Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Improve water reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polycarboxylic acid retarding water reducer

The invention belongs to the technical field of methods for preparing polycarboxylic acid water reducers. A method for preparing a polycarboxylic acid water reducer comprises the following: a step 1 of esterification, in which a poly(ethylene glycol methyl ether)acrylate macromonomer is synthesized by using methoxy polyethylene glycol and acrylic acid in a molar ratio of 1:1.1 to 1:1.5 at 100 to 120 DEG C, water is separated out in a reaction process, and the molecular weight of the macromonomer is 1,250 to 3,000; and a step 2 of polymerization, in which aqueous solution of the macromonomer is prepared, an unsaturated monomer and a catalyst A are added in turn at 40 to 50 DEG C, the temperature is kept constant at 28 to 40 DEG C, aqueous solution of anhydrous sodium hydrogensulfite or vitamin c is dripped, the concentration of a solid content is kept between 35 to 45 percent by adjusting water content, stirring is stopped, and the solution is allowed to stand for 1 to 1.5 hours, the pH value is kept between 6 and 8 by alkaline reagent after the reaction is finished, and the catalyst A is peroxyacetic acid or potassium peroxydisulfate. The invention has the advantages of low cost, simple process and high product performance.

Owner:河北智胜工程技术有限公司

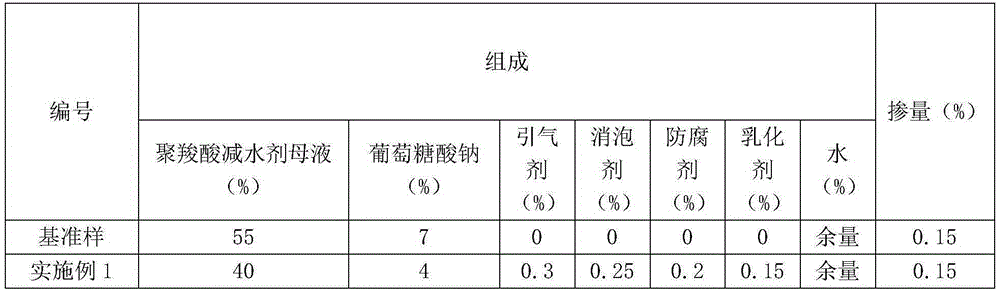

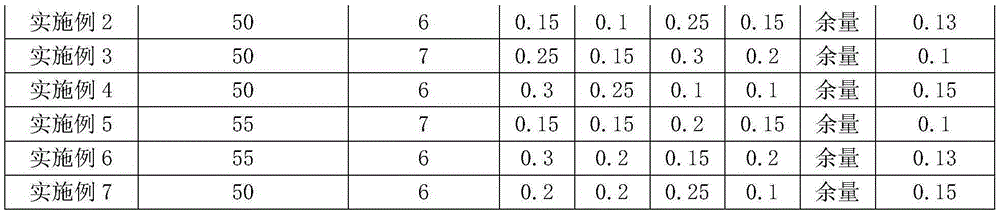

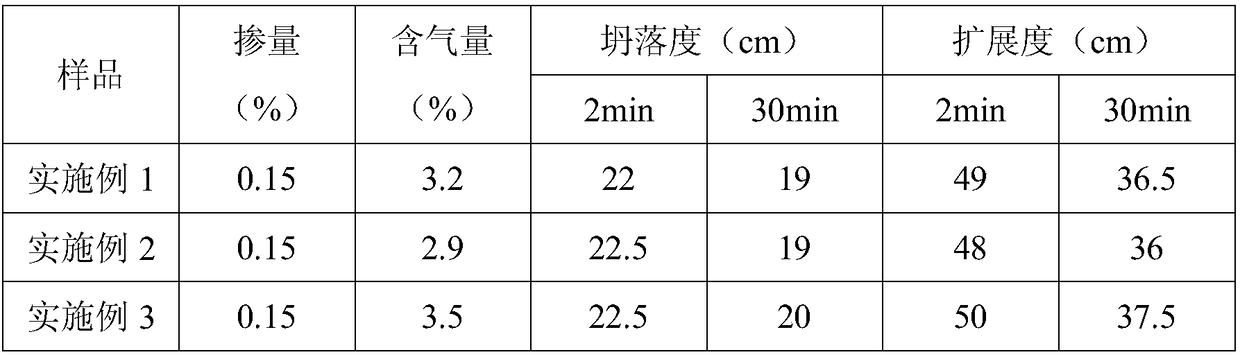

Anticorrosive composite polycarboxylate superplasticizer with high slump loss resistance, and preparation method and application thereof

