A kind of oil well cement liquid retarder and preparation method thereof

An oil well cement and retarder technology, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve problems such as heterogeneity, and achieve stable chemical properties and thickening. The effect of short transition times and easy thickening times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

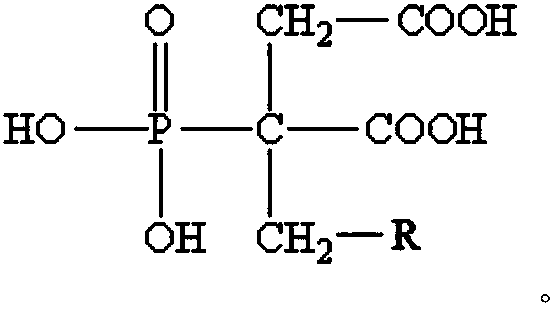

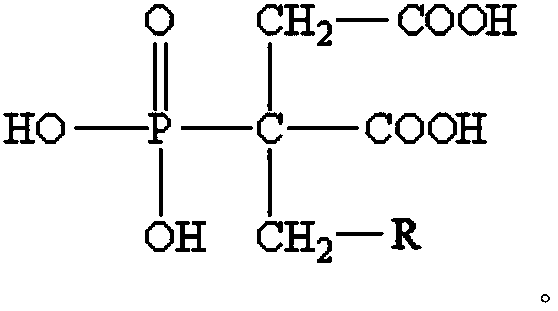

[0051] The synthetic process of the embodiment of the present invention 1 phosphonic acid carboxylate is as follows:

[0052] In a 500mL there-necked flask with an electric stirrer, a thermometer and a condenser, add 100g of ethyl phosphite, 50g of methyl acrylate and 50g of dimethyl oxalate, etc., add 6g of methanol as a catalyst, ventilate nitrogen and heat after the reaction ( temperature is 100°C), use a dropping funnel to slowly add 10 g of hydrochloric acid dropwise into a three-necked flask, continue to react for 3 hours, then add sodium hydroxide to neutralize the solution so that the pH value of the solution is 7, and finally obtain a phosphonic acid carboxylic acid Salt.

