Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "High curing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

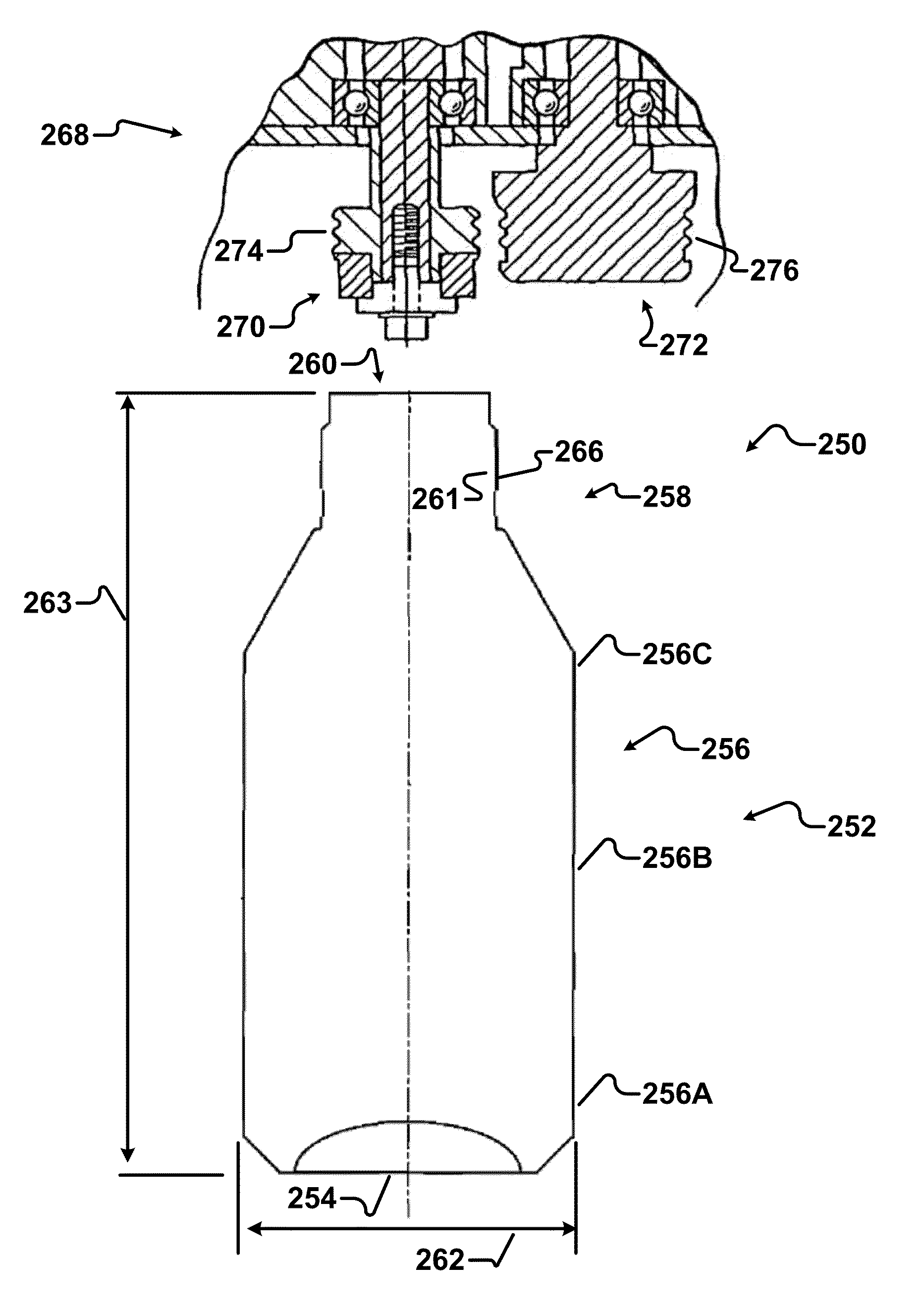

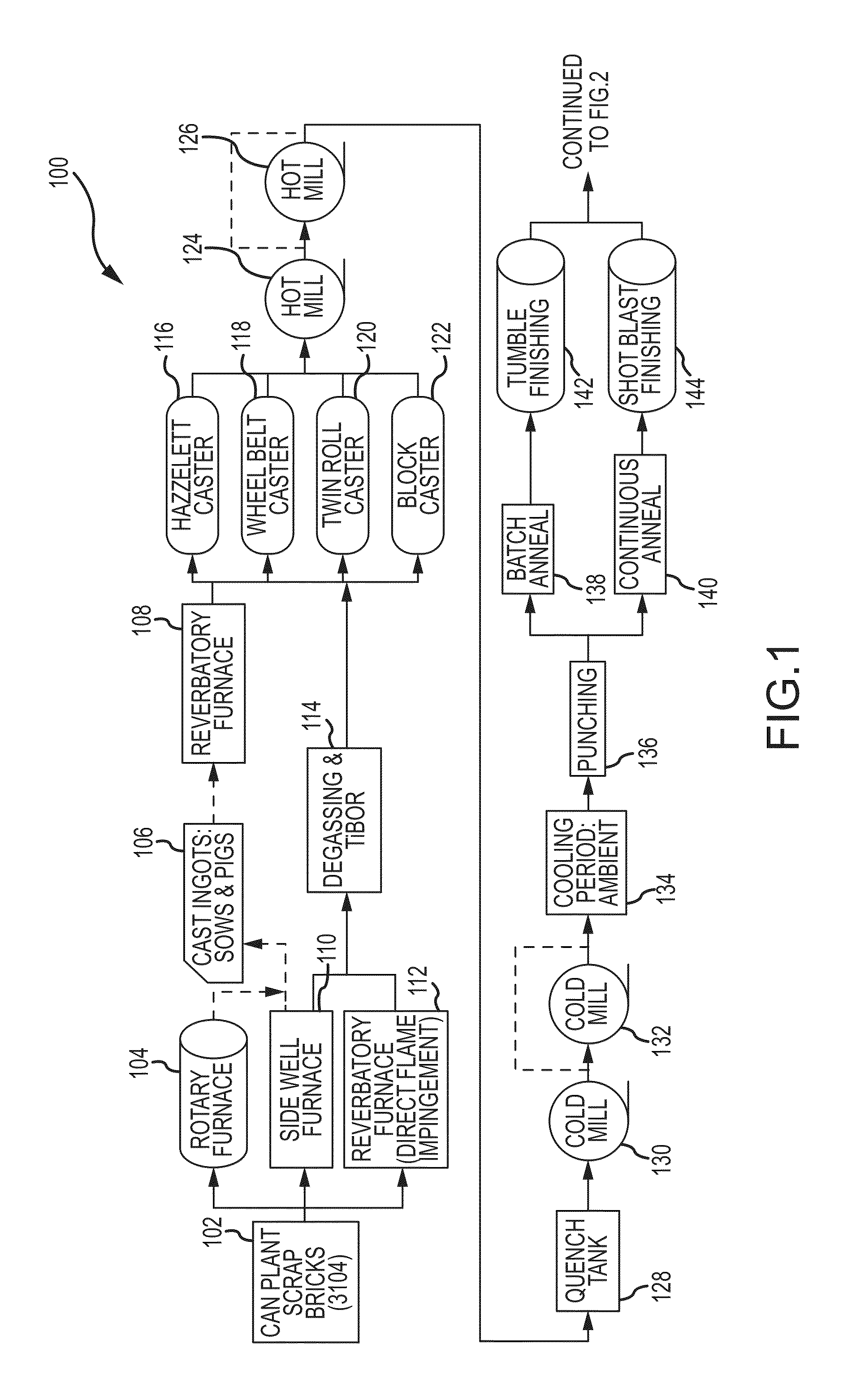

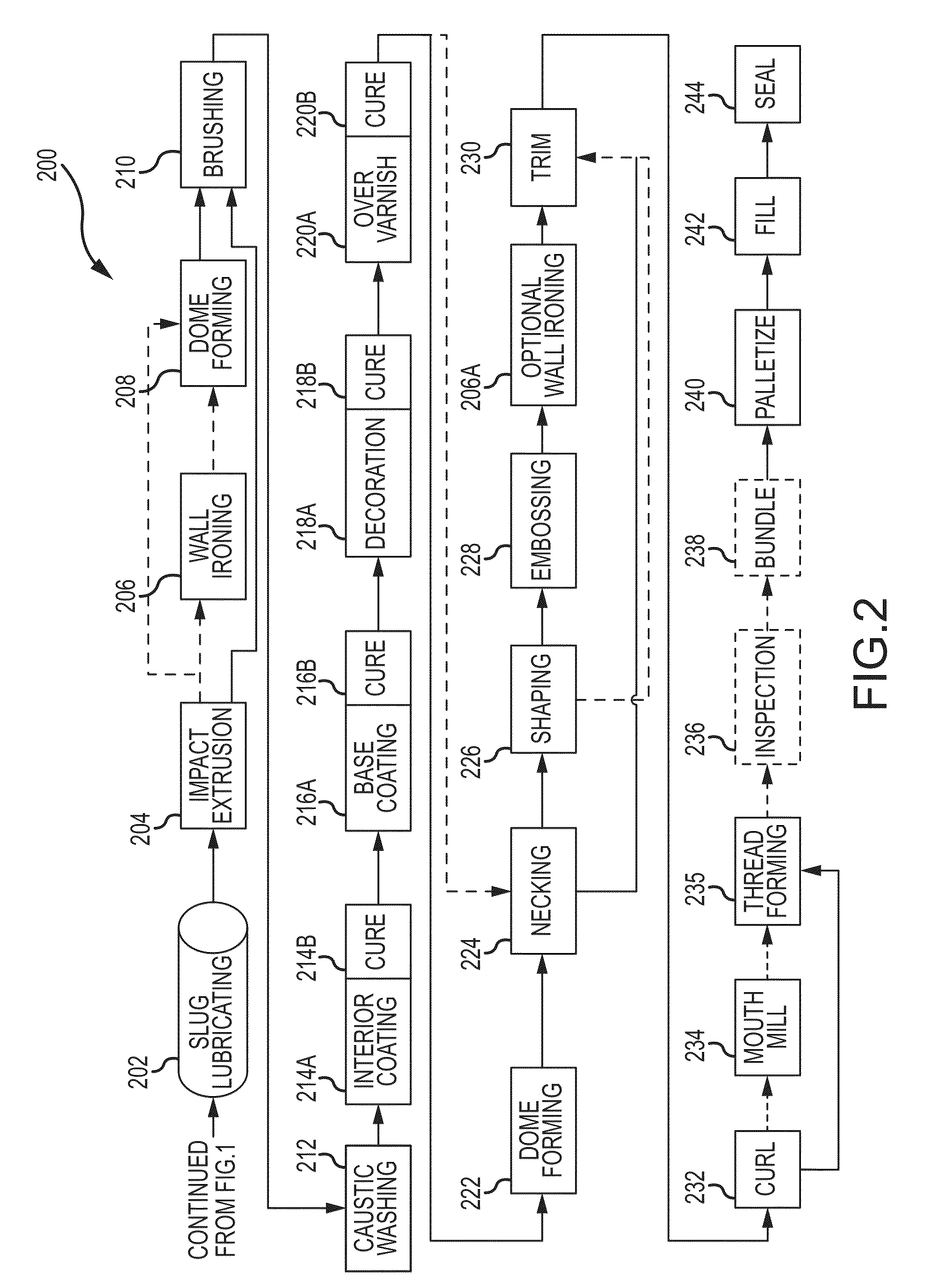

Aluminum impact extruded bottle with threaded neck made from recycled aluminum and enhanced alloys

