Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Prolong the retarding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

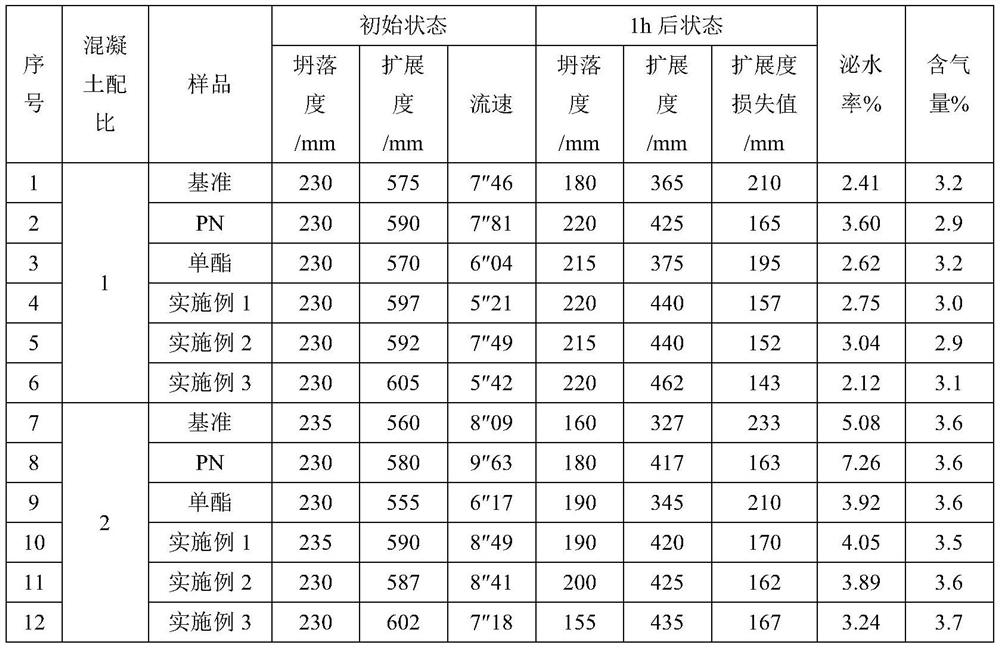

Modified chitosan efficient retarding and water-reducing agent and preparation method and using method thereof

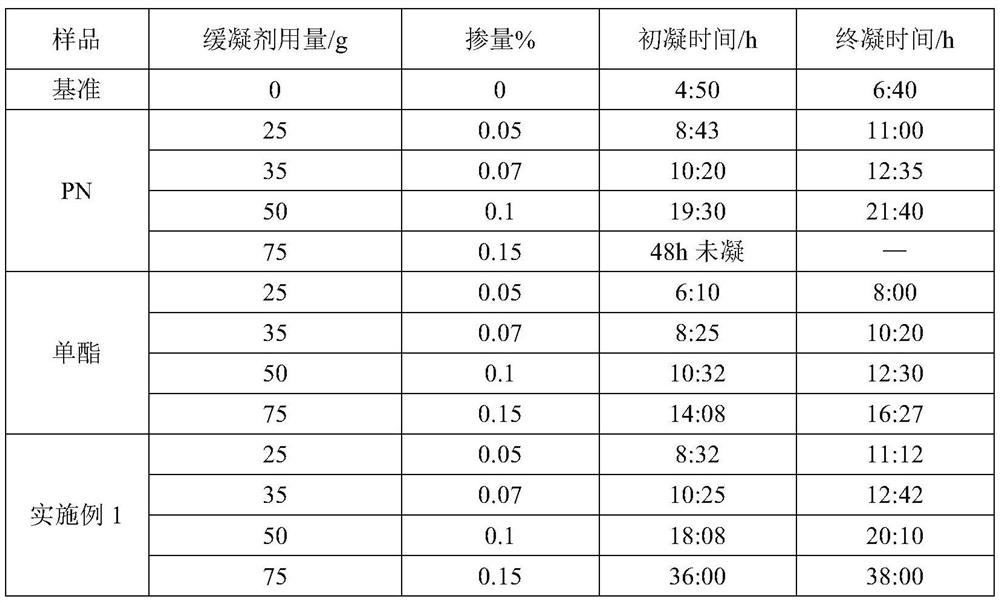

The invention discloses a modified chitosan efficient retarding and water-reducing agent and a preparation method and a using method thereof. Chitosan and itaconic anhydride react to prepare double-bond modified chitosan; the modified chitosan, acrylic monomer and sodium allysulfonate are subjected to copolymerization reaction; the product of polymerization reaction is compounded with a retarder to obtain the modified chitosan efficient retarding and water-reducing agent. The modified chitosan efficient retarding and water-reducing agent prepared by the preparation method provided by the invention has the characteristics of high water-reducing efficiency, high adaptability, long retarding time, capability of being used together with a polycarboxylate-type water-reducing agent, and the like.

Owner:江西富创新材料有限公司

Modified starch water reducing agent and preparation method and use method thereof

The invention discloses a modified starch water reducing agent and a preparation method and a use method thereof; with natural starch as a main raw material, the modified starch water reducing agent is prepared through oxidative degradation and grafting copolymerization reaction with a mixed monomer and has the characteristics of high water reducing rate, strong adaptability, good delayed coagulation effect and good compatibility with other additives, the water reducing rate can reach 26-28%, and the delayed coagulation time is 3-4 hours. When the product prepared by the method is in cooperation use with a polycarboxylate-type water reducing agent, can increase the delayed coagulation time of the polycarboxylate-type water reducing agent to reach 4-5 hours, can effectively prevent the polycarboxylate-type water reducing agent from generating water overflowing, segregation and other phenomena, and improves the adaptability of the polycarboxylate-type water reducing agent on mud-containing dinas.

Owner:FUSHUN LUTONG CHEM

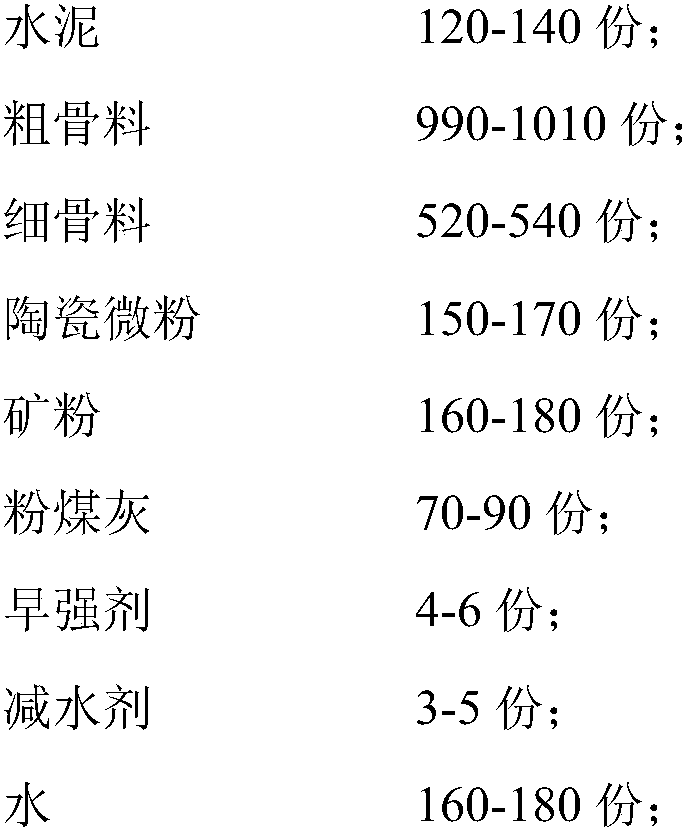

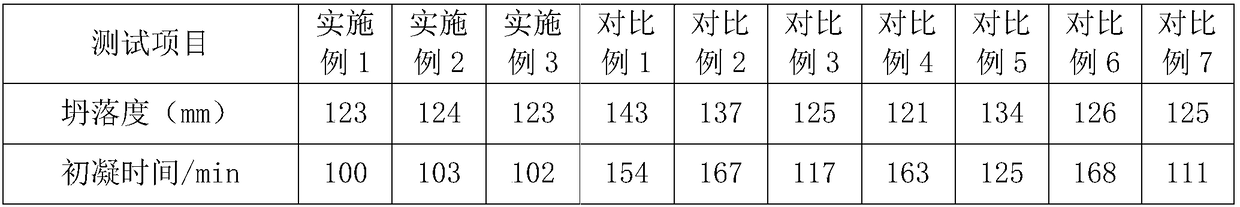

Heat-resistant concrete and preparation method thereof

The invention discloses heat-resistant concrete and a preparation method thereof and belongs to the technical field of concrete. According to key points of the technical scheme, the heat-resistant concrete comprises the following components in parts by weight: cement, coarse aggregate, fine aggregate, ceramic ultrafine powder, mineral powder, fly ash, an early strength agent, a water reducing agent and water. The coarse aggregate refers to basalt gravel and barite gravel; the fine aggregate refers to grain slag; the early strength agent comprises calcium formate and sodium silicate; the waterreducing agent comprises an early strength polycarboxylic water reducer. By replacing medium sand with grain slag, the grain slag can be effectively utilized, the long-term strength of the concrete can be improved, the heat resistance of the concrete is improved by the basalt gravel, the barite gravel and the ceramic ultrafine powder, the defects that low early strength of the concrete is broughtby the grain slag and the water demand is large can be overcome through the early strength agent and the water reducing agent, the compactness of the concrete is improved, and the compressive strengthof the concrete is improved.

