Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1606 results about "Diphenylmethane diisocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic polyurethane elastomer and manufacturing method thereof

The invention relates to the manufacturing field of a special extrusion grade T-die thermoplastic elastomer, in particular to a manufacturing formula and a manufacturing method thereof. The formula comprises the following components: 20-40% of 4,4'-diphenylmethane-diisocyanate, 15-70% of polybutylene adipate the molecular weight of which is 1000 or 2000, 0-50% of poly butylene glycol adipate the molecular weight of which is 2000, 5-15% of 1,4-butanediol, 0-5% of glycol, 0.1-1.0% of antioxidant, 0.1-1.0% of lubricant, 0.001-0.1% of environment-friendly catalyst, 0.1-1.0% of ultraviolet absorbent, 0.1-1.0% of light stabilizer and 0.1-1.0% of hydrolysis resistant agent. Continuous production processes are used for synthesizing TPU (thermoplastic polyurethane). The product of the invention has the advantages of stable quality, excellent performance, few T-die extrusion crystal points, good transparency (more than 4mm), stable extrusion, no occurrence of separation of additives, high hydrolysis resistance and high UV (ultraviolet) resistance, and the indexes and the performance of the product can reach the indexes of international like products. The invention provides a thermoplastic polyurethane elastomer and a manufacturing method thereof.

Owner:SHANGHAI LIANJING MATERIAL ASSETAB

Viscoelastic polyurethane foams

A viscoelastic foam is produced by reacting (a) an isocyanate component that includes at least 25% by weight of diphenylmethane diisocyanate having a monomeric content of from 50 to 90% by weight, (b) an isocyanate-reactive component, (c) at least one catalyst, (d) at least one surface active agent, and (e) liquid carbon dioxide. These foams are characterized by a ball rebound of less than 20%. Particularly preferred foams are characterized by a 95% height recovery time greater than 4 seconds.

Owner:COVESTRO LLC +1

Two-package curing type polyurethane paint and preparation thereof

InactiveCN101565590ALow viscosityImprove the level ofFibre treatmentPolyurea/polyurethane coatingsApparent viscosityPolyol

The invention relates to a two-package curing type polyurethane paint and preparation thereof. The raw material system of the paint comprises a polyether polyol, a isocyanate, a small molecular chain expander and a solvent, wherein polydihydrofuran ether glycol with molecular weight between 700 to 1500 is used as the plyether polyol; methyl diphenylene diisocyanate is used as the isocyanate, 1,4-butanediol is used as the small molecular chain expander, dimethylformamide is used as the solvent. Weight proportion between the plyether polyol, the small molecular chain expander and the solvent is 1:0.7 - 0.85:8 - 15. Colloidal viscosity of the polyether polyol at 25 DEG C. is between 3000 and 2000cps. The paint is obtained by primarily charging DMF as the solvent, the polyether polyol and the chain expander into the reaction container simultaneously at one time, and then gradually charging the isocyanate for the reaction. By using MDI to substitute TDI for preparation of the polyurethane paint preparation, the invention is low in viscosity, great in levelability, easy for hardness adjustment, low in cost, safe and environment friendly in use.

Owner:顾建荣

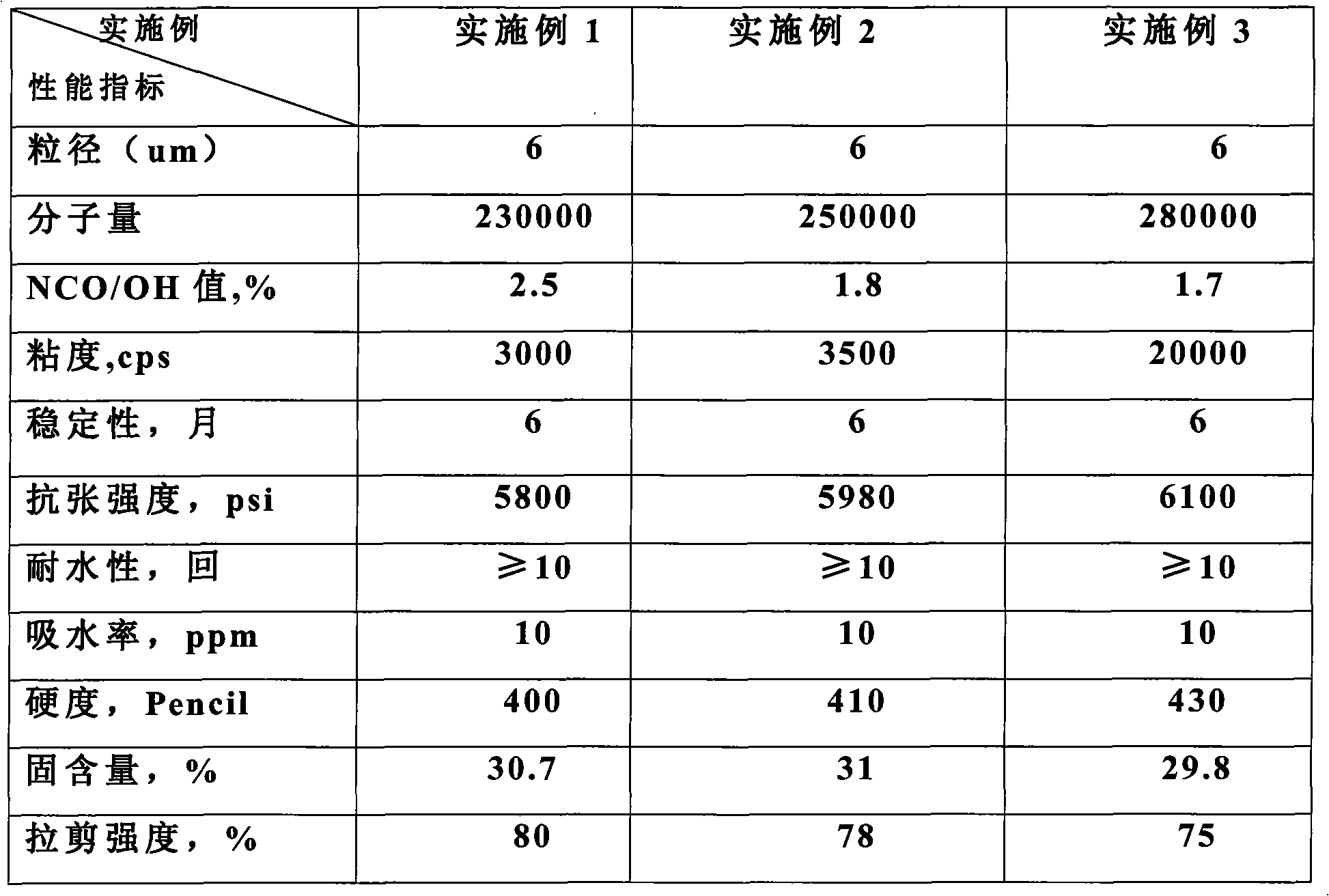

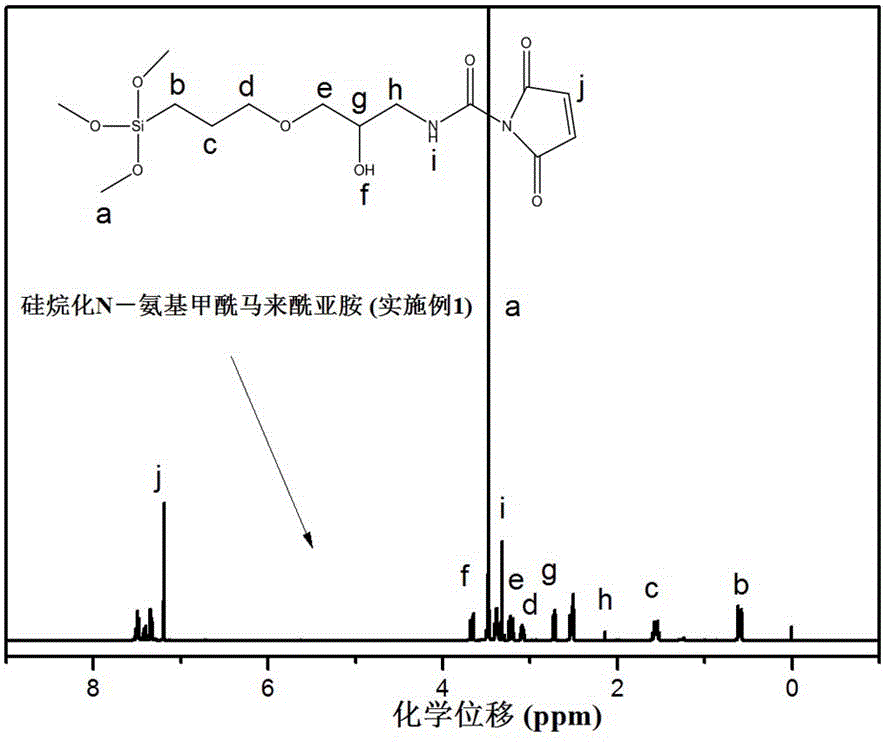

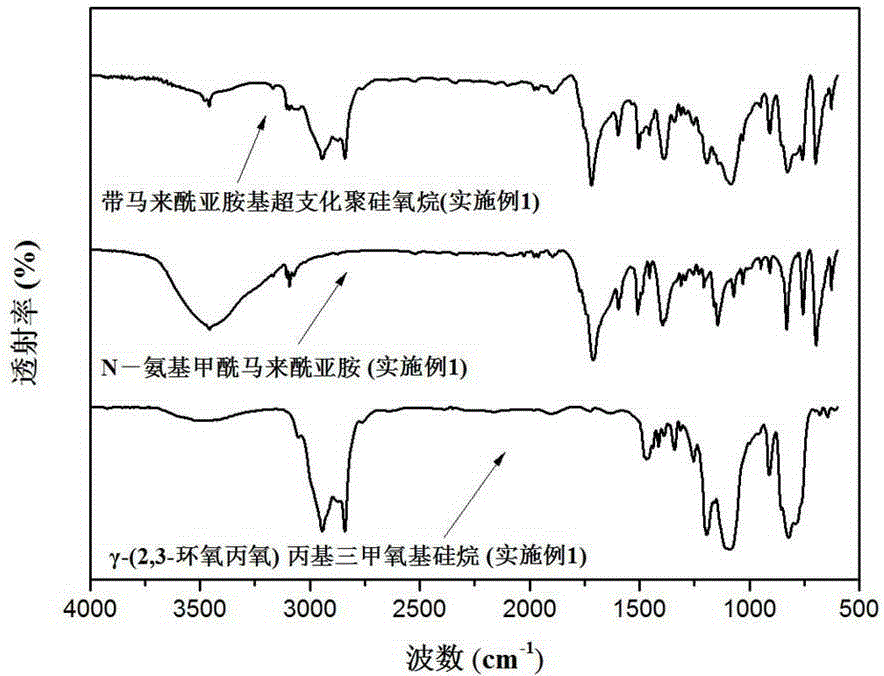

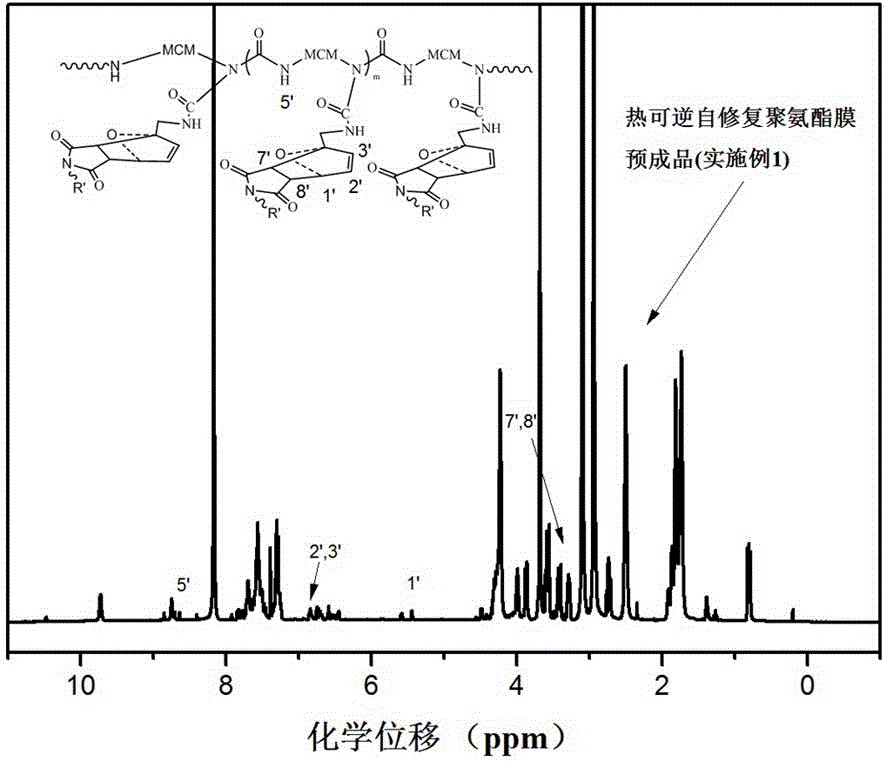

Thermal-reversible self-repair polyurethane membrane and preparation method therefor