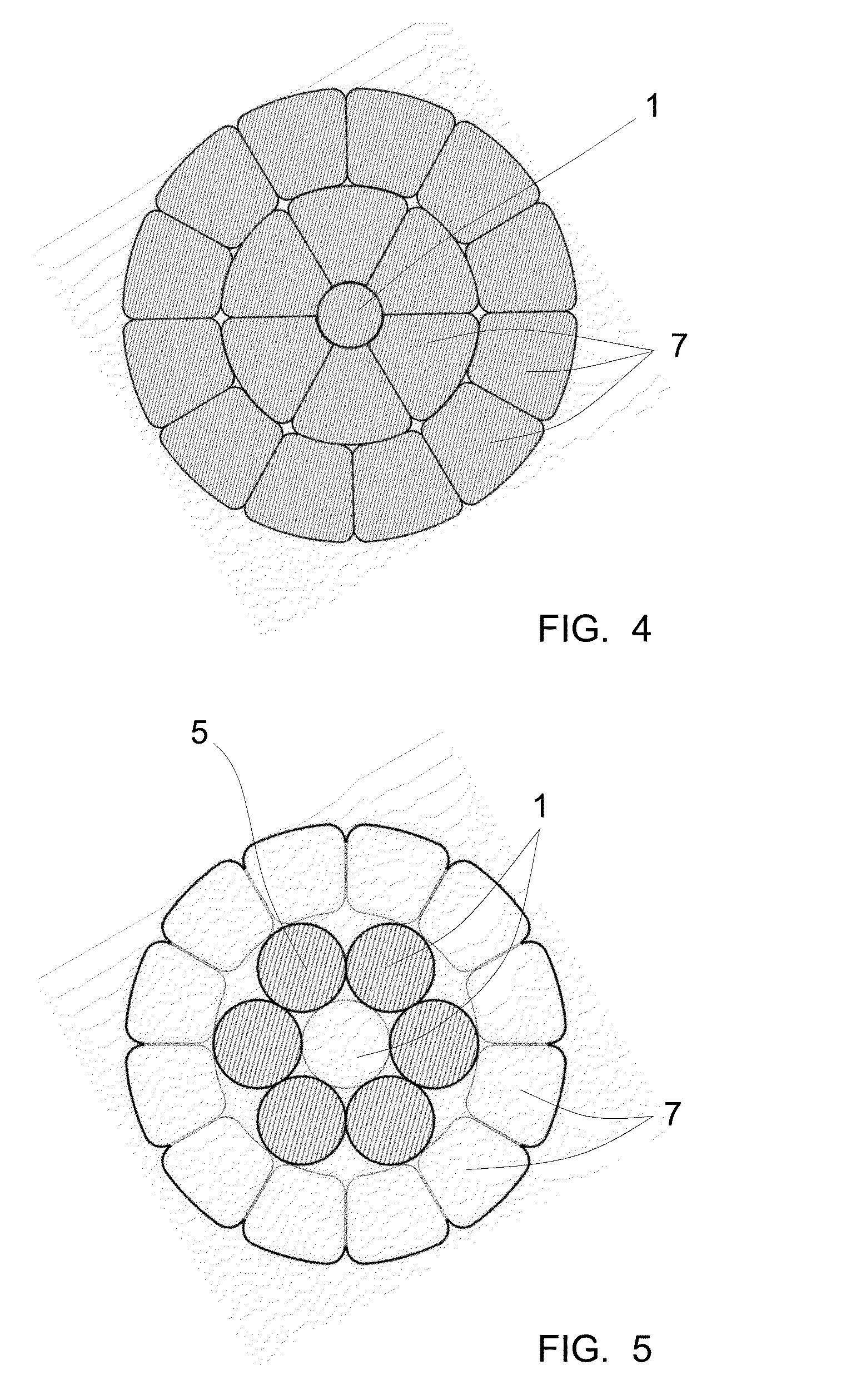

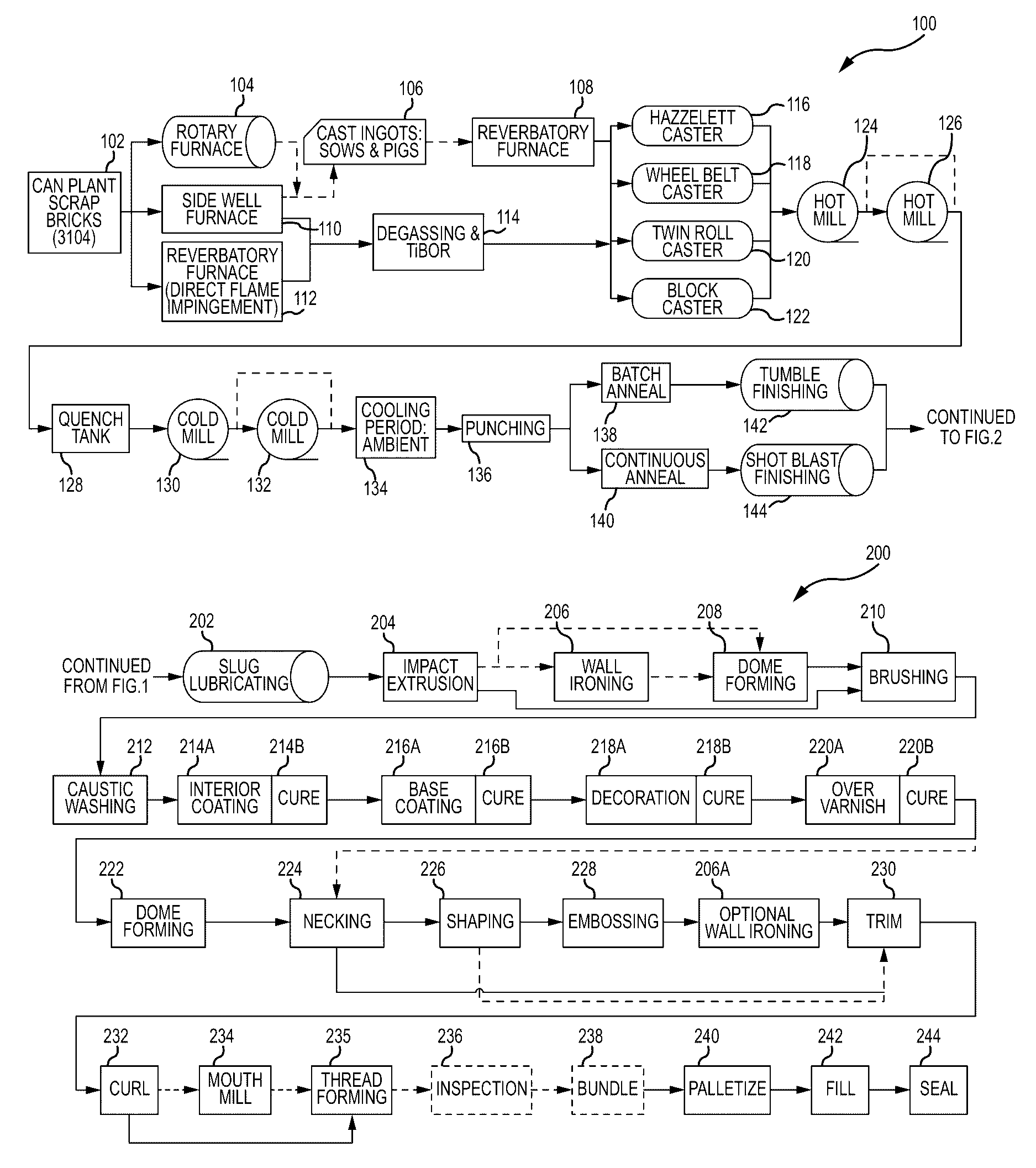

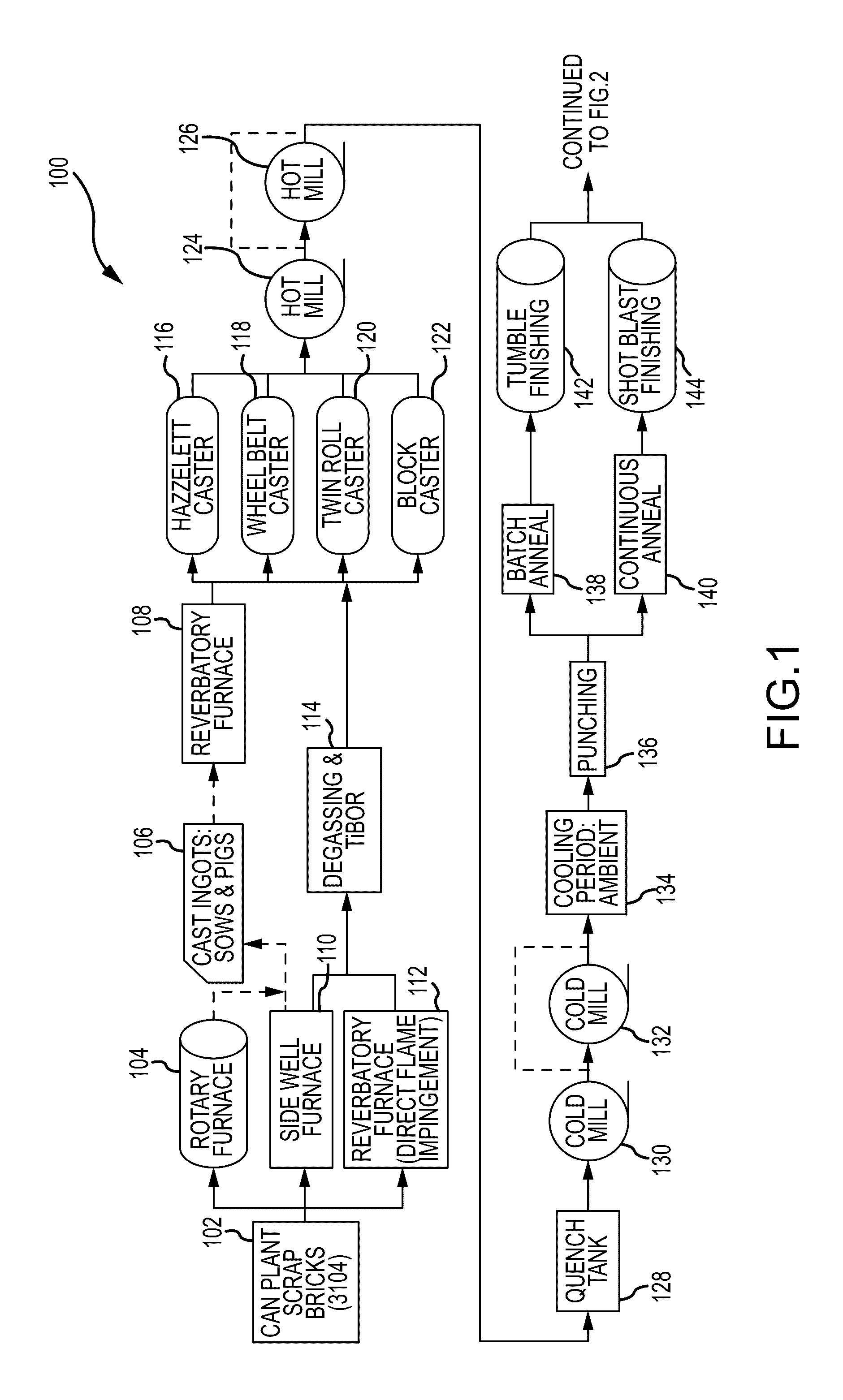

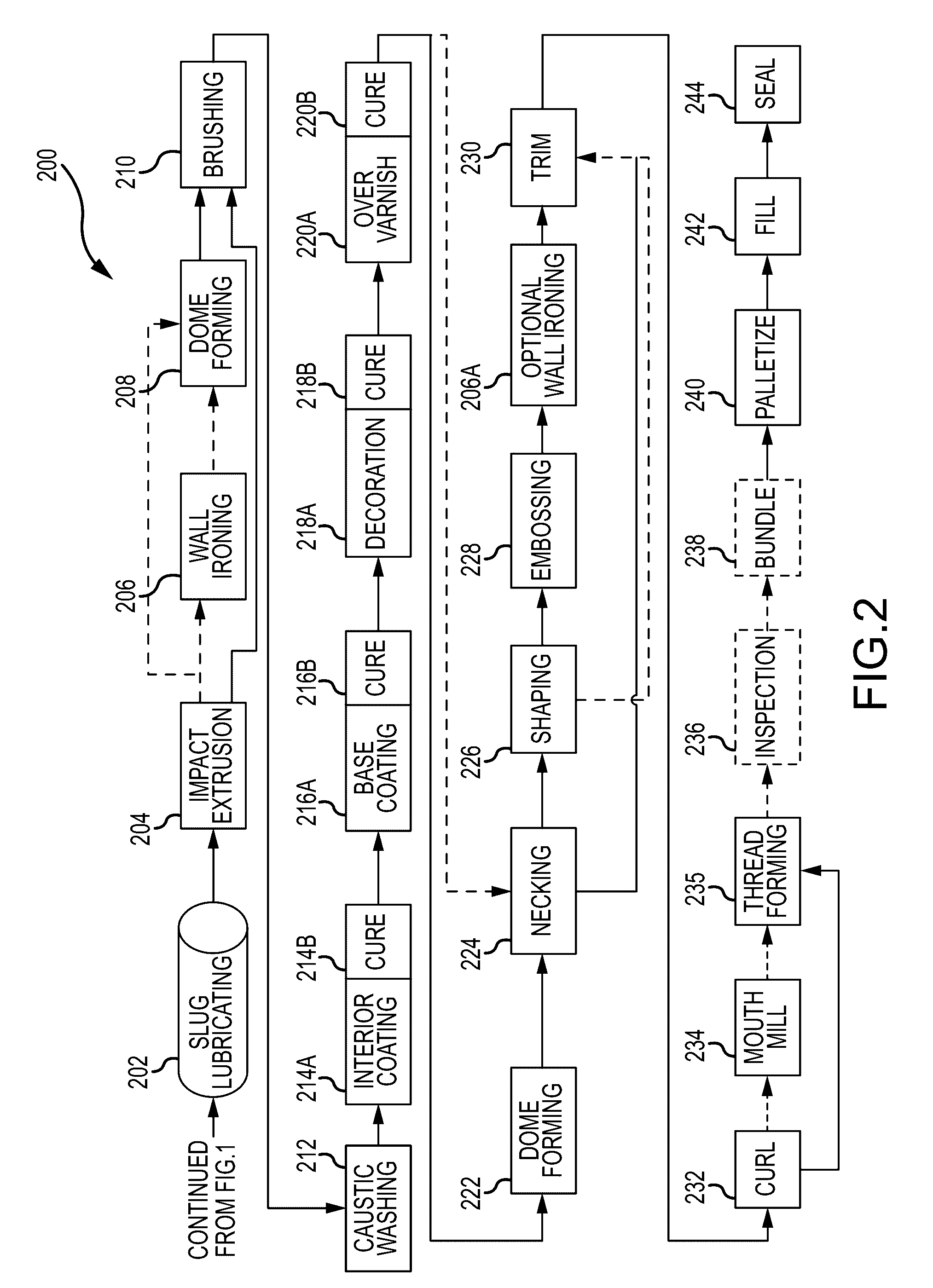

ActiveUS20140298641A1High mechanical strengthLow costMetal rolling stand detailsClosure capsBottleUltimate tensile strength

The present invention relates generally to forming a threaded neck in a metal bottle manufactured by a process known as impact extrusion. More specifically, the present invention relates to methods, apparatus and alloy compositions used in the impact extrusion manufacturing of containers and other articles with sufficient strength characteristics to allow threading the container necks to receive a threaded closure on the threaded neck.