Owner:北京建工新型建材有限责任公司

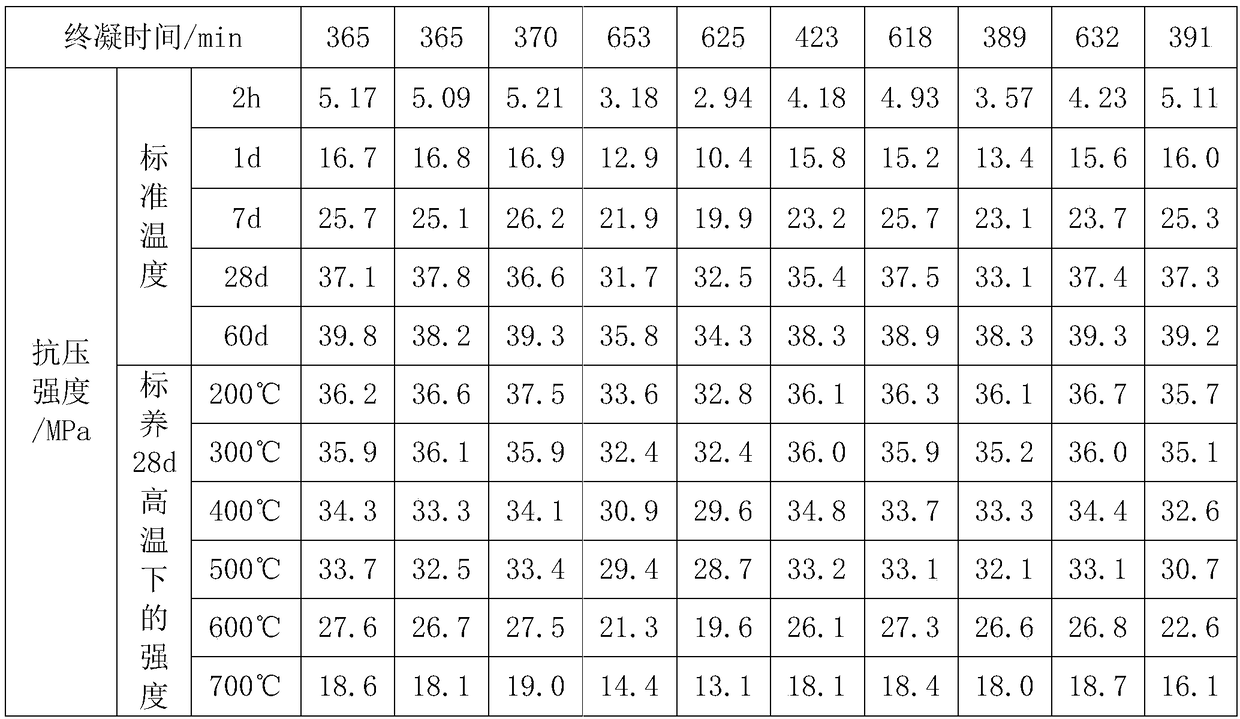

Hyperbranched polyester-polycarboxylate water reducing agent and preparation method for same

The invention discloses a hyperbranched polyester-polycarboxylate water reducing agent and a preparation method for the same. The method comprises the following steps: synthesizing hyperbranched polyester, adding oligosaccharide, ammonium persulfate, a polycarboxylate water reducing agent and a catalyst, performing end group modification on the hyperbranched polyester under the action of the catalyst, and synthesizing the hyperbranched polyester-polycarboxylate water reducing agent. According to the hyperbranched polyester-polycarboxylate water reducing agent and the preparation method for the same, a synthesis process is researched from the designability and controllability of branching degree and molecular weight during the synthesis of the hyperbranched polyester to further prepare a novel polycarboxylate water reducing agent product with high performance and adaptability, an experimental basis is provided for industrial application and popularization, and meanwhile, important theoretical value and economic benefits are created.

Owner:SHANDONG HONGYI TECH

Cement concrete composite ultra retarder

This invention relates to a compound super-retarder of cement, which takes industrial phosphate and PBTC as the raw materials and produces it according to an ordinary method, which can be mixed with different cements and increases post strength and durability of concrete, so it's used in summer installation, concrete needing adjusting operation time and large volume of concrete pouring or mixing pre-mixed mortar.

Owner:CHONGQING UNIV

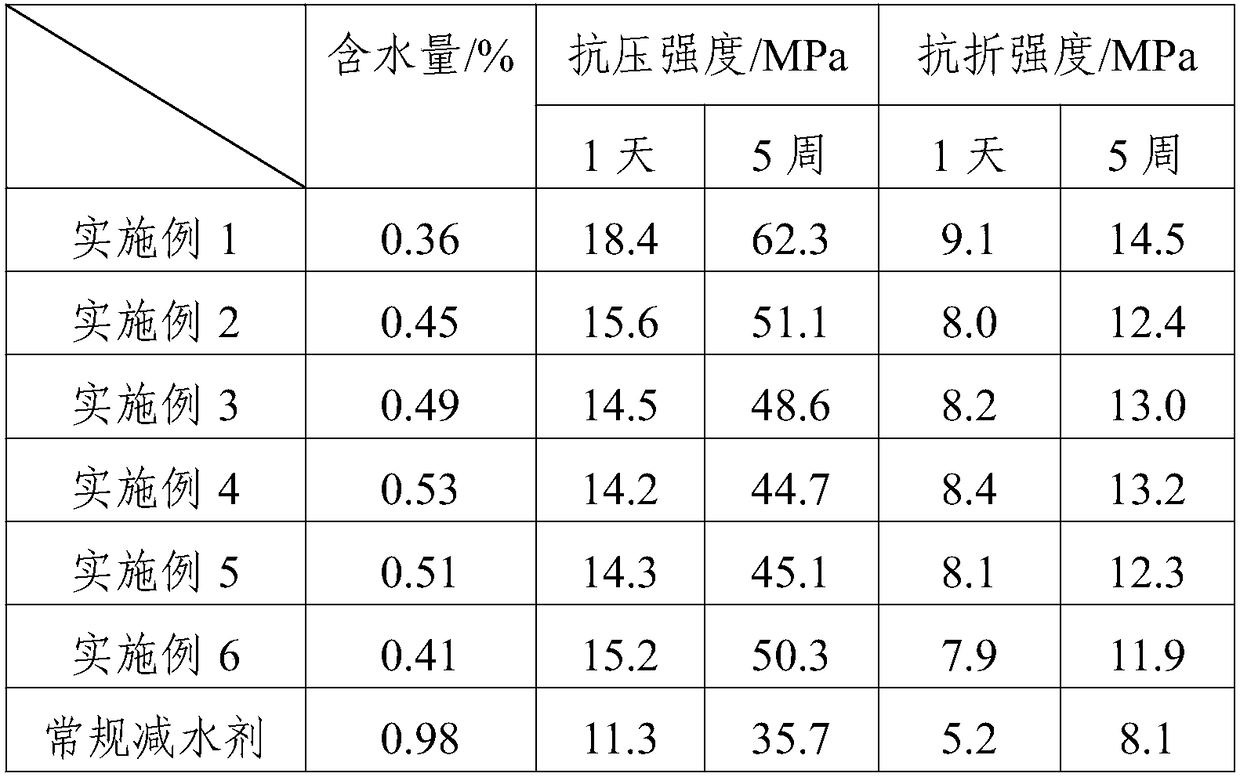

Special water reducing agent for gypsum and preparation method thereof

The invention discloses a special water reducing agent for gypsum. The special water reducing agent is prepared from allyl ether, acrylic acid and allyl phosphonate which are used as monomers as well as a cationic monomer, an alkali neutralizer and an initiator through copolymerization reaction. The special water reducing agent for the gypsum is high in water reducing rate, strong in delayed coagulation and good in adaptability to the gypsum, avoids formaldehyde pollution in the production process, and is particularly adaptive to building gypsum and other gypsum products.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH +1