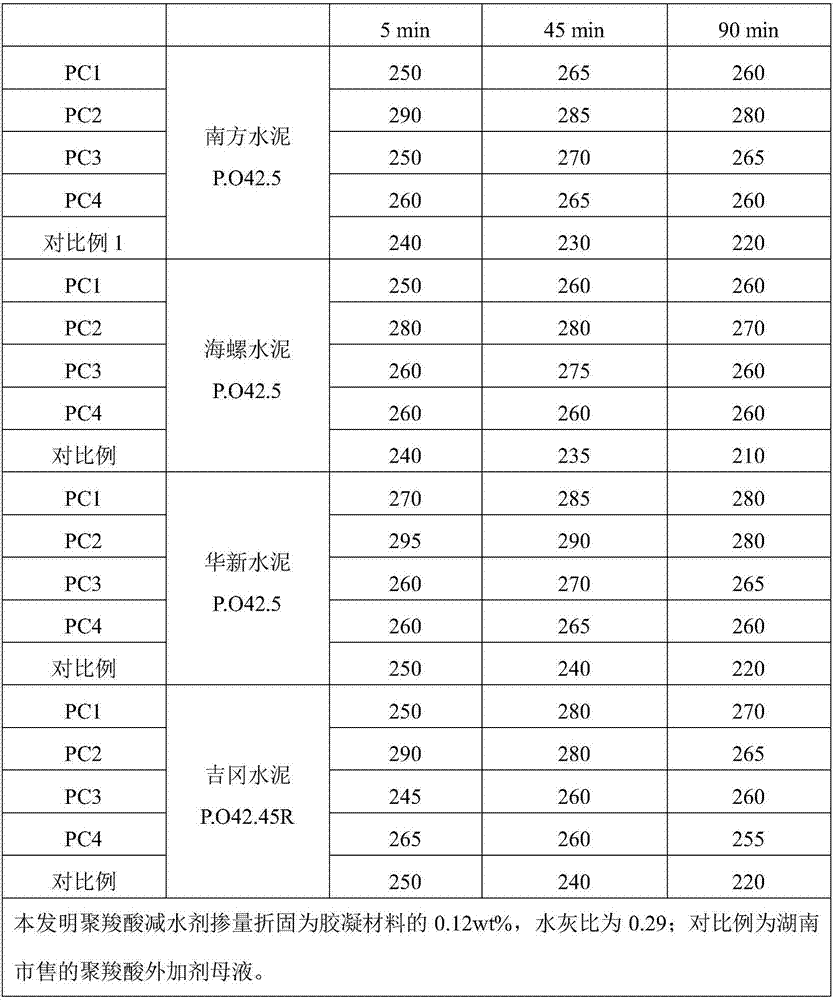

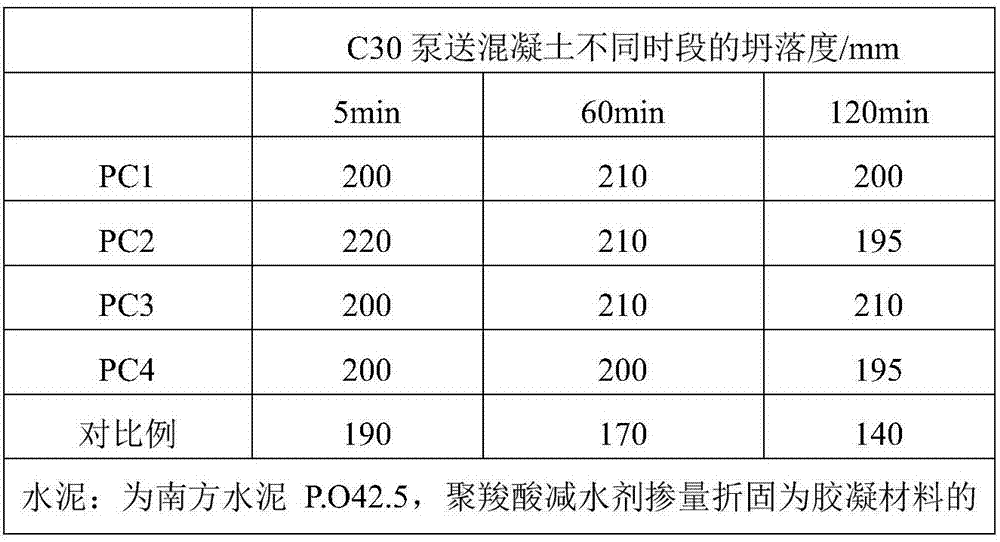

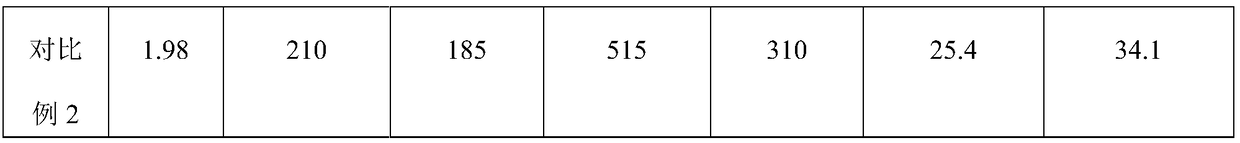

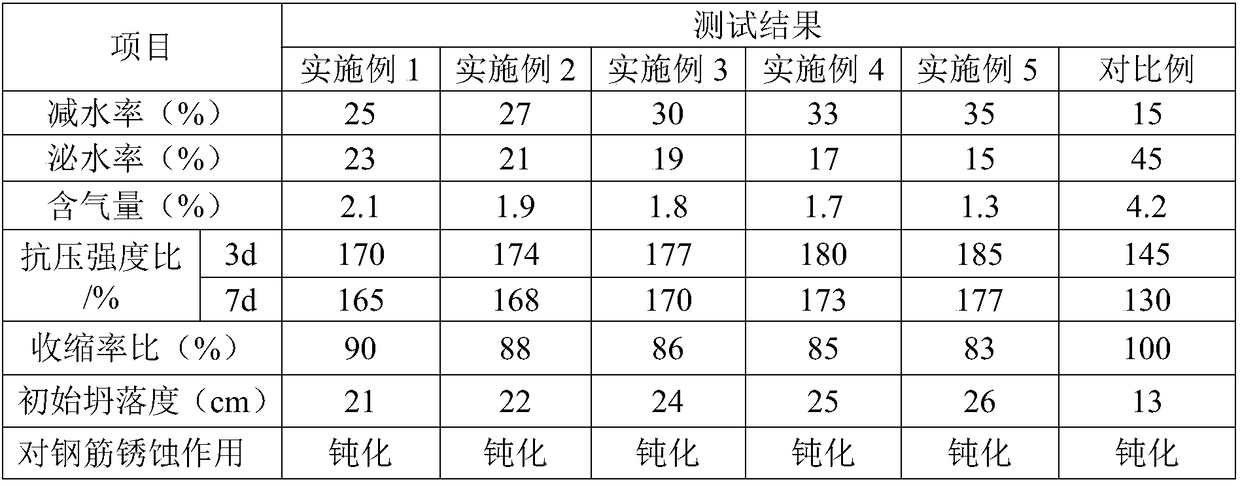

The invention relates to an anticorrosive composite polycarboxylate superplasticizer with high slump loss resistance, and a preparation method and application thereof. The composite polycarboxylate superplasticizer comprises, by mass, 40 to 55% of mother liquor of a polycarboxylate superplasticizer, 4 to 7% of sodium gluconate, 0.15 to 0.3% of an air entraining agent, 0.1 to 0.25% of an antifoaming agent, 0.05 to 0.2% of an emulsifying agent and 0.1 to 0.3% of an anticorrosive bactericide, with the balance being water, wherein the mass percents of every component sum to 100%. The composite polycarboxylate superplasticizer is prepared by placing the mother liquor of the polycarboxylate superplasticizer, sodium gluconate, the air entraining agent, the antifoaming agent, the anticorrosive bactericide and the water in a container together according to the above-mentioned mass percents under the conditions of normal temperature and normal pressure and carrying out uniform mixing under stirring. In use, the composite polycarboxylate superplasticizer is added into a concrete cementing material according to a mass ratio of the composite polycarboxylate superplasticizer to the concrete cementing material of 0.1-0.15: 100. Compared with the prior art, the composite polycarboxylate superplasticizer provided by the invention has the advantages of convenience in usage, stable performance, no phenomena of mildew, smelliness and layering due to long-term storage, capacity of introducing small bubbles when used in fresh mixed concrete, and excellent water-reducing and slump-retaining performances.

Owner:TONGJI UNIV

Preparation method and application of mud-resistant polycarboxylate superplasticizer

The invention provides a preparation method and application of a mud-resistant polycarboxylate superplasticizer. The mud-resistant polycarboxylate superplasticizer has the advantages of being low in mixing amount, high in water-reducing rate, long in slump resisting time and high in mud resistance when serving as a cement dispersing agent. The synthesis process is simple, the raw material utilization rate is high, a solvent is convenient to recycle, and production cost is low. According to the preparation method of the mud-resistant polycarboxylate superplasticizer, the mud-resistant polycarboxylate superplasticizer is obtained through the free radical polymerization reaction of specific unsaturated acid monomers, specific unsaturated polyether macromonomers and poly(N-vinyl pyrrolidone) chain containing PVP macromonomers, and the molar weight of the unsaturated polyether macromonomers is 50% to 100% that of the PVP macromonomers.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

Early strength type water reducing agent for precast concrete

The invention discloses an early strength type water reducing agent for precast concrete. The early strength type water reducing agent comprises the following components by weight percent: 5.00-6.00% of polycarboxylic acid water reducing agent, 0.50-2.00% of inorganic lithium salt, 1.00-5.00% of inorganic sodium salt, 0.00-10.00% of inorganic calcium salt, 0.01-0.30% of deformer and the balance of filling material. The early strength type water reducing agent has the characteristics that the doped amount is low, the air bleeding is low, the water reduction is high, slump is well maintained, and the early strength is rapidly increased; and by utilizing the early strength type water reducing agent, the steam heating and maintenance of the precast concrete are shortened or avoided, thereby reducing the production cost of the precast concrete.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

High-slump-resistance polycarboxylate water reducer

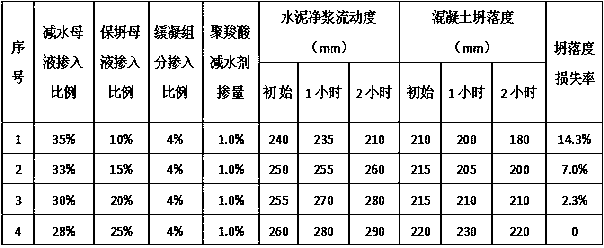

The invention provides a high-slump-resistance polycarboxylate water reducer. The high-slump-resistance polycarboxylate water reducer is composed of, by weight percentage, 10-25% of polycarboxylate slump-resistant mother liquor, 28-35% of polycarboxylate water reducing mother liquor, 4% of setting retarding components and water as balance. By adding in hydrophobic slow release ester groups, the high-slump-resistance polycarboxylate water reducer can avoid being adsorbed by cement particles during the early stage of cement hydration and meanwhile can be slowly released inside alkaline solutioninto water reducer molecules with water reducing effects to achieve water-reduced dispersion; the release speed can be adjusted according to requirements on environment, alkalinity and construction and by changing the number of slow release groups and the molar mass ratio of acid esters. By compounding the polycarboxylate slump-resistant mother liquor and the polycarboxylate water reducing motherliquor, the high-slump-resistance polycarboxylate water reducer is low in mixing amount and high in water-reducing and slump-resistant performance; the slump-resistant time can be flexibly adjusted according to the requirements on construction concrete transportation distance and time, the concrete slump-resistant time can be prolonged by 1-4 hours, so that high cement adaptability can be achieved.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