Owner:BALL CORP

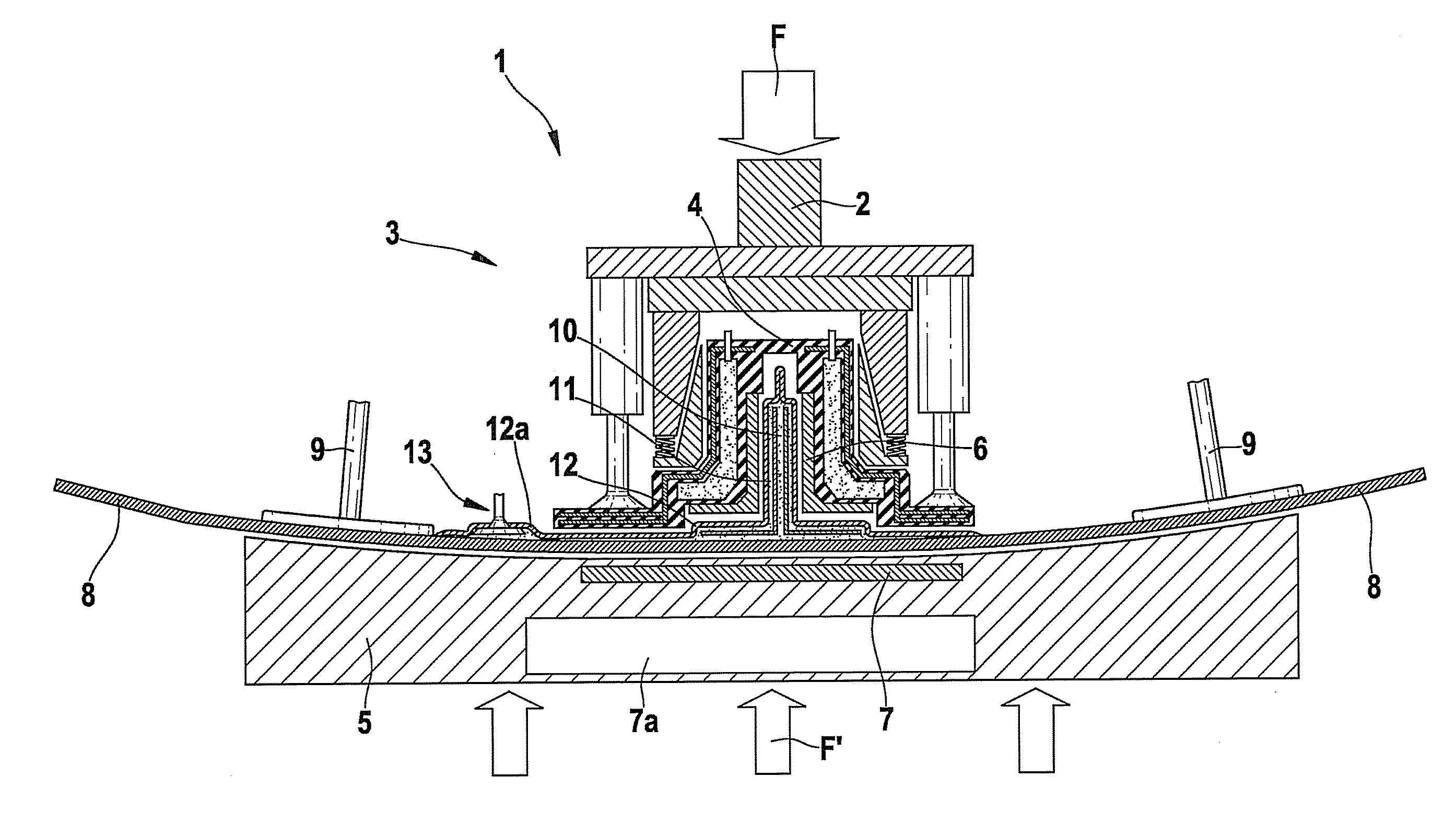

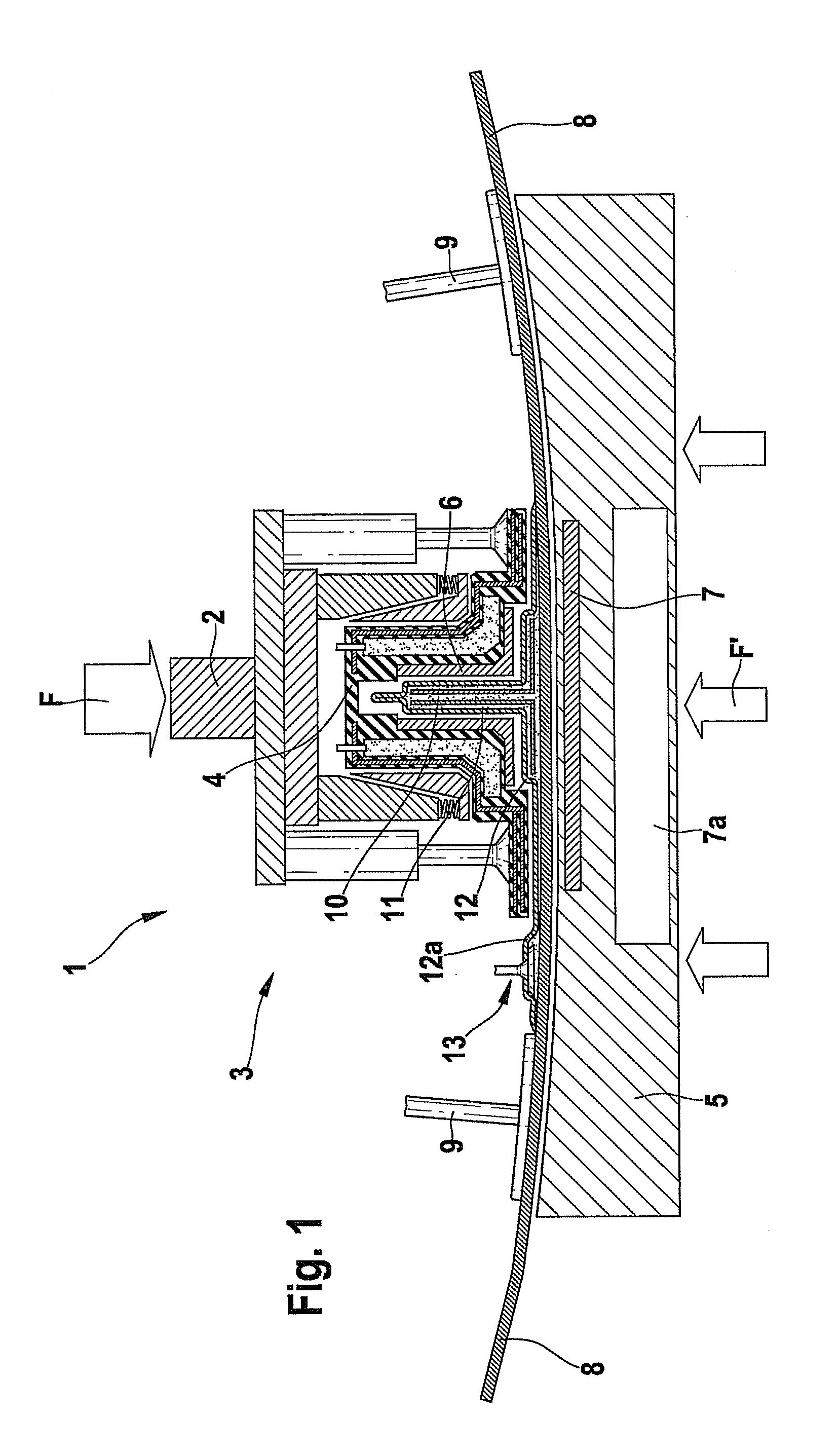

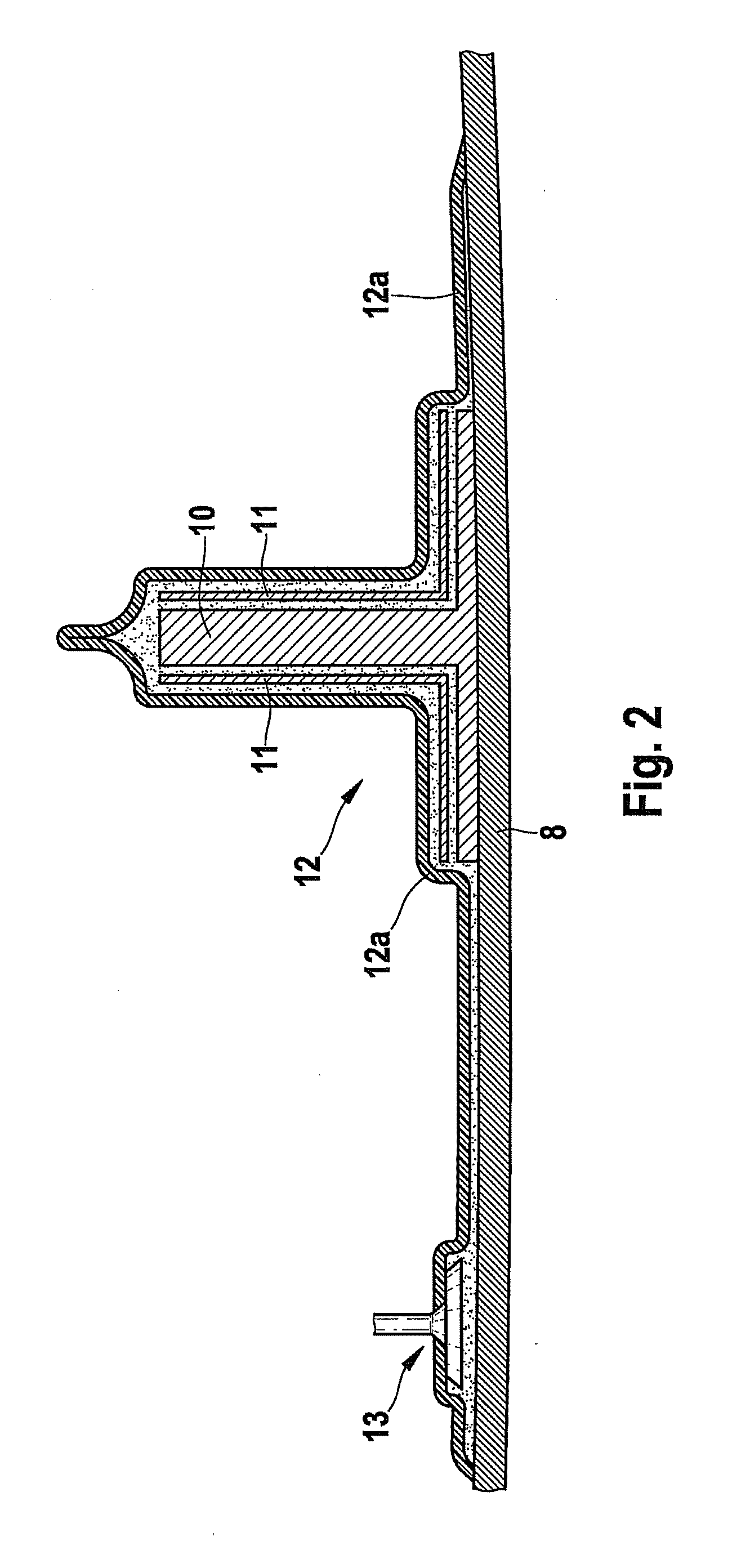

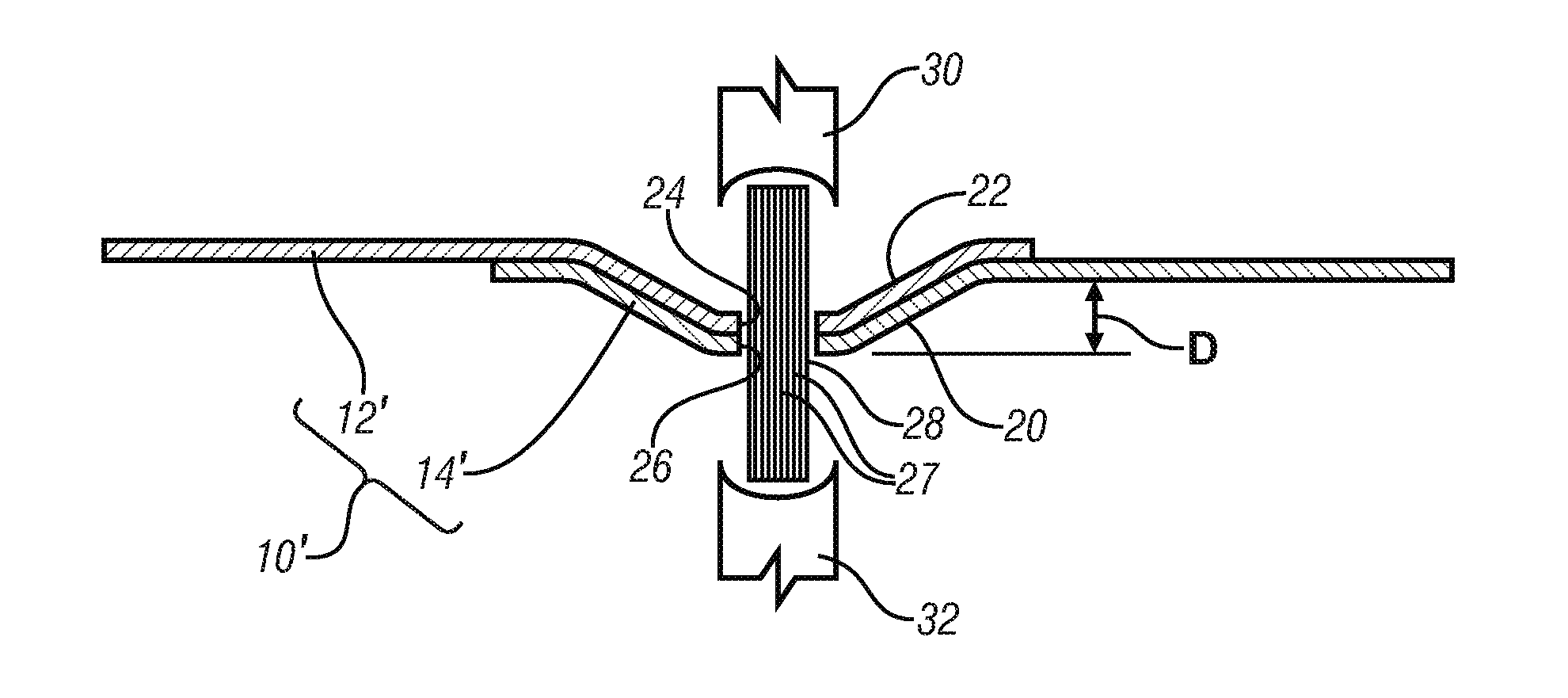

Method for at least partially reworking or replacing a reinforcement element of a fibre composite structure and associated connecting device

ActiveUS20120061006A1Enhanced surface contactImprove heat transfer performanceLayered productsLaminationComposite structureEngineering

The invention relates to a method for at least partially reworking or replacing a reinforcement element of a fibre composite structure. In a first method step, at least one fibre layer is arranged on a surface section of the reinforcement element and / or at least one replacement section of the reinforcement element of the same material and same layer structure is arranged on a surface reinforcement section of the fibre composite structure. In a second method step, at least a pressure mat adjusted to the contour of the reinforcement element is disposed above the at least one fibre layer and / or the at least one replacement section of the reinforcement element, wherein the at least one pressure mat is supported and fixed in a nominal position by a fixing frame adjusted to the contour of the reinforcement element. In a third method step, the at least one pressure mat is then acted upon by a pressure medium in order to press the same against the reinforcement element and the fixing frame. In a fourth method step, a hardening of the at least one fibre layer and / or the at least one replacement section of the reinforcement element is carried out. The invention further relates to a corresponding connecting device for carrying out the method.

Owner:AIRBUS OPERATIONS GMBH

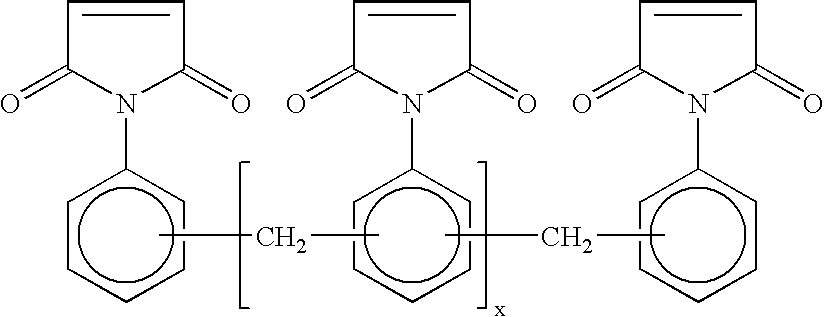

Flexible bismaleimide, benzoxazine, epoxy-anhydride adduct hybrid adhesive

ActiveUS20140199549A1Improve thermal stabilityLow water absorptionSilicaAcid polymer adhesivesPolyethylene terephthalate glycolThermal expansion

A resin composition which has low stress, and good adhesive property in high temperature and high moisture environments and which is useful in adhesive applications in low stress, high moisture sensitivity level electronic packages. Preferably, a flexible epoxy anhydride adduct modified solid bismaleimide and solid benzoxazine resin composition that can survive high temperature and high moisture conditions and maintain good adhesion strength and minimize the stress resulting from a coefficient of thermal expansion mismatch between a silicon die and a substrate which is Ball Grid Array solder mask or a smart card polyethylene terephthalate or silver or copper metal lead frame.

Owner:PROTAVIC KOREA

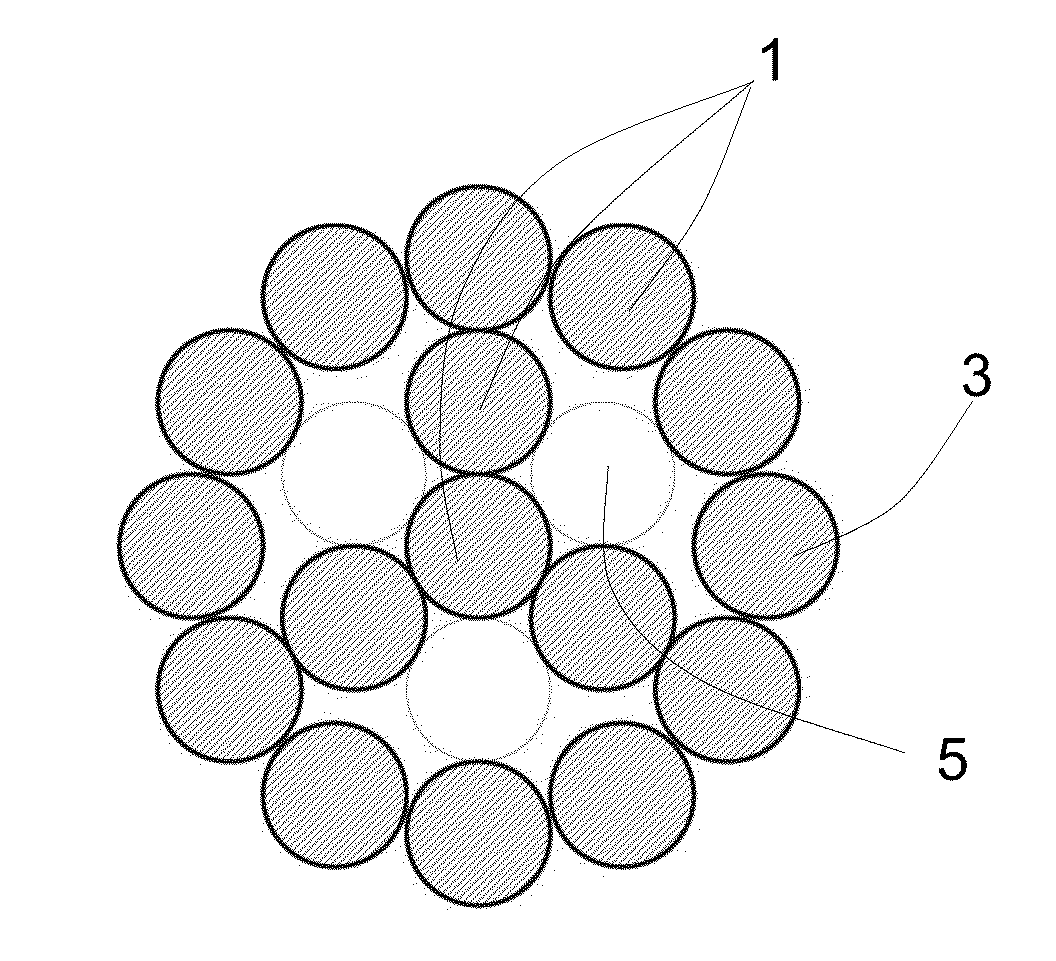

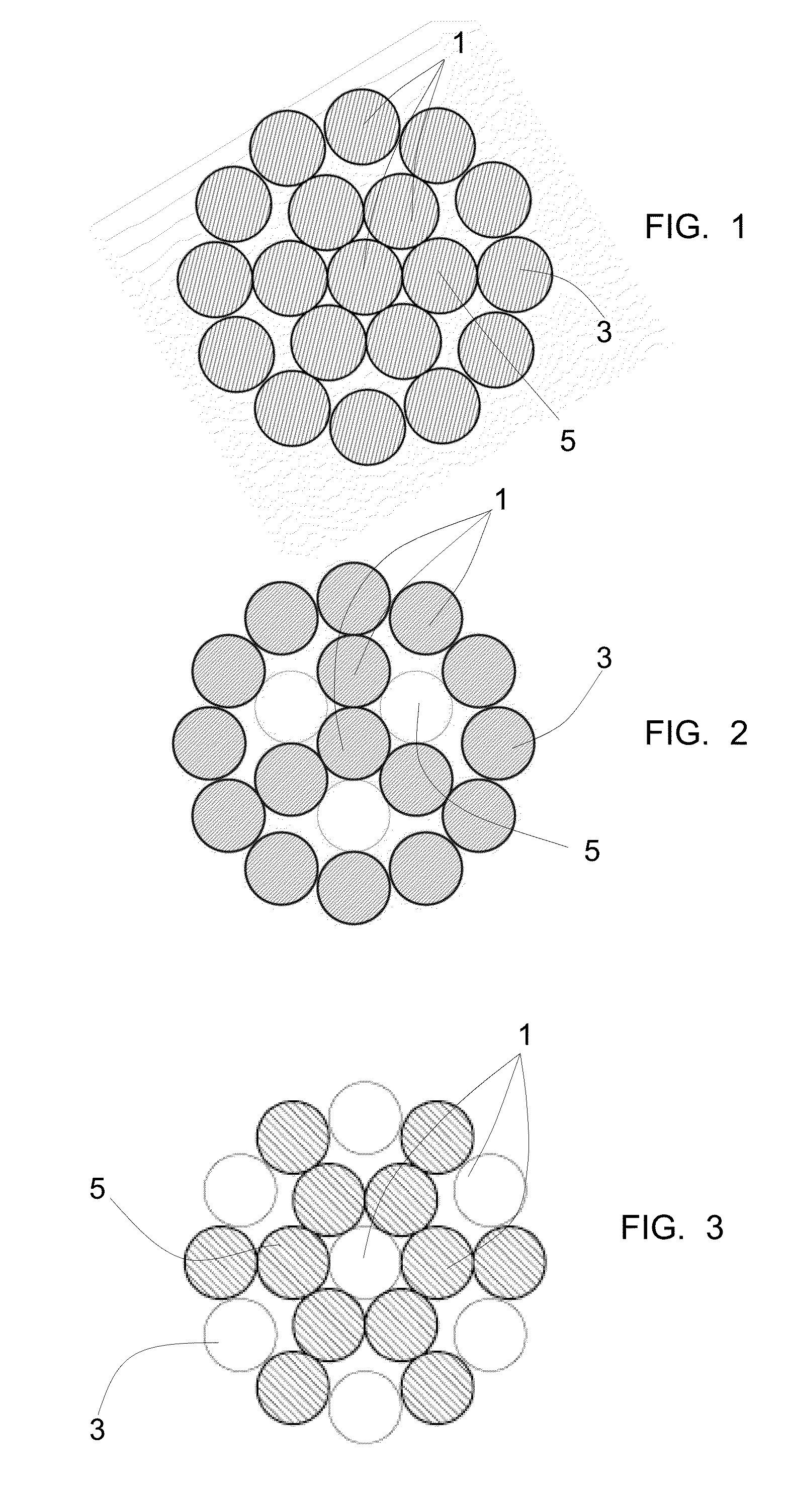

Electrical Conductor for Transporting Electrical Energy and Corresponding Production Method

