Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

214results about How to "Excellent water and oil repellency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing short-chain branch water and oil repellent finishing agent containing modified nano-oxide and fluorine

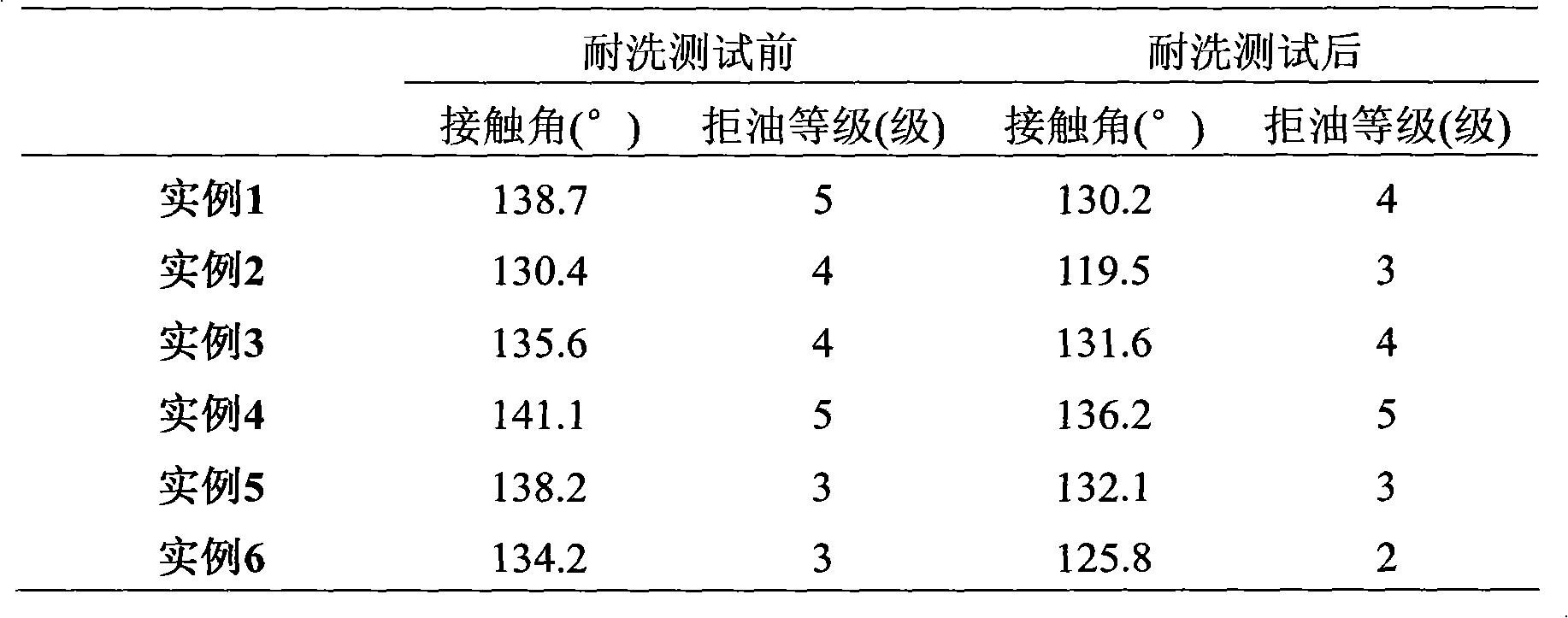

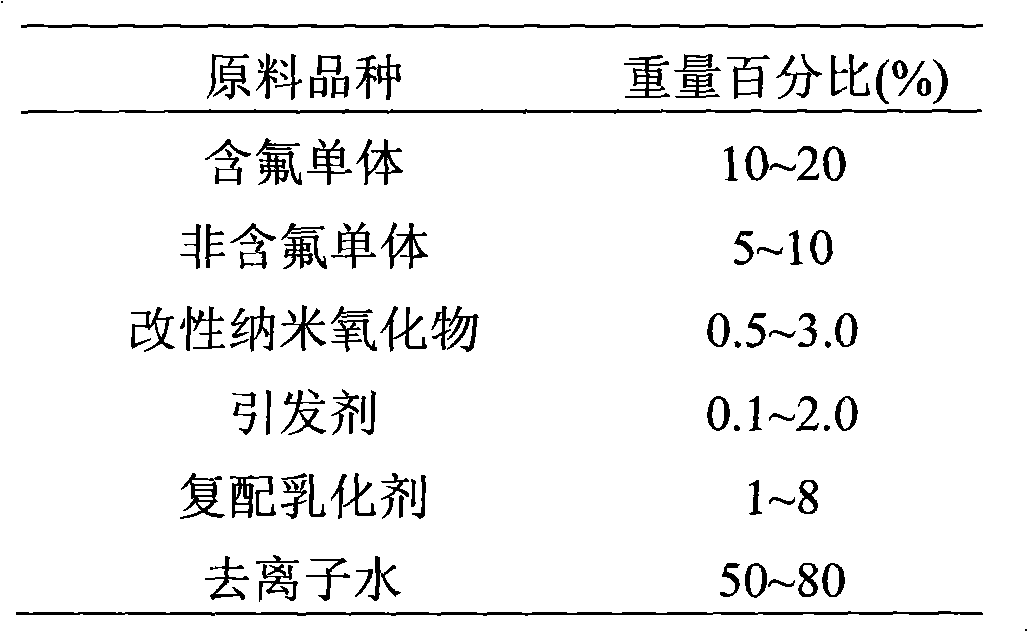

InactiveCN102041681AImprove securityFeel goodFibre treatmentFunctional monomerEmulsion polymerization

The invention relates to a latex type short-chain branch perfluoroalkyl water and oil repellent finishing agent and a preparation method thereof, belonging to the field of fine chemical industry. The latex type short-chain branch perfluoroalkyl water and oil repellent finishing agent is prepared by the following steps of: pre-emulsifying short-chain branch perfluoroalkyl acrylate monomer (10-20%), fluorine-free functional monomer (5.0-10%), modified nano-oxide (0.5-3.0%), initiator (0.1-2.0%), compound emulsifier (1.0-8.0%) and deioned water (60-80%); and finally heating for emulsion polymerization. The latex type short-chain branch perfluoroalkyl water and oil repellent finishing agent can be used for water and oil repellent finishing of animal and plant natural fiber fabric and chemical fiber fabric and has excellent water and oil repellent performance; fabric finished with the finishing agent has good handfeel and excellent endurance performance. Compared with the traditional fluorine-containing finishing agent , the finishing agent disclosed in the invention does not contain components harmful to human bodies and well accords with environmental protection requirement.

