Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123 results about "Polybutylene adipate co-terephthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material capable of completely biodegrading and preparation method thereof

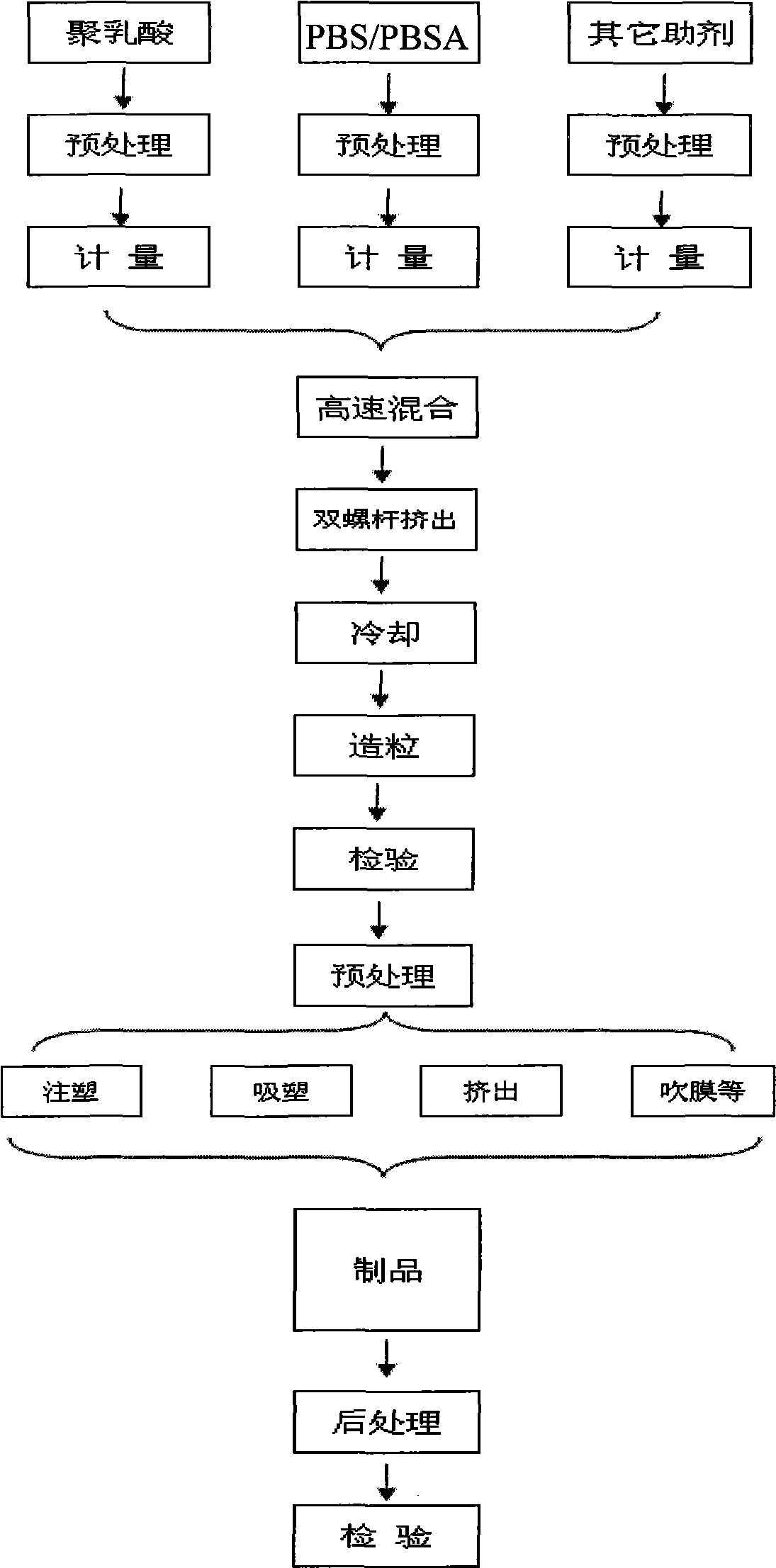

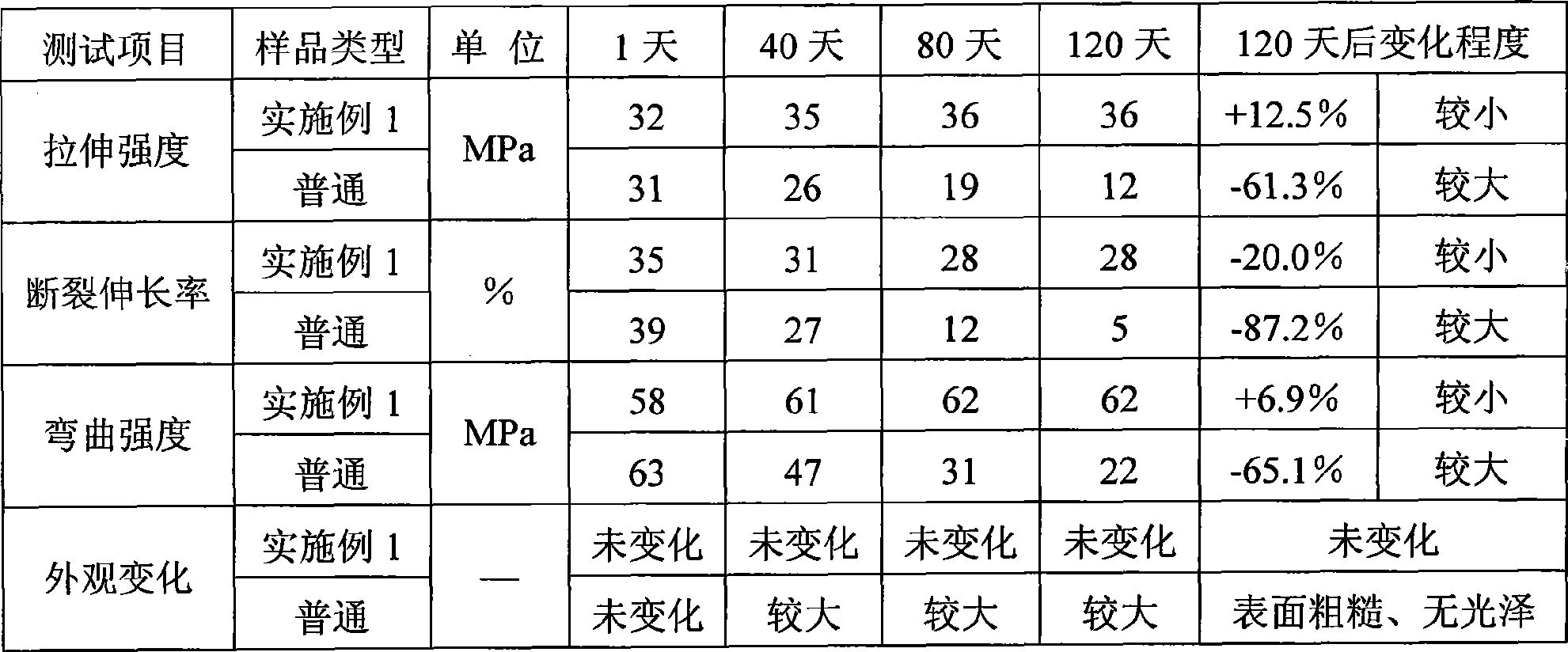

The invention relates to a material capable of completely biodegrading, containing the following parts by weight:100 of polyester resin, 5-100 of polylactic resin and the multipolymer thereof, 10-80 of compounding converted starch, 10-60 of inorganic fillers and 0.1-0.9 of resin acceptor, wherein the polyester resin is at least one of polybutylene succinate resin, polybutylene adipate resin and the multipolymer thereof. The invention also provides a preparation method of the material. The material capable of completely biodegrading can combine the advantages of each component and has high intensity, modules, elongation at break and toughness, good heat resistance, and the like, thereby meeting the property requirements of a plurality of plastic products in the market and in particular products, such as non-returnable containers, mess kits, agricultural films, and the like, which cause serious white pollution, retaining the complete biodegradability of the material and reducing the production cost under the precondition of no influence on the property requirement.

Owner:深圳市未名北科环境材料有限公司 +1

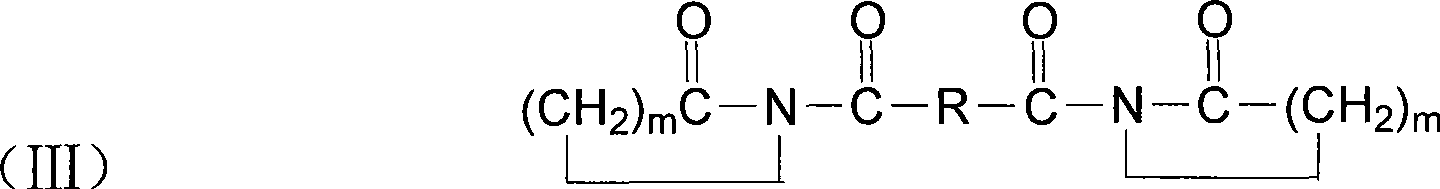

Biaxially oriented polylactic acid film with improved heat seal properties

ActiveUS20100323196A1Lower heat seal initiation temperatureHeat seal rangeSynthetic resin layered productsLaminationPolybutylene adipate co-terephthalatePolylactic acid

Multi-layer biaxially oriented polylactic acid (BOPLA) film with a novel formulation improves the heat seal initiation temperature and heat seal performance of BOPLA films while maintaining good optical clarity. The film may include a core layer including polylactic acid base polymer resin, and a heat sealable layer including amorphous polylactic acid base polymer and a modifier comprising polycaprolactone or poly(butylene-adipate-co-butylene terephthalate).

