Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Feel firm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

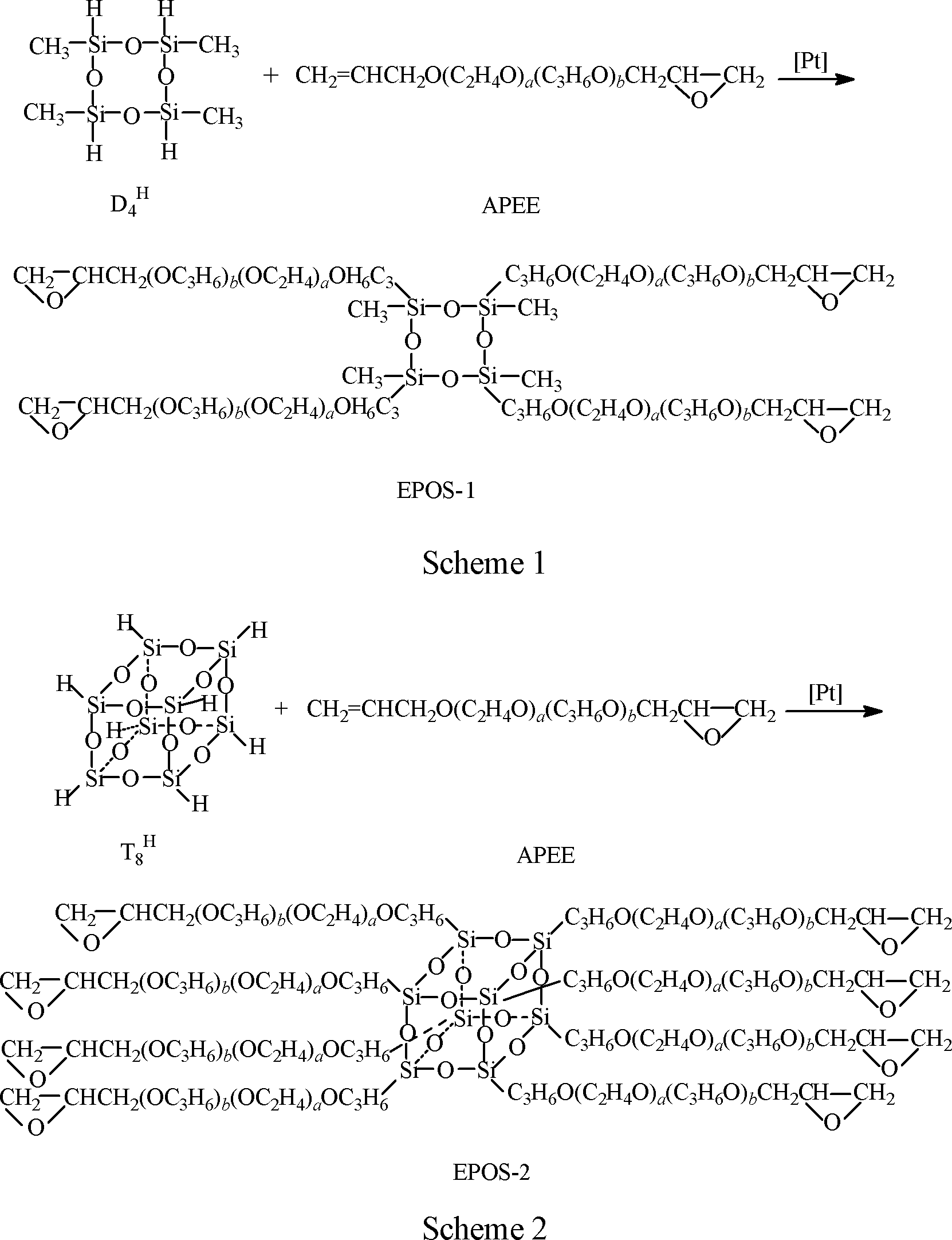

Preparation method of (sesqui) siloxane hybrid modified fluorinated polyacrylate emulsion

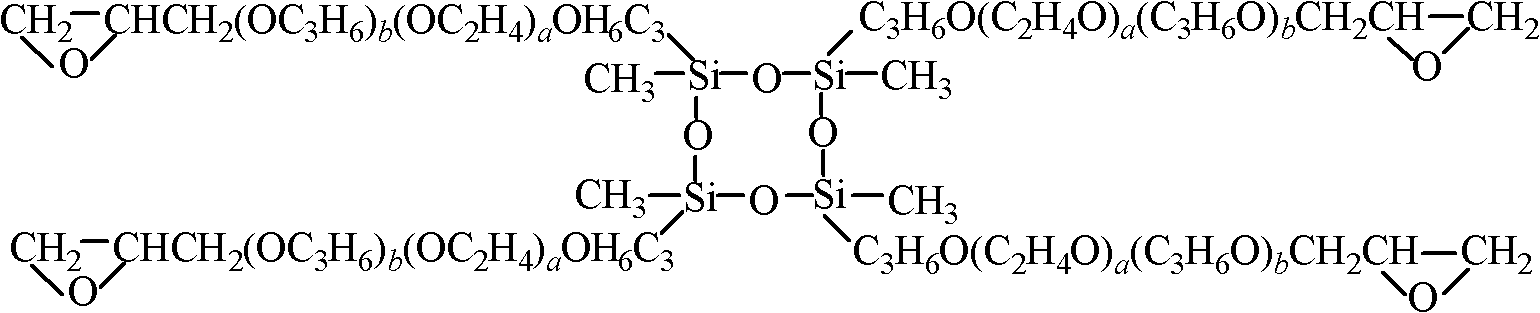

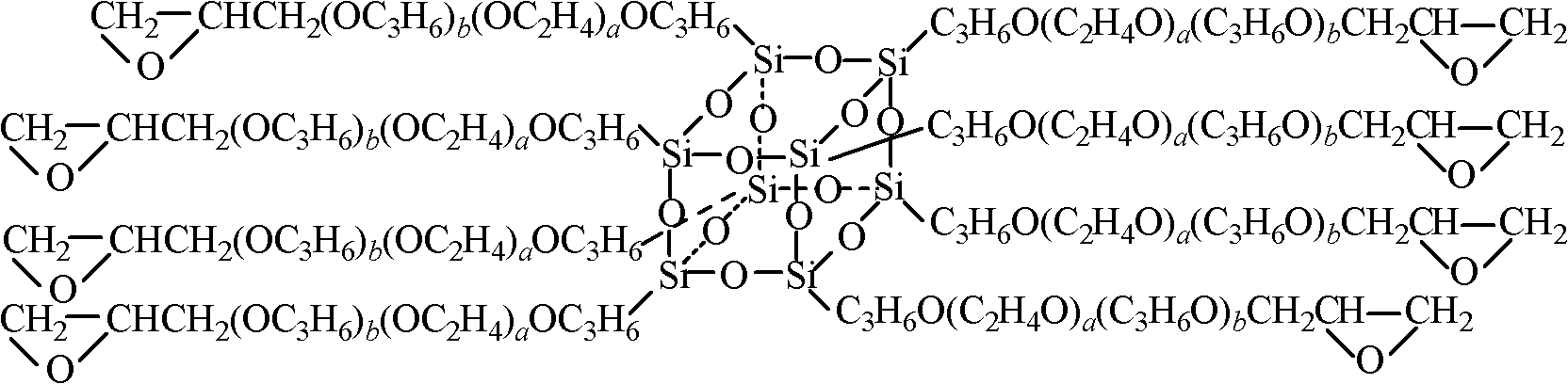

The invention discloses a preparation method of an epoxy polyether-based (sesqui) siloxane hybrid modified fluorinated polyacrylate emulsion, which comprises the following steps of: under the effect of cationic / nonionic or anionic / nonionic surfactants, firstly carrying out seeded emulsion copolymerization on perfluoroalkyl(methyl) acrylate, aliphatic long carbon chain (methyl) acrylate, reactive vinyl monomer and alpha-alkenyl alkoxysilane in an aqueous phase so as to synthesize a silanized long carbon chain fluorinated polyacrylate emulsion; cooling to room temperature; regulating a pH value of the system to be 5.0-6.0; adding an epoxy polyether-based (sesqui) siloxane cross-linking agent and a stiffening agent; continuously stirring for 30 min; and obtaining the (sesqui) siloxane hybrid modified fluorinated polyacrylate emulsion after filtering. The modified fluorinated polyacrylate emulsion disclosed by the invention can be used for after-treatment of textiles after dilution, so that the stiff handfeel of textiles can be improved, and an excellent water-repellent and oil-repellent performance is given to the textiles.