Owner:JIANGNAN UNIV

Preparation method of high-performance fingerprint-resistant agent

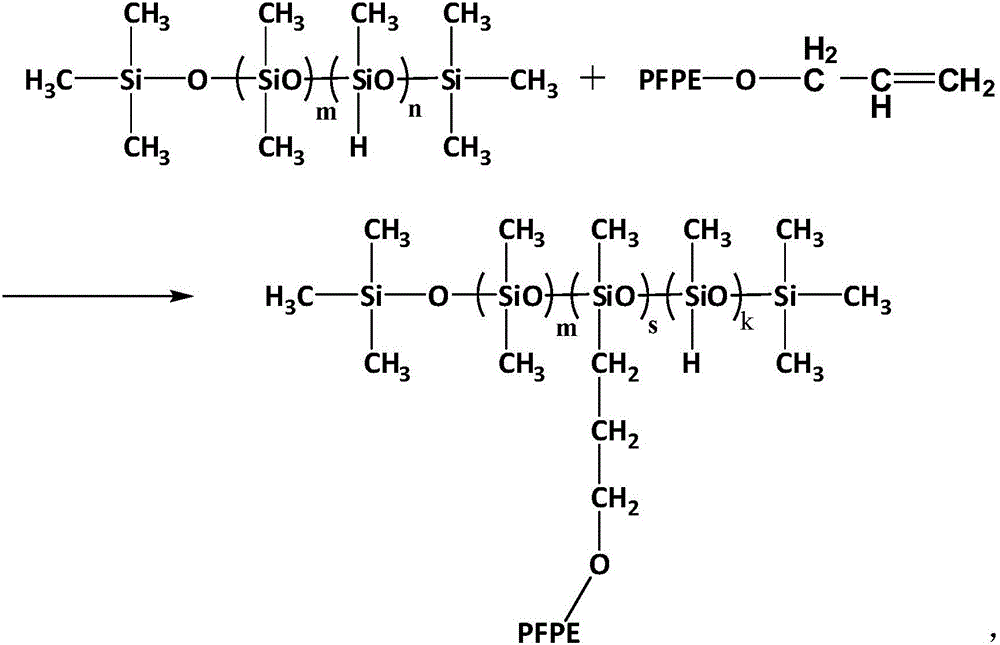

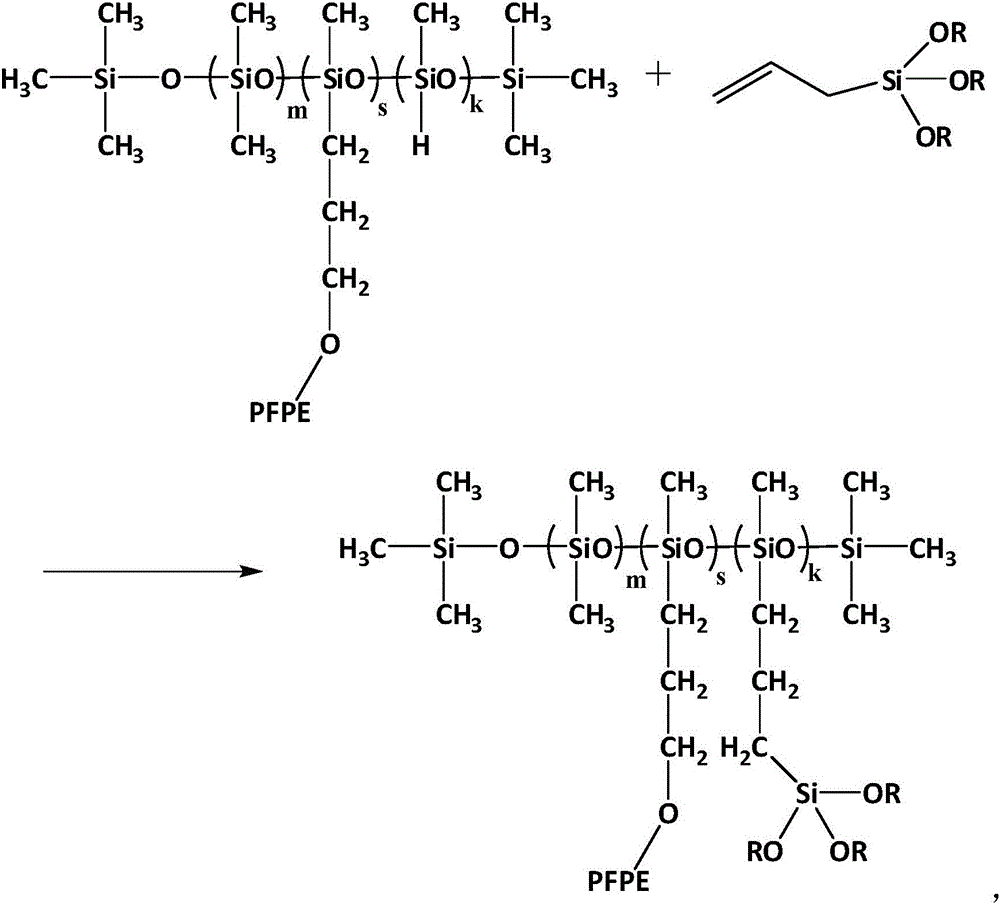

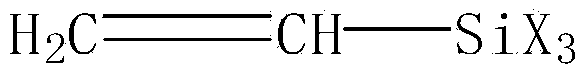

ActiveCN106085227AHigh hardnessImprove wear resistanceAntifouling/underwater paintsPaints with biocidesHydrogenPerfluoropolyether