InactiveUS20130264093A1Small catenary sagImprove electrical performanceNon-insulated conductorsConductive materialElectrical conductorSkin effect

An electrical conductor for transmission of electrical power, having a total cross-section equal to or above 10 mm2 and comprising a plurality of stranded filamentary members, where at least one of the filamentary members is made from microalloyed copper or microalloyed aluminium having annealing temperatures higher than 250° C., and has the side surface thereof totally coated with a fluorinated polymer. The conductor has a better behavior relative to the skin effect and allows operation at high temperatures. Furthermore, if the electrical conductor is suspended, it has a smaller sag and prevents or reduces the accumulation of ice and / or snow.

Owner:LA FARGA LACAMBRA

Aluminum impact extruded bottle with threaded neck made from recycled aluminum and enhanced alloys

The present invention relates generally to forming a threaded neck in a metal bottle manufactured by a process known as impact extrusion. More specifically, the present invention relates to methods, apparatus and alloy compositions used in the impact extrusion manufacturing of containers and other articles with sufficient strength characteristics to allow threading the container necks to receive a threaded closure on the threaded neck.

Owner:BALL CORP

High-strength high-permeability chemical sand prevention agent, and preparation method and application thereof

InactiveCN104650840AObvious advantageObvious effectFluid removalDrilling compositionHigh humidityOil water

The invention provides a high-strength high-permeability chemical sand prevention agent, and a preparation method and an application thereof. The high-strength high-permeability chemical sand prevention agent is composed of a proppant, a cementing agent, an accelerator, a curing agent and a coupling agent according to a certain ratio. The preparation method comprises the following steps: above raw materials are mixed at a specific temperature, and are stirred, and the obtained mixture is cured for a certain period of time to obtain the high curing strength sand prevention agent. The sand prevention agent has good tolerance to acid, water, salt and oil, has high stability in high temperature and high humidity environment, and is mainly used in chemical sand prevention well extract production, serious casing deformation well sand prevention, and sand prevention of wells without mechanical sand prevention and oil water wells with low reservoir temperature in order to increase liquid production of the oil well, prolong the period of validity of well sand prevention, increase the amount of oil and reduce the production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

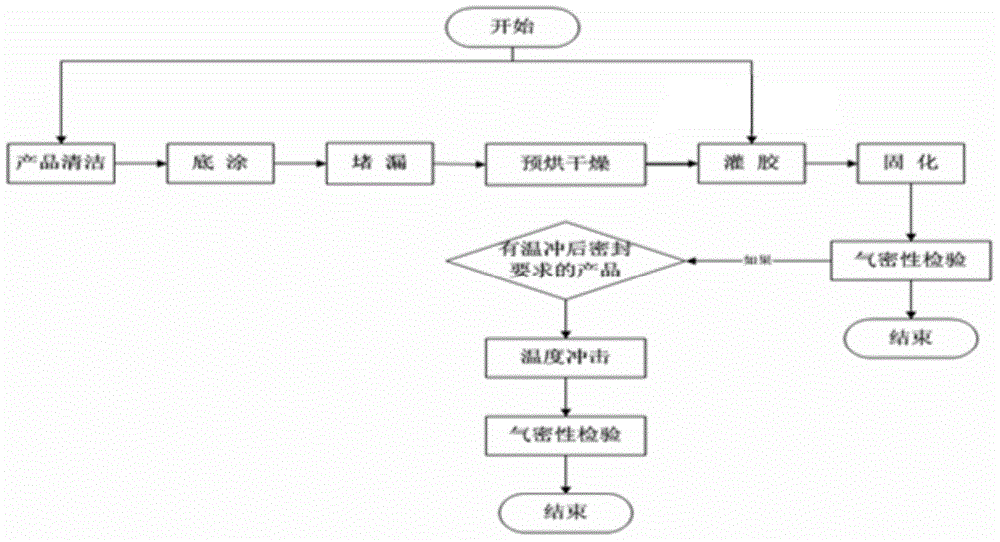

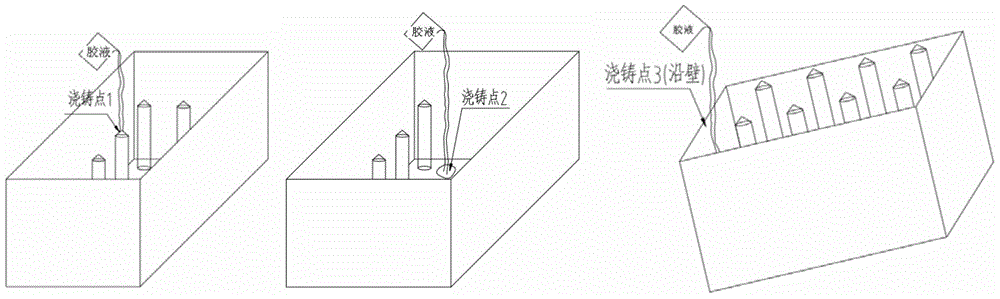

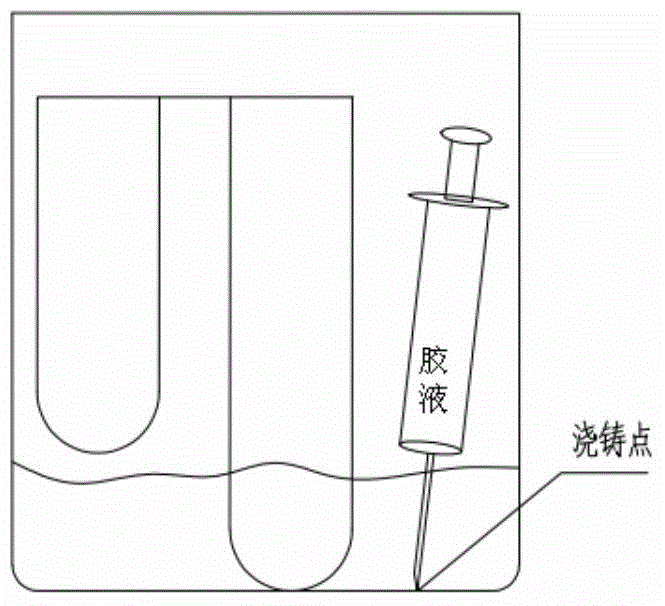

Method for using polyurethane adhesive to encapsulate electrical connector product

ActiveCN104577635AImprove airtight pass rateSolve the sealing problemContact member cases/bases manufactureElectricityPolyurethane adhesive

The invention discloses a method for using a polyurethane adhesive to encapsulate an electrical connector product. The method comprises the steps of cleaning the product, first coating, stopping leakage, pre-drying, pouring the polyurethane adhesive, solidifying, checking the airtightness, and the like, wherein the specific technologic method for each step is provided. According to the method disclosed by the invention, the airtightness qualification rate of the encapsulated product is increased, and the problem that the encapsulated product fails to be sealed or adhesive overflows after temperature shock can be solved.

Owner:杭州航天电子技术有限公司

Lignocellulose fiber-resin composite material

InactiveUS7396438B2Degree of reductionHigh curing temperatureFibreboardNon-fibrous pulp additionCellulose fiberSlurry

Owner:TEMBEC INC

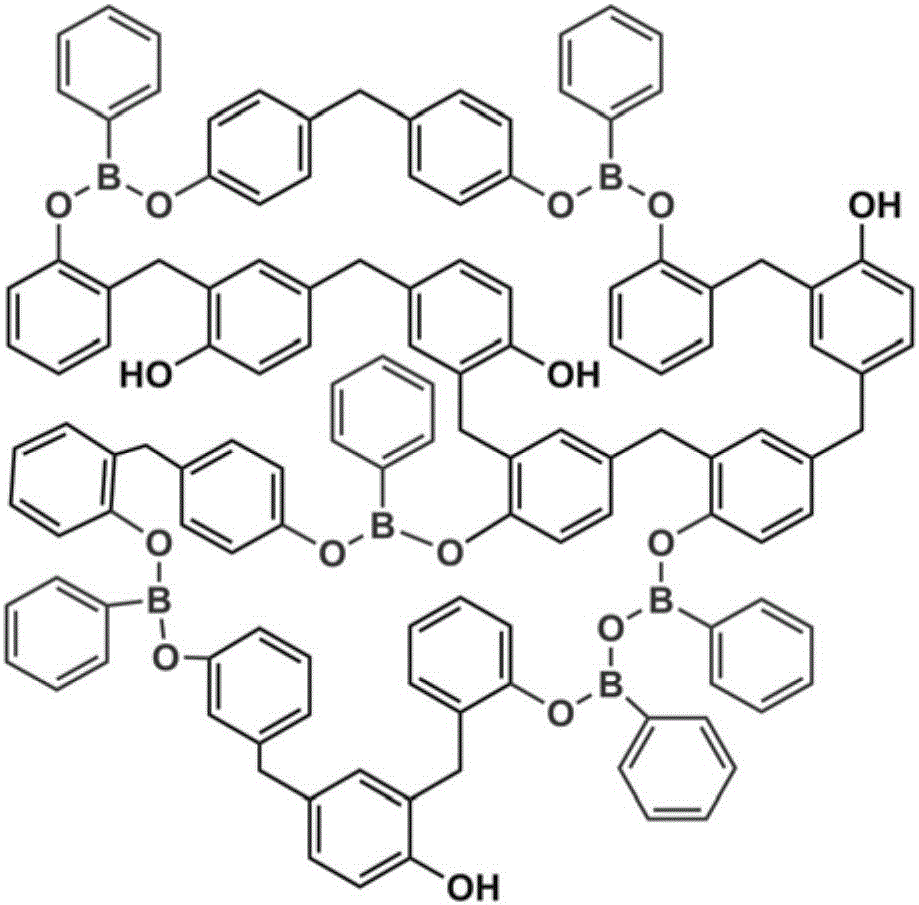

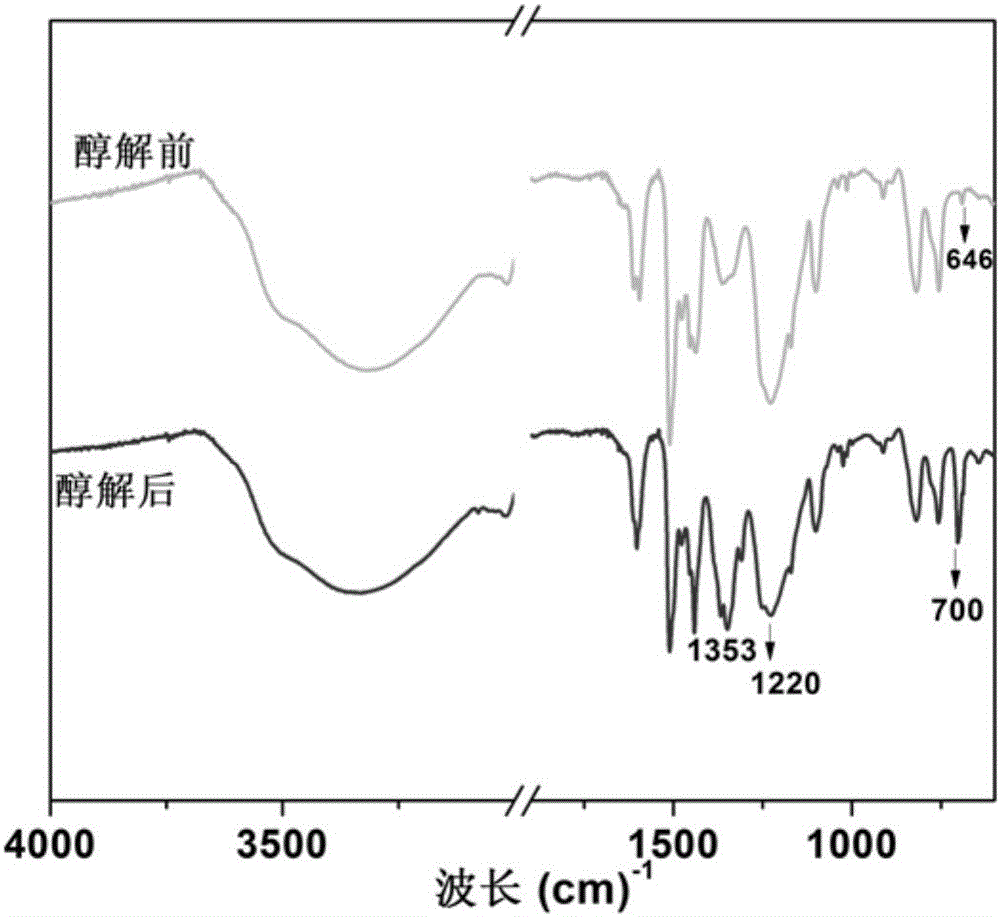

Preparation method of room-temperature regenerated phenolic resin and recycling technology and application thereof

ActiveCN106750064ALow softening temperatureReduce melt viscosityPlastic recyclingOrganic solventAlcohol

The invention relates to a preparation method of room-temperature regenerated phenolic resin and a recycling technology and application thereof. The preparation method comprises the following steps of according to parts by mass, melting and blending 100 parts of thermoplastic phenolic resin and 18.4 to 55 parts of boric acid compound at the temperature of 60 to 100 DEG C, so as to obtain boron-containing thermoplastic phenolic resin; or, dissolving 100 parts of thermoplastic phenolic resin and 20 to 50 parts of boric acid compound into an organic solvent with low boiling point at the temperature of 40 to 60 DEG C, so as to obtain the boron-containing thermoplastic phenolic resin; curing, so as to obtain the room-temperature regenerated phenolic resin. The preparation method has the advantages that the preparation technology of the resin is simple; the resin is dissolved into the mixing solvent of ethyl alcohol and water at room temperature, so that the resin can be recycled; the resin can be used for preparing the recyclable fiber reinforced boron-containing thermoplastic phenolic resin-based composite material. The prepared boron-containing thermoplastic phenolic resin has the advantages that the function of arylboronic acid ester structure promoting the heat-resistant property of the thermoplastic phenolic resin is fully realized, and the technology of the resin and the mechanical property of the composite material can be simultaneously realized.

Owner:XI AN JIAOTONG UNIV +1

Phenolic resin compositions containing etherified hardeners

ActiveUS20060020102A1Long application periodMinimizing and eliminating void and pinholePolymer sciencePolyol

This invention relates to a resin composition capable of being thermally cured while minimizing or eliminating voids in the resulting composite, the composition having both a long pot life at low temperatures and a fast curing rate at higher temperatures containing a mixture of (a) a phenol-formaldehyde resole resin, and (b) an etherified hardener, the etherified hardener being prepared from an alkoxylated polyol or a mono epoxy functional diluent.

