Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Strong retarding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slushing agent for concrete and preparation method thereof

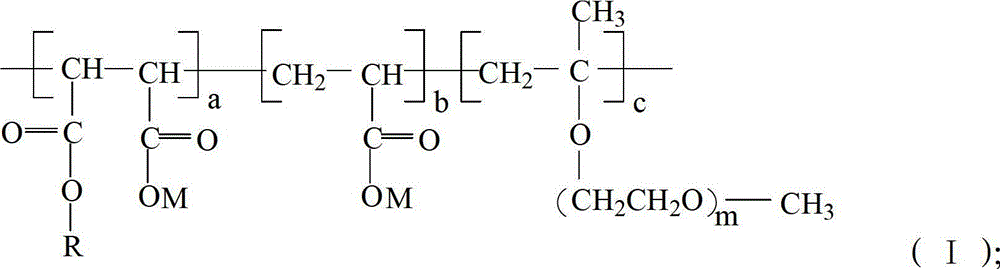

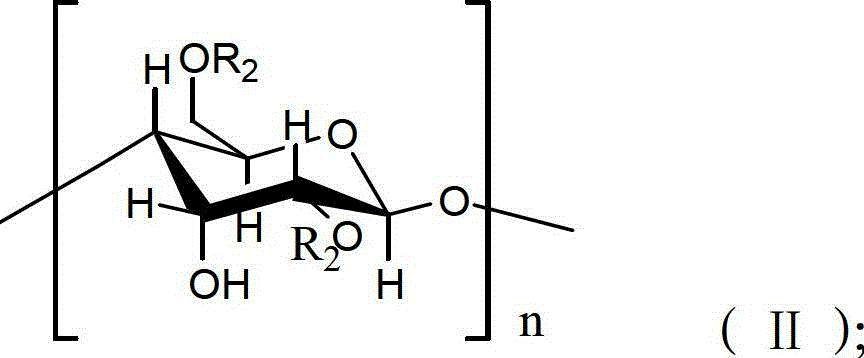

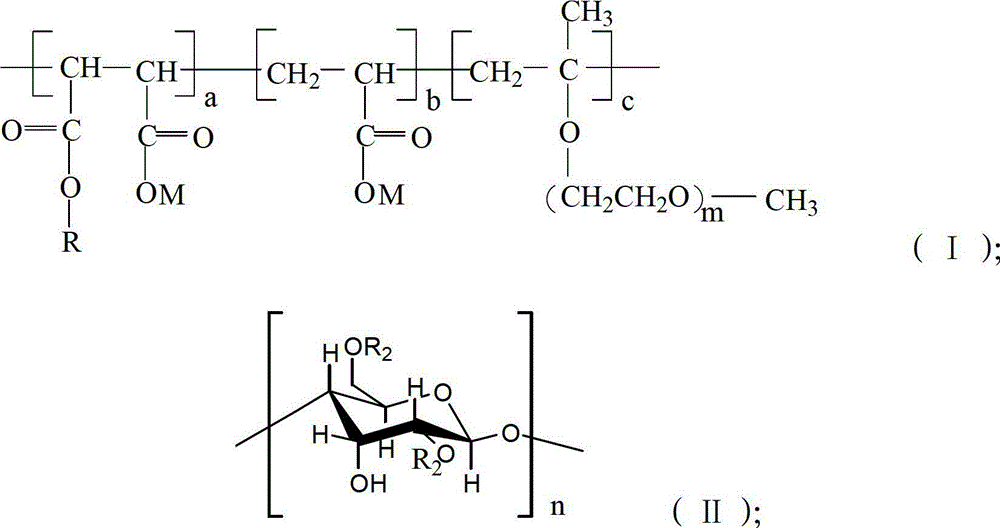

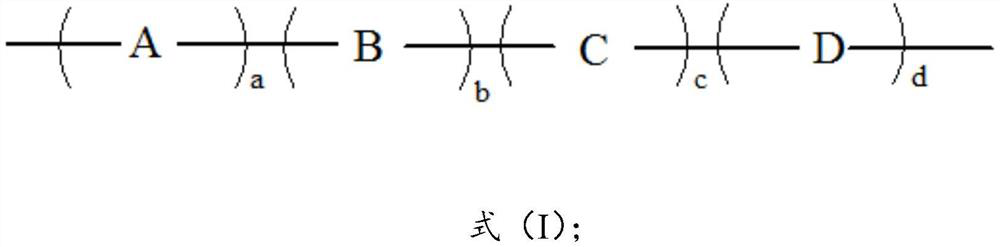

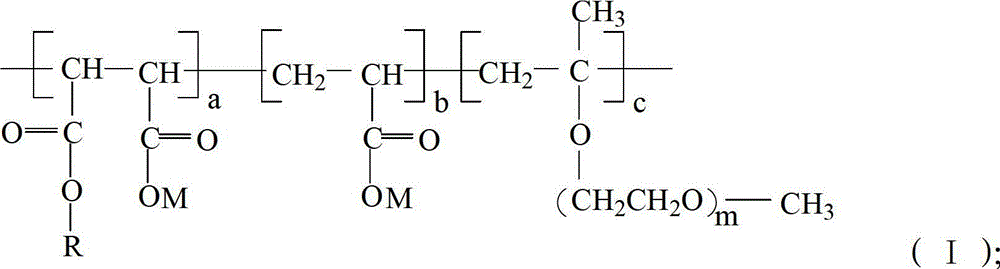

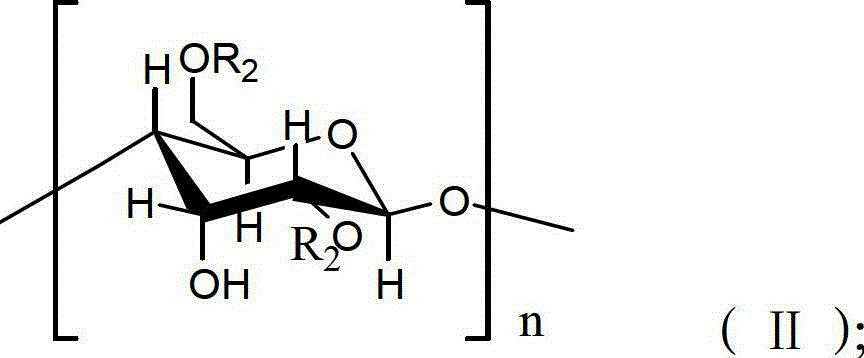

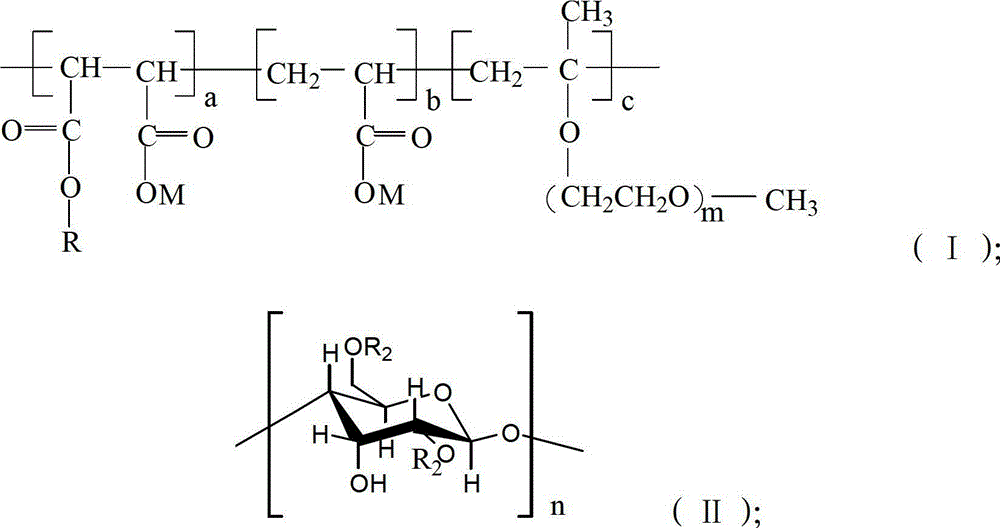

The invention provides a preparation method of a slushing agent for concrete. The preparation method comprises the following steps in sequence: implementing the first reaction between maleic anhydride and hydroxypropyl methyl cellulose in glacial acetic acid under the catalysis of acetate, so as to obtain the hydroxypropyl methyl cellulose monomaleate; and carrying out free radical polymerization between methyl allyl polyoxyethylene ether, acrylic acid solution and hydroxypropyl methyl cellulose monomaleate under an oxidentive-reductive initiation system, so as to obtain the slushing agent for concrete. According to the slushing agent for concrete, prepared by the preparation method provided by the invention, the molecular structure contains the hydroxypropyl methyl cellulose molecular structure unit, so that the macromolecules of the slushing agent can be entangled with each other to form a net-shaped structure to wrap cement and water for effectively preventing the moisture in the mortar from evaporating, and as a result, the slump keeping property is good. The invention also provides the slushing agent for concrete, and the slushing agent for concrete has the structure as shown in formula (1).