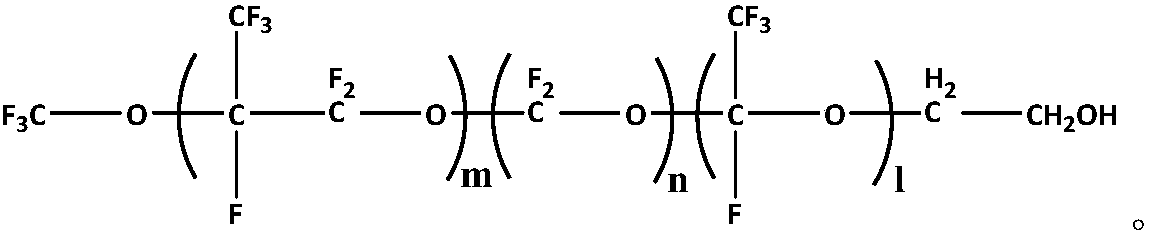

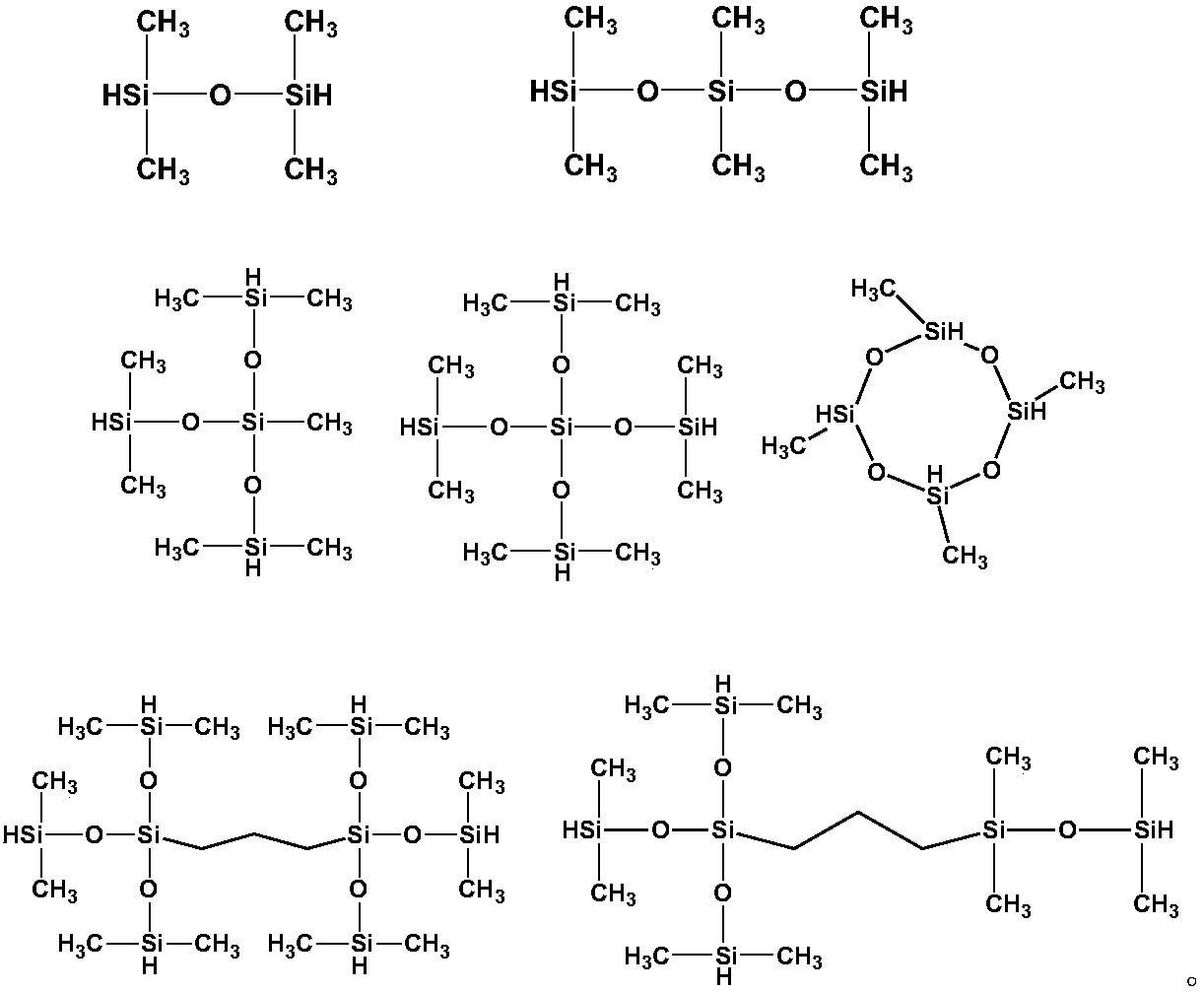

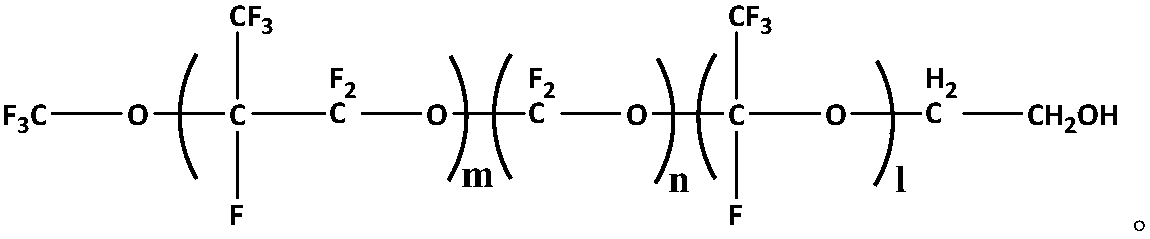

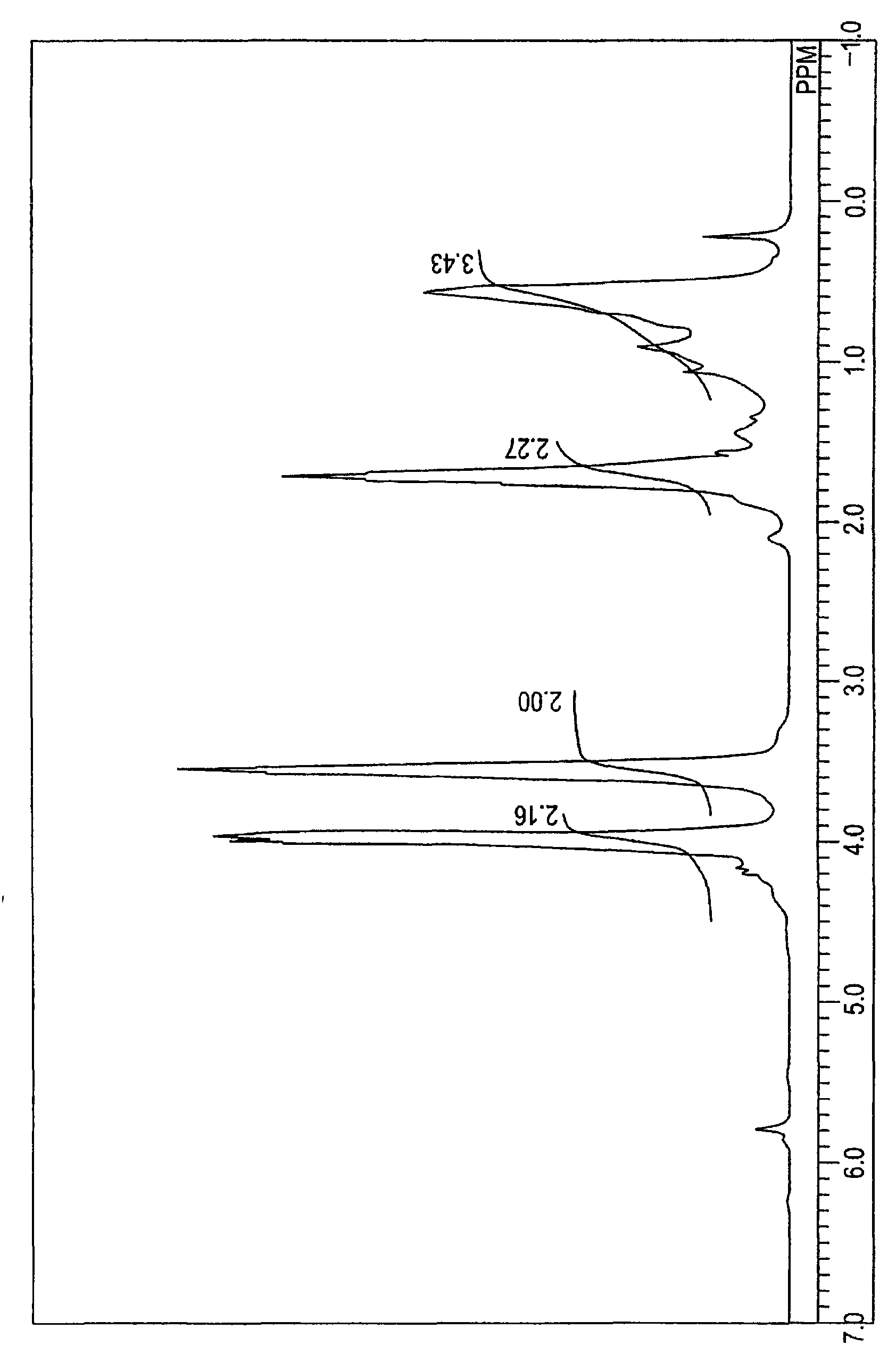

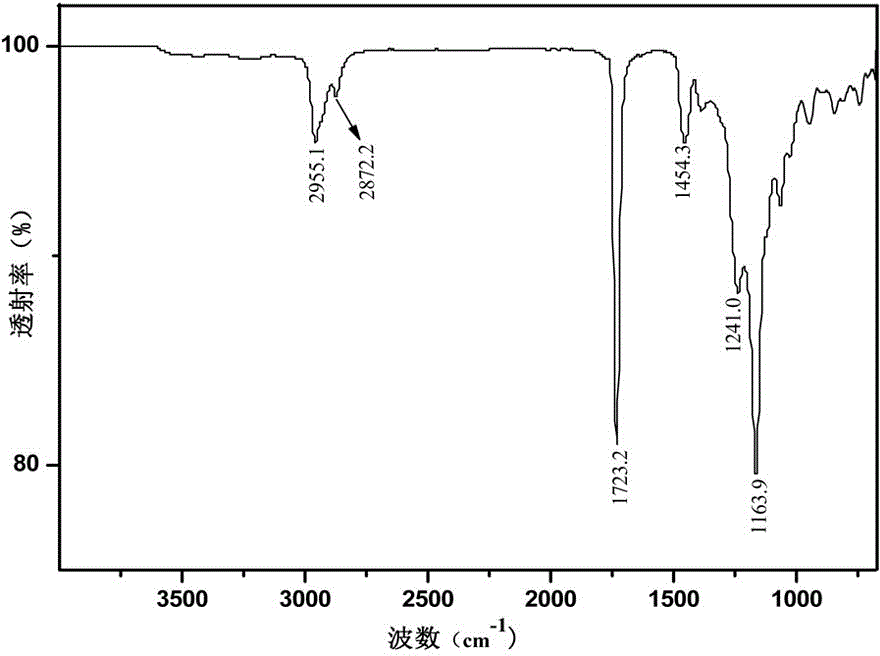

The invention discloses a preparation method of a high-performance fingerprint-resistant agent. The preparation method includes the following steps that hydroxyl-terminated perfluorinated polyether and allyl bromide react to obtain allyl-terminated perfluorinated polyether; allyl-terminated perfluorinated polyether and hydrogen-containing silicone oil are subjected to a layer adding reaction through silicone hydrogen, and perfluorinated polyether-hydrogen-containing silicone oil (unreacted hydrogen still exists in silicone oil) is obtained; the obtained product and allyl siloxane continue to be subjected to a silicone hydrogen water adding reaction to obtain a needed target product pectinate perfluorinated polyether-siloxane; then pectinate perfluorinated polyether-siloxane is prepared into the fingerprint-resistant agent. The prepared fingerprint-resistant agent has the advantages of being good in hydrophobic and oleophobic performance, excellent in anti-fouling property and good in fingerprint easy-to-move property, a fingerprint-resistant coating and a glass base material are high in bonding force, the product is good in abrasion resistance, and compared with the prior art, the durability and abrasion resistance of the fingerprint-resistant agent are greatly improved.

Owner:QUZHOU FLUORIDE & SILICON RES INST

Preparation of water dispersed fine emulsion of fluorine acrelate copolymer for anti-oil and anti-water agent

Aqueous dispersible fine emulsion of complete acrylic ester copolymer as oil- and water-resisting agent is prepared by: preparing complete alkyl copolymerized monomer fine emulsion dispersed uniformly, and then polymerizing without organic solvent and emulsifying to aid it. It is stable for restore or dilution, and can be used for substrate materials of fabrics, leathers or paper as waterproof and oil-proof finishing agent.

Owner:ZHEJIANG UNIV

Water-repellent/oil-repellent composition

InactiveCN101006149AExcellent water and oil repellencyImprove stabilityOther chemical processesFibre treatmentOrganic solventWater soluble

Disclosed is an aqueous water-repellent / oil-repellent composition containing the following components (A), (B) and (C). Fluorine-containing copolymer (A): a copolymer containing a polymerizable monomer (a1) having a perfluoroalkyl group with 1-6 carbon atoms or a perfluoroalkenyl group wherein the amount of (a1) is not less than 20% by weight relative to the copolymer. Surfactant (B): a surfactant essentially containing a sorbitan ester or an alkylene oxide addition product thereof. Aqueous medium (C): a medium substantially containing water only or water and a water-soluble organic solvent.

Owner:DAIKIN IND LTD

Production technology of double-faced cotton fabric

ActiveCN101713153AExcellent water and oil repellencyDoes not affect the positive effectDyeing processVegetal fibresSoftened waterAdhesive

The invention relates to a production technology of a double-faced cotton fabric. The production technology comprises the following steps: 1. drying the dyed or whitened double-faced cotton fabric to prepare grey cloth for standby; 2. mixing 10wt% of adhesive WSF, 3wt% of water and oil repellent AFF300 %, 1.76wt% of thickener FN and 85.24wt% of softened water evenly to prepare printing paste; 3. coating the printing paste on one side of the grey cloth, sending to a printing machine to perform coating layer printing treatment, sending to a dryer for drying; 4. sending the dried grey cloth to a tentering and forming machine for curing treatment; and 5. adding 30g of hydrophilc agent RWS per 1L of water in the groove of the stentering forming machine, after the curing treatment, and sending the grey cloth to the tentering and forming machine again to perform tentering and forming and hydrophilic finishing treatments. The production technology of the invention can be used to ensure that the front of the fabric has interface structure with complimentary geometry and shows good water repellent and oil repellent properties; and the back of the fabric has hydrophilic and moisture transmission performances under the premise of not affecting the properties of the front of the fabric.

Owner:QINGDAO JIFA GROUP

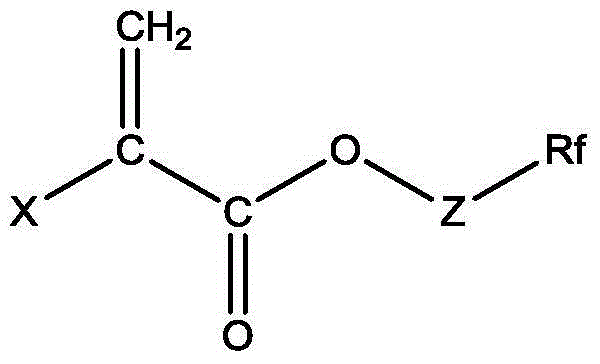

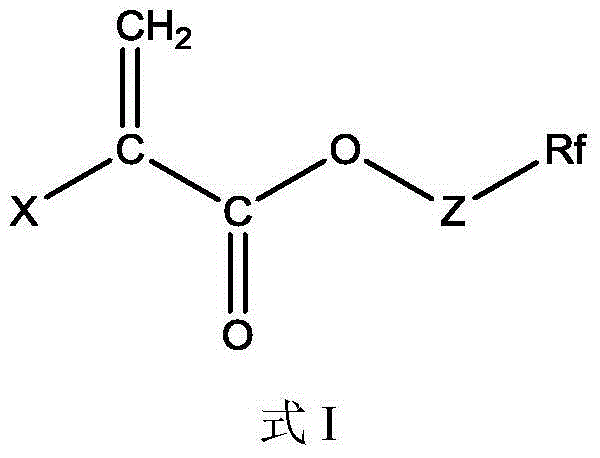

Method for preparing fluorine-containing acrylate

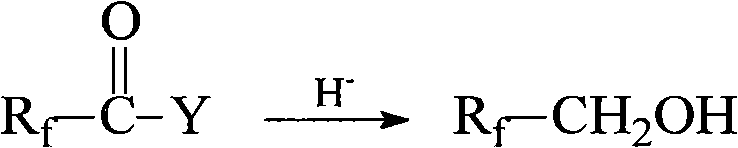

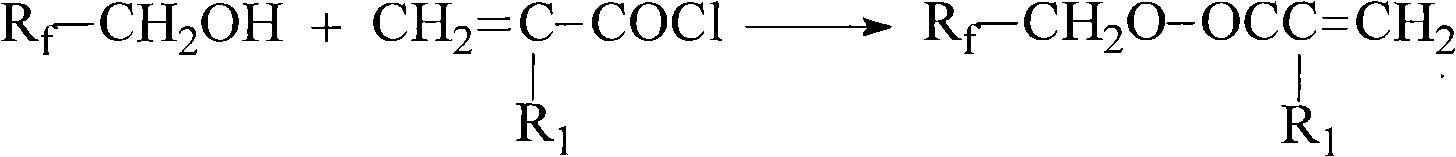

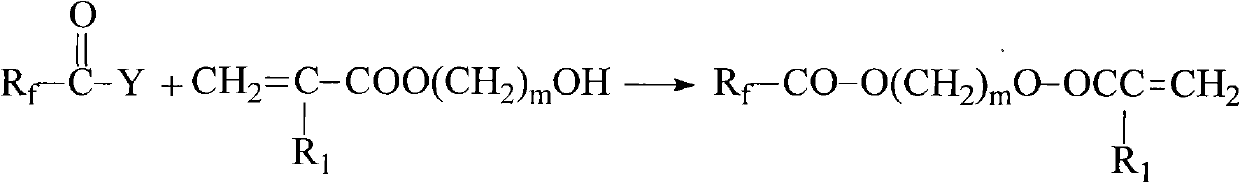

ActiveCN102010334ANo destructionExcellent water and oil repellencyPreparation from carboxylic acid halidesVegetal fibresHuman healthBioaccumulation

The invention belongs to the technical field of textile fabric finishing agents, and relates to a method for preparing an intermediate fluorine-containing acrylate monomer of a water-proof and oil-proof organic fluorine fabric finishing agent. The method is characterized by comprising the following steps of: (1) in the presence of a reducing agent, preparing polyfluoroalcohol by using a perfluoroalkylacyl compound as a raw material; and (2) slowly dripping (methyl) acryloyl chloride to prepare fluorine-containing acrylate in the presence of a catalyst by using the polyfluoroalcohol prepared in the step (1) and using phenothiazine as a polymerization inhibitor. The number of long-chain perfluoroalkyl carbon atoms in the prepared fluorine-containing acrylate is less than 8, and the fluorine-containing acrylate can be degraded and has no biological accumulation. The fluorine-containing acrylate has no hidden dangers of long-chain perfluoroalkyl to destroy the environment and harm human health. Fluorine-containing acrylate copolymer emulsion prepared by using the prepared fluorine-containing acrylate monomer is used as a water-proof and oil-proof finishing agent for textiles, and the finished textiles have excellent water-proof and oil-proof performance.