The invention discloses a thermal-reversible self-repair polyurethane membrane and a preparation method therefor. Under protection of inert gases, 4,4-diphenylmethane diisocyanate, polycaprolactone glycol and N,N-dimethyl formamide are mixed uniformly, a reaction is carried out at a temperature of 50-60 DEG C, then the solution is cooled to a temperature of less than 5DEG C, 2-furan methylamine is added in the solution, the temperature is risen to 95-105 DEG C, the reaction is carried out for 10-11h, then hyperbranched polysiloxane with maleimide groups is added, the pre-finishing product prepared after the reaction is finished is poured into a die and dried, and a thermal-reversible self-repair polyurethane membrane is obtained. By utilization of the Diels-Alder (DA) reaction, thermal-reversible self-repair of a polyurethane membrane is achieved, the prepared polyurethane membrane has advantages of excellent thermal stability and high hardness, and raw materials have wide sources. The preparation method has characteristics of simple technology, strong practicality, wide applicability and the like.

Owner:SUZHOU UNIV

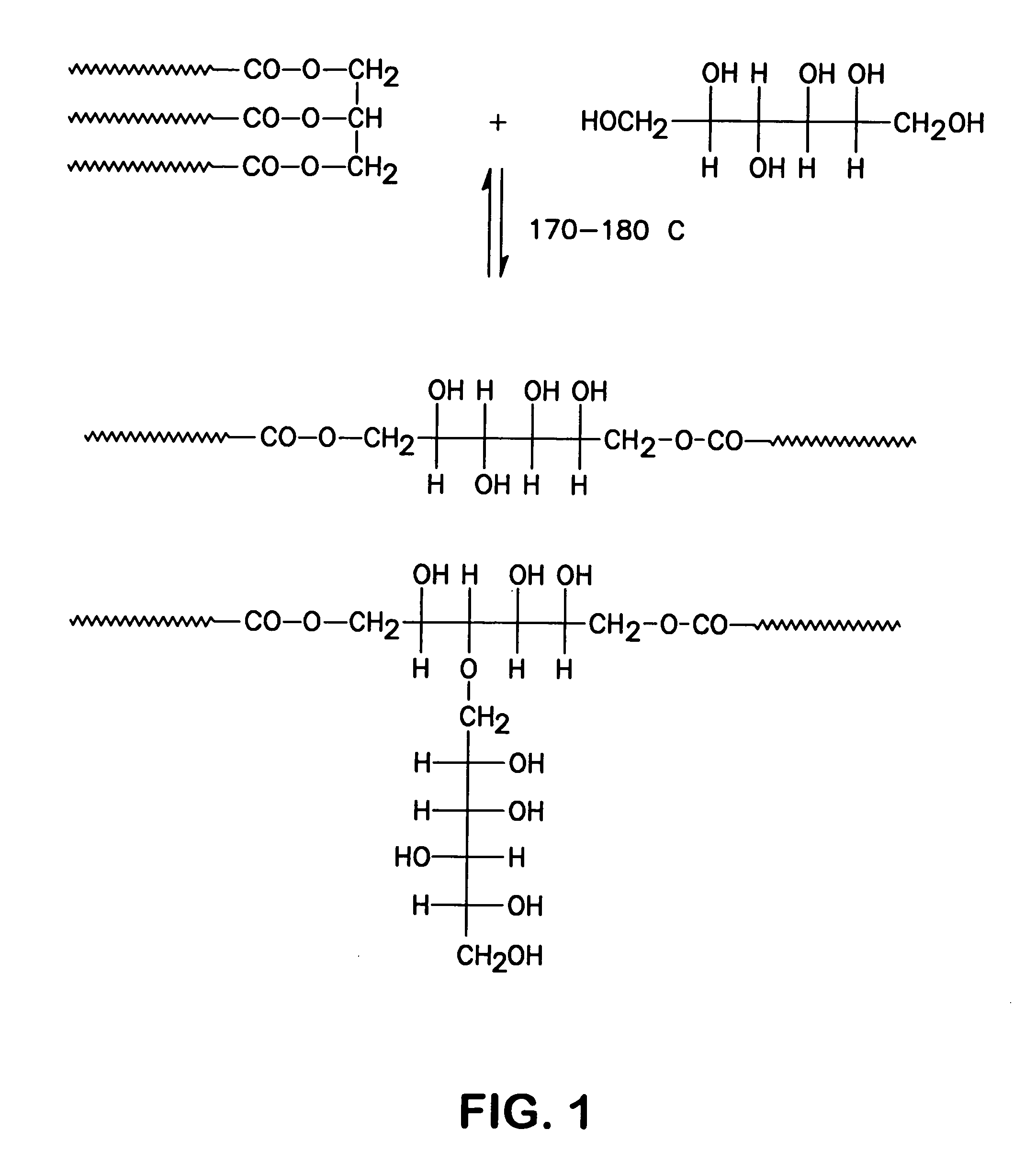

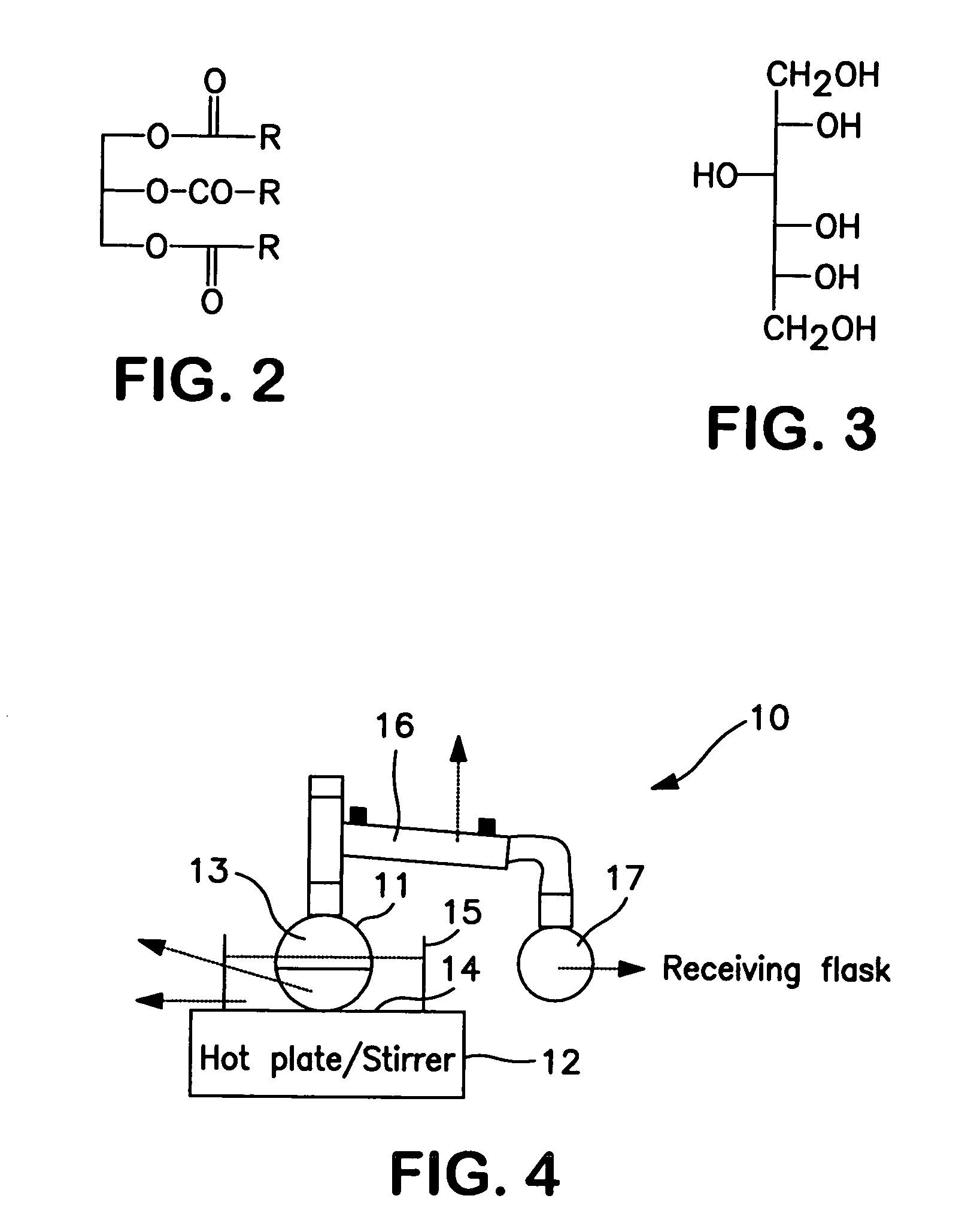

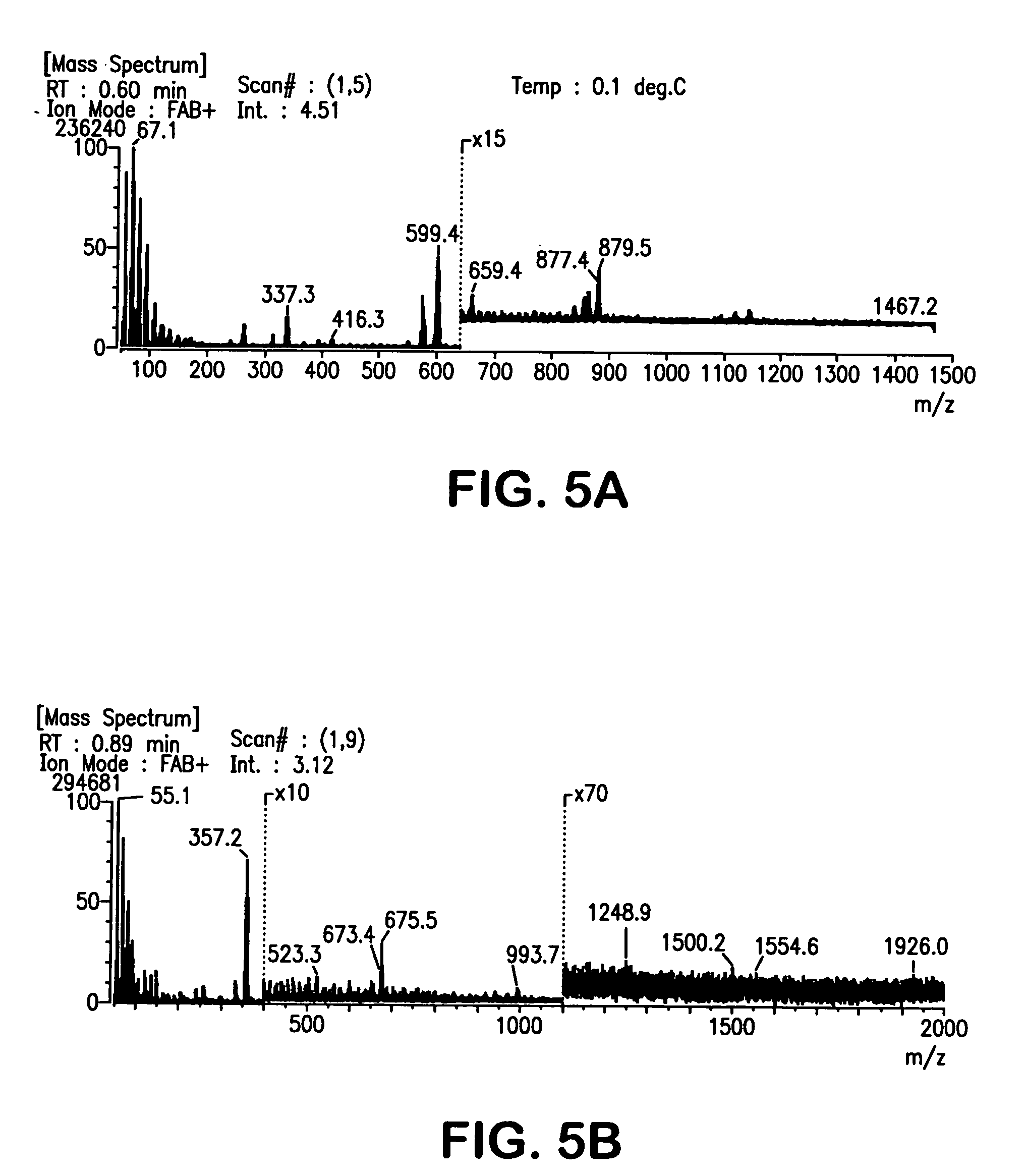

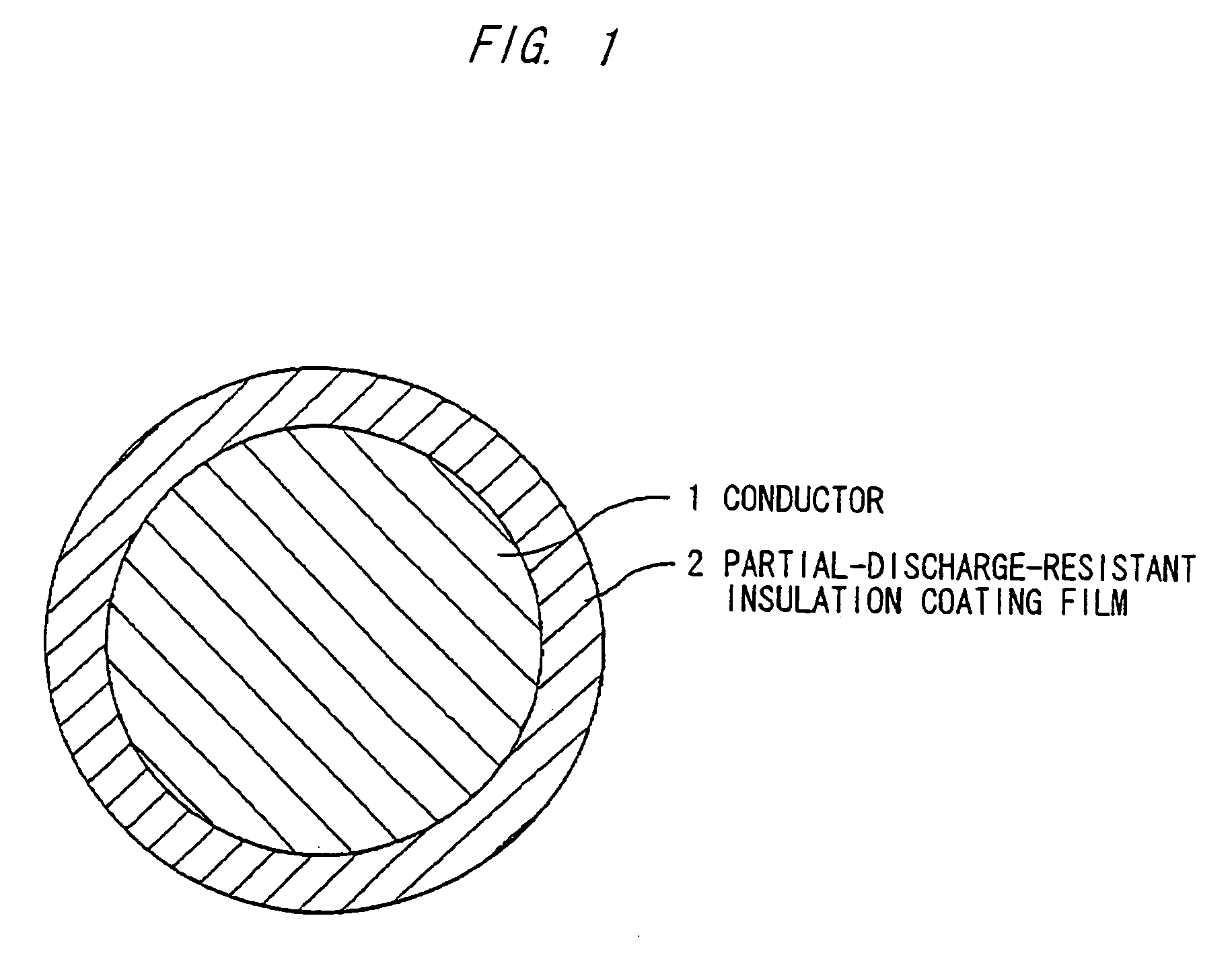

Polyol fatty acid polyesters process and polyurethanes therefrom

InactiveUS7125950B2Overcome deficienciesFatty oils/acids recovery from wasteSugar derivativesPolyesterNatural source

A solvent-free process for making a polyol fatty acid polyester composition useful for preparation of polyurethanes is described. These compositions are preferably made by reaction of a natural oil (from plant or animal) with a multi-functional hydroxyl compound derived from a natural