Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Improve resistance to chloride ion penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

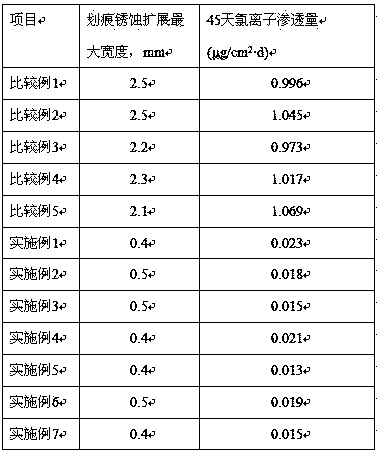

Organic composite reinforced concrete rust inhibitor and preparation method thereof

ActiveCN102432220AImprove resistance to chloride ion penetrationImprove permeabilityAlcoholReinforced concrete

The invention discloses an organic composite reinforced concrete rust inhibitor and a preparation method thereof. According to the invention, the rust inhibitor is prepared from well-mixed materials of, by weight: 30-40% of alcohol amine carboxylate, 5-10% of sodium monofluorophosphate, 0.1-0.5% of an anionic surfactant, and balance of water. The rust inhibitor has a good diffusion performance inconcrete, and can simultaneously acts upon the cathodes and the anodes of steel bars. The trust inhibitor forms stable chelate rings with the steel bars, and has an excellent rust inhibiting performance. Also, the anions in the rust inhibitor can be combined with calcium ions in the concrete, such that precipitates are formed. With the precipitates, capillary pores in the concrete can be obstructed, and the chloride ion penetration resistance of the concrete can be improved.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +1

Modified metakaolin-based permeation-resistant and crack-resistant agent for concrete

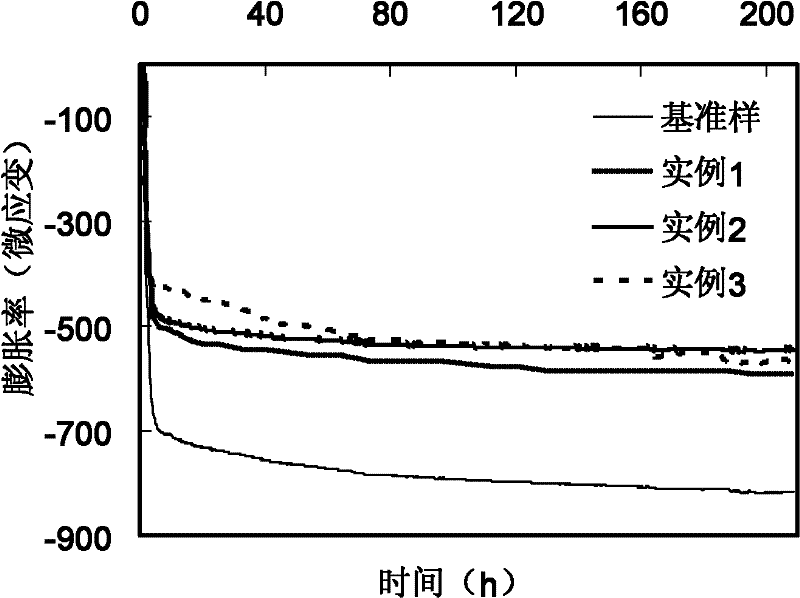

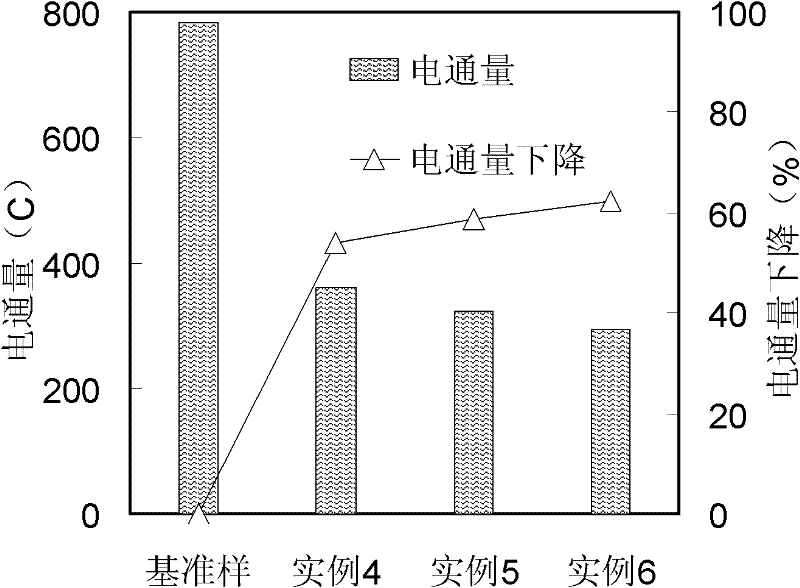

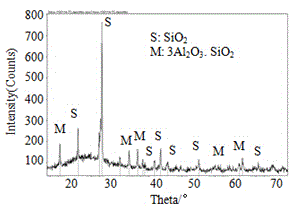

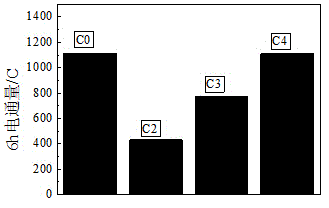

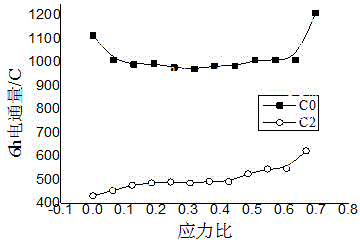

The invention discloses a modified metakaolin-based permeation-resistant and crack-resistant agent for concrete. The modified metakaolin-based permeation-resistant and crack-resistant agent for concrete comprises: by mass, 10 to 75% of modified metakaolin, 5 to 40% of fine limestone powder, 4 to 40% of superfine coal ash, 1 to 20% of calcined hydrotalcite, 2 to 40% of fine quartz sand and 0.2 to 20% of solid silane powder. A preparation method of the modified metakaolin comprises the following steps of putting dry and washed kaolin into a bowl mill, carrying out grinding to obtain kaolin powder, carrying out calcination of the kaolin powder at a temperature of 500 to 1000 DEG C for 0.5 to 6.0 hours to obtain metakaolin, putting the metakaolin into a dispersion machine, adding an organic modifier of sulfamate or triethanolamine into the metakaolin, wherein a mass ratio of the metakaolin and the organic modifier is in a range of (5000: 1) to (100: 1), and carrying out dispersion to obtain the modified metakaolin having a contact angle of 50 to 100 degrees and a specific surface area of 8000 to 15000m<2> / kg. The modified metakaolin-based permeation-resistant and crack-resistant agentfor concrete can be utilized as a concrete additive, improves strength of concrete at different ages, does not produce obvious influences on concrete work performances, obviously improves anti-chloride ion penetration capability of concrete, reduces total shrinkage of concrete and improves crack resistance of concrete.

Owner:WUHAN UNIV OF TECH +1

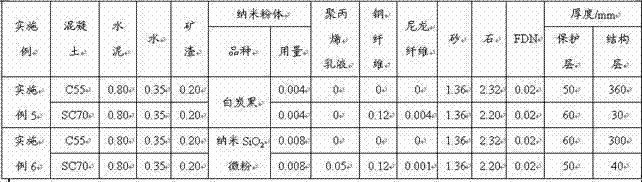

High-performance functionally-gradient shield lining segment and preparation method thereof