Owner:TORAY PLASTICS AMERICA

Preparation of biodegradable block copolyester

The invention belongs to the technical field of macromolecular materials, and in particular relates to a preparation method for biodegradable blocked copolyester. The preparation method comprises the following steps: carrying out esterification reaction between adipate and 1,4 butanediol in the presence of catalyst, wherein the reaction time is 3 to 5h, nitrogen is adopted for protection, the reaction pressure is between 0.1 and 0.8MPa and the reaction temperature is between 130 and 180 DEG C during a first stage; and the reaction time is 1.5 to 5h, the reaction pressure is between 0.3 and 0.6MPa and the reaction temperature is between 150 and 200 DEG C during a second stage so as to generate polybutylene adipate; and carrying out ester exchange reaction of dimethyl terephthalate (DMT) and 1,4 butanediol in the presence of catalyst, wherein the nitrogen is adopted for protection, the reaction time is 2 to 5h, the reaction pressure is between 0.1 and 0.7MPa and the reaction temperature is between 150 and 170 DEG C so as to generate polybutylene terephthalate (pbt); and mixing both prepolymers and carrying out melt copolycondensation reaction under negative pressure, wherein the vacuum degree is controlled to be between 0 and 200Pa, the reaction temperature is between 210 and 260 DEG C and the reaction time is 3 to 8h. The preparation method carries out esterification reaction and ester exchange reaction, and the esterification reaction has two stages so as to effectively reduce secondary reaction of 1,4 butanediol. A prepared product has a characteristic viscosity number above 1.2dl / g, a melting point controlled between 100 and 140 DEG C, a tensile strength between 18 and 37MPa and a breaking elongation ratio from 800 to 1,500 percent.