Owner:SHAANXI UNIV OF SCI & TECH

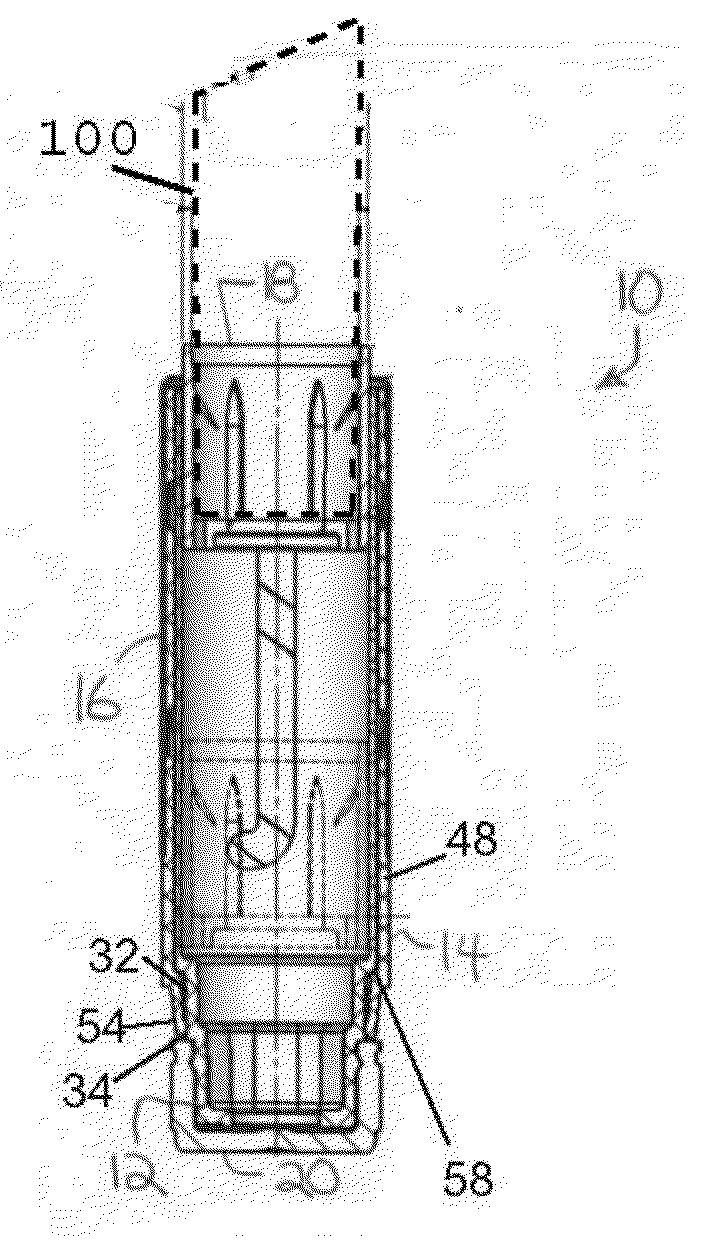

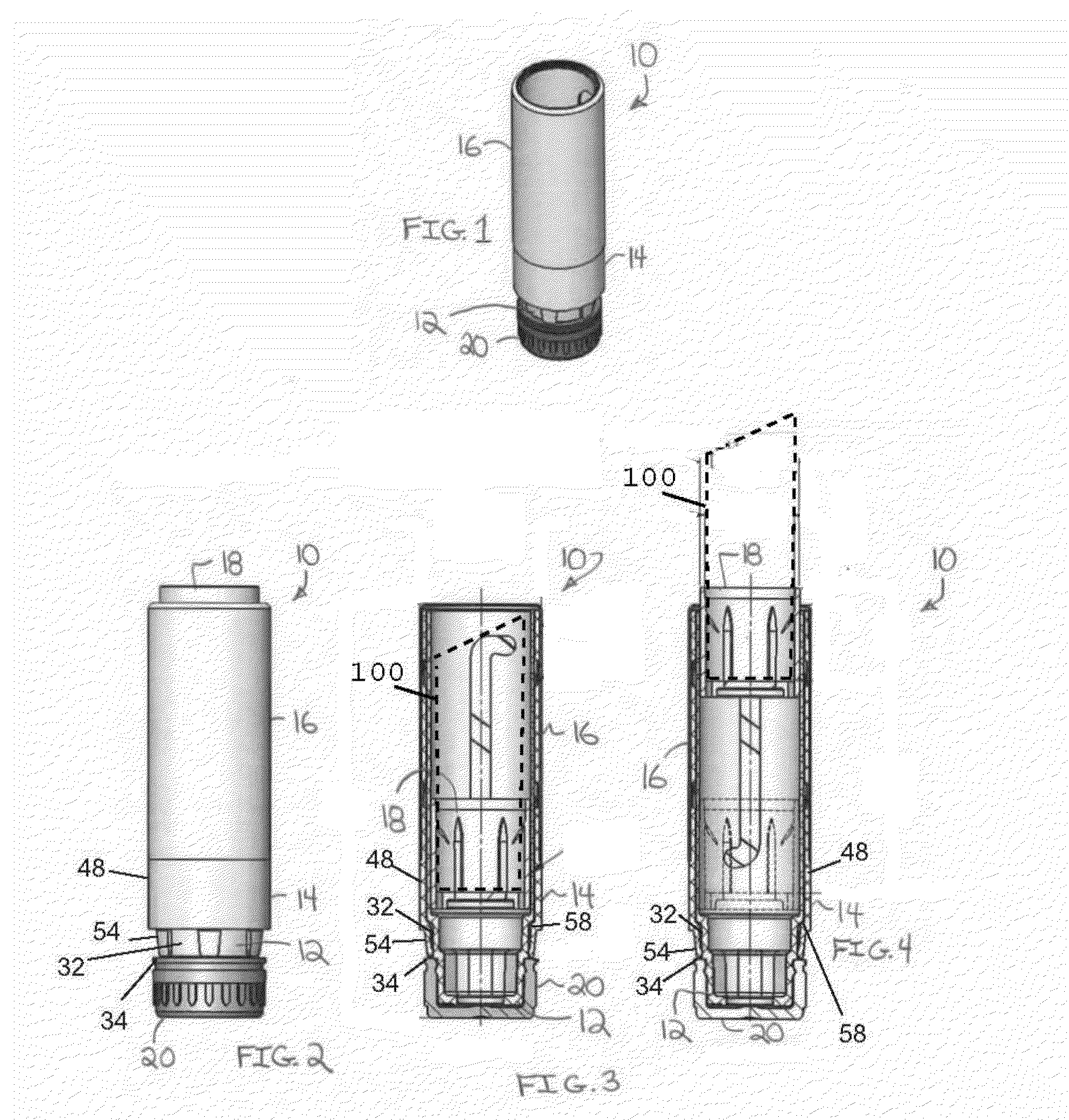

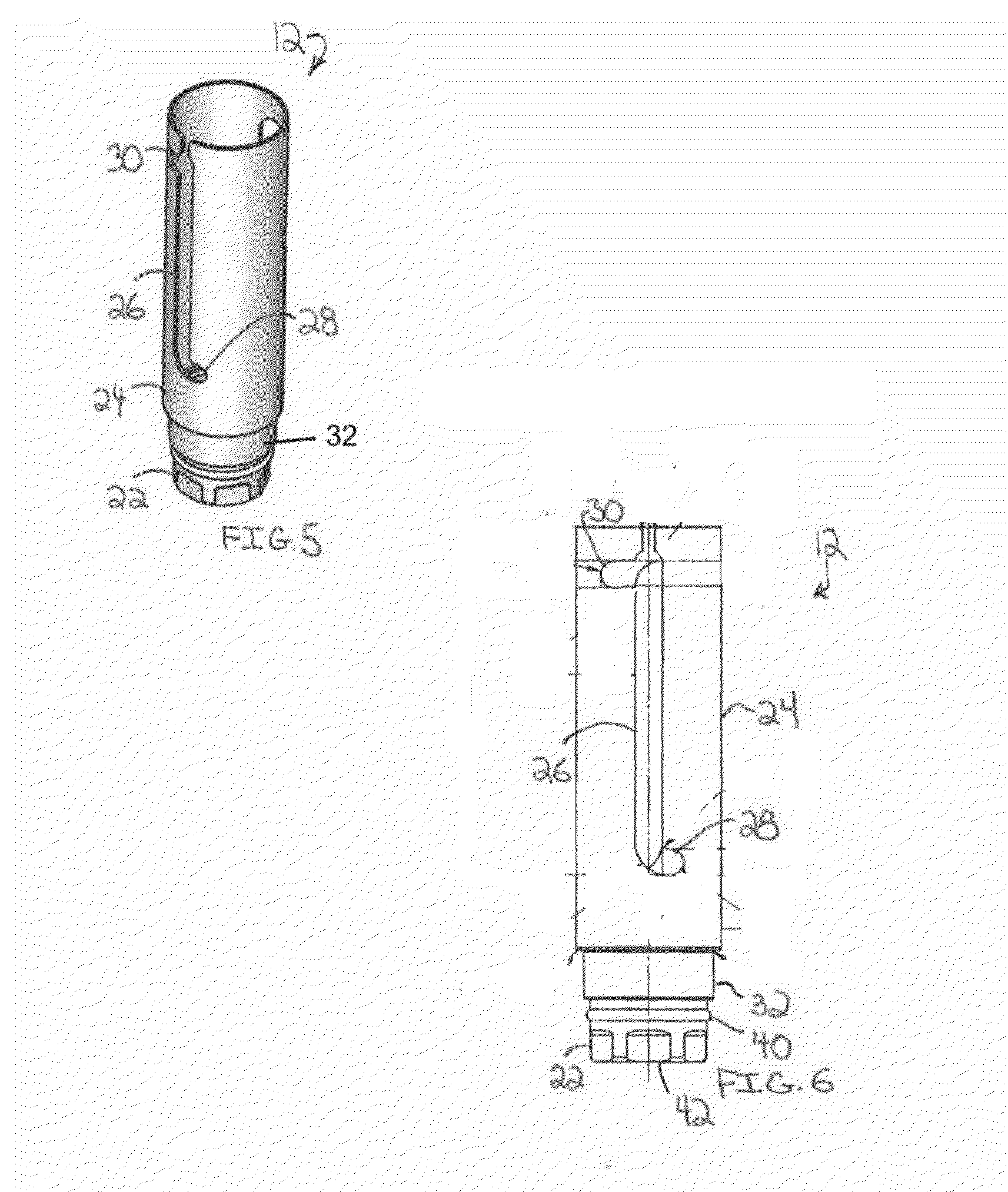

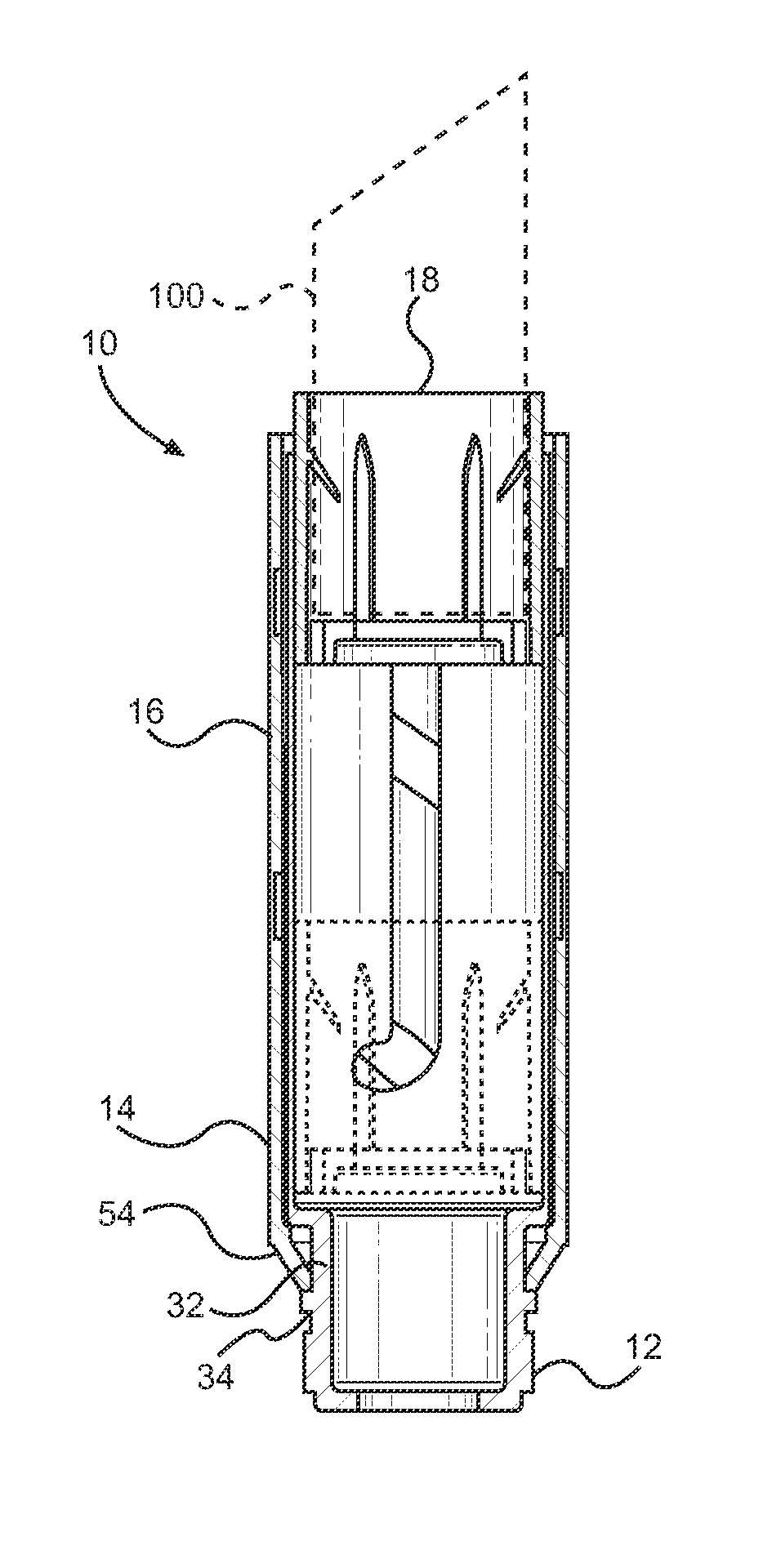

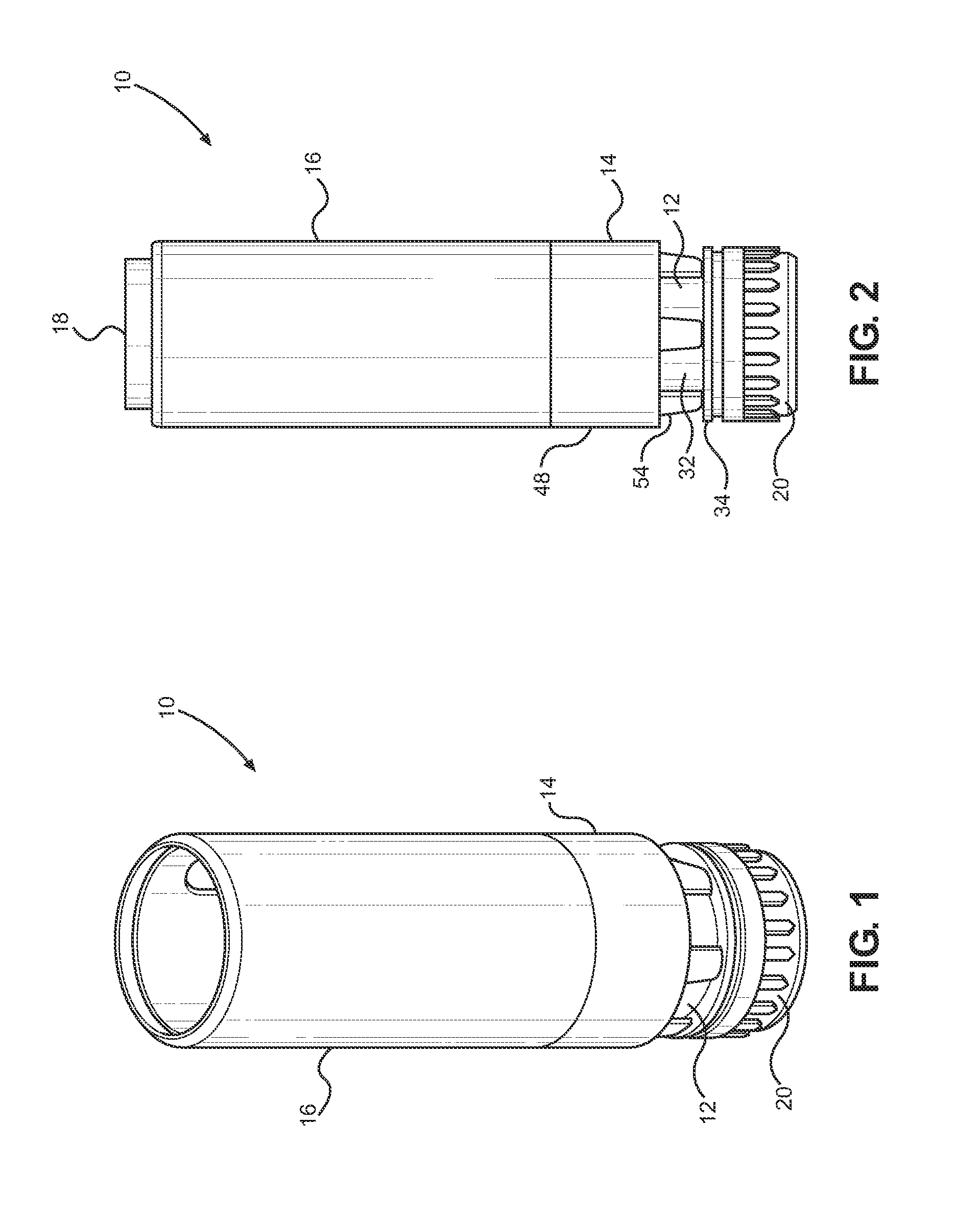

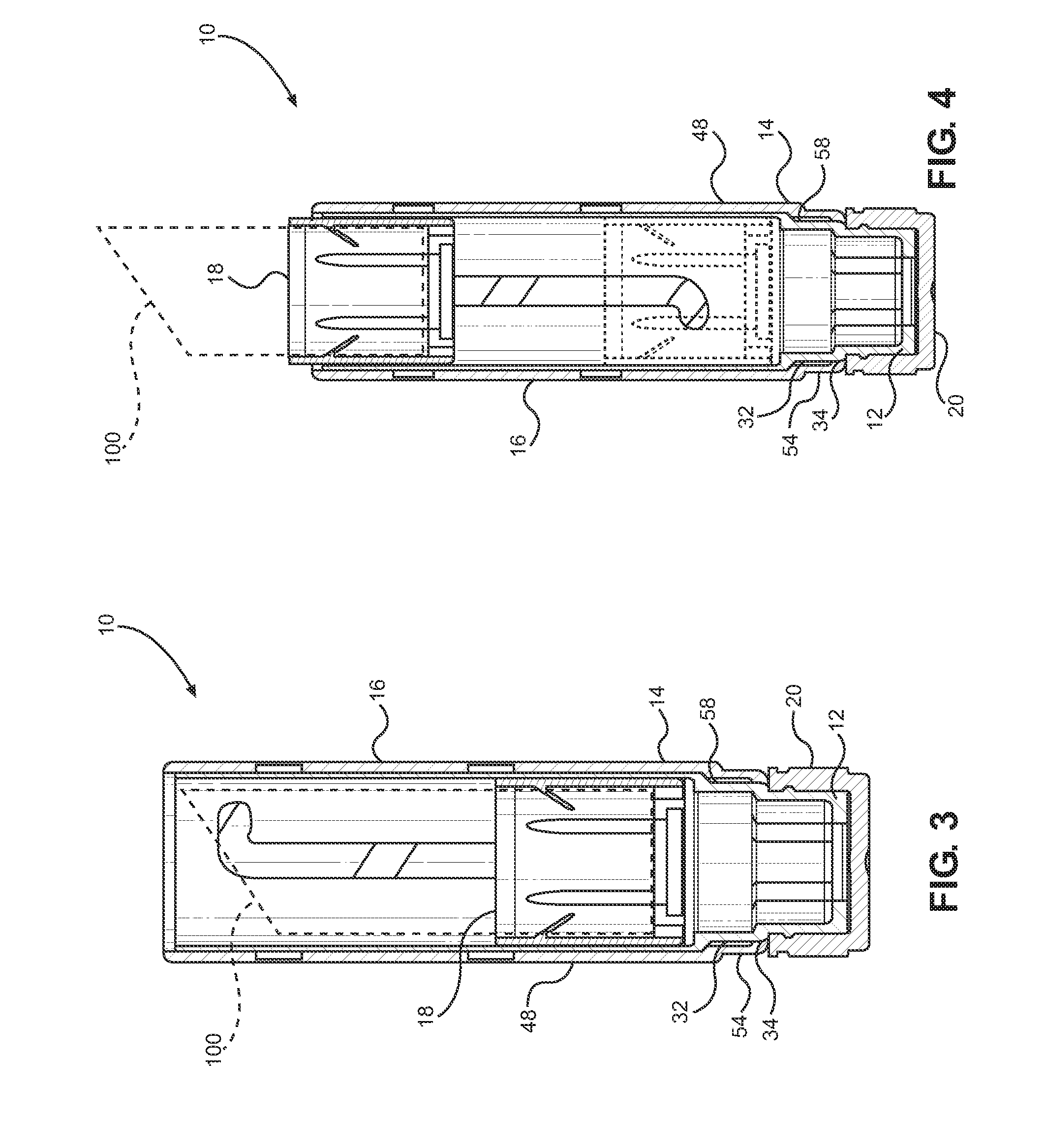

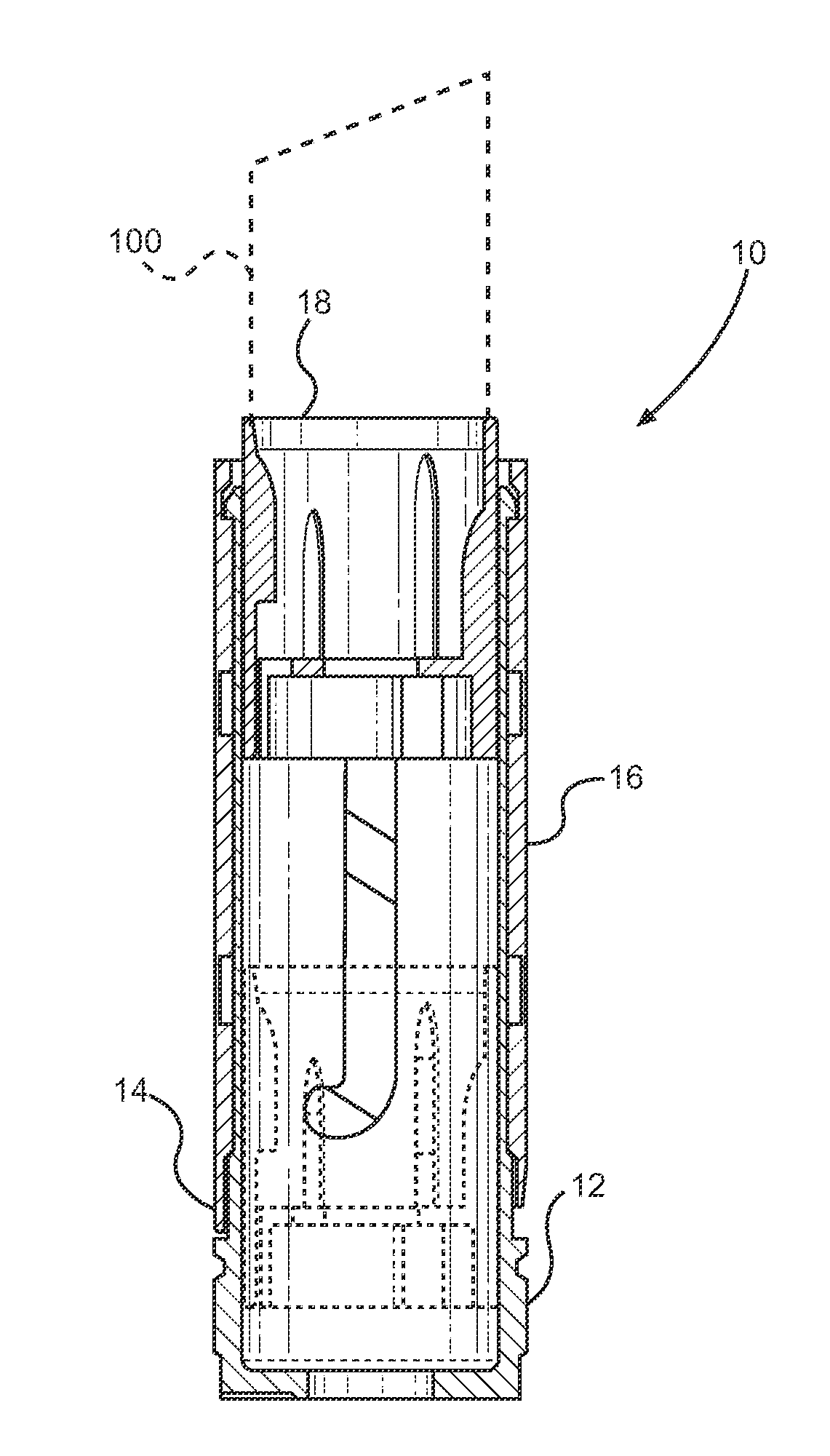

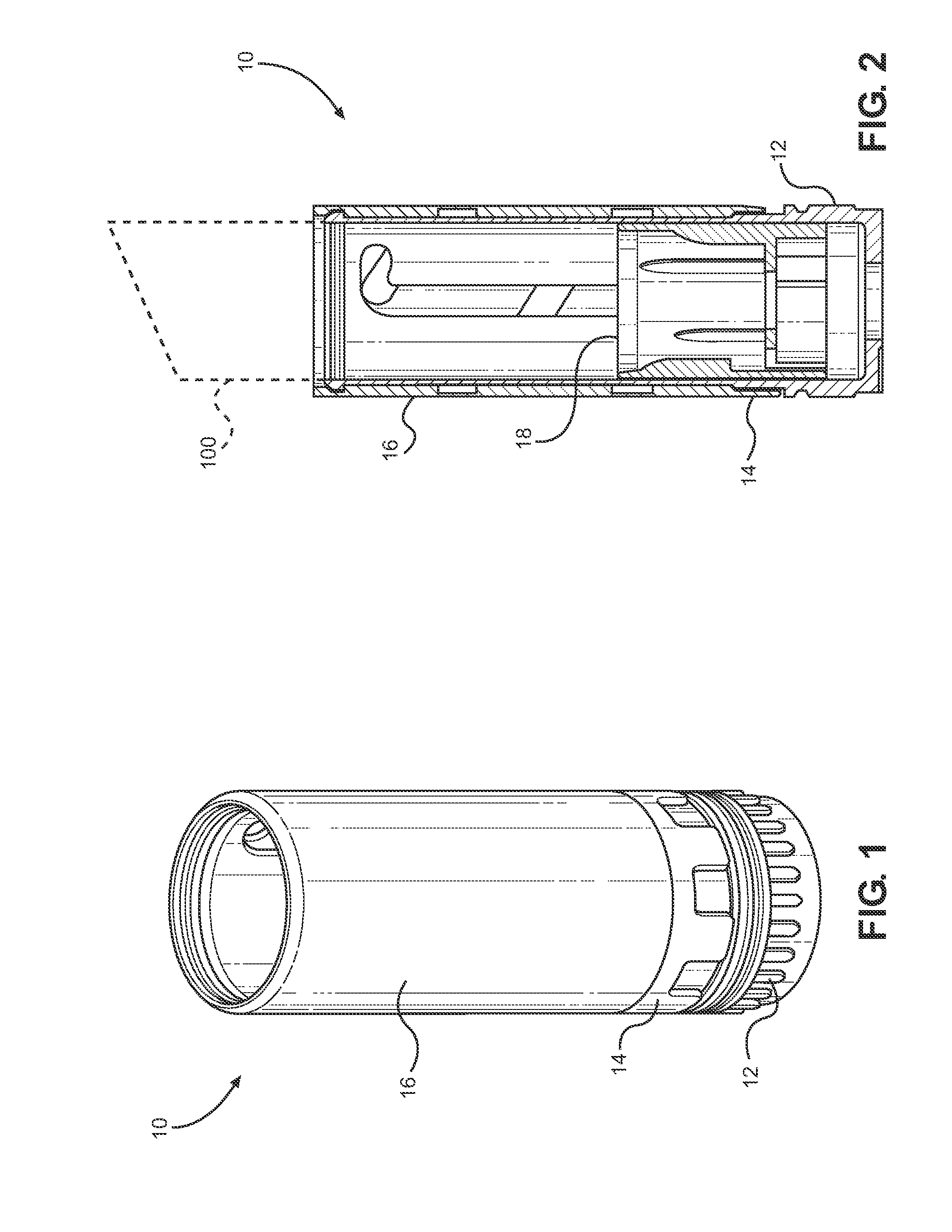

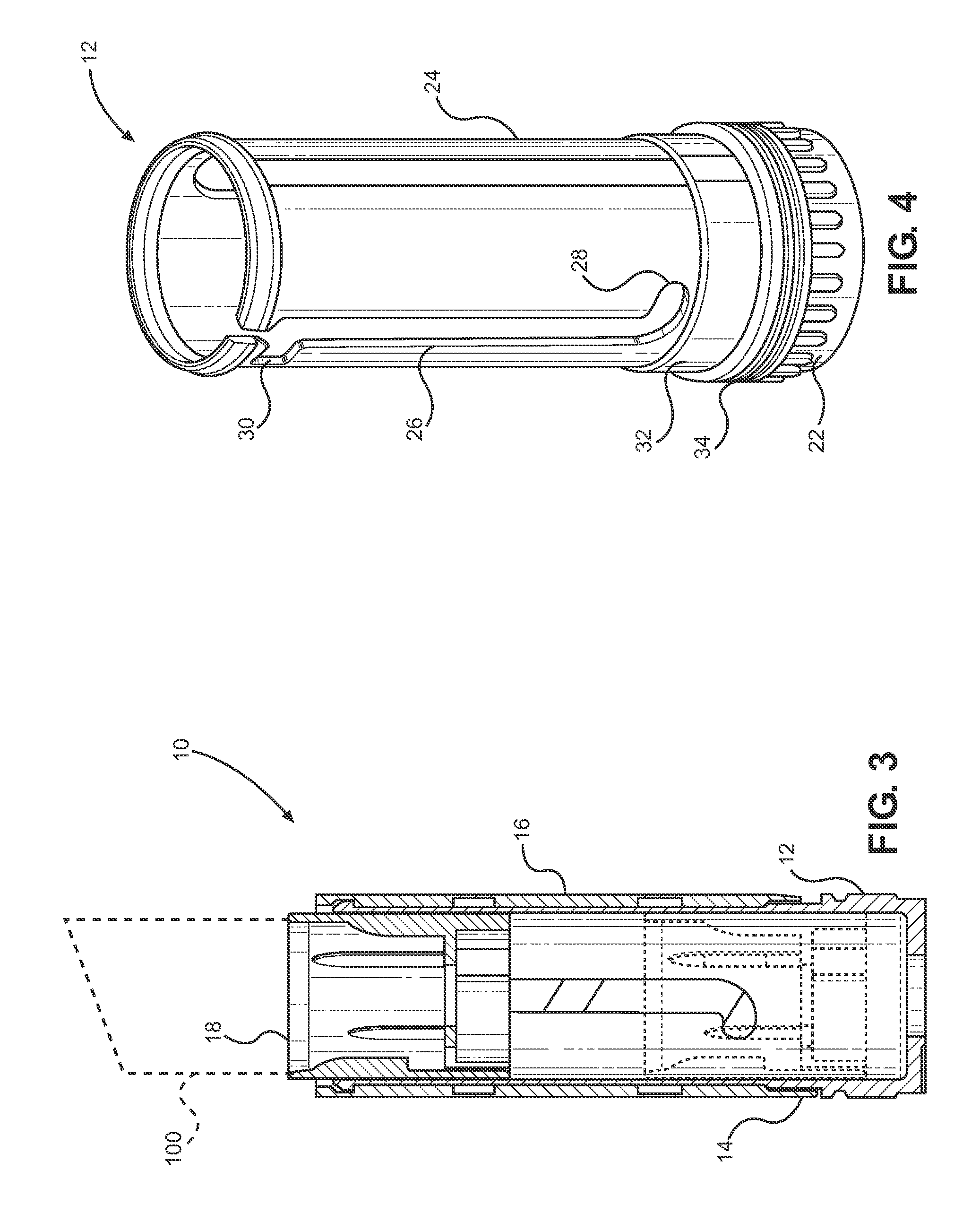

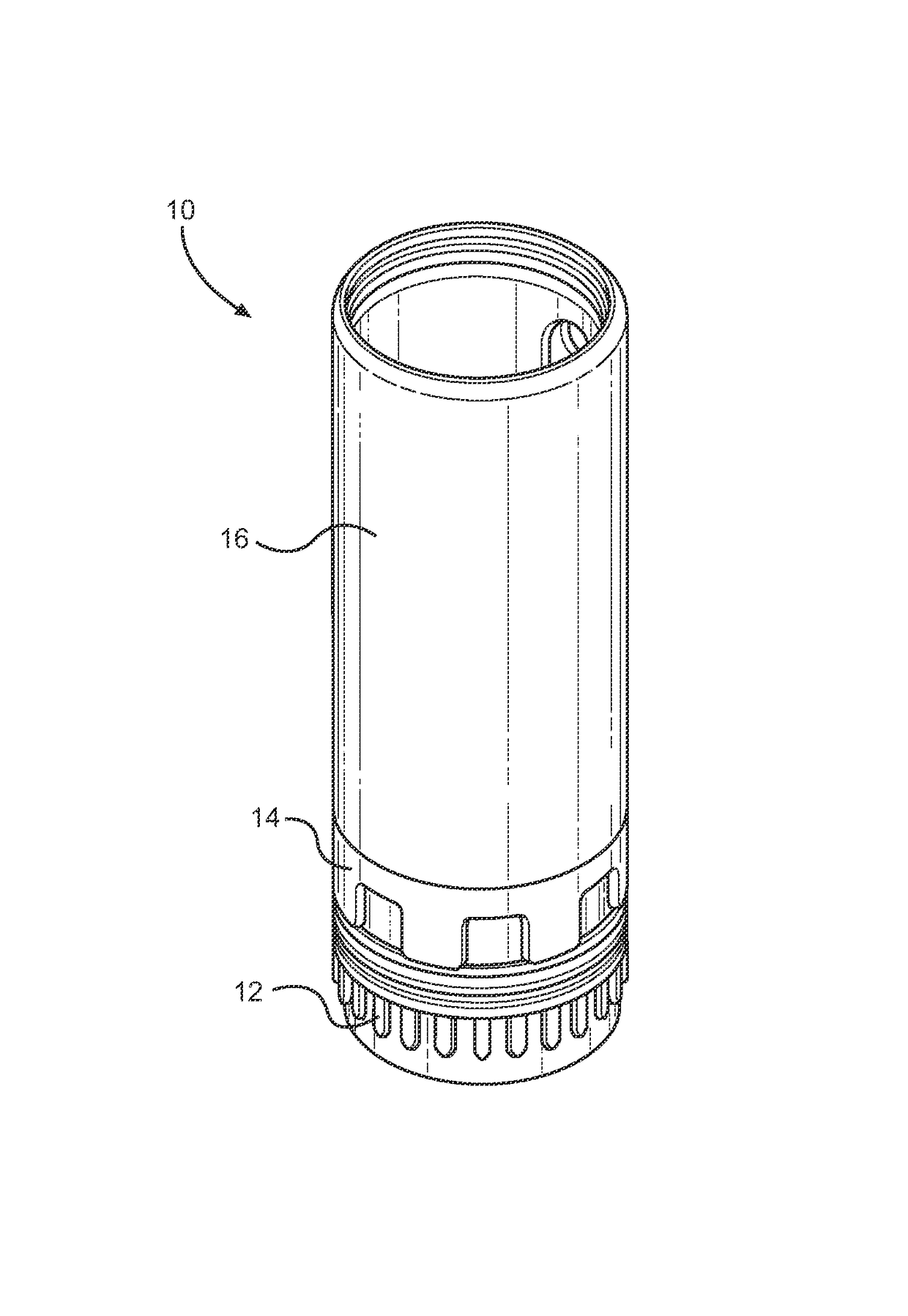

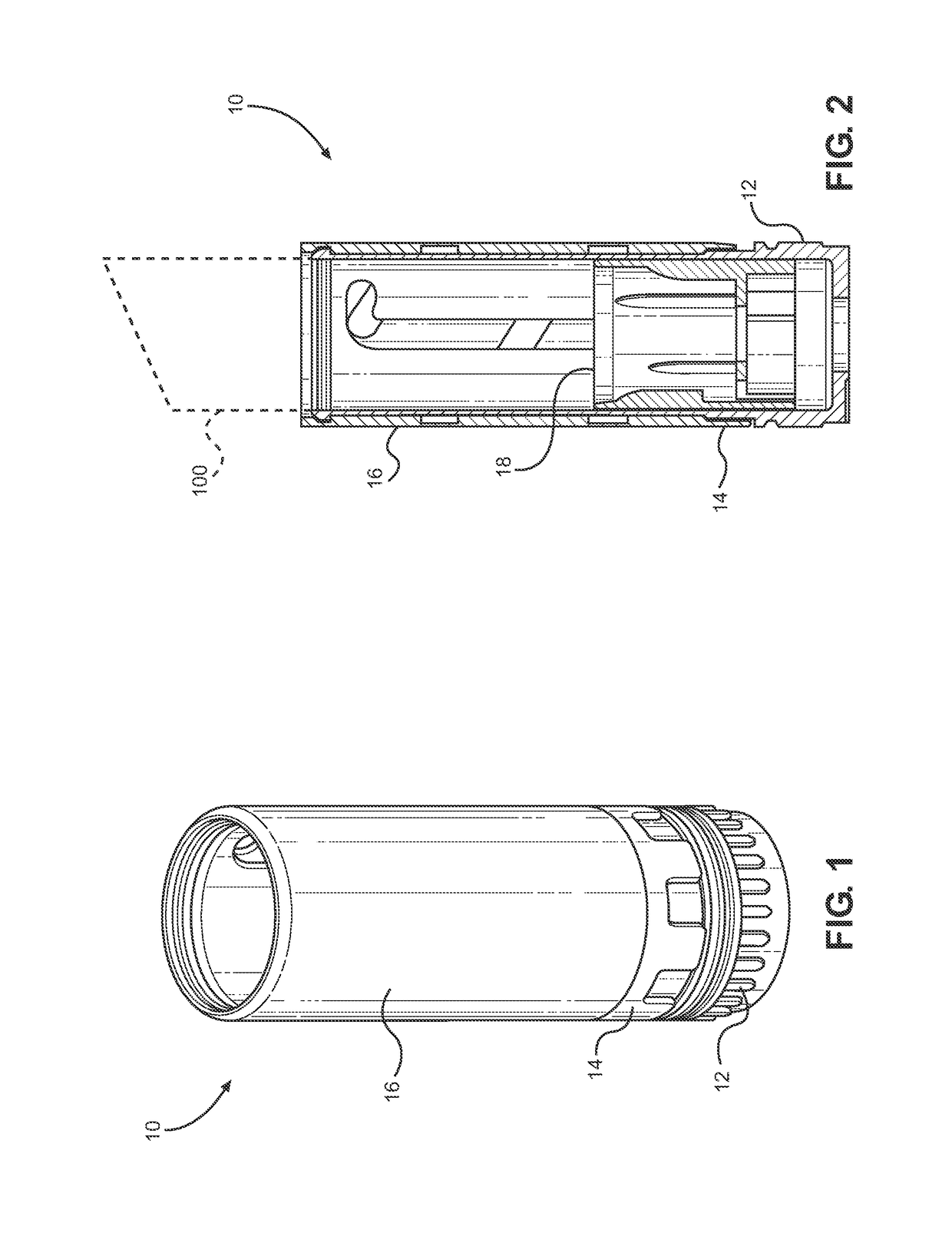

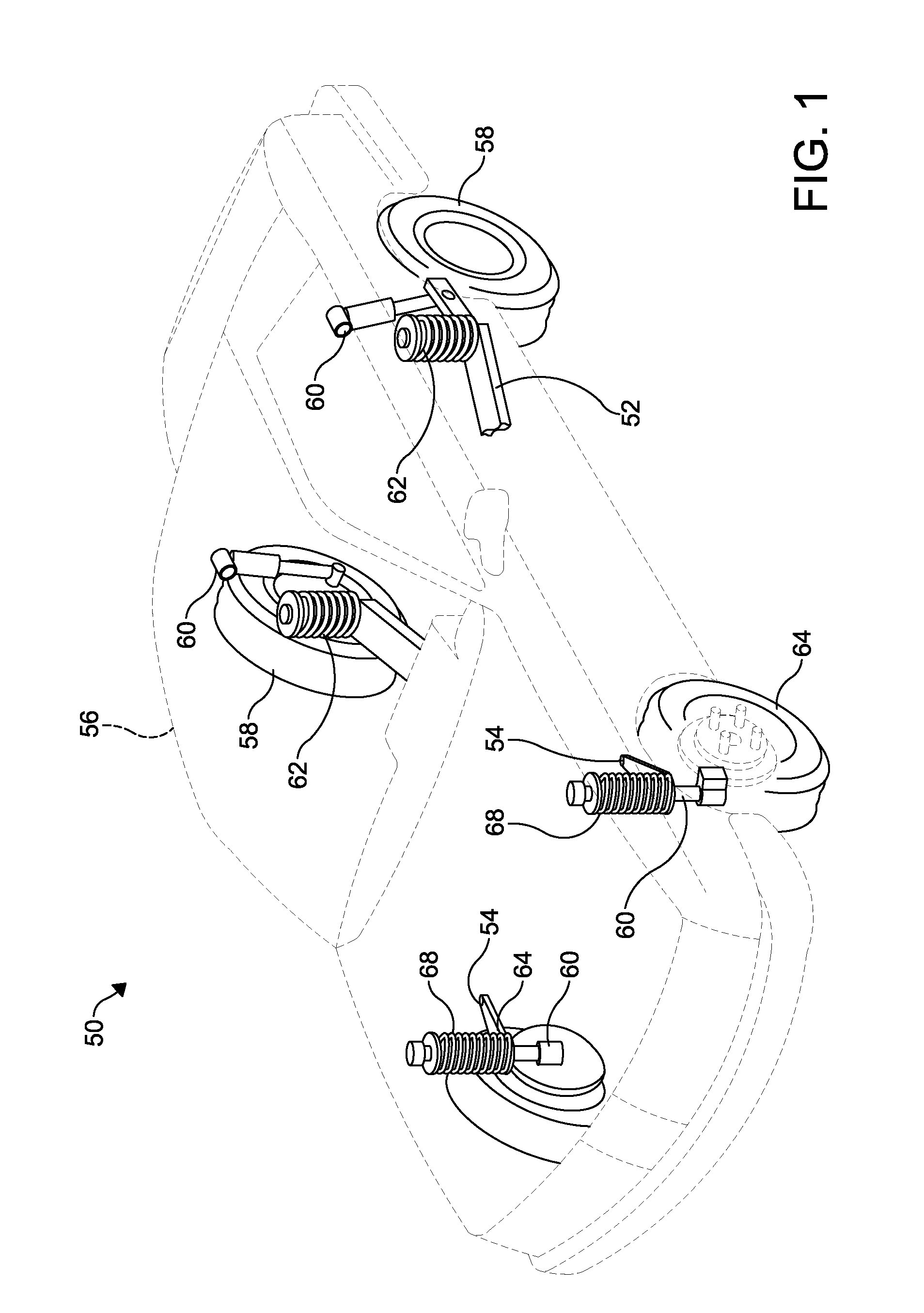

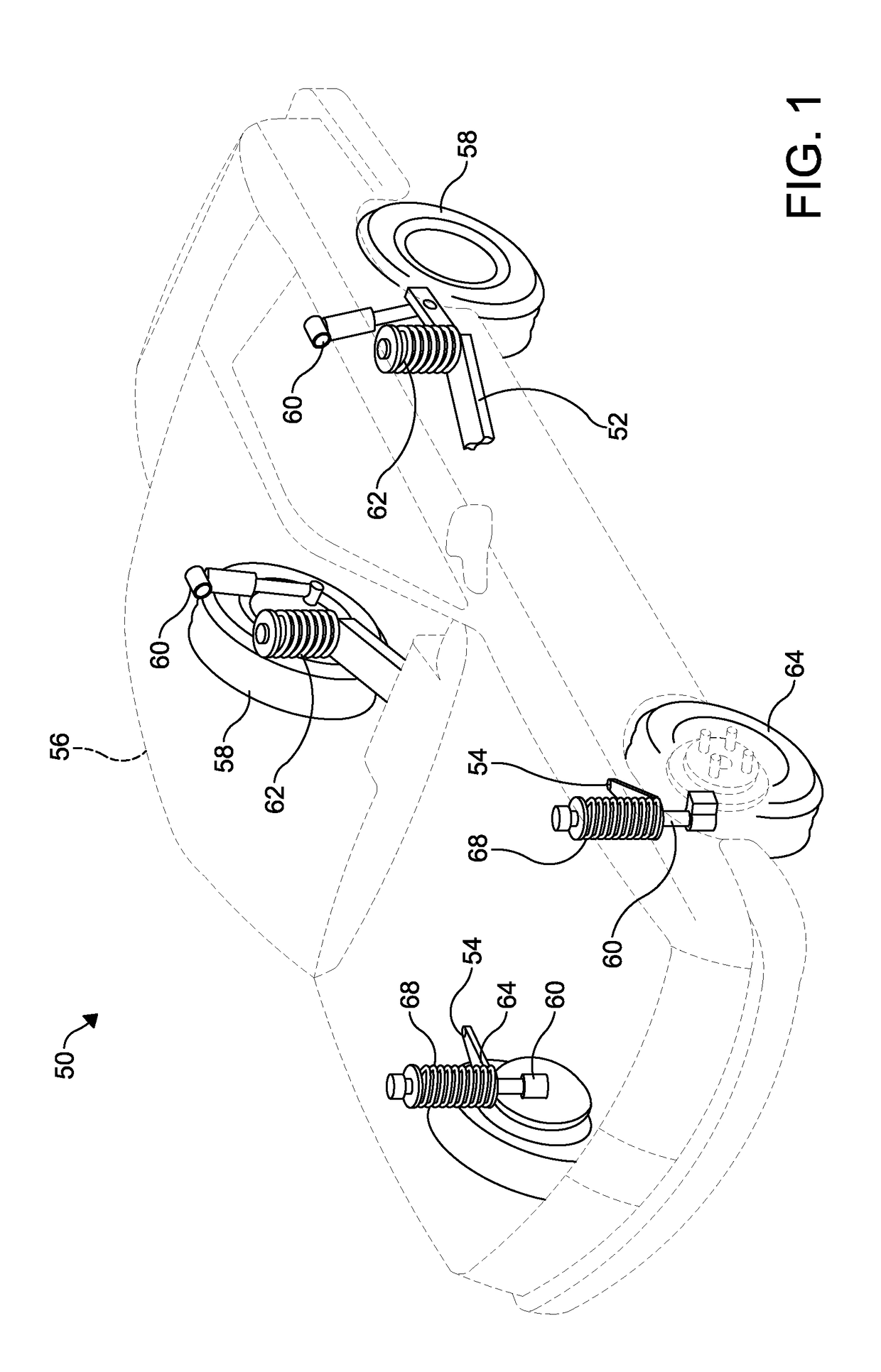

Cosmetic Dispenser with Frictional Resistance

ActiveUS20150208785A1Avoid harmful effectsFeel firmPropelling pencilsPackaging toiletriesEngineeringBearing surface

A cosmetic dispenser with an inner body rotatably engaged with a spiral member. An elevator cup retains a cosmetic pomade, and the spiral member has spiral formations along an inner surface thereof for engaging lugs of the elevator cup that pass through longitudinal tracks in the inner body. The inner body can have lateral and longitudinal bearing surfaces with the lateral bearing surface aligned longitudinally with a longitudinal axis of relative rotation of the spiral member and the inner body and the longitudinal bearing surface orthogonal thereto. Fingers can project inwardly from the inner body to be in slidable, frictional contact with both the longitudinal and lateral bearing surfaces so that the fingers are restrained laterally and longitudinally. The fingers can be inwardly angled establish an effective circumference with the fingers tangent thereto smaller than the circumference of the lateral bearing surface.

Owner:HCP PACKAGING USA

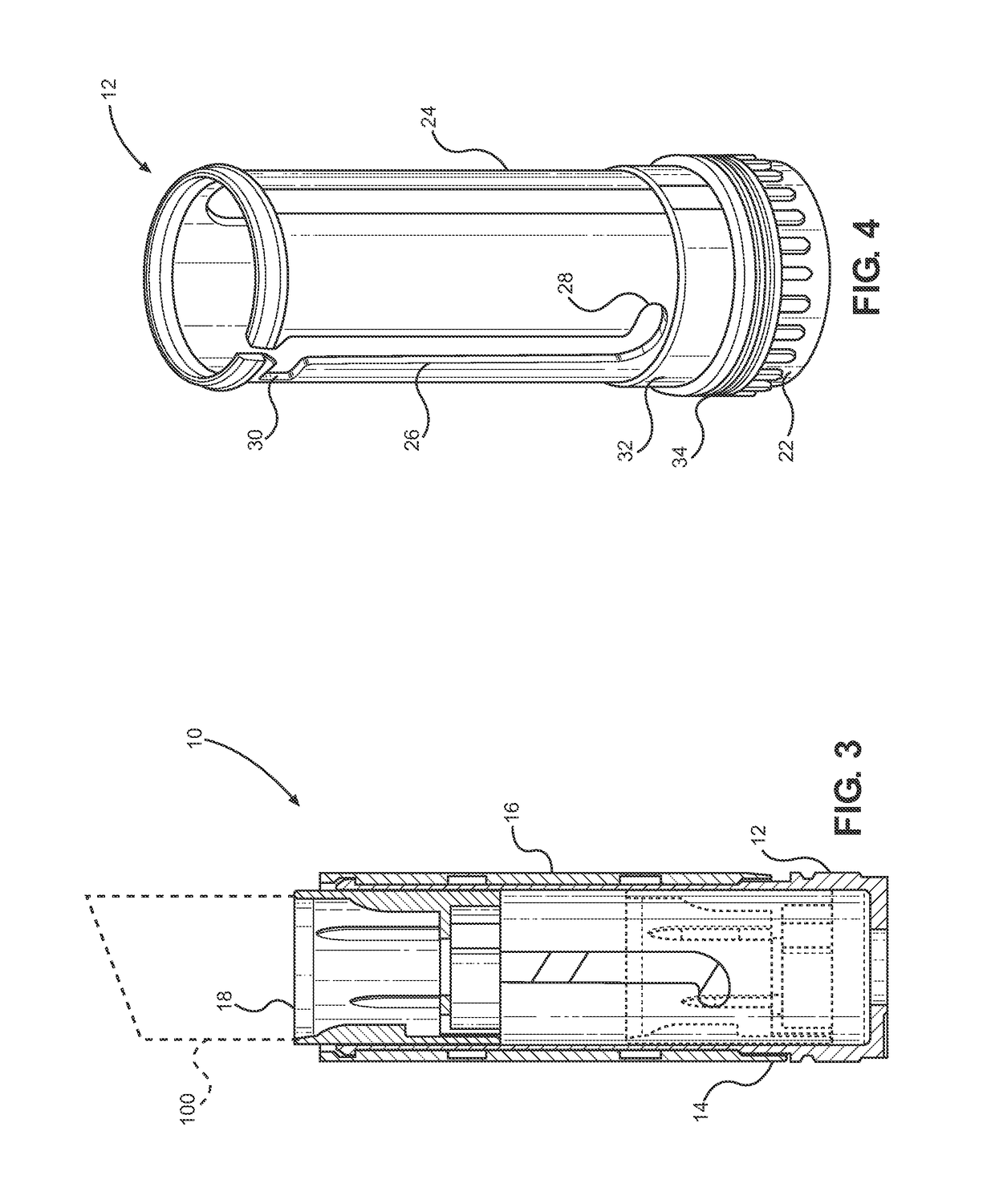

Cosmetic dispenser with frictional resistance

ActiveUS9474349B2Avoid harmful effectsFeel firmPackaging toiletriesPackaging cosmeticsEngineeringBearing surface

A cosmetic dispenser with an inner body rotatably engaged with a spiral member. An elevator cup retains a cosmetic pomade, and the spiral member has spiral formations along an inner surface thereof for engaging lugs of the elevator cup that pass through longitudinal tracks in the inner body. The inner body can have lateral and longitudinal bearing surfaces with the lateral bearing surface aligned longitudinally with a longitudinal axis of relative rotation of the spiral member and the inner body and the longitudinal bearing surface orthogonal thereto. Fingers can project inwardly from the inner body to be in slidable, frictional contact with both the longitudinal and lateral bearing surfaces so that the fingers are restrained laterally and longitudinally. The fingers can be inwardly angled establish an effective circumference with the fingers tangent thereto smaller than the circumference of the lateral bearing surface.

Owner:HCP PACKAGING USA

Process for tanning and softening sheepskin by multi-carboxylic nano compound chrome tanning additive

InactiveCN103509889AFulfil requirementsRequirements meetTanning treatmentPre-tanning chemical treatmentLiquid wasteFiber

