Low viscosity polyimide copolymerized thermosetting resin and preparation method and application thereof

A polyimide and oligomer technology, which is applied in the field of low-viscosity copolymerization thermosetting polyimide materials and its preparation, can solve the problems that the processing performance has not been improved, and it is difficult to improve heat resistance, so as to reduce viscosity and improve Improvement of fluidity and heat resistance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation of embodiment 1 polyimide oligomer PI-2

[0054] (1) Take the raw material ratio a:b:c:d=0.8:3.2:3:2, the specific operation is: add c component 6.9g, d component 3.88g and 50ml solvent absolute ethanol in the three-necked flask , the oil bath was refluxed at 70°C for 3h, the reaction solution changed from turbid to clear, and was left to cool to room temperature.

[0055] (2) 0.55 g of component a and 5.9 g of component b were sequentially added to the above reaction solution, and stirred and reacted at 25° C. for 12 hours to obtain a yellow clear polyamic acid solution (solid content 30±5%). The obtained solution was placed in a vacuum oven to remove the solvent, then placed in a tube furnace at 260° C. for 1.5 h, cooled naturally, and ground to obtain a yellow polyimide prepolymer powder. This prepolymer was named "prepolymer PI-2".

[0056] According to the method similar to Example 1, adjust the dosages of the four components respectively as shown...

Embodiment 2

[0059] The preparation of embodiment 2 thermosetting polyimide materials

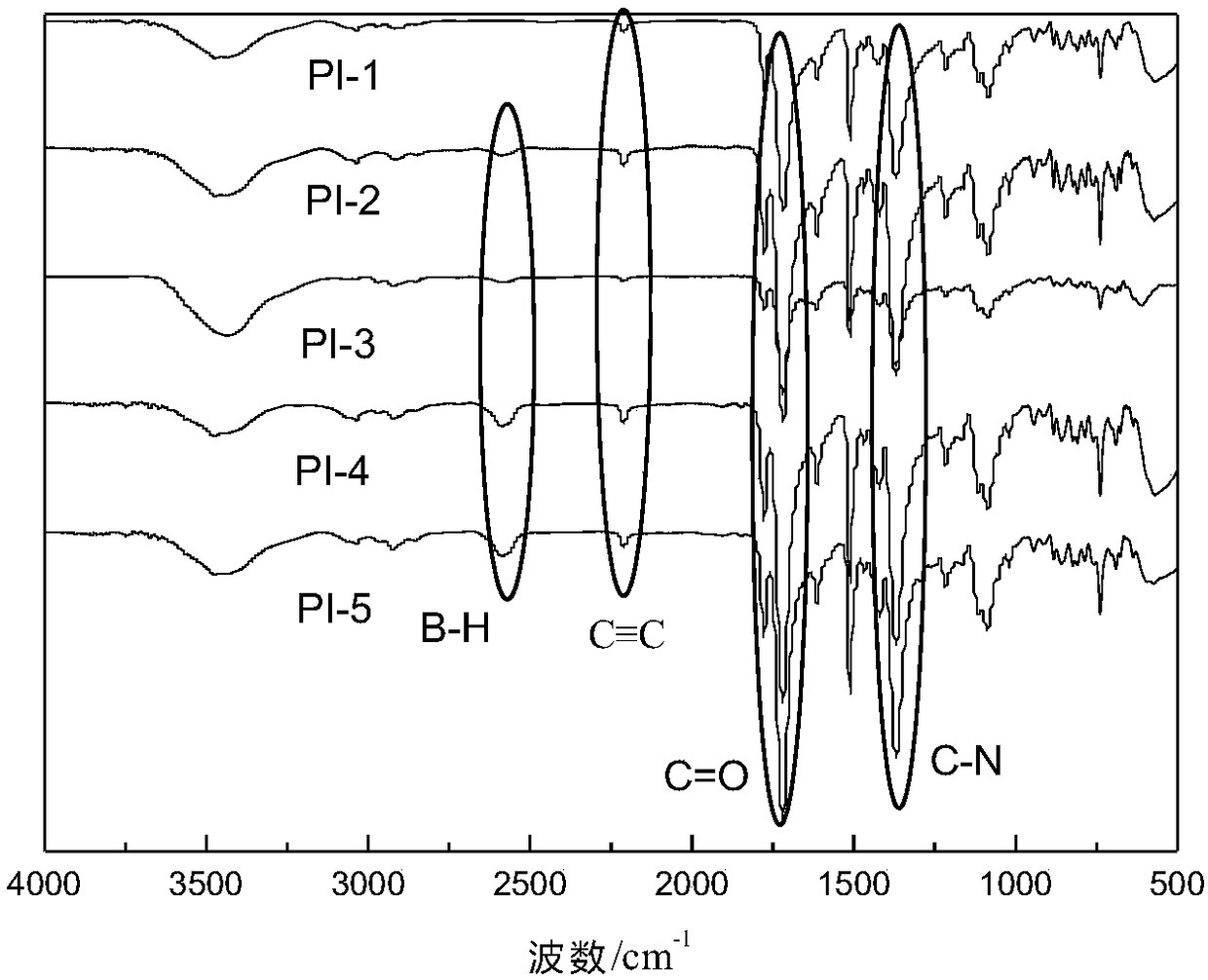

[0060] The prepolymer obtained in Example 1 was cured in a vacuum tube furnace according to the following procedures: within 60 minutes, the temperature was raised from room temperature to 320 °C and kept for 10 minutes; within 20 minutes, the temperature was raised to 370 °C and kept for 2 hours, and naturally cooled to obtain the corresponding polyamide Imines PI-2, PI-3, PI-4 and PI-5.

Embodiment 3

[0061] The preparation of embodiment 3 polyimide composite material

[0062] (1) Preparation of carbon fiber prepreg: the polyamic acid ethanol solution (for the polyamic acid mentioned in Example 1) with a solid content of 30% is evenly coated on the T700 carbon fiber unidirectional woven cloth, and placed in a blast Stand in an oven at 40°C for 6 hours to evaporate most of the solvent, and you get it;

[0063] (2) Preparation of composite materials: Cut the prepreg into 7 layers of sheets with a size of 100mm×100mm and spread them in the mold, and then place the mold on a hot press for thermal imidization of the prepolymer and resin curing process, that is Obtain a T700 carbon fiber / polyimide composite laminate with a thickness of 2mm. See the appendix for the specific heating program Figure 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com