Thermosetting resin able to realize high temperature heating and curing in high frequency magnetic field and preparation method thereof

A high-frequency magnetic field and thermosetting technology, which is applied in the field of thermosetting resin systems, can solve the problems of uneven material properties, difficult processing and molding, and low curing efficiency, and achieve the effects of short curing time, controllability, and elimination of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

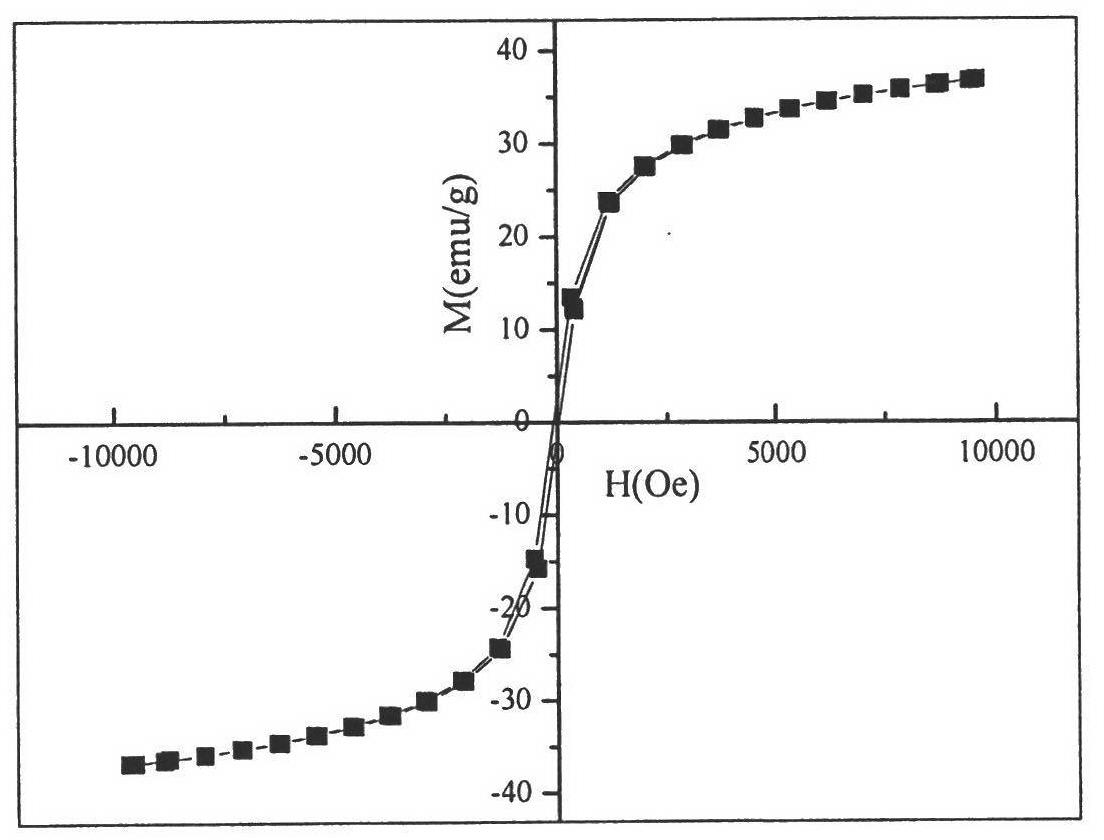

Image

Examples

Embodiment 1100

[0033] Example 1100 parts by weight of thermosetting epoxy resin E-51 and 5 parts by weight of 2-phenylimidazole add 1 part of Fe with a magnetic content of 71.40%. 3 o 4 magnetic nanospheres.

[0034] 11.6584g of epoxy resin E-51 is added with Fe with a magnetic content of 71.40% 3 o 4 1.0336g of magnetic particles and 0.5706g of 2-phenylimidazole are mixed evenly and heated in an alternating magnetic field. Under the experimental conditions of SPG-06A series high-frequency induction heating equipment I=6.6A, f=150KHz, relying on magnetic microspheres The resulting thermally cured resin was used to measure the internal temperature of the resin system over time with a kerosene thermometer.

[0035] image 3 It is the curing time chart of the thermosetting resin system of this embodiment.

Embodiment 2100

[0036] Example 2 Add 2 parts of Fe with a magnetic content of 71.40% to 100 parts by weight of epoxy resin E-51 and 5 parts by weight of 2-phenylimidazole 3 o 4 Special magnetic particles.

[0037] 11.0838g of epoxy resin E-51 was added Fe with a magnetic content of 71.40% 3 o 4 1.4478g of magnetic particles and 0.5610g of 2-methylimidazole are mixed evenly and heated in an alternating magnetic field. Under the experimental conditions of SPG-06A series high-frequency induction heating equipment I=6.6A, f=150KHz, relying on magnetic microspheres The resulting heat-cured epoxy resin was tested with a kerosene thermometer to measure the internal temperature of the resin as a function of time.

[0038] Figure 4 It is the curing time chart of the thermosetting resin system of this embodiment.

Embodiment 3100

[0039] Example 3 Add 3 parts of Fe with a magnetic content of 71.40% to 100 parts by weight of epoxy resin E-51 and 5 parts by weight of 2-phenylimidazole3 o 4 Special magnetic particles.

[0040] 9.2762g of epoxy resin E-51 is added with Fe with magnetic content of 71.40% 3 o 4 Magnetic particles (the active ingredient of magnetic particles accounts for 10%) and 0.4638g of 2-phenylimidazole are mixed evenly and then heated in an alternating magnetic field. In the SPG-06A series of high-frequency induction heating equipment I=6.6A, f=150KHz Under the experimental conditions, the heat-cured resin produced by magnetic microspheres was used to test the internal temperature of the resin over time with a kerosene thermometer.

[0041] Figure 5 It is the curing time chart of the thermosetting resin system of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com