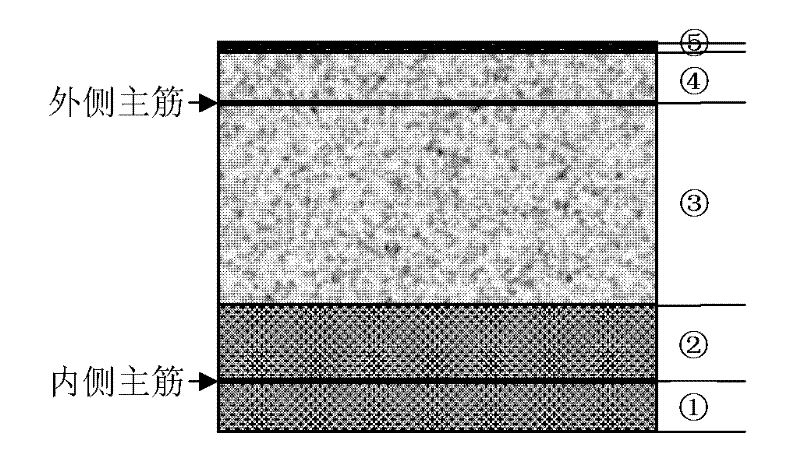

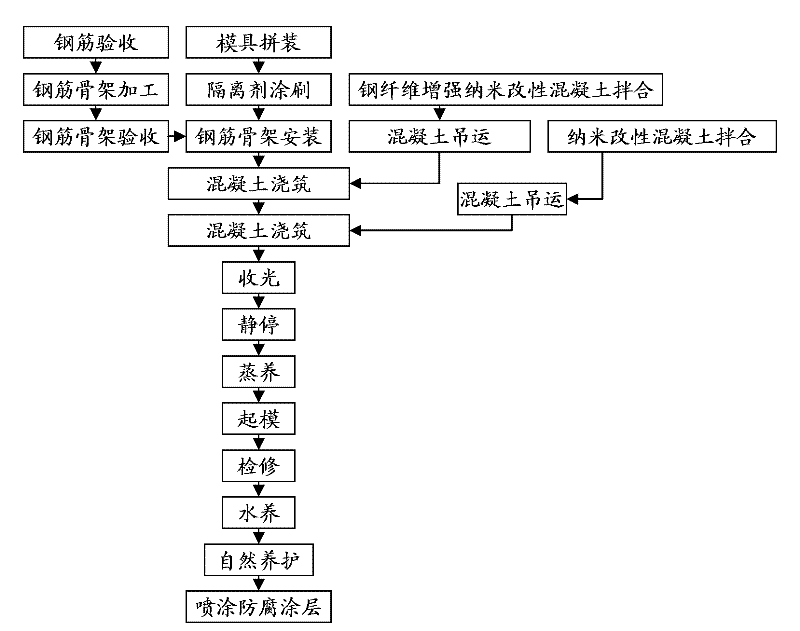

InactiveCN102207000AReduce breakage rateImproves carbonation resistanceUnderground chambersWater-setting substance layered productFiberReinforced concrete

The invention discloses a high-performance functionally-gradient shield lining segment and a preparation method thereof. The high-performance functionally-gradient shield lining segment, from top to bottom, sequentially comprises an external nano-modified concrete protection layer, an external nano-modified concrete structure layer, an internal steel fiber reinforced nano-modified concrete toughening structure layer and an internal steel fiber reinforced nano-modified concrete toughening protection layer, wherein the external nano-modified concrete protection layer and the external nano-modified concrete structure layer are connected into a whole; and the internal steel fiber reinforced nano-modified concrete toughening structure layer and the internal steel fiber reinforced nano-modifiedconcrete toughening protection layer are connected into a whole. The invention effectively solves the problems that the existing reinforced concrete segment is easy to damage, poor in durability and low in cost and the like because the existing reinforced concrete segment is completely prepared from high-toughness concrete.

Owner:ZHEJIANG UNIV OF TECH +1

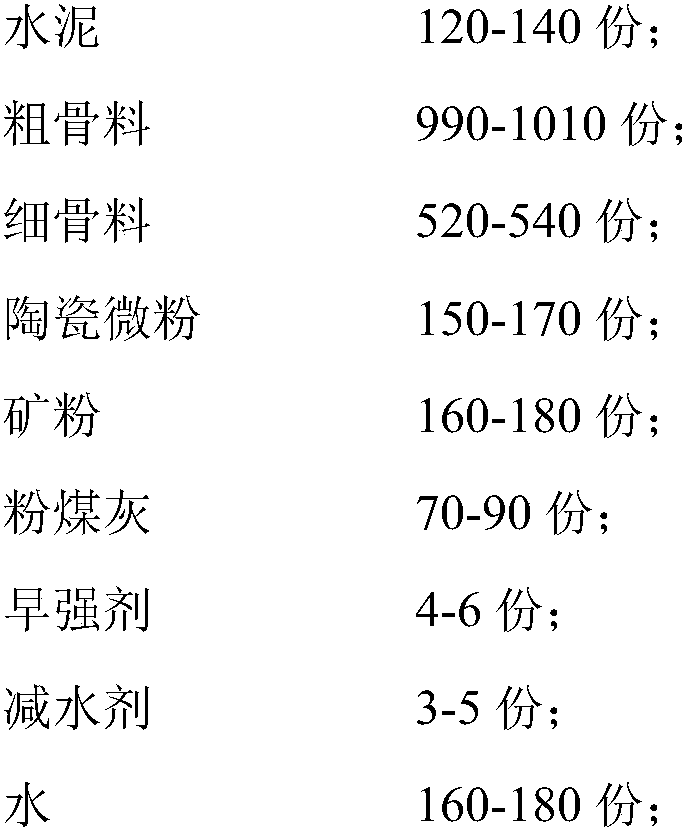

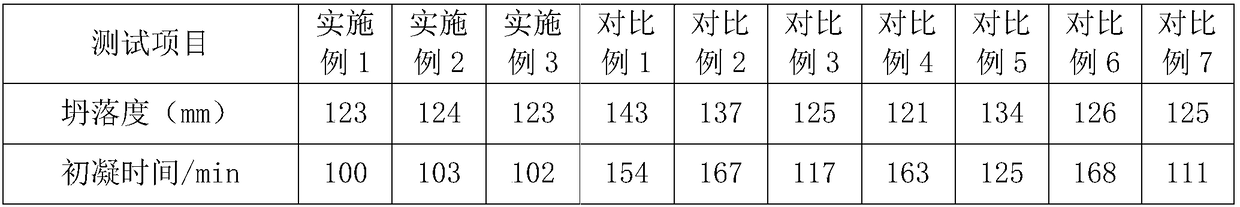

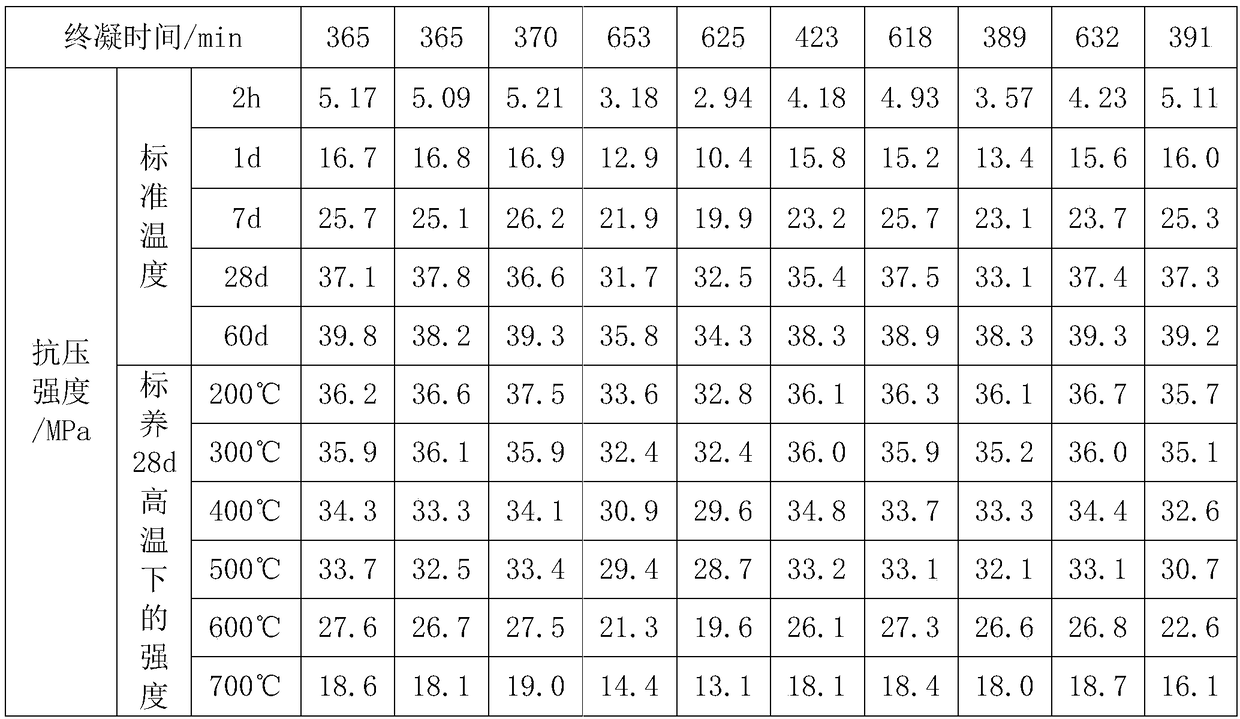

Heat-resistant concrete and preparation method thereof

The invention discloses heat-resistant concrete and a preparation method thereof and belongs to the technical field of concrete. According to key points of the technical scheme, the heat-resistant concrete comprises the following components in parts by weight: cement, coarse aggregate, fine aggregate, ceramic ultrafine powder, mineral powder, fly ash, an early strength agent, a water reducing agent and water. The coarse aggregate refers to basalt gravel and barite gravel; the fine aggregate refers to grain slag; the early strength agent comprises calcium formate and sodium silicate; the waterreducing agent comprises an early strength polycarboxylic water reducer. By replacing medium sand with grain slag, the grain slag can be effectively utilized, the long-term strength of the concrete can be improved, the heat resistance of the concrete is improved by the basalt gravel, the barite gravel and the ceramic ultrafine powder, the defects that low early strength of the concrete is broughtby the grain slag and the water demand is large can be overcome through the early strength agent and the water reducing agent, the compactness of the concrete is improved, and the compressive strengthof the concrete is improved.