Owner:TONGJI UNIV

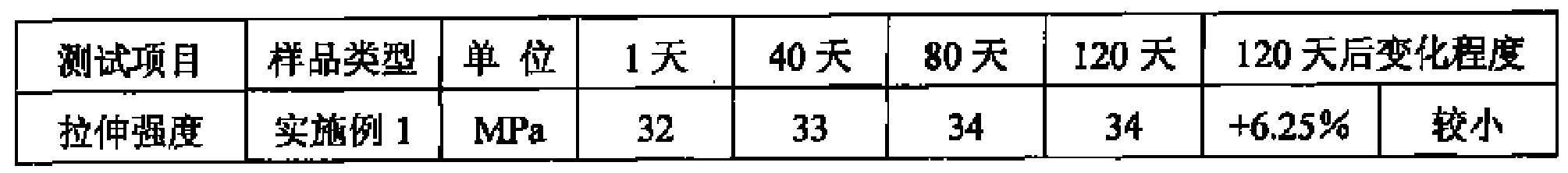

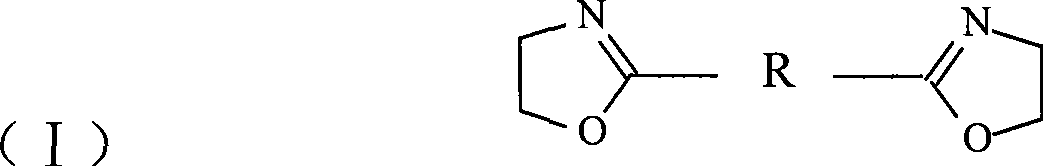

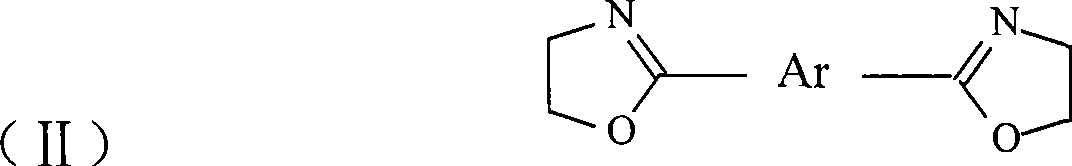

Method for preparing high molecular weight biodegradable polyester by combined chain extension

The invention relates to a method for preparing biodegradable polyester. Firstly, melt polycondensation is conducted through diol and dicarboxylic acid and a low molecular weight polyester prepolymer with number average molecular weight between 2, 000 and 20, 000 or intrinsic viscosity below 0.64dL / g is prepared; binary oxadiazoline and diacyl bis-caprolactamate are combined to extend chain, and chain extension is carried out at a certain temperature; and the biodegradable polyester is obtained. The number average molecular weight of polybutylene adipate (PBA) can reach up to 39, 000 and the intrinsic viscosity to 1.13dL / g. For poly (butylene succinate) (PBS) with relatively high melting point, the intrinsic viscosity after chain extension is up to 0.99dL / g.

Owner:BEIJING UNIV OF CHEM TECH

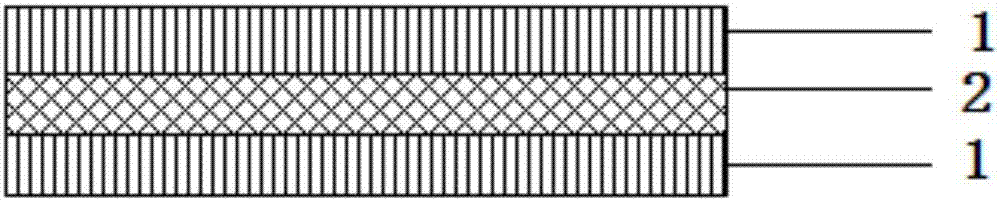

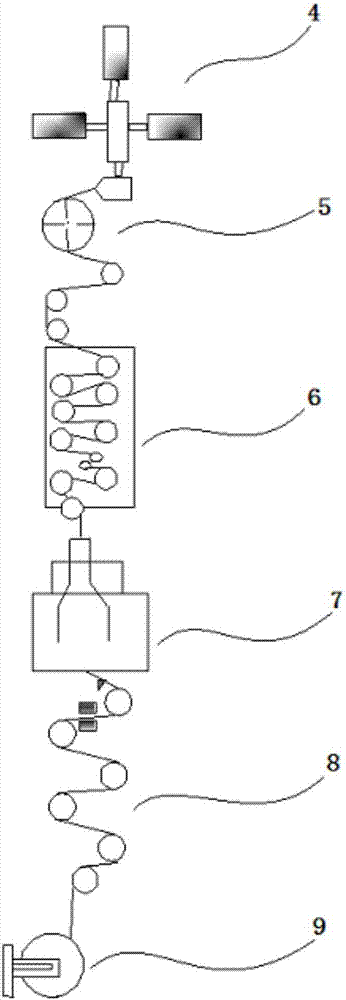

Biodegradable multilayer co-extrusion material and preparation method thereof

ActiveCN107031153APromote degradationWith natural propertiesSynthetic resin layered productsFlat articlesPolybutyleneMedical product

The invention provides a biodegradable multilayer co-extrusion material. The material is characterized by comprising two surface functional layers and a middle layer located between the two surface functional layers, components of the surface functional layers and the middle layer include biodegradable materials, and the biodegradable materials refer to one or more of polybutylene succinate, polylactic acid, polyhydroxyalkanoate and polybutylene adipate-polybutylene terephthalate. The invention further discloses a preparation method of the material. The biodegradablity of four selected master batches of the multilayer co-extrusion material is good, and adopted inorganic minerals are natural, so that the co-extrusion material has completely biodegradable properties and can be widely used in various types of food packages, medical products, environmental protection labels, advertisements and all kinds of environmental-protection products.

Owner:齐庆德

Resin Composition, Molded Product From Resin Composition and Method for Preparing Resin Composition

InactiveUS20070270527A1Eliminate the problemImprove flame retardant performanceConductive materialOrganic conductorsCellulosePolybutylene

Disclosed is a biodegradable resin composition containing at least one biodegradable organic high molecular compound, a flame retardant additive containing a phosphorus-containing compound, and a hydrolysis suppressing agent suppressing the hydrolysis of the at least one biodegradable organic high molecular compound. An aliphatic polyester resin is polylactic acid, polycaprolactone, polyhydroxy lactic acid, polyhydroxy valeric acid, polyethylene succinate, polybutylene succinate, polybutylene adipate, polymalic acid, polyesters synthesized by fermentation, or a copolymer containing at least one of them. A polysaccharide is cellulose, starch, chitin, chitosan, dextrane, a derivative of at least one of them, or a copolymer containing at least one of them.

