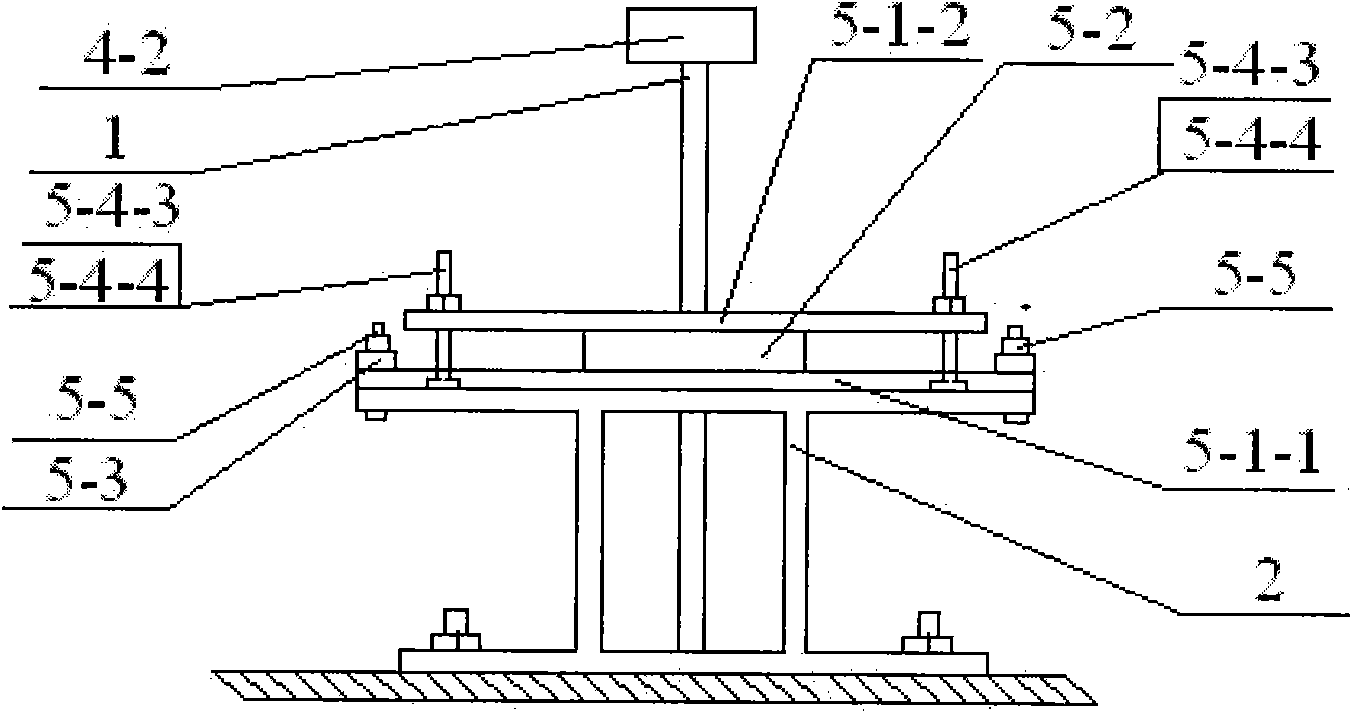

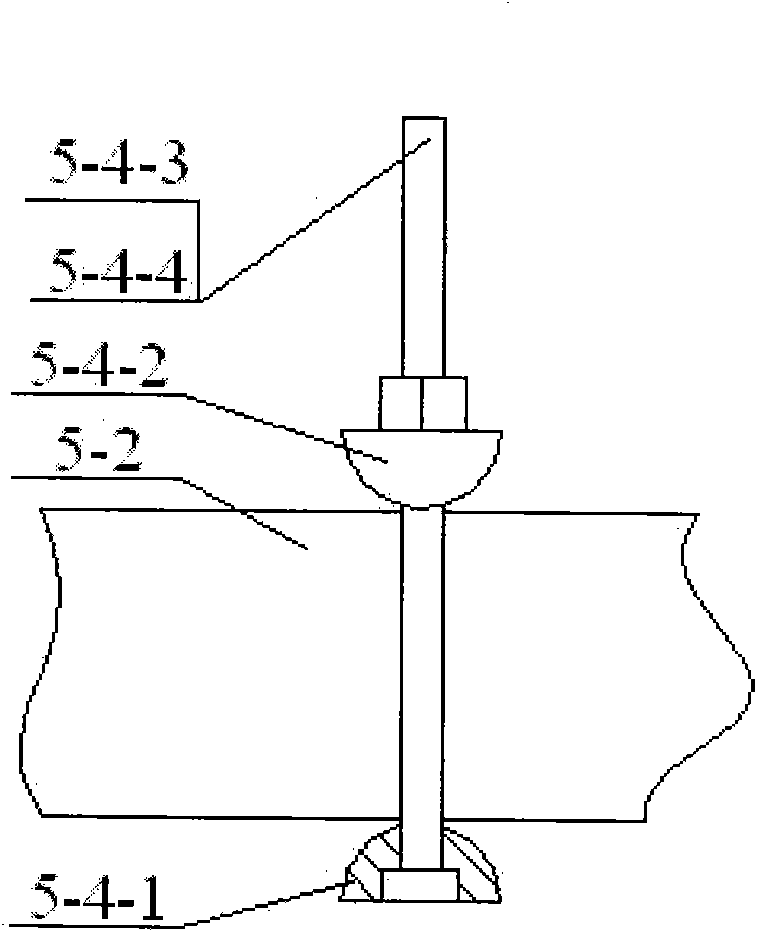

Image

Examples

specific Embodiment approach 1

[0015] Embodiment 1: In this embodiment, each cubic meter of high-durability vibration-damping concrete consists of 480kg of cement, 28.8kg of rubber powder, 220kg of water, 605kg of medium sand and 1075kg of gravel.

[0016] The high-durability vibration-damping concrete described in this embodiment is prepared by stirring and mixing the components constituting the concrete.

[0017] The cement used in this embodiment is 32.5 ordinary Portland cement, the basic physical and mechanical properties of 32.5 ordinary Portland cement are shown in Table 1, and the chemical composition (%) of 32.5 ordinary Portland cement is shown in Table 2.

[0018] Table 1

[0019]

[0020] Table 2

[0021]

[0022] The sand used in this embodiment is medium sand, and the particle gradation of the medium sand is the II zone gradation. The performance index of the sand is shown in Table 3:

[0023] table 3

[0024]

[0025] The performance index of stone used in the present embodiment i...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the rubber powder is Latex powder. Others are the same as in the first embodiment.

[0029] The rubber powder used in this embodiment is produced by Wacker Chemicals Company in Germany Latex powder. It is a spray-dried powder of high molecular polymer emulsion. If these latex powders are dispersed in water, a stable emulsion will be formed again, and its physical properties are the same as the original emulsion.

specific Embodiment approach 3

[0030] Embodiment 3: In this embodiment, each cubic meter of high-durability vibration-damping concrete consists of 480kg of cement, 2.4kg of carbon fiber, 210kg of water, 638kg of medium sand, 1042kg of stones, 4.8kg of water reducing agent and 38.4kg of silicon powder.

[0031] The silicon powder used in this embodiment is produced by Chengdu Donglanxing Company, and its chemical composition and physical properties are shown in Table 5:

[0032] table 5

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com