Owner:GEORGIA PACIFIC CHEM LLC

Epoxy resin-based low-temperature conductive silver paste and preparation method thereof

InactiveCN111261320AImprove conductivityHigh curing temperatureNon-conductive material with dispersed conductive materialCable/conductor manufactureScreen printingSilver paste

The invention belongs to the technical field of conductive silver paste and relates to epoxy resin-based low-temperature conductive silver paste and a preparation method thereof. The paste is preparedfrom the following components in parts by weight: 20-40 parts of starch; 55 to 75 parts by weight of silver powder; 5 to 15 parts of epoxy resin; 0.3 to 10 parts of curing agent; 0.05 to 5 parts of curing accelerator; 2 to 18 parts of diluents; 0.01 to 1 part of inhibitor; 0.1 to 3 parts of rheological additive; and 0.5 to 5 parts of additive. The paste has relatively low curing temperature and relatively low viscosity, and is suitable for a silk-screen printing process.

Owner:常州烯奇新材料有限公司

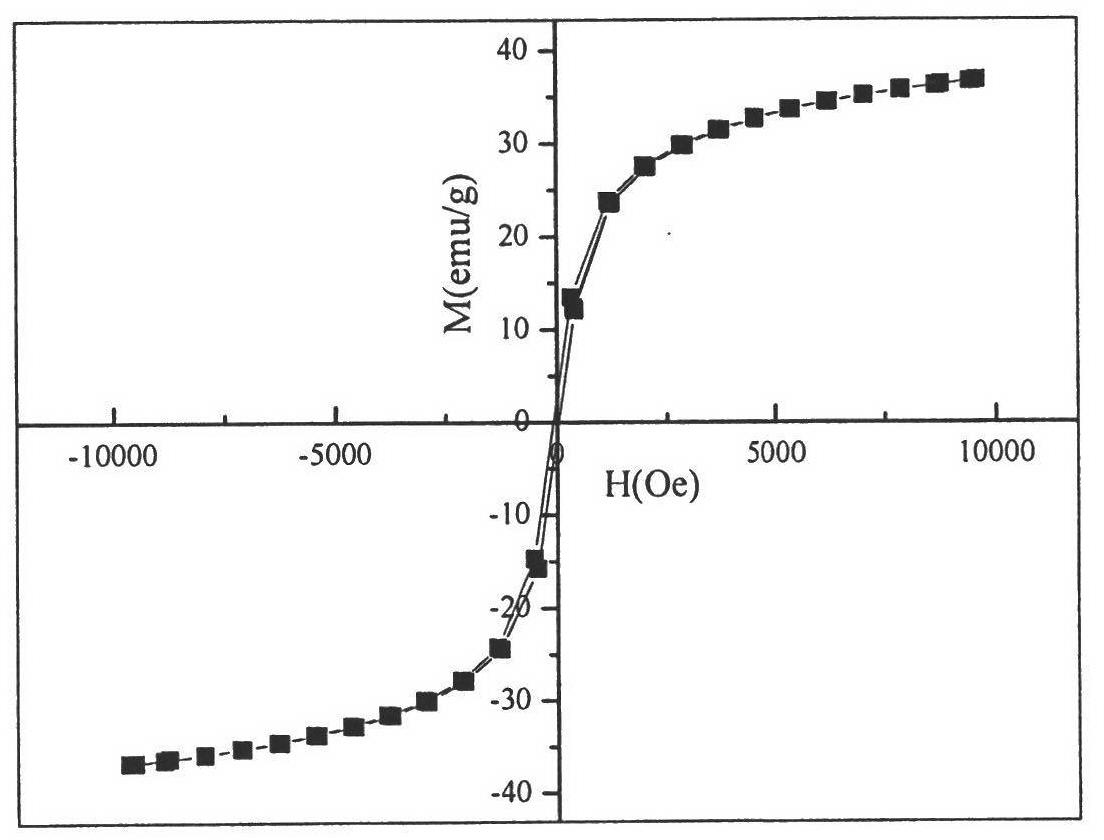

Thermosetting resin able to realize high temperature heating and curing in high frequency magnetic field and preparation method thereof

InactiveCN102408680AOvercome the Dispersion ProblemEvenly dispersedPolymer scienceAC - Alternating current

The invention relates to thermosetting resin able to realize high temperature heating and curing in high frequency magnetic field and a preparation method thereof. The method of the invention is technically characterized by: adopting thermosetting resin as the matrix and special Fe3O4 magnetic particles as filler, placing the resin system in a high frequency magnetic field generated by alternating current, making use of the heat generated from the Neel relaxation effect of the special Fe3O4 magnetic particles to cure thermosetting resin. The heating and curing technology in a high frequency magnetic field of in the invention realizes high efficiency curing of thermosetting resin. In the invention, by adjusting the mass ratio of special Fe3O4 magnetic particles in a thermosetting resin system, an optimum proportion of a heat production rule and the thermosetting resin curing system of the technology can be determined.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Water dispersion composite sand-fixing agent formula

The invention relates to a formula of water dispersing compounding sand consolidation agent. It is made up from modified phenol-formaldehyde resin 5-8%, organic silicon resin 0.02-0.25%, furfural compounding 5-15%, alcohol compounding 0.5-5%, phosphoric acid series compounding 0.05-0.15% and water 89.43-81.6%. The benefit is that the sand consolidation agent has low viscosity, low usage quantity, low cost, etc.

Owner:赵彧

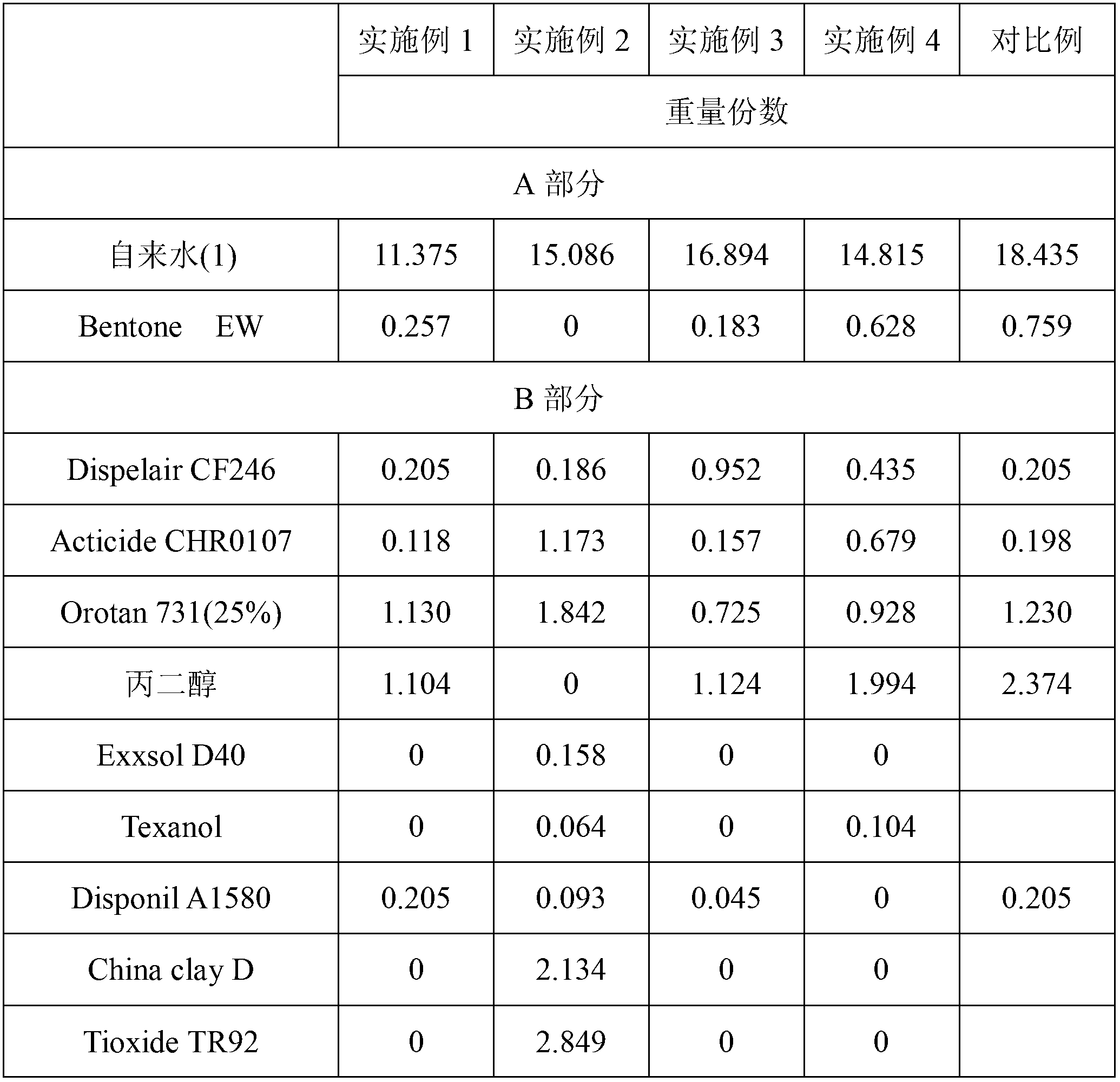

Flame-retardant coating composition

The invention relates to a halogen-free flame-retardant coating composition which comprises the components: 10-80% of film-forming polymer and 5-70% of inorganic flame-retardant material, and is characterized in that the flame-retardant material comprises flame-retardant filler microparticles and metallic tin benzoate and / or basic metallic tin benzoate, wherein the total PVC (polyvinyl chloride) content in the composition is 75-97%, and the film-forming polymer contains organic silicon resin.