Owner:江苏梅兰化工有限公司

Preparation method of ultraviolet-curable water-borne fluorinated paint with low surface energy

InactiveCN102659995ALower surface energyLow water and oil repellencyPolyurea/polyurethane coatingsAcid valueBottle

The invention discloses a preparation method of ultraviolet-curable water-borne fluorinated paint with low surface energy. The preparation method comprises the following steps: (1), adding a (methyl) acrylate monomer, a monohydroxy (methyl) acrylate monomer, a fluorinated acrylate monomer and part of an initiator into a three-opening bottle, reacting for 3-5 hours at a temperature of 70-90 DEG C, supplementing the initiator, and further reacting for 1.5-3 hours; (2), adding polyisocyanate into another three-opening bottle, and reacting for 4-5 hours at a temperature of 30-50 DEG C; (3), dripping a reaction product in the step (2) into a reaction product in the step (1), and reacting for 10-12 hours; and (4), testing a reaction product in the step (3), determining the acid value, adding a salt-forming agent and deionized water in a certain ratio, shearing and removing the solvent. The ultraviolet-curable water-borne fluorinated paint combines performances of polyurethane and acrylate paint, is free of solvent emission, meets environment-friendly requirements, and is simple and feasible to spray and short in film-forming and curing time.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for preparing fluorine-containing acrylate copolymer textile finishing agent

ActiveCN102002129ANo serious problem of damageExcellent water and oil repellencyFibre treatmentHuman healthNitrogen gas

The invention belongs to the technical field of fabric finishing agents, and particularly relates to a method for preparing a fluorine-containing acrylate copolymer textile finishing agent, which is characterized by sequentially comprising the following steps of: 1, preparing fluorine-containing acrylate: slowly dripping a perfluor alkyl acyl compound by using (methyl) acrylic hydroxy alkyl ester as a raw material and phenothiazine as a polymerization inhibitor in the presence of a catalyst; and 2, preparing a fluorine-containing acrylate copolymer: pre-emulsifying polymer monomer by adding an emulsifying agent, and dripping an initiator into pre-emulsion for polymerizing the emulsion under the protection of nitrogen. The fluorine-containing acrylate copolymer emulsion is used as a waterproof oil resistant finishing agent for fabrics; and the finished fabrics present excellent waterproof oil resistance property. Carbon atoms of long-chain perfluor alkyl in the fluorine-containing acrylate monomer prepared by the method are not less than 8, and hidden dangers of damaging the environment and harming human health by the long-chain perfluor alkyl waterproof oil resistant fabric finishing agent do not exist.

Owner:江苏梅兰化工有限公司

Water-dispersible water-and-oil repellant composition

InactiveUS6395821B1Reduce the amount requiredExcellent water and oil repellencyOther chemical processesSynthetic resin layered productsWater dispersibleHydrostatic pressure

The invention relates to a water dispersion type water and oil repellent composition which satisfies both repeated washing durability of water and oil repellency and durability of hydrostatic pressure resistance. A water dispersion type water and oil repellent composition comprising (A) a fluorine-containing copolymer having hydroxy groups, (B) a fluorine-containing copolymer having epoxy groups, (C) a compound having a blocked isocyanate group and having no carbon-carbon unsaturated bond and (D) an amino resin, as effective components.

Owner:ASAHI GLASS CO LTD

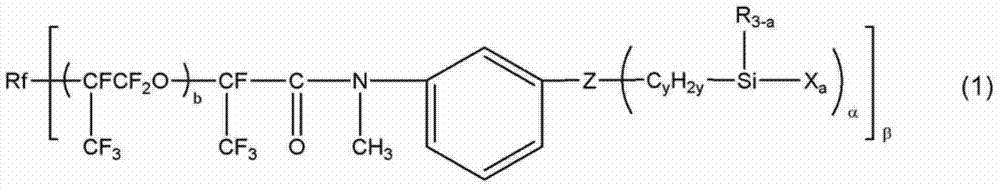

Lens with stain resistant surface layer

ActiveUS6958191B2Easy to wipeIncreased durabilityLayered productsPretreated surfacesHalogenSurface layer

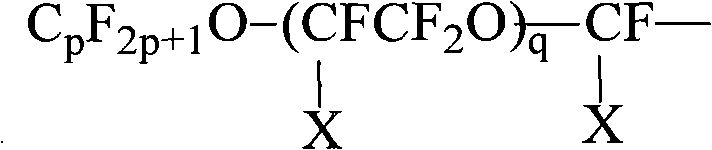

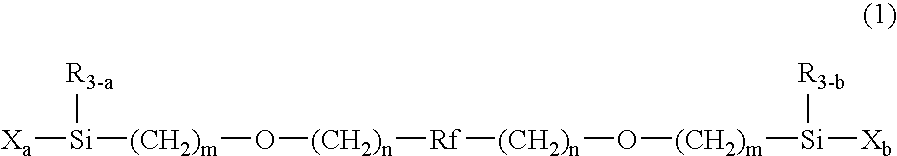

A lens including a lens substrate, a surface layer, and a backing member provided beneath the surface layer, in which the backing member may be either the same as the lens substrate or a separate layer from the lens substrate, and wherein the surface layer includes a hydrolysis-condensation product of a perfluoropolyether modified silane with a hydrolysable functional group or a halogen atom X at both terminals, represented by a general formula (1) shown below: (wherein, Rf is a bivalent group with a straight chain perfluoropolyether structure containing no branching, which incorporates a unit represented by a formula —(CkF2kO)— (wherein, k represents an integer from 1 to 6)) is resistant to the adhesion of contaminants to the surface thereof, can be easily wiped to remove any adhered contaminants, provides a slippery surface that is difficult to scratch, and moreover displays excellent durability and is capable of retaining the above properties over extended periods.

Owner:SHIN ETSU CHEM IND CO LTD

Preparation method of high-performance anti-fingerprint agent

InactiveCN107698768AStrong combinationImprove bond fastnessAntifouling/underwater paintsPaints with biocidesFingerprintWear resistance

The invention discloses a preparation method of a high-performance anti-fingerprint agent. The preparation method comprises the following steps that firstly, allyl terminated perfluoropolyether reactswith a siloxane compound containing silicon-hydrogen bonds for obtaining a perfluoropolyether silane compound containing silicon-hydrogen bonds, the obtained product reacts with methyl vinyl dichlorosilane for obtaining perfluoropolyether-silane with dichlorosilane modified terminal groups, the obtained perfluoropolyether-silane with dichlorosilane modified terminal groups reacts with allyl magnesium bromide for obtaining terminal allyl modified perfluoropolyether-silane with polyfunctional groups, the obtained terminal allyl modified perfluoropolyether-silane with polyfunctional groups reacts with methyldichlorosilane for obtaining dichlorosilane modified perfluoropolyether-silane, dendritic terminal allyl modified perfluoropolyether-silane is obtained by repeated reaction; and then theobtained dendritic multi-functional perfluoropolyether-silane reacts with a siloxane compound containing silicon-hydrogen bonds for obtaining the dendritic perfluoropolyether alkoxy silane compound with polyfunctional groups. The anti-fingerprint agent prepared by the method provided by the invention has a good hydrophobic oleophobic property and excellent antifouling property, and has excellent bonding fastness to glass substrates, and the wear resistance and the durability are greatly improved.

Owner:QUZHOU FLUORIDE & SILICON RES INST

Method of preparing fluorinated polyurethane paint and fluorinated polyurethane anticorrosive paint

InactiveCN104293158ALower surface energyExcellent water and oil repellencyAnti-corrosive paintsPolyurea/polyurethane coatingsPolyolMixed materials

The invention provides a method of preparing fluorinated polyurethane paint. The method is characterized by comprising the following steps: a step of preparing a component A, namely adding 15-60 parts of fluorinated polyether polyol and 0.01-0.03 part of dibutyltin dilaurate into a three-necked flask with a stirring rod in sequence, and stirring for 30 minutes to obtain the component A; a step of preparing a component B, namely adding 10-40 parts of 4,4-diphenyl methane diisocyanate and 0-30 parts of collaborative anticorrosive filler into 20-60 parts of a solvent system to stir and dissolve to obtain the component B; and a step of preparing fluorinated polyurethane anticorrosive paint, namely adding the component B into the three-necked flask filled with the component A, stirring for 8-10 minutes, grinding the mixed materials in the three-necked flask until fineness is 40-50 mu m after uniformly stirring, coating a metal sheet with the grinded mixed materials and curing for 24 hours to obtain the fluorinated polyurethane anticorrosive paint.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Preparation method of (sesqui) siloxane hybrid modified fluorinated polyacrylate emulsion

The invention discloses a preparation method of an epoxy polyether-based (sesqui) siloxane hybrid modified fluorinated polyacrylate emulsion, which comprises the following steps of: under the effect of cationic / nonionic or anionic / nonionic surfactants, firstly carrying out seeded emulsion copolymerization on perfluoroalkyl(methyl) acrylate, aliphatic long carbon chain (methyl) acrylate, reactive vinyl monomer and alpha-alkenyl alkoxysilane in an aqueous phase so as to synthesize a silanized long carbon chain fluorinated polyacrylate emulsion; cooling to room temperature; regulating a pH value of the system to be 5.0-6.0; adding an epoxy polyether-based (sesqui) siloxane cross-linking agent and a stiffening agent; continuously stirring for 30 min; and obtaining the (sesqui) siloxane hybrid modified fluorinated polyacrylate emulsion after filtering. The modified fluorinated polyacrylate emulsion disclosed by the invention can be used for after-treatment of textiles after dilution, so that the stiff handfeel of textiles can be improved, and an excellent water-repellent and oil-repellent performance is given to the textiles.

