Novel high-strength polyurethane waterproofing paint and preparation method thereof

A technology of polyurethane waterproofing and coating, which is applied in the direction of coating, etc., which can solve the problems of inability to prolong the operable time of coating construction, fail to meet the construction requirements, and poor operable time, so as to prolong the operable time of construction, low toxicity, and low residual TDI Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

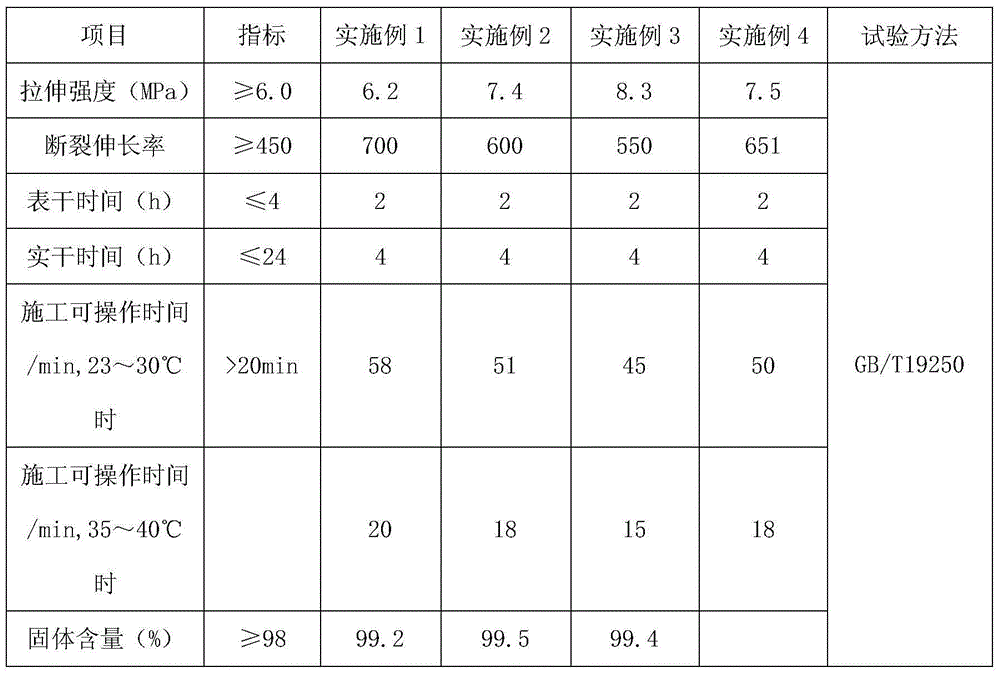

Examples

Embodiment 1

[0025] Preparation of component A: In a 1000mL four-necked bottle equipped with a stirrer, condenser, thermometer, and thermocouple, first add 200 parts of polyether diol and 20 parts of polyether triol, and slowly Raise the temperature to 120°C, and evacuate it to below -0.098Mpa, keep it for 2h, and lower the temperature; then add 60 parts of toluene-2,4-diisocyanate (TDI) at 80°C, control the temperature at 70-90°C, and keep stirring and react for 2.5 hours; then add 20 parts of diphenylmethane diisocyanate (MDI), the temperature is also controlled at 80°C, and react for 2.5 hours. The material is filled with nitrogen to protect the A component.

[0026] Preparation of component B: Add 80 parts of chlorinated paraffin, 30 parts of dibutyl phthalate, and 60 parts of polyether triol into a 1000 mL four-necked bottle equipped with a stirrer, reflux condenser, thermometer and thermocouple Inside, after slowly raising the temperature to 100°C, slowly add 40 parts of 3,3-dichlor...

Embodiment 2

[0029] Preparation of component A: In a 1000mL four-necked bottle equipped with a stirrer, condenser, thermometer, and thermocouple, first add 160 parts of polyether diol and 60 parts of polyether triol, and slowly Raise the temperature to 100°C, and evacuate it below -0.098Mpa, keep it for 2h, and then lower the temperature; then add 40 parts of toluene-2,4-diisocyanate (TDI) at 100°C, and control the temperature at 90°C. React for 3 hours; then add 50 parts of diphenylmethane diisocyanate (MDI), the temperature is also controlled at 90 ° C, and react for 3 hours. The material is filled with nitrogen to protect the A component.

[0030] Preparation of component B: add 50 parts of aromatic oil, 60 parts of chlorinated paraffin, 50 parts of polyether trihydric alcohol, and 10 parts of polyether diol In the four-necked bottle, after slowly raising the temperature to 80°C, slowly add 50 parts of 3,3-dichloro-4,4-diphenylmethanediamine (MOCA), 5 parts of 1,4-butanediamine under h...

Embodiment 3

[0033] Preparation of component A: In a 1000mL four-necked bottle equipped with a stirrer, condenser, thermometer, and thermocouple, first add 100 parts of polyether diol and 120 parts of polyether triol, and slowly Raise the temperature to 130°C, and evacuate to below -0.098Mpa, keep it for 2 hours, and then lower the temperature; then add 20 parts of toluene-2,4-diisocyanate (TDI) at 60°C, and control the temperature at 70°C. React for 2 hours; then add 60 parts of diphenylmethane diisocyanate (MDI), the temperature is also controlled at 70 ° C, react for 2 hours, after the reaction is over, cool down; finally add 50 parts of chlorinated paraffin, stir evenly, discharge, and fill with nitrogen Protection is the A component.

[0034] Preparation of component B: Add 80 parts of aromatic oil, 30 parts of chlorinated paraffin, and 60 parts of polyether trihydric alcohol into a 1000 mL four-necked bottle equipped with a stirrer, reflux condenser, thermometer and thermocouple, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com