The invention belongs to the field of leather tanning process and relates to a process for tanning and softening sheepskin by a multi-carboxylic nano compound chrome tanning additive. In a traditional chrome tanning method, the use of various chemicals in picking and chrome tanning procedures causes damage to the ecological environment. According to leather tanning mechanisms and structural features of collagenous fiber and the multi-carboxylic nano compound chrome tanning additive, the process used for leather tanning and skin softening is characterized in that the shrinkage temperature of blue wet leather can reach 105 DEG C, the grain side is flat and fine, and the requirements of goat skin garment leather can be met; compared with the method that 8 percent of chromium powder is adopted for conventional tanning liquid waste, liquid waste is characterized in that the content of Cr2O3 in the liquid waste is reduced to 172 mg / L from 1,952 mg / L, and the content of chromium in the liquid waste is reduced greatly; compared with the conventional chrome tanned leather, the chrome tanned leather treated through the process has the advantages that excellent effects to follow-up backwater, neutralization, and control to chromium pollution in dying and oiling liquid waste are achieved, the physical and mechanical performance of crust leather is similar, compact hand feeling is achieved, the filling performance and the softness are excellent, and the requirements of the goat skin garment leather can be met.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of multi-component flame retardant easy-to-clean filtering material and non-woven filtering material

The invention discloses a preparation method of a multi-component flame retardant easy-to-clean filtering material and a non-woven filtering material, and relates to a preparation method of a filtering material. The preparation method of the multi-component flame retardant easy-to-clean filtering material comprises the steps of unpacking and checking 30-40% of melting point polyester staple fiber, 20-30% of flame retardant polyester staple fiber in 20-30% of three types of fibers and 8-15% of aramid staple fiber according to percentage by mass for evenly mixing, then loosening and carding, lapping after carding, adding lapped raw materials into a hot melt forming area, enabling low-melting-point polyester staple fiber of the filtering material to melt firstly at high temperature of 190-215 DEG C and be subjected to hot melting and bonding with evenly-lapped high-melting-point polyester staple fiber and the aramid staple fiber to form a whole body which is a finished product. The preparation method is simple; the product is environmentally friendly and safe; the strength of the filtering material after spray finishing is improved; the hand feel of the filtering material is stiff, thus facilitating pleating; the effective filtering area is increased; and the filtering material is stable and durable in flame retardant performance and good in decontamination effect.

Owner:NANCHANG CHENGLE NEW MATERIAL

Cosmetic Dispenser with Crenelated Wall for Frictional Resistance