Owner:SHANDONG HONGYI TECH

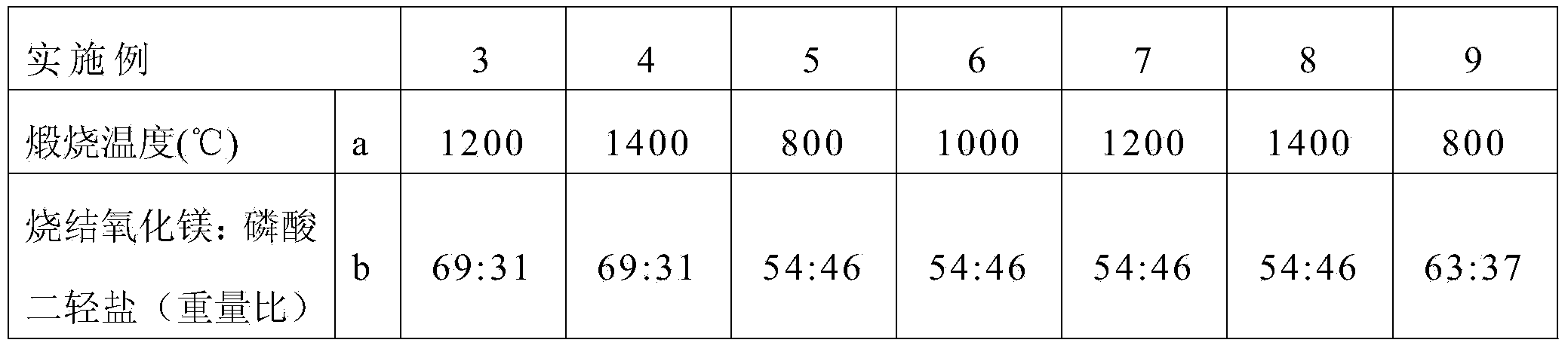

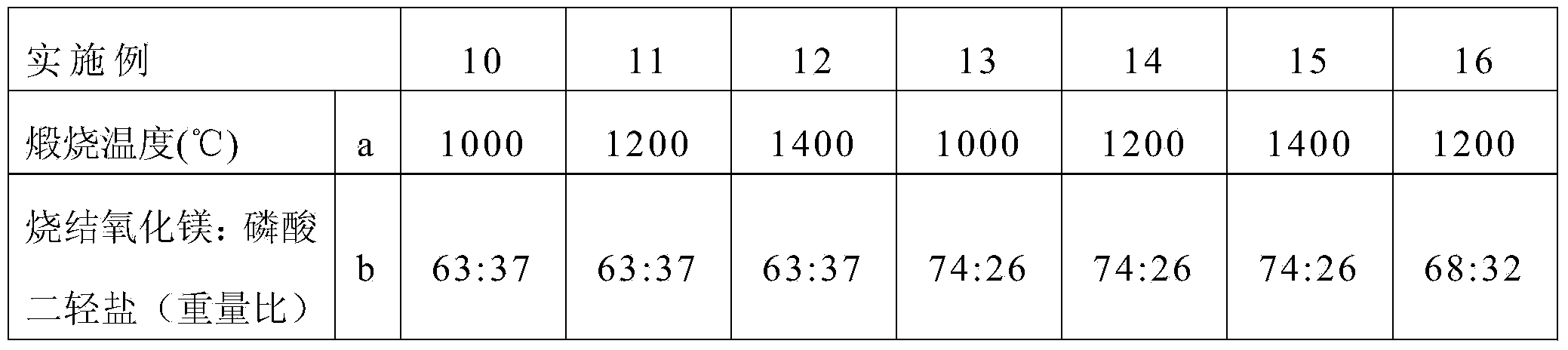

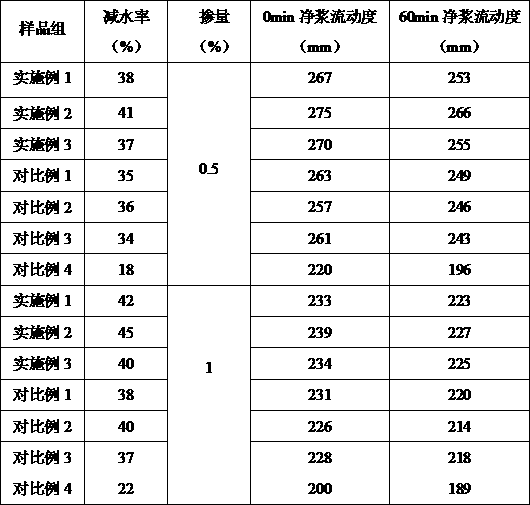

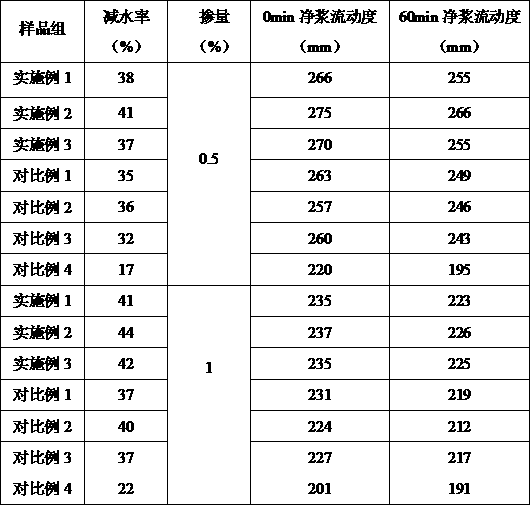

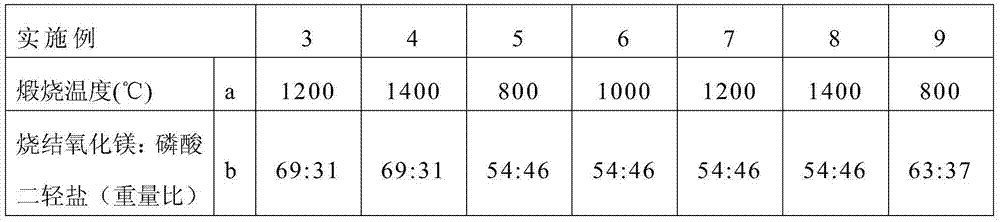

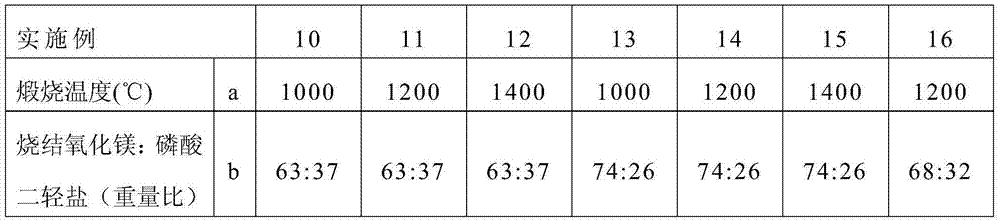

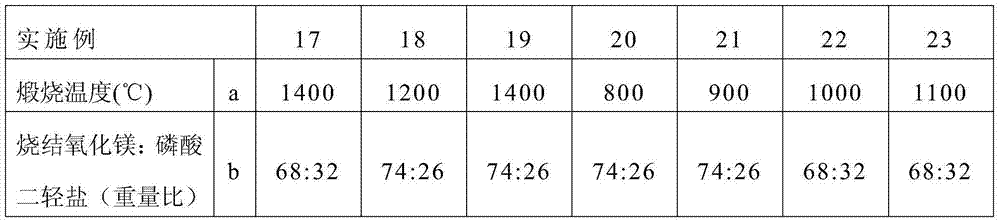

Fast-setting early strength magnesium phosphate cement without additional retarder

The invention belongs to the technical field of building materials, and in particular discloses a fast-setting early strength magnesium phosphate cement without additional retarder. The fast-setting early strength magnesium phosphate cement without additional retarder comprises the following components by weight: 54-80 parts of sintered magnesium oxide and 20-46 parts of dihydric phosphate. Through calcination at low temperature by the invention, the sintered magnesium oxide raw material with good performance and low price can be prepared, so as to not only solve the problem of ''magnesium harm'' in lithium extraction from saline lake but also provide a new low-cost raw material approach for the production of magnesium phosphate cement. The prepared sintered magnesium oxide contains a small amount of free boron trioxide, which has good delayed coagulation effect on magnesium phosphate cement. The prepared magnesium phosphate cement material has the characteristics of high early strength and no decrease of long-term strength.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

