Air entraining agent and application thereof in preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

A composite superplasticizer and cassava starch technology, which is applied in the field of building materials, can solve the problems of ineffective workability of freshly mixed concrete, toxicity of superplasticizer products, and uneven distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

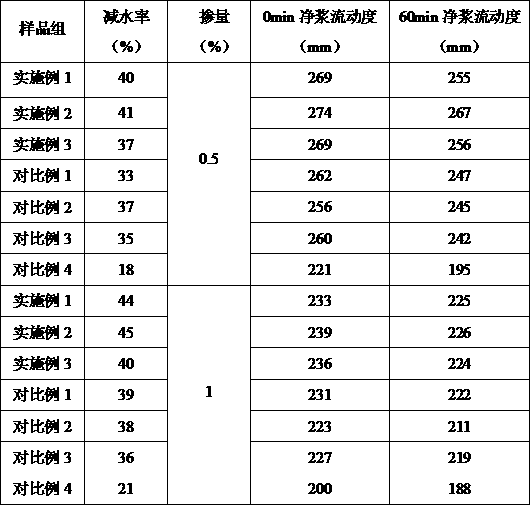

Examples

Embodiment 1

[0043] An air-entraining agent comprising the following components in parts by weight: 48 parts of rosin powder, 55 parts of p-toluenesulfonic acid, 37 parts of sodium hydroxide, 18 parts of pentaerythritol, 7 parts of tall oil and 9 parts of petroleum sulfonate .

[0044] The preparation method of described air-entraining agent, comprises the following steps:

[0045] S1: Put rosin powder, p-toluenesulfonic acid and sodium hydroxide into the reaction kettle to obtain mixture A, add water with 50% of the total mass of mixture A, mix and stir for 30min, heat to 80°C, keep warm for 50min, and heat up to 80°C , keep warm for 45min to obtain mixed solution A;

[0046] S2: Heat the mixture A to 85°C, slowly add pentaerythritol and tall oil, keep it warm for 35 minutes, then raise the temperature to 70°C, slowly add petroleum sulfonate, keep it warm for 1 hour, to obtain the air-entraining agent.

[0047] A modified tapioca starch-polycarboxylic acid composite water reducer, compr...

Embodiment 2

[0057] An air-entraining agent comprising the following components in parts by weight: 52 parts of rosin powder, 44 parts of p-toluenesulfonic acid, 32 parts of sodium hydroxide, 20.5 parts of pentaerythritol, 11 parts of tall oil and 7 parts of petroleum sulfonate .

[0058] The preparation method of described air-entraining agent, comprises the following steps:

[0059] S1: Put rosin powder, p-toluenesulfonic acid and sodium hydroxide into the reaction kettle to obtain mixture A, add water with 50% of the total mass of mixture A, mix and stir for 30min, heat to 80°C, keep warm for 50min, and heat up to 80°C , keep warm for 45min to obtain mixed solution A;

[0060] S2: Raise the temperature of the mixture A to 85°C, slowly add pentaerythritol and tall oil, keep it warm for 35 minutes, then raise the temperature to 85°C, slowly add petroleum sulfonate, keep it warm for 1 hour, to obtain the air-entraining agent.

[0061] A modified tapioca starch-polycarboxylic acid composi...

Embodiment 3

[0071] An air-entraining agent comprising the following components in parts by weight: 60 parts of rosin powder, 38 parts of p-toluenesulfonic acid, 25 parts of sodium hydroxide, 22 parts of pentaerythritol, 14 parts of tall oil and 5 parts of petroleum sulfonate .

[0072] The preparation method of described air-entraining agent, comprises the following steps:

[0073] S1: Put rosin powder, p-toluenesulfonic acid and sodium hydroxide into the reaction kettle to obtain mixture A, add water with 50% of the total mass of mixture A, mix and stir for 30min, heat to 80°C, keep warm for 50min, and heat up to 80°C , keep warm for 45min to obtain mixed solution A;

[0074] S2: Heat the mixture A to 85°C, slowly add pentaerythritol and tall oil, keep it warm for 35 minutes, then raise the temperature to 70°C, slowly add petroleum sulfonate, keep it warm for 1 hour, to obtain the air-entraining agent.

[0075] A modified tapioca starch-polycarboxylic acid composite water reducer, comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com