ActiveUS20150296958A1Avoid harmful effectsFeel firmPropelling pencilsPackaging toiletriesGear wheelEngineering

A cosmetic dispenser with an inner body, an outer body, and an elevator cup has a rotary extension and retraction mechanism, a first annular bearing surface retained relative to the inner or outer body and an annular wall retained relative to the other of the outer or inner body. The annular wall can be a skirt of the outer body and can be crenelated into arcuate merlons and crenels. The merlons establish an effective circumference that overlaps with the circumference of the first annular bearing surface to provide frictional resistance to a rotation of the inner body relative to the outer body. The merlons can surround the first annular bearing surface and establish a circumference smaller than the circumference of the first annular bearing surface. The annular bearing surface can be a lateral bearing surface, and a second annular bearing surface can form a longitudinal bearing surface.

Owner:HCP PACKAGING USA

Foaming flame-retardant coating for curtain

InactiveCN105544215AAdd flame retardant protection functionEnsure safetyStain/soil resistant fibresHeat resistant fibresFiberAssociation type

The invention relates to a foaming flame-retardant coating for a curtain. The coating comprises matrix emulsion composed of ethylene-vinyl acetate copolymerized resin, 3(2, 3-dibromopropyl) isocyanurate, association type waterborne polyurethane emulsion, polyacrylate emulsion, fumed silica, sulfo succinate, sulfo succinamide, a silicon-nitrogen compound, oxirane / epoxypropane segmented copolymer, modifier, wood fiber powder and aluminic acid ester. By means of the finishing process of the foaming flame-retardant coating for the curtain, the requirement for the finishing process of a heavy fabric can be met, physical foaming is directly conducted on the coating through a mechanical foaming machine, and then coating finishing is conducted, and meanwhile the defects that an original curtain fabric is poor in moisture absorption performance, carries static electricity easily, is poor in air permeability and the like are overcome.

Owner:陈东东

Method for preparing water polyurethane hot dissolving coating adhesive used for sofa-like leatheret

InactiveCN101148492AImprove adhesion fastnessHigh strengthPolyureas/polyurethane adhesivesFibre treatmentHydrophilic monomerPolymer science

The present invention is process of preparing heat dissolving coating adhesive of water soluble polyurethane for adhesion of fabric and artificial leather. The preparation process includes the first reaction of diisocyanate and ester compound to produce pre-polymer with -NCO end group, the subsequent chain expanding reaction with hydrophilic monomer and 1, 4-butanediol, and the final pH regulation to neutrality with amine and adding deionized water through stirring. The heat dissolving coating adhesive has great adhesion strength, capacity of resulting in soft hand feeling of the adhered leather, no volatilization of harmful solvent and environment friendship.