source, such as sorbitol, in presence of an alkali metal salt or base such as potassium hydroxide as a catalyst which also acts to saponify the reaction mixture. The hydroxyl content of the prepared composition depends on the amount of the multi-functional hydroxyl compound used in the preparation. In another embodiment, the hydroxyl groups of these compositions are reacted with an isocyanate, such as the polymeric diphenylmethane diisocyanate (also known as 4,4′-diphenyl methane diisocyanate, or MDI) to form polyurethanes in a conventional manner.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Partially blocked polyurethane curing agent and preparation method thereof

The invention discloses a partially blocked polyurethane curing agent and a preparation method thereof. The preparation method mainly comprises the following steps that end-NCO isocyanate prepolymer is obtained from the addition reaction of diphenylmethane diisocyanate and low-molecular polyol in ester solvent, and then the end-NCO isocyanate prepolymer reacts with isocyanate sealant to form the curing agent. The partially blocked polyurethane curing agent has the following characteristics that: a) according to the calculation of NCO by weight, the blocked-NCO content is between 1.0 and 5.0 percent; b) the solid content by weight of the curing agent is 75+ / -2 percent, and the percentage content of the NCO by weight is between 12.0 and 13.0 percent (according to the calculation of the effective percentage of the NCO, the percentage content of the NCO including blocked NCO radicals); and c) the viscosity of the curing agent at 25 DEG C is between 1,500 and 2,500 mPa. s. The invention has the advantages of low toxicity, good storage stability, adjustable curing speed and the like.

