Preparation method of high-performance fingerprint-resistant agent

An anti-fingerprint agent, high-performance technology, applied in the fields of architectural glass, touch screen, optical glass, can solve problems such as performance degradation and durability, and achieve the effect of improving hardness, firm bonding, and improving bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

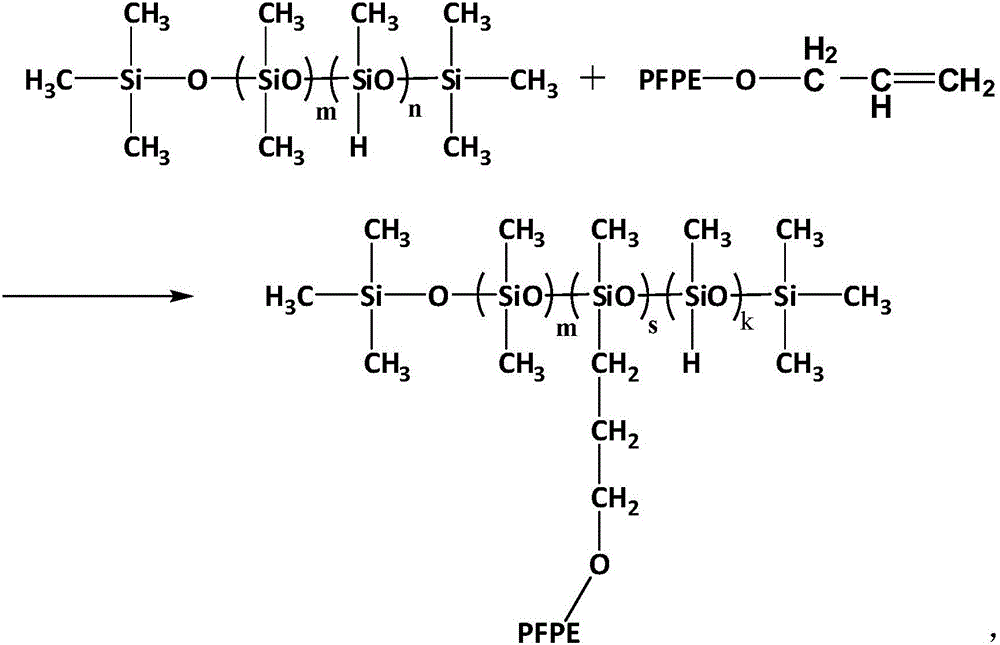

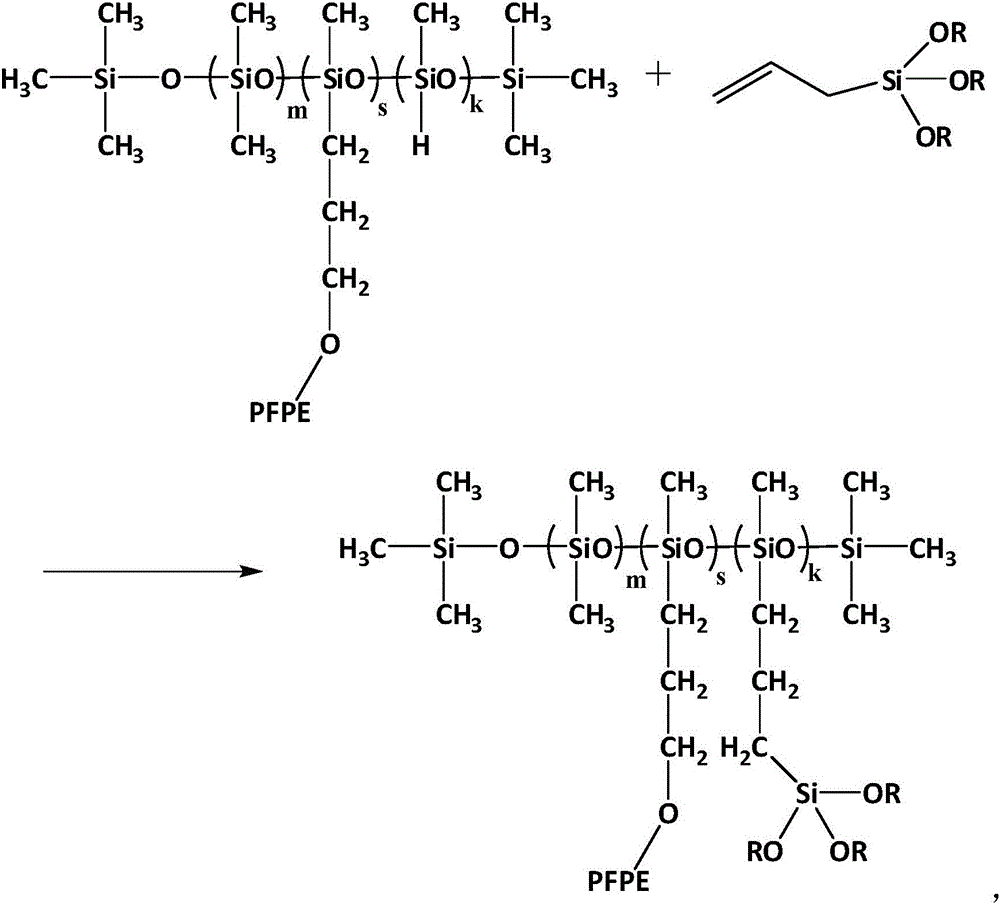

[0027] A kind of preparation method of high-performance anti-fingerprint agent of the present invention comprises the following steps:

[0028] 1) Under the protection of nitrogen, NaOH solution is added to the fluoroether solution of hydroxyl-terminated perfluoropolyether (PFPE-OH) as a catalyst. The molecular weight of hydroxyl-terminated perfluoropolyether (PFPE-OH) is 2000-8000, and the structural formula is as follows Show:

[0029]

[0030] Wherein m is an integer of at least 1, n and I are each an integer of at least 0, the concentration of the NaOH solution is 20% to 50%, and the molar ratio of NaOH to hydroxyl-terminated perfluoropolyether is (5:1) to (20: 1), then add allyl bromide, reflux for 6 to 8 hours, wash with water, and distill off the solvent and residual water under reduced pressure. One or more mixtures to obtain allyl-terminated perfluoropolyether, the reaction equation is as follows;

[0031]

[0032] 2) Use a three-necked flask device with a ref...

Embodiment 1

[0041] 1) In the three-necked flask device that reflux condenser and constant pressure funnel are equipped with, add 20g hydroxyl-terminated perfluoropolyether (PFPE-OH, molecular weight is 2500) and 7200 hydrofluoroether of 100ml 3M Company, under nitrogen protection Add 8 g of 20% NaOH solution as a catalyst, then add 3.84 g of allyl bromide, reflux for 6 hours, wash with water, and distill under reduced pressure to remove the solvent and residual water to obtain 18.6 g of allyl-terminated perfluoropolyether;