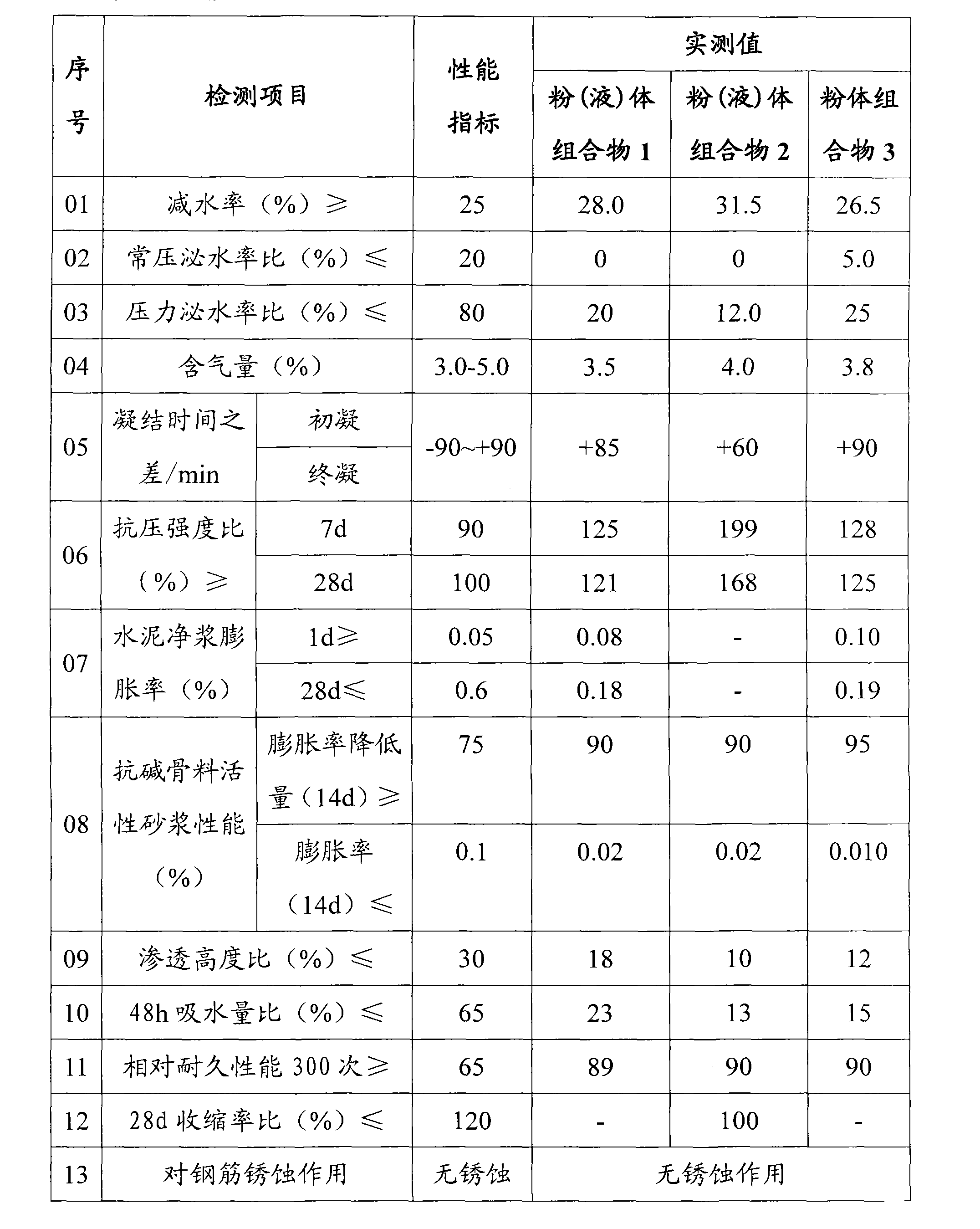

Composition for inhibiting concrete alkali aggregate reaction and preparation thereof

The invention belongs to the technical field of concrete engineering, and in particular relates to a composition for inhibiting concrete alkali-aggregate reaction and a preparation method thereof. The composition for inhibiting the concrete alkali-aggregate reaction comprises the following compositions: 10 to 50 percent of plasticizing agent, 10 to 70 percent of aluminate and 10 to 30 percent of alkali metal salt or alkaline-earth metal salt, wherein the alkali metal salt or the alkaline-earth metal salt is selected from at least one group of lithium compounds, barium compounds or calcium-magnesium compounds, and the total content of various compositions is 100 percent. The composition can cover or coat active elements of aggregate, prevent or isolate contact reaction between alkali metal ions such as K<+> and Na<+> and the active elements of the aggregate, prevent generation of soluble swelled gel and generation of insoluble compounds, and further eliminate alkali-aggregate reaction and improve the durability of concrete.

Owner:苏笮斌

Polycarboxylic acid water reducer with solid raw materials and preparing process of the polycarboxylic acid water reducer

The invention relates to a polycarboxylic acid water reducer for concrete, and belongs to the technical field of concrete admixture. The water reducer is prepared from the following solid raw materials: unsaturated polyoxyethylene macromonomer, unsaturated dicarboxylic acid or anhydride thereof, unsaturated sulfonate monomer, an oxidant, a reducer and sodium hydroxide at a molar ratio of 1:1-4:0.2-1:0.05-0.2:0.015-0.08:0.5-3. The polycarboxylic acid water reducer has the following beneficial effects: the producing condition requirements are less, so that the water reducer is easy to produce industrially; the raw materials are convenient to transport and store, and obvious pungent smells are not generated from the raw materials and in the process of production, environmental conditions for production are greatly improved, and discharge of waste gas, waste water and waste materials is avoided. The obtained product is featured with high water reducing performance, high slump loss resistance, good adaptability to various admixtures of cement and concrete at a low mixing amount, and high cost performance, and is suitable for popularization and application.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

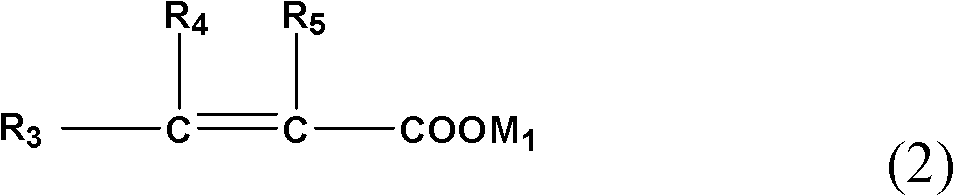

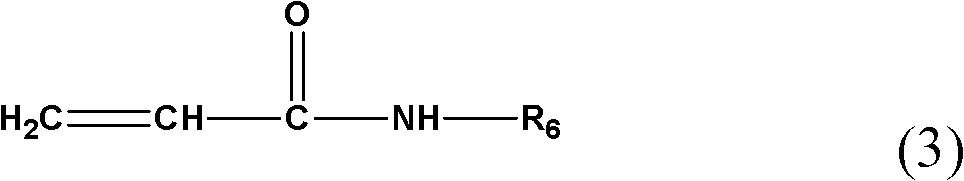

Ternary random copolymer and its preparation method

ActiveCN103183790AReasonable main and side chain density distributionAdaptablePolymer scienceSide chain

The invention discloses a ternary random copolymer and its preparation method. The ternary random copolymer is composed of the structural units of three monomers, i.e. X, Y and Z respectively shown in formula (1)-(3). The mole ratio of the three structural units, i.e. X:Y:Z is 1:2-5:0.4-1, and the copolymer has a weight average molecular weight of 10000-30000, with the meaning of each symbol in the formulas being shown in the specification. The copolymer is prepared from the three monomers through aqueous solution copolymerization in the presence of an initiator. The copolymer can be used as an early strength type concrete polycarboxylic water reducer. Because of the introduction of an amide structural unit, the water reducer can reduce the coagulation retarding effect of concrete and improve the early strength of concrete. In addition, as the copolymer has reasonable main and side chain density distribution, the water reducer also has the characteristics of high water reduction, high slump retaining and strong adaptability to cement.