Owner:SHAANXI UNIV OF SCI & TECH

Perfluoropolyether-modified polysilazane and surface treatment agent using same

InactiveCN101628980ACurable at room temperatureGood antifoulingAntifouling/underwater paintsPaints with biocidesPerfluoropolyetherOrganic group

A perfluoropolyether-modified polysilazane is provided. The polysilazane consists of units having formula (1): F(C x F 2x O) m C y F 2y -Q-Si(NH) 1.5 ( 1 ) wherein Q represents a divalent organic group, m represents an integer of 1 or greater, and x and y each represents an integer of 1 to 3. The polysilazane can be cured at normal temperatures, forms a tough coating on a substrate surface without application of a primer, and is useful as a surface treatment agent that is capable of maintaining water and oil repellency and releasability and the like, over a long period of time.

Owner:SHIN ETSU CHEM IND CO LTD

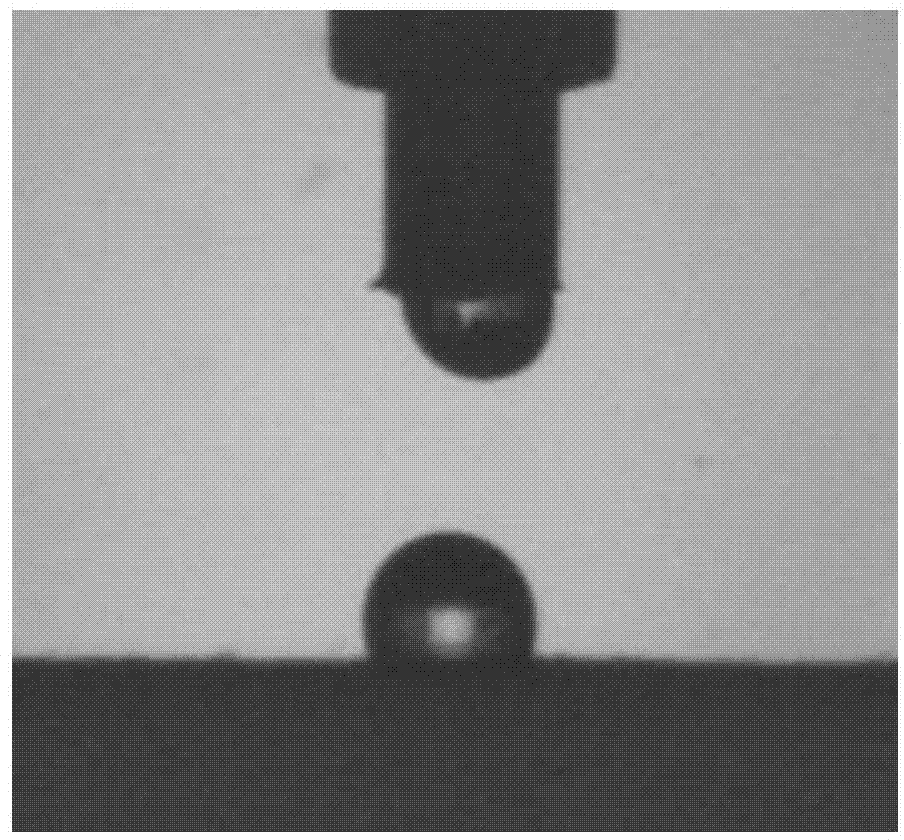

Self-cleaning nano protective liquid used for glass and preparation method

The present invention relates to a self-cleaning nano protective liquid used for glass and a preparation method. According to the self-cleaning nano protective liquid used for glass, a thin film coating formed by the nano protective liquid is provided with a similar structure of a lotus leaf surface in nature, wherein the structure is a nano-micro composite layer structure, and the coating is a colorless transparent thin film coating, with a thickness of 400-1000nm. The coating provided by the present invention has superior properties of water-proofing, oil-proofing, anti-fouling, anti-fogging, moisture-proofing, and the like. A contact angle of the coating and water is 140-155 DEG (a droplet volume is measured as 4 mu L), a roll angle of a water droplet on a coating surface is less than 5 DEG (a droplet volume is measured as 4 mu L). The water droplet existed on the the coating surface is freely rollably, meanwhile contaminations of dust and the like are removed, and thereby achieving the superior properties of anti-fogging, anti-fouling and the like.

Owner:王金书

Water and oil repellent finishing agent for fabrics and preparation method of finishing agent

ActiveCN104594045AImprove shielding effectExcellent water and oil repellencyFibre treatment(Hydroxyethyl)methacrylateEmulsion

The invention discloses a water and oil repellent finishing agent for fabrics and a preparation method of the finishing agent. The active ingredient of the finishing agent refers to perfluoroalkyl silicone acrylate copolymer. The preparation method comprises the following steps: mixing perfluoroalkyl silicone acrylate, butyl acrylate, methyl methacrylate and hydroxyethyl methylacrylate, initiating free radical emulsion copolymerization by virtue of a water-soluble initiator under the emulsification actions of a nonionic surfactant and an anionic surfactant, thereby obtaining the emulsion type perfluoroalkyl silicone acrylate water and oil repellent finishing agent with high stability for fabrics. The finishing agent is applied for finishing cotton fabrics, and the water and oil repellent effects are obviously improved. The water and oil repellent finishing agent provided by the invention is mild in preparation conditions, simple and convenient in preparation process and suitable for industrial production.

Owner:苏州章贡纺织科技有限公司

Core-shell type fluorinated acrylate fabric water repellent and preparation method thereof

ActiveCN103788303AExcellent water and oil repellencyDoes not affect breathabilityFibre treatmentEmulsionMoisture permeability

The invention relates to a core-shell type fluorinated acrylate fabric water repellent which comprises the components by weight percent: 25-50% of monomer, 50-75% of deionized water, an initiator and an emulsifying agent, wherein the weight of the initiator is 0.5-1.5% of the total weight of the monomer, and the weight of the emulsifying agent is 1.0-3.5% of total weight of the monomer. A preparation method of the water repellent comprises the steps of respectively preparing shell emulsion and core emulsion, and then dripping the shell emulsion and the initiator into the core emulsion for reaction to obtain the core-shell type fluorinated acrylate fabric water repellent. The core-shell type fluorinated acrylate fabric water repellent is applied to water and oil repellent finishing of the fabric, so that the fabric has excellent water and oil repellent property, and the problems that the existing water and oil repellent is poor in use durability, low in fastness and the like in the aspect of wearability can be solved; furthermore, the performances such as air permeability, moisture permeability and the like of the fabric are not influenced, and the environmental pollution is not caused.

Owner:广东奕美化工科技有限公司

Fluorine-containing copolymer

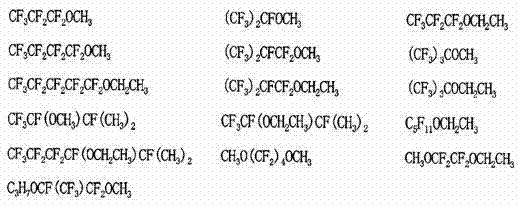

ActiveCN103080165ALow concentration of the environmentLow bioaccumulationCosmetic preparationsToilet preparationsHydrogen atomAlcohol

Owner:UNIMATEC CO LTD

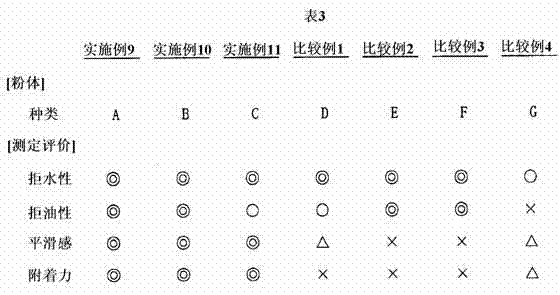

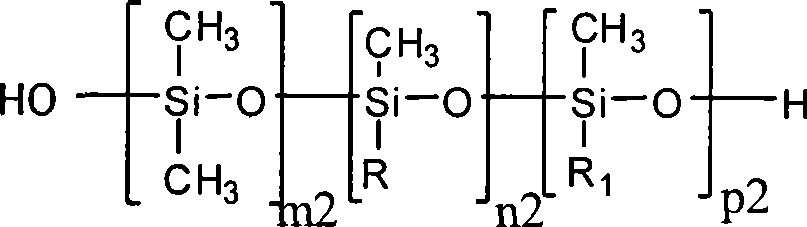

Organosilicon fluorine multifunctional fabric finishing agent and preparing method thereof

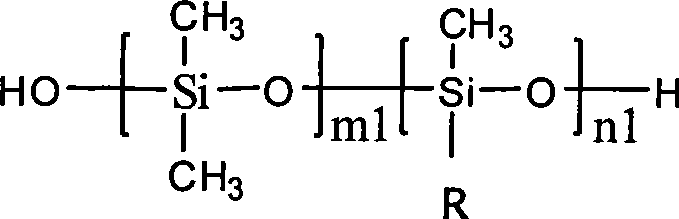

The invention discloses an organic fluosilicic multifunctional textile finishing agent. Aiming at the problem existing in the current commercially available organic silicone finishing agent, a small amount of organic fluorin radical is introduced to the organic silicone finishing agent; under the condition of not changing the original effect of the organic silicone finishing agent, the smooth property of the finishing agent is further improved, simultaneously, water-and-oil-repellent effect is increased to a certain extent; the finishing agent is innocuous and pollution-free, and has high cost performance and wide application prospect. The invention also discloses a preparation method of the organic fluosilicic multifunctional textile finishing agent which has simple technological operation, the prepared latex has strong stability and difficult emulsion breaking, delamination does not happen after the latex is placed for a long time, the use is simple, the hand-feeling of the textile is obviously improved and the additional value is increased.