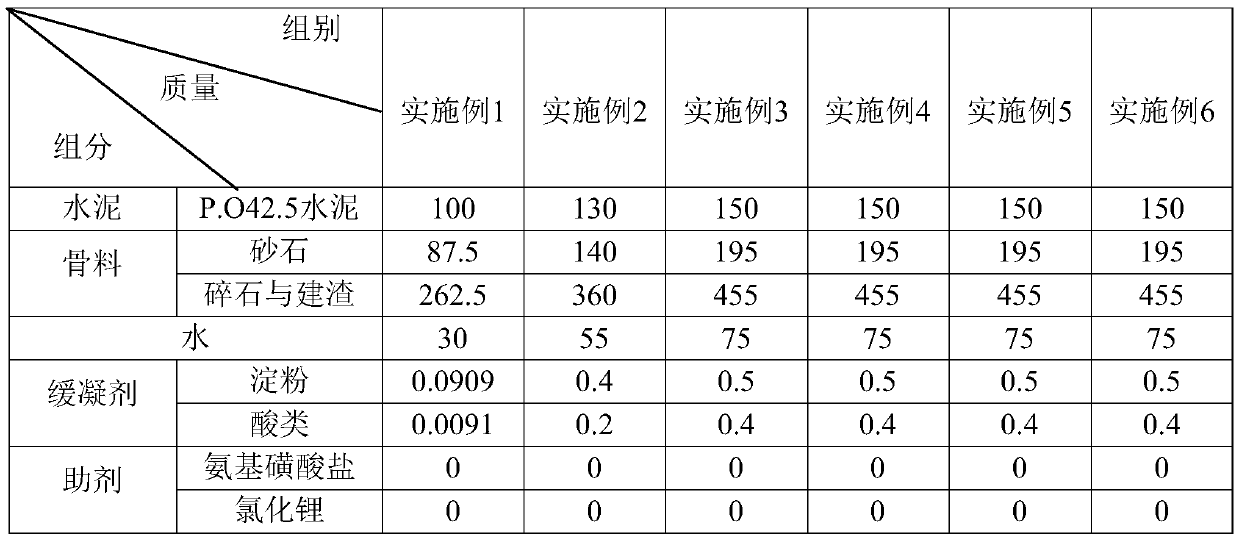

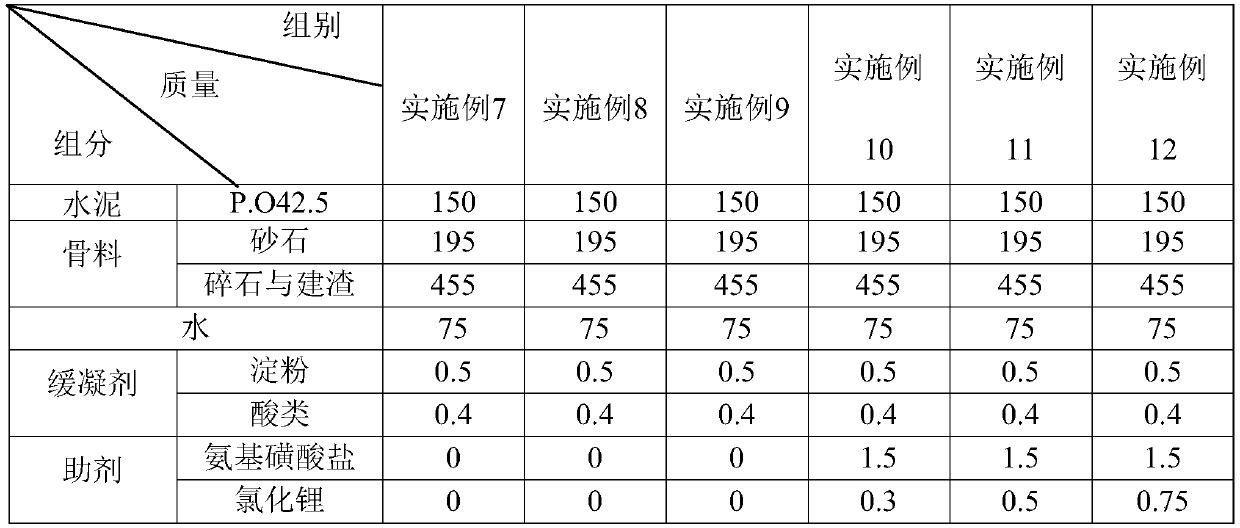

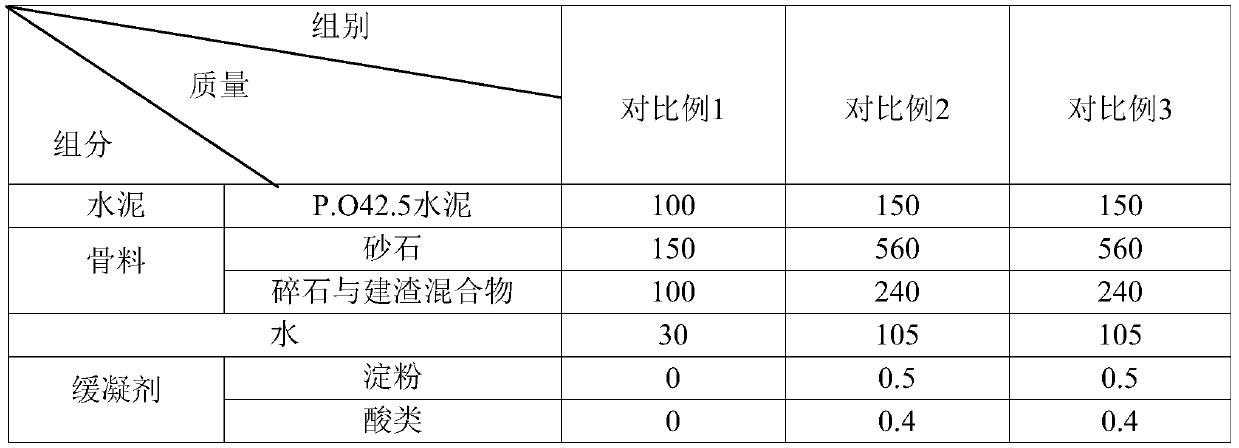

Concrete and preparation method thereof

ActiveCN110128081AInhibits hydration processGuaranteed normal transportationPhosphoric acidCarboxylic acid

The invention discloses a concrete and a preparation method thereof, belongs to the technical field of building materials, and solves the problem that the hardening of the concrete cannot be avoided after the long-term transportation of the concrete. The concrete comprises 100-150 parts of an adhesive material; 250-800 parts of an aggregate; 30-105 parts of water; and 0.1-0.9 part of a retarder; wherein the adhesive material is cement, and the retarder is composed of starch and an acid composition at a weight percentage ratio of 1:(0.1-0.8); the acid composition consists of an organic acid andan inorganic acid at a weight percentage ratio of (0.7-2):1, the organic acid is one or more of hydroxycarboxylic acids and aminocarboxylic acids, and the inorganic acid is one of hydrochloric acid,sulfuric acid, and phosphoric acid; and the crosslinking degree of the starch is 5%-15%, and the amylopectin in the starch accounts for 70%-90% of the total weight of the starch. The method achieves the effects of retarding and retarding time adjustment by the retardation of the starch and the hydrolysis of the acid composition.

Owner:广东腾基建设有限公司

Super retarder for concrete

ActiveCN108046651AProlong the retarding timeReduce heat of hydrationCompressive strengthSucrose measurement

The invention discloses a super retarder for concrete. The super retarder for concrete is characterized by being prepared from the following materials in parts by weight: 5 to 10 parts of sodium polyacrylate, 12 to 16 parts of diethyleneglycolmonoethylether, 5 to 9 parts of polyglutamic acid / chitosan oligosaccharide hydrogel, 3 to 5 parts of ammonium bicarbonate, 8 to 12 parts of starch compound,8 to 12 parts of saccharose and 20 to 30 parts of water. The retarding time of the super retarder for concrete disclosed by the invention is long, the initial setting time is longer than or equal to 24 hours, the occurrence of hydration temperature peak is delayed, the hydration heat of cement is decreased, and moreover, by dosage, the retarding effect can be controlled; the super retarder for concrete has a later enhancement effect on concrete strength, and can increase the 28-day compressive strength of concrete; and the super retarder for concrete is highly compatible with water reducing agent, and can remarkably improve the quality stability of concrete products.

Owner:RIZHAO FEM NEW MATERIAL TECH

P*S*A grade retarded cement and preparation method thereof as well as concrete road

The invention provides P*S*A grade retarded cement, and belongs to P*S*A grade retarded cement. The retarded cement comprises the following raw materials by weight percentage: 51% to 59% of Portland cement clinker, 32% to 37% of granulated blast furnace slag powder, 4% to 6% of fly ash and 4% to 6% of desulfurized gypsum. The invention also provides a preparation method of the P*S*A grade retardedcement, and the method comprises the following steps: mixing and grinding the Portland cement clinker, the fly ash, the granulated blast furnace slag powder and the desulfurization gypsum, or grinding after mixing. The P*S*A grade retarded cement prepared with the preparation method is long in retarded time.

Owner:山东永正水泥有限公司 +1

Polycarboxylic acid water reducing agent preparation method, and retarder and preparation method thereof

The present invention discloses a polycarboxylic acid water reducing agent preparation method, and a retarder compounded with the prepared polycarboxylic acid water reducing agent. According to the method, a water phase free radical copolymerization reaction is performed in water by using acrylic acid and other unsaturated acids as a small monomer, using isobutylene alcohol polyoxyethylene ether as a large monomer, using persulfate as an initiator, and using thioglycolic acid and / or mercaptopropionic acid as a chain transfer agent. According to the present invention, the retarder comprises, byweight, 75-90 parts of the polycarboxylic acid water reducing agent (calculated as the weight of the effective component), 1-10 parts of sodium tripolyphosphate, 10-25 parts of citric acid, and 1-10parts of a calcium increasing agent, has good retarding effect, and can significantly prolong the retarding time of desulfurized building gypsum, such that the desulfurized gypsum can overcome the drawbacks that the construction requirement cannot be met due to the rapid solidification, and the strength loss of the desulfurized gypsum after solidification is low.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Polycarboxylic acid water reducing agent preparation method, and retarder and preparation method thereof

The present invention discloses a polycarboxylic acid water reducing agent preparation method, and a retarder compounded with the prepared polycarboxylic acid water reducing agent. According to the method, a water phase free radical copolymerization reaction is performed in water by using acrylic acid and other unsaturated acids as a small monomer, using isobutylene alcohol polyoxyethylene ether as a large monomer, using hydrogen peroxide and L-ascorbic acid as an initiation system, and using thioglycolic acid and / or mercaptopropionic acid as a chain transfer agent. According to the present invention, the retarder comprises, by weight, 75-90 parts of the polycarboxylic acid water reducing agent, 1-10 parts of sodium tripolyphosphate, 10-25 parts of citric acid, and 1-10 parts of a calciumincreasing agent, has good retarding effect, and can significantly prolong the retarding time of desulfurized building gypsum, such that the desulfurized gypsum can overcome the drawbacks that the construction requirement cannot be met due to the rapid solidification, and the strength loss of the desulfurized gypsum after solidification is low.

Owner:BEIJING NEW BUILDING MATERIAL

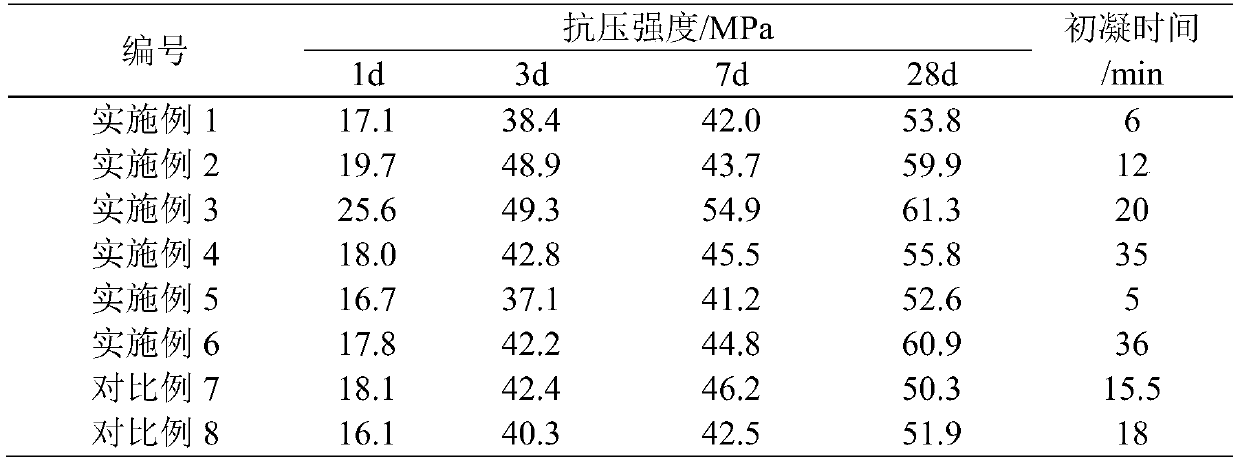

Quick repairing material for magnesium phosphate cement and preparation method thereof

The invention discloses a quick repairing material for magnesium phosphate cement and a preparation method thereof. The quick repairing material for magnesium phosphate cement, as a composite, is mainly made from, by weight, 25 parts of magnesium oxide, 15-20 parts of monopotassium phosphate, 0.5-1.5 parts of ethylenediamine tetraacetic acid dipotassium salt dihydrate, and 5-10 parts of water. Theethylenediamine tetraacetic acid dipotassium salt dihydrate is used herein as a retardant to replace borax used in the traditional magnesium phosphate cement. The quick repairing material has good retarding effect; setting time of the magnesium phosphate repairing system is greatly extended; the magnesium phosphate repairing system ensures early strength of a magnesium phosphate cement sample, and late strength of the magnesium phosphate repairing system is improved to certain extent.