Owner:LIAONING OXIRANCHEM INC

Reduction and early strength polymer additive

The invention discloses a reduction and early strength polymer additive which is obtained by copolymerizing 60-95 percent of monomer A, 1-10 percent of monomer B, 3-16 percent of monomer C and 0-30 percent of monomer D in an aqueous solution at 50-100 DEG C in the presence of an initiator and a chain transfer agent. The polymer additive has the advantages of high water reduction rate, high early strength, low shrinkage, and the like when used for mortar or concrete.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

Slump retention type solid poly carboxylic acid water reducing agent and preparation method thereof

Owner:SHANXI SUNWAY INTION TRADE CO LTD

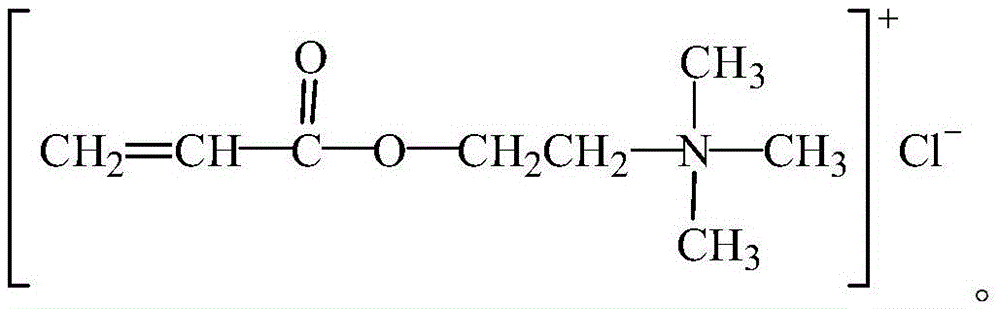

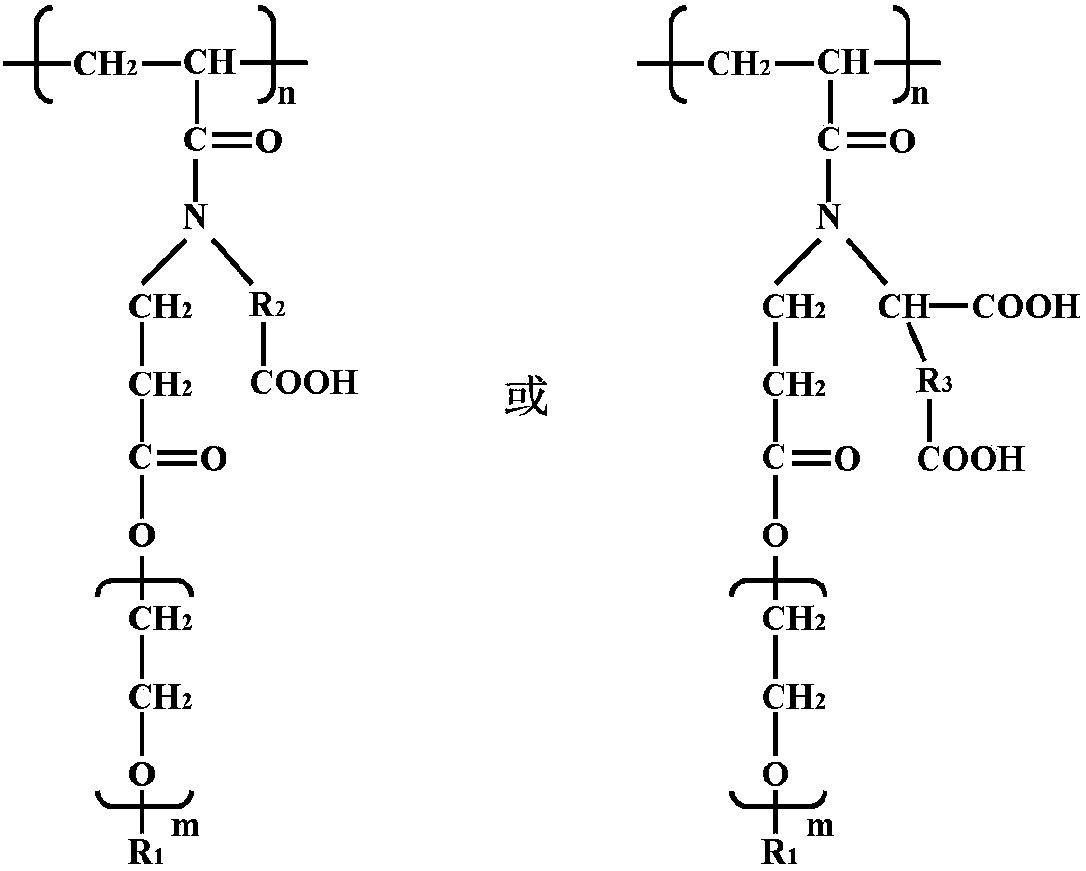

Preparation method for cationic side chain esterified-grafted highly-mud-resistant cement dispersing agent

ActiveCN106117564AExpanding the theoretical connotation of the design-structure-performance of moleculesBroaden research ideasPolymer sciencePolyethylene glycol

The invention discloses a preparation method for a cationic side chain esterified-grafted highly-mud-resistant cement dispersing agent, and belongs to the field of dispersing agents. The preparation method comprises the following steps: performing free radical polymerization on an unsaturated carboxylic acid monomer serving as a reactant to obtain a polycarboxylic acid main chain under the action of an initiator and a chain transfer agent, performing free radical polymerization on an unsaturated cationic quaternary ammonium salt monomer serving as a reactant to obtain a hydroxyl-terminated cationic side chain under an oxidization-reduction initiation system formed by high-valence ceric salt and alcohol, and performing esterification-grafting reaction on the polycarboxylic acid main chain, the hydroxyl-terminated cationic side chain and a polyethylene glycol compound in the presence of a catalyst. According to the preparation method, a process is simple and easy to control, and the preparation method is low in cost, energy-saving, efficient, environment-friendly and free of pollution; a composite side chain structure is modified and synthesized by a molecular structure design, so that side chain steric hindrance effects are successfully achieved, cationic charge arrangement is successfully implemented, water reduction and slump retaining characteristics and clay side effect suppression capabilities higher than those of an ordinary polycarboxylic acid water reducing agent are achieved, and the dispersing agent has broad market prospect and great popularization and application potential.

Owner:BEIJING UNIV OF TECH

Arginine-terminated polyethylene glycol methacrylate, and preparation method and application thereof

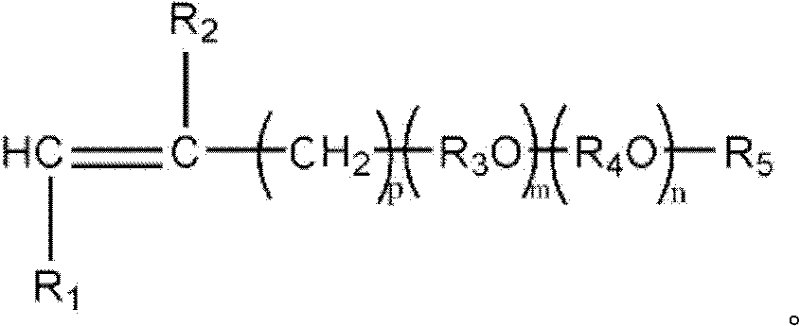

InactiveCN104387574AImprove water reductionIncrease retardingOrganic compound preparationSulfonic acids salts preparationArginineStructural formula

The invention discloses arginine-terminated polyethylene glycol methacrylate with a structural formula as described in the specification. The invention also discloses a preparation method for the structural formula. The arginine-terminated polyethylene glycol methacrylate provided in the invention is applied to a water reducing agent; the arginine-terminated polyethylene glycol methacrylate effectively enhances the adsorption-complexation and steric hindrance effects of the molecules of the water reducing agent by modifying the long chain of macromonomer of the water reducing agent via amino acids, increases functions of the water reducing agent and enables the water reducing agent to have a water reducing function, a corrosion inhibition function, etc.