Owner:北京建工新型建材有限责任公司

High-performance concrete admixture in use of waste ceramic powder and implementing method thereof

InactiveCN104817287AThe stability result is qualifiedImprove liquiditySolid waste managementEnvironmental resistanceFiber

The invention discloses a high-performance concrete admixture in use of waste ceramic powder and an implementing method thereof. The high-performance concrete admixture is prepared by the following steps: utilizing waste ceramics as a main material and utilizing active seed crystals and a modified enhancer as auxiliary materials; performing modified treatment and high-temperature smelting on various materials, then putting into a cement mill to mill the materials to be pre-finished products with specific area of 300-450 m2 / kg, and finally, doping mixed fibers. The high-performance concrete admixture comprises the raw materials in parts by weight: 80-100 parts of waste ceramic powder, 6-9 parts of active seed crystal, 2-6 parts of modified enhancer and 5-10 parts of mixed fibers. By adopting mixed ceramic powder, density of cement mortar is effectively increased; strength of concrete is improved and durability of concrete is remarkably improved. Energy problems are solved, and meanwhile, an environmental protection purpose is considered; the high-performance concrete admixture has remarkable technical, economic and social benefits.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Compound concrete anti-corrosion and rust-resistant agent

The invention discloses a compound concrete anti-corrosion and rust-resistant agent which comprises the following components in parts by weight: 15-30 parts of a polycarboxylic acid water reducing agent, 3-12 parts of sodium dodecyl sulfate, 15.7-20.6 parts of N-dimethylethanolamine, 1-5 parts of sodium molybdate, and 50-60 parts of water. The compound concrete anti-corrosion and rust-resistant agent can block capillary holes in the concrete, improves the chloride ion permeability resistance of concrete, can significantly alleviate the damage of chloride ions on a reinforcing steel bar passivation film, enhances the sulfate corrosion resistant ability of the concrete, has excellent rust-resistant performance and good repair performance, can enhance durability of the concrete and the comprehensive anti-corrosion ability of the concrete, and significantly improves the durability of buildings.

Owner:HUNAN CONSTR ENG GRP COR +1

Fiber reinforced concrete and preparation method thereof

ActiveCN106116364AImprove mechanical propertiesImprove resistance to chloride ion penetrationElastic modulusCement slurry

The invention discloses fiber reinforced concrete and a preparation method thereof. The fiber reinforced concrete is prepared from the following components in parts by weight: portland cement 500-600 parts, flyash 600-800 parts, sand 200-300 parts, water 250-300 parts, polyvinyl chloride modified glass fibers 50-80 parts, a water reducer 20-30 parts, and nano packing 50-70 parts. Polyvinyl chloride slices are used for modifying the glass fibers so as to improve mechanical performance of fibers, and the tensile strength, elastic modulus and the like of the fibers are improved by about 10%. Then the fibers are added in cement slurry, chloride penetration resistance of a cement base body can be improved remarkably, the impermeability is improved by 20-30%, the mechanical performance is improved by 25-30%, the bending deflection can reach 20-30 mm, the fiber reinforced concrete can well adapt to effect of repeated load of a bridge structure, the structure repair and reinforcement effect can be improved remarkably, and the service life is prolonged.

Owner:江苏狮腾工程材料有限公司

High-durability damping concrete and preparation method thereof

The invention discloses a high-durability damping concrete and a preparation method thereof, and relates to several concretes and a preparation method thereof. The invention solves the problems of low damping capability and poor durability of the conventional concrete structure material per se. The high-durability damping concrete is prepared by stirring and mixing cements, rubber powder, water, medium sand, stones, and adding fibers and silicon powder. In the invention, c the loss factors of the high-durability damping concrete are improved by about 80-200 percent compared with that of pain concrete under the condition of different frequencies. After maintenance for 28 days, the concrete prepared by using the method has chloridion-resistant permeability and carbonizing-resistant capability both superior to that of blank concretes.

Owner:刘铁军

High-performance nanofiber modified polymer cement-based repairing mortar and preparation method thereof

The invention relates to a high-performance nanofiber modified polymer cement-based repairing mortar. The repairing mortar comprises, by mass, 25.0-29.5% of cement, 52.2-52.7% of quartz sands, 1.4-2.0% of dispersible latex powder, 0.4-1.0% of nano-SiO2, 3.5-5.2% of fly ash, 1.8-3.5% of metakaolin, 0.07-0.14% of fibers, 0.18-0.24% of a water reducer, 0.03-0.04% of a silicone antifoaming agent, 0.01-0.02% of cellulose ether, and the balance of water. The invention discloses a preparation method of the repairing mortar. The method of the invention is simple and is easy to implement, and the obtained repairing mortar has excellent performances, and is suitable for repairing the reinforced concrete structure.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