Owner:WANHUA CHEM BEIJING +1

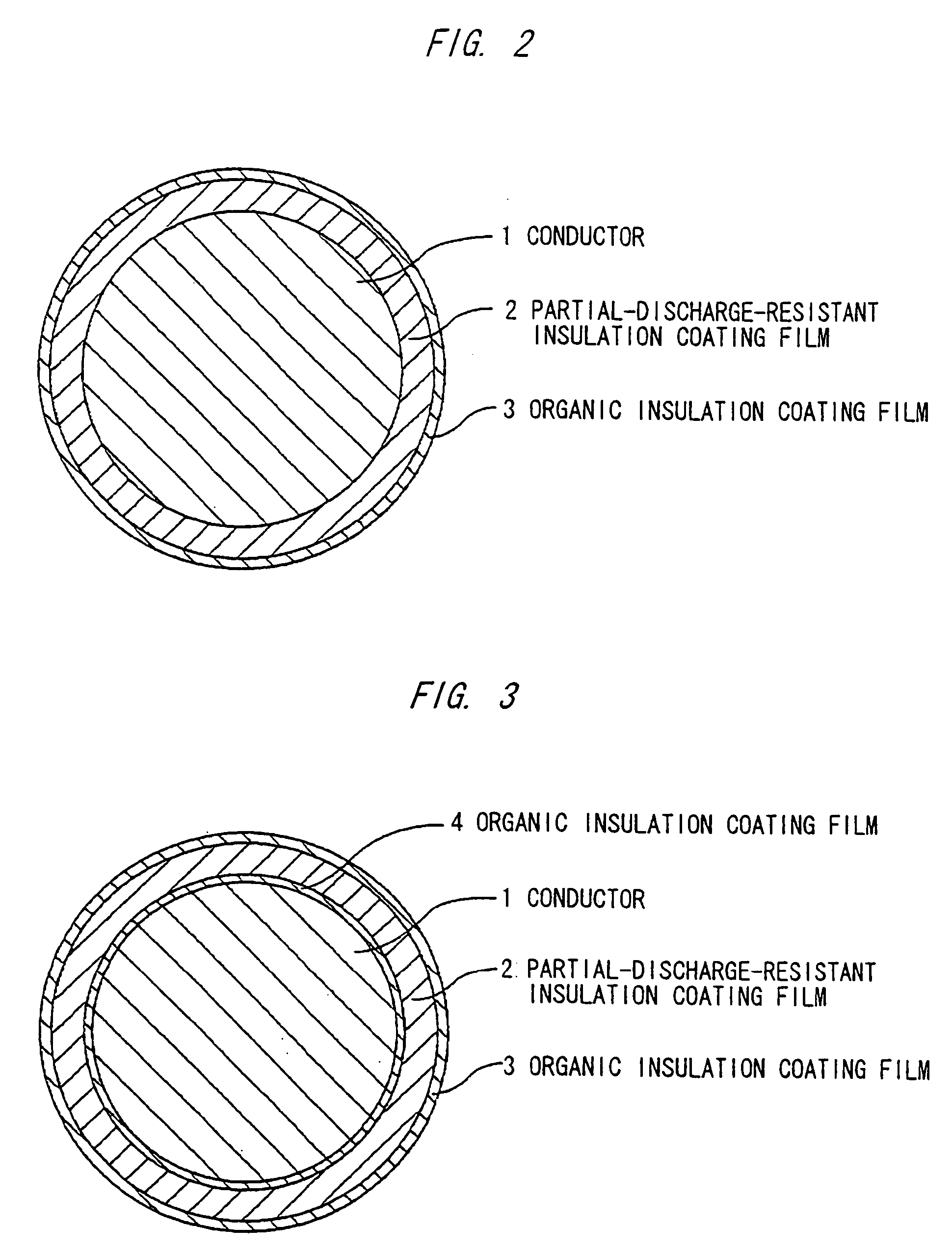

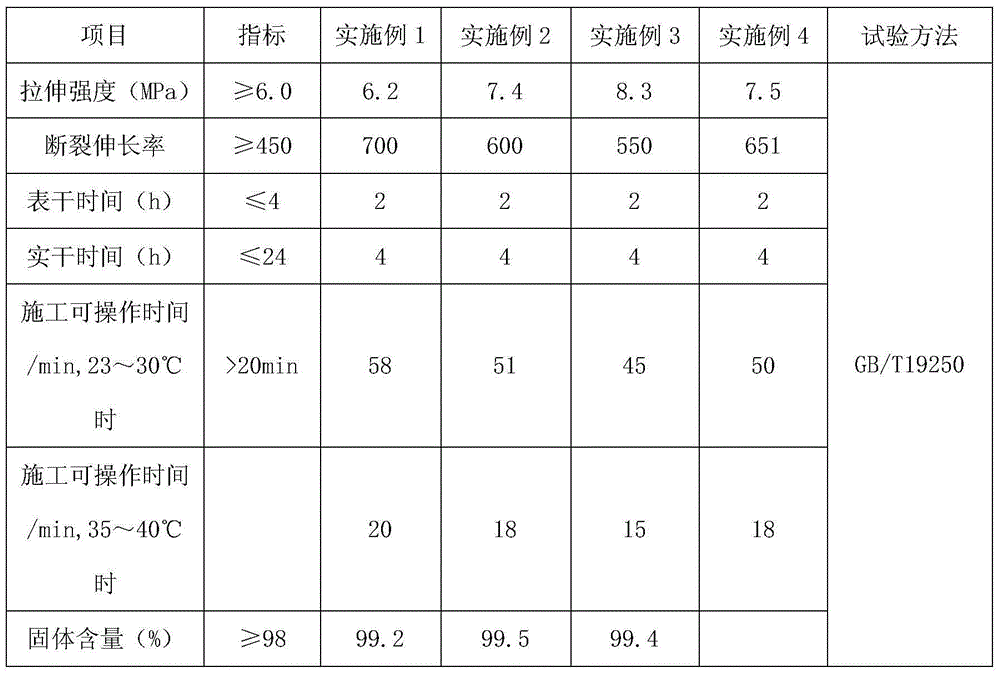

Polyamide-imide resin insulating coating material, insulated wire and method of making the same

ActiveUS20060240255A1Evenly dispersedInhibit aggregationLiquid surface applicatorsInsulatorsPolyamide-imideInsulative paint

A polyamide-imide resin insulating coating material, which is obtained by reacting an isocyanate component with an acid component, has a main solvent component of γ-butyrolactone. In the coating material, a total compounding ratio of 4,4′-diphenylmethane diisocyanate (MDI) and trimellitic anhydride (TMA) is 85 to 98 mol %, where the total compounding ratio is given by averaging a compounding ratio of MDI to the isocyanate component and a compounding ration of TMA to the acid component.

Owner:HITACHI METALS LTD

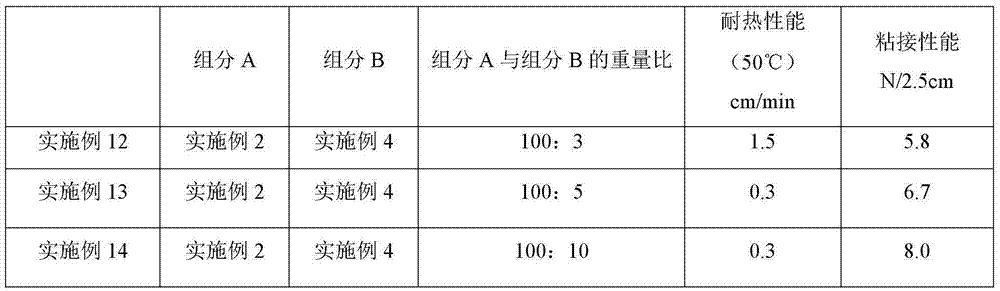

Novel high-strength polyurethane waterproofing paint and preparation method thereof

InactiveCN104673076ALong construction timeHigh strengthPolyurea/polyurethane coatingsToluene diisocyanatePlasticizer

The invention discloses a novel high-strength polyurethane waterproofing paint which consists of a component A and a component B. The component A is prepared from the following components in parts by weight: 140-350 parts of polyether polyol, 20-60 parts of TDI (toluene diisocyanate), 20-60 parts of diphenylmethane diisocyanate and 50-100 parts of a plasticizer; the component B is prepared from the following components in parts by weight: 50-100 parts of polyether polyol, 40-200 parts of a plasticizer, 20-80 parts of a chain extender, 100-300 parts of pigment and filler, 0.1-0.5 part of a catalyst, 0.1-0.5 part of a polymerization inhibitor and 0.1-1 part of a high-performance accessory ingredient defoaming agent. The invention also comprises a preparation method of the high-strength polyurethane waterproofing paint. The high-strength polyurethane waterproofing paint disclosed by the invention has relatively long operable construction time and excellent physical and mechanical properties such as high strength, high elongation rate and high bonding strength, and is low in residual TDI and toxicity. The novel high-strength polyurethane waterproofing paint can be widely applied to infrastructure construction and municipal traffic engineering, and particularly to water resistance of important projects such as high-speed railways and highway bridges.

Owner:XUZHOU WONIUSHAN NEW WATERPROOF MATERIALS

Distillation for processing admixture of isomeric compound of diphenylmethane diisocyanate

ActiveCN101003497AEasy to operateEasy to manufactureIsocyanic acid derivatives purification/separationDistillation methodDiphenylmethane diisocyanate

This invention relates to a method for distilling an isomer mixture of isocyanate. The method comprises: adding an isomer mixture of diphenylmethane diisocyanate into a separator, and distilling to obtain at least one product mixture, which comprises: 2,4'-MDI 50-60 wt.%, 4,4'-MDI 40-50 wt.%, 2,2'-MDI less than 1.5 wt.%, 2,4'-MDI less than 1 wt.%, and 4,4'-MDI greater than 99 wt.%. Compared with present distillation methods, the method has such advantages as saved distillation steps, reduced distillation column number, saved energy input, reduced isocyanate loss, and high 4,4'-MDI purity in the product mixture.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD

Single-component moisture-curing polyurethane adhesive and preparation method thereof

ActiveCN104263310AMeet the actual requirementsHigh activityPolyureas/polyurethane adhesivesPolyesterAdhesive cement

The invention discloses a single-component moisture-curing polyurethane adhesive and a preparation method thereof. The preparation method of the adhesive is characterized by comprising the following step: by adopting an organic solvent as a solvent, performing reaction on polyether glycol and / or polyester glycol, diphenyl methane diisocyanate, polymethylene polyphenyl isocyanate and triatomic primary alcohol of which the molecular weight is less than 200 to prepare the adhesive. The average degree of functionality of an obtained high-functionality NCO-terminated prepolymer is more than or equal to 3, and the single-component moisture-curing polyurethane adhesive disclosed by the invention is suitable for splicing and tenoning (or assembling) of woods and bonding and compounding of stone materials, fireproof plates, plastic aluminum plates, bakelite plates, oak boards, some metals such as aluminum and iron, zinc-plating plates, PVC membranes and the like, is especially suitable for adhesion of rosewoods and red woods, and can meet the special requirements of some products.

Owner:周建明

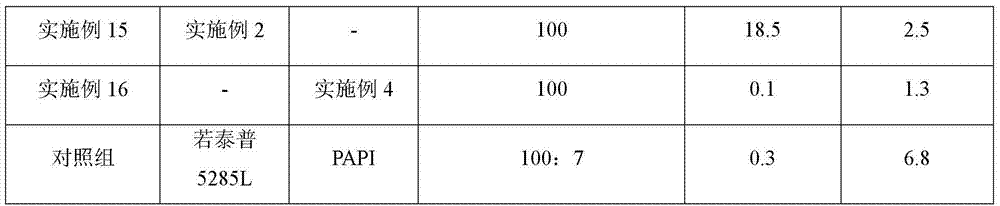

Double-component polyurethane adhesive and preparation method thereof

ActiveCN104745138AGood adhesionImprove heat resistancePolyureas/polyurethane adhesivesPolyesterEpoxy

The invention belongs to the field of polyurethane adhesives, relates to coating adhesive for woodworking industry, in particular to a double-component polyurethane adhesive and a preparation method thereof. The double-component polyurethane adhesive is obtained by compounding a component A and a polyurethane component B containing an isocyanate-terminated group, wherein the component A is polyurethane synthesized by polyester polyol and diphenylmethane diisocyanate (MDI) as well as accessory ingredients; the polyurethane component B containing the isocyanate-terminated group is synthesized by polyester polyol and / or polyether polyol, isocyanate, epoxy resin and accessory ingredients. The double-component polyurethane adhesive disclosed by the invention is good in adhesion performance, high in early-stage bonding strength and final bonding strength, and good in heat resistance, does not bounce at 80 DEG C, and is colorless, low in smell and low in cost.

Owner:重庆中科力泰高分子材料有限公司

Vegetable oil based polyurethane acrylic ester, preparing process and use thereof

InactiveCN101497684AWide variety of sourcesEasy to makePolyurea/polyurethane coatingsSurface treatment compositionsAlkaneVegetable oil

