Fluorinated textile finishing agent composition and preparation method therefor

A technology for fabric finishing agent and composition, which is applied in the directions of fiber treatment, textile and paper making, etc., can solve the problems of insufficient oil repellency and unsatisfactory oil repellency of the composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] According to the preparation method provided by the above-mentioned technical scheme:

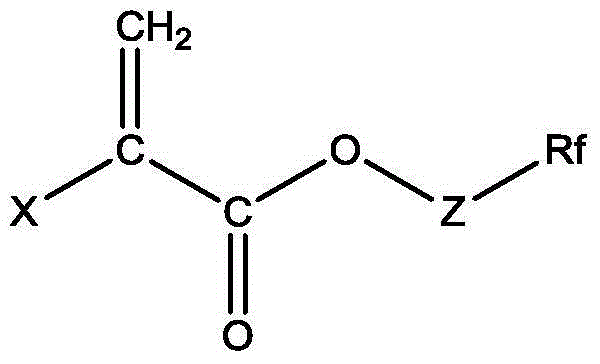

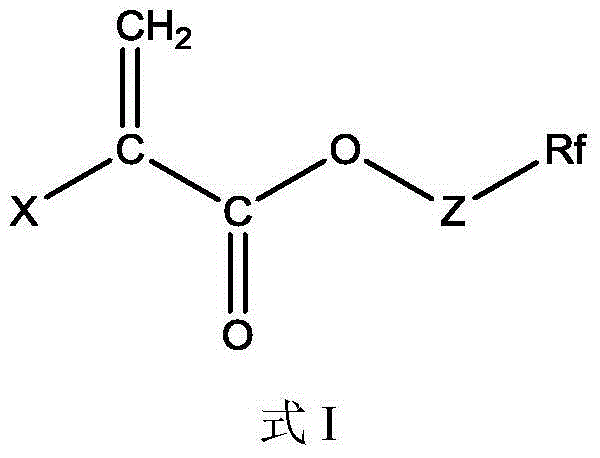

[0034] In some embodiments, in Formula I, Rf is selected from perfluoroalkyl groups with 4 or 6 carbon atoms.

[0035] In some embodiments, the perfluoroalkyl acrylate monomer is selected from perfluorobutyl (meth)acrylate, perfluorohexyl (meth)acrylate, perfluorobutyl acrylate, perfluorohexyl acrylate one or both.

[0036] In some embodiments, based on a total of 100 parts by mass, the added amounts of perfluoroalkyl acrylate monomers, fatty alcohol acrylate monomers, and crosslinking monomers are 30-60 parts, 20-50 parts, 2- 10 parts, the balance is reinforcing monomer.

[0037] In some embodiments, the emulsifier is a composite emulsifier of a cationic emulsifier and a nonionic emulsifier, wherein the cationic emulsifier is selected from dodecyltrimethylammonium bromide, cetyltrimethylammonium bromide, One of cetyltrimethylammonium chloride and octadecyltrimethylammonium chlori...

specific Embodiment approach

[0058] What is described below is the embodiment of the present invention, and what the present invention protects is not limited to the following embodiment. It should be pointed out that for those skilled in the art, some modifications and improvements made on the basis of this inventive concept all belong to the protection scope of the present invention. The raw materials used in the examples are all commercially available.

[0059] The percentages described in the following examples are mass fractions unless otherwise specified.

Embodiment 1

[0061] With 165g perfluorobutyl (meth) ethyl acrylate, 105g octadecyl acrylate, 24g N-methylol acrylamide, 8g alkylphenol polyoxyethylene (10) ether; 8g polyoxyethylene sorbitan fatty acid ( 80) Ester, 8g of cetyltrimethylammonium chloride, 160g of polyethylene glycol, 0.5g of n-hexadecylmercaptan, and 560g of deionized water were added to the container, mechanically stirred at 50°C and 700rpm for 10min, at room temperature, 12000rpm high-speed disperser was used for pre-emulsification for 15 minutes, the pre-emulsion was cooled to below 30°C, and 36g of vinylidene chloride was added; 1.7g of ammonium persulfate was added at 70°C, and the polymerization was carried out for 3.5h. The resulting emulsion had a solids content of about 27%. Dilute to 0.5% emulsion with deionized water, add 2% fiber crosslinking agent, and carry out after-treatment on cotton, polyester and nylon fabrics respectively.

[0062] Carry out waterproof test, oil resistance level test and washing durabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com