Owner:华明扬

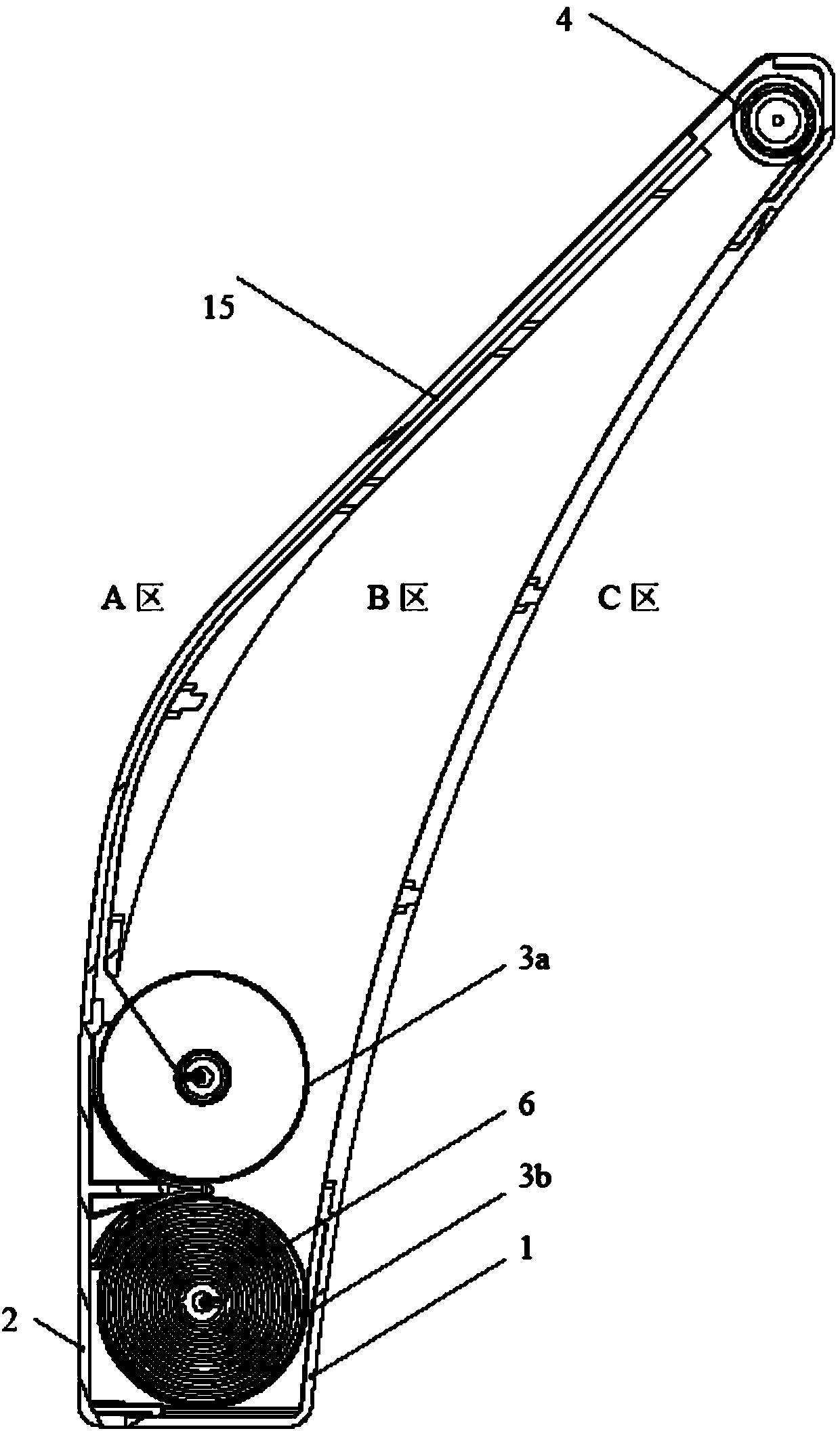

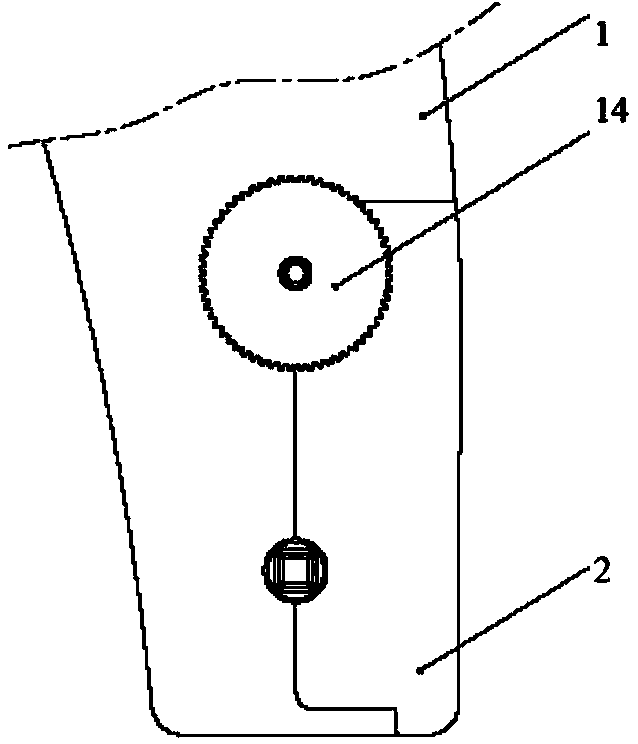

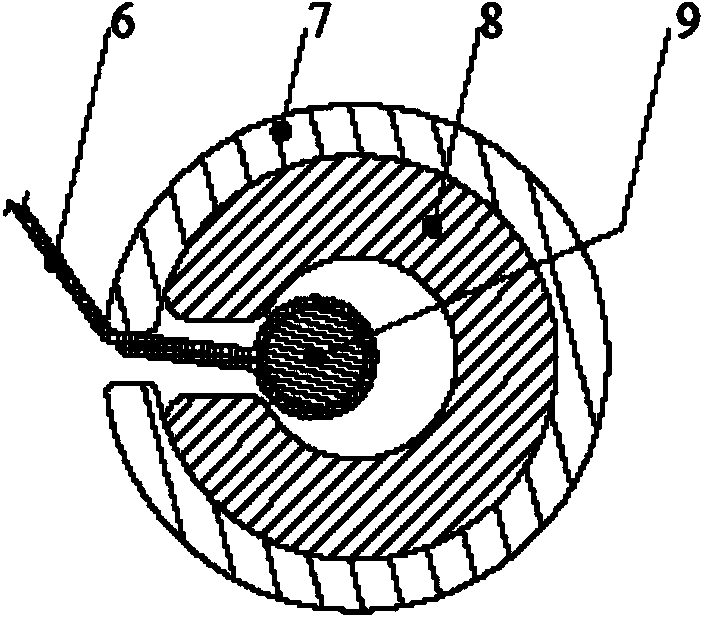

Air filter device and purpose thereof

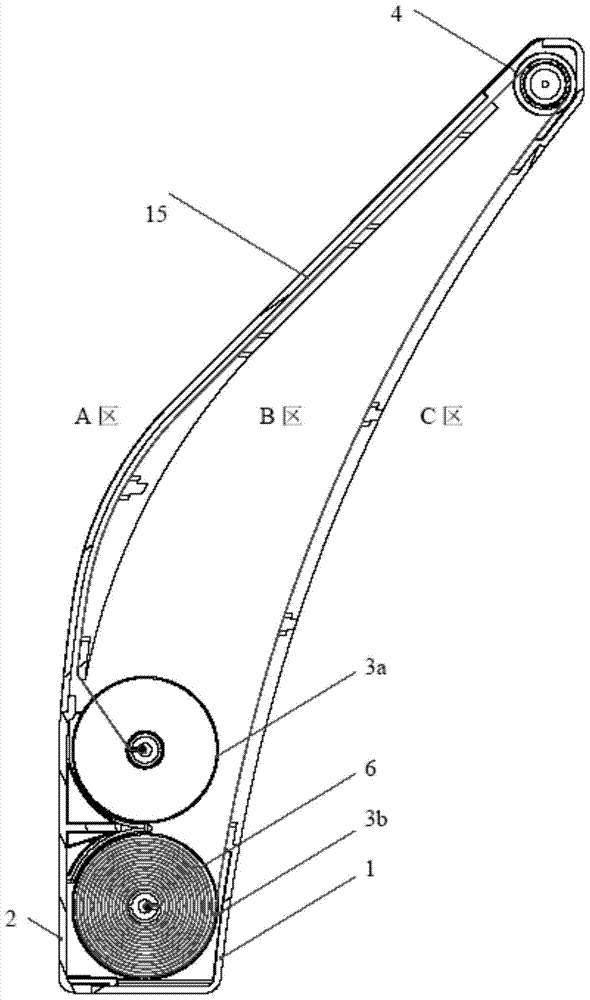

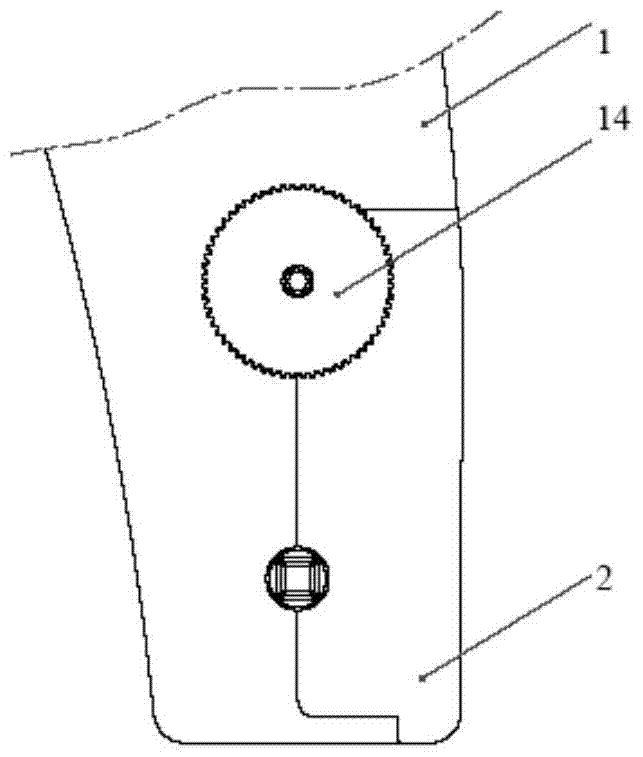

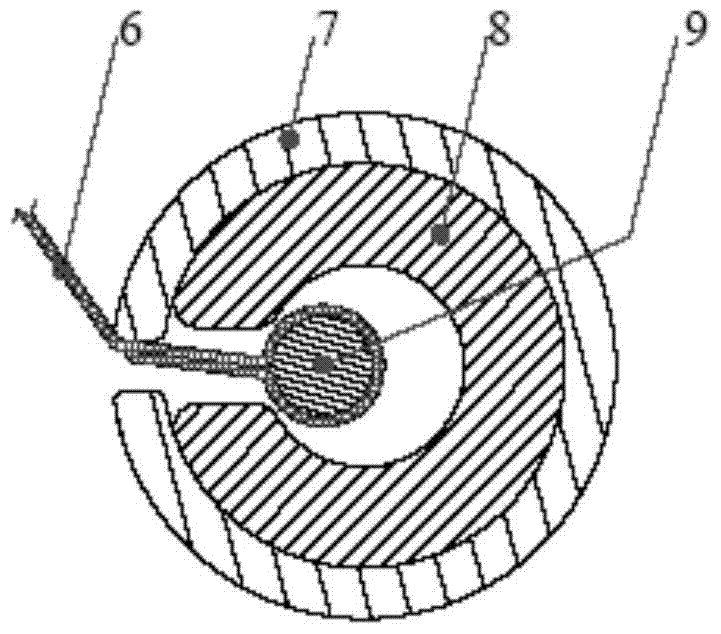

ActiveCN104197497AFeel firmHigh strengthLighting and heating apparatusSpace heating and ventilation detailsAir filtrationParticulates

The invention relates to an air filter device which comprises an outer shell 1, a cover plate 2, net winding and unwinding mechanisms 3a and 3b, a transfer mechanism 4, a gear 14 and a filter net component 6. The net winding and unwinding mechanism 3a or 3b is connected with the gear 14, and the filter net component 6 is led out from the net winding and unwinding mechanism 3a or 3b, covers an air inlet face, then covers an air outlet face after passing through the transfer mechanism 4, and then returns to the net winding and unwinding mechanism 3b or 3a. The filter net component 6 is synchronous with the net winding and unwinding mechanisms 3a and 3b through the gear 14, the filter net component 6 circulates in the net winding and unwinding mechanism 3a or 3b through the transfer mechanism 4 to be collected by the net winding and unwinding mechanism 3a or 3b, and the other net winding and unwinding mechanism 3b or 3a synchronously releases the filter net component 6. The air filter device can be applied to filter devices or components in air conditioners, and is used for filtering out and adsorbing PM particles in air.

Owner:ZHEJIANG GOLDENSEA ENVIRONMENT TECH

Elastic woven-like warp-knitted fabric with snagging prevention function and without spandex

The invention relates to an elastic woven-like warp-knitted fabric with a snagging prevention function and without spandex. The elastic woven-like warp-knitted fabric with the snagging prevention function and without spandex comprises a fabric body formed by weaving at least two guide bars on a single needle bed warp-knitting machine, and is characterized in that the fabric body comprises a compact surface layer and an elastic layer, wherein the compact surface layer is formed by weaving at least one guide bar with fiber yarns through a weaving chain and a plain or satin weave; the elastic layer is formed by weaving at least one guide bar with non-spandex elastic yarns by adopting warp pile or satin stitch; the compact surface layer and the elastic layer are integrally woven; and the elastic layer keeps a retracted state and pulls the compact surface layer. The elastic woven-like warp-knitted fabric with the snagging prevention function and without spandex has the characteristics of compact and smooth cloth surface structure, stiff hand feeling and difficulty in snagging.

Owner:BEST PACIFIC TEXTILE

Novel environment-friendly waterborne textile coating polyfoam

ActiveCN105926294AMeet the new demands of finishingGood storage stabilityFibre treatmentEmulsionPolymer chemistry

The invention discloses novel environment-friendly waterborne textile coating polyfoam. The textile coating polyfoam is prepared from waterborne acrylate emulsion, a stearyl amine additive, a TiO2 additive, thickener, mould inhibitor, preservative, dispersant and a leveling agent. The invention further discloses a method for preparing the novel environment-friendly waterborne textile coating polyfoam.