Owner:ZHEJIANG RUNTU +1

Preparation method of pyrohydrolysis-resistant meta-position aramid fiber material

ActiveCN102628222AAvoid hydrolysisMembrane structure intactFibre typesSynthetic resin layered productsWater vaporDifferential pressure

The invention relates to a preparation method of a pyrohydrolysis-resistant meta-position aramid fiber material. The preparation method is characterized in that: a meta-position aramid fiber three-layer structural body made by adopting a no-weaving technology is taken as a filter material green body, the meta-position aramid fiber three-layer structural body is subjected to padding by pyrodydrolysis-resistant finishing liquor which contains polytetrafluoroethylene and epoxy phenolic resin mainly and then is subjected to low temperature antimigrant primary drying and high temperature crosslinking, thus a membrane structure which is completely coated and is uniformly distributed with polytetrafluoroethylene particles, high temperature water vapor is isolated from contacting fibers, retention rate of longitudinal and transverse breaking forces of hydrolysis at higher continuous working temperature are 100-107%, water repellency level and oil repellency level are obviously improved, the filter material is difficult to damage, is easy to clean ash, does not paste bag and does not harden, differential pressure of a dust removal system is small, service life of a filter bag is prolonged, and the filter material can be widely applied to high temperature flue gas dedusting and filtering of steel and iron, electricity generation, cement, a coal-fired boiler and the like. The preparation method disclosed by the invention can directly use the traditional production equipment and has a simple process and low production cost.

Owner:江苏东方滤袋股份有限公司 +1

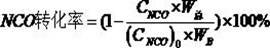

Environment-friendly fluorinated polyurethane-polyacrylate emulsion and preparation method thereof

ActiveCN104744651AGood storage stabilityImprove water resistancePolyurea/polyurethane coatingsPrepolymerFluorinated monomers

The invention discloses an environment-friendly fluorinated polyurethane-polyacrylate emulsion and a preparation method thereof. The preparation method comprises the following steps: polymerizing diisocyanate, dimethylolpropionic acid, a functional monomer and an anionic hydrophilic chain extender under the presence of a catalyst so as to obtain an isocyanate-terminated double-bond prepolymer; neutralizing with alkali and adding the water solution of a hydrophilic small-molecule chain extender for dispersing, and further initiating a fluorinated monomer and an acrylic monomer under the effect of a water-soluble initiator so as to obtain the environment-friendly fluorinated polyurethane-polyacrylate emulsion. The emulsion adopts a self-emulsifying method, and is subject to a post-chain extension method and free from any organic solvent or small-molecule emulsifier; and the emulsion is good in storage stability, and by introducing fluorine atoms, the water resistance and the solvent resistance of waterborne polyurethane are effectively improved. The emulsion is applicable to a waterborne coating, and a prepared coating film has the properties of excellent water and oil-proofing performance, heat resistance, being non-toxic, safe and highly glazed, and the like.

Owner:广东拓普合成科技股份有限公司

Fluorinated textile finishing agent composition and preparation method therefor

ActiveCN105085793AImprove performanceExcellent water and oil repellencyFibre treatmentCross-linkFatty alcohol

The invention discloses a fluorinated textile finishing agent composition and a preparation method therefor. The composition comprises a polymer which is prepared through emulsifying monomers and other adjuvants by an emulsifier to initiate polymerization, wherein the monomers consist of the ingredients in parts by mass: 30-70 parts of perfluoroalkyl acrylate monomer, 10-60 parts of fatty alcohol acrylate monomer, 1-30 parts of cross-linking monomer and the balance of reinforcing monomer, and all the ingredients are 100 parts in total. The method comprises the following steps: stirring to disperse the perfluoroalkyl acrylate monomer, the fatty alcohol acrylate monomer, the cross-linking monomer, the emulsifier, a cosolvent, a chain transfer agent and water in a reactor, and then, carrying out pre-emulsification; adding the reinforcing monomer into the pre-emulsification at the temperature of 0-30 DEG C; and heating the reinforcing monomer added pre-emulsification to the temperature of 50-80 DEG C, and adding an initiator into the heated pre-emulsification so as to carry out polymerization reaction. The textile finishing agent prepared according to the method is environment-friendly and is low in cost, excellent in waterproof and oilproof performance and good in durability.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

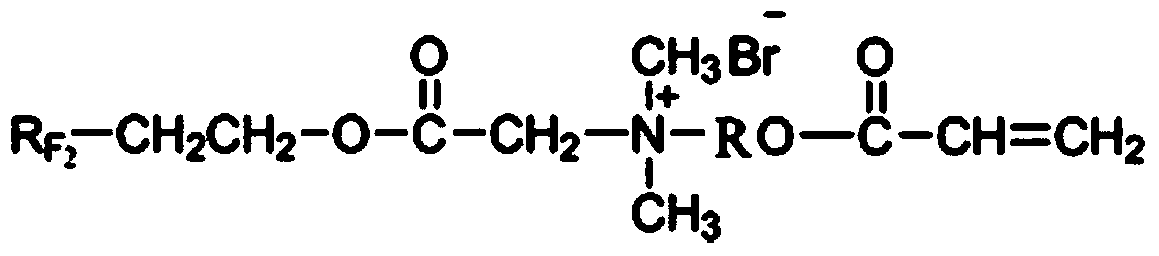

Environment-friendly type self-crosslinking water and oil repellent textile finishing agent and preparation method thereof

The invention discloses an environment-friendly type self-crosslinking water and oil repellent fluorinated acrylate textile finishing agent and a preparation method thereof. The preparation method comprises the following steps: mainly introducing a reaction type cation fluorinated emulsifier and a polymerizable cross-linking agent, applying the emulsifier and the cross-linking agent to seeded emulsion polymerization of short fluorocarbon chain perfluoroalkyl acrylate, in situ forming an macromolecular cation organic fluorine copolymer emulsifier during the seeded polymerization process, and in the follow-up emulsion polymerization, enabling the fluorine-containing group to be stably arranged in an emulsion particle shell layer under the action of the polymerizable cross-linking agent; with the results of comprehensive functions of the emulsifier and the polymerizable cross-linking agent, the resin can be used as the textile finishing agent to show up good water repellency, oil repellency and processing continuity.

Owner:ANHUI LINGDA CHEM TECH

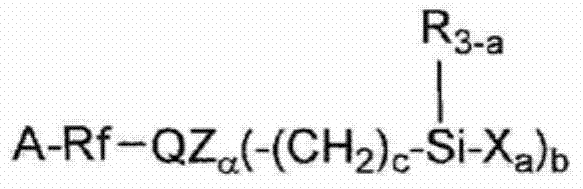

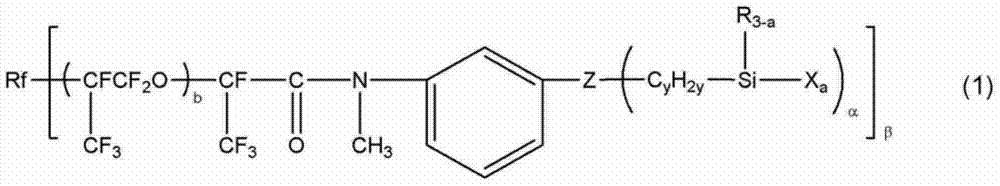

Polymer modification silane containing fluoro oxidation alkylene, surface treating agent relating same and object

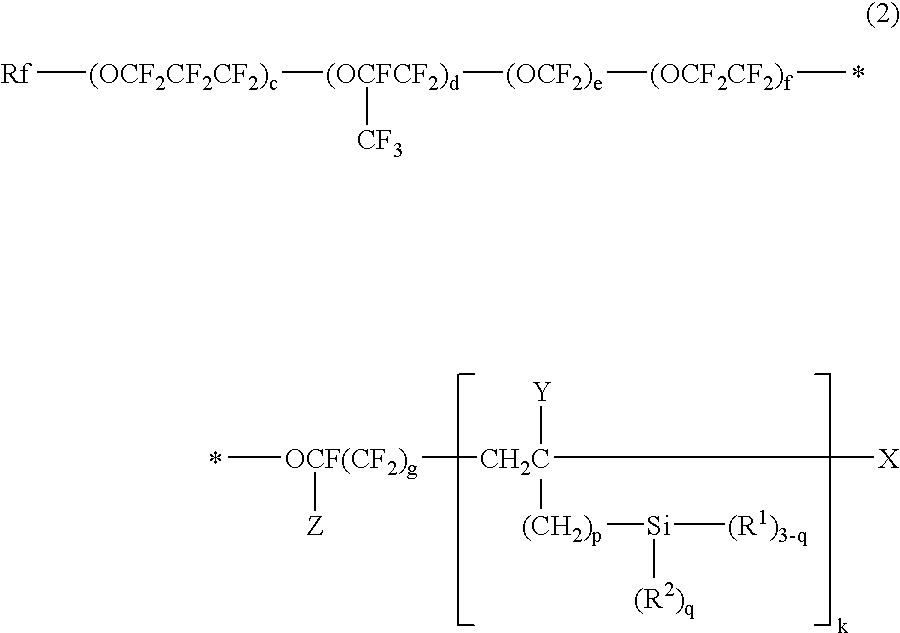

ActiveCN104119524AImprove water and oil repellencyExcellent water and oil repellencyPolyether coatingsPolymer sciencePolymer modified

The invention provides a polymer modification silane containing fluoro oxidation alkylene and having a waterproof oilproof layer of excellent heat proof property, a surface treating agent having the silane and / or partial hydrolytic condensation product, and an object processed by the surface treating agent. The polymer modification silane containing fluoro oxidation alkylene is indicated by a following formula (1) (wherein, Rf refers to univalent or divalent linear link polymer residue containing fluoro oxidation alkylene, b is averagely 0-10, Z is a single 2-6valent group containing siloxane bond, R is singly alkyl or phenyl of 1-4 carbon atoms, X is a single hydrolytic group, a is a single 2 or 3, y is an integer between1-5 of each unit, alpha is an integer of 1-5, and beta is 1 or 2).