Owner:LERNER DAVID LITTENBERG KRUMHOLZ & MENTLIK LLP

Ternary copoly ester capable of biological degradation and its preparation method

A biodegradable three-element copolymer with high mechanical and thermal performance is prepared from the raw material used for synthesizing butanediol polysuccinate, the raw material used for synthesizing ethanediol polysuccinate, hexanediol polysuccinate, etc, and the raw materialused for synthesizing ethanediol polyterephthalate, etc through atactic copolymerizing.

Owner:SICHUAN UNIV

Medical soft polychloroethylene plastic without o-benzene series plasticiser

InactiveCN101434732ANo adverse effects on physiological processesImprove low temperature performancePolybutylenePolyvinyl chloride

The invention relates to a medical soft polyvinyl chloride plastic that does not contain a phthalic plasticizer and a manufacturing method thereof. The medical soft polyvinyl chloride plastic comprises the following raw materials: polyvinyl chloride resins, plasticizers, stabilizers, auxiliary stabilizers and lubricants. The medical polyvinyl chloride plastic is characterized in that the plasticizers are divided into solid plasticizers and liquid plasticizers; the mass portions of all the components are as follows: 100 portions of polyvinyl chloride resins, 10 portions to 50 portions of solid plasticizers, 20 portions to 80 portions of liquid plasticizers, 1 portion to 5 portions of stabilizers, 0 portion to 5 portions of accessory stabilizers and 0.1 portion to 2 portions of lubricants. The solid plasticizers are ethylene-butyl acrylate carboxylic copolymers. The liquid plasticizers are one or combination of more than one of tetraoctyl pyromellitate, tetra-2-ethylhexyl pyromellitate, polypropylene adipate, polybutylene sebacate, polydiethylene glycol sebacate and polypropylene glycol ester sebacate. The medical polyvinyl chloride plastic is characterized by little toxicity and side effect and little possibility for the plasticizers to be drawn out.

Owner:FOSHAN JINKANGYE PLASTIC

A kind of preparation method of polyurethane hot-melt transfer adhesive

InactiveCN102286262AUniform coatingImprove wettabilityFilm/foil adhesivesDuplicating/marking methodsWater bathsPolybutylene

The invention discloses a preparation method of polyurethane hot-melt transfer printing adhesive, which relates to a transfer printing adhesive. Put the polybutylene adipate into the container, after dehydration under reduced pressure, install the stirring rod and the condenser, and then put it in the water bath until the polybutylene adipate is cooled to room temperature, add diphenyl Methane-4,4'diisocyanate and catalyst di-n-butyltin dilaurate, after stirring, take a water bath, heat up to react, then add a small molecule chain extender to continue the reaction to obtain a polyurethane hot melt adhesive solution; adjust the prepared polyurethane hot melt adhesive solution Viscosity and solid content, coated on the ink layer of the thermal transfer film, after the solvent evaporates, the ink layer is firmly transferred to the thermal transfer adhesive film on various materials such as metal, glass, ceramics, plastics, and fabrics . Not only has good wettability with the ink layer of the thermal transfer film, but also has good adhesion with metal, glass, ceramics, various plastics, fabrics and other materials, and can firmly bond the ink layer to the substrate , is a widely used hot melt transfer adhesive.

Owner:XIAMEN UNIV

Waterborne polyurethane emulsion, coating and preparation method and application of waterborne polyurethane emulsion

The invention relates to a waterborne polyurethane emulsion, a coating and a preparation method and application of the waterborne polyurethane emulsion. The waterborne polyurethane emulsion is mainlyprepared from the following components (by mass): polyols, isocyanate, a catalyst, a hydrophilic chain extender, an end-capping reagent, a neutralizer and water, wherein the polyols comprise a polyolA and a polyol B; the polyol A is carbon dioxide copolymer polyol, and the polyol B is at least one of polycarbonate diol, polybutylene adipate diol and polytetrahydrofuran diol. The preparation method comprises the following steps: mixing polyol A and polyol B for use; and matching isocyanate, a catalyst, a hydrophilic chain extender, an end-capping reagent, a neutralizer and water and controlling the mass parts of all the components. Thereby, the microphase separation of the waterborne polyurethane emulsion and the interaction between hydrogen bonds can be improved, and the waterborne polyurethane has good stability, water resistance and chemical reagent corrosion resistance.

Owner:广州康狄夫环保科技有限公司

Full-biodegradable plastic mulching film, preparation method and application thereof

InactiveCN112980153AAffect mechanical strengthIncrease the range that can be addedClimate change adaptationPlant protective coveringsButanedioic acidPlastic mulch

The invention provides a full-biodegradable plastic mulching film, a preparation method and application thereof. The full-biodegradable plastic mulching film comprises the following components in parts by weight: 100 parts of a full-biodegradable resin, 10-30 parts of an auxiliary agent, 10-60 parts of modified starch and 10-100 parts of modified calcium carbonate, wherein the full-biodegradable resin is prepared from one or more of poly (butylene succinate) (PBS), polylactic acid (PLA), polyhydroxyalkanoate (PHA), poly (butylene adipate-butylene terephthalate) (PBAT) and polypropylene carbonate (PPC). According to the biodegradable mulching film, the contradiction that crops need longer service life of the mulching film and lower thickness of the mulching film and the requirement on the lowest thickness of a polyethylene plastic mulching film can be solved, and the technical scheme of the biodegradable mulching film also has the effects of slow degradation in the early stage, strong protection capability and accelerated degradation in the later stage, so that the influence of the biodegradable mulching film on the planting of succeeding crops is reduced.