Owner:SOUTHEAST UNIV

Method for preparing polycarboxylic acid water reducer by itaconic acid waste liquid

The invention discloses a method for preparing a polycarboxylic acid water reducer by itaconic acid waste liquid. The water reducer is prepared from, by weight, 290-340 parts of methyl allyl polyoxyethylene ether, 3-4.5 parts of hydrogen peroxide, 20-25 parts of acrylic acid, 50-80 parts of itaconic acid waste liquid, 1.2-2.5 parts of mercapto-propionic acid and 1.2-2 parts of vitamin C. Accordingto the synthesis method of the water reducer, free radical polymerization is triggered by an oxidation-reduction system, reaction can be performed at room temperature, the dosage of the acrylic acidin the polymerization process is reduced, the itaconic acid waste liquid contains delayed coagulation components, addition of the delayed coagulation components in the final-period water reducer is reduced, the slump holding capacity of concrete can be improved, the ratio of oxidizing agents to reducing agents is adjusted, the dosage of all monomers is determined, conversion rate is increased, rawmaterial waste is prevented, and side reaction is effectively controlled. The water reducer has high water reducing rate, good slump holding performance and wide applicable range and is suitable forindustrial large-scale production.

Owner:萧县沃德化工科技有限公司 +1

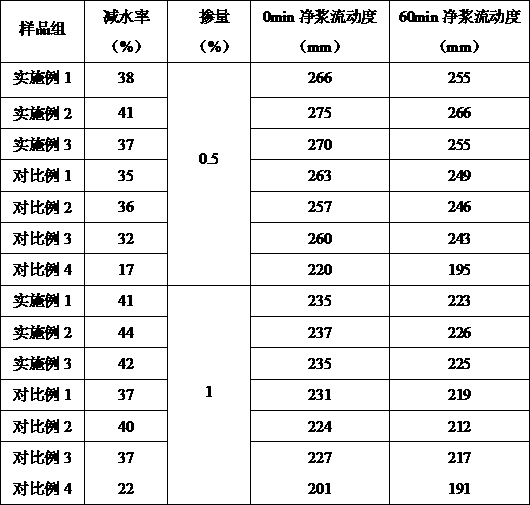

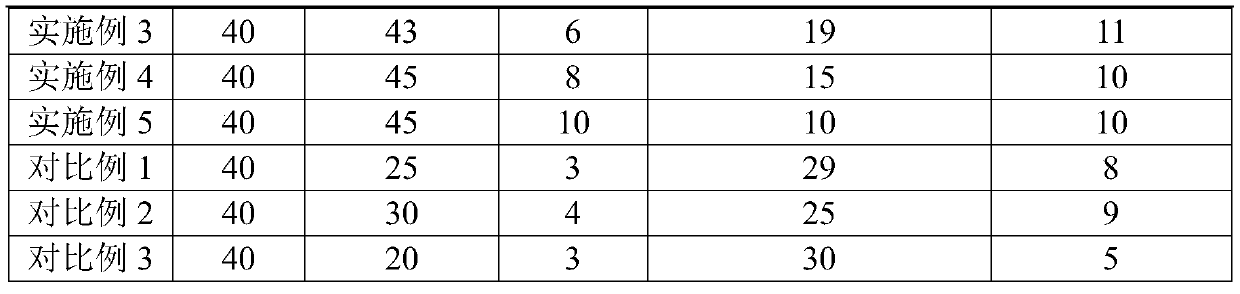

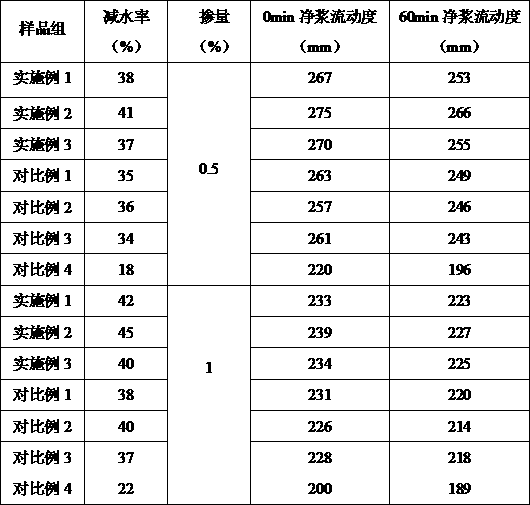

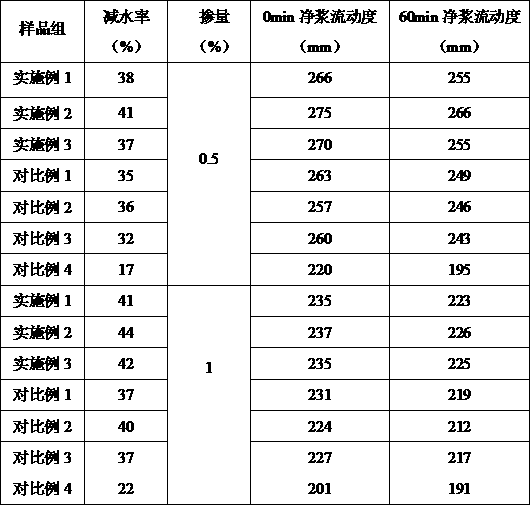

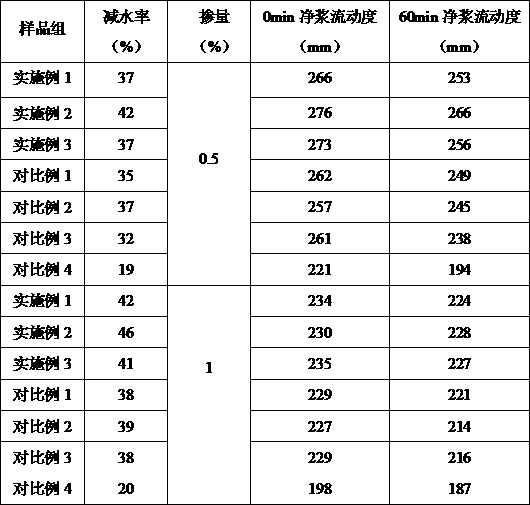

Retarder and application thereof in preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses a retarder and application thereof in preparation of a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongs to the field of building materials. The retarder is prepared from the following components in parts by weight: 43 to 60 parts of sodium gluconate, 30 to 37 parts of sodium citrate, 22 to 29 parts of sodium tripolyphosphate, 13 to 19parts of sodium pyrophosphate, 3 to 8 parts of ammonium borate, 2 to 4 parts of ferrous sulfate and 1 to 3 parts of magnesium sulfate. The cassava starch is subjected to oxidation, acidification, etherification, grafting, neutralization and other reaction processes to prepare the starch-containing composite water reducing agent. By adopting the composite water reducing agent containing the retarder, the setting time of concrete can be adjusted, the performance of the concrete can be improved, and meanwhile, the effects of specifically improving the net slurry fluidity of the concrete, reducingthe construction energy consumption and the like can be achieved. Development and application of the cassava starch water reducing agent are beneficial to improvement of the water reducing agent processing technology, improvement of the water reducing agent product quality and reduction of environmental pollution.

Owner:NANNING TONGCAI TECH CO LTD

A modified chitosan high-efficiency retarding water reducer and its preparation method and use method

Owner:江西富创新材料有限公司

Modified malt syrup retarder as well as preparation method and application thereof

The invention discloses a modified maltose syrup retarder as well as a preparation method and application thereof. The modified maltose syrup retarder is prepared from maltose syrup, acrylic acid, an activating agent, unsaturated acid, esters, acrylamide, an initiator, deionized water and liquid caustic soda in a mass part ratio of (79-157):(10-40):(0.5-3.2):(40-80):(20-40):(20-40):(1-5):(500-750):(8-15). The preparation method comprises the following steps: putting malt syrup and acrylic acid into a No.1 reaction kettle according to the mass part ratio of (4-8):1, further adding an activating agent which is 0.5-2% of the total amount of the malt syrup, heating to 70-90 DEG C, stirring and reacting for 4 hours, and cooling to room temperature to obtain an intermediate product A; then adding the intermediate product A, unsaturated acid, esters, acrylamide, an initiator and deionized water in a mass ratio of (100-200):(40-80):(20-40):(20-40):(1-5):(500-750) into a No.2 reaction kettle, heating to 85-90 DEG C, stirring the mixture to react for 4 hours, cooling a reaction product to room temperature, and regulating the pH value to be about 7 by using liquid caustic soda to obtain the modified malt syrup retarder.

Owner:云南森博混凝土外加剂有限公司

A special water reducer for gypsum and its preparation method

The invention discloses a special water reducing agent for gypsum. The special water reducing agent is prepared from allyl ether, acrylic acid and allyl phosphonate which are used as monomers as well as a cationic monomer, an alkali neutralizer and an initiator through copolymerization reaction. The special water reducing agent for the gypsum is high in water reducing rate, strong in delayed coagulation and good in adaptability to the gypsum, avoids formaldehyde pollution in the production process, and is particularly adaptive to building gypsum and other gypsum products.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH +1

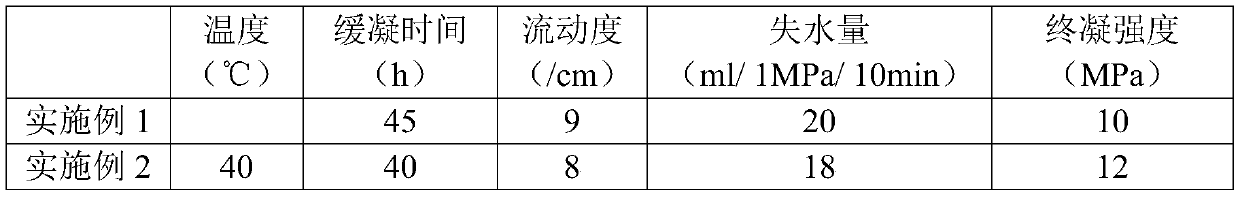

Delayed coagulation cement paste for freezing shaft sinking construction

ActiveCN110482968ASatisfy the seal water requirementImprove freeze-thaw resistanceSealing/packingGlycerolCement slurry

The invention discloses delayed coagulation cement paste for freezing shaft sinking construction and belongs to the technical field of slurry. The cement slurry comprises the following components in parts by weight: 190-210 parts of cement, 780-820 parts of fly ash, 970-1030 parts of water, 180-200 parts of glycerol and 1.3-4 parts of sulfonated lignite resin. On the premise that the final settingstrength of the cement paste reaches 10 MPa, the cement paste can be set slowly for 45 hours at the high temperature of 40 DEG C, and meanwhile, the cement paste has high flowability and low water loss.

Owner:CHINA COAL FIRST CONSTR +1

Modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongs to the field of building materials. The modified cassava starch-polycarboxylic acid composite water reducing agent is prepared from the following raw materials in parts by weight: 20 to 35 parts of modified cassava starch, 30 to 120 parts of sodium hydroxide, 2 to 6 parts of retarder,0.5 to 4 parts of defoaming agent and 1 to 5.5 parts of air entraining agent. The content of the modified cassava starch in the composite water reducing agent reaches 20% or above, and when the mixingamount of the water reducing agent is 0.3%, the coagulation time exceeds 24 h, and the requirement of the super retarder is met; and when the mixing amount of the composite water reducing agent is 1%, the initial fluidity of the cement paste is greater than 200mm. The development and application of the cassava starch water reducing agent are beneficial to improving the processing technology of the water reducing agent, improving the product quality of the water reducing agent and reducing the environmental pollution, and can effectively solve the problem of output of Guangxi agricultural products and improve the additional value of the products.