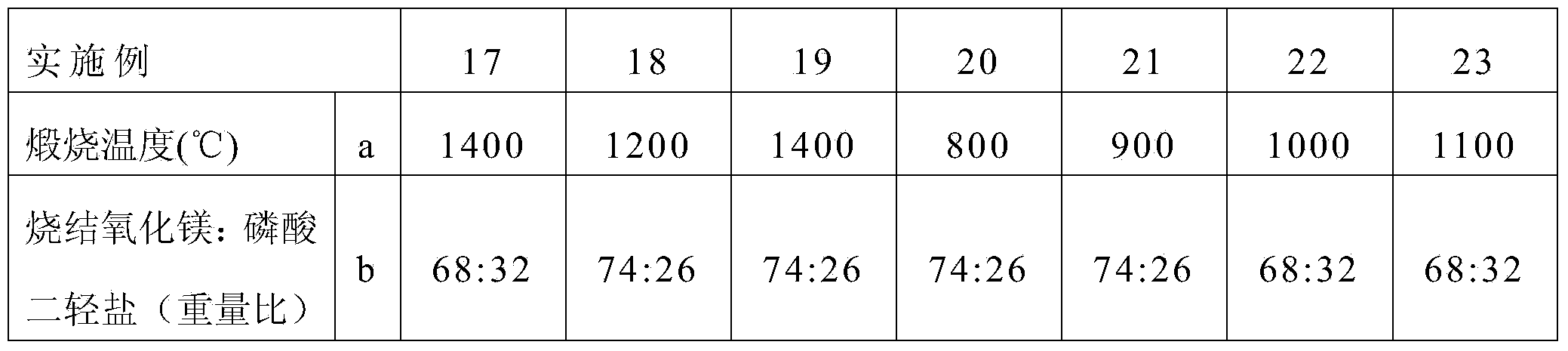

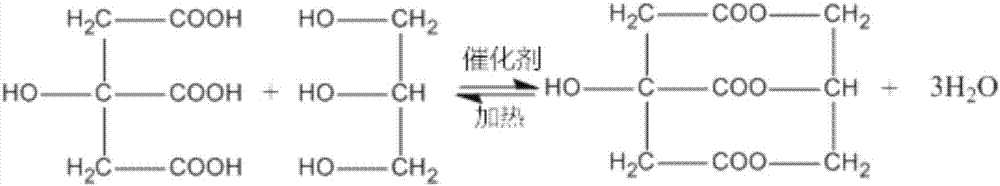

Long-acting retarder and preparation method thereof

The invention discloses a long-acting retarder and a preparation method thereof and relates to the technical field of building materials. A hydroxycarboxylic acid-type retarder and a polyol-type retarder in the retarder undergo an esterification reaction, and the product delayed coagulation component is postponed to be released in the middle and later period of the concrete solidification process. In addition, a plurality of retarders having different action mechanisms are prepared so that the long-acting retarder has a good delayed coagulation effect in the early stage of the solidification process of the concrete to reach long-lasting delayed coagulation in the middle and later period. The preparation method comprises mixing the hydroxycarboxylic acid-type retarder and a part of the polyol retarder to obtain a first mixed liquid, adding a second mixed liquid containing an esterification catalyst into the first mixed liquid, fully mixing the first mixed liquid and the second mixed liquid for an esterification reaction, and then compounding the reaction product and other retarders. The preparation method is easy to operate, has low demands for equipment, can easily and efficiently produce esterification products and is suitable for large-scale industrial production.

Owner:重庆石博士新材料有限公司

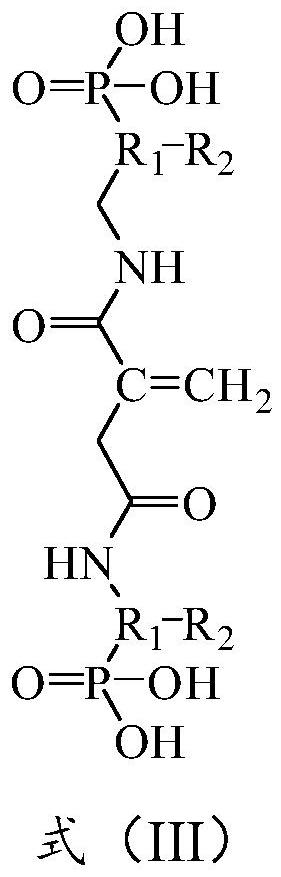

Temperature response type amphoteric polymer retarder and preparation method thereof

InactiveCN105273135AStrong retardationGood adjustabilityDrilling compositionMaleic anhydride2-Methyl propane

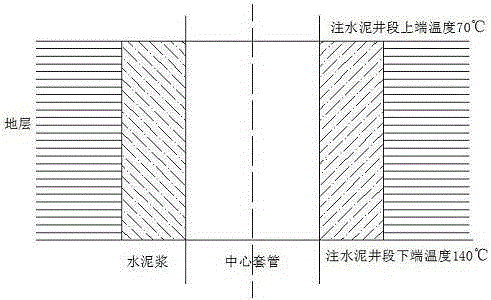

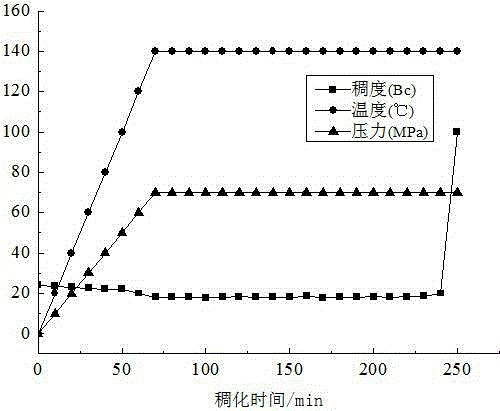

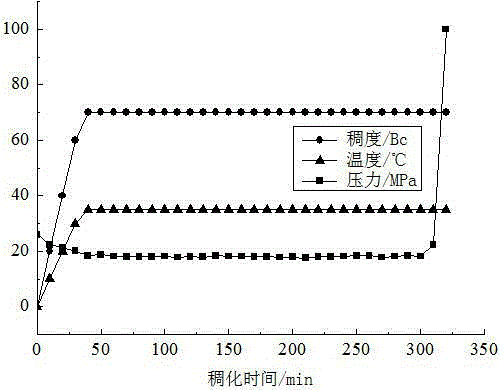

The invention relates to an oil well cement retarder in the field of oil gas well exploration and development and a preparation method of the oil well cement retarder. The amphoteric polymer retarder is prepared from, by mass, 10-20% of dimethyldiallylammonium chloride (DMDAAC), 20-30% of 2-acrylamide-2-methyl propane sulfonic acid (AMPS), 30-50% maleic anhydride (MA) and 10-30% of acrylic amide (AM). Due to lateral groups in an amphoteric polymer structure, a self-response type response can be made for the temperature of surroundings, and the temperature adaptability is high. The delayed coagulation of cement paste within the whole temperature region with 70 DEG C and 140 DEG C as the upper and lower end temperatures of a cementing well section is achieved, the thickening time of the cement paste and the retarder added amount are in the good linear relation, the right-angled thickening effect is obvious, the temperature and the added amount sensitivity are low, and the cement paste comprehensive performance can meet the requirement for well cementation construction; in addition, the retarder is simple in synthesis technology, low in cost, high in operability and capable of achieving large-scale production and application.

Owner:SOUTHWEST PETROLEUM UNIV

Polycarboxylate water reducing agent for concrete

The invention discloses a polycarboxylate water reducing agent for concrete. The polycarboxylate water reducing agent is characterized by mixing the following raw materials in parts by weight: 40-50 parts of a high-property polycarboxylate water reducing agent, 5-7 parts of borax, 1-2 parts of triethanolamine, 1-2 parts of magnesium borate, 2-3 parts of cyanuric acid triene propyl ester, 1-2 parts of calcium chloride, 1-2 parts of fatty alcohol-polyoxyethylene ether sodium sulfate, 0.3-1 part of dimethyl sulfoxide, 2-4 parts of sulfamic acid and 0.8-2 parts of thickening agent. The water reducing agent disclosed by the invention has a good water reducing effect and remarkable delayed coagulation action, and is capable of improving strength of concrete at early stage and different stages and capable of improving the mechanical properties of the concrete, reducing surface shrinkage and crack and improving anti-permeability and durability of the concrete.