Owner:北京惠林苑生物科技有限公司 +1

Pesticide microcapsule

InactiveCN101073318AEasy and economical to prepareAchieve degradationBiocideAnimal repellantsAlcoholCopolyester

The invention is concerned with the pesticides microcapsule, which the material of the wall is the fat group polyester macromolecule and can be biodegradation; it is made of the method that latex solvent volatilization - condensing. The main material of the microcapsule is the poly butane diacid dibastic alcohol ester and the copolyester with better degradation feature and film-forming feature, or poly hexane diacid butanediol butylenes glycol ester, the cost of the shell is lower, the preparing technics is simple.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Polyurethane resin for hydrolysis-resistant film nubuck and preparation method of polyurethane resin

ActiveCN104277202AImprove hydrolysis resistanceUniform and dense vertical cell structureTextiles and paper1,4-ButanediolAdipic acid

The invention provides polyurethane resin for hydrolysis-resistant film nubuck and a preparation method of the polyurethane resin. The polyurethane resin for the hydrolysis-resistant film nubuck is prepared by adopting the following components in percentage by weight: 5.0%-12.0% of poly(adipic acid) 1,4-butanediol esterdiol, 7.0%-9.0% of poly(adipic acid) phthalic anhydride neopentyl glycol esterdiol, 4.0%-8.0% of polypropylene oxide glycol, 0.01%-0.10% of antioxidants, 1.0%-3.0% of chain extenders, 0.05%-0.50% of auxiliary agents, 9.0%-13.0% of 4,4-diphenylmethane diisocyanate, 0.05%-0.50% of methanol and 55%-73% of dimethyl formamide. The film nubuck prepared from the polyurethane resin provided by the invention has a uniform and compact upright cellular structure, has good color development after being smoothed and is high in hydrolysis resistance and low in cost.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Polylactic acid ternary blended modified film and preparation method thereof

InactiveCN109553944AHigh molecular weightEnhancing molecular chain entanglementElastomerEnvironmental resistance

The invention relates to a polylactic acid ternary blended modified film and a preparation method thereof, belonging to the field of polymer materials. The polylactic acid ternary blended modified film is prepared from the following raw materials by weight: 50 to 65 parts of polylactic acid, 25 to 40 parts of a toughening agent namely polybutylene adipate-co-terephthalate, 5 to 8.9 parts of a maleic anhydride functionalized ethylene-octene copolymer elastomer, 0.5 to 1 part of a plasticizer, 0.1 to 1 part of a chain extender and 0.5 to 2 parts of an opening agent. The polylactic acid ternary blended modified film provided by the invention has the following advantages: the problem of poor stability of heat sealing performance of a product is solved; and the use requirements of the product in the field of packaging is guaranteed. Industrialization of polylactic acid facilitates the demands of long-term development of energy and material resources; deep processing of agricultural productsis promoted; dependence on petroleum is reduced; white pollution is solved; the development of the novel environmental protection material industry is promoted; and great economic and social significance are achieved.

Owner:JILIN COFCO BIOCHEM +1

Modified corn straw granule enhanced PBAT [poly(butyleneadipate-co-terephthalate)] starch composite material and preparation method thereof

The invention discloses a modified corn straw granule enhanced PBAT [poly(butyleneadipate-co-terephthalate)] starch composite material, and a preparation method and application thereof, and belongs to the technical field of biodegradable composite materials. The composite material is prepared from the following components in percentage by weight: 30 to 80 percent of PBAT, 10 to 50 percent of plasticized starch, 10 to 40 parts of modified corn straw granules, 0 to 1 percent of a lubricating agent and 0 to 1 percent of an antioxidant. The modified corn straw granule enhanced PBAT starch composite material provided by the invention is safe and non-toxic, has excellent mechanical performance, can be biologically degraded and can be applied in the fields of cultivation and seed breeding, food packaging, agricultural mulching films and the like. A corn straw granule grafted butyl methacrylate copolymer is prepared firstly and then is filled in a PBAT / starch composite material, so the system is enhanced effectively; furthermore, the modified corn straw granules have higher compatibility with the PBAT and can be dispersed in the system well.

Owner:葛袁园

Biodegradable heat-shrinkable material, biodegradable heat-shrinkable film and preparation method of biodegradable heat-shrinkable film

InactiveCN102993653ASimple processing technologySuitable for productivityPolymer sciencePolybutylene

The invention relates to a biodegradable heat-shrinkable material, a biodegradable heat-shrinkable film and a preparation method of the biodegradable heat-shrinkable film. The heat-shrinkable material is a slice obtained through melting mixing and extrusion granulating of a polylactic acid composition in a screw extruder and drying, the polylactic acid composition comprises 95-99.5wt% of a resin component and 0.5-5wt% of a plasticizer, the resin component is prepared through mixing polylactic acid having a weight-average molecular weight of 20000-250000, polybutylene adipate glycol having a weight-average molecular weight of 6000-100000 and polycaprolactone having a weight-average molecular weight of 30000-200000 according to a weight ratio of 1:0.05-1:0.05-1, and the plasticizer is a polyethylene glycol m-phthalate copolymer having a number-average molecular weight of 8000-10000 and a melting point of 110-150DEG C. The heat-shrinkable material and the heat-shrinkable film have the advantages of especially good heat-shrinkable performance and simple processing technology.

Owner:JIANGSU CHUNSHENTANG PHARMA

Fabrication method of track damping base plate

ActiveCN102153854AImprove water resistanceImprove low temperature resistanceRail fastenersFoaming agentPolybutylene

The invention discloses a fabrication method of a track damping base plate, including the following steps: subjecting 1,4-butanediol, 4,4'-diphenylmethane diisocyanate and polybutylene adipate to reaction to obtain thermoplastic polyurethane (TPU) and simultaneously adding assistant and foaming agent that is guaranteed to account for 0.01-80% of the total quantity; and then putting the mixture to reaction by means of pouring, injection molding, rolling and the like at 50-350 DEG C to obtain the damping base plate. By overcoming various defects of PVC (polyvinyl chloride) and Pu (polyurethane), TPU owns not only most characteristics of rubber and common plastic, but also excellent comprehensive physical and chemical property. Therefore, the damping base plate formed by TPU, the foaming agent and the assistant has the characteristic of resistance to water, low temperature and ageing, and can naturally degrade when buried underground, causing no harm or toxin to the nature.