Owner:TIANCHANG YINHU PAINT

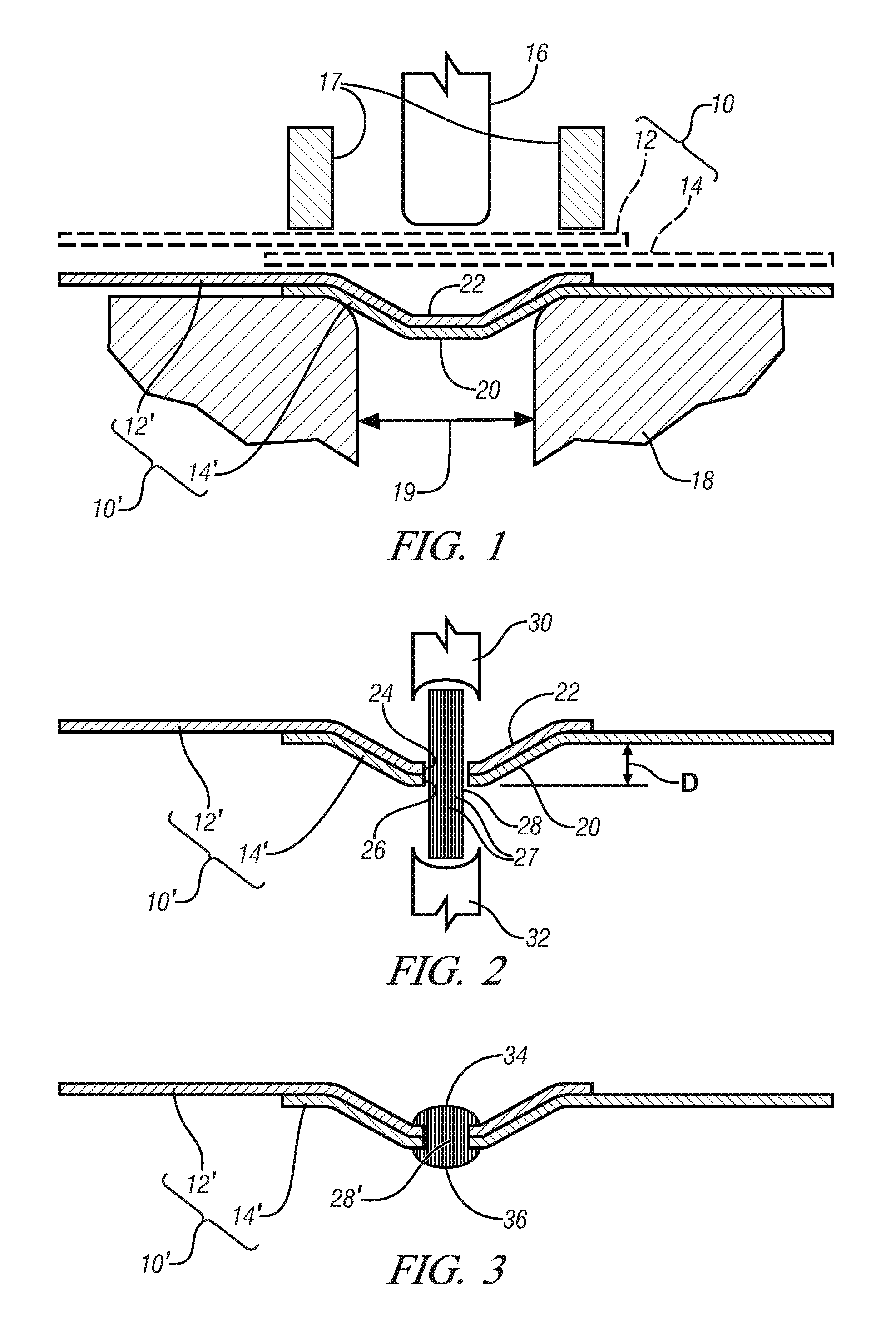

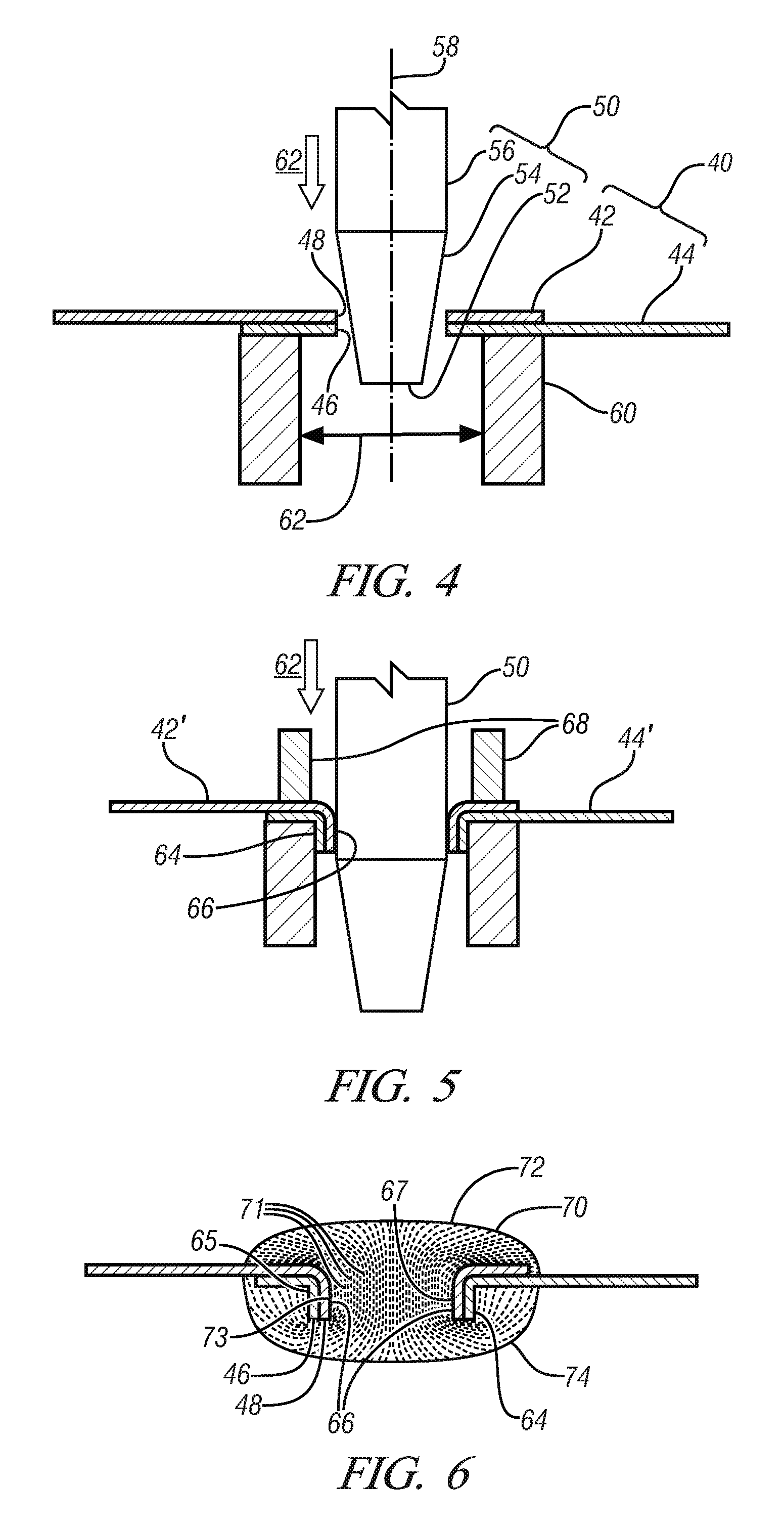

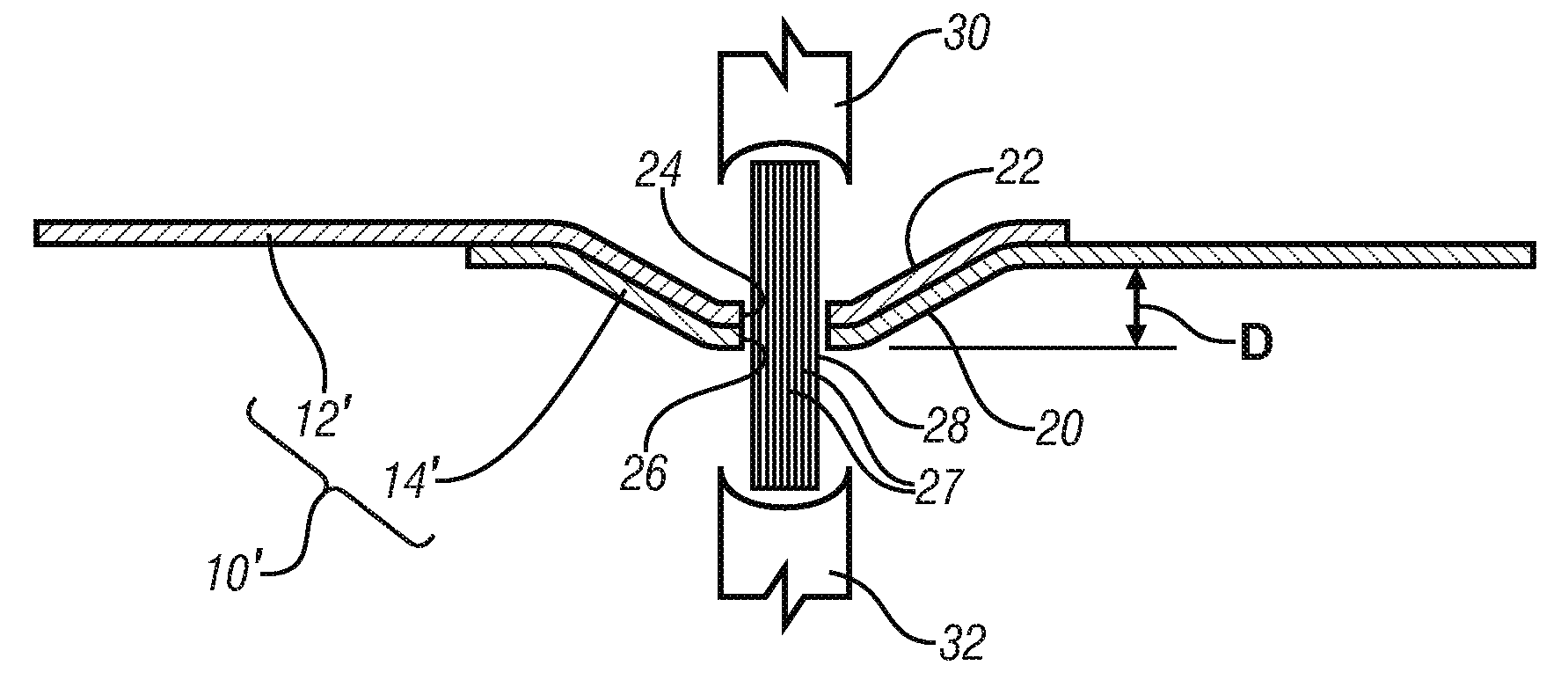

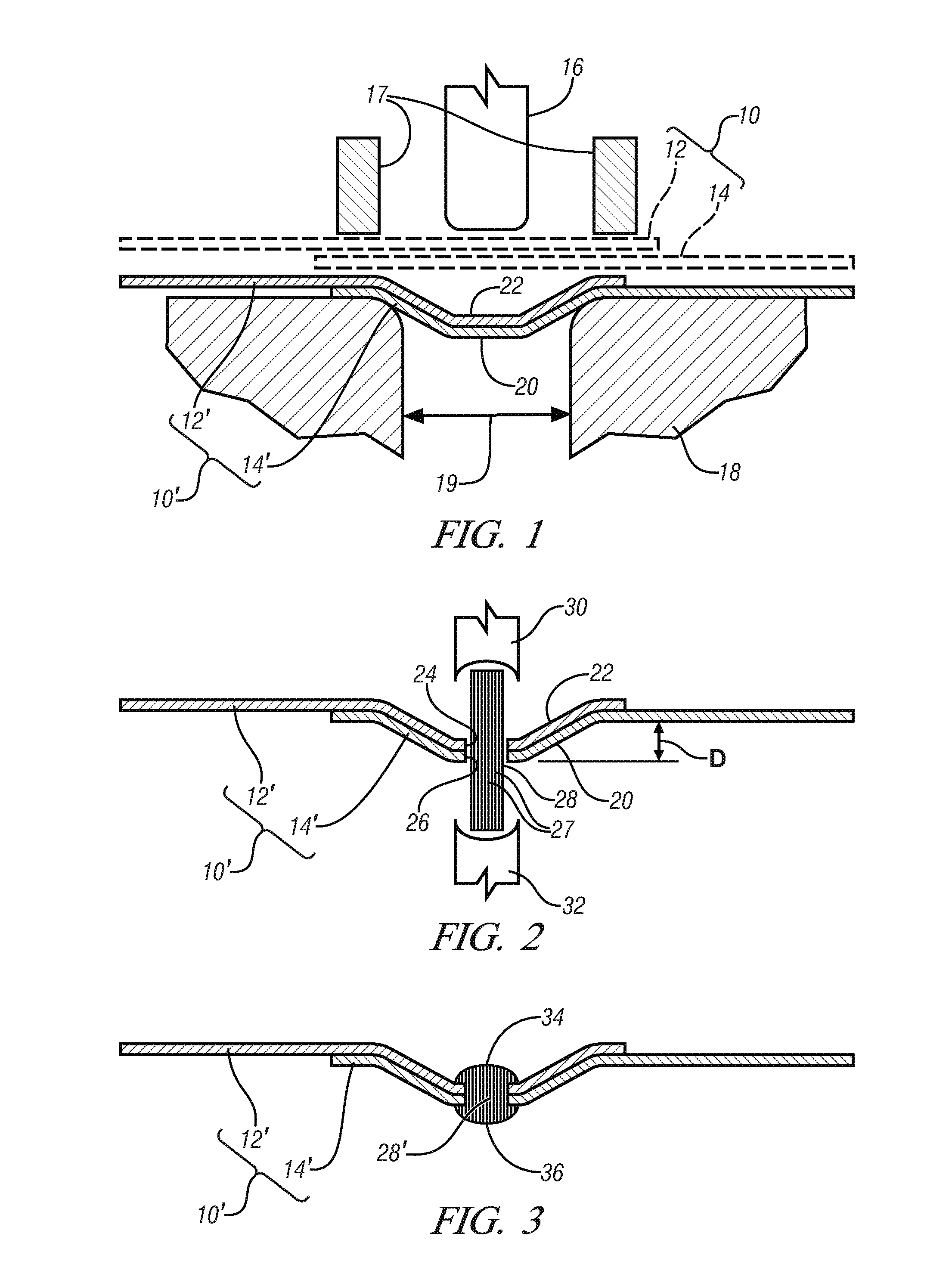

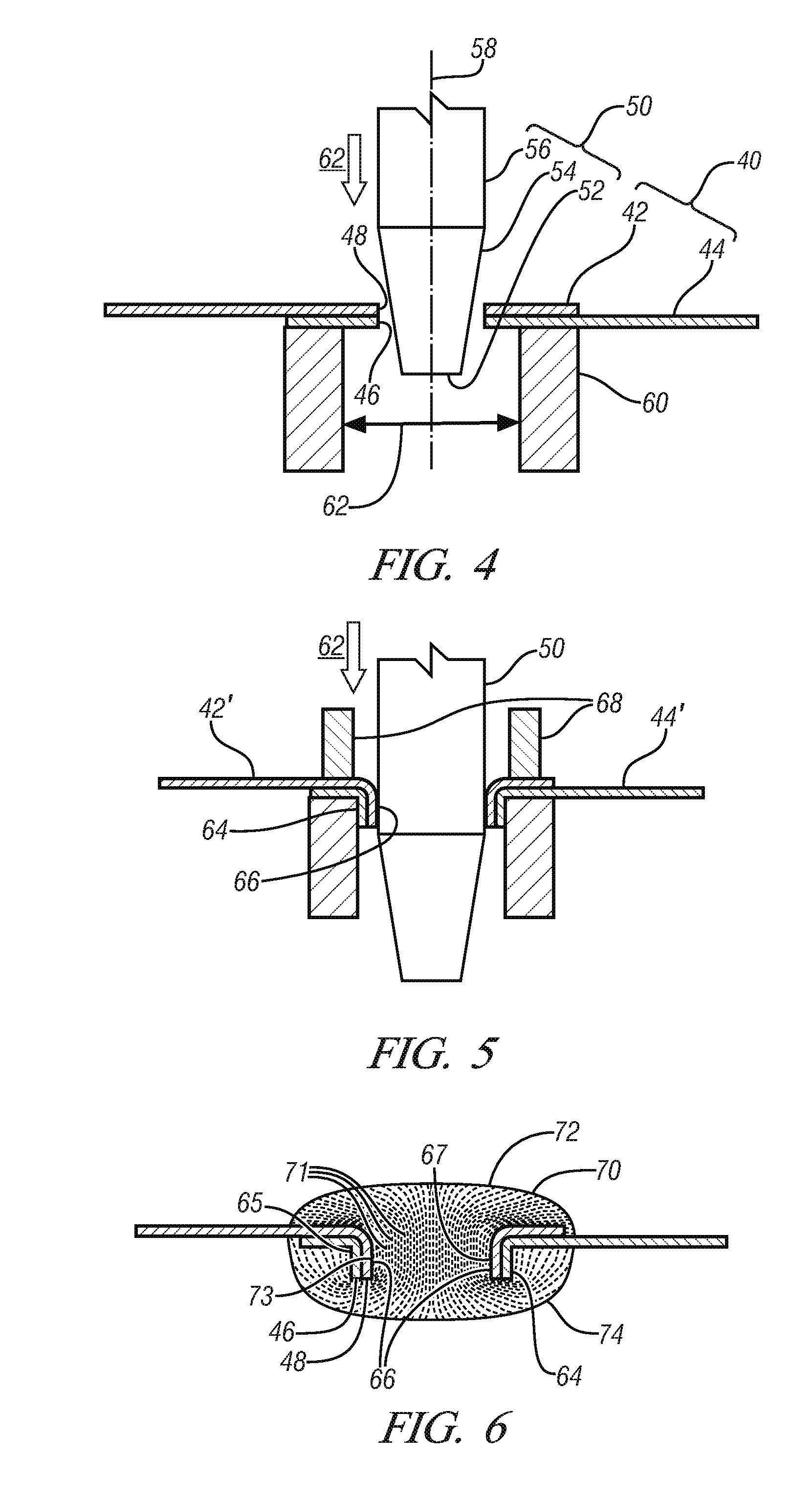

Joining magnesium with reinforced polymer composite fasteners

ActiveUS8448324B2Superior creep resistance and dimensional stabilityImprove deformationSheet joiningMetal working apparatusThin metalPolymer composites

A method is disclosed for forming corrosion-resistant joints in a plurality of overlapping thin metal sheet workpieces, at least one of which comprises at least 85% by weight of magnesium sheets. The fastener is a fiber-reinforced polymer rod shaped and sized for insertion into a coaxial opening formed in each sheet and subsequently upset on each end to form a head. The workpiece sheets are deformed to form mechanically-interfering features which cooperatively complement the strength of the fastener, under at least some joint loading patterns. The method may be used for other workpiece and fastener compositions.

Owner:GM GLOBAL TECH OPERATIONS LLC

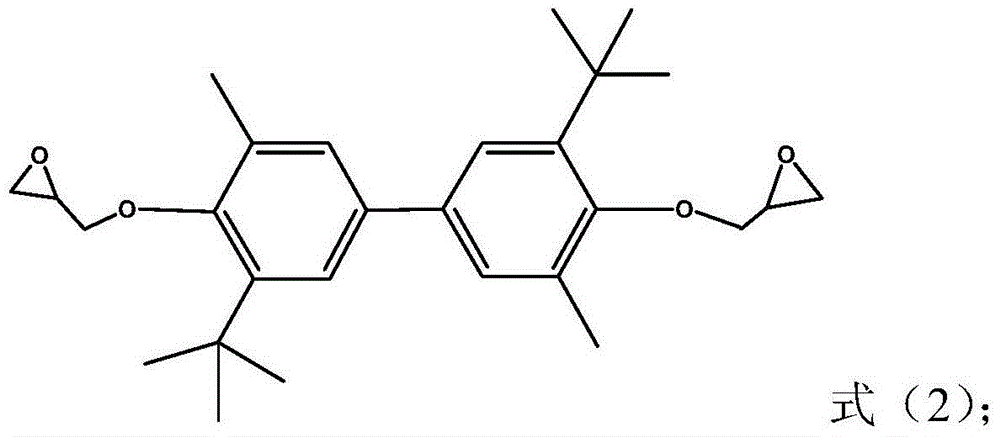

Liquid crystal epoxy resin as well as preparation method and application thereof

The invention discloses liquid crystal epoxy resin as well as a preparation method and an application thereof. The preparation method comprises the following steps: reacting 3,5'-di-tert-butyl-5,3'-dimethyl biphenol with excessive epichlorohydrin in the presence of a phase transfer catalyst, thereby obtaining 3,5'-di-tert-butyl-5,3'-dimethyl diphenyl diglycidyl ether, wherein the softening point of 3,5'-di-tert-butyl-5,3'-dimethyl diphenyl diglycidyl ether is measured to be 10 DEG C through DSC, and the 3,5'-di-tert-butyl-5,3'-dimethyl diphenyl diglycidyl ether is a thick non-solid product at the room temperature; then, selecting a proper curing agent to pre-cure at a low temperature, enabling a biphenyl rid-rod-shaped structure to orientate and arrange with enough time, curing and cross-linking at a high temperature, thereby obtaining a liquid crystal structure. Compared with the conventional preparation method for the rigid-rod-shaped epoxy resin, the preparation method disclosed by the invention is low in curing cost.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