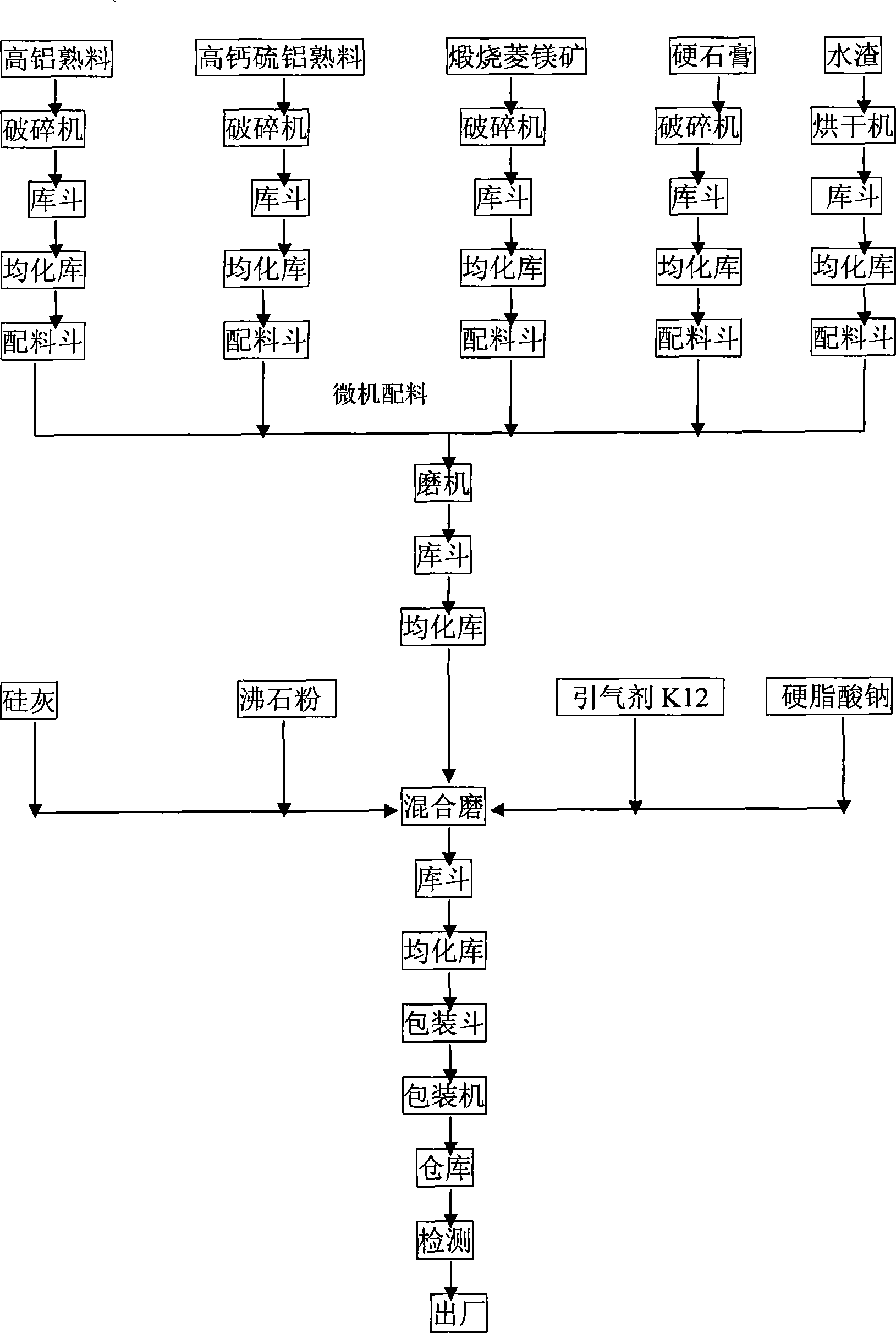

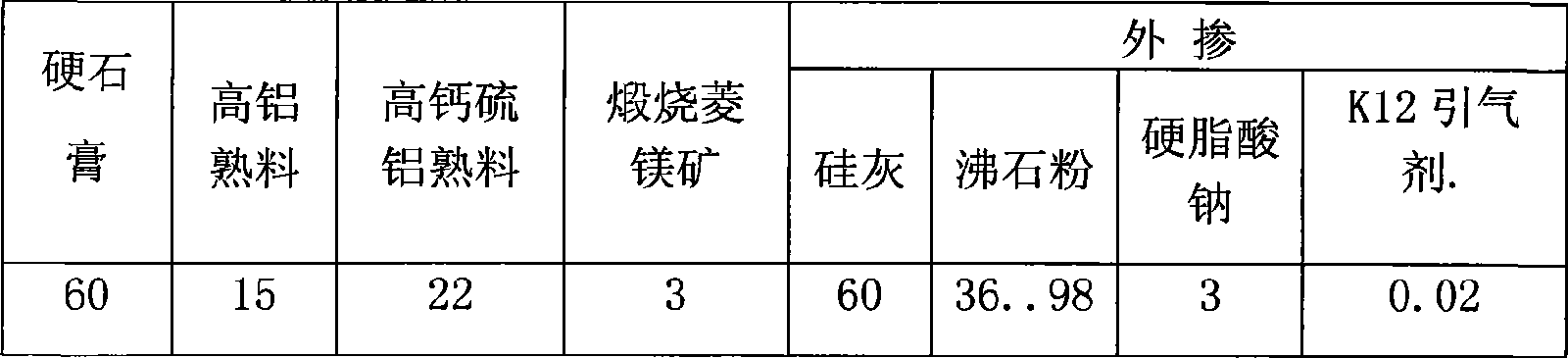

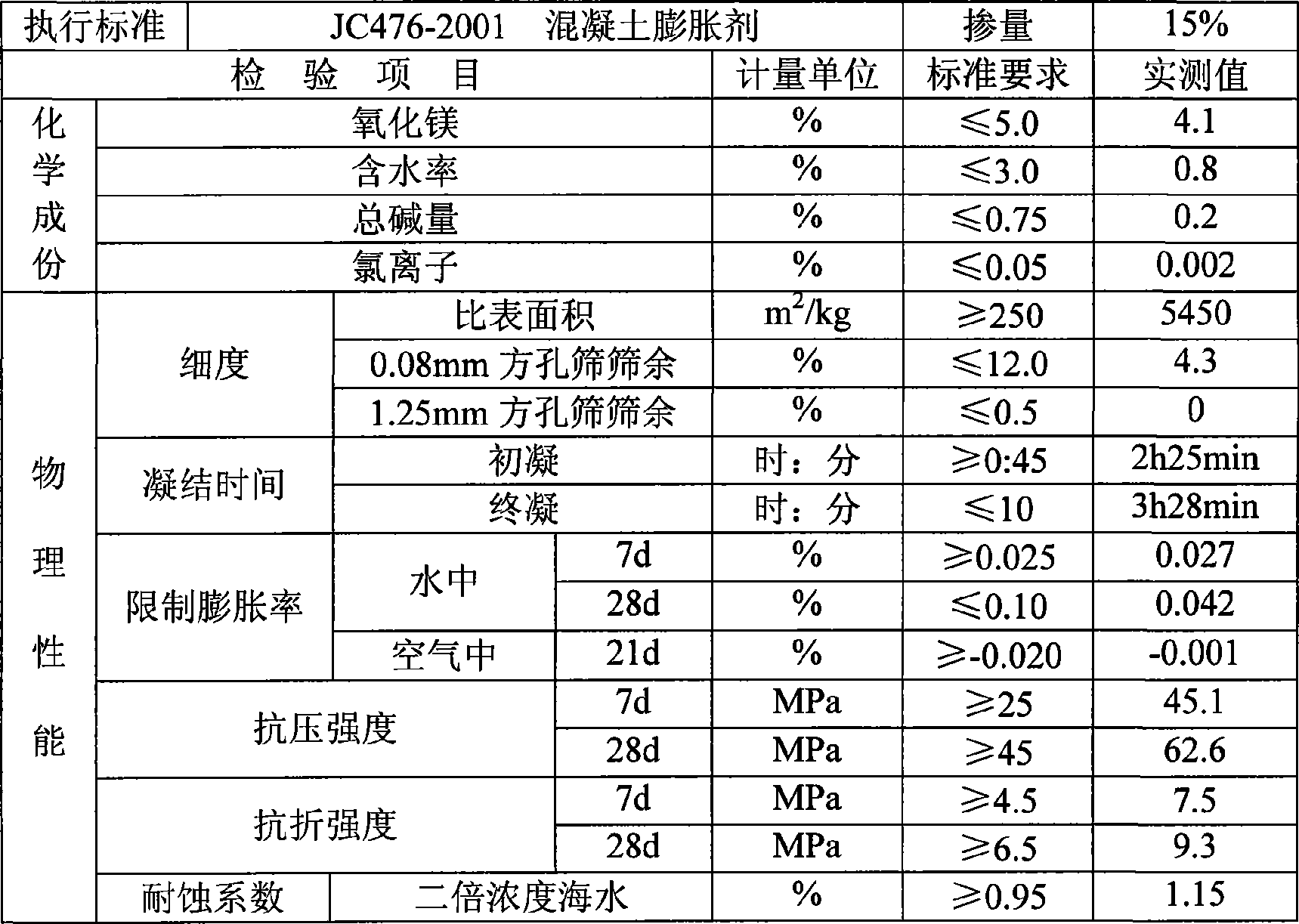

Durable type three-expansion source cement expansive material

InactiveCN101456694AImprove resistance to chloride ion penetrationImprove permeabilitySolid waste managementSodium stearateCrack resistance

The invention discloses durable three expansion source concrete expanding agent, which is characterized by comprising anhydrite, high-aluminum clinker, high calcium-sulfur-aluminum clinker, calcined magnesite and the like as the preparation raw materials according to a weight proportion, in addition, the raw materials are added with air entraining agent K12, siliceous dust, zeolite powder and water repellent sodium stearate. A preparation method comprises steps of crushing, common blending, blended powder grinding and external finished product blending. The expanding agent has low alkali content, has certain expansibility, and improves cracking resistance and impermeability of concrete. The expanding agent after being added into the concrete can remarkably improve compactness, impermeability, anti-scouring property and abrasion-resisting property of the concrete, reduces permeability and water absorption greatly so that the concrete has higher self-defending capability and environmental medium erosion resistance, improves sulphate erosion resistance and carbonizing resistance of the concrete greatly, is favorable for improving safety and durability of the reinforced concrete, and is suitable for various concretes.