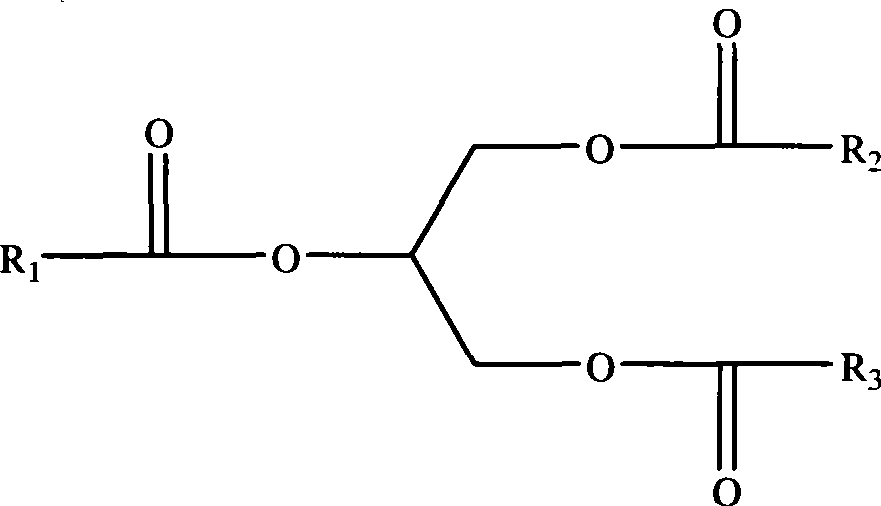

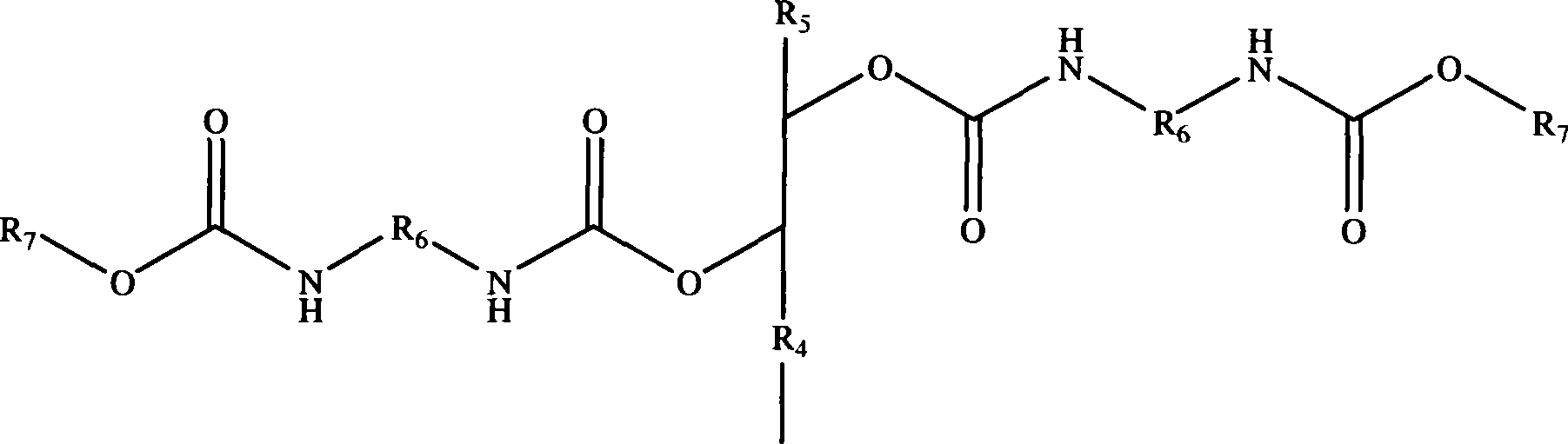

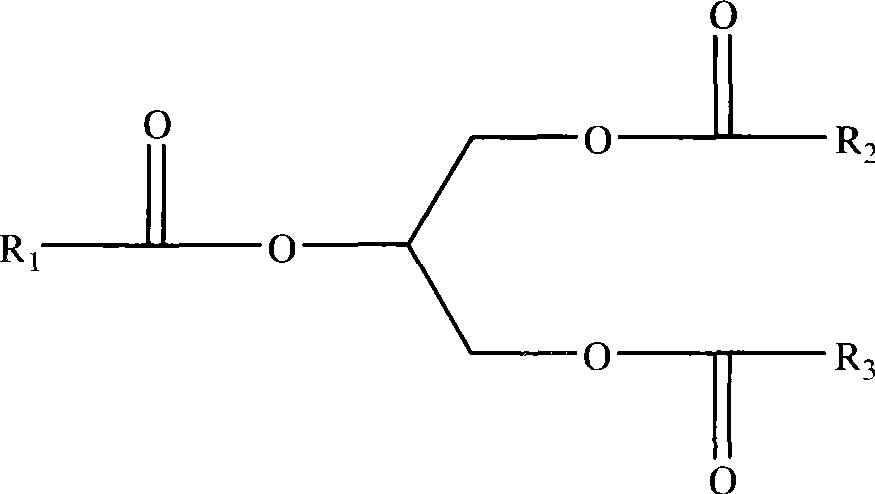

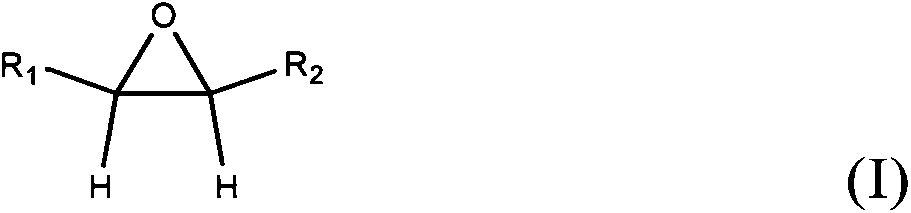

The invention relates to vegetable oil based polyurethane acrylic ester, belonging to the field of photosensitive polymer material. The vegetable oil based polyurethane acrylic ester is characterized in that the general chemical formula is Formula I, wherein R1, R2 and R3 are respectively chosen from alkane of C1-C18, at least one of the alkane is chosen from Formula II, R4 and R5 are respectively chosen from alkane of C1-C16, R6 is diphenyl methane-4,4'-diisocyanate, or hexamethylene diisocyanate, or isophorone diisocyanate or residue of 2,4-toluene diisocyanate with two isocyanate functional group removed, and R7 is 2-hydroxyethyl acrylate, or hydroxypropyl acrylate, or residue of pentaerythritol triacrylate with hydroxy functional group removed.

Owner:天津市天骄辐射固化材料有限公司

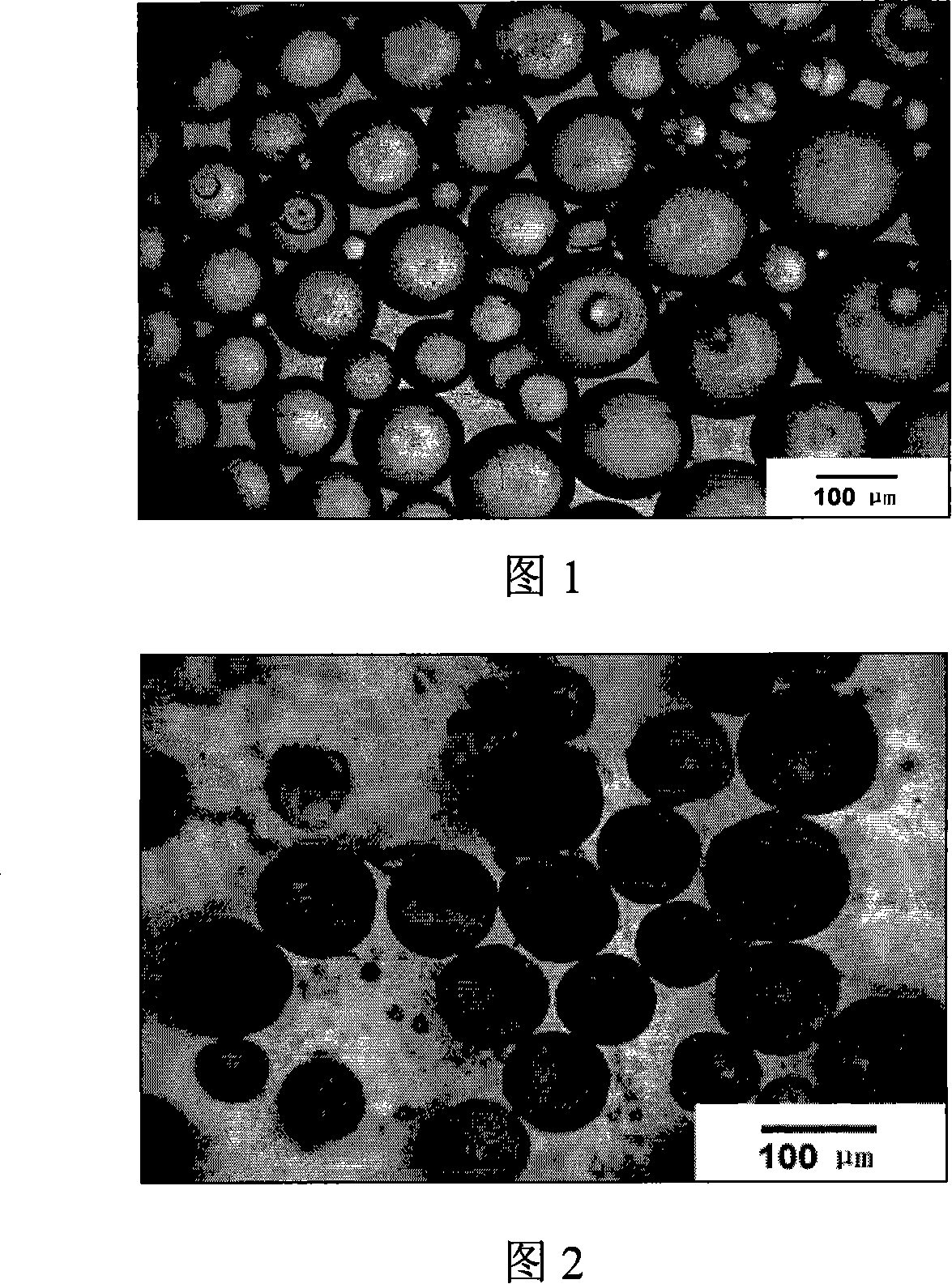

Polyureas microcapsule and its preparation method

InactiveCN101125290AImproved generated morphologySimple structureMicroballoon preparationMicrocapsule preparationDiethylenetriamineSurface-active agents

Owner:EAST CHINA UNIV OF SCI & TECH

Polishing pad and production method thereof

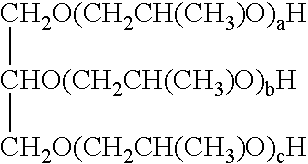

InactiveUS20080313967A1Improve polishing stabilityHigh polishing rateIndoor gamesOther chemical processesPolypropylene glycolWater soluble

There are provided a polishing pad which exhibits excellent polishing stability and excellent slurry retainability during polishing and even after dressing, can prevent a reduction in polishing rate effectively and is also excellent in an ability to flatten an substrate to be polished, and a method for producing the polishing pad. The method comprises dispersing water-soluble particles such as β-cyclodextrin into a crosslinking agent such as a polypropylene glycol so as to obtain a dispersion, mixing the dispersion with a polyisocyanate such as 4,4′-diphenylmethane diisocyanate and / or an isocyanate terminated urethane prepolymer, and reacting the mixed solution so as to obtain a polishing pad having the water-soluble particles dispersed in the matrix.

Owner:JSR CORPORATIOON

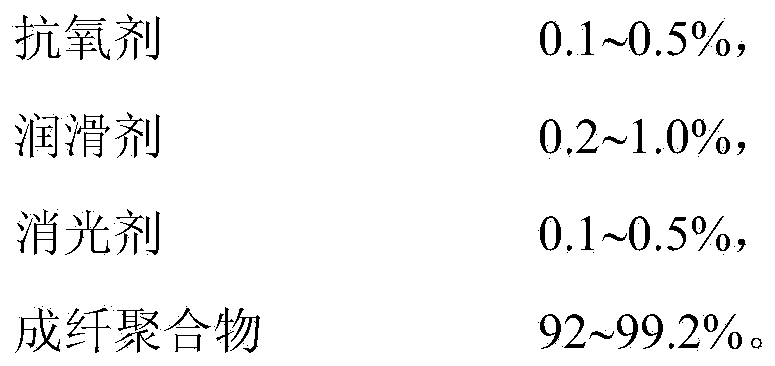

High-resilience urethane elastic fiber as well as preparation method thereof

ActiveCN103436983AHigh reboundImprove the degree of microphase separation of soft and hard segmentsMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberEthylenediamine

The invention relates to a preparation method of a high-resilience urethane elastic fiber. The preparation method comprises the following steps: (1) mixing raw materials, namely, polytetramethylene ether glycol (PTMEG) and 4, 4-diphenylmethane diisocyanate (MDI) to carry out reaction so as to obtain a prepolymer; (2) adding a certain amount of a mixed diamine chain extender into the prepolymer to form polymer liquor; (3) quickly adding polyamine (the number of functional groups is greater than 2) into the polymer liquor while stirring to carry out reaction so as to form polyurethaneurea liquor; (5) carrying out reaction on MDI and polyether polyhydric alcohol and blocking with ethanediamine to prepare oligomers; (6) blending nano attapulgite with the oligomers to prepare a prepreg; and (7) mixing the polyurethaneurea liquor with the prepreg to prepare a spinning dope, and spinning to form the high-resilience urethane elastic fiber. The preparation method of the high-resilience urethane elastic fiber provided by the invention satisfies the demands on the high-resilience urethane elastic fiber in certain special fields, and the resilience of the urethane elastic fiber is improved.