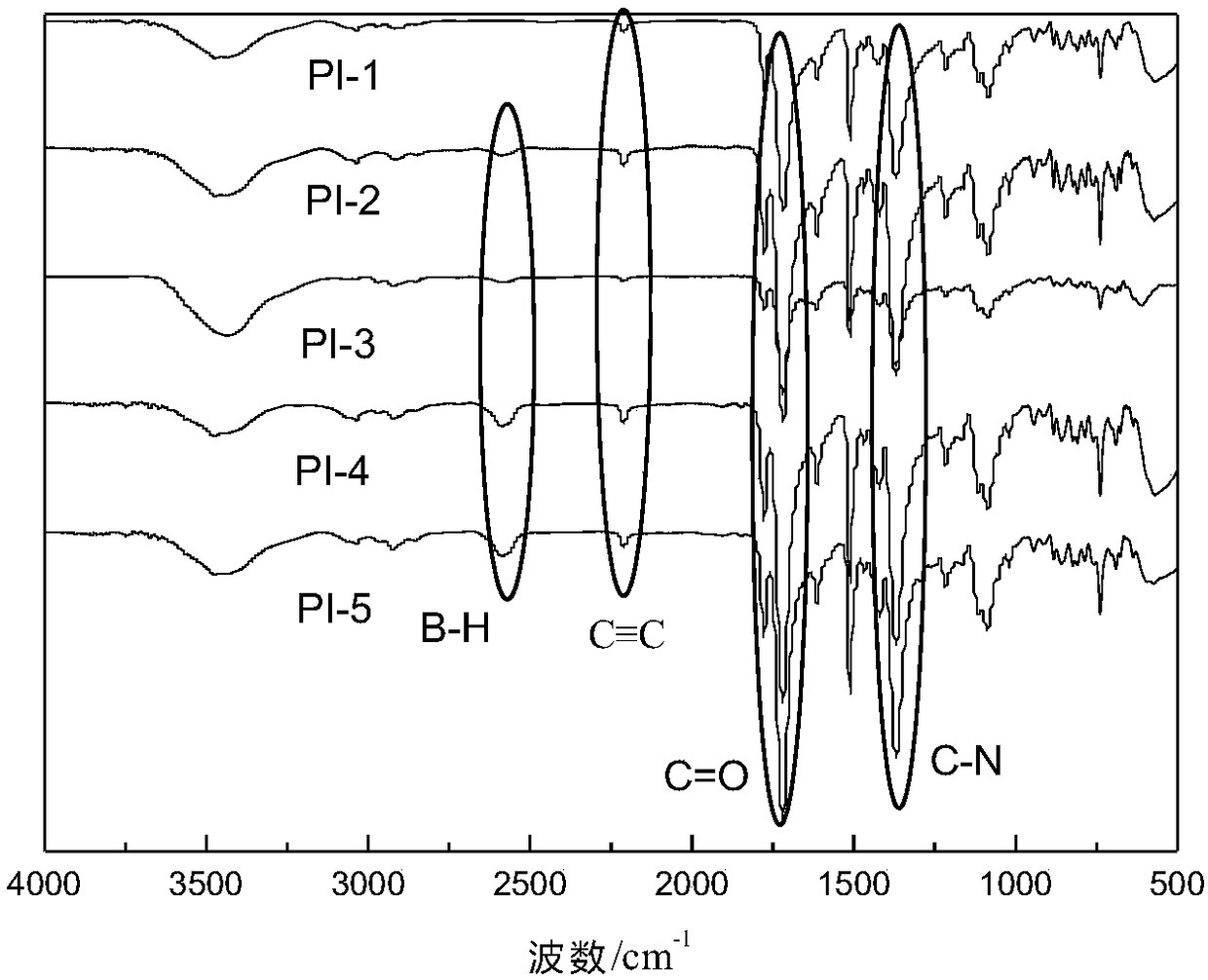

Low viscosity polyimide copolymerized thermosetting resin and preparation method and application thereof

The invention relates to the technical field of high molecular materials, and particularly relates to copolymerized polyimide thermosetting resin comprising a carborane structure and a preparation method and an application thereof. The copolymerized polyimide resin is prepared by thermally cross-linking and solidifying polyimide oligomers represented by a formula I as a raw material. The oligomersintroduce the carborane of a certain composition into a conventional thermosetting polyimide resin system by means of a copolymerization method, so that the conventional thermosetting polyimide resinhas relatively low hot melt viscosity and a higher glass-transition temperature (higher than 500 DEG C) and also has more excellent thermal oxidation resistance and heat stability resistance. Therefore, the thermosetting resin has the extremely low hot melt viscosity. The resin is more easily prepared into a composite material part of a complex structure through a conventional processing technology, can improve the thermal oxidation resistance of the material to a great extent, and has very high application value and innovation to prepare a light high strength high-temperature-resistant easily processed polyimide composite material for a structural material in the aerospace field.

Owner:BEIHANG UNIV

Joining magnesium with reinforced polymer composite fasteners

ActiveUS20120124816A1Superior creep resistance and dimensional stabilityImprove deformationSheet joiningMetal working apparatusPolymer compositesUltimate tensile strength

A method is disclosed for forming corrosion-resistant joints in a plurality of overlapping thin metal sheet workpieces, at least one of which comprises at least 85% by weight of magnesium sheets. The fastener is a fiber-reinforced polymer rod shaped and sized for insertion into a coaxial opening formed in each sheet and subsequently upset on each end to form a head. The workpiece sheets are deformed to form mechanically-interfering features which cooperatively complement the strength of the fastener, under at least some joint loading patterns. The method may be used for other workpiece and fastener compositions.

Owner:GM GLOBAL TECH OPERATIONS LLC

Modified graphene oxide, slurry and composite film, and preparation methods and applications thereof

ActiveCN110818951AImprove imidization rateLow dielectric constantCarbon compoundsSemiconductor/solid-state device manufacturingComposite filmOrganic solvent

The invention provides modified graphene oxide, slurry and a composite film, and preparation methods and applications thereof. The modified graphene oxide is graphene oxide modified by a curing accelerator; the slurry comprises modified graphene oxide, polyimide and / or a polyimide precursor, and an organic solvent; the composite film is formed by solidifying the slurry; the composite film has a high imidization rate, a low dielectric constant and a low curing temperature, so that the composite film can be used as a special functional plastic to be applied to advanced packaging of semiconductors, warping of ultrathin wafers and reconstructed wafers can be well avoided, and damage to heat-labile elements can be effectively avoided.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Smoke-free micro-expansive anhydrous stemming

The invention discloses smoke-free micro-expansive anhydrous stemming, comprising the following components in parts by weight: 10-30 parts of corundum, 15-25 parts of alumina, 10-20 parts of silicon carbide, 10-25 parts of coke, 15-25 parts of clay, 5-10 parts of expanding agent and 15-18 parts of phenolic resin binder. The invention has the advantages that: in the stemming using process, yellow smoke is not generated, pungent smell is less, and the used phenolic resin binder has higher curing temperature and can meet the use requirements of the stemming. Because the expanding agent is added, the stemming can generate micro-expansion at the high temperature so as to fill cracks generated due to inside and outside stresses and modify the high temperature using performance of the stemming.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION

Adhesive with anti-line-explosion function for corrugated paperboard production and preparation method of adhesive

InactiveCN104513636AHigh curing temperatureIncrease moisture contentNon-macromolecular adhesive additivesStarch adhesivesAdhesive cementPaperboard

The invention discloses an adhesive with an anti-line-explosion function for corrugated paperboard production and a preparation method of the adhesive. The adhesive comprises the following components in parts by weight: 1,000 parts of water, 300-400 parts of corn starch, 5-10 parts of sodium hydroxide, 2-4 parts of borax, 7-9 parts of a stabilizer, 2-3 parts of a reinforcing agent and 1-3 parts of sodium chloride. The preparation method adopts a two-step method. Due to the use of the adhesive, the problem of line explosion and breakage of paperboards in a dry climate is effectively solved without adding a spraying system, the production cost of the paperboards is scarcely increased, and the paperboard uniformity is improved.

Owner:XIAN CHANGMING PACKING

Aqueous adhesive for bonding elastomers

ActiveUS20070244240A1Improve adhesionHigh curing temperatureSpecial tyresMixingNatural rubberPolyoxymethylene dimethyl ethers

An adhesive composition containing an aqueous butadiene polymer latex, and an acid scavenging compound, wherein the adhesive comprises essentially no phenolic resin or methylene donor compounds. The aqueous covercoat adhesive is particularly well suited for rubber to metal bonding applications. The adhesive have shown excellent adhesion to a number of compounds but perform best on natural rubber compounds and prefer higher cure temperatures to lower cure temperatures. Further, the formulation has been developed without the need for a methylene donor such as 2-polyoxymethylene dimethylether (gamma POM).

Owner:LORD CORP

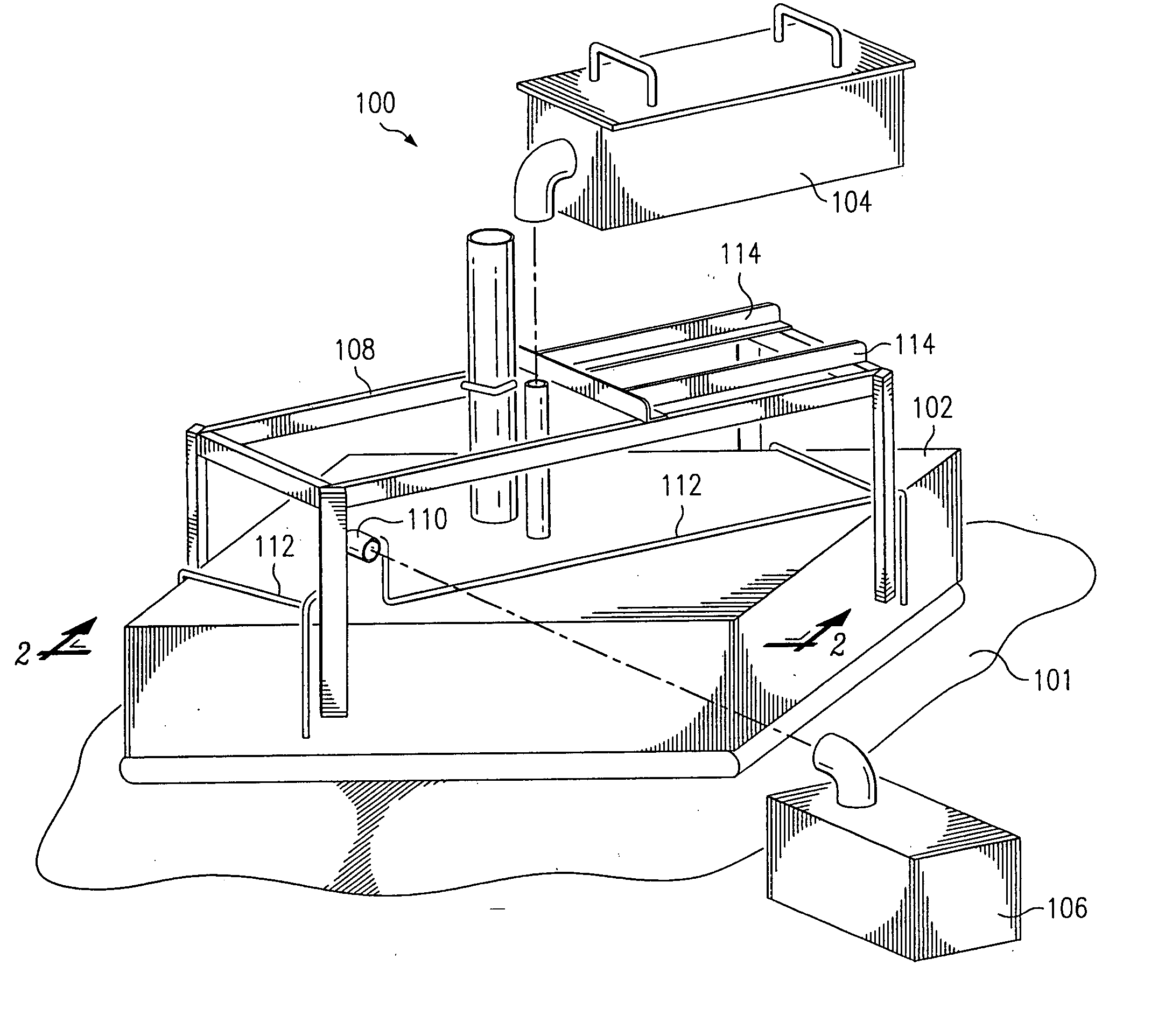

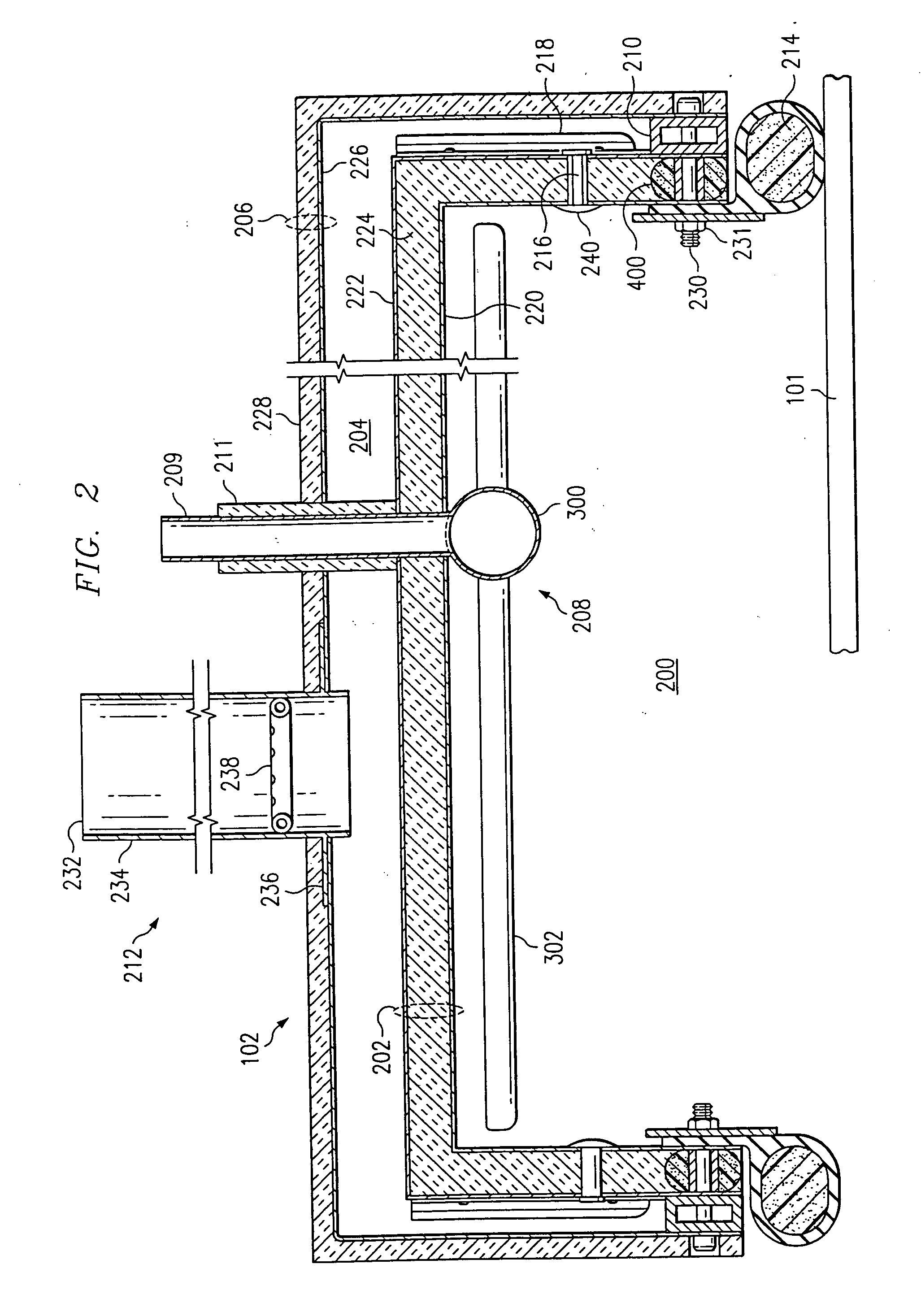

System and method for curing composite material

InactiveUS20050056632A1Inhibit flammabilityHigh curing temperatureMuffle furnacesDrying gas arrangementsCold airChimney

According to one embodiment of the invention, a system for curing a composite material includes an oven having an inner wall defining an inner chamber, an outer wall defining an outer chamber between the inner wall and the outer wall, a hot air distribution manifold disposed within the inner chamber, a cold air distribution manifold disposed within the outer chamber, and an exhaust chimney having a cold air distribution conduit disposed therein coupled to the outer chamber. The system further includes a hot air supply system coupled to the hot air distribution manifold of the oven that is operable to supply hot air to the hot air distribution manifold, a cold air supply system coupled to the cold air distribution manifold and the cold air distribution conduit that is operable to supply cold air to them, and a plurality of hot air exhaust passages formed in the inner wall of the oven. The hot air exhaust passages are adapted to transport hot air within the inner chamber to the outer chamber.

Owner:NORTHROP GRUMMAN SYST CORP

Heat-stable, corrosion-inhibiting polyorganosiloxane resins

InactiveUS20020028296A1Solve the stability is not highHigh curing temperatureOrganic chemistryPretreated surfacesEpoxyPolyol

The present invention provides fora silicone epoxy resin, its preparation, and the use in corrosion-inhibiting, heat-stable coatings. The inventive resins are obtained by a process which comprises reacting: I) siloxanes of the general formula<paragraph lvl="0"><in-line-formula>RaSi(OR')bO(4-a-b) / 2< / in-line-formula>in which OR' is an alkoxy group with primary or secondary aliphatic alcohols, R is identical or different and is an alkyl group or an aromatic group, a is from 0.1 to 2.0, and b is from 0.1 to 1.0, with II) one or more low molecular mass polyhydric alcohols / polyols and III) one or more resins containing epoxide groups, containing at least two 1,2-epoxide groups per molecule, at temperatures in the range from about 100 to about 160° C. with removal of the alcohol HOR' to a degree of conversion of from 20 to 80% and terminating the reaction by cooling to a temperature < about 100° C.