Owner:广西云燕特种水泥建材有限公司

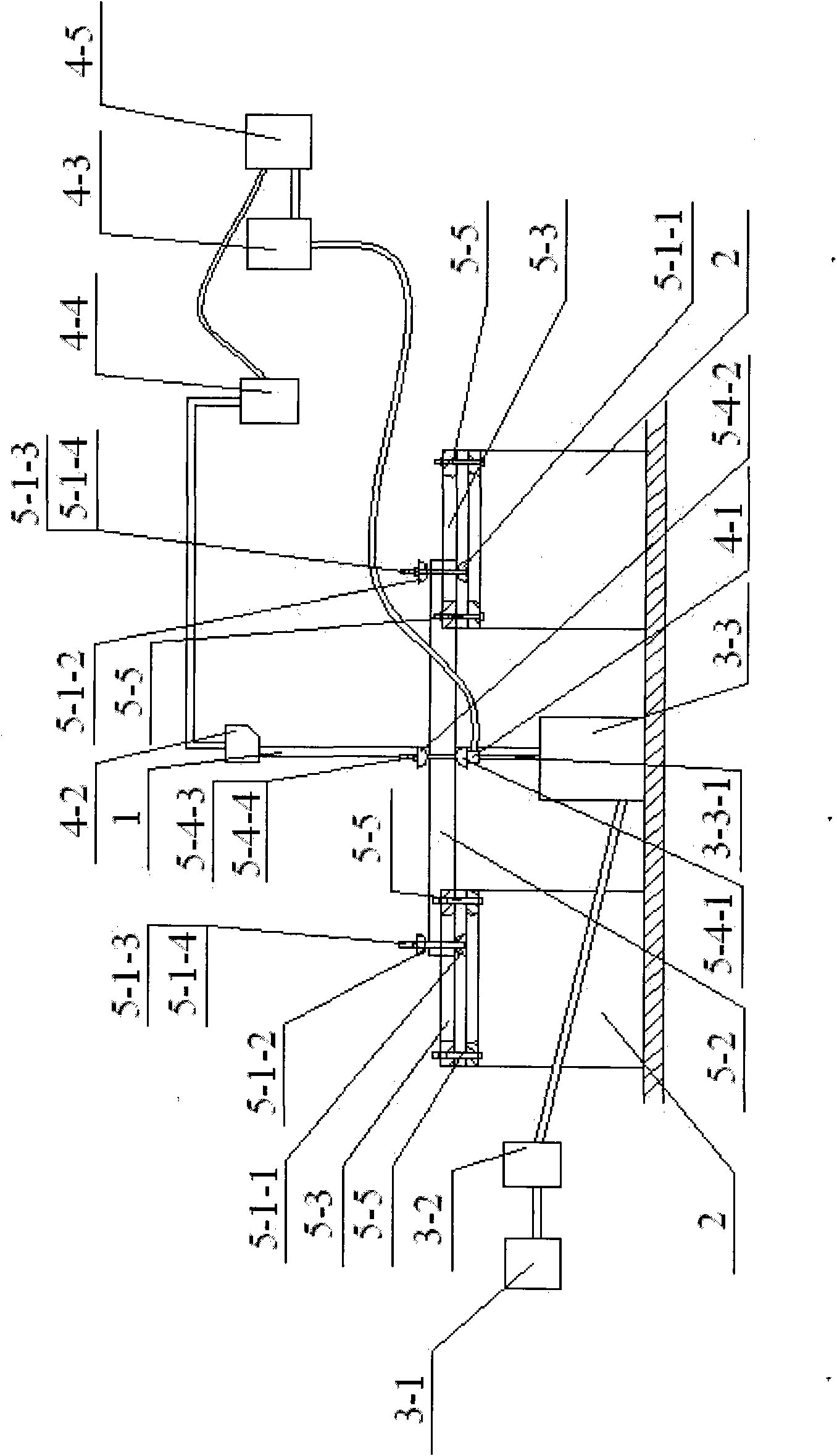

Slope reinforcement improvement device for building municipal engineering

ActiveCN105926649AImprove resistance to chloride ion penetrationExtended service lifeExcavationsArchitectural engineeringEngineering

The invention discloses a slope reinforcement improvement device for building municipal engineering. The slope reinforcement improvement device comprises a long straight hollow cylinder body. An external thread is arranged on the outer wall of the cylinder body, a bearing is fixed to the upper position on the inner wall of the cylinder body, a guide rod is installed on an inner ring of the bearing in an interference manner, and the guide rod and the cylinder body are located on the same axis. A spiral part and a threaded part are sequentially arranged on the lower portion of the guide rod from top to bottom. Gear inserted rods are installed on the two sides of the cylinder body. Each gear inserted rod comprises a gear end and an inserted rod end which are connected, wherein the gear end is rotationally installed on the cylinder body through a rotating shaft, a part of the gear end is located in the cylinder body and engaged with the spiral part of the guide rod. The slope reinforcement improvement device is reasonable in structure design, and stability is improved by combining the unfoldable gear inserted rods and concrete mortar in a drill hole.

Owner:盛晓州 +3

Modified cement and application thereof

InactiveCN103130467APromotes hydrationImprove the resistance to electrochemical corrosionSlagWater reducer

The invention relates to modified cement and application thereof, belonging to the field of preparation of construction materials. The modified cement is characterized in that the modified cement comprises a cementing material and an additive, wherein the cementing material is composed of normal cement and slag micropowder, and the slag micropowder accounts for 40-60% of the total weight of the cementing material; and additive is composed of nano clay particles and a water reducing agent, the weight of the nano clay particles is 1% of the total weight of the cementing material, and the weight of the water reducing agent is 1.5-2% of the total weight of the cementing material. According to the invention, heavily-doped slag micropowder high-performance concrete is prepared by selecting materials as required according to the mixture ratio, the electrochemical etching resistance of the concrete can be obviously enhanced, the impermeability can be enhanced by 40-60%, the freezing resistance can be enhanced by more than 30%, the steel bar rust resistance can be enhanced 2-4 times, and the service life of a concrete structure can be prolonged 3-4 times.

Owner:DALIAN MARITIME UNIVERSITY

Polyaniline coating capable of blocking and controlling chlorine ion penetration and preparation method thereof

ActiveCN103834209APrevent oxidationReduce spreadAnti-corrosive paintsPhysical chemistryPetrochemical

The invention discloses a polyaniline coating capable of blocking and controlling chlorine ion penetration and a preparation method thereof. The polyaniline coating capable of blocking and controlling the chlorine ion penetration comprises the following components in parts by weight: 35-85 parts of film forming substance, 1-25 parts of polyaniline, 0.01-10 parts of chlorine ion blocking and controlling agent, 0.1-5 parts of pigment, 1-15 parts of filler, 0.01-2 parts of anti-sag agent, 0.01-2 parts of dispersing agent, 0.01-2 parts of leveling agent, 0.01-0.5 part of defoaming agent and 5-65 parts of solvent. The preparation method comprises steps that components except polyaniline and chlorine ion blocking and controlling agent are uniformly stirred, then polyaniline and chlorine ion blocking and controlling agent are added, then grinding is carried out in a coating grinder and discharging is carried out after fineness is less than 60 microns. The polyaniline coating capable of blocking and controlling the chlorine ion penetration has the advantage that corrosion resistance and chlorine ion penetration resistance are obviously improved and can be applied to heavy corrosion protection projects such as petrochemical equipment, pipelines, oil platforms on the sea, wharf facilities and ships, especially applicable to heavy corrosion coating operation on the sea.

Owner:HOHAI UNIV

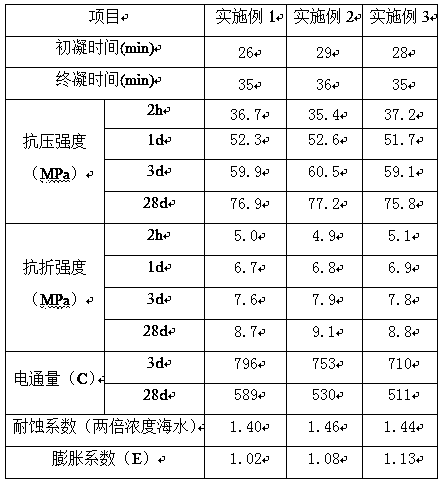

Marine sulphoaluminate cement for rapid construction and preparation method thereof

The invention discloses marine sulphoaluminate cement for rapid construction and a preparation method thereof. The marine sulphoaluminate cement is prepared from the following raw materials in parts by weight: 40-60 parts of sulphoaluminate cement clinker, 5-10 parts of modified nano calcium carbonate, 0.05-0.2 part of an efficient water reducing agent, 0-4 parts of a setting accelerator, 6-8 parts of an anti-cracking waterproof expanding agent, 3-5 parts of redispersible latex powder, 10-15 parts of clinker sea sand, 2-5 parts of silica fume, 6-10 parts of granulated blast furnace slag powderand 0.01-0.1 part of modified graphene. Concrete prepared from the marine sulphoaluminate cement can be quickly cured, has high early strength, can reach the demolding strength earlier, can be widelyapplied to ocean engineering buildings, and meets the requirement of quick construction in an ocean environment.