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

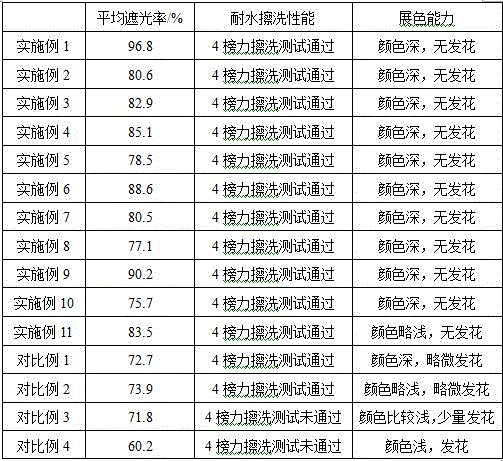

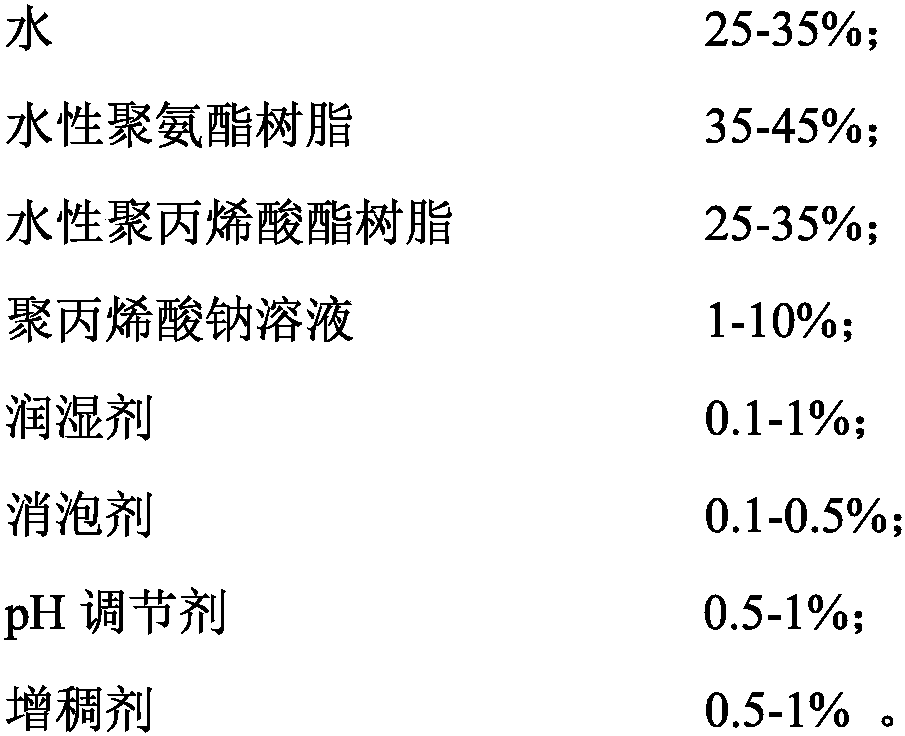

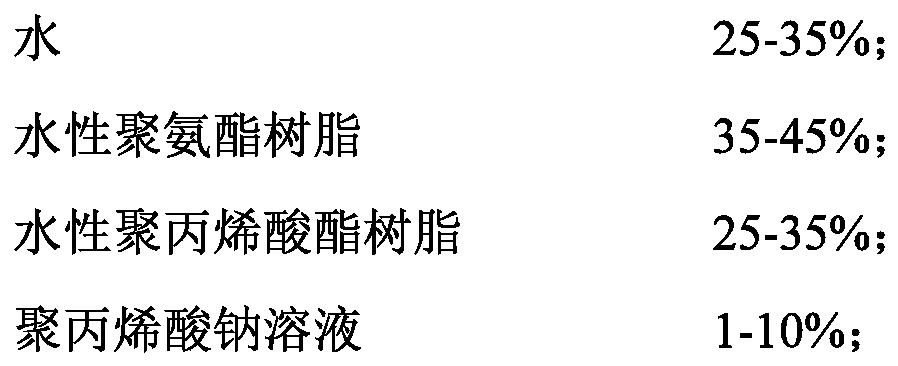

High hardness waterborne polyurethane fabric coating adhesive and preparation method thereof

ActiveCN109736098AAnti-slip strength and hardness of high-strength jointsFeel firmTextiles and paperSodium polyacrylateDefoamer

The invention discloses a high hardness waterborne polyurethane fabric coating adhesive which is prepared from the following raw materials in percent by mass: 25-35% of water, 35-45% of waterborne polyurethane resin, 25-35% of waterborne polyacrylate resin, 1-10% of a sodium polyacrylate solution, 0.1-1% of a wetting agent, 0.1-0.5% of a defoamer, 0.5-1% of a pH regulator and 0.5-1% of a thickener. After a textile is coated with the fabric coating adhesive, the fabric coating product is high in seam slippage strength, hard and stiff in hand feeling and free of crease and fold. A preparation method is simple in process, low in cost and easy to popularize and apply.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

Cosmetic dispenser with crenelated wall for frictional resistance

ActiveUS9642439B2Avoid harmful effectsFeel firmPackaging toiletriesPackaging cosmeticsEngineeringBearing surface

A cosmetic dispenser with an inner body, an outer body, and an elevator cup has a rotary extension and retraction mechanism, a first annular bearing surface retained relative to the inner or outer body and an annular wall retained relative to the other of the outer or inner body. The annular wall can be a skirt of the outer body and can be crenelated into arcuate merlons and crenels. The merlons establish an effective circumference that overlaps with the circumference of the first annular bearing surface to provide frictional resistance to a rotation of the inner body relative to the outer body. The merlons can surround the first annular bearing surface and establish a circumference smaller than the circumference of the first annular bearing surface. The annular bearing surface can be a lateral bearing surface, and a second annular bearing surface can form a longitudinal bearing surface.

Owner:HCP PACKAGING USA

Aqueous polyurethane hot coating sol for case-bag artificial leather and preparation method thereof

InactiveCN101157842BImprove adhesion fastnessHigh strengthPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsHydrophilic monomerEnd-group

The invention relates to waterborne polyurethane thermosol for coating used for artificial leather of bags and a preparation method thereof. The polyurethane thermosol for coating made by the method is mainly used for bonding of fabric and synthesized artificial leather, characterized in that Diisocyanate and ester compound can be mixed to make prepolymer, the terminal group of which is -NCO, andthen hydrophilic monomer and 1,4-butanediol are added to do chain extending reaction. In the end after amine being used for adjusting the pH value to neutrality, deionized water is added and stirred.The waterborne polyurethane thermosol for coating is obtained. The adhesion strength of the thermosol is higher than that of solvent type PU adhesive. The thermosol can stand strong intensity. The bonding fabric is soft. The rigidity is in accordance with the technical demands for various artificial leather of bags and the performance. The invention has another characteristic, which is no volatilization of poisonous solvent when the invention is sprayed, scraped and solidified, and completely accords with the environmental and technical demands for chemical addition.

Owner:江阴市诺科生物新材料科技有限公司

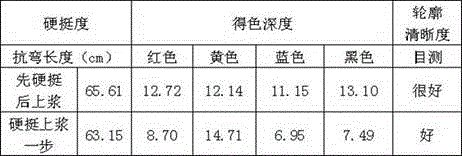

Manufacturing method for performing cross-stitch inkjet printing on dacron

The invention relates to a method for making polyester fabric ink-jet printing cross-stitch, comprising: (1) preparing a stiffening agent of a certain concentration first, adopting a padding method to stiffen the required printed fabric, and drying. (2) Prepare an acidic digital printing paste with a certain viscosity, stir it evenly, use the padding method to sizing the stiffened fabric, and dry it. (3) Finally, use acid ink digital inkjet printing, the inkjet volume is 100%, after printing, steam and dry. The present invention adopts the imitation cross-stitch style production method of digital ink-jet printing to replace the traditional manual cross-stitch, which has the characteristics of accurate positioning, realistic effect, simple method and higher efficiency.

Owner:广东德美高新材料有限公司

Method for producing double-layer heavy change plain fabric and product

The invention provides a method for producing a double-layer heavy change plain fabric and a product. The texture of a back shirt is cotton, fancy yarns on the surface are polyester and cotton, two raw materials are kept parallel and the tension of the two materials is controlled in the spinning process, overdying is performed after spinning, the polyester is dyed first and then the cotton is dyed to achieve a double-color effect, and weaving is performed finally. According to the double-layer heavy change plain fabric, the texture of the back shirt is the cotton, the fancy yarns on the surface are the polyester and the cotton, warp yarns are 21S / 2 cotton+2N polyester-cotton fancy yarns, weft yarns are 10 cotton+2N polyester-cotton fancy yarns, warp and weft density is (12+6)*(12.5+6.3) / cm, and the ratio of the polyester to the cotton in the 2N polyester-cotton fancy yarns is 3:7. The double-color effect, double-layer texture and rigid handfeel of a cloth cover are achieved, and the double-color effect achieved in actual operation is ideal.

Owner:YIXING ZHONGDA TEXTILE

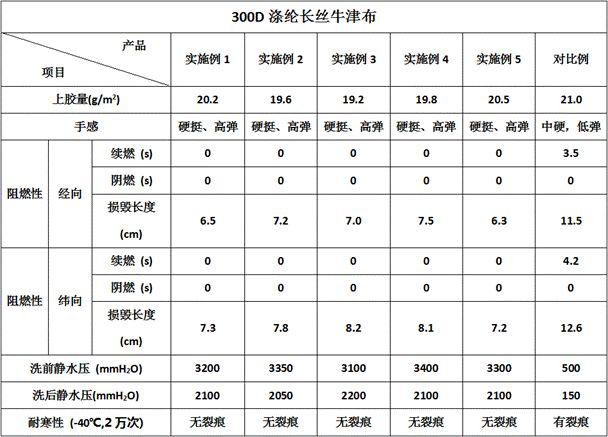

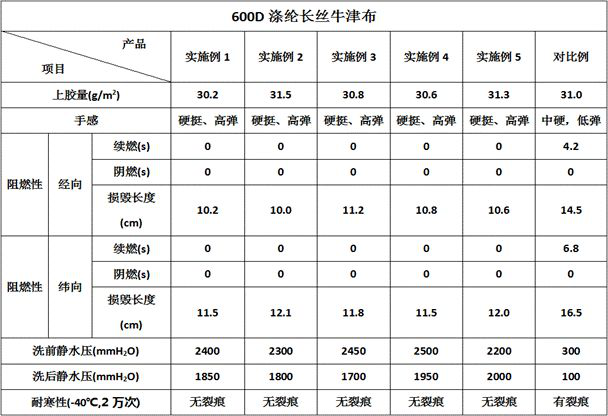

Preparation method of water-based flame-retardant water-pressure-resistant polyurethane emulsion for fabrics

The invention relates to a preparation method of a water-based flame-retardant water-pressure-resistant polyurethane emulsion, which is prepared from isophorone diisocyanate, hydrogenated phenylmethane diisocyanate, polyoxypropylene triol, tris(dipropylene glycol)phosphite, linear dihydroxyalkyl siloxane, melamine cyanurate, dimethylolpropionic acid, 2-methyl-1,3-propylene glycol, triethylamine, hydrazine hydrate and deionized water through a prepolymerization reaction, a neutralization reaction, an emulsification reaction and a chain extension reaction. The fabric is stiff and dry in hand feeling and is high in elasticity, high in fastness, cold-resistant, high in water pressure resistance, good in flame retardance, environmentally friendly and low in production cost.