Owner:ZHEJIANG HUAFENG SPANDEX

Environment-friendly type polyurethane combined material and using method

The invention discloses an environment-protective polyurethane composition of indoor playground, which consists of component A and component B, wherein the component A contains basic component and organic bismuth catalyst; the basic component is composed of polyether polyol, filler, crosslinking agent, plasticizer, pigment, age resister and ultraviolet absorber; the component B concludes methane diphenyl diisocyanate (MDI)and polyester polyol; the blending rate of component A and component B is 2-5: 1 evenly, which are paved and solidified to produce the product without TDI, MOCA and DOP. The invention is superior to international index of runway, which is especially for paving indoor playground.

Owner:SHANGHAI DONGDA CHEM

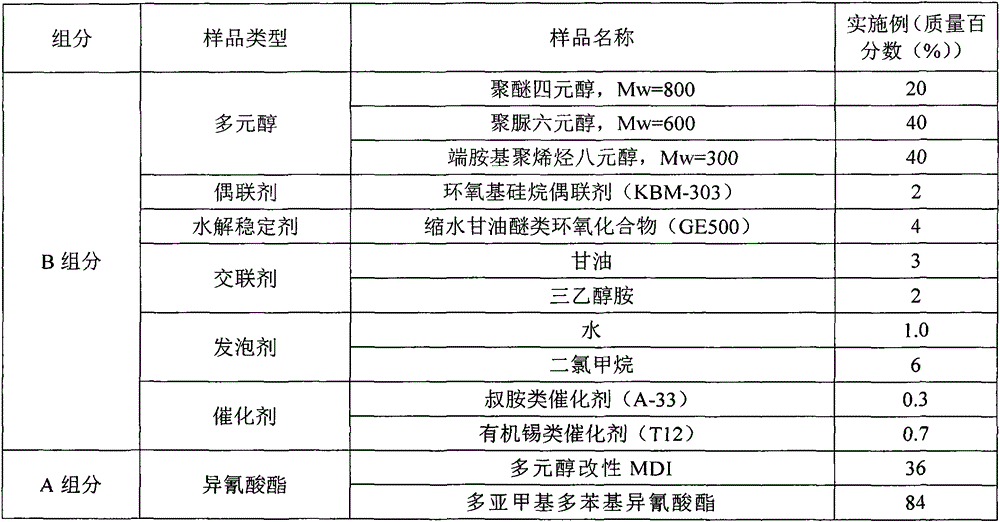

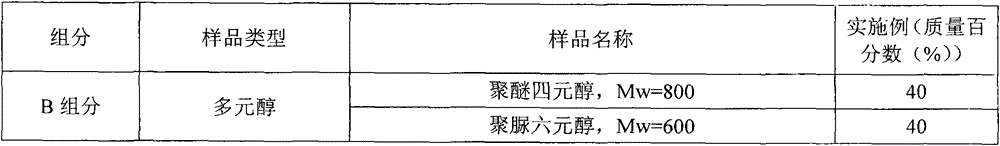

Polyurethane patching material used for settlement repairing of ballastless track structure for high-speed railway

ActiveCN104693413AThe distribution ratio is scientific and reasonableImprove performanceCross-linkPolyolefin

The invention relates to a polyurethane patching material used for settlement repairing of a ballastless structure for a high-speed railway. The polyurethane patching material is formed by hybrid reaction of an A component material and a B component material by a high-pressure impact. The volume ratio of the A component and the B component is 1:1-1:1.8. The A component is a mixture formed by polyhydric alcohol modified diphenylmethane diisocyanate and multi-methylene multi-phenyl isocyanate. The viscosity of the A component ranges from 100 mPa.s to 200 mPa.s at the 25 DEG C temperature. The B component is a mixture formed by polyhydric alcohol, a coupling agent, a hydrolytic stabilizing agent, a cross-linking agent, a foam stabilizing agent, a catalyst agent and a foaming agent. The viscosity of the B component ranges from 150 mPa.s to 300 mPa.s at the 25 DEG C temperature. The B component is characterized in that at least a part of end amido polyolefin polyhydric alcohol with 8 functionalities is in the polyhydric alcohol, and the content of the end amido ranges from 60%-80%. According to the polyurethane repairing material, the chemical reaction speed is high, the expansibility is high, the mechanical strength is high, the binding power is high, the size stability is high, the anti-hydrolysising property is good, and the deformation of accumulated residues is low. The polyurethane repairing material can be used for the settlement repairing of the ballastless structure for the high-speed railway, and can also be used for the pavement structure repairing of an expressway and the settlement repairing of an industrial building terrace.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

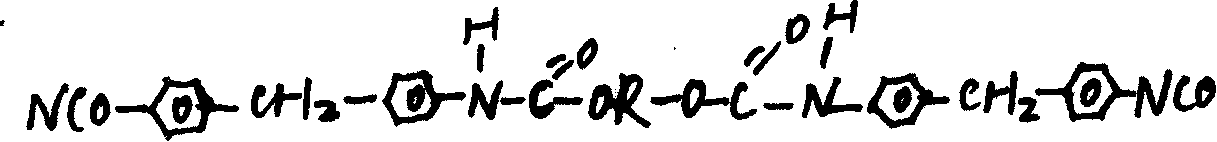

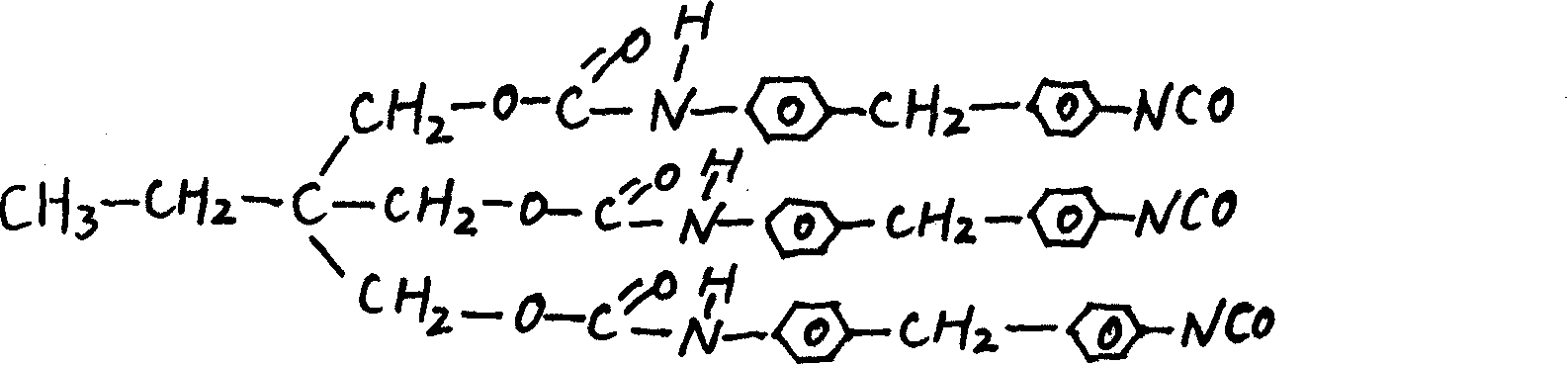

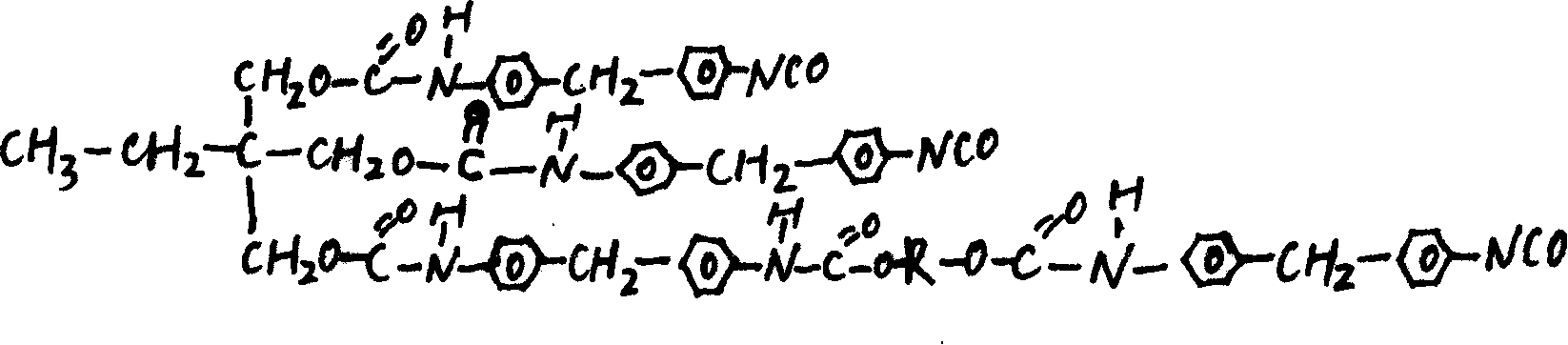

Curing agent 4,4'-biphenyl methane diisocyanate prepolymer and preparation method thereof

The invention relates to a curing agent, namely, 4, 4 (1)-diphenylmethane diisocyanate prepolymer and a preparation method thereof. The method comprises the steps that molten 4, 4(1)-MDI and an organic solvent are added into a reaction vessel, and stirred uniformly, the temperature is raised to 65 DEG C, polyhydric alcohol dehydrated through evacuation is added, to react for 2 to 4 hours at 60 to 100 DEG C, and then an MDI modifier is produced; when being stirred, the mixed liquor of trimethylol propane and the organic solvent is titrated into the reaction vessel for 1 to 4 hour(s), the titration temperature is 60 to 100 DEG C, heat preservation and reaction are performed for 1 to 3 hour(s), then the temperature is raised to 90 to 100 DEG C and the heat preservation and the reaction are performed again for 1 to 4 hour(s), the temperature is reduced, and the organic solvent is added for dilution to appropriate viscosity. The curing agent has the advantages that the application scope is broad, the molecular structure of the polyhydric alcohol can be adjusted according to the requirements of users to produce the prepolymer of polyurethane coating, adhesive, and the curing agent, the storage stability is good, the curing speed is quick, the toxicity is low, the price is low, products with high solid content can be obtained, etc.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

