Polyurethane/polyacrylate copolymer modified by organic fluoride and ultraviolet curing coating prepared by polyurethane/polyacrylate copolymer

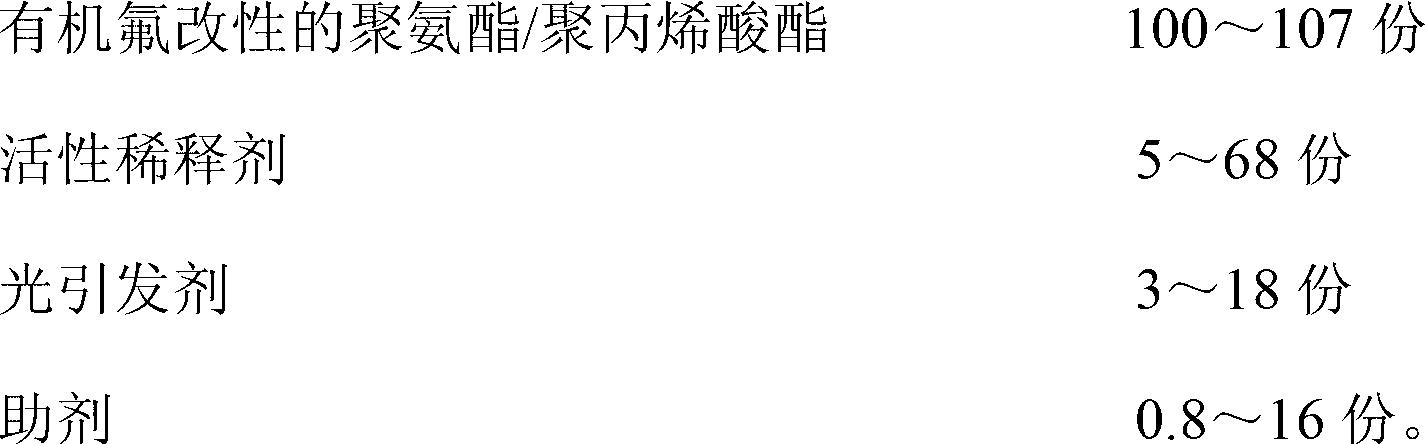

A technology of polyacrylate and polyurethane prepolymer, applied in the direction of coating, can solve the problems such as the inability to effectively improve the performance of the coating film and the poor compatibility of fluorine-containing small molecules, and achieve outstanding wear resistance and temperature resistance, Reduced surface energy, improved durability and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