Owner:苏州润厚晓新材料有限公司

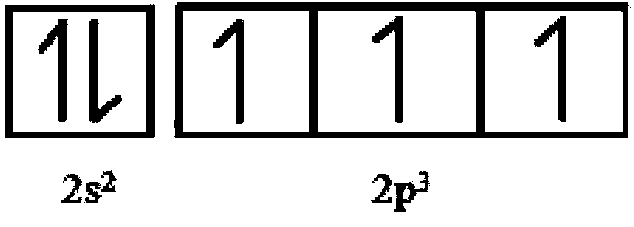

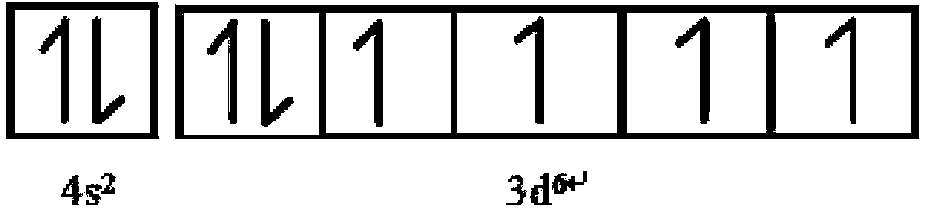

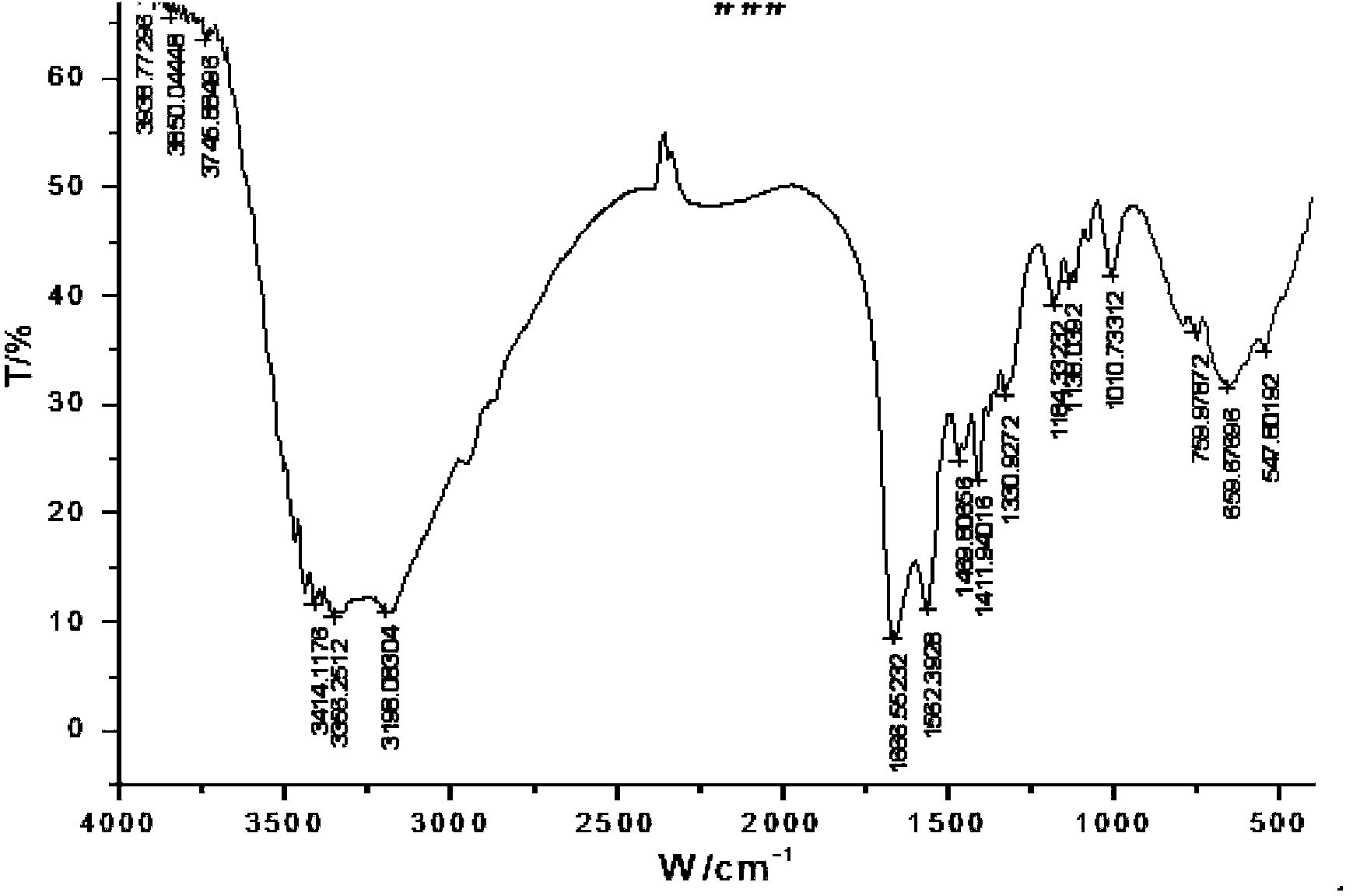

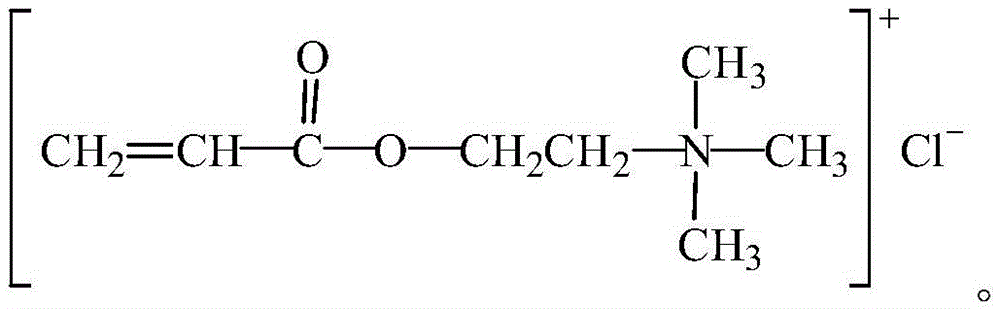

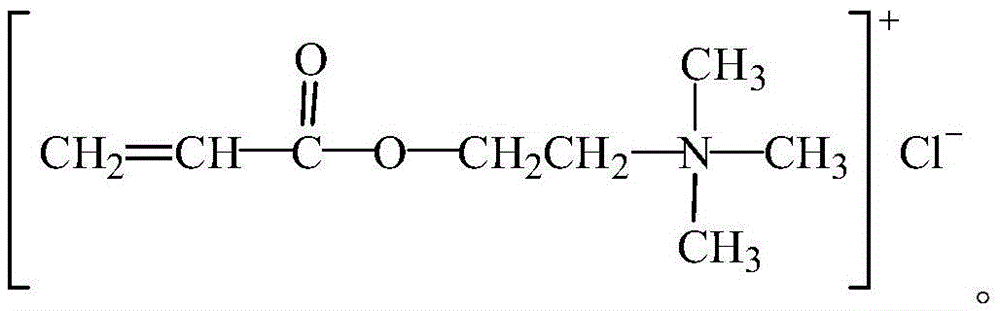

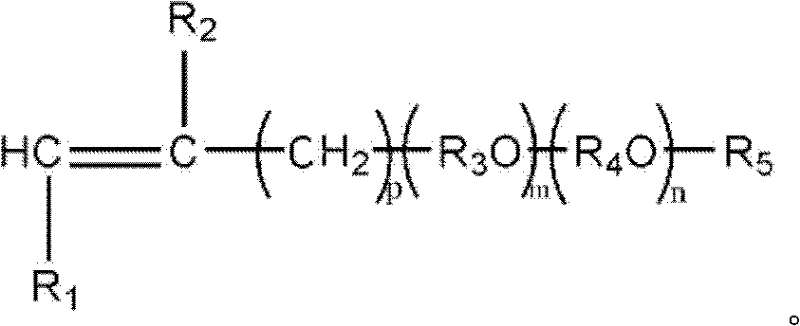

Organic monomer for synthesizing amphoteric polycarboxylic superplasticizer and preparation method

ActiveCN105541646AImprove water reductionGood dispersionOrganic compound preparationAmino-hyroxy compound preparationChemistryAcrylate

The invention discloses an organic monomer for synthesizing an amphoteric polycarboxylic superplasticizer, which has a molecular structure shown in the description. The invention further discloses a preparation method of the organic monomer for synthesizing the amphoteric polycarboxylic superplasticizer and comprises the following steps: preparing a dimethylaminoethyl acrylate intermediate and a cationic active organic monomer; adopting one-time charging at the normal temperature; and selecting a reasonable type of catalyst to prepare the organic monomer. The method has reduced cost, plays an important part in process simplification, and has characteristics of high reaction conversion rate, high yield, and high purity. Compared with an anionic polycarboxylic superplasticizer sold in the market, under a condition of a relatively low mixing amount, the amphoteric polycarboxylic superplasticizer enables neat cement paste or concrete to have excellent performance of good water reduction, high dispersion, good plasticity preservation, and high early-stage compressive strength.