Owner:ANHUI FUNAN LVYUAN CHEM

Prepn of retardant for magnesite binding material

The retarding agent of magnesite cementing material is made up by using (wt%) water 25-35%, aluminium hydroxide 20-30%, tartaric acid 10-20% and phosphoric acid 25-35%. It can effectively delay initial setting time of slurry material, and can raise water-proof property of product.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

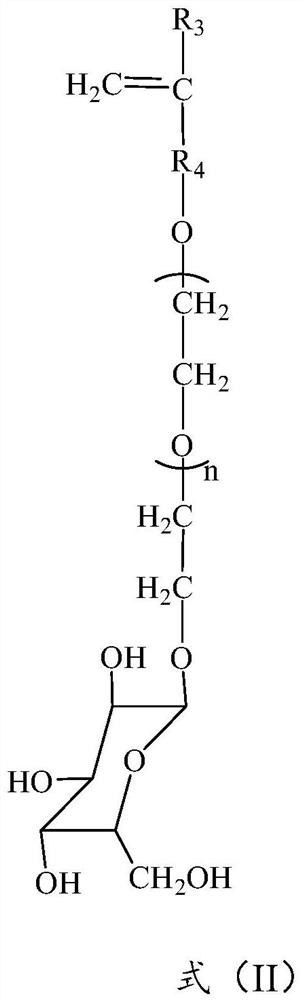

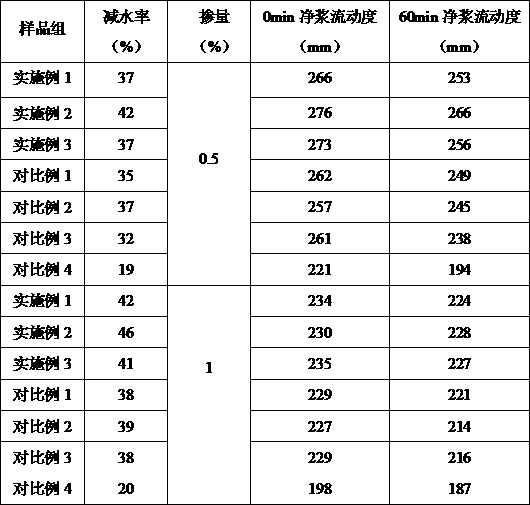

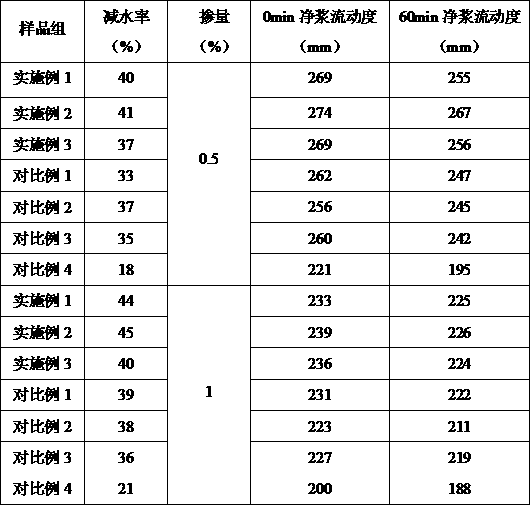

Low-sensitivity water-reducing slump-retaining polycarboxylic acid water reducer and preparation method thereof

ActiveCN113444210AHigh water-reducing and slump-retaining performanceGood mud and weather resistanceAcid waterEnvironmental engineering

The invention discloses a low-sensitivity water-reducing slump-retaining polycarboxylic acid water reducer and a preparation method thereof, and relates to the technical field of concrete admixtures. The invention provides a structural formula and a preparation method of a low-sensitivity type water-reducing and slump-retaining polycarboxylic acid water reducer, and also provides application of the low-sensitivity type water-reducing and slump-retaining polycarboxylic acid water reducer in preparation of concrete. The water reducer provided by the invention has high water reducing and slump retaining properties, also has good mud-resistant and weather-resistant characteristics, and meets the workability of concrete under the conditions of raw material fluctuation, high temperature, long-distance transportation and the like.

Owner:河北红墙新材料有限公司

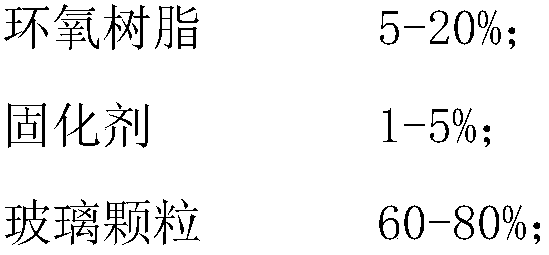

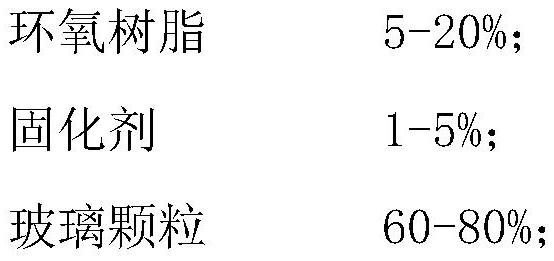

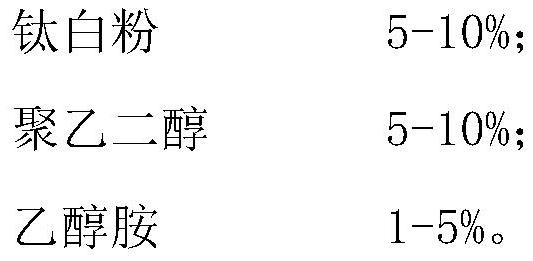

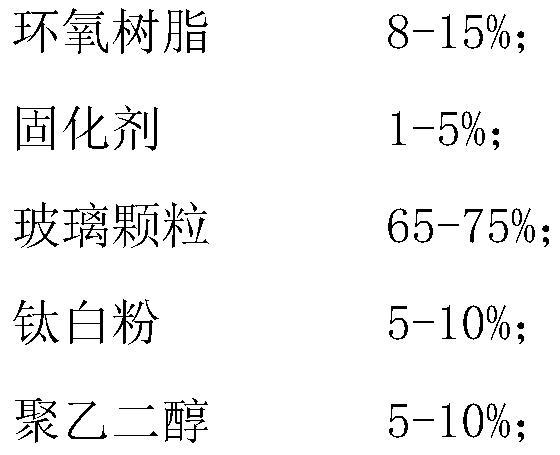

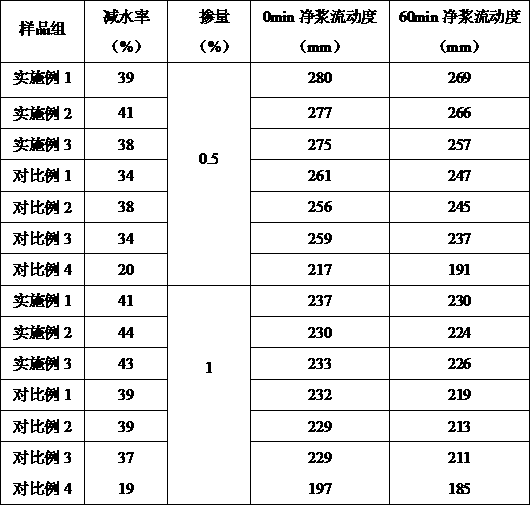

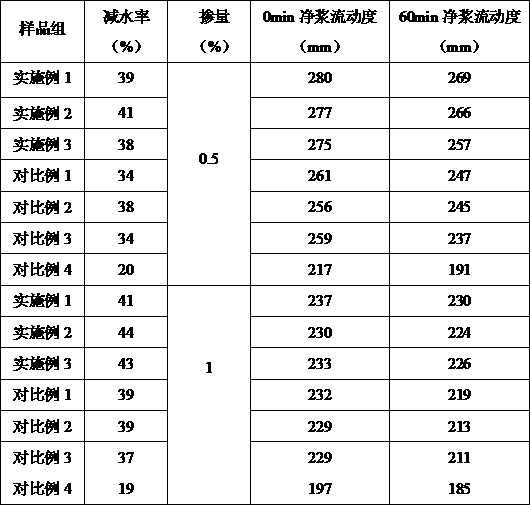

High-durability concrete and preparation method thereof

ActiveCN108328967AIncreased durabilityImprove photoelectric conversion efficiencyIonInteraction forces