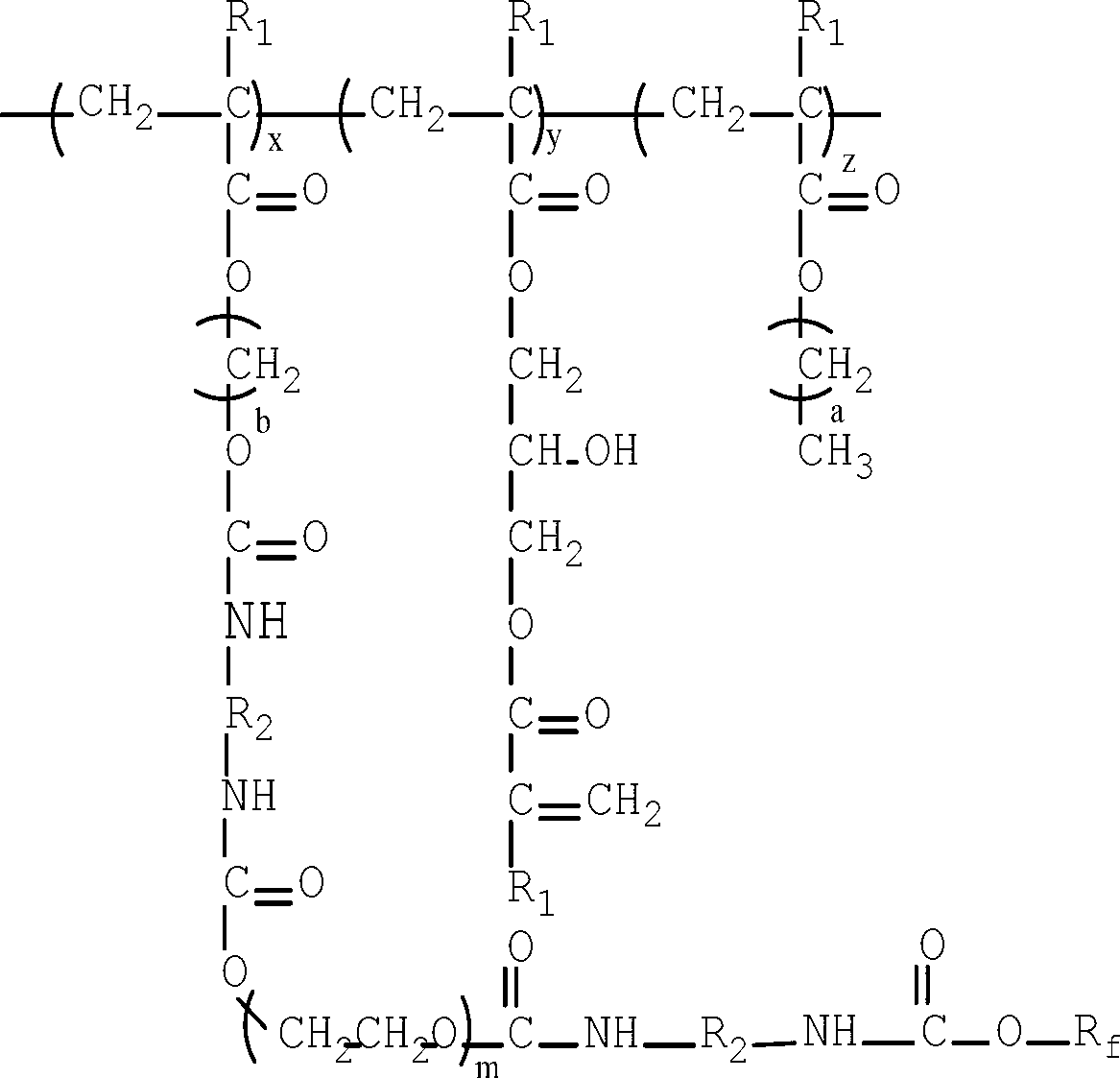

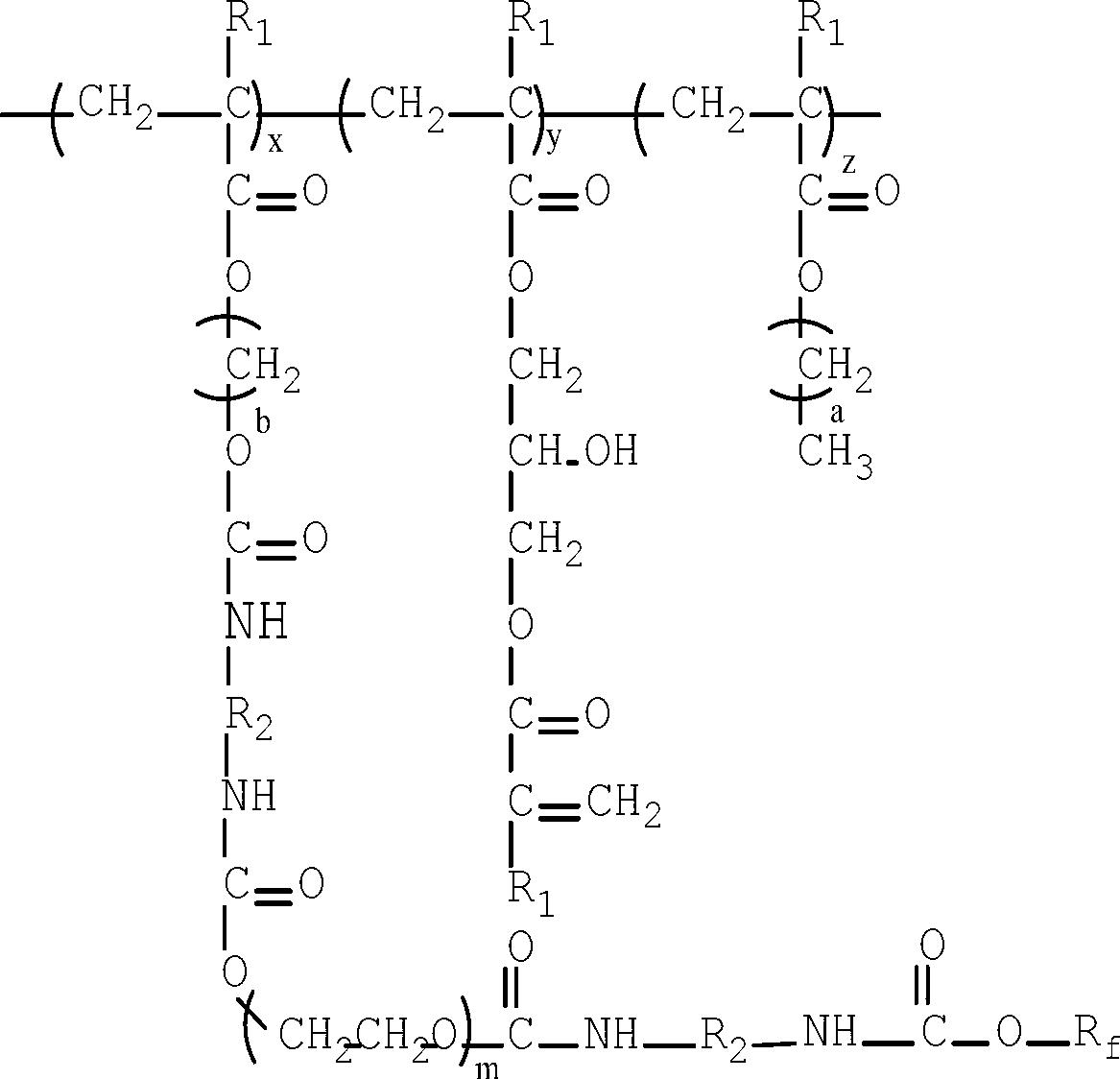

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of organic fluorine-modified polyurethane prepolymer: In parts by weight, take 100 parts of polyether diol N210 (relative molecular weight: 1000) into a reactor equipped with a stirrer and a thermometer, heat and stir to 60°C Then, 34 parts of toluene diisocyanate (TDI) was added and reacted for 3 hours to obtain a polyurethane prepolymer. Then add 21 parts of octafluoropentanol, continue to react at 60°C for 4 hours, then take a sample for testing, the results of its infrared spectrum show that at 3335cm -1 The -NH- stretching vibration peak appeared at 1730cm -1 The carbonyl stretching vibration peak appeared at 3650cm -1 The O-H stretching vibration peak disappeared, indicating that the isocyanate group of toluene diisocyanate reacted with polyether diol, and then the terminal -NCO reacted with the hydroxyl group of octafluoropentanol to obtain partially octafluoropentanol-capped polyurethane Prepolymer PU1.

[0038] (2) Preparation of (meth)acryla...

Embodiment 2

[0043] (1) Preparation of organic fluorine-modified polyurethane prepolymer: In parts by weight, take 100 parts of polyether diol N210 (relative molecular weight: 1000) into a reactor equipped with a stirrer and a thermometer, heat and stir to 80°C Then, 34 parts of toluene diisocyanate (TDI) was added and reacted for 3 hours to obtain a polyurethane prepolymer. Then add 21 parts of octafluoropentanol, react at 80°C for 4 hours, then