Owner:LIAONING FIXED STAR FINE CHEM

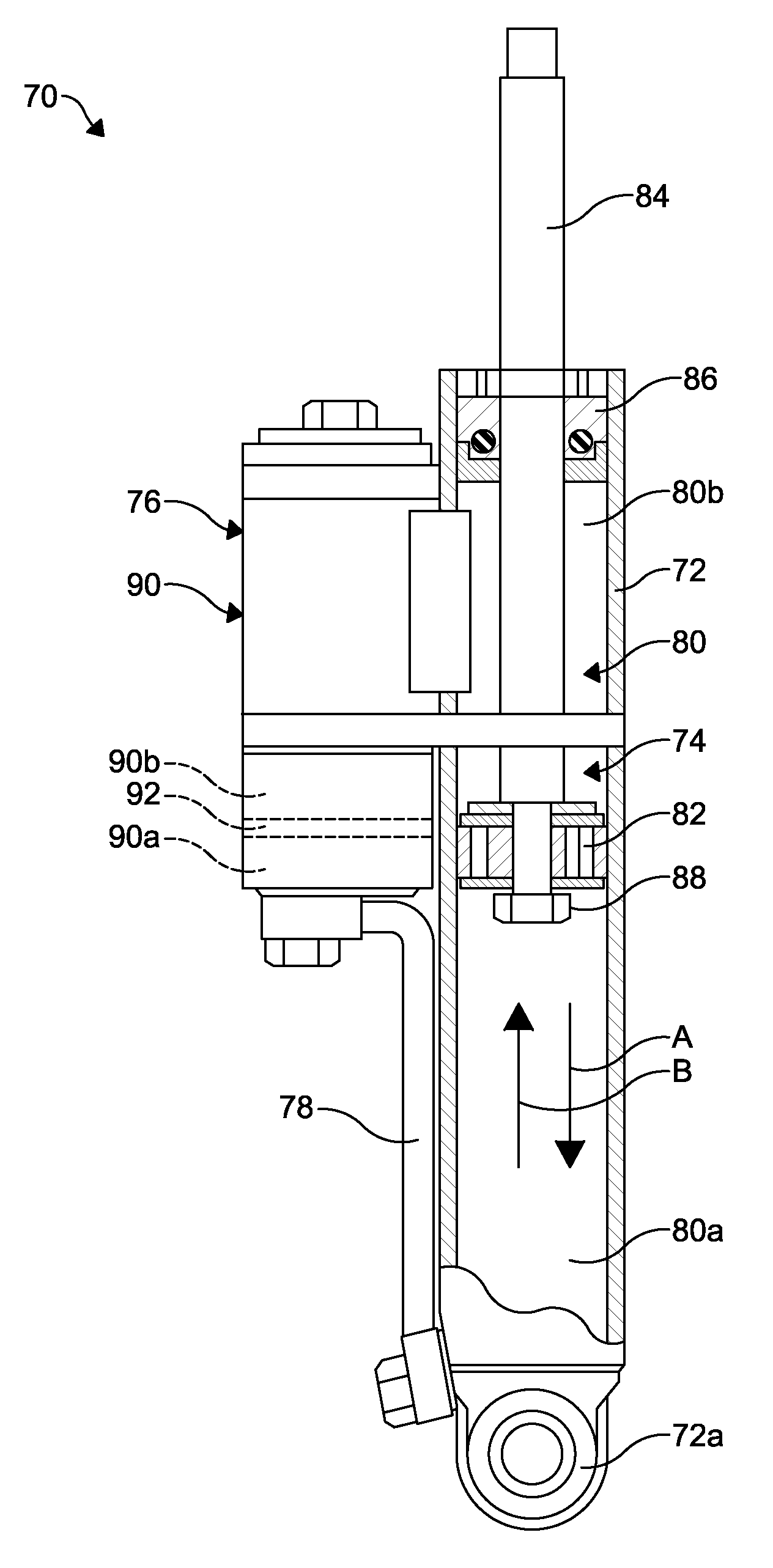

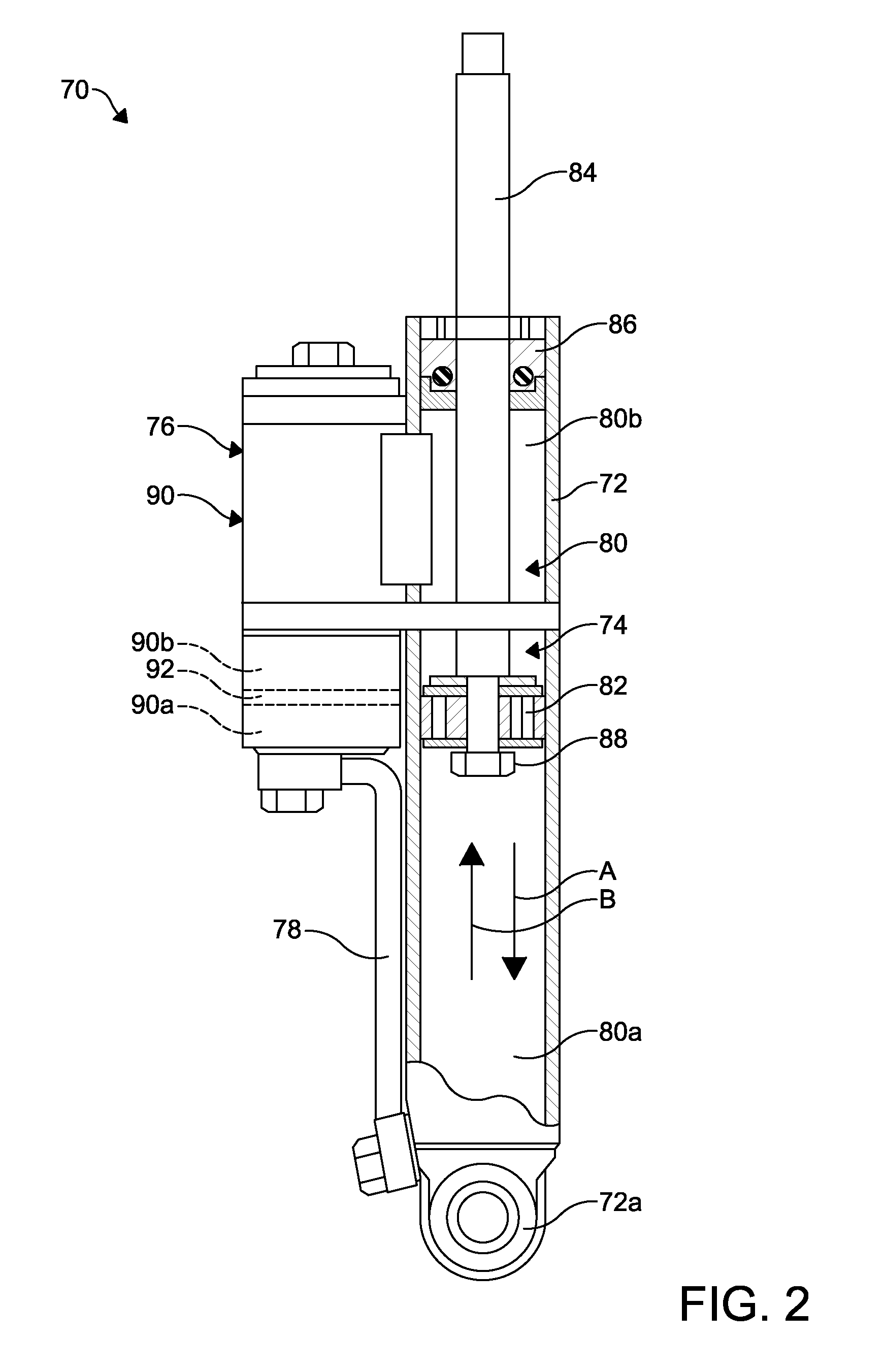

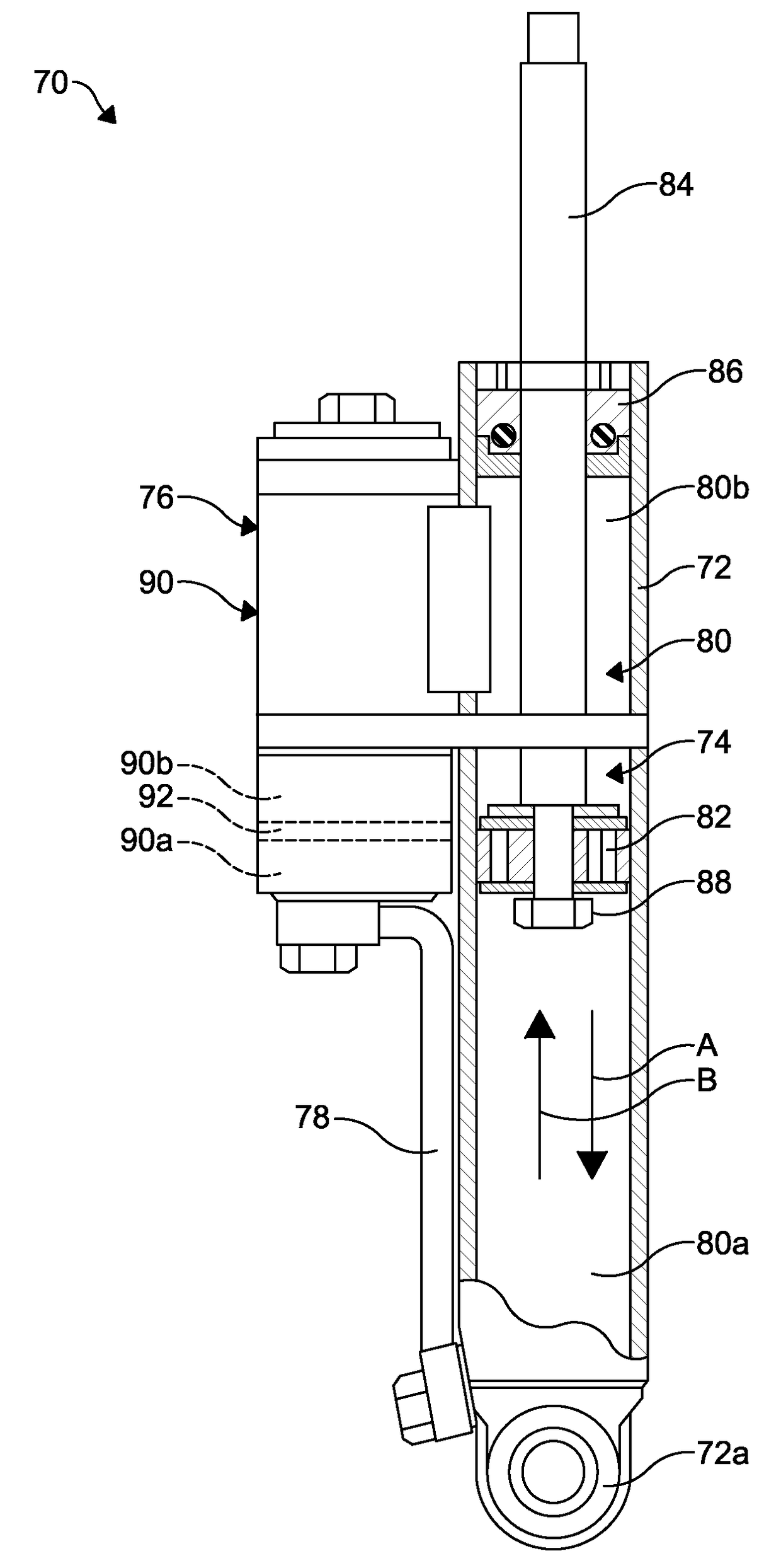

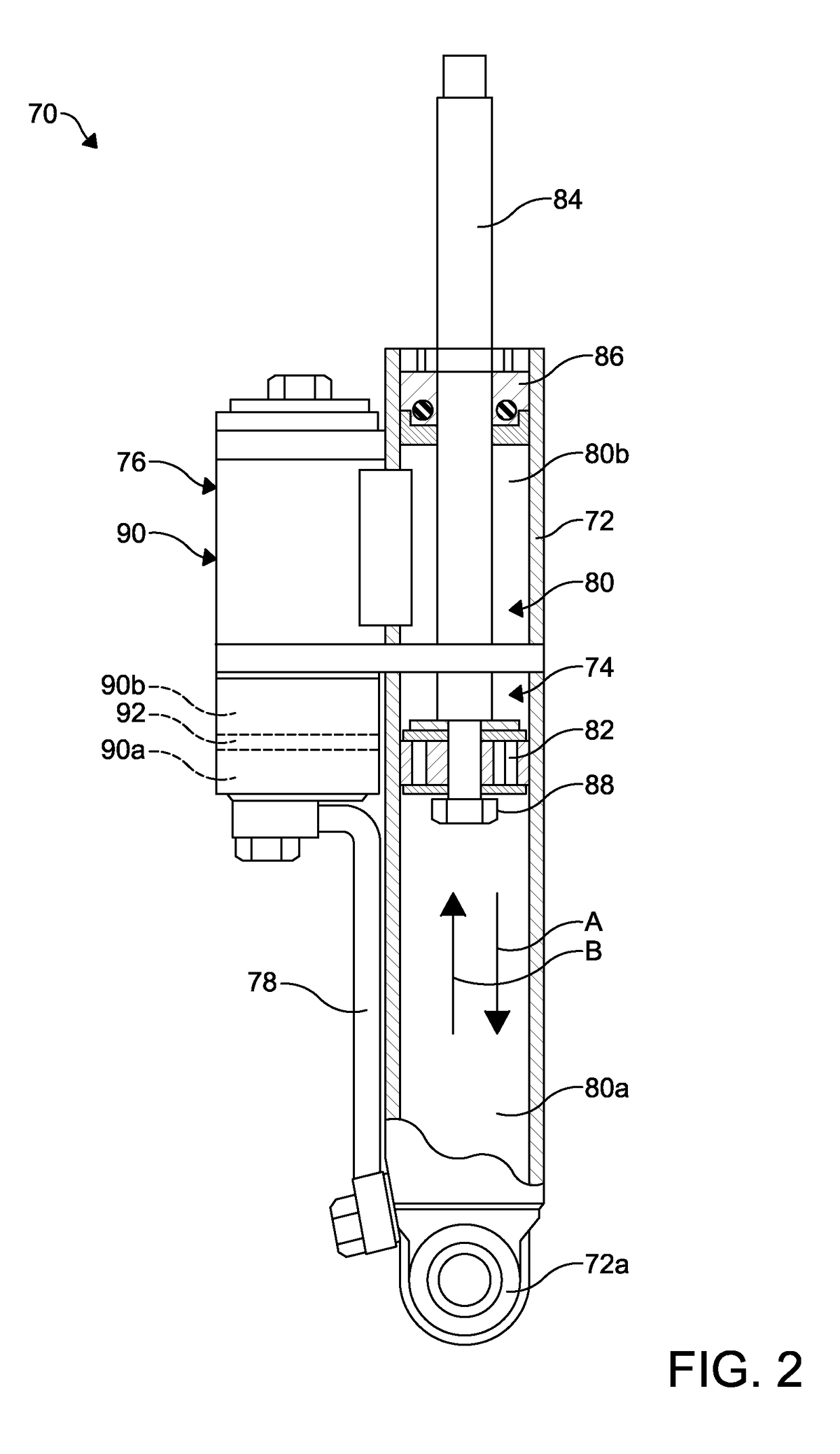

Three Speed Adjustable Shock Absorber Having One Or More Microvalves

An adjustable shock absorber includes a housing defining an enclosed working space. A wall is formed in the working space and separates the working space into first and second fluid chambers. A compression valve is formed in the wall and a microvalve is attached to the compression valve and is operable to control fluid flow through the compression valve.

Owner:DUNAN MICROSTAQ

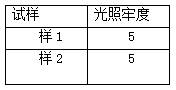

A kind of preparation method of environment-friendly semi-vegetable tanned-metal tanned mildew-proof light-resistant suede leather

ActiveCN112779372BSuper lightfastImprove permeabilityTanning treatmentPre-tanning chemical treatmentSodium bicarbonatePulp and paper industry

The present invention provides an environment-friendly semi-contamination which can overcome the shortcomings of a single non-chrome tanning process, greatly improve the light fastness, dyeability and mildew resistance of the suede, realize chrome-free tanning, and greatly reduce the pollution problems such as formaldehyde. The preparation method of vegetable-tanned-metal-tanned mildew-proof and light-resistant suede leather includes the following steps in sequence: Step 1: add bovine split leather, white tannin extract, and Litopo GLH in a rotating drum and rotate for 55-65 minutes, and then Add Davitan ZAT multi-metal tanning agent for retanning and rotate for 160-200 minutes, then add sodium formate and rotate for 15-25 minutes, and then add sodium bicarbonate and rotate for 25-35 minutes; Step 2: Add alkali extraction agent again, adjust pH to 3.5 ‑4.5, rotate for another 100‑140 minutes, and discharge the solution in the drum after rotation.

Owner:FENGAN LEATHER

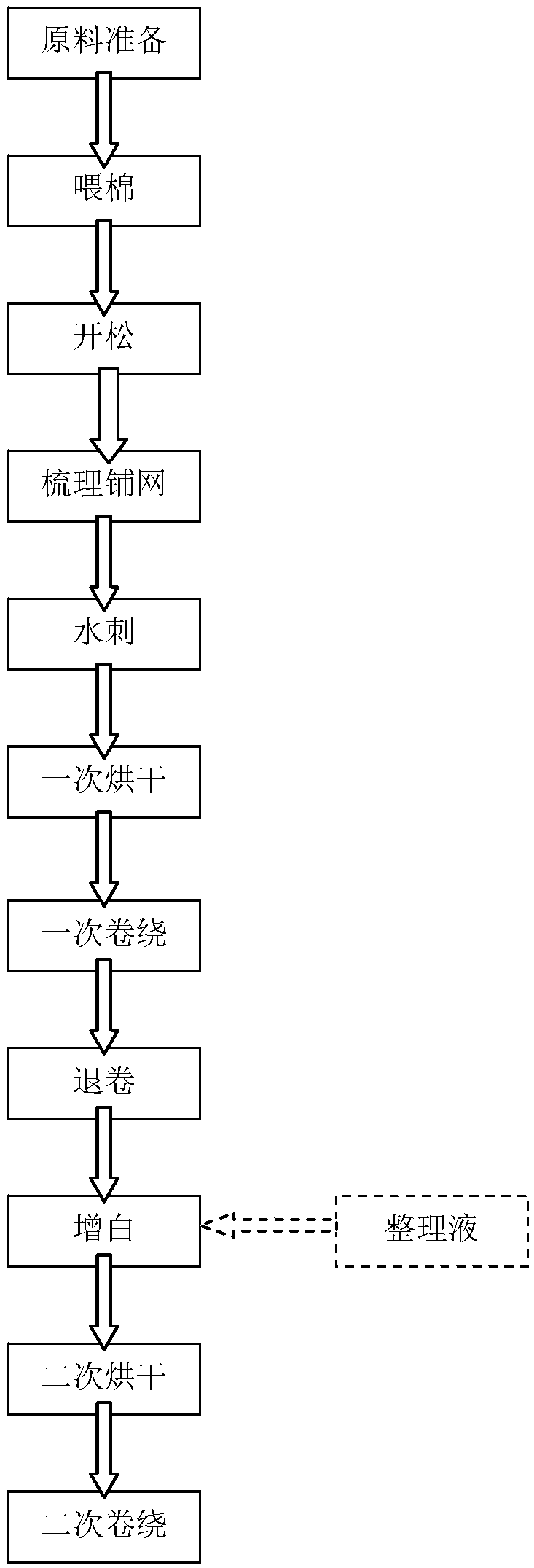

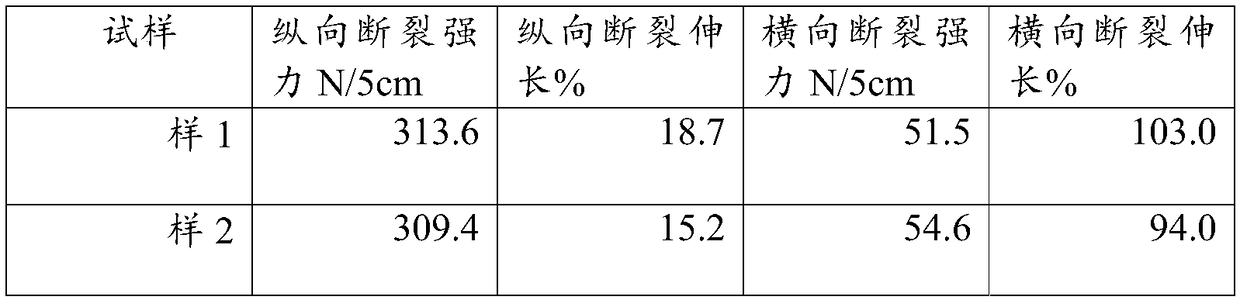

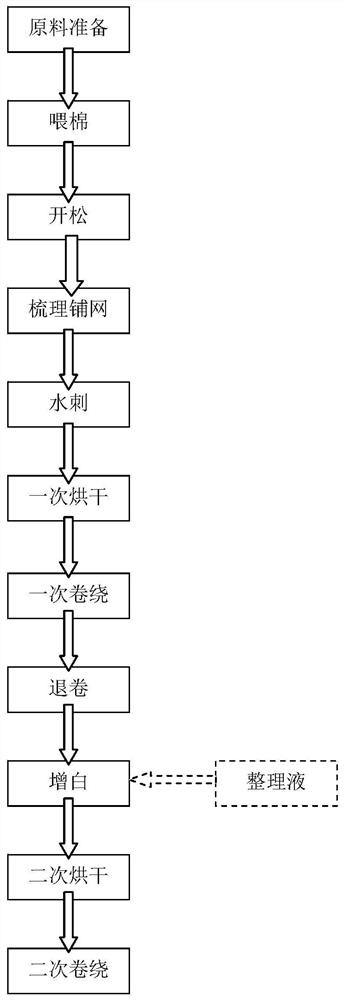

Spunlace non-woven curtain fabric and production method thereof

The invention relates to a production method of spunlace non-woven curtain fabric. The method comprises the following sequential steps of cotton feeding, opening, carding, spunlace, primary drying, primary rolling, unrolling, whitening, secondary drying and secondary rolling. The invention further relates to the spunlace non-woven curtain fabric produced by the method. According to the productionmethod, the production cost is lowered, raw materials and energy are saved, and the strength of products is improved. The direct products are rigid in handfeeling, bright and clean in fabric surface and high in whiteness and do not deform after being folded and formed.

Owner:XINLONG HLDG GROUP

A kind of spunlace nonwoven curtain fabric and its production method

ActiveCN108411488BIncrease productivityReduce manufacturing costNon-woven fabricsPolymer scienceEngineering

The invention relates to a production method of spunlace nonwoven curtain cloth, which sequentially includes the following steps: cotton feeding, opening, carding, spunlace, primary drying, primary winding, unwinding, whitening, secondary drying Dry, secondary winding. The present invention also relates to a spunlace nonwoven curtain fabric produced by the above method. The invention reduces production cost, saves raw materials and energy, and improves product strength. The direct product of the invention has firm hand feeling, smooth cloth surface, high whiteness, and no deformation after being folded and formed.

Owner:XINLONG HLDG GROUP

Preparation method of environment-friendly semi-vegetable tanning-metal tanning mould-proof light-resistant suede leather

ActiveCN112779372AFirm skinFine suedeTanning treatmentPre-tanning chemical treatmentSodium bicarbonatePulp and paper industry

The invention provides a preparation method of environment-friendly semi-vegetable tanning-metal tanning mildew-resistant light-resistant suede leather, and the method can overcome the defects of a single non-chrome tanning process, greatly improve the light resistance, dyeing property and mildew resistance of the suede leather, realize chrome-free tanning and greatly reduce formaldehyde and other pollution problems. The method comprises the following steps in sequence: step 1, adding cow split leather, Tara tannins and Lutapol GLH into a rotary drum, conducting rotating for 55-65 minutes, then adding a Dowelltan ZAT multi-metal tanning agent, conducting retanning, conducting rotating for 160-200 minutes, then adding sodium formate, conducting rotating for 15-25 minutes, then adding sodium bicarbonate, and conducting rotating for 25-35 minutes; and 2, adding an alkali extracting agent, adjusting the pH value to 3.5-4.5, conducting rotating for 100-140 minutes, and discharging the solution in the rotary drum after rotating.