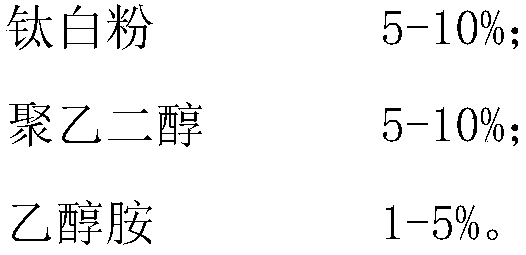

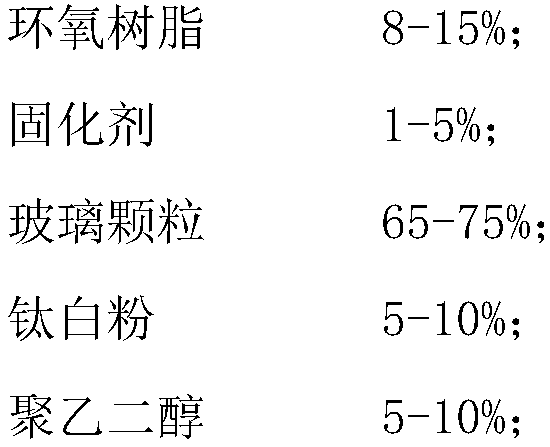

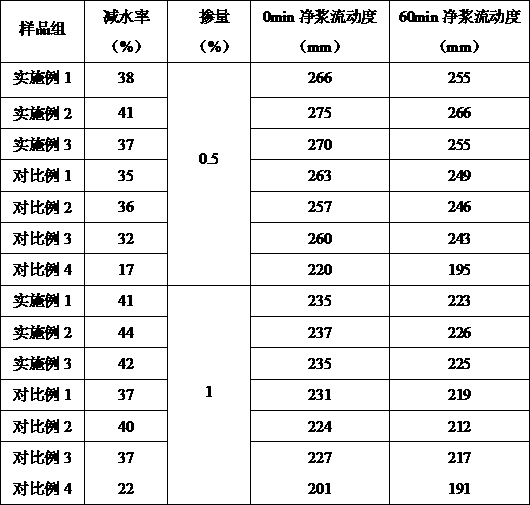

The invention discloses high-durability concrete and a preparation method thereof. The high-durability concrete is made from, by weight, 5-20% of epoxy resin, 1-5% of a curing agent, 60-80% of glass granules, 5-10% of titanium dioxide, 5-10% of polyethylene glycol, and 1-5% of ethanol amine. Through interactions of ion bonds, covalent bonds and hydrogen bonds, Van der Waals' force and other forces, the components enable the internal structure of the concrete to be more stable, so that compressive strength, corrosion resistance, anti-freezing property and other durability properties are improved for the concrete, the toughness and anti-radiation property are improved for the concrete, the service life of the concrete is extended, and the concrete rarely cracks and has good workability. Thepreparation method is simple and low in cost.

Owner:湖北联建新材料有限公司

Preparation technology of high-efficiency set retarder

The invention discloses a manufacturing process of a high-efficiency retarder, which comprises the following steps: 1) weighing an organosilicon modified acrylic emulsion, a film-forming agent, a water reducing agent and polyethylene glycol in parts by weight, and mixing them uniformly; 2) placing them in water Add amantadine ethylamine, phosphorous acid, sodium glucoheptonate, stir and heat to 60-80 ℃, and add formaldehyde solution dropwise; 3) after dissolving white sugar, add citric acid, tartaric acid, borax, maltodextrin, stir and mix. 4) Mix the slurry prepared in steps 1), 2), and 3) together, stir, and mix to obtain a retarder. The retarder of the invention has good retardation effect, stable chemical properties when applied to cement slurry, easy adjustment of thickening time, can avoid premature coagulation of cement, reduce the loss rate of cement strength, and has good Regularity and operability, low cost and simple operation.

Owner:四川宏升石油技术开发有限责任公司

Retarder and application thereof in preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses a retarder and application thereof in preparation of a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongs to the field of building materials. The retarder is prepared from the following components in parts by weight: 43 to 60 parts of sodium gluconate, 30 to 37 parts of sodium citrate, 22 to 29 parts of sodium tripolyphosphate, 13 to 19parts of sodium pyrophosphate, 3 to 8 parts of ammonium borate, 2 to 4 parts of ferrous sulfate and 1 to 3 parts of magnesium sulfate. The cassava starch is subjected to oxidation, acidification, etherification, grafting, neutralization and other reaction processes to prepare the starch-containing composite water reducing agent. By adopting the composite water reducing agent containing the retarder, the setting time of concrete can be adjusted, the performance of the concrete can be improved, and meanwhile, the effects of specifically improving the net slurry fluidity of the concrete, reducingthe construction energy consumption and the like can be achieved. Development and application of the cassava starch water reducing agent are beneficial to improvement of the water reducing agent processing technology, improvement of the water reducing agent product quality and reduction of environmental pollution.

Owner:NANNING TONGCAI TECH CO LTD

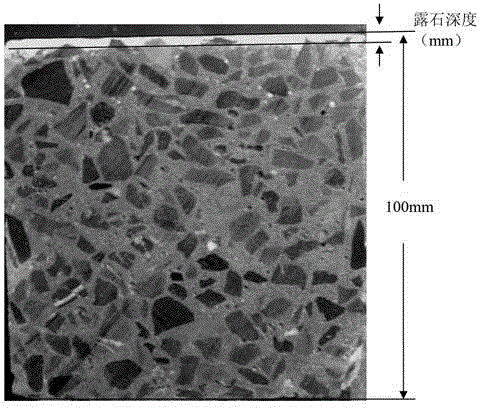

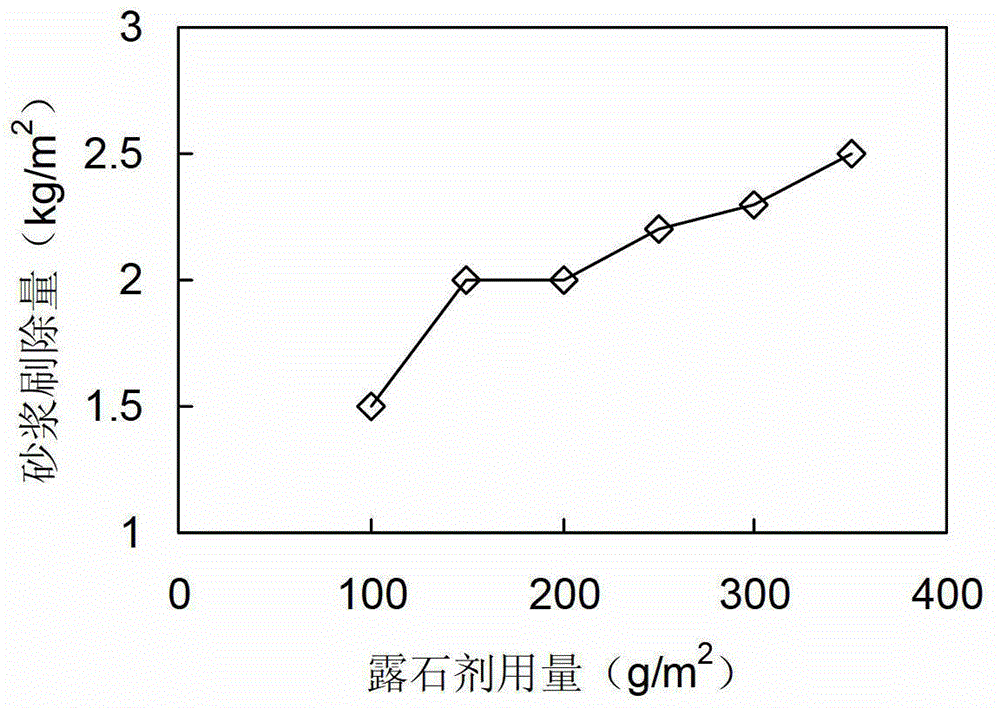

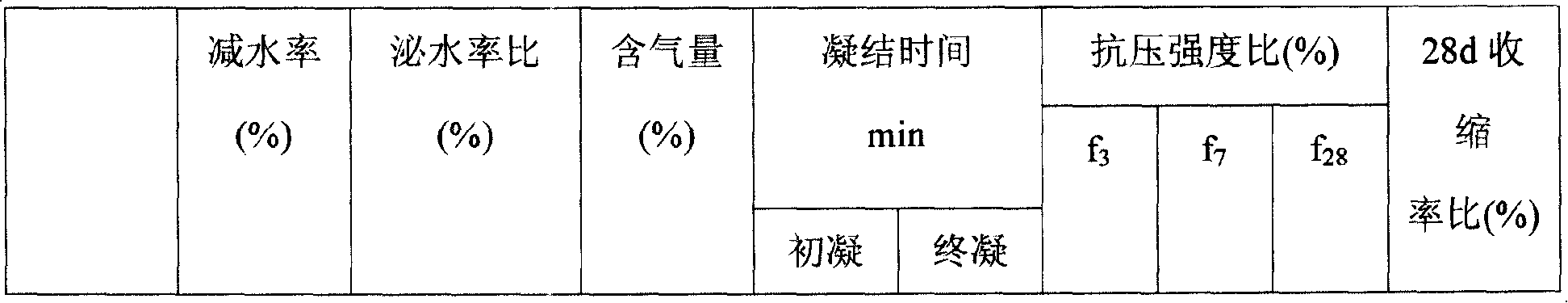

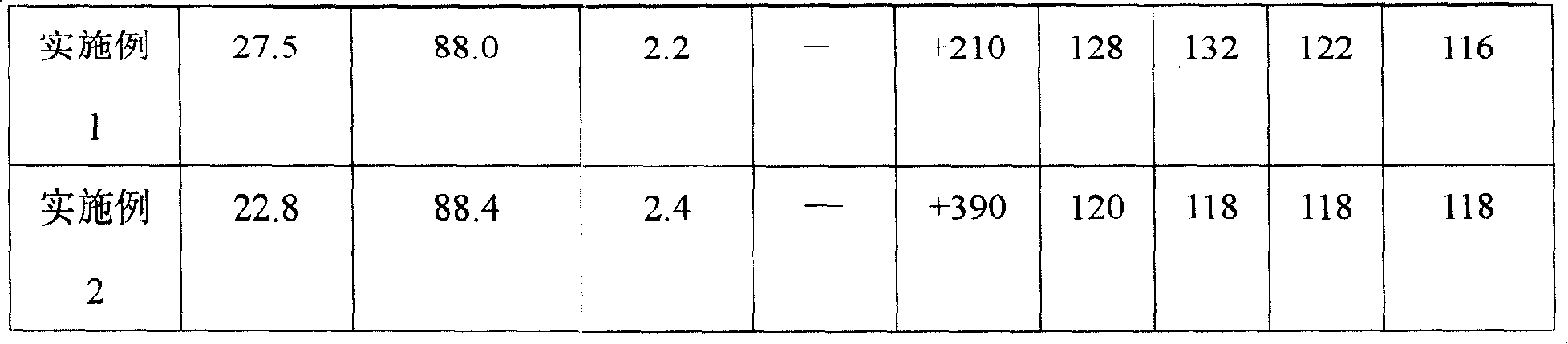

High-performance concrete exposed aggregate agent as well as preparation method and application method for same