Owner:SHIN ETSU CHEM IND CO LTD

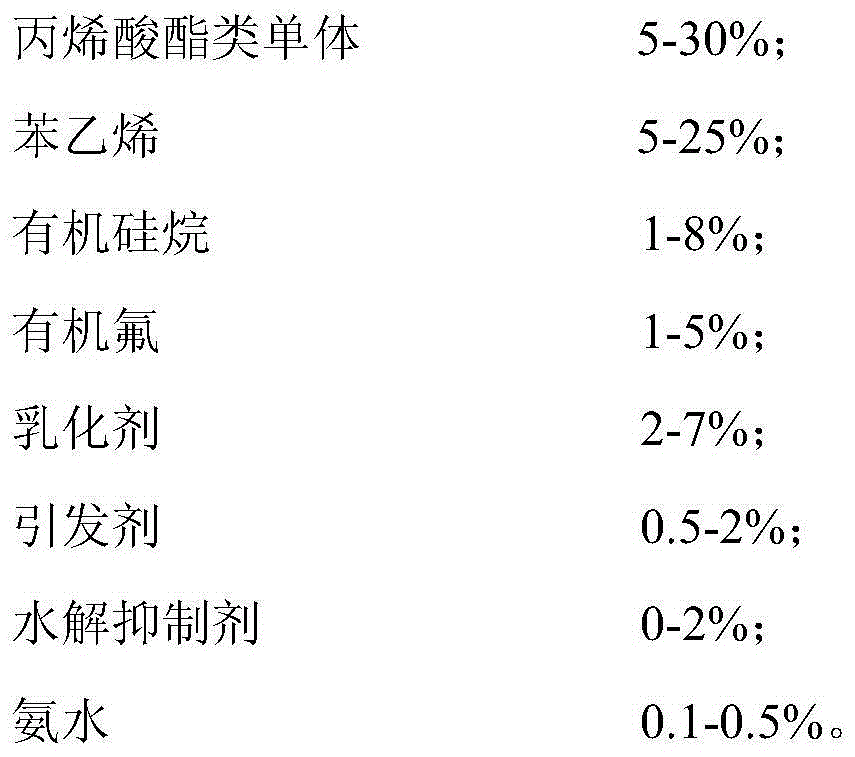

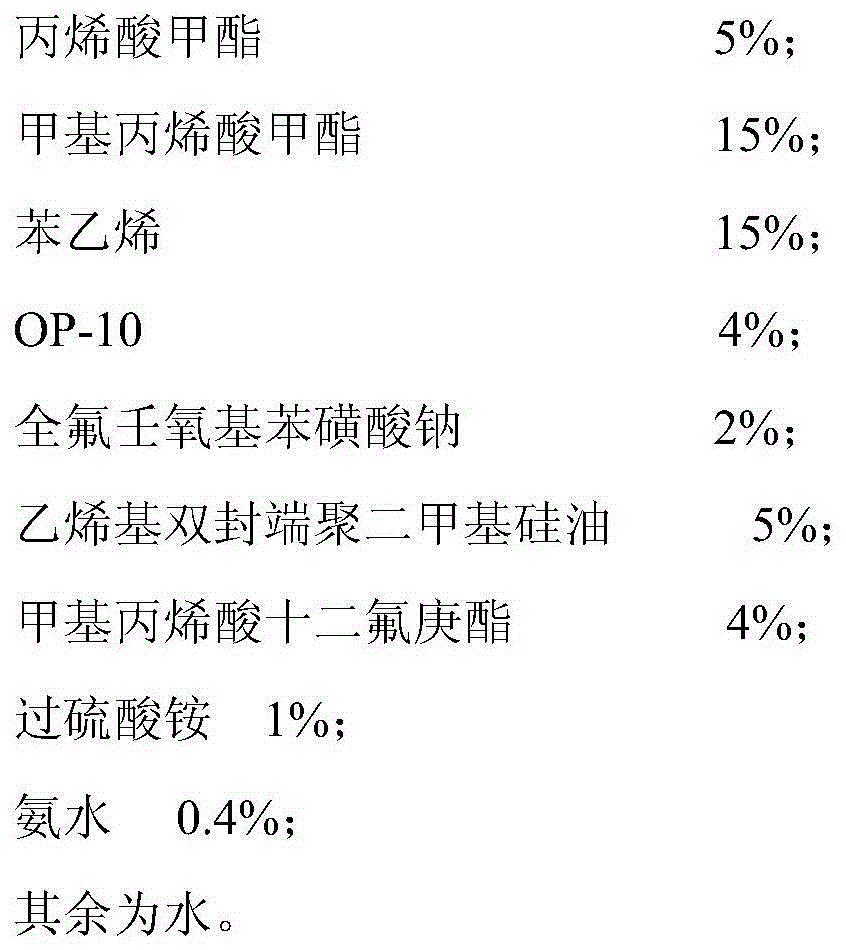

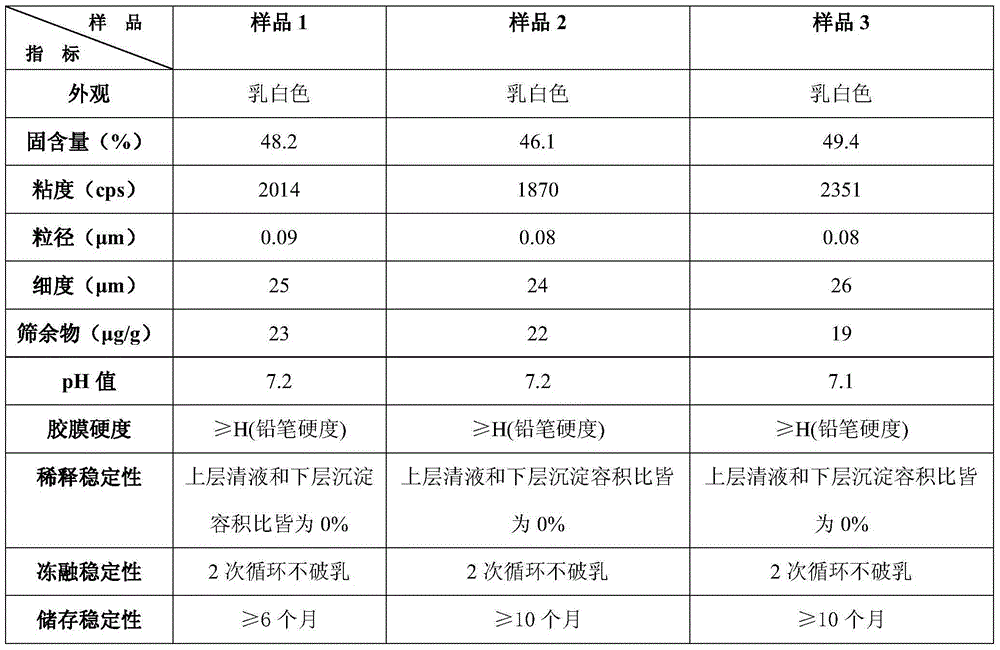

Silicon-fluorine-containing styrene-acrylic emulsion and preparation method thereof

The invention provides a silicon-fluorine-containing styrene-acrylic emulsion and a preparation method thereof. The silicon-fluorine-containing styrene-acrylic emulsion mainly comprises the following components in percentage by mass: 5-30% of acrylate monomer, 5-25% of styrene, 1-8% of organosilane, 1-5% of organic fluorine, 2-7% of emulsifier, 0.5-2% of initiator, 0-2% of hydrolysis inhibitor and 0.1-0.5% of ammonia water. The styrene-acrylic emulsion provided by the invention has the advantages of the organosilicon and organic fluorine, can effectively lower the emulsion cost, and has better water resistance and oil resistance.

Owner:GUANGZHOU GLORYSTAR CHEM

Preparation method of washable three-proofing and easy-decontamination antibacterial fabric

InactiveCN111535026AMeet environmental protection requirementsImprove washing resistanceStain/soil resistant fibresBiochemical fibre treatmentProcess engineeringCross linker

The invention discloses a preparation method of a washable three-proofing and easy-decontamination antibacterial fabric. The preparation method is characterized by comprising the following steps of: soaping, to be specific, after desizing, scouring, bleaching and mercerizing the fabric in advance, removing impurities on the cloth cover by a soaping process, and then drying; and performing one-bathprocess washable three-proofing and easy-decontamination antibacterial finishing, to be specific, shaping and processing the soaped and dried fabric on a shaping machine, drying, baking and finishing, thereby obtaining the washable three-proofing and easy-decontamination antibacterial fabric. A working solution which simultaneously contains a C6 durable three-proofing finishing agent, a purifiedcotton durable fluorine-free waterproof agent, a durable crosslinking agent, an antibacterial agent and a special waterproof penetrant is contained in a rolling groove of the shaping machine, and thefabric is subjected to padding, then is dried and baked to obtain the washable three-proofing and easy-decontamination antibacterial fabric. The preparation method solves the contradiction between thethree-proofing and the easy decontamination, and also solves the problems between the three-proofing and the bacteria prevention; and meanwhile the fabric is endowed with the function of washing resistance, and can meet the overall actual needs for functional fabrics in actual situations.

Owner:江苏康乃馨纺织科技有限公司

Shell-core type fluoride containing emulsion

The invention discloses a core-shell type acrylic acid ester latex containing fluorine (methyl) which is prepared from monomers, emulsifying agent, initiating agent, pH regulator and water through supersonic wave pre-emulsion by employing core-shell emulsion polymerization. Compared with the prior art, the invention is characterized in that the fluorine monomer is enriched in the shell layer, thus greatly reducing the consumption of fluorine monomer.