Owner:LIMING VOCATIONAL UNIV

Preparation method of poly carboxylic acid water reducing agent with regular sequence structure

The invention discloses a preparation method of a poly carboxylic acid water reducing agent with a regular sequence structure. The preparation method comprises the following steps of performing Michael addition reaction on a polyethylene glycol ester acrylate macromer A and amino group containing carboxylic acid B for 5-12h, then cooling the temperature to 0 DEG C, dropwise adding acryloyl chloride slowly at a constant speed, and continuously performing reaction for 12h under the condition with normal temperature after dropwise addition is finished to obtain a carboxyl group containing polyether macromer C; and fully mixing the carboxyl group containing polyether macromer C, a small molecular RAFT reagent, an initiator and water, keeping the polymerization mass concentration be 30-60 percent, rising the temperature to 60-80 DEG C at the atmosphere of N2, and performing reaction for 2-5h to obtain the poly carboxylic acid water reducing agent with the regular sequence structure. The poly carboxylic acid water reducing agent prepared by the preparation method is suitable for regions with high mud content of sandstone aggregates and has the advantages of low mixing amount, high waterreducing ability and high slump loss resistance. The preparation method provided by the invention is simple in preparation technology as well as is environmentally friendly and is low in cost in the production process.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

Method for preparation of high mud resistant polycarboxylic acid dispersant by unsaturated halogenated hydrocarbon copolymerization and grafting with cationic side chain

ActiveCN106188557AThe polymerization process is mild and stableLess side effectsAlcoholPolyethylene glycol

Belonging to the field of dispersants, the invention provides a method for preparation of high mud resistant polycarboxylic acid dispersant by unsaturated halogenated hydrocarbon copolymerization and grafting with a cationic side chain. The method consists of: employing an unsaturated carboxylic acid monomer, an unsaturated halogenated hydrocarbon monomer, an unsaturated cationic quaternary ammonium salt monomer, a polyethylene glycol compound and the like as the raw materials, firstly conducting main chain copolymerization, then polymerizing the cationic side chain, performing functionalization, and finally carrying out etherification grafting so as to synthesize the excellent performance high mud resistant polycarboxylic acid dispersant material with unsaturated halogenated hydrocarbon copolymerized and grafted with cationic side chain, i.e. taking unsaturated carboxylic acid and unsaturated halogenated hydrocarbon as the reactants, conducting free radical polymerization to obtain a carboxylic acid-halogenated hydrocarbon copolymer main chain, using high valence cerium salt-alcohol to initiate polymerization of an unsaturated cationic quaternary ammonium salt monomer so as to obtain a hydroxyl terminated cationic side chain, then modifying the hydroxyl terminated cationic side chain and the polyethylene glycol compound to obtain a functionalized side chain, and carrying out etherification grafting of the functionalized side chain on the carboxylic acid-halogenated hydrocarbon copolymer main chain. The method provided by the invention realizes high water reduction, slump loss resistance, high clay resistance and other multiple effects.

Owner:BEIJING UNIV OF TECH

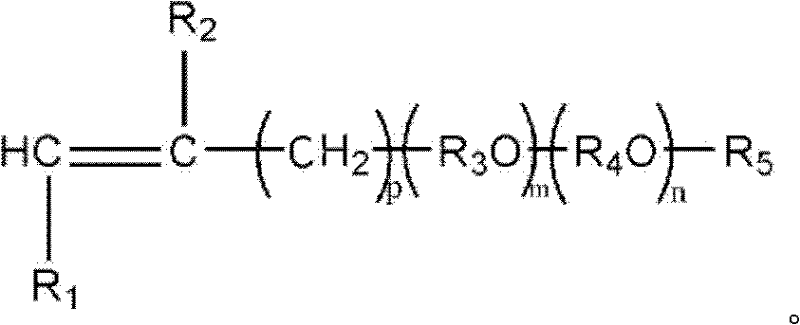

Unsaturated ester and preparation method thereof

ActiveCN104341325AExpand the direction of esterification reactionIncrease retardingOrganic compound preparationSulfonic acids salts preparationThreonineCarboxylic acid

The invention discloses an unsaturated ester prepared from an amino acid which takes threonine as a representative and contains hydroxyl groups. The invention further discloses a preparation method of the unsaturated ester shown in the specification. The preparation method comprises the following steps: modifying an unsaturated carboxylic acid with the amino acid, carrying out an esterification reaction so as to esterify the threonine containing hydroxyl groups by virtue of the unsaturated carboxylic acid, and feeding carboxyl groups, amino groups and sulfonic groups into the hydroxyl groups of the amino acid so as to synthesize an unsaturated amino acid ester.

Owner:JIANGSU UNIV OF SCI & TECH

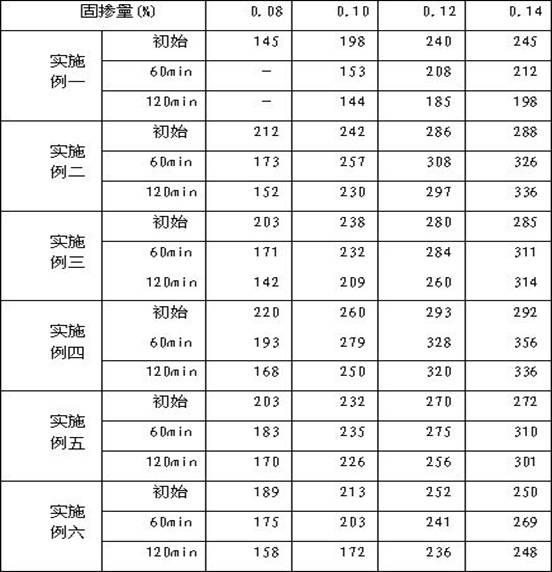

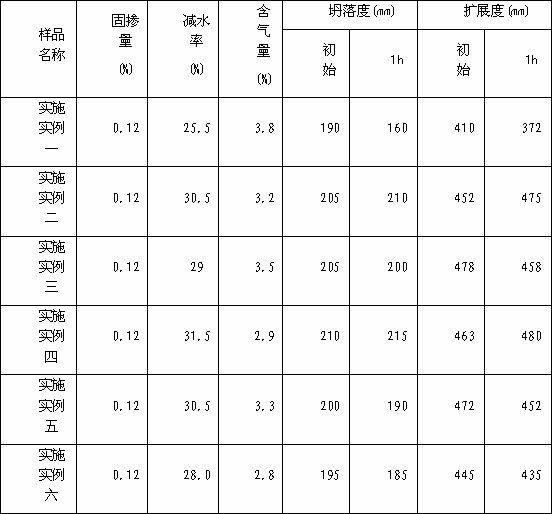

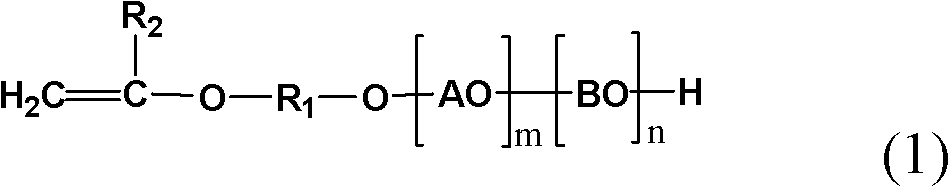

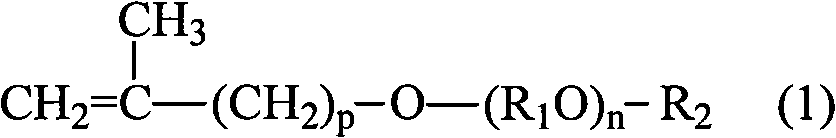

Low-dosage high-water-reduction type polycarboxylic acid water reducer and preparation method thereof

The invention discloses a low-dosage high-water-reduction type polycarboxylic acid water reducer and a 'one step one kettle' preparation method thereof, and belongs to the technical field of cement concrete water reducers. The polycarboxylic acid water reducer adopts the 'one step one kettle' method; a block type polyoxyalkylene ether monomer A, an unsaturated acid or unsaturated acid derivative monomer B, an alkenyl sulfonic acid monomer C and an azo or peroxy peroxy D are once thrown into a reaction kettle; free radicals are polymerized in an aqueous solution; and finally, the aqueous solution is neutralized by using an alkaline solution, so as to obtain the polycarboxylic acid water reducer. The polycarboxylic acid water reducer prepared by adopting the method disclosed by the invention has excellent performance such as easily-obtained material, simple formula, low dosage, high water reduction, high slump loss resistance, strong cement adaptability, and the like. The preparation method has the advantages of simple process, short reaction period, wild reaction condition and low requirement for equipment, is simple and convenient to operate and is easy to control; and the polymerization is conducted in the aqueous solution, so that three wastes cannot be discharged and the preparation method belongs to clean production.