Owner:广西云燕特种水泥建材有限公司

Antifouling and corrosion-resistant marine cement and preparation method thereof

InactiveCN110698142AOvercome the problem of high chloride ion concentrationImprove resistance to chloride ion penetrationCrushed stoneGARLIC POWDER

The invention discloses antifouling corrosion-resistant marine cement and a preparation method thereof. The marine cement is prepared from the following raw materials in parts by weight: 32-48 parts of marine silicate cement clinker, 1-1.5 parts of a modified polycarboxylic acid water reducing agent, 5-15 parts of laver powder, 2-6 parts of garlic powder, 10-15 parts of acrylate, 1-5 parts of silane coupling agent microcapsules, 30-40 parts of basalt crushed stone, 3-5 parts of nano silica, 0.5-1 part of calcined attapulgite and 10-15 parts of clinker marine sand. The slurry structure preparedby the marine cement product has good compactness and volume stability, and the formed concrete has excellent impermeability, bacteriostasis, antifouling and crosslinking properties, and has high chloride ion diffusion resistance and sulfate erosion resistance, thus meeting the requirements of marine engineering construction.

Owner:广西云燕特种水泥建材有限公司

Salt-freezing-resisting high-performance repairing mortar for repairing road concrete bridge

The invention relates to salt-freezing-resisting high-performance repairing mortar for repairing a road concrete bridge. The salt-freezing-resisting high-performance repairing mortar is prepared fromthe following raw materials: ordinary portland cement, granulated blast-furnace slag powder, fly ash, silicon ash, quartz sand, modified sulfonated melamine, redispersible latex powder, a de-foaming agent, starch ether and polyacrylonitrile fibers. The salt-freezing-resisting high-performance repairing mortar provided by the invention has the advantages that the salt-freezing-resisting high-performance polymer repairing mortar has relatively high durability and especially has extremely high salt freezing ablation resisting performance, freezing and thawing resisting performance and chloride ions penetration resisting performance.

Owner:LIAONING PROVINCIAL TRANSPORTATION PLANNING & DESIGN INST

High anti-permeability basalt fibre concrete and preparation method thereof

InactiveCN107010900AImprove workabilityImprove resistance to chloride ion penetrationStructure of the EarthBasalt fiber

The invention discloses high anti-permeability basalt fibre concrete. The high anti-permeability basalt fibre concrete is prepared from, by weight, 22 parts of cement, 35 parts of fine aggregate, 16 parts of coarse aggregate, 8 parts of water, 0.05 part of water reducing agent and 0.1 part of synergist. The concrete raw material further comprises doping material, and the doping material refers to short-cutting basalt fiber and fly ash, wherein the doping amount of short-cutting basalt fiber is 1.2 kg / m3, and the doping amount of fly ash is 30wt% of total weight of concrete gel. Through optimizing the mixture ratio of short-cutting basalt fiber and fly ash, the chloridion permeability resistance of concrete is effectively improved; the prepared concrete is applicable to the underground structure enriched in underground water, maritime work structures built in coastal regions, and other concrete projects; the economic loss is greatly reduced, and the concrete industry development is significantly promoted.

Owner:FUJIAN JIANGXIA UNIV

Preparation method of ductile retarding fine aggregate concrete with initial setting time of 48-72 hours

ActiveCN111533512AImprove pore structureImprove early strengthReinforced concreteArchitectural engineering

The invention discloses a preparation method of ductile retarding fine aggregate concrete with initial setting time of 48-72 hours, belongs to the technical field of building construction, and particularly relates to a preparation technology of the ductile retarding fine aggregate concrete. Cement, fly ash, slag powder and a reinforcing compacting agent are adopted to form a cementing material, and the fly ash, the slag powder and the reinforcing compacting agent not only improve the performance of a concrete mixture, but also can improve the early-stage or later-stage strength of concrete, improve the pore structure and improve the compaction performance of the concrete; meanwhile, the effects of saving resources and protecting the environment are achieved. The concrete is suitable for pier wall reinforced concrete structures in the fields of construction engineering, water conservancy engineering, traffic engineering, water transportation engineering and the like, a layer of ductileretarding concrete is poured at the root of the pier wall, and the concrete can also be suitable for underground secant piles and structural construction joints needing to be poured by several times.

Owner:JIANGSU WATER CONSERVANCY SCI RES INST +5

Graphene concrete composite material resistant to chloride ion penetration and preparation method thereof

The invention relates to a graphene concrete composite material resistant to chloride ion penetration and a preparation method thereof. The composite material includes, by mass, 6-20 parts of cement,1-10 parts of fly ash, 12-33 parts of sand, 25-50 parts of aggregate and 3-8 parts of a solution containing graphene and a water reducing agent, with the sum of the components being 100 parts. The solution containing the graphene and the water reducing agent is prepared by adding graphite into a water-ethanol mixture solution containing the water reducing agent, and then performing ultrasonic treatment, wherein the mass percentage of graphene is 0.5-10%. Research proves that the composite material has obviously improved mechanical performance and obviously improved resistance to chloride ion penetration and is of great significance to development of high-performance highly-functional cement concrete materials.

Owner:陕西燕园众欣石墨烯科技有限公司

Reinforcing steel bar rust-prevention material applicable to interior of concrete and application of reinforcing steel bar rust-prevention material

The invention relates to the technical field of building materials, in particular to a reinforcing steel bar rust-prevention material applicable to the interior of concrete and application of the reinforcing steel bar rust-prevention material.The reinforcing steel bar rust-prevention material is formed by mixing solid powder and mixed liquid in proportion and can directly act on the surfaces of reinforcing steel bars inside the concrete without affecting cohesiveness between the reinforcing steel bars and the concrete.The reinforcing steel bar rust-prevention material is simple in application method, more direct in rust-prevention effect and longer in anti-rust effect, and meanwhile the material has the advantages of being great in chloridion curing capability and great in surface alkality, so that the material is greater in anti-rust capability.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

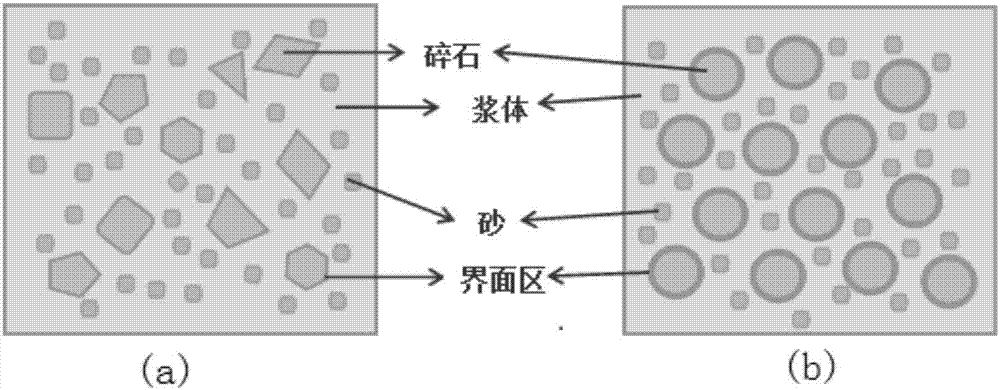

High-strength lightweight aggregate concrete based on arch shell-shaped interface region and preparation method thereof