Owner:NANNING TONGCAI TECH CO LTD

Preparation method of retarder applied to preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses a preparation method of a retarder applied to preparation of a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongs to the field of buildingmaterials. The preparation method of the retarder comprises the following steps: uniformly mixing sodium gluconate, sodium citrate, sodium tripolyphosphate, sodium pyrophosphate, ammonium borate and water, adjusting the pH value of the solution to 5.5-6.5, adding magnesium sulfate, introducing nitrogen, and adding ferrous sulfate at 60 DEG C for free radical polymerization; observing the reactiontemperature, starting timing when the temperature is the highest, and obtaining the retarder after 2 hours. The composite water reducing agent containing the retarder prepared by adopting the processdisclosed by the invention can adjust the setting time of concrete and improve the performance of the concrete, and also has the effects of specifically improving the net slurry fluidity of the concrete, reducing the construction energy consumption and the like.

Owner:NANNING TONGCAI TECH CO LTD

Preparation method of air entraining agent applied to preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses a preparation method of an air entraining agent applied to preparation of a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongs to the fieldof building materials. The preparation method of the air entraining agent comprises the following steps: putting rosin powder, p-toluenesulfonic acid and sodium hydroxide into a reaction kettle, adding water accounting for 50% of the total mass of the mixture A, mixing and stirring for 30 minutes, heating to 80 DEG C, keeping the temperature for 50 minutes, heating to 80 DEG C, and keeping the temperature for 45 minutes; heating the mixed solution A to 85 DEG C, slowly adding pentaerythritol and tall oil, keeping the temperature for 35 minutes, heating to 70-85 DEG C, slowly adding mahogany petroleum sulfonate, and keeping the temperature for 1 hour to obtain the air entraining agent. The air entraining agent has a good air entraining effect, the average pore diameter of air entraining bubbles is small, the durability of concrete is remarkably improved, meanwhile, the workability of the concrete is obviously improved, the slump loss of the concrete is reduced, and the strength of theconcrete is not reduced.

Owner:NANNING TONGCAI TECH CO LTD

Preparation method for thermal insulation type gypsum board

InactiveCN108147758AImprove heat storage and heat exchange efficiencyChange shapeCeramicwareThermal insulationAxial growth

The invention relates to a material for buildings, and in particular to a preparation method for a thermal insulation type gypsum board. The preparation method utilizes fermented oxytetracycline fungus residue as a raw material to prepare an additive for the preparation process of phosphogypsum. Fermentation is firstly carried out, the cooperation between microwave heating and basic hydrolysis isthen utilized, so that the hydrolysis reaction of the fungus residue is intensified, consequently, the time of hydrolysis is greatly shortened, and the efficiency of the hydrolysis reaction is effectively improved. Fungus residue protein belongs to single-cell protein, and the molecular weight is lower. The content of free amino acid in a set retarder is higher, a small amount of small peptide substance is also contained, main chelating functional groups which are produced by the set retarder and calcium ions are the amino group and the carboxyl group, calcium chelate colloid can be adsorbed onto the surfaces of gypsum crystal nucleus, consequently, the axial growth of the crystal nucleus is inhibited, the morphology of gypsum is changed, the crystallization speed of the gypsum is retarded, and thereby the time of gypsum setting retardation is prolonged.

Owner:常州鼎众冷暖设备工程有限公司

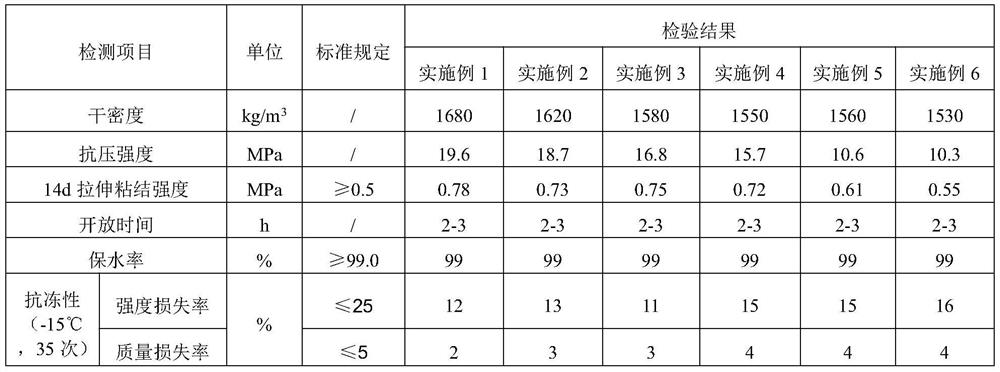

Special ultrathin-layer masonry mortar for sintered building blocks made of regenerated fine powder containing red bricks

ActiveCN112592131AImprove resource utilizationSolve the problem of comprehensive utilizationSolid waste managementCelluloseFiber

The invention aims to provide special ultrathin-layer masonry mortar for sintered building blocks made of regenerated fine powder containing red bricks. The special ultrathin-layer masonry mortar comprises the following components in parts by weight: 250-430 parts of cement, 195-375 parts of regenerated fine powder containing red bricks, 300-525 parts of fine sand, 6-10 parts of redispersible latex powder, 1.5-2 parts of hydroxypropyl methyl cellulose ether, 0.2-1.05 parts of water reducing agent and 0.3-0.5 part of wood fiber. According to the ultrathin-layer masonry mortar, all components utilize red brick-containing recycled fine powder, sorting and powder removal are not needed in the processing process of red brick-containing construction waste, the production process is low-carbon and environment-friendly, the cost is low, and the utilization problem of the sand powder mixture which is most difficult to utilize in the construction waste recycling process is successfully solved. The regenerated fine powder is adopted to partially replace natural fine sand, the mortar joint thickness of the obtained ultrathin-layer masonry mortar is not larger than 2 mm, and the ultrathin-layermasonry mortar has the advantages of being high in activity, high in water-retaining property, good in construction performance, capable of insulating heat and saving energy, environmentally friendlyand the like.