[0042] 2) Use a three-necked flask device with a reflux condenser and a constant pressure funnel, add 50ml of a 7300 solution of 12.4g of hydrogen-containing silicone oil to the constant pressure funnel, and add 10g of a 7200 solution of allyl perfluoropolyether to the three-necked flask. 50ml of the solution, stirred and mixed evenly, controlled the temperature at 80°C, added 0.1g of chloroplatinic acid catalyst, slowly added hydrogen-containing silicone oil dropwise,...

Embodiment 2

[0045] 1) In a three-necked flask device equipped with a reflux condenser and a constant pressure funnel, add 20g of hydroxyl-terminated perfluoropolyether (PFPE-OH, with a molecular weight of 5000) and 100ml of 7300 hydrofluoroether from 3M Company, under nitrogen protection Add 8 g of 10% NaOH solution as a catalyst, then add 3.84 g of allyl bromide, reflux for 6 hours, wash with water, and distill under reduced pressure to remove the solvent and residual water to obtain 19.8 g of allyl-terminated perfluoropolyether;

[0046] 2) Use a three-necked flask device with a reflux condenser and a constant pressure funnel, add 50ml of a 7300 solution of 12.4g of hydrogen-containing silicone oil to the constant pressure funnel, and add 10g of a 7300 solution of allyl perfluoropolyether to the three-necked flask. 50ml of the solution, stirred and mixed evenly, controlled the temperature at 100°C, added 0.1g of chloroplatinic acid catalyst, slowly added hydrogen-containing silicone oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com