Owner:EAST CHINA UNIV OF TECH

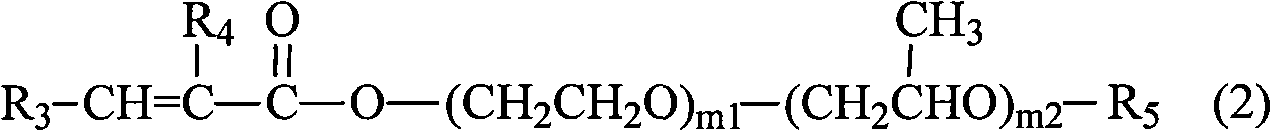

Environmental-friendly high-performance polycarboxylate superplasticizer and synthetic method thereof

The invention discloses an environmental-friendly and high-performance polycarboxylate superplasticizer and a synthetic method thereof. The synthetic method of the superplasticizer in the invention comprises the following steps: reacting a polyether macromonomer A1, an unsaturated carboxylic acid or anhydride monomer A2 and an unsaturated sulfonic acid monomer A3 in the presence of a reducing agent and a molecular weight modifier so as to obtain a copolymerization product; and regulating the pH value to be 6-7 by using a sodium hydroxide solution, thereby obtaining the high-performance polycarboxylate superplasticizer. The high-performance polycarboxylate superplasticizer synthesized by the method has the characteristics of high water reducing property, high slump retaining property, high adaptability and excellent peaceability when used in concrete; and meanwhile, the synthetic process is simple and environmental-friendly, and is low in energy consumption, easy to operate and high in repeatability.

Owner:永兴隆诚高新材料有限公司

Polycarboxylate mother liquor with high water-reducing, slump-retaining and sludge-resisting properties and manufacturing method thereof

The invention provides a polycarboxylate mother liquor with high water-reducing, slump-retaining and sludge-resisting properties and a manufacturing method thereof. The polycarboxylate mother liquor is composed of 28 to 40 parts of a polyether superplasticizer macromonomer, 3 to 8 parts of acrylic acid, 0.1 to 0.9 part of sodium hypophosphite, 0.1 to 0.8 part of hydrogen peroxide with a concentration of 30%, 0.1 to 0.6 part of ammonium persulfate, 0.1 to 0.3 part of vitamin C and 58 to 65 parts of deionized water. The polycarboxylate mother liquor with high water-reducing, slump-retaining andsludge-resisting properties provided by the invention is compatible in water-reducing and slump-retaining properties on the basis of the prior art; the performance of high sludge-resisting property isincreased; and a formula for a superplasticizer mother liquor with high water-reducing, sludge-resisting and slump-retaining properties is obtained.

Owner:张玉广

Environment-friendly concrete water reducer and preparation method thereof

InactiveCN109279804ASimple manufacturing methodRaw materials are easy to getSuccinic acidWater reducer

The invention provides an environment-friendly concrete water reducer. The concrete water reducer comprises the following components in parts by weight: 30-40 parts of a triethanolamine oleic soap-based polyacrylic acid copolymer, 10-15 parts of modified activated clay, 5-10 parts of 4-aminophenyl fucoside, 4-6 parts of polyether amine, 10-15 parts of isopropanol and 30-40 parts of water, whereinthe triethanolamine oleic soap-based polyacrylic acid copolymer is prepared by copolymerization of triethanolamine oleic soap, (2R,3S,4S)-rel-2-carboxyl-4-(1-methylvinyl)-3-pyrrolidine acetic acid, sulfo succinic acid-1-(2-propenyl)-4-tridecylester sodium salt and N-acryloyltris(hydroxymethyl)aminomethane. The invention further discloses a preparation method of the environment-friendly concrete water reducer. The environment-friendly concrete water reducer disclosed by the invention has the advantages that comprehensive performance is excellent, the water reducing effect is more obvious, the mixing amount is smaller, plasticizing performance is more excellent, cost is lower, influence on the environment is smaller, and use is safer and more environmentally friendly.

Owner:魏菊宁

Preparation method of high mud-resistant concrete water reducer with graft copolymerized cationic side chains

ActiveCN106117468BAchieving a Transformation in Application PerformanceExpanding the theoretical connotation of the design-structure-performance of moleculesSide chainPolyethylene glycol

The invention discloses a preparation method of a highly mud resistant water reducing agent with graft copolymerization of a cation side chain for concrete, belonging to the field of water reducing agents. The highly mud resistant water reducing agent material with graft copolymerization of a cation side chain for concrete is synthesized by a method of carrying out cation side chain polymerization reesterification first and then graft copolymerization, i.e. an unsaturated cation quaternary ammonium salt monomer as a reactant carries out free radical polymerization in an oxidation-reduction initiation system composed of high-valence cerium salt and alcohols to obtain a terminal hydroxyl cation side chain, then unsaturated carboxylic acid, the terminal hydroxyl cation side chain and methoxy polyethylene glycol carry out esterification under the effect of a catalyst to produce two macromonomers, and then an unsaturated carboxylic acid monomer, a cation side chain macromonomer and a polyether side chain macromonomer as reactants carry out free radical graft copolymerization under the effects of an initiator and a chain transfer agent to obtain the highly mud resistant water reducing agent with graft copolymerization of the cation side chain for concrete. The process of the preparation method has the advantages of simple steps, high efficiency, immediacy, convenience in regulation and control, energy saving and environment protection, a composite side chain structure is synthesized creatively, and the effects of water reducing, slump loss resistance and inhibition in clay side effects are realized.

Owner:中铁一局集团工业贸易有限公司

Fair-faced concrete and preparation method thereof

InactiveCN112341076ASimple manufacturing methodEasy to operate and controlAggregate (composite)Metal-organic framework

The invention discloses fair-faced concrete and a preparation method thereof. The concrete is prepared from the following components in parts by weight: 30-40 parts of cement, 15-25 parts of volcanicash, 3-6 parts of nano hybrid hyperbranched polymer HB-SiO2, 75-85 parts of silica sand, 85-95 parts of coarse aggregate, 3-5 parts of basalt fibers, 1-3 parts of graphene oxide fibers, 7.5-8.5 partsof a composite additive, 15-20 parts of water, 1-3 parts of a carboxyl metal organic framework, 1-3 parts of zirconium citrate and 2-5 parts of zinc oxide nanofibers. The invention also provides a preparation method of the fair-faced concrete. The fair-faced concrete provided by the invention is better in comprehensive performance, higher in compressive strength and flowability, lower in bleedingrate, better in durability, environmental protection property and decorative effect, very good in appearance, smooth in surface and less in pores.

Owner:韩昌龙

Preparing method for fatty-group-modified polycarboxylate water reducer

The invention provides a preparing method for fatty-group-modified polycarboxylate water reducer, and relates to the technical field of building materials. The preparing method includes the followingsteps that (1) sodium sulfite, sodium pyrosulfite and liquid caustic soda are added into deionized water, and a solution A is prepared; (2) formaldehyde, acetone and cyclohexanone are stirred to be even, and a solution B is prepared; (3) the solution B is dropwise added into the solution A, and aldehyde-ketone condensation liquid is obtained; (4) the aldehyde-ketone condensation liquid, methyl allyl polyoxyethylene ether and hydrogen peroxide are added into the deionized water, and a solution C is prepared; (5) crylic acid is taken and added into the deionized water, the mixture is mixed, anda solution D is prepared; (6) initiating agent and chain transfer agent are taken and added into the deionized water, the mixture is mixed and stirred to be even, and a solution E is prepared; (7) under the normal temperature condition, the solution D is added into the solution C, and meanwhile the solution E is dropwise added into a base solution; (8) dropwise adding is completed, and heat preservation stirring is carried out for 50 min. The preparing method has the advantages of being high in water reduction, low in mixing amount, high in water-reducing rate and the like.

Owner:萧县沃德化工科技有限公司 +1

Method for preparing polycarboxylic acid retarding water reducer

The invention belongs to the technical field of methods for preparing polycarboxylic acid water reducers. A method for preparing a polycarboxylic acid water reducer comprises the following: a step 1 of esterification, in which a poly(ethylene glycol methyl ether)acrylate macromonomer is synthesized by using methoxy polyethylene glycol and acrylic acid in a molar ratio of 1:1.1 to 1:1.5 at 100 to 120 DEG C, water is separated out in a reaction process, and the molecular weight of the macromonomer is 1,250 to 3,000; and a step 2 of polymerization, in which aqueous solution of the macromonomer is prepared, an unsaturated monomer and a catalyst A are added in turn at 40 to 50 DEG C, the temperature is kept constant at 28 to 40 DEG C, aqueous solution of anhydrous sodium hydrogensulfite or vitamin c is dripped, the concentration of a solid content is kept between 35 to 45 percent by adjusting water content, stirring is stopped, and the solution is allowed to stand for 1 to 1.5 hours, the pH value is kept between 6 and 8 by alkaline reagent after the reaction is finished, and the catalyst A is peroxyacetic acid or potassium peroxydisulfate. The invention has the advantages of low cost, simple process and high product performance.

