A kind of concrete retarder and preparation method thereof

A technology of concrete and setting retarder, which is applied in the field of concrete admixtures to achieve the effects of increasing compressive strength, high compressive strength and increasing retardation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

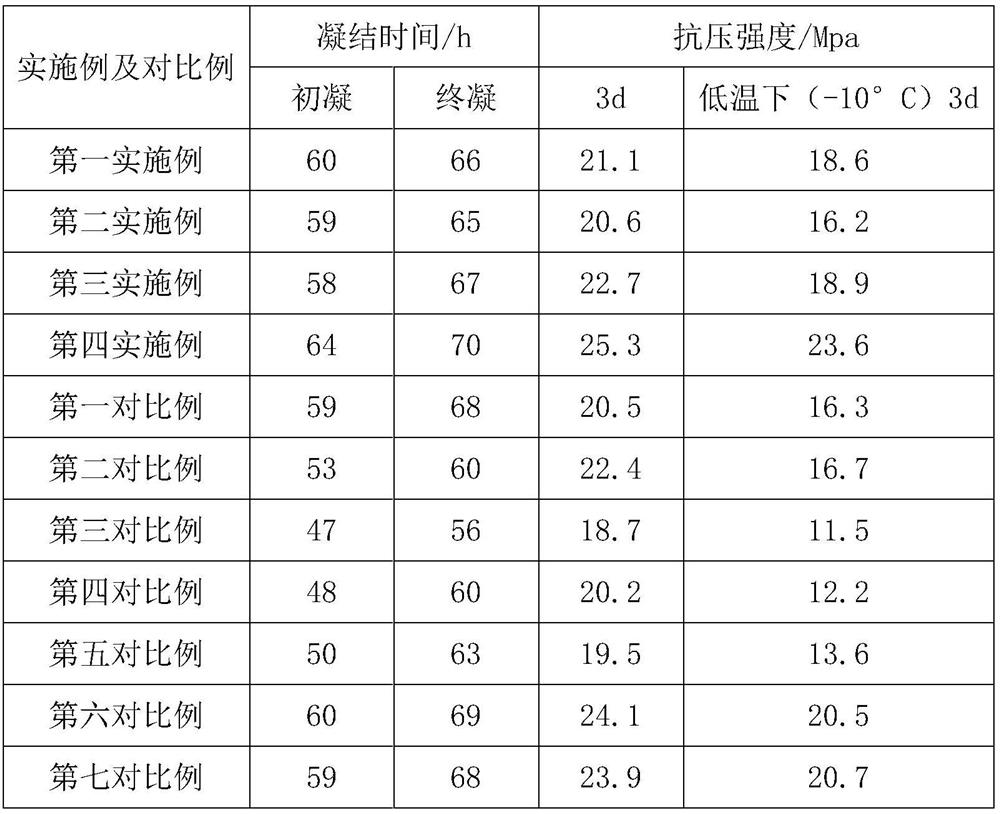

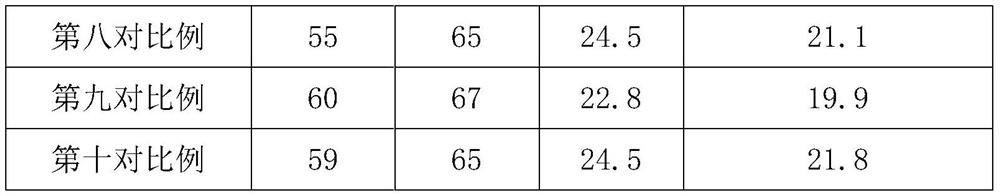

Examples

preparation example Construction

[0030] The preparation process of the first retarding component is as follows:

[0031] Add corn stalks to 55% acetic acid solution, soak them at 60°C for 3 hours, dry and pulverize them to obtain straw fibers; then mix the obtained straw fibers with water at a mass ratio of 1:200, and place them in an ultrasonic Ultrasonic dispersion in the machine for 30 minutes to obtain the first raw material;

[0032] Stir the sodium hydroxide and water evenly according to the ratio of mass ratio of 1:10, add acrylic acid to the evenly stirred sodium hydroxide solution to obtain a sodium acrylate solution, and obtain a second raw material;

[0033] Then uniformly mix the weighed acrylamide, N-(methylol)acrylamide and water according to a certain ratio to obtain the third raw material;

[0034] uniformly mixing the first raw material, the second raw material, and the third raw material to obtain a mixed liquid;

[0035] Put the mixed solution in the reaction kettle, control the heating t...

no. 1 example

[0047] The concrete retarder that the first embodiment of the present application provides, described concrete retarder comprises the first retarder component, the second retarder component, zinc sulfate;

[0048] Wherein, the weight ratio of the first retarding component, the second retarding component, and zinc sulfate is 10:1:0.1;

[0049] The preparation process of the first retarding component and the second retarding component is as follows:

[0050] Add 1 kg of corn stalks to 55% acetic acid solution, soak at 60°C for 3 hours, dry and pulverize to obtain straw fibers; then mix the obtained straw fibers with water at a mass ratio of 1:200, place in Ultrasonic dispersion in an ultrasonic machine for 30 minutes to obtain the first raw material;

[0051] Stir 100g of sodium hydroxide and water evenly according to the mass ratio of 1:10, add 50g of acrylic acid to the evenly stirred sodium hydroxide solution to obtain a sodium acrylate solution, and obtain a second raw materi...

no. 2 example

[0059] The concrete retarder that the second embodiment of the present application provides, described concrete retarder comprises the first retarder component, the second retarder component, zinc sulfate;

[0060] Wherein, the weight ratio of the first retarding component, the second retarding component, and zinc sulfate is 10:4:0.1;

[0061] The preparation process of the first retarding component and the second retarding component is as follows:

[0062] Add 1 kg of corn stalks to 55% acetic acid solution, soak at 60°C for 3 hours, dry and pulverize to obtain straw fibers; then mix the obtained straw fibers with water at a mass ratio of 1:200, place in Ultrasonic dispersion in an ultrasonic machine for 30 minutes to obtain the first raw material;

[0063] Stir 100g of sodium hydroxide and water evenly according to the mass ratio of 1:10, add 50g of acrylic acid to the evenly stirred sodium hydroxide solution to obtain a sodium acrylate solution, and obtain a second raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com