The invention discloses a high-performance concrete exposed aggregate agent as well as a preparation method and an application method for the same. The exposed aggregate agent comprises a component A and a component B, wherein the component A is formed by stepwise mixing and stirring water, hydroxyl carboxylate, organic phosphine, fluosilicate, a penetrant, a stabilizer, a surfactant and a pigment, and the total solid content of the component A is 10-30 wt%; and the component B is composed of water, industrial sodium silicate, sodium hydroxide and a modifier. The application method comprises the following steps of: staying concrete until obvious moisture residue is inexistent on the surface after forming and plastering; spraying the component A on the surface of the concrete, and waiting for 5-20 minutes; spraying the component B on the surface of the concrete, and maintaining for 12-72 hours; and performing scouring removal treatment by scouring mortar on the surface with running water. The exposed aggregate agent has the double effects of aggregate exposure and maintenance, and does not need a process of membrane-covering curing, thus increasing construction efficiency and reducing construction cost. The exposed aggregate agent is stable in aggregate exposure effect and adjustable in aggregate exposure time, as well as has the characteristics of being low in dosage, easy to control an aggregate exposure depth, and level and smooth in aggregate exposure depth.

Owner:WUHAN UNIV OF TECH

Efficient retarding and water reducing agent for concrete

The present invention relates to one kind of efficient retarding and water reducing agent for concrete suitable for commercial concrete, pumped concrete and bulk concrete. The efficient retarding and water reducing agent consists of water reducing agent 0-90 wt%, retarder I 1-15 wt%, retarder II 0.5-25 wt% and shrinkage reducing agent 0.05-0.2 wt%. The efficient retarding and water reducing agent has simple preparation process, and has the effects of delaying the setting of concrete, raising early strength, reducing water, etc.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

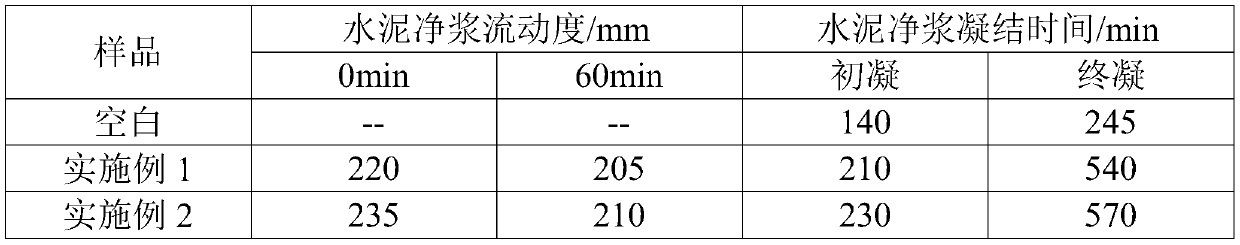

Modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongs to the field of building materials. The modified cassava starch-polycarboxylic acid composite water reducing agent is prepared from the following raw materials in parts by weight: 20 to 35 parts of modified cassava starch, 30 to 120 parts of sodium hydroxide, 2 to 6 parts of retarder,0.5 to 4 parts of defoaming agent and 1 to 5.5 parts of air entraining agent. The content of the modified cassava starch in the composite water reducing agent reaches 20% or above, and when the mixingamount of the water reducing agent is 0.3%, the coagulation time exceeds 24 h, and the requirement of the super retarder is met; and when the mixing amount of the composite water reducing agent is 1%, the initial fluidity of the cement paste is greater than 200mm. The development and application of the cassava starch water reducing agent are beneficial to improving the processing technology of the water reducing agent, improving the product quality of the water reducing agent and reducing the environmental pollution, and can effectively solve the problem of output of Guangxi agricultural products and improve the additional value of the products.

Owner:NANNING TONGCAI TECH CO LTD

Set retarding superplasticizer making use of flue gas desulfurization ash

The invention discloses a set retarding superplasticizer making use of flue gas desulfurization ash. The set retarding superplasticizer is prepared from, by weight, 240-250 parts of TPEG, 25.2-26.0 parts of acrylic acid, 1.6-1.65 parts of ammonium persulfate, 0.53-0.55 part of mercaptoacetic acid, 13-14 parts of lignin, appropriate amount of sodium hydroxide solution with concentration being 10wt%, appropriate amount of deionized water, 26-28 parts of graphene oxide, 1.5-2 parts of texanol, 3-4 parts of dispersible adhesive powder, 0.9-1.2 parts of sodium hydroxide, 1.3-1.5 parts of sodium sulfate, 2-3 parts of triethanolamine, 7-8 parts of converter steel slag, 9-11 parts of flue gas desulfurization ash and 4-5 parts of sodium alginate. The set retarding superplasticizer has an excellent set retarding function and is capable of enhancing early strength of concrete, solid wastes are reduced, cement content is decreased, and land occupation of the solid wastes and pollutant generation in cement production are reduced simultaneously.

Owner:ANHUI XINRUN NEW MATERIALS

Preparation method of retarder applied to preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses a preparation method of a retarder applied to preparation of a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongs to the field of buildingmaterials. The preparation method of the retarder comprises the following steps: uniformly mixing sodium gluconate, sodium citrate, sodium tripolyphosphate, sodium pyrophosphate, ammonium borate and water, adjusting the pH value of the solution to 5.5-6.5, adding magnesium sulfate, introducing nitrogen, and adding ferrous sulfate at 60 DEG C for free radical polymerization; observing the reactiontemperature, starting timing when the temperature is the highest, and obtaining the retarder after 2 hours. The composite water reducing agent containing the retarder prepared by adopting the processdisclosed by the invention can adjust the setting time of concrete and improve the performance of the concrete, and also has the effects of specifically improving the net slurry fluidity of the concrete, reducing the construction energy consumption and the like.

Owner:NANNING TONGCAI TECH CO LTD

Preparation method of air entraining agent applied to preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses a preparation method of an air entraining agent applied to preparation of a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongs to the fieldof building materials. The preparation method of the air entraining agent comprises the following steps: putting rosin powder, p-toluenesulfonic acid and sodium hydroxide into a reaction kettle, adding water accounting for 50% of the total mass of the mixture A, mixing and stirring for 30 minutes, heating to 80 DEG C, keeping the temperature for 50 minutes, heating to 80 DEG C, and keeping the temperature for 45 minutes; heating the mixed solution A to 85 DEG C, slowly adding pentaerythritol and tall oil, keeping the temperature for 35 minutes, heating to 70-85 DEG C, slowly adding mahogany petroleum sulfonate, and keeping the temperature for 1 hour to obtain the air entraining agent. The air entraining agent has a good air entraining effect, the average pore diameter of air entraining bubbles is small, the durability of concrete is remarkably improved, meanwhile, the workability of the concrete is obviously improved, the slump loss of the concrete is reduced, and the strength of theconcrete is not reduced.

Owner:NANNING TONGCAI TECH CO LTD

A fast-setting early-strength magnesium phosphate cement without additional retarder

The invention belongs to the technical field of building materials, and in particular discloses a fast-setting early strength magnesium phosphate cement without additional retarder. The fast-setting early strength magnesium phosphate cement without additional retarder comprises the following components by weight: 54-80 parts of sintered magnesium oxide and 20-46 parts of dihydric phosphate. Through calcination at low temperature by the invention, the sintered magnesium oxide raw material with good performance and low price can be prepared, so as to not only solve the problem of ''magnesium harm'' in lithium extraction from saline lake but also provide a new low-cost raw material approach for the production of magnesium phosphate cement. The prepared sintered magnesium oxide contains a small amount of free boron trioxide, which has good delayed coagulation effect on magnesium phosphate cement. The prepared magnesium phosphate cement material has the characteristics of high early strength and no decrease of long-term strength.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Defoaming agent and application thereof in preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses a defoaming agent and application thereof in preparation of a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongs to the field of building materials. The defoaming agent is prepared from the following components in parts by weight: 30 to 65 parts of hydrogen silicone oil, 20 to 40 parts of high-carbon alcohol fatty acid ester compound, 10to 17 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 10 to 15 parts of octamethylcyclotetrasiloxane, 5 to 9 parts of polyether silicone oil and 3 to 6 parts of polyoxypropylene polyoxyethylene glyceryl ether. The cassava starch is subjected to oxidation, acidification, etherification, grafting, neutralization and other reaction processes to prepare the starch-containing composite water reducing agent. The strength of concrete is reduced by harmful bubbles generated in the concrete, and the quality of the concrete is influenced; the defoaming agent is good in defoaming effect, the harmful bubbles in the concrete can be efficiently eliminated, and air holes influencing the performance are prevented from being formed. When the mixing amount of the water reducing agent is 1%, the initial fluidity of cement paste is larger than 200 mm, and the water reducing agent has a good water reducing effect.