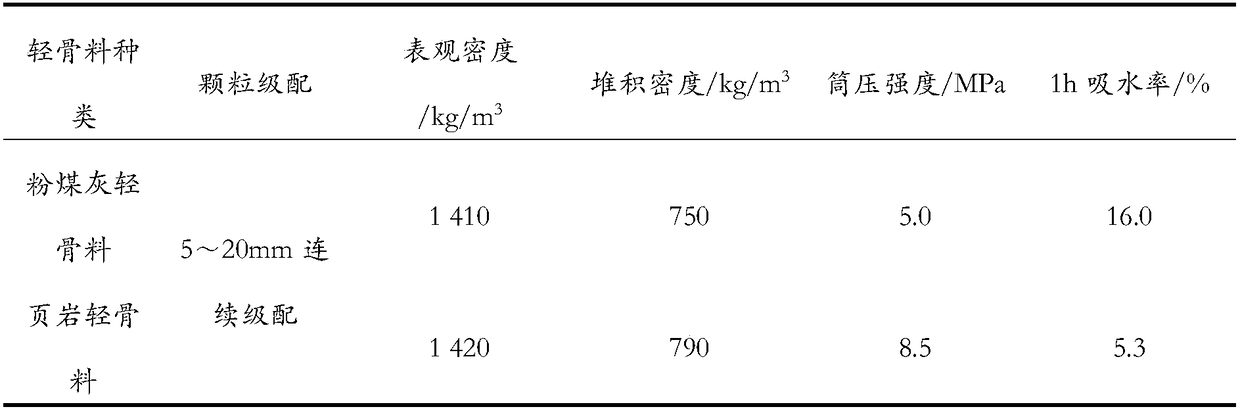

The invention belongs to the field of building materials, and concretely relates to a high-strength lightweight aggregate concrete based on an arch shell-shaped interface region and a preparation method thereof. The high-strength lightweight aggregate concrete is prepared from the components: 400 to 500 kg / m<3> of cement, 40 to 80 kg / m<3> of pulverized fuel ash, 10 to 60 kg / m<3> of silica fume, 520 to 640 kg / m<3> of lightweight aggregate, 600 to 800 kg / m<3> of river sand, 6 to 8 kg / m<3> of high-efficient water reducer, 0.2 to 0.3 kg / m<3> of tackifier, 18 to 24 g / m<3> of air entraining agent, and 140 to 170 kg / m<3> of water. The high-strength lightweight aggregate concrete provided by the invention mainly adopts a spheroidal lightweight aggregate as an aggregate, and an internal curing effect and an arch shell interface effect of a prewet spheroidal lightweight aggregate are utilized, so that the lightweight aggregate concrete has performances of light weight, high strength, impermeability and corrosion resistance, the workability of the high-strength lightweight aggregate concrete is better, the lightweight aggregate is not easy to float upwards, and the concrete is high in strength, good in endurance quality and not easy to crack.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE +1

Slope reinforcing device for construction municipal civil engineering

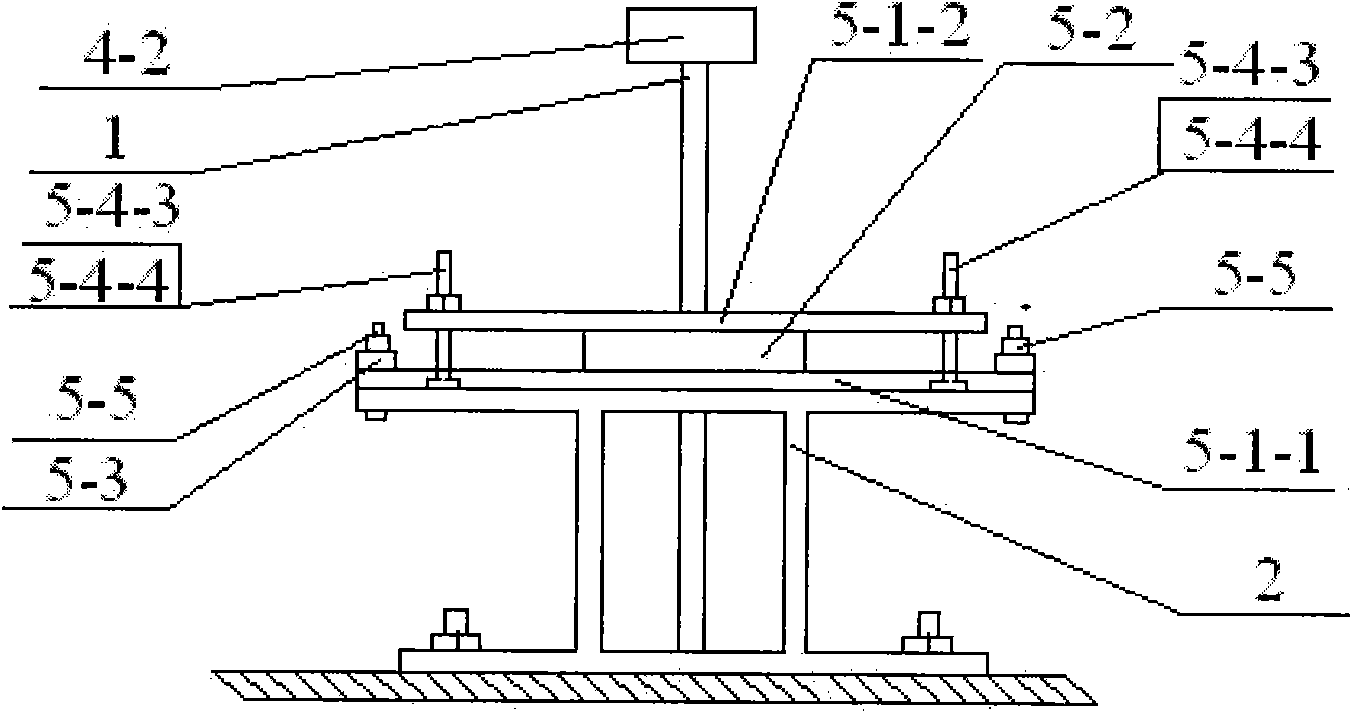

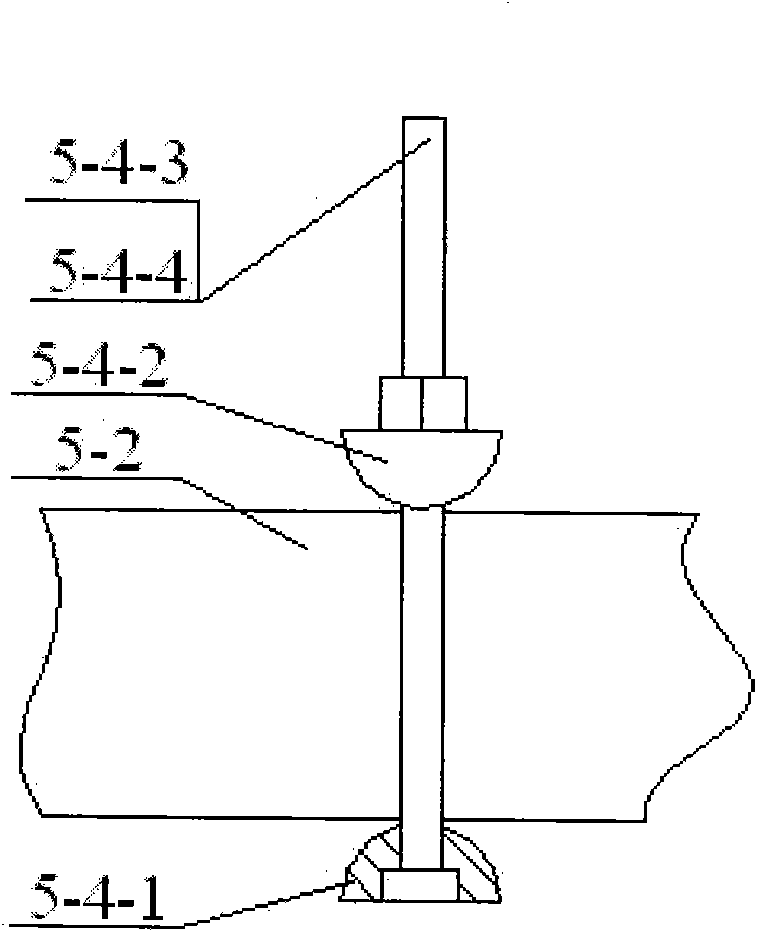

ActiveCN106149735AImprove resistance to chloride ion penetrationExtended service lifeAnti-corrosive paintsExcavationsGear wheelScrew thread

The invention discloses a slope reinforcing device for construction municipal civil engineering. The slope reinforcing device for construction municipal civil engineering comprises a hollow, long and straight barrel body, wherein external threads are formed in the outer wall of the barrel body, a bearing is fixed to the upper portion of the inner wall of the barrel body, a guide rod is installed on the inner ring of the bearing in an interference manner, the guide rod and the barrel body are located on the same axis, a screw portion and a thread portion are arranged on the lower portion of the guide rod from top to bottom in sequence, gear insertion rods are installed on the two sides of the barrel body, each gear insertion rod comprises a gear end and an insertion rod end which are connected, each gear end is rotationally installed on the barrel body through a rotary shaft, and part of each gear end is located inside the barrel body and is meshed with the screw portion of the guide rod. The slope reinforcing device for construction municipal civil engineering is reasonable in structural design, and because the foldable gear insertion rods are combined with the concrete mortar in drill holes, stability is improved.