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Heat resistant waterproof high strength polyurethane adhesive and preparing method thereof

ActiveCN105348469AHigh peel strengthImprove temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention discloses a heat resistant waterproof high strength polyurethane adhesive and a preparing method thereof. The heat resistant waterproof high strength polyurethane adhesive is prepared from a main component and an improver component with a mass ratio of (10 to 15):1. The synthetic raw materials of the main component comprise poly ethylene succinate, poly hexanediol adipate, castor oil-modified polyhydric alcohol H-1823, castor oil-modified polyhydric alcohol H-52, castor oil-modified polyhydric alcohol AC-006, isocyanate a and the like; synthetic raw materials of the improver component comprise: chain extender b, isocyanate b and ethyl acetate. The polyurethane adhesive has very good initial adhesive force, higher peel strength and temperature resistant performance due to the two kinds of high crystallinity polyester polyols and an addition proportion thereof, and the waterproofness of the polyurethane adhesive is improved due to the addition of the castor oil-modified polyhydric alcohols. The heat resistant waterproof high strength polyurethane adhesive is particularly suitable for offshore equipment such as a rubber dinghy; the preparing method has less procedures, the steps are easy to operate and convenience for industrialized production is realized.

Owner:SHANDONG NORTH MODERN CHEM IND

Application of polyurethane prepolymer to preparation of wood powder/polrvinyl chloride composite material

The invention relates to new application of special polyurethane prepolymer. The polyurethane prepolymer is characterized in that polrvinyl chloride plasticizer is used as a raw material of a soft segment when the prepolymer is synthesized, and the polyurethane prepolymer is used as compatilizer which improves the performance of a wood powder / polrvinyl chloride composite material. The soft segment comprises polyatomic alcohol. The polyatomic alcohol at least comprises polybutylene adipate esterdiol polyol, and polycaprolactone polyol. After the special polyurethane prepolymer is added during processing of the material, the breaking strength and the impact property of the wood powder / polrvinyl chloride composite material are greatly improved. The wood powder / polrvinyl chloride composite material with the high performance is corrosion resistant and waterproof, and can be used as an outdoor building material so as to reduce the using amount of wood.

Owner:WUHAN QIEN SCI & TECH DEV

Modified bagasse strengthening PBAT/starch complete biodegradation composite material and preparing method and application thereof

The invention discloses a modified bagasse strengthening PBAT / starch complete biodegradation composite material and a preparing method and an application thereof, and belongs to the technical field of biodegradation composite material. The composite material is prepared from, by weight, 30-80% of poly(butyleneadipate-co-terephthalate)(PBAT), 10-50% of plastics starch, 10-40% of modified bagasse, 0-1% of lubricating agent and 0-1% of antioxygen. The modified bagasse strengthening PBAT / starch complete biodegradation composite material is safe and non-toxic, has an excellent mechanical property, can achieve biodegradation, and can be applied to the field of cultivating and breeding, food packaging, agricultural plastic mulching film and the like. According to the preparing method, bagasse stem grafting butyl methacrylate copolymer is firstly prepared, then the bagasse stem grafting butyl methacrylate copolymer is filled in the PBAT / starch composite material, thus the system is strengthened effectively, and the modified bagase and PBAT have better consistency and are more easily dispersed in the system.

Owner:SOUTH CHINA UNIV OF TECH

Resin composition, molded product from resin composition and method for preparing resin composition

InactiveUS7645823B2Improve flame retardant performanceConductive materialOrganic conductorsCellulosePolybutylene