Owner:EAST CHINA UNIV OF SCI & TECH

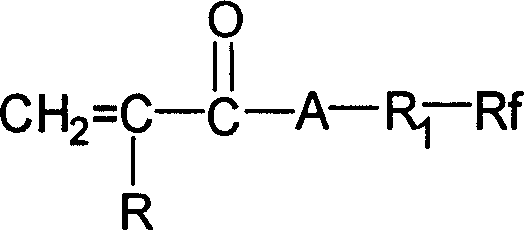

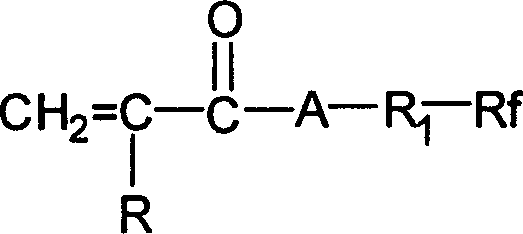

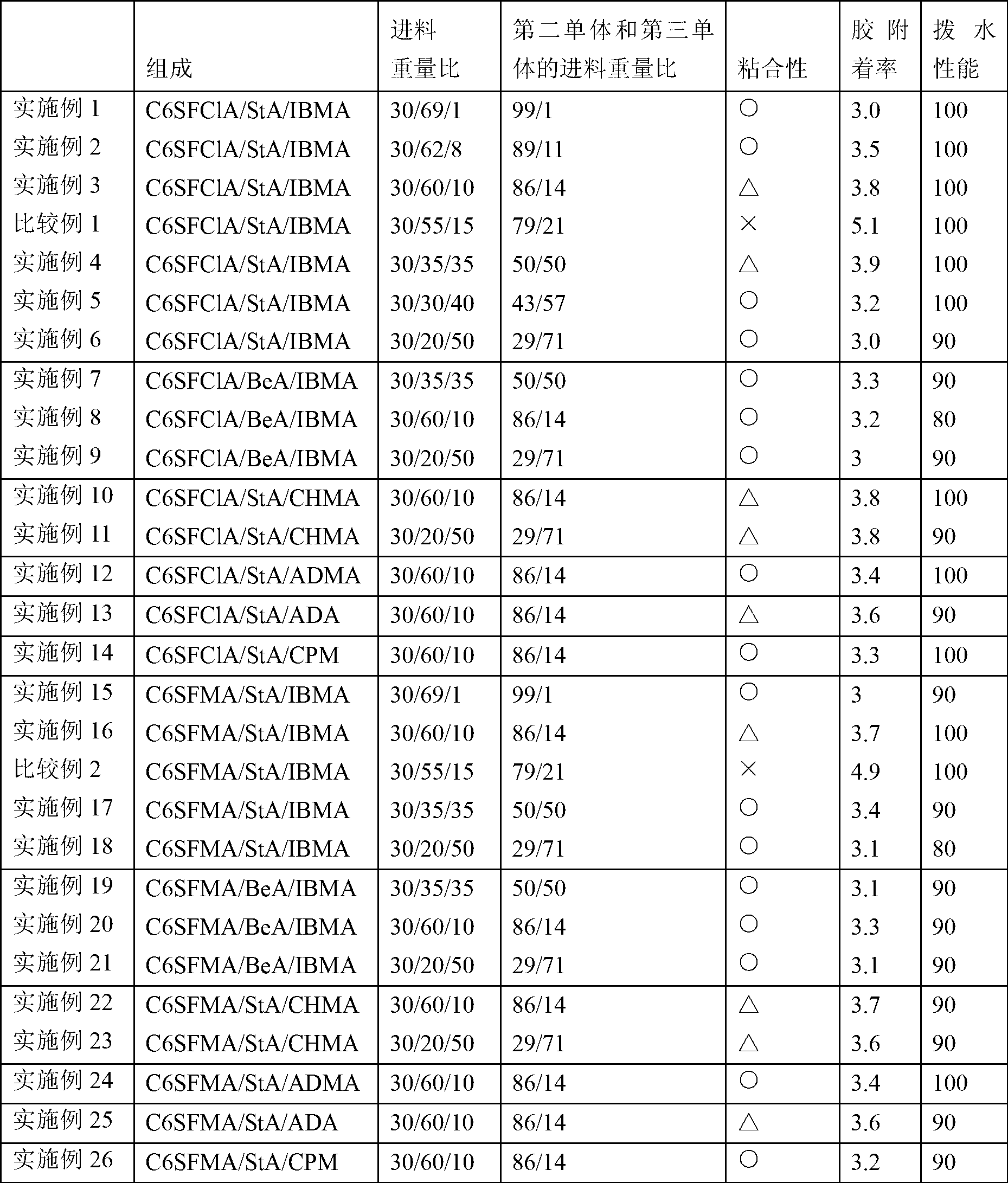

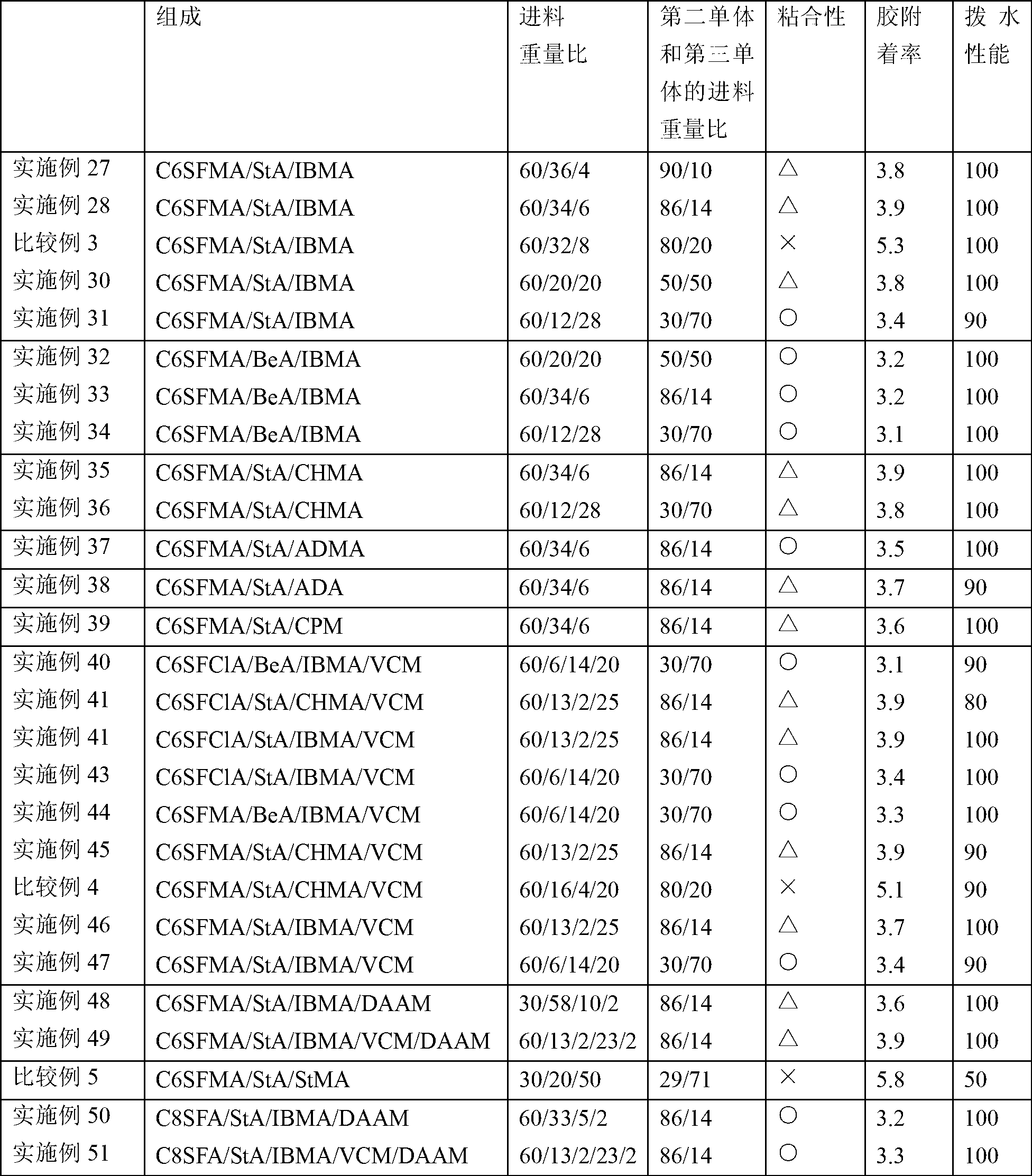

Fluorine containing composition and fluorine containing polymer

ActiveCN103183775AGood adhesionExcellent water and oil repellencyNon-fibrous pulp additionOther chemical processesFiberGlass transition

The invention provides a water-repellent oil-repellent composition imparting excellent water- repellency and oil-repellency to substrates such as fiber products, and preventing the adhesion of the polymer on a roller in processing. The water-repellent oil-repellent composition is a fluorine-containing composition comprising a fluorine-containing polymer, and the fluorine-containing polymer has: (a) repeating units derived from a fluorine-containing monomer having a fluoroalkyl group, (b) repeating units derived from a second monomer, wherein the second monomer is a straight-chain or branched-chain hydrocarbon acrylate monomer having a carbon atom number of 12 to 30, and (c) repeating units derived from a third monomer, wherein the third monomer is an acrylate monomer with homopolymer glass transition temperature (Tg) or the melting point (Tm) of more than 50 DEG C (methyl); and in the fluorine-containing polymer, relative to the total amount of the second monomer (b) and the third monomer (c) being 100 parts by weight, the second monomer (b) is in an amount of 82 to 99.9 parts by weight or 2 to 60 parts by weight, and the third monomer (c ) in an amount of 0.1 to 18 parts by weight or 40 to 98 parts by weight.

Owner:DAIKIN IND LTD

Preparation method for polyphenylene sulfide fiber filter material resisting instant high-temperature oxidization

ActiveCN102634979APrevents thermo-oxidative cross-linking reactionsExtended service lifeFibre typesSynthetic resin layered productsDifferential pressureWorking temperature

The invention relates to a preparation method for polyphenylene sulfide fiber filter material resisting instant high-temperature oxidization. The preparation method is characterized in that a three-layer polyphenylene sulfide fiber structure made by non-weaving technology is used as a filtering material blank, is in padding by instant high-temperature oxidization resistant finishing liquor mainlyconsisting of polytetrafluoroethylene emulsion and epoxy phenolic resin, and then is in low-temperature antimigrant preliminary drying and high-temperature crosslinking curing, so that a membrane structure uniformly distributed with polytetrafluoroethylene particles in a scattered manner is completely wrapped on the surfaces of fibers of the filtering material, oxygen is isolated from the fibers,breaking strength retention rate of the prepared filtering material at the high instant working temperature ranges from 98% to 110%, both water repellency grade and oil repellency grade are remarkably increased, the filtering material is not easy to be damaged, easy to clean and free of being caked, burning of a filtering bag is prevented, differential pressure of a dust removal system is low, the service life of the filtering bag is prolonged, and the filtering bag can be widely used for high-temperature smoke dust removal filtering for iron and steel, power generation, cement, coal-fired boilers and the like. In addition, existing production equipment can be directly used in the method, a process is simple, and production cost is low.

Owner:江苏东方滤袋股份有限公司 +1

Composition for increasing hydrophobic and oleophobic behavior of paper product and method of making the same

InactiveCN1629399AGuaranteed printing effectExcellent water and oil repellencyWater-repelling agents additionPaper coatingParaffin waxEmulsion

The invention provides a composition for increasing hydrophobic and oleophobic behavior of paper product and method which comprises, preparing slurry from 50-100 parts of gasket material, or gasket material and pigment, high speed agitating, low speed agitating and charging 1-20 parts of bonding agent, 1-10 parts of organic fluorine resin emulsion, 0.5-15 parts of crosslinkable wax emulsion, 0.05-5 parts of flowing deformation modifier, diluting to obtain a solid content of 20-80%.

Owner:中科纳米技术工程中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com