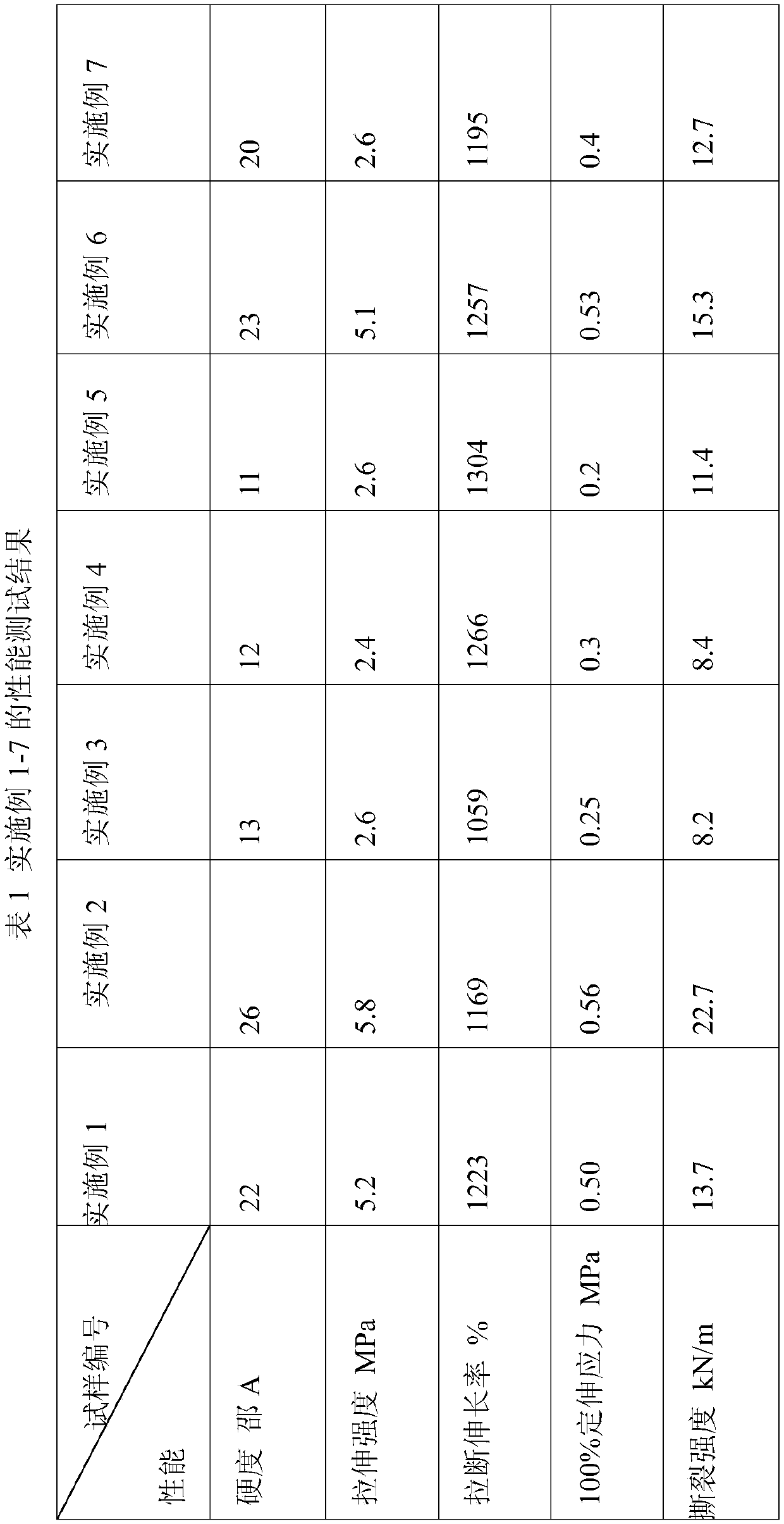

Plasticizer-free low-hardness high-fracture-elongation-rate polyurethane elastomer material composition and preparation method thereof

The invention provides a plasticizer-free low-hardness high-fracture-elongation-rate polyurethane elastomer material composition. A prepolymer obtained through the reaction of polyoxypropylene ether polyalcohol and methyl diphenylene diisocyanate is used as one ingredient; polyether polyol, alcohol chain extenders, catalysts, anti-aging agents and other ingredients form a polymer polyalcohol ingredient; the two ingredients are mixed at the normal temperature, and are cast and cured to obtain the polyurethane elastomer material. Compared with the existing low-hardness polyurethane elastomer product, the plasticizer-free low-hardness high-fracture-elongation-rate polyurethane elastomer material composition has the advantages that no plasticizer ingredient exists in the recipe; the problems of plasticizer removal and the like are solved; meanwhile, the requirements of the fracture elongation rate being greater than 1000 percent and the hardness being lower than ShaoA30 can be met; good physical and mechanical properties can be maintained.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method of bi-component siloxane modified polyurethane sealant

InactiveCN101838513AGood adhesionImprove operational stabilityNon-macromolecular adhesive additivesOther chemical processesSealantMechanical property

The invention discloses a preparation method of a bi-component siloxane modified polyurethane sealant, which belongs to the technical field of sealants. The method comprises the following steps: preparing a polyurethane prepolymer; carrying out synthetic reaction to obtain the polyurethane prepolymer under certain conditions by using two-function polyether glycol, diphenylmethane diisocyanate, plasticizer and siloxane containing amino groups; using the prepared prepolymer, inorganic filler, plasticizer and organosilicon adhesion accelerant as the first component of the sealant; and using inorganic filler, diluter, curing agent, surfactant, and dibutyltin dilaurate or tertiary amine catalyst as the second component. By designing the structure of the end silane polyurethane prepolymer and adjusting the proportion of the inorganic filler, in cooperation with a proper curing system and catalysis system, the prepared sealant has the characteristics of high curing speed, good adhesion effect and the like. The sealant has the advantages of high mechanical properties, good elasticity, no toxicity, no irritative gas emission and outstanding weatherability.

Owner:BEIJING COMENS NEW MATERIALS

Polyurethane composition for preparing polyurethane composite material

The invention relates to a polyurethane composition for preparing a polyurethane composite material. The initial viscosity of the polyurethane composition at 25DEG C is 10-600mPas. The composition comprises: a) a polyisocyanate component, wherein the polyisocyanate component includes 10-56wt% of 2,2'-diphenylmethane diisocyanate and 2,4'-diphenylmethane diisocyanate; and b) an isocyanate responsive component, wherein he isocyanate responsive component includes 30-100wt% of one or more glycerin-initiated polyether polyol, the hydroxyl value of the polyether polyol is 120-450mg KOH / g, and the viscosity of the polyether polyol is 50-450mPas. The invention also relates to a polyurethane composite material prepared by using the polyurethane composition, and a preparation method of the composite material.

Owner:COVESTRO DEUTSCHLAND AG

Polyurethane hot melt adhesive for high-grade lining cloth and preparation method thereof

InactiveCN101570676AOvercome difficult bonding problemsDoes not affect damagePolyureas/polyurethane adhesivesPolyesterToluene diisocyanate

The invention discloses the polyurethane hot melt adhesive for high-grade lining cloth, which is obtained through the reaction among polyester polyols with the relative molecular weight thereof being 2,000 to 2,200, 4,4-diphenylmethane diisocyanate (MDI), toluene diisocyanate (TDI), 1,4-butanediol (1,4-BDO) and aromatic diamine extender, wherein, the molecular weight of the polyurethane hot melt adhesive is 85,000 to 95,000. The polyurethane hot melt adhesive has the advantages of low thermal-bonding temperature and rapid crystallization, thereby facilitating the machining operations, preventing the polyurethane hot melt adhesive from being stuck to cloth and further preventing the polyurethane hot melt adhesive from penetrating and bleeding on ultra-thin loose base cloth; furthermore, the polyurethane hot melt adhesive has outstanding resistance to dry-cleaning and washing as well as washing under various caustic conditions. The invention further discloses a method for preparing the polyurethane hot melt adhesive for high-grade lining cloth.

Owner:长兴三伟热熔胶有限公司

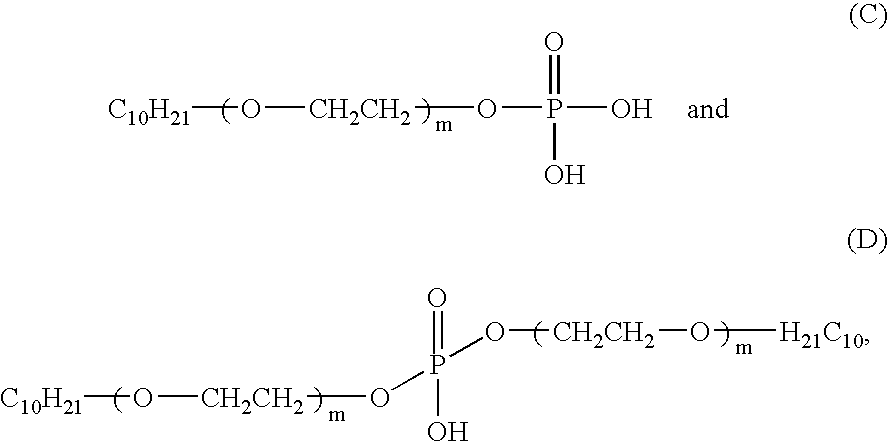

Lignocellulosic composite material and method for preparing the same

InactiveUS20050242459A1Improved stability and storage lifeWood working apparatusDomestic articlesCelluloseDiphenylmethane

A lignocellulosic composite material and a method for preparing the lignocellulosic composite material are disclosed. The composite material includes lignocellulosic particles and a binder resin being a mixture of a polyisocyanate component and a release agent. The release agent is formed from a first component having hydroxyl groups and a second component having isocyanate groups in excess of the hydroxyl groups. The first component is selected from at least one of i) an acid phosphate and ii) pyrophosphates represented by those derived from the acid phosphates (i) and mixtures of the acid phosphates (i). The first component is passivated by mixing it with the second component which is preferably monomeric diphenylmethane diisocyanate selected from at least one of diphenylmethane-4,4′-diisocyanate, diphenylmethane-2,4′-diisocyanate, and diphenylmethane-2,2′-diisocyanate.

Owner:BASF CORP

Method of preparing fluorinated polyurethane paint and fluorinated polyurethane anticorrosive paint

InactiveCN104293158ALower surface energyExcellent water and oil repellencyAnti-corrosive paintsPolyurea/polyurethane coatingsPolyolMixed materials

The invention provides a method of preparing fluorinated polyurethane paint. The method is characterized by comprising the following steps: a step of preparing a component A, namely adding 15-60 parts of fluorinated polyether polyol and 0.01-0.03 part of dibutyltin dilaurate into a three-necked flask with a stirring rod in sequence, and stirring for 30 minutes to obtain the component A; a step of preparing a component B, namely adding 10-40 parts of 4,4-diphenyl methane diisocyanate and 0-30 parts of collaborative anticorrosive filler into 20-60 parts of a solvent system to stir and dissolve to obtain the component B; and a step of preparing fluorinated polyurethane anticorrosive paint, namely adding the component B into the three-necked flask filled with the component A, stirring for 8-10 minutes, grinding the mixed materials in the three-necked flask until fineness is 40-50 mu m after uniformly stirring, coating a metal sheet with the grinded mixed materials and curing for 24 hours to obtain the fluorinated polyurethane anticorrosive paint.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Temperature-sensitive hydrophilic cross-linking crystal type polyurethane coating agent, preparation method thereof and application thereof

InactiveCN101709197AGood waterproof and moisture permeabilityHigh precisionSynthetic fibresPolyurea/polyurethane coatingsPolyesterCross-link

The invention discloses a temperature-sensitive hydrophilic cross-linking crystal type polyurethane coating agent, a preparation method thereof and application thereof, and belongs to the technical field of textile chemical engineering. The preparation thereof comprises the following steps of: using a prepolymer method, taking 4,4'-diphenylmethane diisocyanate (pure MDI) as a hard segment, taking polyester polyol or polyether polyol as a soft segment, adding micromolecular diol chain-extension into the segments, and performing self-emulsification to obtain the polyurethane coating agent. After textile is coated by adopting a proper process, the capability of hydrostatic pressure and moisture permeability of the textile is greatly improved, and the moisture permeability of the textile represents higher response accuracy and sensitivity to environmental temperature changes. The response range of the moisture permeability of the finished coated textile to the environmental temperature changes is between about 17.0 and 28.0 DEG C so as to furthest meet the requirement of a human body on comfort.