Owner:LERNER DAVID LITTENBERG KRUMHOLZ & MENTLIK LLP

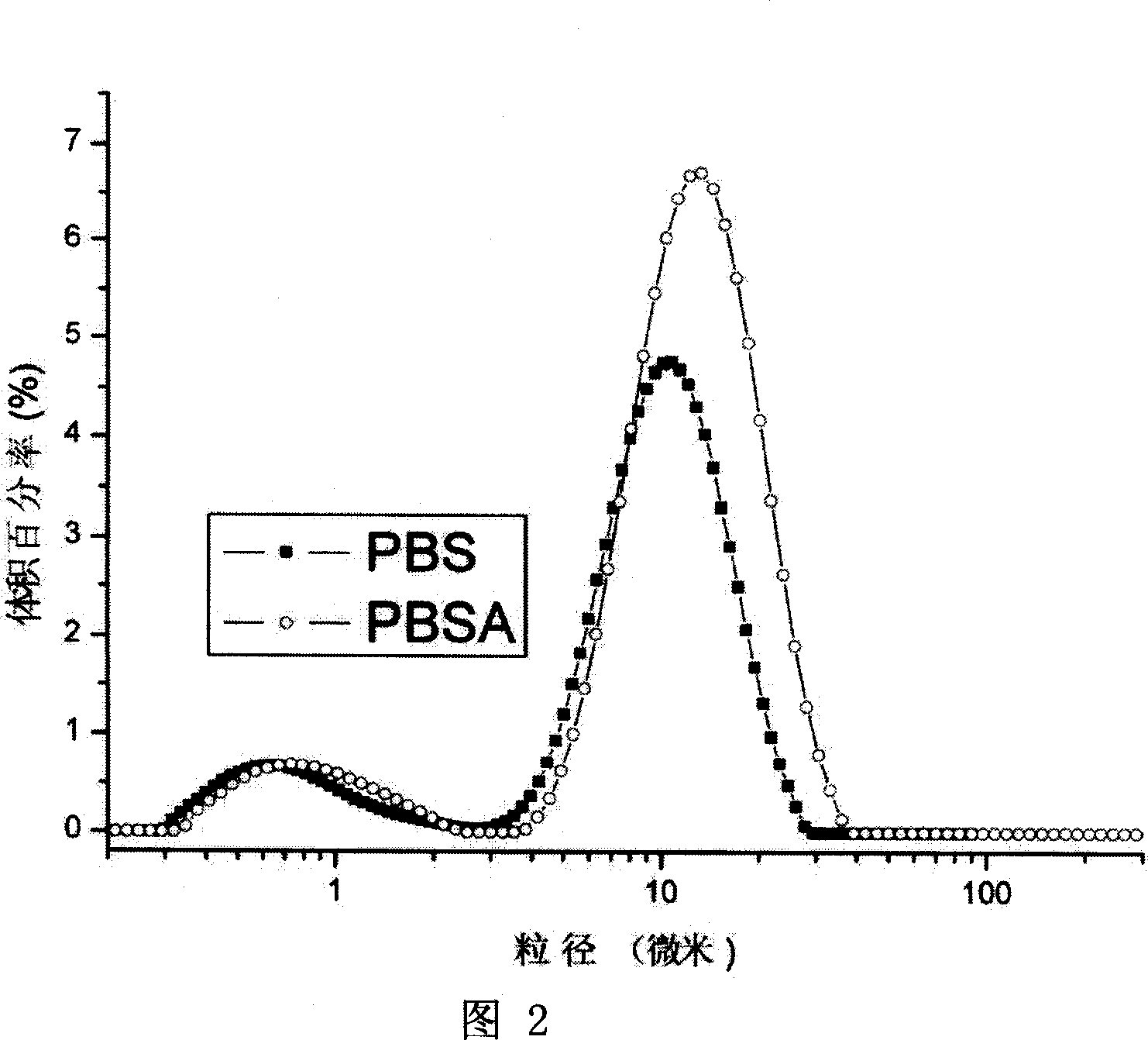

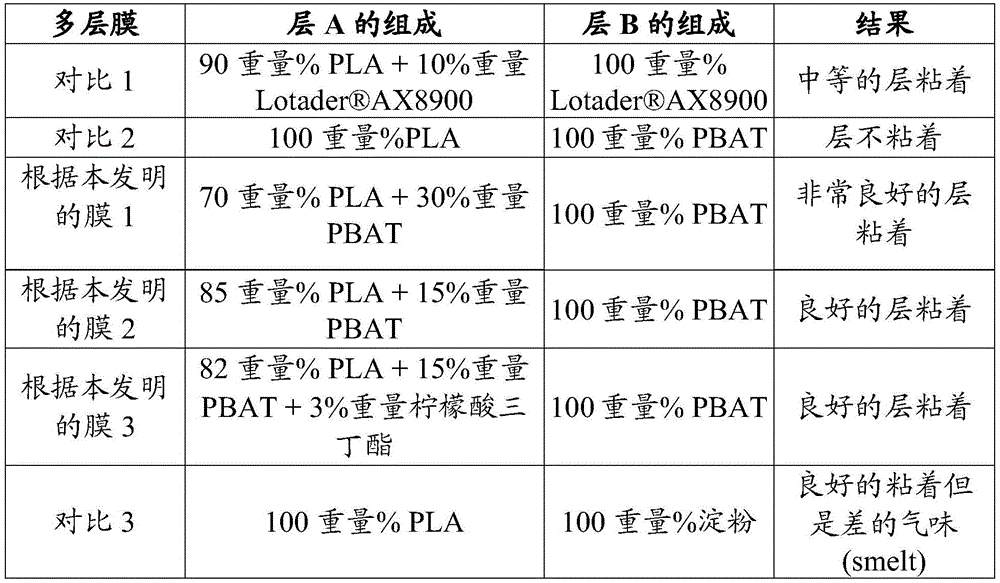

Multilayer film comprising biopolymers

The present invention relates to a multilayer film comprising: - at least one layer A comprising poly(butylene adipate-co-terephthalate) (PBAT) and an aliphatic polyester selected from polylactic acid (PLA), polyhydroxyalkanoate, polycaprolactone, and polyesteramides; and - at least one layer B: comprising poly(butylene adipate-co-terephthalate) (PBAT), wherein said layer A comprises at least 15% by weight of poly(butylene adipate-co- terephthalate) based on the total weight of layer A and at least 60% by weight of aliphatic polyester based on the total weight of layer A; and wherein said layer B comprises from 70 to 100% by weight of poly(butylene adipate- co-terephthalate) based on the total weight of layer B. The present invention also relates to a process for preparing a multilayer film as described previously; comprising the step of co-extruding at least one layer A with at least one layer B to form said multilayer film. The present invention also relates to the use of the multilayer film previously described, and to a substrate coated therewith.

Owner:富特罗股份有限公司

Biodegradable heat shrinking film

The invention relates to a biodegradable heat shrinking film, and belongs to the technical field of high polymer materials. The heat shrinking film is prepared through the steps that dialdehyde starch, polyvinyl alcohol, chitosan and sodium carboxymethylcellulose are added into a reaction kettle and subjected to a reaction on the sealed condition to obtain modified dialdehyde starch; a stirring mixer is adopted for stirring polylactic acid, high density polyethylene, polybutylene adipate, the modified dialdehyde starch, polypropylene glycol, a plasticizer, a cross-linking agent, a bulking agent, a surface active agent, a photo-decomposing agent, an inorganic filler, a nucleating agent and a coupling agent to be uniform; the mixed raw materials are placed into a double-screw extruder for extrusion granulation. The heat shrinking film has the good biodegradability and the good physical performance.