Owner:XUCHANG JINKE RESOURCE RECYCLING CO LTD

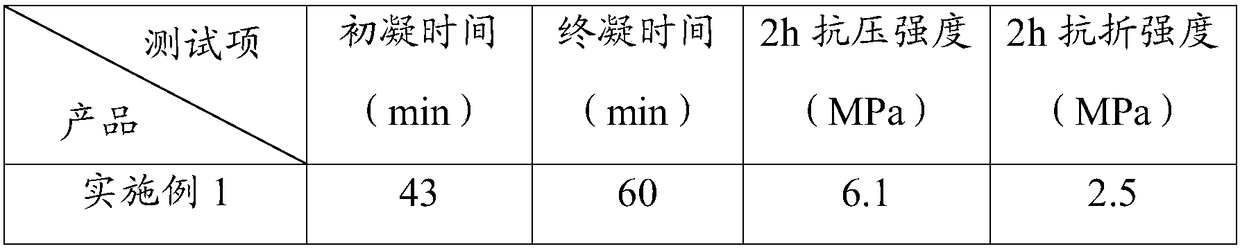

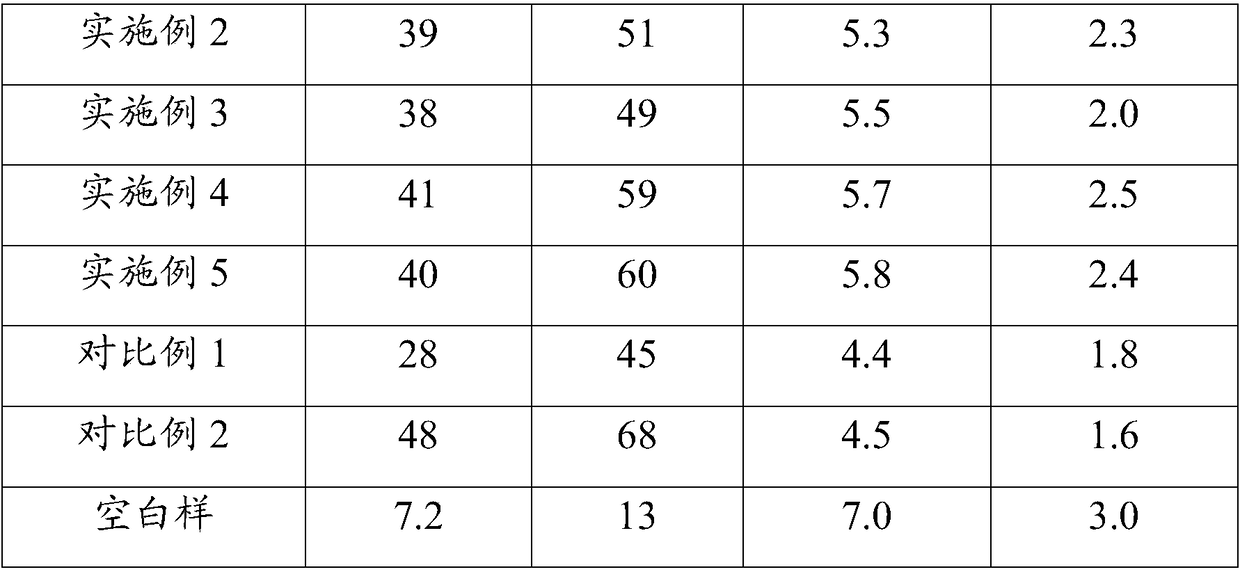

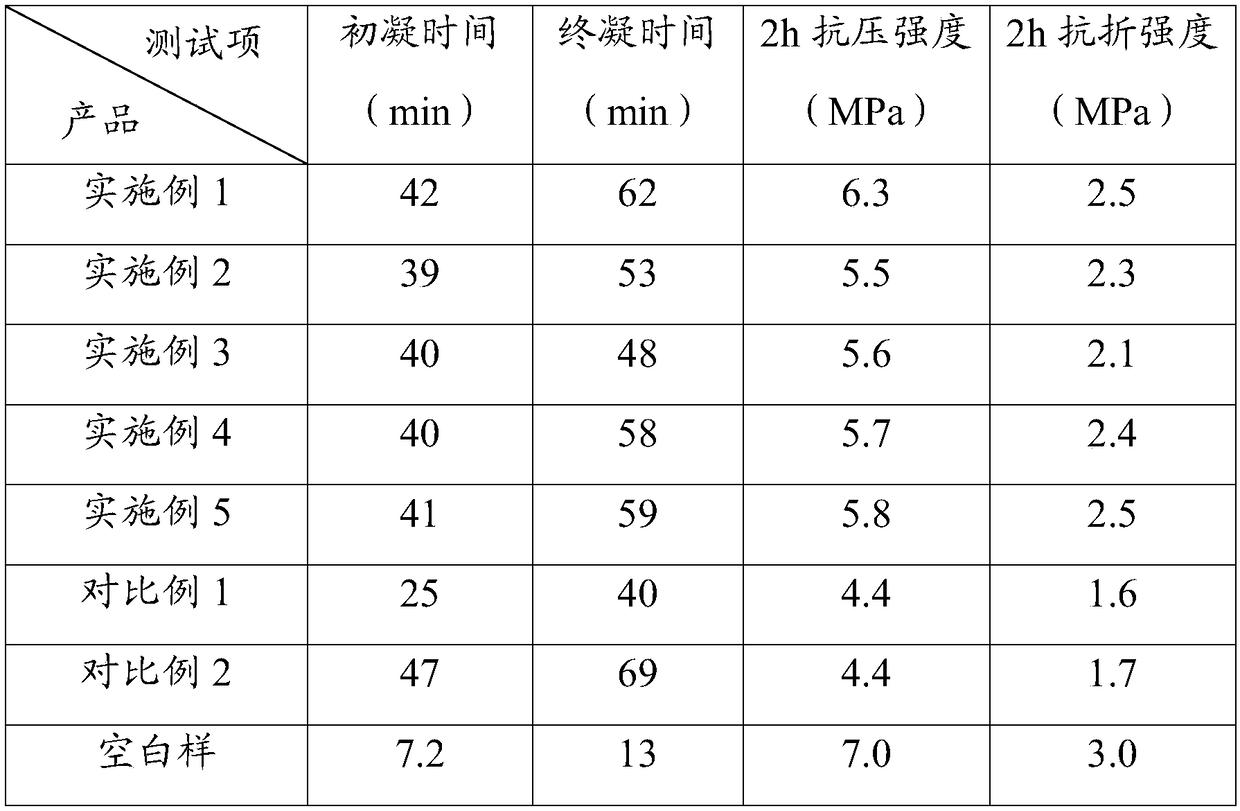

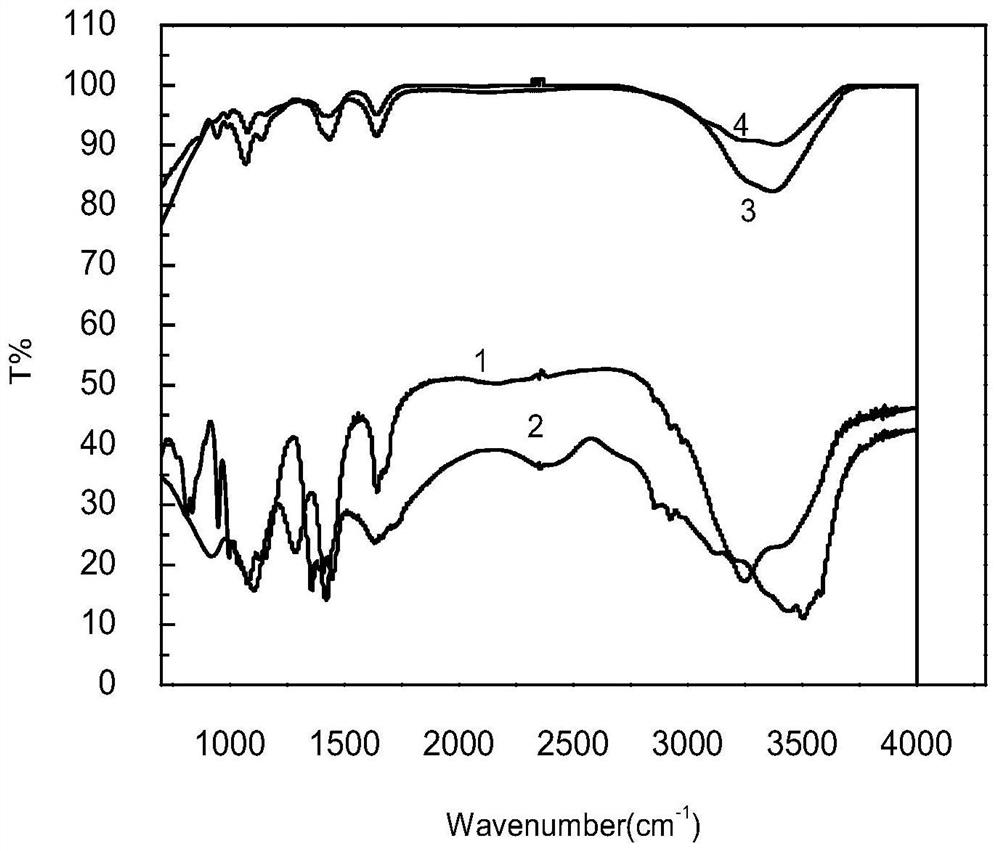

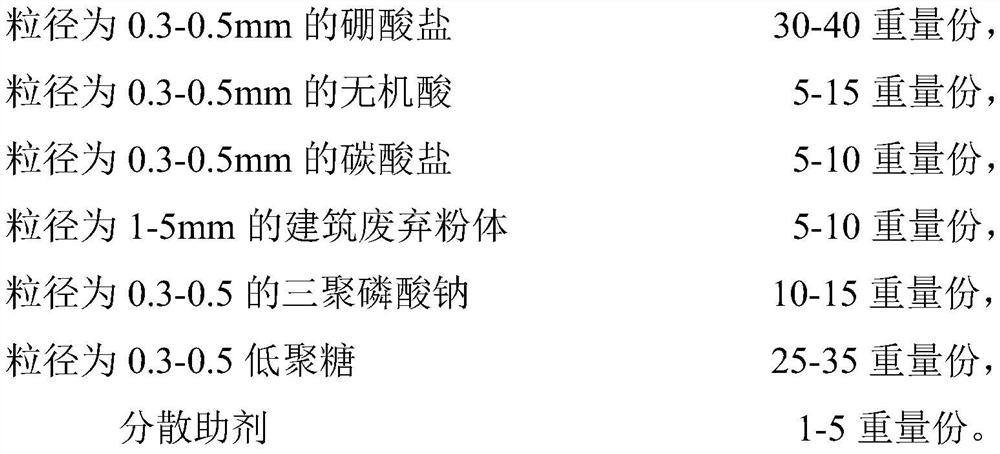

Retarder for novel water-resistant quick-hardening inorganic cementing material and preparation method thereof

The invention discloses a retarder for a novel water-resistant quick-hardening inorganic cementing material and a preparation method thereof. The retarder is characterized by being prepared from the following raw materials: borate, an inorganic acid, carbonate, construction waste powder, sodium tripolyphosphate, oligosaccharide and a dispersing aid according to a weight ratio of (30-40): (5-15): (5-10): (5-10): (10-15): (25-35): (1-5). Firstly, borate, inorganic acid, carbonate and sodium tripolyphosphate are mixed to prepare an inorganic retarder, and then the inorganic retarder, organic retarder oligosaccharide and construction waste powder are mixed. The inorganic retarder and the organic retarder cooperate with each other to achieve a retarding effect on the novel water-resistant quick-hardening inorganic cementing material. The method is simple and easy to implement and low in production cost, the prepared retarder has a good retarding effect on a novel water-resistant quick-hardening inorganic cementing material, and a foundation is laid for industrial application of the novel water-resistant quick-hardening inorganic cementing material.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Defoaming agent and application thereof in preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses a defoaming agent and application thereof in preparation of a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongs to the field of building materials. The defoaming agent is prepared from the following components in parts by weight: 30 to 65 parts of hydrogen silicone oil, 20 to 40 parts of high-carbon alcohol fatty acid ester compound, 10to 17 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 10 to 15 parts of octamethylcyclotetrasiloxane, 5 to 9 parts of polyether silicone oil and 3 to 6 parts of polyoxypropylene polyoxyethylene glyceryl ether. The cassava starch is subjected to oxidation, acidification, etherification, grafting, neutralization and other reaction processes to prepare the starch-containing composite water reducing agent. The strength of concrete is reduced by harmful bubbles generated in the concrete, and the quality of the concrete is influenced; the defoaming agent is good in defoaming effect, the harmful bubbles in the concrete can be efficiently eliminated, and air holes influencing the performance are prevented from being formed. When the mixing amount of the water reducing agent is 1%, the initial fluidity of cement paste is larger than 200 mm, and the water reducing agent has a good water reducing effect.

Owner:NANNING TONGCAI TECH CO LTD

Air entraining agent and application thereof in preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses an air entraining agent and application of the air entraining agent in preparation of a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongsto the field of building materials. The air entraining agent is prepared from the following components in parts by weight: 48 to 60 parts of rosin powder, 38 to 55 parts of p-toluenesulfonic acid, 25to 37 parts of sodium hydroxide, 18 to 22 parts of pentaerythritol, 7 to 14 parts of tall oil and 5 to 9 parts of petroleum sulfonate. The cassava starch is subjected to oxidation, acidification, etherification, grafting, neutralization and other reaction processes to prepare the starch-containing composite water reducing agent. By adopting the air entraining agent disclosed by the invention, bubbles in concrete can be proper and stable in size, and meanwhile, the compressive strength of the concrete is remarkably improved. The content of the modified cassava starch in the composite water reducing agent reaches 20% or above, and when the mixing amount of the water reducing agent is 0.3%, the coagulation time is longer than 24 h, and the requirement of the super retarder is met.