Owner:NANNING TONGCAI TECH CO LTD

Air entraining agent and application thereof in preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses an air entraining agent and application of the air entraining agent in preparation of a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongsto the field of building materials. The air entraining agent is prepared from the following components in parts by weight: 48 to 60 parts of rosin powder, 38 to 55 parts of p-toluenesulfonic acid, 25to 37 parts of sodium hydroxide, 18 to 22 parts of pentaerythritol, 7 to 14 parts of tall oil and 5 to 9 parts of petroleum sulfonate. The cassava starch is subjected to oxidation, acidification, etherification, grafting, neutralization and other reaction processes to prepare the starch-containing composite water reducing agent. By adopting the air entraining agent disclosed by the invention, bubbles in concrete can be proper and stable in size, and meanwhile, the compressive strength of the concrete is remarkably improved. The content of the modified cassava starch in the composite water reducing agent reaches 20% or above, and when the mixing amount of the water reducing agent is 0.3%, the coagulation time is longer than 24 h, and the requirement of the super retarder is met.

Owner:NANNING TONGCAI TECH CO LTD

Slushing agent for concrete and preparation method thereof

The invention provides a preparation method of a slushing agent for concrete. The preparation method comprises the following steps in sequence: implementing the first reaction between maleic anhydride and hydroxypropyl methyl cellulose in glacial acetic acid under the catalysis of acetate, so as to obtain the hydroxypropyl methyl cellulose monomaleate; and carrying out free radical polymerization between methyl allyl polyoxyethylene ether, acrylic acid solution and hydroxypropyl methyl cellulose monomaleate under an oxidentive-reductive initiation system, so as to obtain the slushing agent for concrete. According to the slushing agent for concrete, prepared by the preparation method provided by the invention, the molecular structure contains the hydroxypropyl methyl cellulose molecular structure unit, so that the macromolecules of the slushing agent can be entangled with each other to form a net-shaped structure to wrap cement and water for effectively preventing the moisture in the mortar from evaporating, and as a result, the slump keeping property is good. The invention also provides the slushing agent for concrete, and the slushing agent for concrete has the structure as shown in formula (1).

Owner:SHANDONG HONGYI TECH

A kind of high durability concrete and preparation method thereof

The invention discloses a high-durability concrete and a preparation method thereof, which is made of the following components in weight percent: 5-20% of epoxy resin, 1-5% of curing agent, 60-80% of glass particles, and 5-10% of titanium dioxide %, polyethylene glycol 5‑10%, ethanolamine 1‑5%. Due to the interaction forces such as ionic bond, covalent bond, hydrogen bond and van der Waals force between the components of the present invention, the internal structure of the concrete is more stable, the durability of the concrete such as compression resistance, corrosion resistance, and frost resistance is improved, and the increase in The toughness and anti-radiation performance of concrete can improve the service life of concrete and make the concrete not easy to crack and have good workability. Moreover, the preparation process is simple and the cost is low.

Owner:湖北联建新材料有限公司

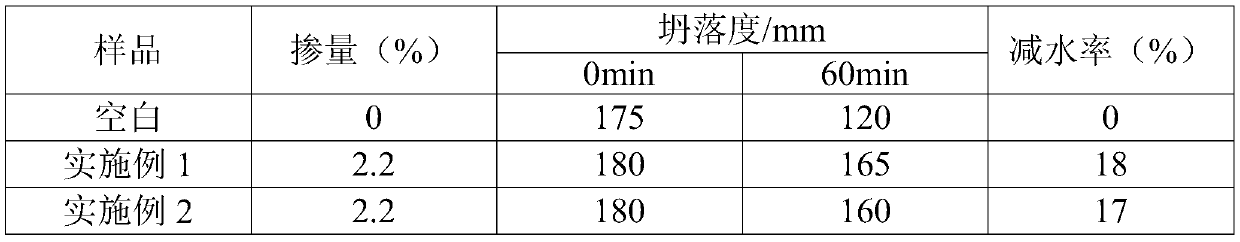

Building gypsum retarder and preparation method thereof

ActiveCN114835424AStrong retarding effectReduced impact strengthSolid waste managementPropionatePropanoic acid

The preparation method specifically comprises the following steps: dissolving 3-4 parts of alkali in water, adding 30-50 parts of furfural residues, and soaking for 5-40 minutes; heating to 70-85 DEG C, adding 5-15 parts of calcium beta-hydroxy-beta-methyl butyrate, stirring to react for 30-70 minutes, then adding 1-8 parts of calcium propionate and 0.5-3 parts of vinyl versatate, continuing to react for 2-10 minutes, cooling, and filtering to obtain the gypsum retarder. The retarder prepared by taking the furfural residues as the main raw material can keep a good retarding effect on the building gypsum under neutral and alkaline conditions, has small influence on the strength of the building gypsum, and solves the problems that the retarding effect of a common retarder is reduced under the alkaline condition and the strength loss of the building gypsum is large.

Owner:HEBEI CHEM & PHARMA COLLEGE

Preparation method of magnesite cementing material retarders

The invention relates to magnesite cementing material modifiers, in particular to a preparation method of magnesite cementing material retarders. The magnesite cementing material retarders comprise, by mass, 50-60% of water, 15-20% of phosphoric acid, 10-20% of tartaric acid and 5-10% of sodium gluconate. The preparation method includes: adding the raw materials which are weighed by mass into a reaction kettle, and stirring for 60-90 minutes at the normal temperature prior to taking out for packaging. By the preparation method, initial setting time of magnesite cement can be effectively prolonged, operability of slurry is improved, and water-resistant and halogen-resistant performances of products can be improved. Besides, the preparation method can be widely applied to production of various magnesite products in a high-temperature production environment.

Owner:杨永

Concrete containing modified cassava starch-polycarboxylic acid composite water reducing agent

InactiveCN111377677AImprove pulp fluidityFluidity parameter variation range is smallChemistrySodium carboxymethylcellulose

The invention discloses concrete containing a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongs to the field of building materials. The concrete containing the modified cassava starch-polycarboxylic acid composite water reducing agent is prepared from the following raw materials in parts by weight: 30 to 65 parts of general purpose Portland cement, 60 to 130 parts of sand, 105 to 227.5 parts of stone, 12 to 40 parts of fly ash, 5 to 9 parts of sodium carboxymethyl cellulose, 0.5 to 1 part of modified cassava starch-polycarboxylate superplasticizer and 0.1to 1 part of ferrous sulfate. The composite water reducing agent is prepared through the reaction processes of oxidation, acidification, etherification, grafting, neutralization and the like. The concrete product of the invention is smooth in appearance and good in durability, sand holes and air holes are not formed in the surface of the concrete product, and high compressive strength is achieved;when the mixing amount of the composite water reducing agent is 0.3%, the coagulation time is longer than 24 hours, and the requirements of the super retarder are met.

Owner:NANNING TONGCAI TECH CO LTD

Preparation method of concrete containing modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses a preparation method of concrete containing a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongs to the field of building materials. The preparation method of the concrete comprises the following steps: adding the general portland cement, the fly ash, 75 parts of the water, the sodium carboxymethyl cellulose, the sand and the stones intoa stirrer and stirring for 15 minutes; adding the modified cassava starch-polycarboxylate superplasticizer, stirring for 5 minutes, and standing for 15 minutes; and adding ferrous sulfate into a ferrous sulfate stirrer, stirring for 4 minutes, and putting into a corresponding template to obtain the product. The concrete preparation method provided by the technical scheme has the advantages of easiness in operation, easiness in large-scale production and the like; the obtained concrete is smooth in appearance and good in durability, sand holes and air holes are not formed in the surface of theconcrete, and good mechanical properties such as high compressive strength are achieved.