Owner:李杰

Waterborne polyurethane, preparation method thereof, waterborne polyurethane automotive interior adhesive and preparation method thereof

InactiveCN105801790AImprove hydrolysis resistanceImprove mechanical propertiesNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveFumed silica

The invention relates to waterborne polyurethane, a preparation method thereof, a waterborne polyurethane automotive interior adhesive and a preparation method thereof, and belongs to the field of waterborne adhesives. The technical problem that existing waterborne polyurethane is poor in water resistence and poor in mechanical property is solved. The waterborne polyurethane comprises polycaprolactone polyol and poly ethylene succinate polyol besides poly(carbonic ester-ether)polyol. The invention further provides a waterborne polyurethane automotive interior adhesive which is prepared from waterborne polyurethane, a waterborne thickening agent, a waterborne defoaming agent, a waterborne dispersing agent, AMP-95, talcum powder, titanium dioxide, fumed silica and a water waterborne curing agent. The invention further provides a preparation method of the waterborne polyurethane automotive interior adhesive. The release force of a glue film of the prepared waterborne polyurethane automotive interior adhesive is 368 N / cm-405 N / cm, and the release force is 327 N / cm-385 N / cm after one cycle; after four cycles of high-low temperature impact and damp and hot weather resistance tests are carried out, the glue film is not warped or unglued, and the release force is 290 N / cm-348 N / cm.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Biodegradable toughening polylactic acid plastic and preparation method thereof

The invention relates to the field of plastic, and discloses a biodegradable toughening polylactic acid plastic and a preparation method thereof. The biodegradable toughening polylactic acid plastic comprises components of polylactic acid resin and copolymers thereof, polybutylene adipate resin, tributyl citrate and barium sulfate and surfactant thereof. The invention aims to provide a biodegradable toughening polylactic acid plastic and a preparation method thereof, so as to overcome a problem of difficultly degraded general-purpose plastic products and a defect of weak shock resistance of polylactic acid, raise comprehensive properties of polylactic acid, and provide a preparation method of a toughening polylactic acid plastic.

Owner:SHENZHEN KEJU NEW MATERIAL

Resin composition, molded product, and method for producing the resin composition

A biodegradable resin composition comprising at least one biodegradable organic polymeric compound, a flame retardant additive containing a phosphorous compound, and a hydrolysis inhibitor capable of inhibiting the hydrolysis of at least one organic polymeric compound. As an aliphatic polyester resin, use is made of polylactic acid, polycaprolactone, polyhydroxybutyric acid, polyhydroxyvaleric acid, polyethylene succinate, polybutylene succinate, polybutylene adipate, polymalic acid, microbially synthesized polyester or a copolymer containing at least one of these. As a polysaccharide, use is made of cellulose, starch, chitin, chitosan, dextran, a derivative of any of these or a copolymer containing at least one of these.

Owner:SONY CORP

Reflective material for protecting electric power facilities and preparation method of reflective material

The invention provides a reflective material for protecting electric power facilities and a preparation method of the reflective material. The reflective material comprises poly ethylene succinate, trimethylolpropane, 1, 6-hexamethylene diisocyanate, silicon carbide powder, ethyl orthosilicate, lecithin, polystyrene, polyamide resin, ethylene propylene diene monomer, glyoxal, nanometer titania, compatilizers, terpilenol, antioxidants, cellulose and coco fatty acid diethanol amide. The preparation method includes the steps: firstly preparing elastomer by the poly ethylene succinate, the trimethylolpropane, the 1, 6-hexamethylene diisocyanate, the silicon carbide powder and the ethyl orthosilicate, and then mixing the elastomer with the lecithin to obtain yellow-resistant powder; finally, mixing remaining components with the yellow-resistant powder, adding mixture into a double-screw extruder for extrusion, and pelleting and cooling the mixture to obtain the reflective material. The reflective material for protecting the electric power facilities has excellent mechanical property and heat resistance, is not easy to yellow and good in reflective effect, and can still keep good reflective effect after long-time use.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY

Polyurethane modified epoxy resin and preparation method and electrophoretic coating thereof

InactiveCN107163210AStrong metal adhesionCorrosion resistantPolyurea/polyurethane coatingsPaints for electrolytic applicationsEpoxyPolybutylene

The invention discloses polyurethane modified epoxy resin. The polyurethane modified epoxy resin is prepared from the following raw materials by weight percent: 20-30% of epoxy resin, 15-20% of toluene diisocynate, 3-6% of polybutylene adipate, 5-10% of polyether polyol, 2-5% of dimethylolpropionic acid, 0.5-1.5% of dibutyltin dilaurate, 4-8% of cyclohexanedimethanol, 3-7% of propylene glycol monomethyl ether acetate, 3-7% of triethylamine and 15-25% of butanone. The invention further discloses a preparation method of the polyurethane modified epoxy resin and an electrophoretic coating prepared from the polyurethane modified epoxy resin. The weatherability, the corrosion resistance and the glossiness of the water-borne epoxy resin electrophoretic coating are improved.

Owner:GUANGDONG KODEST EP SC CO LTD

Single component low-temperature polyurethane foaming adhesive and preparation method thereof

ActiveCN104312521ALong dry timeHigh curing temperaturePolyureas/polyurethane adhesivesPolyesterAdhesive

The invention discloses a single component low-temperature polyurethane foaming adhesive which is characterized by comprising the following components in parts by weight: 150-200 parts of polypropylene glycol adipate or polybutylene adipate, 5-10 parts of trimethylolpropane, 10-30 parts of polyester 330N, 0.1-0.3 part of a catalyst, 80-150 parts of a black material and 200-340 parts of a solvent. The single component low-temperature polyurethane foaming adhesive disclosed by the invention is relatively long in surface dry time, relatively low in curing temperature and relatively short in real-dry time, so that the application range of the foaming adhesive is widened, the resource is saved, and the working efficiency of an operator is improved; the single component low-temperature polyurethane foaming adhesive disclosed by the invention is simple in preparation method and convenient to operate, so that the production cost of the single component low-temperature polyurethane foaming adhesive is lowered, and the popularization and the application are facilitated.

Owner:湖北和乐门业有限公司

Disposable Items Made From Bioplastic Resins

Disposable items made from bioplastic resins include a biodegradable resin selected from the group consisting of polylactic acid (PLA), cellulose based PH, polycaprolate (PCL), polybutyleneadipatetetephathalate (PBT), polyhydroxyalkanoate (PHA), green polyethylene (GPE), green polyethylene terephthalate (GPET), poly-D-lactide (PDLA), and poly-L-lactide (PLLA); a plasticizer intermixed with the resin to provide a generally homogenous bioplastic; and a device formed from the bioplastic, where the device is at least one of a multidose syringe, a sharps container, or a suction canister. Embodiments include green indicators.

Owner:INNOVATIVE BOTTLES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com