Owner:NANNING TONGCAI TECH CO LTD

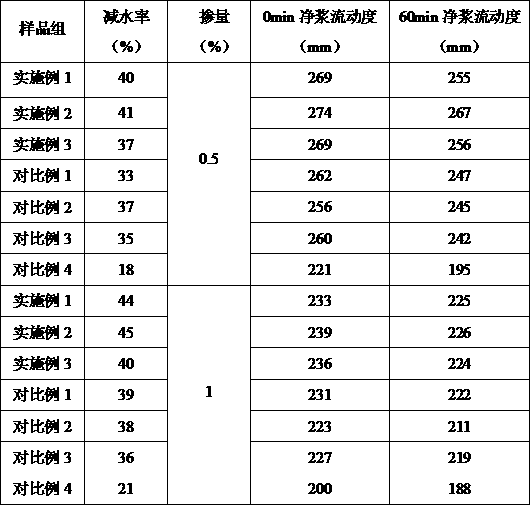

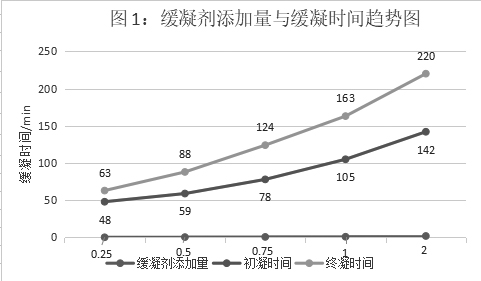

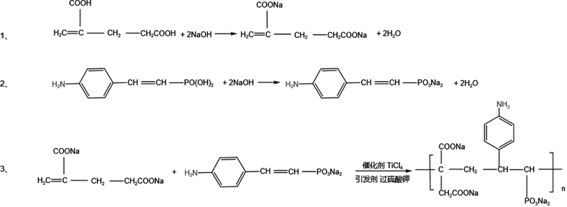

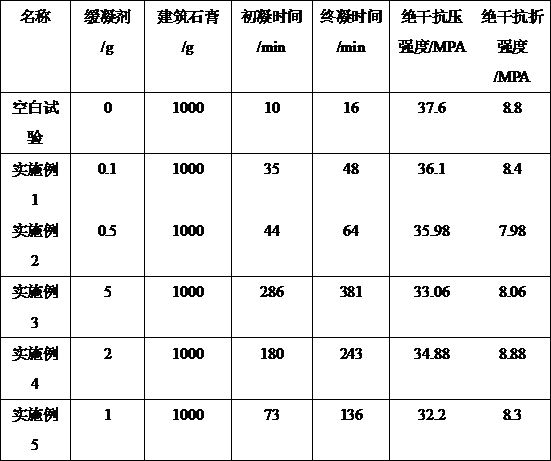

Composite gypsum retarder and preparation method thereof

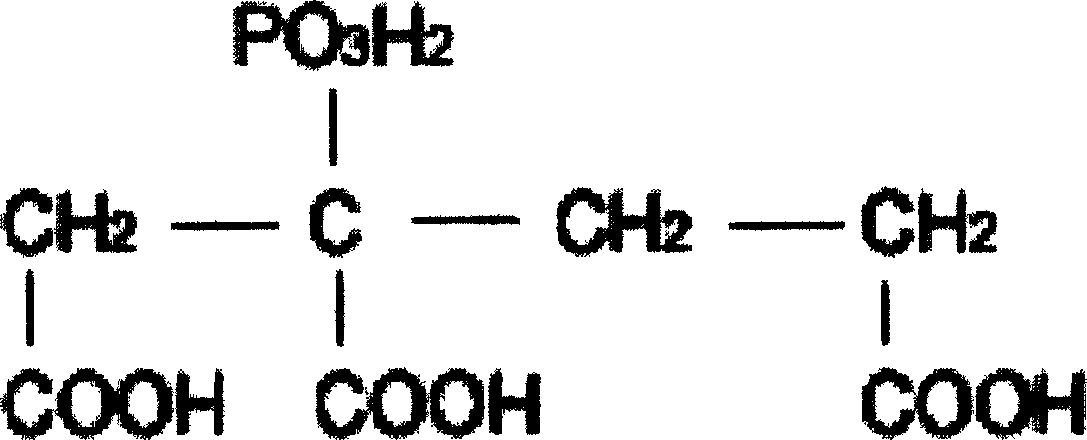

ActiveCN114656188AProlong the retarding timeLittle loss of strengthSolid waste managementInorganic saltsSulfonate

The invention belongs to the field of gypsum building materials, and relates to a composite gypsum retarder, which is prepared from the following raw materials in parts by weight: 30 to 50 parts of itaconic acid-p-amino styrene phosphoric acid copolymer, 15 to 25 parts of magnesium salt, 13 to 20 parts of organic acid salt and 5 to 25 parts of sulfamate. The invention also discloses a preparation method of the composite gypsum retarder. Compared with the prior art, the invention has the following advantages: from the two macroscopic indexes of setting time and strength loss, compared with other inorganic salt retarders, the invention has the advantages of long retarding time and small strength loss; the time of the retarder is not suddenly changed due to the change of the mixing amount, the mixing amount and the retarding time are in a linear relationship, and the setting time of gypsum can be randomly adjusted according to the operation time.

Owner:SCI GREEN SHANDONG ENVIRONMENT TECH CO LTD

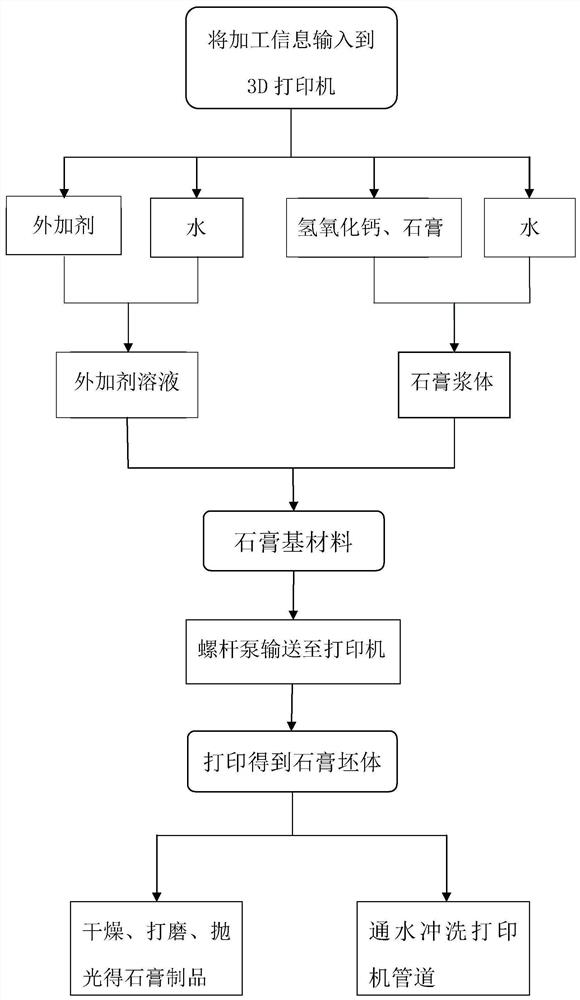

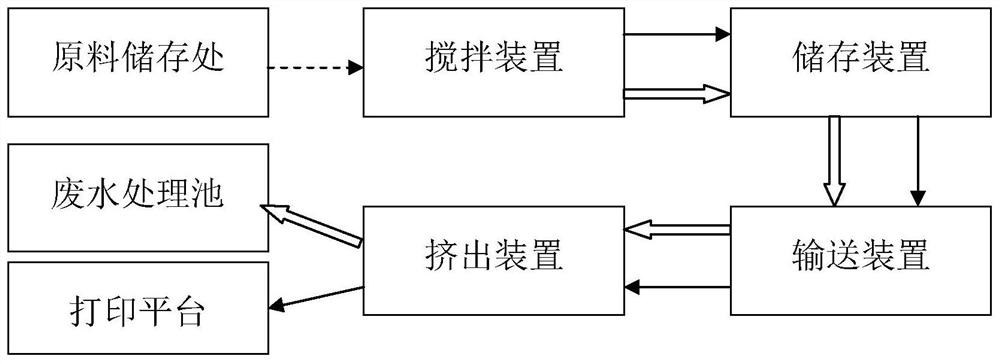

A kind of gypsum-based 3D printing material and preparation method thereof

ActiveCN110436869BReduce usageProlong the retarding timeAdditive manufacturing apparatusCeramic shaping apparatusCalcium hydroxideWater reducer

The present invention provides a gypsum-based 3D printing material and a preparation method thereof. The gypsum-based 3D printing material comprises the following components in parts by weight: gypsum: 100 parts, retarding component: 0.01-1 part, calcium hydroxide : 0‑0.1 part, water reducer: 0‑1 part, thixotropic thickening modifier: 0.1‑4 part. The gypsum-based 3D printing material of the present invention uses admixtures to modify the gypsum, so that it has a longer retarding time, higher yield strength, and better stacking performance, and the present invention avoids the existing gypsum-based 3D printing The use of cement in the material greatly reduces the production cost and is environmentally friendly.

Owner:WUHAN UNIV OF TECH

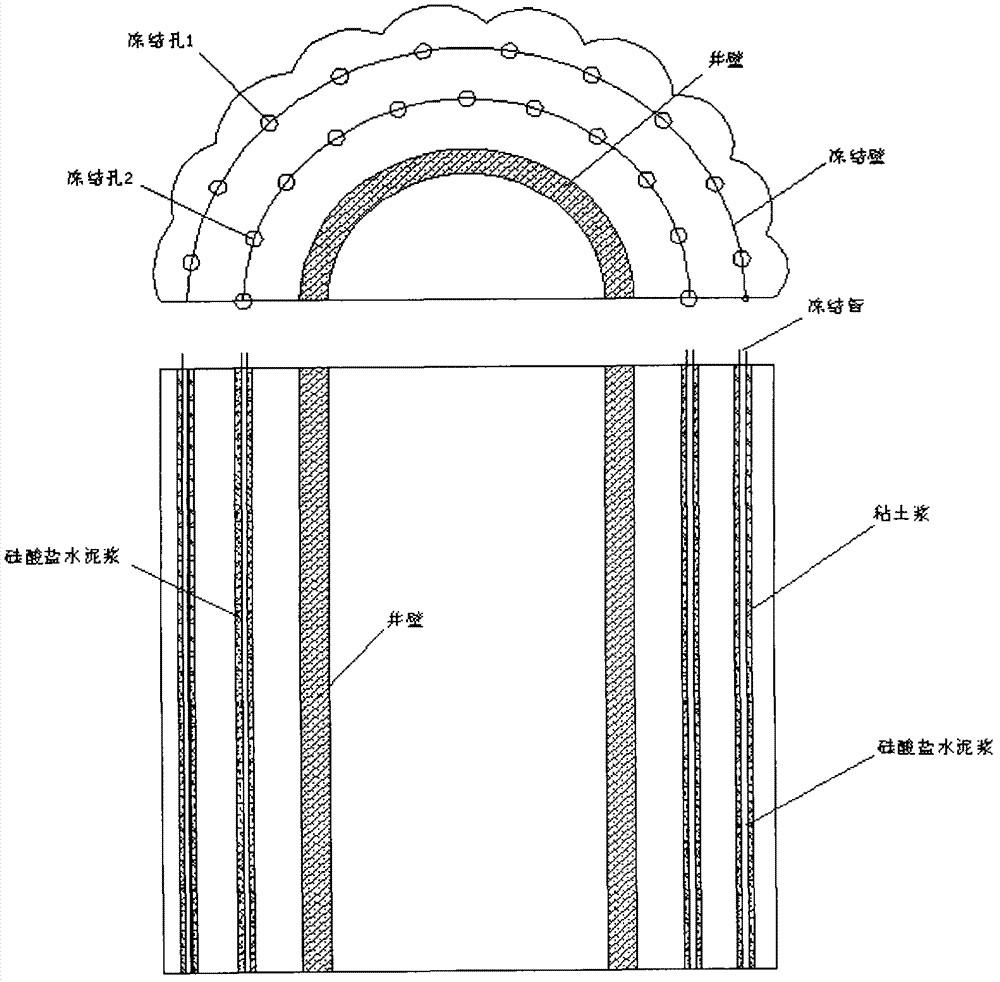

Retarding cement slurry composite for replacement of super-deep freezing hole and preparation method thereof