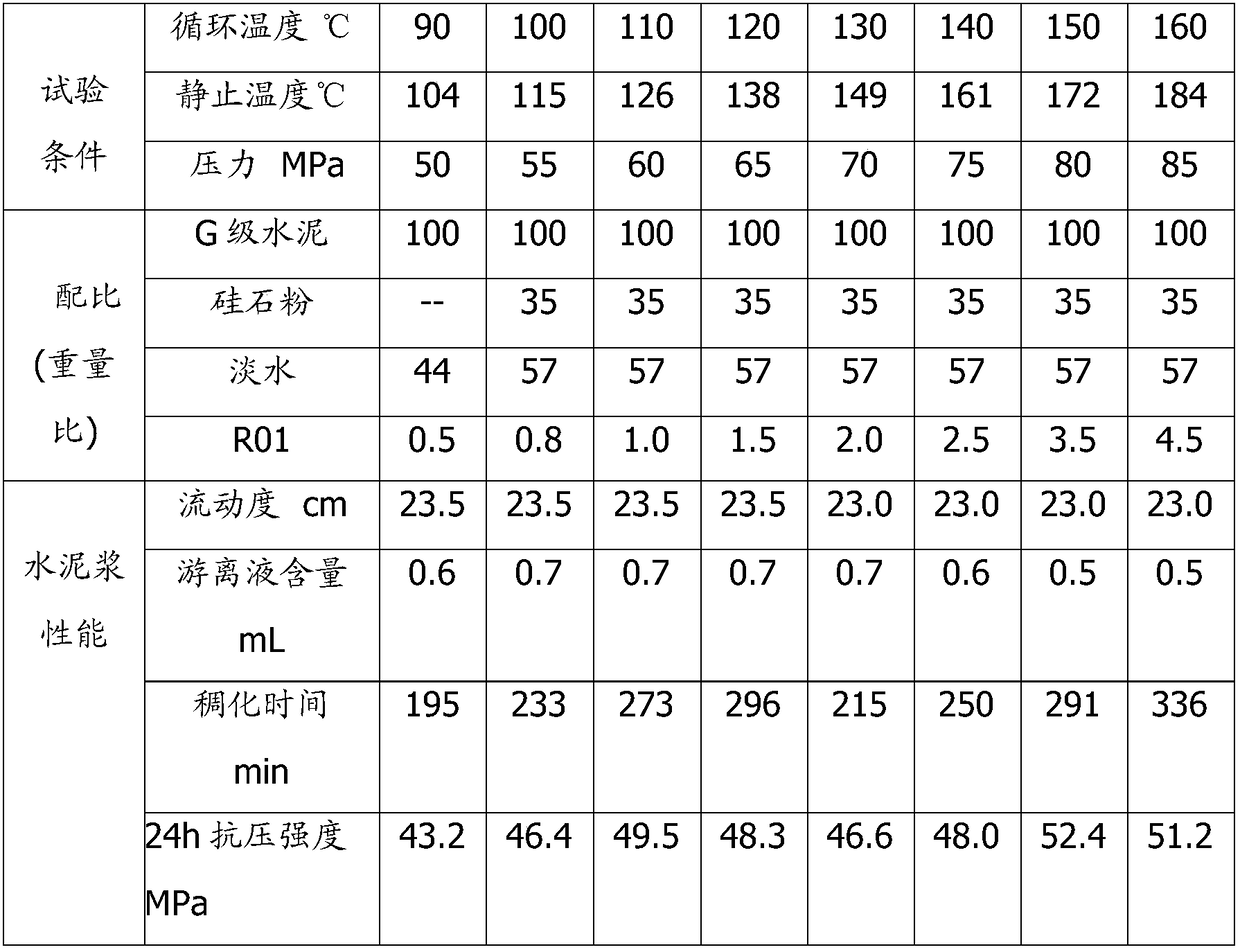

[0053] Take by weighing the phosphonic acid group carboxylate that the above-mentioned embodiment 1 of 1 weight part obtains, the sodium citrate of 0.20 weight part, the potassium sodium tartrate of 0.05 weight part and the gluconolactone of 0.15 weight part, then mix homogeneously in beaker , mad...

Embodiment 2

[0057] The synthetic process of the embodiment of the present invention 2 phosphonocarboxylates is as follows:

[0058] In a 500mL three-neck flask equipped with an electric stirrer, a thermometer and a condenser, add 150g of ethyl methyl phosphate, 75g of butyl methacrylate and 75g of ethyl oxalate, etc., add 9g of methanol as a catalyst, blow nitrogen and heat the reaction Finally (the temperature is 120°C), slowly drop 25g of hydrochloric acid into the three-necked flask with a dropping funnel, continue the reaction for 3h, and then add sodium hydroxide to neutralize the solution so that the pH of the solution is 6, and finally obtain the phosphonic acid group Carboxylate.

[0059] Take by weighing the phosphonic acid group carboxylate that the above-mentioned embodiment 2 of 1 weight part obtains, the sodium citrate of 0.10 part, the potassium sodium tartrate of 0.05 part and the gluconolactone of 0.05 part, then mix homogeneously in beaker, make Medium and high temperatu...

Embodiment 3

[0063] The synthetic process of the embodiment of the present invention 1 phosphonic acid carboxylate is as follows:

[0064] In a 500mL there-necked flask with an electric stirrer, a thermometer and a condenser, add 200g of ethyl phosphite, 100g of methyl acrylate and 100g of dimethyl oxalate, etc., add 20g of methanol as a catalyst, nitrogen and heat the reaction ( temperature is 110°C), use a dropping funnel to slowly add 50 g of dilute sulfuric acid dropwise into a three-necked flask, continue the reaction for 4 hours, then add sodium hydroxide to neutralize the solution to make the pH of the solution 7, and finally obtain the phosphonic acid carboxyl salt.

[0065] The phosphonic acid group carboxylate that the above-mentioned embodiment 3 of taking 1 part of weight obtains, the sodium citrate of 0.15 part, the potassium sodium tartrate of 0.05 part and the gluconolactone of 0.10 part, then mix homogeneously in beaker, make Medium and high temperature liquid retarder, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com