Owner:广东广纺检测技术股份有限公司

Process for the production of 4,4'-diphenylmethane diisocyanate

InactiveUS20070117997A1Simple processOrganic compound preparationIsocyanic acid derivatives purification/separationDiphenylmethaneDistillation

The present invention relates to a process for the production of 4,4′-diphenylmethane diisocyanate (4,4′-MDI) by acid-catalyzed condensation of aniline with formaldehyde, reaction of the mixtures of di- and polyamines obtained with phosgene to form the corresponding mixture of MDI isomers and homologues (di- and polyisocyanates of the diphenylmethane series) and subsequent separation of the mixture by distillation to form 4,4′-MDI and polymeric MDI.

Owner:BAYER MATERIALSCIENCE AG

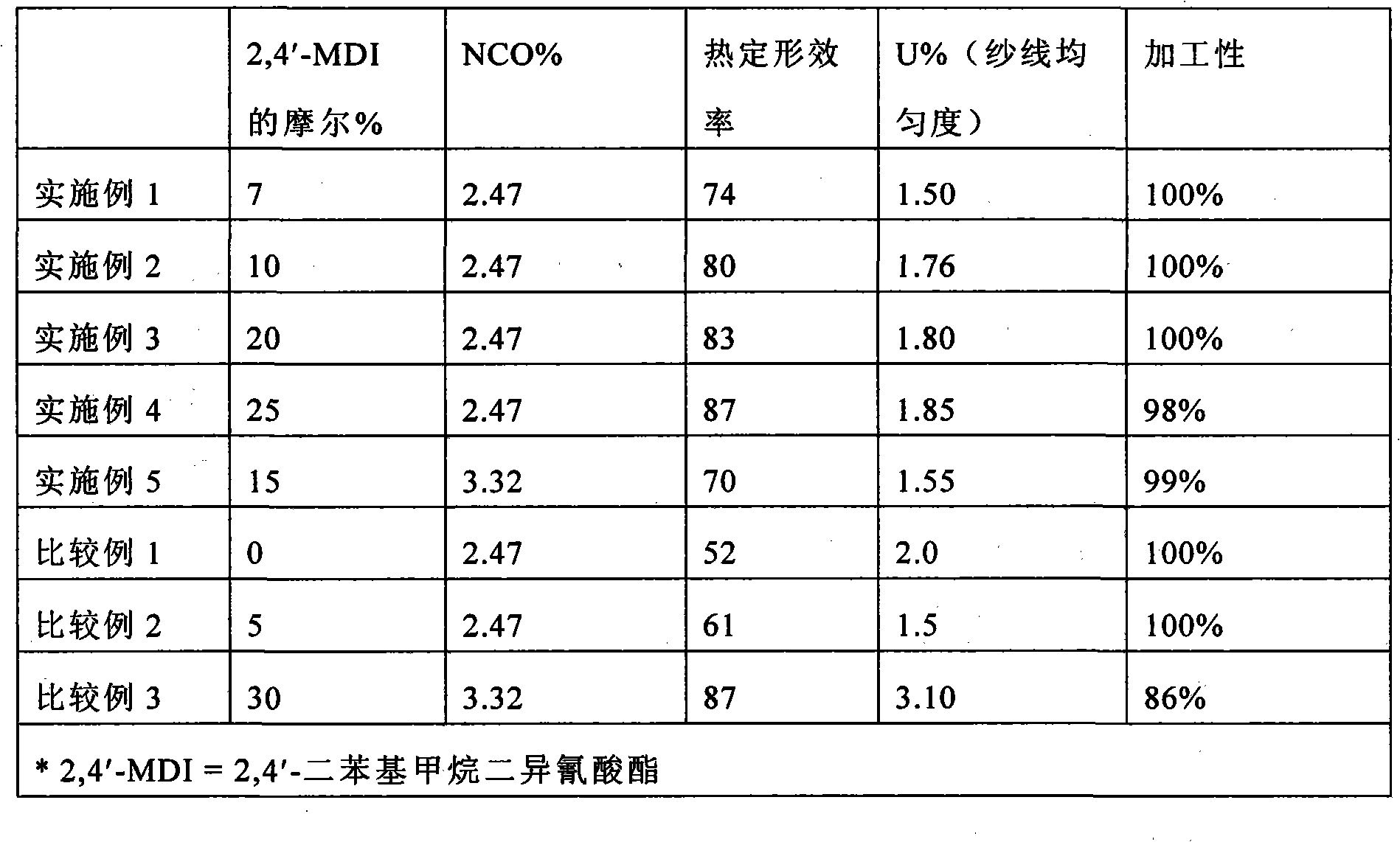

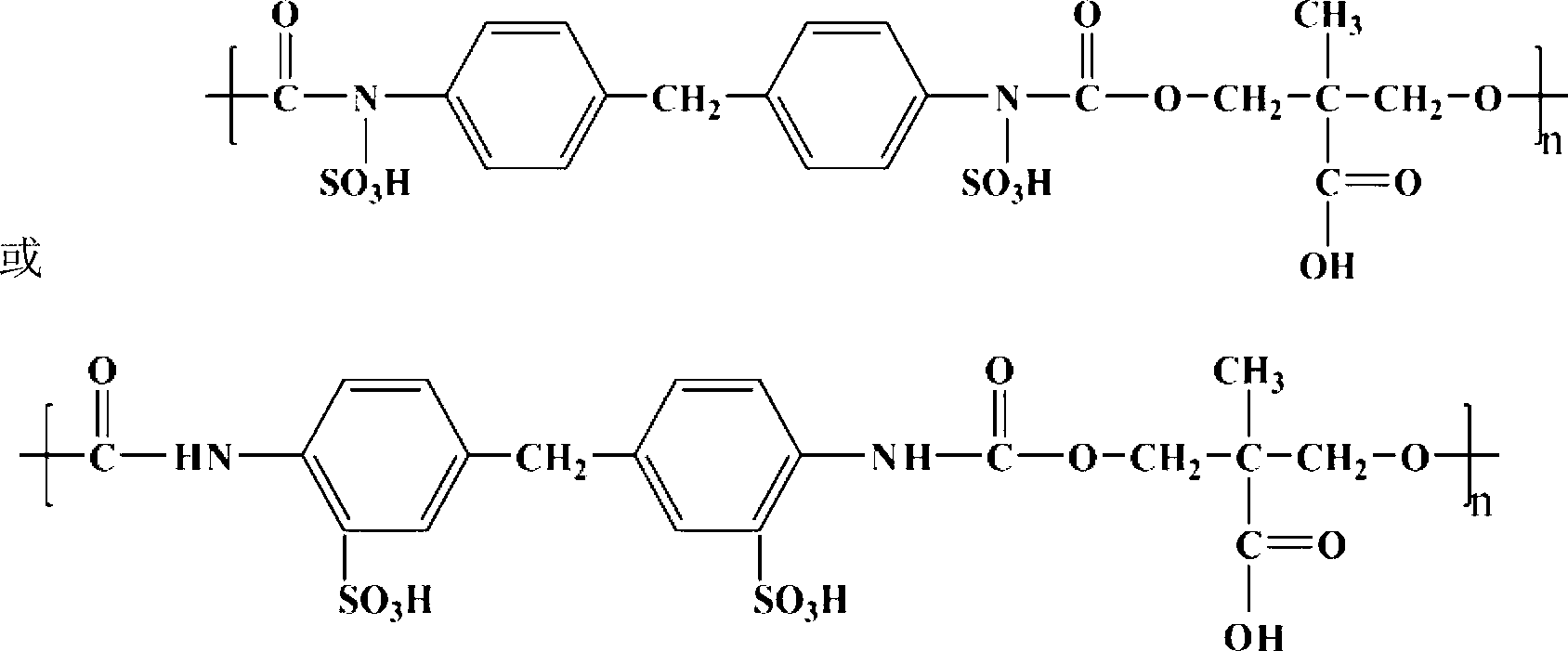

Method for preparing polyurethaneurea elastic fiber with improved heat settability and polyurethaneurea elastic fiber prepared by the same

InactiveCN101849048AHigh heat setting efficiencyPrevent thermal degradationMonocomponent polyurethanes artificial filamentPrepolymerIsocyanate

The present invention relates to a method for preparing polyurethaneurea elastic fiber, the method comprising reacting a mixture of at least one diisocyanate comprising 4,4'-diphenylmethanediisocyanate and 7 to 25 mole % of 2,4'-diphenylmethanediisocyanate with polyol to produce a prepolymer, and polyurethaneurea elastic fiber prepared by the same. The polyurethaneurea elastic fiber of the present invention has superior spinning workability, improved yarn evenness, and high heat-set efficiency even at low temperature.

Owner:HYOSUNG CORP

Liquid partially trimerized and allophanized polyisocyanates based on toluene diisocyanate and diphenylmethane diisocyanate

InactiveUS7553963B2Urea derivatives preparationIsocyanic acid derivatives preparationPrenylationToluene diisocyanate

This invention relates to storage-stable, liquid, partially trimerized and allophanized polyisocyanates having an NCO group content of 15 to 41% by weight, and comprising 5 to 85% by weight of toluene diisocyanate, 5 to 85% by weight of a polyisocyanate of the diphenyl-methane series and an organic compound or mixture thereof. The present invention also relates to a process for the preparation of the storage-stable, liquid, partially trimerized and allophanized polyisocyanates; to storage-stable, liquid urethane prepolymers of these partially trimerized and allophanized polyisocyanates; and to a process for the production of these storage-stable, liquid, urethane prepolymers.

Owner:BAYER MATERIALSCIENCE AG

Polyurethane sealing pouring adhesive and its preparing process

InactiveCN101210167ASimple preparation processEasy to controlOther chemical processesPolyureas/polyurethane adhesivesAdhesiveSealant

The invention provides a polyurethane potting sealant, which is composed of a component A and a component B. The polyurethane potting sealant includes a diluting agent containing fatty acid methyl ester or dioctyl phthalate and a catalyst containing dibutyltin laurate or stannous octoate. The component A contains (by weight percentage) hydroxyl-terminated polybutadiene (HTPB) 60% to 80%, the diluting agent 10% to 25%, and carbon black 5% to 15%. The component B contains (by weight percentage) liquefied diphenylmethane-diisocyanate (DMI) 80% to 95% and the catalyst 5% to 20%. The polyurethane potting sealant of the invention has the advantages of low potting viscosity, good leveling property and less formation of air vents.

Owner:TIANJIN LANGRUNSICHUANG TECH DEV

Heparan polyurethane blended modified polyethersulfone hollow fiber membrane and preparation method and application thereof

ActiveCN103055725AGood physical and chemical stabilityNot easy to precipitateDialysisFiberHollow fibre membrane

The invention discloses a preparation method and application of a heparan polyurethane blended modified polyethersulfone hollow fiber membrane. The preparation method is characterized by comprising the following steps of: adding 10 to 25 weight parts of diphenylmethane diisocyanate, 5 to 13 weight parts of dimethylolpropionic acid and 62 to 85 weight parts of solvent into a dissolving kettle, performing reaction for 4 to 12 hours at a temperature of 70 to 90 DEG C, washing the product with methanol and distilled water and drying to obtain carboxyl-containing polyurethane; adding 10 weight parts of polyurethane into 100 weight parts of concentrated sulfuric acid to carry out sulfonation to obtain polyurethane containing carboxyl and a sulfonic acid group; adding 1 to 10 weight parts of heparan polyurethane, 10 to 25 weight parts of polyethersulfone and 70 to 89 weight parts of solvent into the dissolving kettle to dissolve for 2 to 24 hours at a temperature of 75 to 95 DEG C so as to obtain hollow fiber membrane spinning dope; and preparing the hollow fiber membrane with excellent blood compatibility, permanent hydrophilicity, capacity of resisting to protein pollution and an anticoagulation function by adopting a dry spraying and wet spinning technology.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com