Anticorrosive composite polycarboxylate superplasticizer with high slump loss resistance, and preparation method and application thereof

A composite water-reducing agent and polycarboxylic acid technology, which is applied in the field of concrete additives, can solve the problems of polycarboxylate water-reducing agent being prone to mildew and odor, poor slump retention effect, etc., and achieves stable long-term storage performance, enhanced mutual solubility, excellent water reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

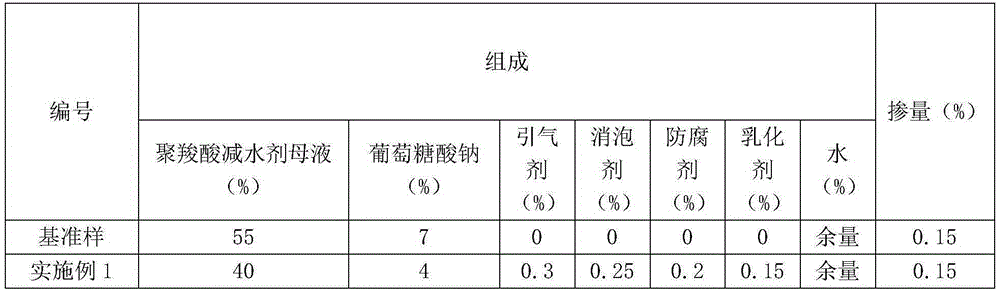

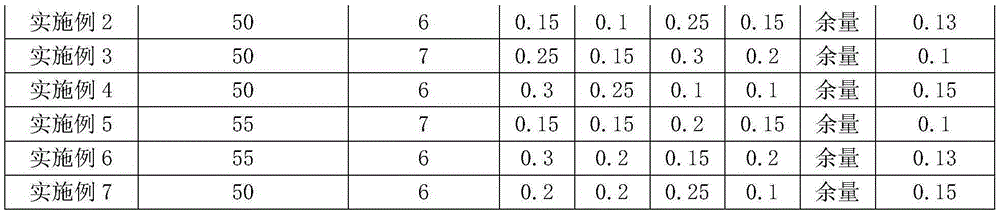

[0040] Under normal temperature and pressure, each component is prepared according to the mass percentage of each component in each embodiment in Table 1, and the prepared polycarboxylate superplasticizer mother liquor, sodium gluconate, air-entraining agent, defoaming agent Antiseptic, antiseptic and bactericide, emulsifier and water are placed in a container and stirred until uniform, and the antiseptic and high slump retention polycarboxylate composite water reducer is prepared.

[0041] In each embodiment, the air-entraining agent adopts sodium lauryl sulfate; the defoamer adopts modified polydimethylsiloxane; One of them; the emulsifier uses nonylphenol polyoxyethylene ether.

[0042] Add water to the mixture mainly composed of cement, fly ash, sand and stone, and stir for 1-10 minutes to obtain concrete. The mass ratio of polycarboxylic acid composite water reducer to concrete cementitious material is 0.1-0.15:100, According to the weight percentage listed in Table 1, t...

Embodiment 8

[0054] In this embodiment, an anti-corrosion and high-slump polycarboxylate composite water-reducer is composed of the following components and mass percentage content: polycarboxylate water-reducer mother liquor 46%, sodium gluconate 6%, air-entraining agent 0.2%, defoaming agent 0.2% of emulsifier, 0.1% of emulsifier, 0.3% of preservative and fungicide, and 47.2% of water.

[0055] Among them, the polycarboxylate water reducer mother liquor is a TPEG type polycarboxylate mother liquor with a solid content of 40%; the air-entraining agent is selected from commercially available sodium lauryl sulfate; The solid content of methyl siloxane is 20%; the emulsifier is selected from commercially available nonylphenol polyoxyethylene ether; the antiseptic and bactericide is selected from sodium benzoate and sodium sorbate.

[0056] The preparation method of the anti-corrosion high-slump polycarboxylate composite water-reducer in this embodiment specifically includes the following ste...

Embodiment 9

[0061] This embodiment is an anti-corrosion high-slump polycarboxylate composite water-reducer, which is composed of the following components and mass percentage content: polycarboxylate water-reducer mother liquor 52%, sodium gluconate 6%, air-entraining agent 0.3%, defoaming 0.1% of emulsifier, 0.2% of emulsifier, 0.1% of preservative and bactericide, and 41.3% of water.

[0062] Among them, the polycarboxylate water reducer mother liquor is a TPEG type polycarboxylate mother liquor with a solid content of 40%; the air-entraining agent is selected from commercially available sodium lauryl sulfate; Methyl siloxane, the solid content is 20%; the emulsifier is selected from commercially available nonylphenol polyoxyethylene ether; the antiseptic and bactericide are sodium benzoate, sodium nitrite and isothiazolinone.

[0063] The preparation method of the anti-corrosion high-slump polycarboxylate composite water-reducer in this embodiment specifically includes the following ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com