Environment-friendly type self-crosslinking water and oil repellent textile finishing agent and preparation method thereof

A fabric finishing agent, water-repellent and oil-repellent technology, applied in fiber treatment, textiles and papermaking, etc., can solve the problems of continuous processing, affect the quality stability of finished textiles, affect the utilization rate of finishing agents, etc., and achieve excellent water repellency Effect of oil repellency, improvement of processing continuity, and reduction of migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

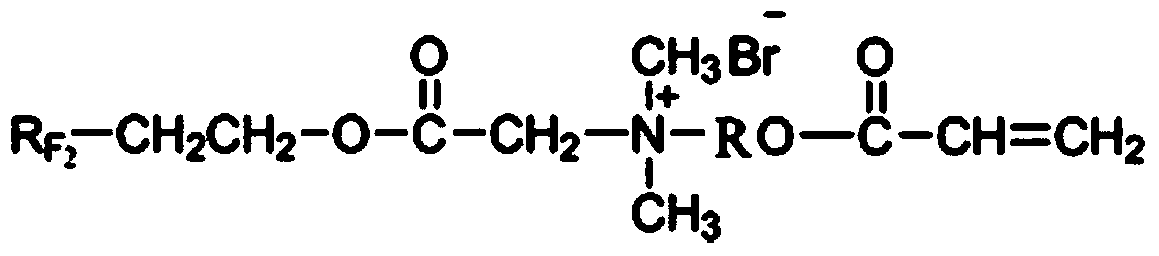

[0034] 0.8g Span 80, 0.5g octadecyl trimethyl chloride (bromide) ammonium, 2.0g N-(perfluorooctylethyl acetate)-N-(ethanol acrylate) dimethyl bromide Mix ammonium, 1.4g butyl acrylate, 0.6g glycidyl acrylate, 0.2g azobisisobutyronitrile and 40g deionized water, stir and emulsify at high speed under nitrogen protection for 15-20 minutes, and heat up to 65°C-70°C , keep warm for 25 minutes to prepare the seed emulsion;

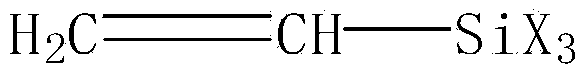

[0035] The emulsion changes from gray to blue light translucence, and 12.6g of butyl acrylate, 5.4g of glycidyl acrylate, 4g of perfluorohexylethyl acrylate, 0.6g of azobisisobutyronitrile and 2g of vinyl are continuously added to the above seed emulsion Add the mixed solution of trimethoxysilane dropwise within 2 hours under the condition of 65°C-70°C; after adding all the materials, keep it warm for 2 hours; cool down to below 50°C; finally, filter to obtain the product.

[0036] In this embodiment, the total amount of organic fluorine materials accounts for ...

Embodiment 2

[0038] 0.5g Span 85, 0.5g hexadecyl trimethyl quaternary ammonium salt, 3.6g N-(perfluorooctyl isobutyl acetate)-N-(butanol acrylate) dimethyl ammonium bromide , 1.4g butyl acrylate, 0.1g azobisisoheptanonitrile, 0.2g V50 and 45g deionized water were mixed together, stirred and emulsified at high speed under nitrogen protection for 20 minutes, heated to 60°C-65°C, kept for 30 minutes, prepared get seed emulsion;

[0039] The emulsion changes from gray to blue light translucent, and 10g of butyl acrylate, 4g of methyl methacrylate, 6g of perfluorohexyl ethyl acrylate, 0.4g of azobisisobutyronitrile, 0.3g of V50 and 4g of The mixed solution of vinyltriethoxysilane is added dropwise within 2 hours under the condition of 60℃~65℃; after all the materials are added, it is kept for 2 hours; the temperature is lowered to below 50℃; finally, the product is obtained by filtration.

[0040] In this embodiment, the total amount of organic fluorine materials accounts for 32% of the total ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com