Owner:河北智胜工程技术有限公司

Aqueous solution retarder

The invention provides an aqueous solution retarder. The aqueous solution retarder is prepared from, by weight, 70-85 parts of a polycarboxylate superplasticizer, 1-10 parts of polyphosphate, 5-20 parts of organic acids, 1-5 parts of an anti-freezing agent and 1-10 parts of a calcium increasing agent, wherein the polyphosphate refers to sodium hexametaphosphate or sodium tripolyphosphate, and thecalcium increasing agent refers to calcium hydroxide, calcium oxide and calcium carbonate. The problem of environmental pollution caused by adding of various auxiliary agents in high quantity due to apurpose of improving a retarding function of a water reducing agent in the prior art is solved. A product has advantages of high slump loss resistance, high water reducing rate, high strength, retarding and the like, concrete workability is improved, various mechanical performances of concrete are improved, and high adaptability to various types of cement is achieved. Concrete prepared from the aqueous solution retarder is free of surface bleeding line and bubbles, low in color difference and high in appearance quality, low environment temperature influences are realized, convenience in construction is achieved, and a preparation method is simple and easy to operate.

Owner:南京友西科技集团股份有限公司

A high water-reducing and high-early-strength polycarboxylate water-reducing agent and its non-pyrogenic preparation method

ActiveCN105130269BRealize the dual functions of high water reduction and high early strengthShorten the setting timeDefoaming AgentsMaterials science

The invention belongs to the technical field of concrete admixture in building materials, and provides a high-water-reduction high-early-strength type polycarboxylic acid water reducing agent and a pyrogen-free preparation method thereof. Firstly, a high-early-strength type polycarboxylic acid water reducing agent mother liquid is obtained by using a redox initiation system under a pyrogen-free condition, then an optimized early-strength component, a defoaming agent and water are added, and compounding is carried out to obtain the product, wherein the high-early-strength type polycarboxylic acid water reducing agent mother liquid is prepared from unsaturated polyoxyethylene ether (MW=3800-4000), a chain transfer agent, unsaturated acid and / or an unsaturated acid derivative, an oxidant, a reductant and water. The water reducing agent has low mixing amount, and has the advantages of high water reducing rate, good early strength effect, good cement adaptability and the like; moreover, the process does not need additional pyrogen, can be carried out at normal temperature, has less equipment investment and low cost, and is suitable for large-area popularization and application. The water reducing agent can greatly improve the early strength of concrete, improves the template turnover speed, improves the work efficiency, is beneficial for improving constructional engineering quality and improving the production efficiency, reduces energy consumption, and reduces construction costs.

Owner:大连华建科技有限公司

Method for preparing macro-monomer synthesized polycarboxylate water reducer through alcoholysis of alkenyl-acyl chloride

ActiveCN106117461AExpand the theoretical connotationThe polymerization process is mild and stableIonEther

A method for preparing a macro-monomer synthesized polycarboxylate water reducer through alcoholysis of alkenyl-acyl chloride belongs to the field of water reducers. The method comprises the following steps: firstly polymerizing a cationic chain, and then reacting with the alkenyl-acyl chloride, thus obtaining a macro-monomer; then carrying out copolymerization on the macro-monomer and a carboxylic acid micro-monomer, i.e., polymerizing under an oxidization-reduction initiating system formed by high-valence cerate and alcohols by taking an unsaturated cationic quaternary ammonium salt monomer as a reactant, thus obtaining a terminal hydroxyl cationic long chain; then respectively enabling the terminal hydroxyl cationic long chain and polyethylene glycol monomothyl ether to react with the alkenyl-acyl chloride respectively, thus preparing macro-monomers with different structures; then carrying out free radical polymerization on the macro-monomers and unsaturated carboxylic acid micro-monomers, thus obtaining the macro-monomer composite polycarboxylate water reducer. According to the method disclosed by the invention, the macro-monomers with different structures and functions are successfully synthesized through ways of polymerizing the cationic chain and respectively reacting with the alkenyl-acyl chloride by combining polyether, and a novel comb-structure polycarboxylate water reducer which takes a polycarboxyl acid as a main chain and the cationic long chain and the polyether as polybasic side chains can be finally obtained. A reaction technology is simple and easy, and multiple excellent effects of retaining slump through reducing water, resisting clay, and the like are realized.

Owner:BEIJING UNIV OF TECH

A kind of coagulation-promoting early-strength polycarboxylate superplasticizer and preparation method thereof

ActiveCN109134784BPromotes early hydrationActs as a condensation catalystPlasticizerSuperplasticizer

The invention discloses a coagulating and early-strength-type polycarboxylic acid superplasticizer and a preparing method thereof. The polycarboxylic acid superplasticizer is prepared from, by mass, 70-80 parts of polyoxyethylene ether macromonomer, 1-1.5 parts of reducing agent, 1-1.5 parts of water-based initiator, 40-50 parts of deionized water, feed liquid A and feed liquid B; the feed liquidA is prepared by mixing 7-9 parts of acrylic acid, 0.1-2 parts of coagulating and early-strength monomer, namely unsaturated alhylol amine ester, 0.1-1 part of unsaturated amide and 15-25 parts of deionized water; the feed liquid B is prepared by mixing 0.08-0.15 part of reducing agent Y, 0.3-0.5 part of chain transfer agent and 18-28 parts of deionized water. The preparing method comprises the steps of putting the polyoxyethylene ether macromonomer, the reducing agent and the deionized water into a reaction kettle, raising the temperature, and stirring the materials; adding the water-based initiator into the reaction kettle, dropwsie adding the feed liquid A and the feed liquid B, after dropwise addition is finished, conducting heat preservation for a reaction, cooling to the room temperature, and adding caustic soda liquid to adjust the pH value to 7. By means of the coagulating and early-strength-type polycarboxylic acid superplasticizer and the preparing method thereof, the early strength of concrete is effectively improved, and the coagulating time of the concrete is shortened.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Efficient compound water reducing agent for concrete and preparation method of efficient compound water reducing agent

The invention discloses an efficient compound water reducing agent for concrete and a preparation method of the efficient compound water reducing agent. The efficient compound water reducing agent comprises, by weight, 13-18 parts of aromatic sulfamic acid formaldehyde condensate sodium salt, 11-16 parts of sulfonated humic acid-formaldehyde-sulfonated acetone polymer, 10-15 parts of polymer of 4-amino-sodium benzene sulfonate, formaldehyde and methylphenol, 7-11 parts of alkali lignin, 8-13 parts of sodium polystyrenesulfonate, 5-10 parts of calcium gluconate, 6-12 parts of propylene glycol alginate, 4-7 parts of mannitol, 4-8 parts of sodium lauryl sulfate and 5-10 parts of polyvinyl pyridine. The water reducing agent prepared by the method has the advantages that the water reducing agent is excellent in comprehensive performance, high in water reducing performance, high in early strength, high in reinforcing performance, low in shrinkage, high in slump loss resistance, and the like; the water reducing agent is suitable for high-durability concrete, self-leveling concrete, high-strength pump-delivery commodity concrete, underwater bored pile grouting concrete, bare concrete with high facing requirements, steam-cured concrete and the like.

Owner:安徽炎胜新材料科技有限公司

Method for synthesizing cationic polycarboxylate superplasticizer based on Hoffmann rearrangement reaction

The invention discloses a method for synthesizing a cationic polycarboxylate superplasticizer based on a Hoffmann rearrangement reaction, and belongs to the field of water reducing agents. Unsaturated amide monomers are modified into unsaturated isocyanate, meanwhile, an oxidation-reduction initiating system is formed by high-valence cerate and alcohol to initiate polymeric unsaturated cation quaternary ammonium salt monomers, a hydroxyl-terminated cation side chain is obtained, then isocyanate reacts with the hydroxyl-terminated cation side chain and polyethylene glycol monomethyl ether to obtain cationic macromonomers and polyether macromonomers, then the cationic macromonomers, the polyether macromonomers and small carboxylic acid monomers are subjected to free radical copolymerization, and the cationic polycarboxylate superplasticizer is obtained. Based on the Hoffmann rearrangement reaction principle, unsaturated amide modified amide reacts with the cation side chain and a polyether side chain, the macromonomers with different structures and different functions are designed and synthesized, and the novel pectinated polycarboxylate superplasticizer with polycarboxylic acid as a main chain and cations and polyether as the side chain is obtained finally. The synthesis process is continuous and easy to control, and multiple effects of excellent water reduction, collapse protection, clay resistance and the like are shown.

Owner:中铁一局集团工业贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com