Preparation method of ultraviolet-curable water-borne fluorinated paint with low surface energy

A technology of fluorine-containing coatings and low surface energy, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor physical properties and environmental performance of coatings, achieve improved surface properties and overall performance, and high energy utilization , the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

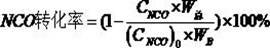

[0019] This example illustrates the acetone-di-n-butylamine method used in testing the conversion rate of isocyanate groups in the reaction.

[0020] The specific test method is as follows:

[0021] 1) Prepare 0.1mol / L HCl standard solution.

[0022] 2) Prepare 0.1mol / L di-n-butylamine-acetone standard solution.

[0023] 3) Titrate 10 ml of di-n-butylamine standard solution with HCl standard solution, use HCl standard solution volume V 1 ml.

[0024] 4) Add W to a 150ml Erlenmeyer flask 1 The sample of the g reactant (the weighing amount can be larger when the conversion rate is higher), add acetone to dissolve, and finally add a small amount of indicator bromophenol blue.

[0025] 5) Add 10 ml of di-n-butylamine standard solution, stir evenly, and keep warm at about 25°C for 15 minutes.

[0026] 6) Titrate with HCl standard solution, the color changes from blue to yellow, use HCl standard solution volume V 2 ml.

Embodiment 2

[0035] This example illustrates the preparation method of the low surface energy ultraviolet light curing water-based fluorine-containing pure acrylic polyurethane acrylate resin provided by the present invention.

[0036] (1) Add 80 parts by weight of xylene and 1.6 parts by weight of azobisisobutyronitrile into the three-necked bottle, adjust the temperature of the oil bath to 80°C, and drop 60 parts by weight into the three-necked bottle at a constant speed with a constant pressure dropping funnel The methyl methacrylate of 15 parts by weight, the acrylic acid of 15 parts by weight, the hydroxyethyl acrylate of 15 parts by weight and the hexafluorobutyl acrylate of 10 parts by weight, the rate of addition is controlled to drop within 2 hours; The heating bath temperature remains unchanged and continues to react for 4 hours; then add 0.4 parts by weight of azobisisobutyronitrile, and after continuing to react for 2 hours, stop the reaction;

[0037] (2) In another three-neck...

Embodiment 3

[0041] This example illustrates the preparation method of the low surface energy ultraviolet light curing water-based fluorine-containing pure acrylic polyurethane acrylate resin provided by the present invention.

[0042] (1) Add 80 parts by weight of butyl acetate and 1 part by weight of azobisisobutyronitrile into the three-necked bottle, adjust the temperature of the oil bath to 90°C, and drop 60 The methacrylate of parts by weight, the acrylic acid of 15 parts by weight, the hydroxyethyl acrylate of 15 parts by weight and the dodecafluoroheptyl methacrylate of 10 parts by weight, the rate of addition is controlled to drip within 2.5 hours; Finally, the temperature of the oil bath remains constant and continues to react for 4 hours; then add 0.3 parts by weight of azobisisoheptanonitrile, and after continuing to react for 2 hours, stop the reaction;

[0043] (2) In another three-necked bottle, add 30 parts by weight of isophorone diisocyanate and 0.1 part by weight of hydroq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com