Owner:江苏远建市政工程有限公司

Chloride ion permeation resistant concrete and construction method thereof

ActiveCN111410461AImprove resistance to chloride ion penetrationHigh hardnessBuilding material handlingSilica fumeBuilding material

The invention belongs to the technical field of concrete building materials, and particularly relates to chloride ion permeation resistant concrete and a construction method thereof. The raw materialsof the chloride ion penetration resistant concrete comprise the following components in parts by weight: 250-280 parts of cement, 50-80 parts of fly ash, 50-60 parts of mineral powder, 620-700 partsof yellow sand, 1000-1200 parts of crushed stone, 120-190 parts of water, 15-28 parts of silica fume, 5-8 parts of a water reducing agent and 6-15 parts of a compacting agent. Through the filling andenhancing effects of the compacting agent and the silica fume and the adjustment of the water reducing agent and the modified fiber, the internal gap of the concrete is compactly filled, so that the chloride ion penetration resistance of the concrete is improved, the impermeability grade of the formed concrete is greater than or equal to P8, and the solid concrete is compact and smooth in surface,free of cracks and good in durability.

Owner:浙江广天构件集团股份有限公司

Erosion-resistant concrete with self-healing capability

The invention discloses erosion-resistant concrete with self-healing capability, which is prepared from the following raw materials in parts by weight: 40 to 65 parts of maritime work Portland cementclinker, 35 to 43 parts of solid waste powder, 6 to 8 parts of alkali-containing waste, 11.4 to 28.4 parts of alkali activator, 1.0 to 10.0 parts of modified straw, 106 to 109 spores per square meterof water, 2 to 3 parts of titanium dioxide, 10 to 15 parts of additive and 1 to 5 parts of capsule binder. The invention aims to solve the technical problems of short service life and weak seawater corrosion resistance caused by high brittleness and low tensile strength of the existing cement.

Owner:SHANGHAI DUOMAO BUILDING MATERIALS CO LTD

Mass concrete and preparation method thereof

The invention relates to the field of concrete, and particularly discloses mass concrete as well as a preparation method and application thereof. The mass concrete is prepared from the following raw materials in parts by weight: 340-355 parts of cement; 40 to 45 parts of fly ash; 100 to 110 parts of mineral powder; 680 to 720 parts of fine aggregate; 1080 to 1100 parts of coarse aggregate; 7-9 parts of a water reducing agent; and 135 to 145 parts of water. The preparation method comprises the following steps: weighing the cement, the fly ash, the mineral powder, the fine aggregate and the coarse aggregate in proportion, and uniformly mixing and stirring to obtain a first mixture; and weighing the water reducing agent and the water according to the proportion, adding the weighed water reducing agent into the water, uniformly mixing, adding the water doped with the water reducing agent into the first mixture, and uniformly stirring to obtain the mass concrete. The mass concrete has the advantages that the crack generation probability is reduced, and the crack generation amount is reduced.

Owner:襄阳嘉众和建材实业有限公司

Rice hull ash modified rubber concrete and preparation method thereof

InactiveCN111875319AImprove mechanical propertiesImprove impermeabilityBreaking strengthCompressive resistance

The invention relates to rice hull ash modified rubber concrete which is prepared from the following raw materials in parts by weight: 154-192 parts of cement, 520 parts of coarse aggregate, 154-192 parts of fine aggregate, 3.8-15.1 parts of rubber particles, 9.6-38.4 parts of rice hull ash and 96 parts of water. The preparation method of the rice hull ash modified rubber concrete comprises the following steps: cleaning 40-80 mesh rubber particles with water, and drying the rubber particles in a drying oven at 80 DEG C to obtain rubber particles; preparing raw materials according to a weight ratio; putting the weighed cement, coarse aggregate, fine aggregate and rubber particles into a stirring pot, starting a stirrer to stir the materials for 1 min, then adding rice hull ash, and continuously stirring the materials for 1 min until the materials are uniformly mixed; and adding water into the stirring pot, continuously stirring the materials for 3 minutes, pouring the mixture into a mold for pouring molding, and curing the molded product for 28 days to obtain the rice hull ash modified rubber concrete. Compared with rubber concrete, the rice hull ash modified rubber concrete has theadvantages that the compressive strength and breaking strength are greatly improved, the durability is improved, and the rice hull ash modified rubber concrete has remarkable environment-friendly, economic, energy-saving and emission-reducing significance.

Owner:ANHUI UNIV OF SCI & TECH

Aggregate treatment method for improving chloride ion permeability resistance of concrete

The invention provides an aggregate treatment method for improving chloride ion permeability resistance of concrete. The method comprises the following steps: pre-wetting plastic steel fiber lightweight aggregate by using mineral admixture slurry or a concrete permanent setting solution. According to the technical scheme of the invention, the lightweight aggregate is pre-wetted by using the mineral admixture slurry or the concrete permanent setting solution, so that chloride ion diffusion parameters of plastic steel fiber lightweight aggregate concrete are effectively reduced, and the chlorideion permeability resistance of the plastic steel fiber lightweight aggregate concrete is improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Method for improving chlorine ion penetration resisting ability of cement-based material

InactiveCN110550919AReduce the degree of reunionImprove work performanceModified carbonChloride ion penetration

The invention provides a method for improving the chlorine ion penetration resisting ability of a cement-based material, and relates to the field of chlorine ion penetration resisting materials. According to the method, cement is taken as a base material, wherein the base material is prepared from main components of high-belite sulfoaluminate cement, and a composite material is prepared from components in parts by mass: 0.1-0.5 part of a modified carbon nanotube, 400-500 parts of high-belite sulfoaluminate cement, 200-250 parts of water, 1200-1400 parts of standard sand, and 0.2-0.4 part of asurfactant. According to the method for improving the chlorine ion penetration resisting ability of the cement-based material, compared with the high-belite sulfoaluminate cement-based material without adding of the carbon nanotube, the chlorine ion penetration resistance is improved.

Owner:BEIJING UNIV OF TECH

Nano recycled concrete, processing technology and application thereof

ActiveCN113307597ARealize water retention functionAids in water retentionAdditive manufacturing apparatusSolid waste managementElectrolytic agentPolyvinyl alcohol

The invention particularly relates to nano recycled concrete, a processing technology and an application thereof. The existing nano recycled concrete also has the following defects that the corrosion prevention effect is not ideal when a conventional marine corrosion prevention technology is applied to a coastal assembly structure for 3D printing, and in addition, interlayer interface bonding and thixotropy of a conventional 3D printing material are insufficient. The invention provides nano recycled concrete. The nano recycled concrete is prepared from the following raw materials: compound cement, recycled sand, fly ash, polyvinyl alcohol, graphene oxide, steel fibers, organic fibers, a water reducing agent, a thickening time control agent, a mineral admixture and water. The 3D printing concrete has good cohesive water-retaining property and adjacent thin layer interface cohesiveness, a micro-capacitor is formed through combination of GO and PVA electrolyte to avoid formation of a corrosion battery in a concrete thin layer, and the 3D printing concrete has good marine durability and has good application prospects when being applied to coastal assembly structure engineering.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

A Chloride Ion Curing Agent

The invention discloses a chloride ion immobilizing agent and an application method thereof, and belongs to the field of civil engineering materials. The chloride ion immobilizing agent is obtained by thoroughly mixing a layered double hydroxide (LDH) and a substance which can be hydrated to generate the LDH in certain parts by mass; chloride ion immobilization is realized by virtue of a chemical reaction between Ca-Al-LDH and a water reducing agent intercalation product (Ca-Al-SP-LDH) thereof, and a chlorine salt and meanwhile by use of the ion exchange characteristic of Ca-Al-Si-LDH and Mg-Al-LDH; as a result, the adverse effect of internal chloride ions on the properties of a cement-based material is reduced, the erosion action of the chloride ions to a reinforcement is relieved, and the chloride ions in the service environment are prevented from permeation and diffusion into the reinforced concrete. When the dosage of the chloride ion immobilizing agent accounts for 2%-5% of the weight parts of a cementing material, the immobilization rate of chloride ions inside the concrete is greater than 90%; internal doping or surface coating protection is capable of enabling the reinforced concrete impermeability to the chloride ions to be improved by I to II levels; the chloride ion immobilizing agent is suitable for sea sand concrete, marine concrete and mortar, magnesium oxychloride cement products, steel structures and reinforcements as well as concrete anticorrosive paints.

Owner:HOHAI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com