Owner:NANNING TONGCAI TECH CO LTD

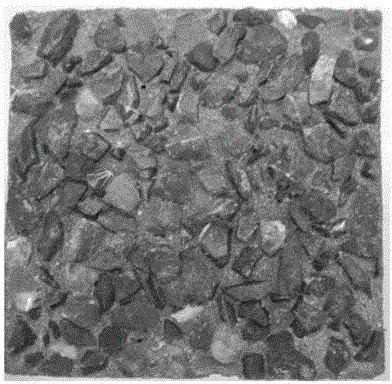

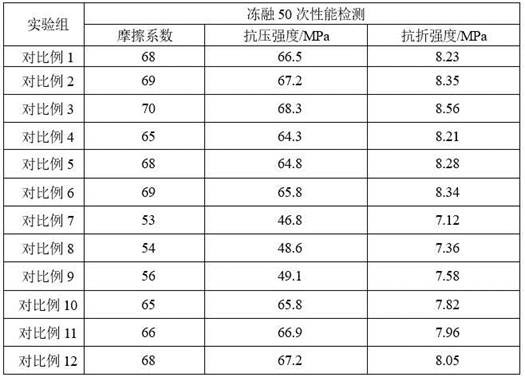

Anti-skid high-strength exposed concrete and preparation method thereof

ActiveCN112500063BImprove skid resistanceHigh mechanical strengthStructural engineeringUltimate tensile strength

Owner:靖江市恒生混凝土制造有限公司

Prepn. of retardant for magnesite binding material

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

Preparation method of delayed coagulation type water reducing agent

The invention discloses a preparation method of a delayed coagulation type water reducing agent, and mainly relates to the field of concrete admixtures. The preparation method comprises the followingsteps: adding metered water, a formula amount of sulfanilic acid or sodium sulfanilate, salicylic acid or sodium salicylate and glucose into a four-neck flask, adjusting to be alkaline by using sodiumhydroxide, heating to 90 DEG C, starting to dropwise add a formaldehyde solution, and reacting at a constant temperature until the end. The method has the beneficial effects that materials with different functional groups are used for condensation reaction, and the delayed coagulation type water reducing agent has the characteristics of high water reduction, controllable retarding time, good adaptability to sandstone materials and the like.

Owner:山东恒丰天利新材料科技有限公司

A kind of alkali-resistant gypsum retarder and preparation method thereof

ActiveCN114180877BStrong retarding effectGood retarding effectSolid waste managementSlagPhysical chemistry

Owner:申辉(河北)精化有限责任公司

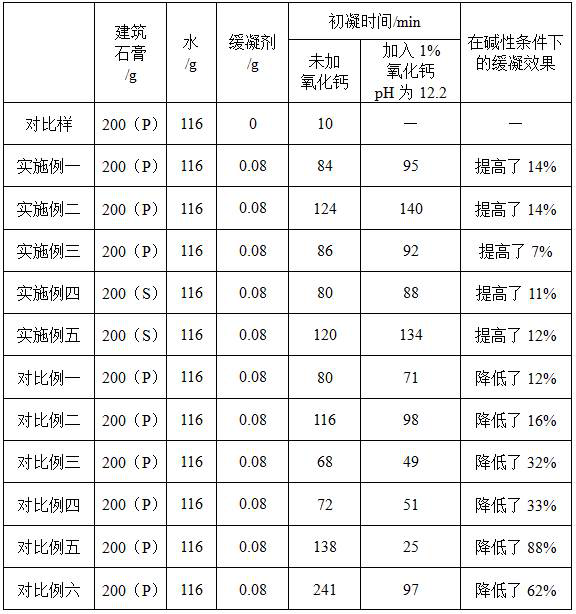

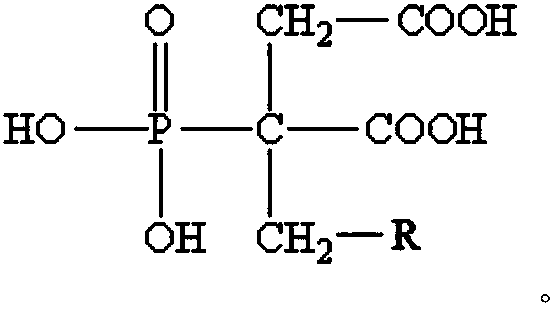

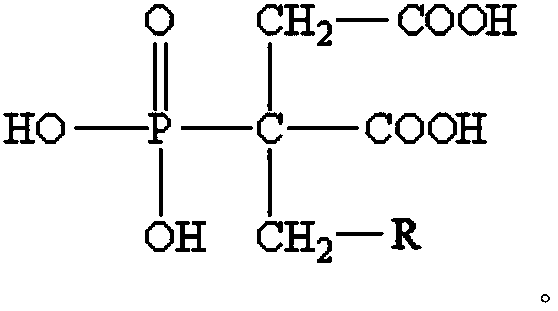

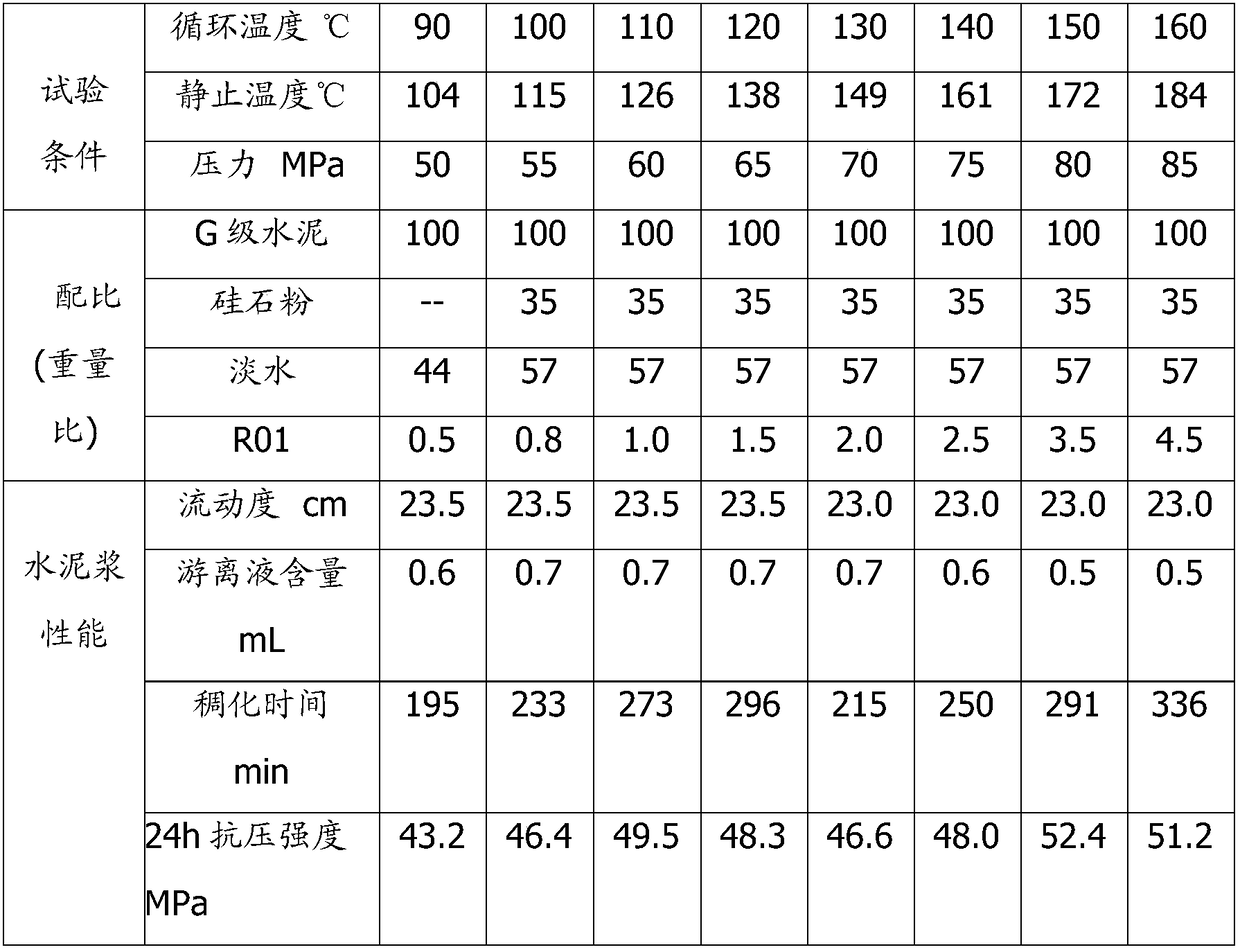

A kind of oil well cement liquid retarder and preparation method thereof

ActiveCN106242342BStrong retarding effectReduce the rate of hydrationGroup 5/15 element organic compoundsOperabilityOil well

The invention provides an oil well cement liquid set retarder and a preparation method thereof. The set retarder comprises, by weight, 1 part of phosphonocarboxylate, 0.15-0.40 parts of hydroxycarboxylate and 0.05-0.20 parts of gluconolactone. The set retarder has the advantages of good set retarding effect, stable chemical performances, easiness in adjustment of the thickening time, and good regularity and operability. The set retarder has a wide application temperature range (90-160 DEG C), is a high-medium temperature set retarder, and can meet dialing needs of growing drilling completion engineering without a set retarding reinforcing agent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com