Owner:EVONIK DEGUSSA GMBH

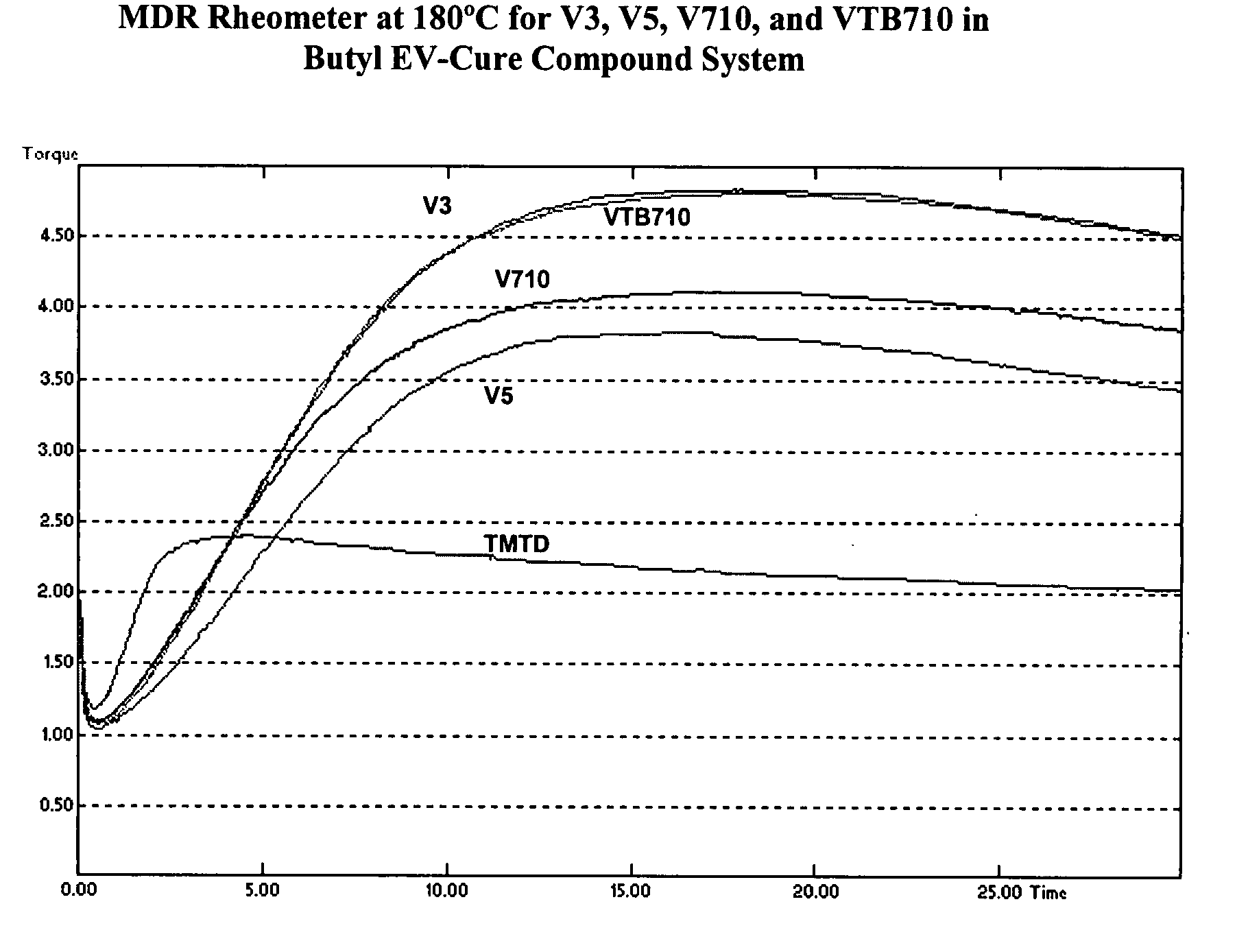

Cure systems for rubber compounds

The invention relates to the use of alkylphenol disulfide accelerators in butyl and halobutyl compounds.

Owner:EXXONMOBIL CHEM PAT INC

Single component low-temperature polyurethane foaming adhesive and preparation method thereof

ActiveCN104312521ALong dry timeHigh curing temperaturePolyureas/polyurethane adhesivesPolyesterAdhesive

The invention discloses a single component low-temperature polyurethane foaming adhesive which is characterized by comprising the following components in parts by weight: 150-200 parts of polypropylene glycol adipate or polybutylene adipate, 5-10 parts of trimethylolpropane, 10-30 parts of polyester 330N, 0.1-0.3 part of a catalyst, 80-150 parts of a black material and 200-340 parts of a solvent. The single component low-temperature polyurethane foaming adhesive disclosed by the invention is relatively long in surface dry time, relatively low in curing temperature and relatively short in real-dry time, so that the application range of the foaming adhesive is widened, the resource is saved, and the working efficiency of an operator is improved; the single component low-temperature polyurethane foaming adhesive disclosed by the invention is simple in preparation method and convenient to operate, so that the production cost of the single component low-temperature polyurethane foaming adhesive is lowered, and the popularization and the application are facilitated.

Owner:湖北和乐门业有限公司

Composition of silicon-containing copolymer, solvent-soluble crosslinked silicon-containing copolymer, and cured articles obtained therefrom

InactiveUS7371433B2Maintain good propertiesIncrease resistanceLayered productsAlternating current plasma display panelsCross-linkSolvent

A composition comprising a silicon-containing copolymer having a number-average molecular weight of 500 to 1,000,000, having SiO bond in the polymer and containing at least the structural units represented by the following general formulae (I) and (II) and, if necessary, one or more of the structural units represented by the following general formulae (III) to (VII) and a cross-linking agent is reacted at −20 to 100° C. for 1 to 3 hours. The resultant reaction composition is coated on a substrate and cured by heating to a temperature of 150° C. or above, for example, 250° C. to obtain a cured product of a silicon-containing copolymer which has a high heat resistance, a high light transmission, a low relative dielectric constant and a high chemical resistance and which has a strong mechanical strength and a good flexibility.wherein R1 to R6, R8 and R9 each independently represents an alkyl group, an alkenyl group, a cycloalkyl group, an aryl group, an aralkyl group, an alkylamino group, an alkylsilyl group or an alkoxy group, R7 represents a divalent group, R10 represents a divalent aromatic group, and A represents NH or O.

Owner:MERCK PATENT GMBH

Process for producing an absorber material

InactiveUS6426380B1Reduce amountHigh curing temperatureSemiconductor/solid-state device detailsConductive materialEngineeringSemiconductor

A method is described for producing an improved addition-crosslinked silicone rubber which is used as a damping material in hermetically sealed housings having a semiconductor.

Owner:ROBERT BOSCH GMBH

Alloy for casting space shuttle liquid hydrogen fuel tank

InactiveCN107400812AImprove purityGuaranteed low temperature resistanceFuel systems for specific fuelsTransportation hydrogen technologyFuel tankSolvent free

The invention discloses alloy for casting a space shuttle liquid hydrogen fuel tank. The alloy is prepared from the following raw materials in parts by weight: 85-90 parts of Al, 2.0-3.0 parts of Li, 2.0-3.0 parts of Cu, 0.1-0.25 parts of Zr and 0.1-0.2 parts of Sr. The alloy has the advantages as follows: with adoption of electron beams for smelting the alloy, harmful impurity elements such as O, N, S and the like can be greatly reduced in the alloy smelting process, purity and content of Al, Ni and Cu in the alloy are increased, low temperature resistance of the alloy is guaranteed, and as the temperature decreases, strength, ductility and toughness of the alloy are greatly improved; the aluminum ingot with the grade of Al99.85 is used as a raw material, purity of Al in the alloy is further improved; an ultra-low-temperature-resistant pressure-sensitive adhesive is solvent-free, the curing temperature is low, curing time is short, the ultra-low-temperature-resistant pressure-sensitive adhesive is used for bonding flexible foam plastic and a pipe rapidly, the on-site construction process is good, the ultra-low-temperature-resistant pressure-sensitive adhesive still realizes a better adhesion effect under the condition of ultra-low temperature; and transmission of low temperature can be better insulated by the soft foam plastic layer.

Owner:NANJING LVZHICHENG PATENT TECH DEV CO LTD

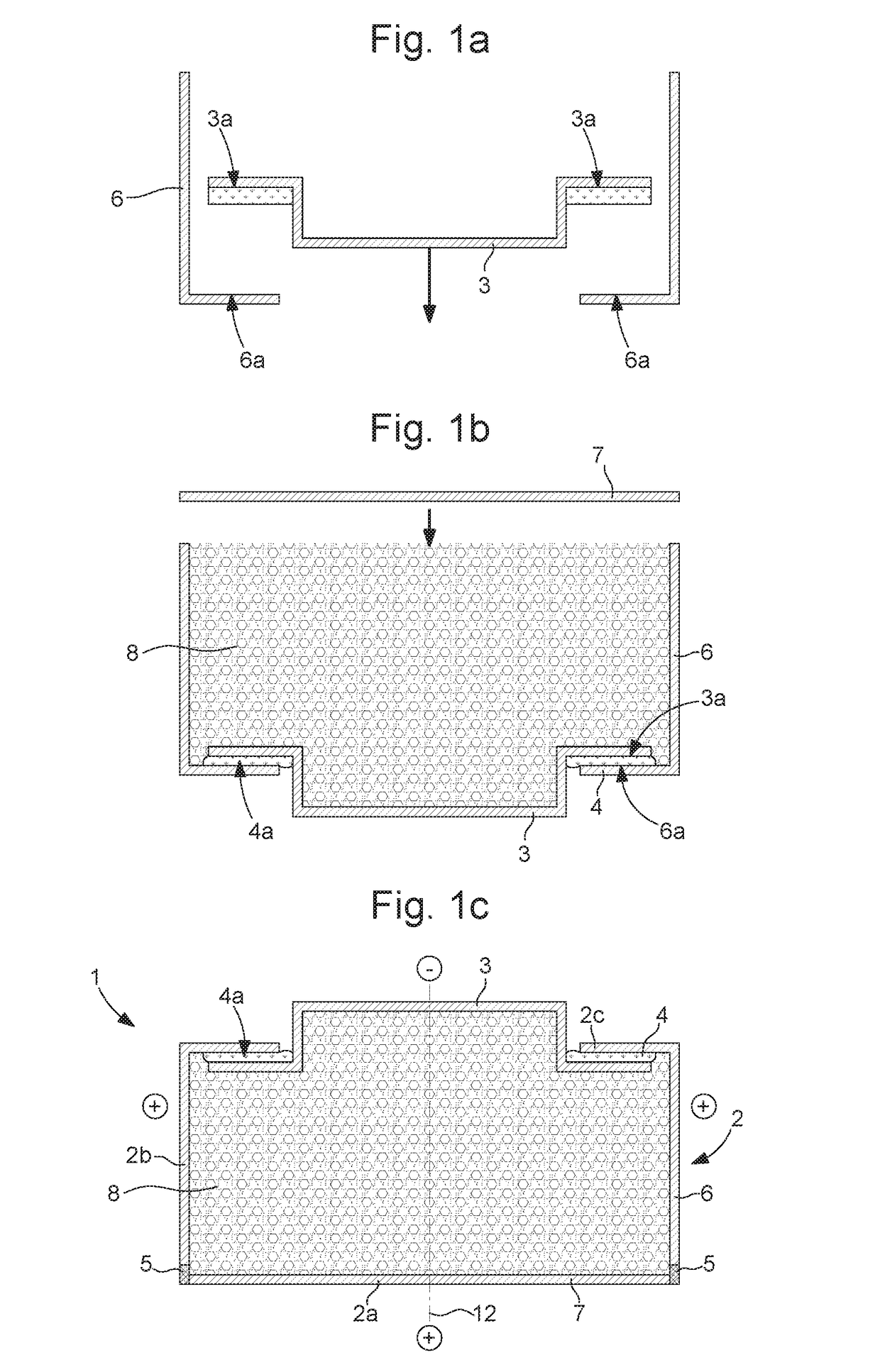

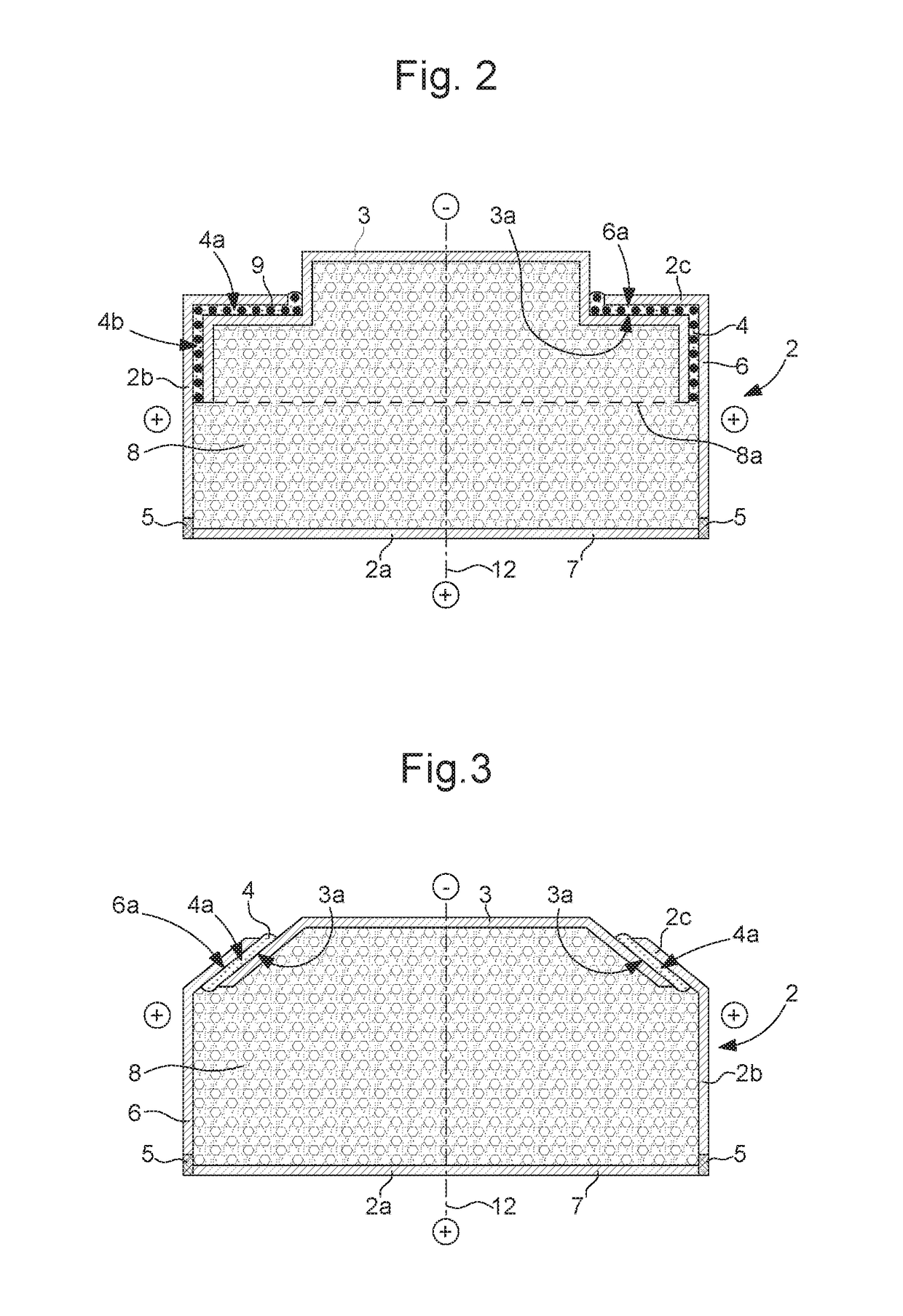

Battery, particularly a button cell, and method for manufacture of such a battery

ActiveUS20180241013A1Without riskAvoid pollutionFinal product manufactureJackets/cases materialsButton batteryBiomedical engineering

The present invention relates to a method for manufacturing a battery comprising a casing provided with a cup and a closure part for said cup, the method comprising the successive steps consisting in:providing at least three parts with a first part defining one pole, and a second part and a third part defining the other pole and intended to form together the cup, the first and second parts respectively comprising a first surface and a second surface (6a) of matching shape, at least one adhesive portion of each of said surfaces extending in a geometric surface non-parallel to the general axis of the battery;bonding the aforementioned first and second surfaces to provide a structure with an adhesive joint between the first and second parts;welding the third part to the second part;the adhesive joint being arranged against an inner face of the cup, the aforementioned adhesive portion of the second part forming a stop, along the general axis, for the first part, which is located inside the cup.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com