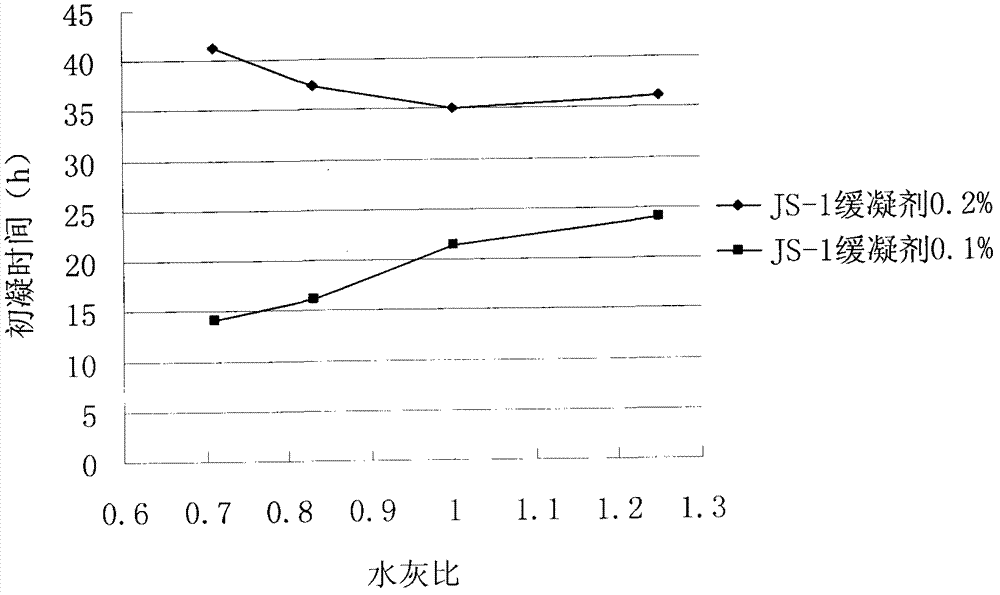

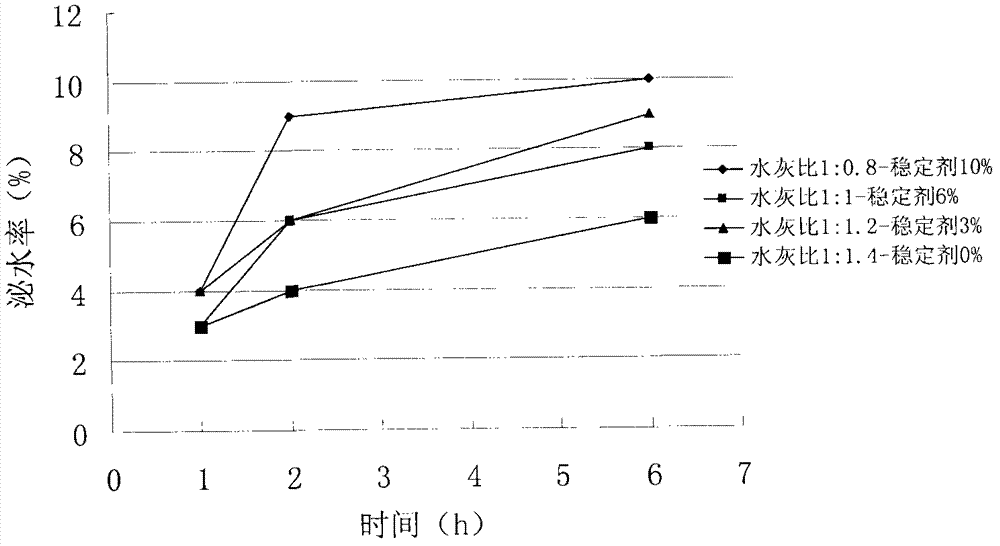

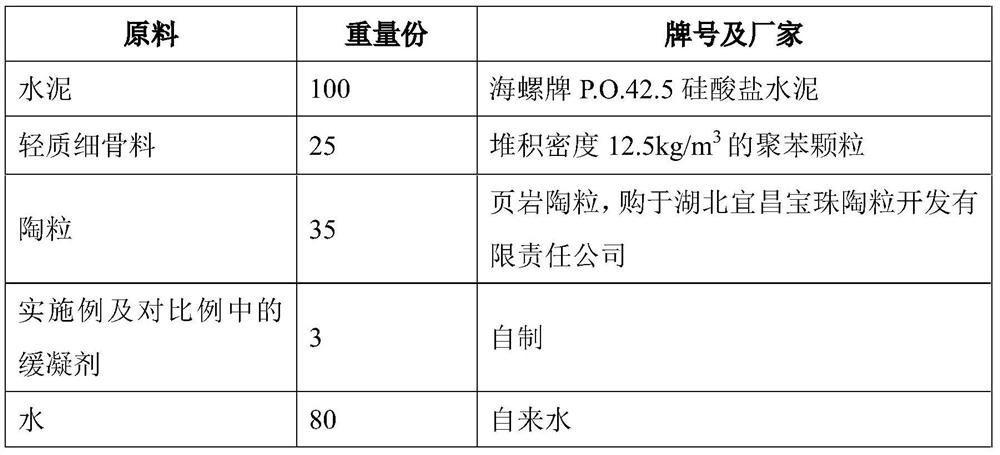

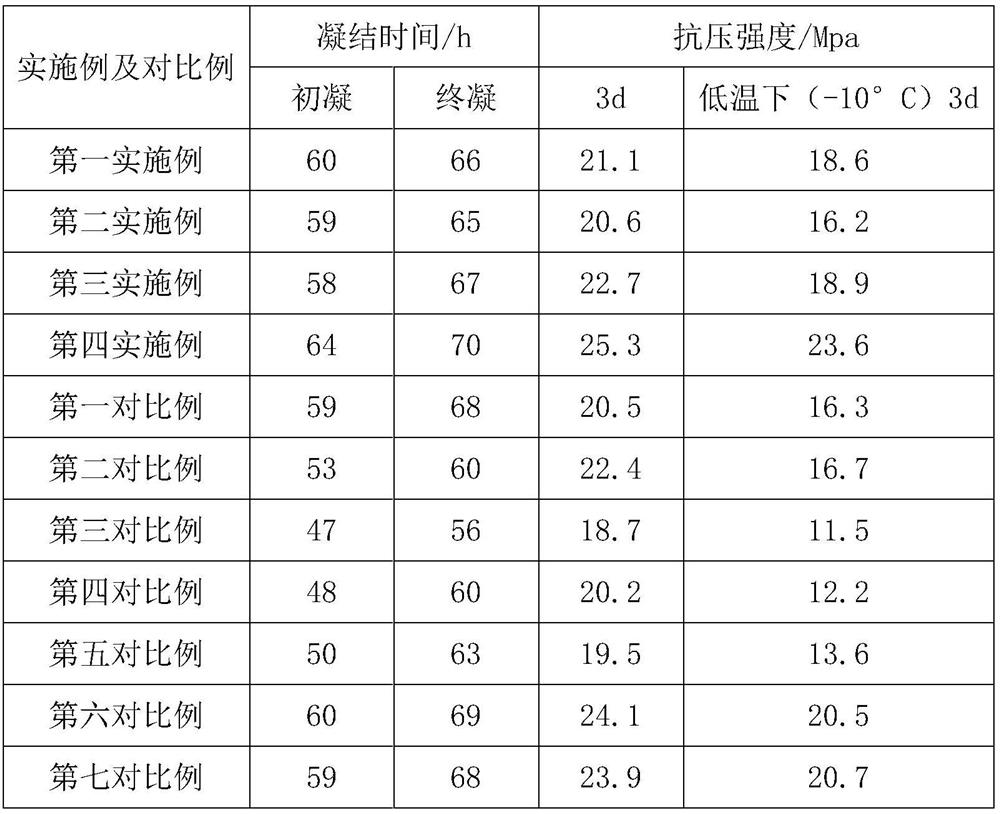

The invention discloses a retarding cement slurry composite for replacement of super-deep freezing hole and a preparation method thereof. The composite consists of silicate cement, retarder, a stabilizing agent and water; and retarding silicate cement slurry is prepared according to the mass ratio of 1:0.7-1:1.5 parts of water and cement, wherein the added retarding agent accounts for 0.1-0.3 parts of the cement; and the added stabilizing agent accounts for 0-10 parts of the cement. The retarding agent is JS-1 type retarding agent and consists of hydroxy carboxylic acid as well as salt thereof and inorganic salt, wherein the hydroxy carboxylic acid and salt thereof accounts for 50-70 parts and the inorganic salt counts for 30-50 parts. The preparation method comprises the following steps of: weighing water, and pouring the water into a stirring box; weighing the retarding reagent and stirring; weighing the bentonite and continuously stirring; and weighing the cement and continuously evenly stirring. The invention has the comprehensive advantages of long retarding time, good replaceability and high concretion intensity, and can be widely applied to industries, such as coal mine, petroleum and the like.

Owner:CHINA COAL SPECIAL DRILLING ENG GROUP +1

A kind of concrete retarder and preparation method thereof

The invention belongs to the technical field of concrete admixtures, in particular to a concrete retarder and a preparation method thereof. The first aspect of the present invention provides a concrete retarder, the concrete retarder includes the first retarder component, the second retarder component, zinc sulfate; wherein, the first retarder component, The second retarding component, the weight ratio of zinc sulfate is 10: (1-4): (0.1-1); The particle size ratio of the first retarding component and the second retarding component is ( 3-10): 1. The second aspect of the present invention provides the preparation method of the above-mentioned concrete retarder, comprising the following steps: S1: placing the second retarder component in water at normal temperature for 2-5 minutes; S2: treating the first The retarding component, the second retarding component and the zinc sulfate are uniformly mixed in proportion to obtain the concrete retarder.

Owner:英德市竣冠新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com