take a sample for testing, the results of the infrared spectrum show that at 3335cm -1 N-H stretching vibration peak appeared at 1730cm -1 The carbonyl stretching vibration peak appeared at 3650cm -1 The O-H stretching vibration peak disappears, indicating that the isocyanate group of toluene diisocyanate reacted with polyether diol, and then the terminal -NCO reacted with the hydroxyl group of octafluoropentanol, indicating that a part of octafluoropentanol-capped Polyurethane prepolymer PU1.

Embodiment 3

[0049] (1) Preparation of organic fluorine-modified polyurethane prepolymer: In parts by weight, take 100 parts of polyether diol N210 (relative molecular weight: 1000) into a reactor equipped with a stirrer and a thermometer, heat and stir to 60°C Then, 34 parts of toluene diisocyanate (TDI) was added and reacted for 3 hours to obtain a polyurethane prepolymer. Then add 21 parts of octafluoropentanol, continue to react at 60°C for 4 hours, then take a sample for testing, the results of its infrared spectrum show that at 3335cm -1 N-H stretching vibration peak appeared at 1730cm -1 The carbonyl stretching vibration peak appeared at 3650cm -1 The O-H stretching vibration peak disappears, indicating that the isocyanate group of toluene diisocyanate reacted with polyether diol, and then the terminal -NCO reacted with the hydroxyl group of octafluoropentanol, indicating that a part of octafluoropentanol-capped Polyurethane prepolymer PU1.

[0050] (2) Preparation of (meth)acryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com