Owner:FENGAN LEATHER

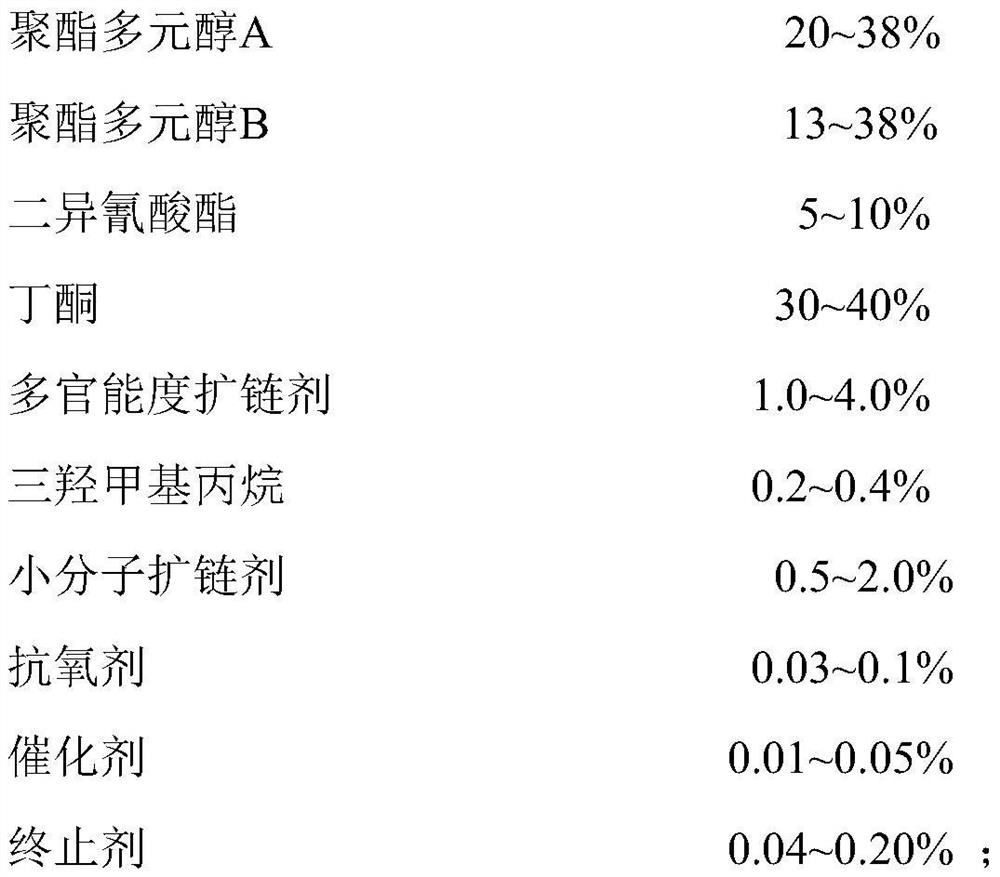

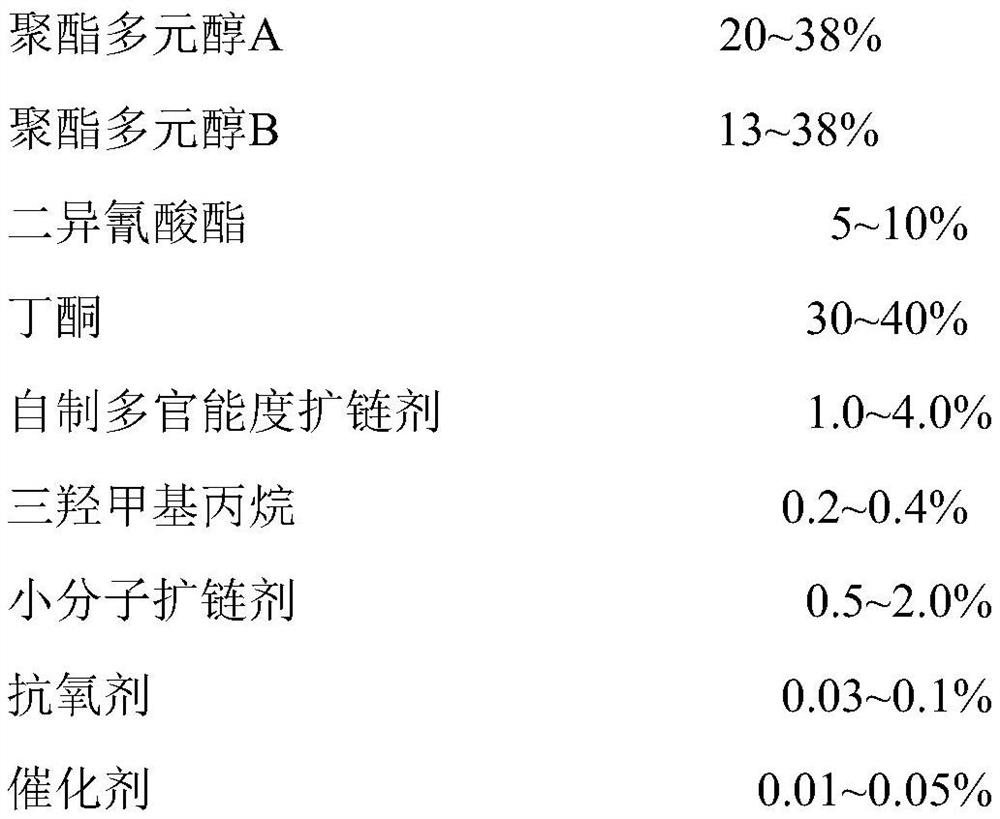

A kind of two-component adhesive layer polyurethane resin for bronzing and its preparation method

ActiveCN111423557BImprove surface brightnessClear textureNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The present invention is a two-component adhesive layer polyurethane resin for bronzing and its preparation method. The polyurethane resin of the present invention is required to be soluble in a high-volatility solvent system, while ordinary polyester diols are easy to crystallize in a high-volatility solvent system and are difficult to preserve Therefore, the modified polyester diol with slightly lower crystallinity is selected to ensure the strength of the polyurethane resin, and the self-made multifunctional chain extender is used to improve the low-temperature curing speed and the strength after curing. The functional chain extender is easy to cause the defect of agglomeration or stickiness of the system, and the product has excellent performance. The present invention uses an all-weak solvent system, and has high adhesion. The bronzing film using the product of the present invention has good surface brightness, clear lines, and a stiff hand feeling. The overall performance of the hot stamping composite product, such as water resistance, is better than that of the existing products.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

A woven fabric with a knitting-like effect capable of shielding ultraviolet light and a manufacturing method thereof

ActiveCN104726995BFunctional DiversificationFeel tightWoven fabricsConjugated synthetic polymer artificial filamentsPolyesterUltraviolet lights

The invention discloses a woven fabric capable of shielding ultraviolet light and imitating knitting effects, which is woven by an air-jet loom with warp and weft yarns, and the raw materials of the warp and weft yarns are made of the following raw materials in parts by weight: isotactic polypropylene 24 ‑35, polyester fiber 20‑25, diatom mud 3‑5, nano titanium dioxide 2‑4, waste cotton fiber 18‑26, bamboo charcoal fiber 20‑26, soybean protein fiber 13‑16, mulberry fiber 19‑27, three Ethylene Propylene Rubber 5‑8, Ethyl Acetate 6‑9, Glycidyl Methacrylate 12‑17, Dibutyltin Dilaurate 0.3‑0.7, Schisandra 2‑4, Perilla Leaf 1‑3, 1‑Butyl -3-methylimidazole acetate 90-110, 1-allyl-3-methylimidazolium chloride 100-120, auxiliary agent 5-8, appropriate amount of water; the woven fabric of the present invention has both tightness and stiffness It also has the advantages of visual effect, antibacterial and warmth preservation.

Owner:安徽省中日农业环保科技有限公司

Air Filters and Their Uses

ActiveCN104197497BFeel firmHigh strengthLighting and heating apparatusSpace heating and ventilation detailsAir filterEngineering

The invention relates to an air filter device which comprises an outer shell 1, a cover plate 2, net winding and unwinding mechanisms 3a and 3b, a transfer mechanism 4, a gear 14 and a filter net component 6. The net winding and unwinding mechanism 3a or 3b is connected with the gear 14, and the filter net component 6 is led out from the net winding and unwinding mechanism 3a or 3b, covers an air inlet face, then covers an air outlet face after passing through the transfer mechanism 4, and then returns to the net winding and unwinding mechanism 3b or 3a. The filter net component 6 is synchronous with the net winding and unwinding mechanisms 3a and 3b through the gear 14, the filter net component 6 circulates in the net winding and unwinding mechanism 3a or 3b through the transfer mechanism 4 to be collected by the net winding and unwinding mechanism 3a or 3b, and the other net winding and unwinding mechanism 3b or 3a synchronously releases the filter net component 6. The air filter device can be applied to filter devices or components in air conditioners, and is used for filtering out and adsorbing PM particles in air.

Owner:ZHEJIANG GOLDENSEA ENVIRONMENT TECH

Preparation method of (sesqui) siloxane hybrid modified fluorinated polyacrylate emulsion

The invention discloses a preparation method of an epoxy polyether-based (sesqui) siloxane hybrid modified fluorinated polyacrylate emulsion, which comprises the following steps of: under the effect of cationic / nonionic or anionic / nonionic surfactants, firstly carrying out seeded emulsion copolymerization on perfluoroalkyl(methyl) acrylate, aliphatic long carbon chain (methyl) acrylate, reactive vinyl monomer and alpha-alkenyl alkoxysilane in an aqueous phase so as to synthesize a silanized long carbon chain fluorinated polyacrylate emulsion; cooling to room temperature; regulating a pH value of the system to be 5.0-6.0; adding an epoxy polyether-based (sesqui) siloxane cross-linking agent and a stiffening agent; continuously stirring for 30 min; and obtaining the (sesqui) siloxane hybrid modified fluorinated polyacrylate emulsion after filtering. The modified fluorinated polyacrylate emulsion disclosed by the invention can be used for after-treatment of textiles after dilution, so that the stiff handfeel of textiles can be improved, and an excellent water-repellent and oil-repellent performance is given to the textiles.

Owner:SHAANXI UNIV OF SCI & TECH

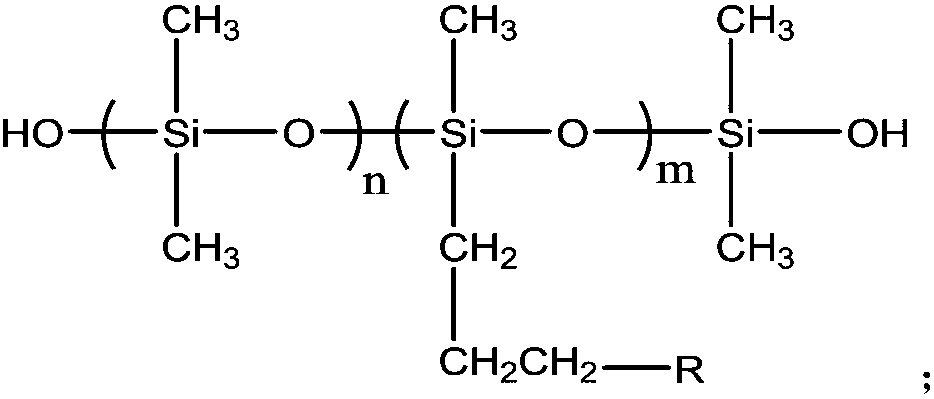

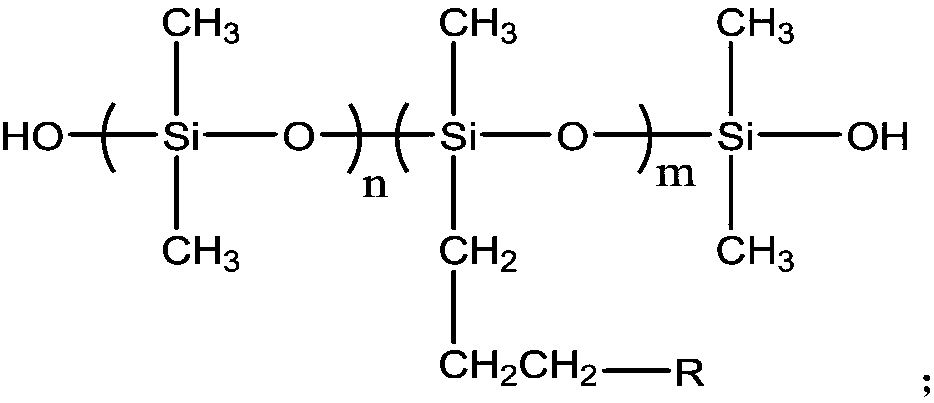

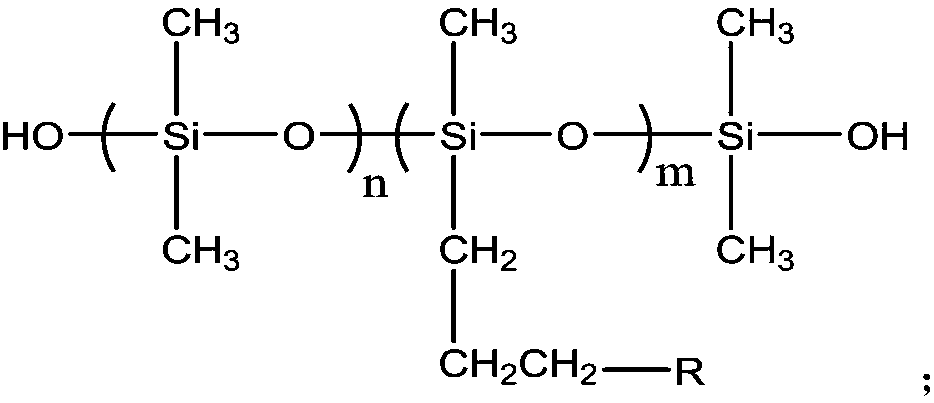

Crude organosilicone oil, silicon-containing stiffening agent and preparation methods for crude organosilicone oil and silicon-containing stiffening agent

The invention discloses a silicon-containing stiffening agent, belonging to the field of textile auxiliary agents. The silicon-containing stiffening agent comprises the following raw materials by weight: 10 to 30 parts of crude intermediate oil, 5 to 10 parts of polyvinyl acetate, 10 to 20 parts of ethyl acetate, 4 to 10 parts of an emulsifier and 30 to 70 parts of deionized water. The preparationmethod for the silicon-containing stiffening agent comprises the following steps: uniformly mixing crude organosilicone oil, the polyvinyl acetate and the ethyl acetate, then adding the emulsifier, carrying out dispersing and emulsifying with a high-speed dispersing machine and a homogenizing machine for 1 to 2 h, and adding water for a plurality of times in batches until a phase of an obtained product is converted into an emulsion-like phase. The silicon-containing stiffening agent provided by the invention has excellent chemical stability against acid, alkali, salt and the like, can endow the hand feelings of stiffness, flatness, smoothness, thickness and solidness to fabrics, and has excellent washing resistance; and the textile treated by using the silicon-containing stiffening agentcan still maintain the hand-feeling styles of stiffness, flatness, smoothness and drape pendency after being washed with water for 5 times or more.

Owner:GUANGDONG CHUANHUA FULIAN FINE CHEM CO LTD

A process for tanning and softening sheepskin with polycarboxy-based nano-composite chrome tanning aids

InactiveCN103509889BFulfil requirementsRequirements meetTanning treatmentPre-tanning chemical treatmentLiquid wasteFiber

The invention belongs to the field of leather tanning process and relates to a process for tanning and softening sheepskin by a multi-carboxylic nano compound chrome tanning additive. In a traditional chrome tanning method, the use of various chemicals in picking and chrome tanning procedures causes damage to the ecological environment. According to leather tanning mechanisms and structural features of collagenous fiber and the multi-carboxylic nano compound chrome tanning additive, the process used for leather tanning and skin softening is characterized in that the shrinkage temperature of blue wet leather can reach 105 DEG C, the grain side is flat and fine, and the requirements of goat skin garment leather can be met; compared with the method that 8 percent of chromium powder is adopted for conventional tanning liquid waste, liquid waste is characterized in that the content of Cr2O3 in the liquid waste is reduced to 172 mg / L from 1,952 mg / L, and the content of chromium in the liquid waste is reduced greatly; compared with the conventional chrome tanned leather, the chrome tanned leather treated through the process has the advantages that excellent effects to follow-up backwater, neutralization, and control to chromium pollution in dying and oiling liquid waste are achieved, the physical and mechanical performance of crust leather is similar, compact hand feeling is achieved, the filling performance and the softness are excellent, and the requirements of the goat skin garment leather can be met.

Owner:SHAANXI UNIV OF SCI & TECH

Three speed adjustable shock absorber having one or more microvalves

Owner:DUNAN MICROSTAQ

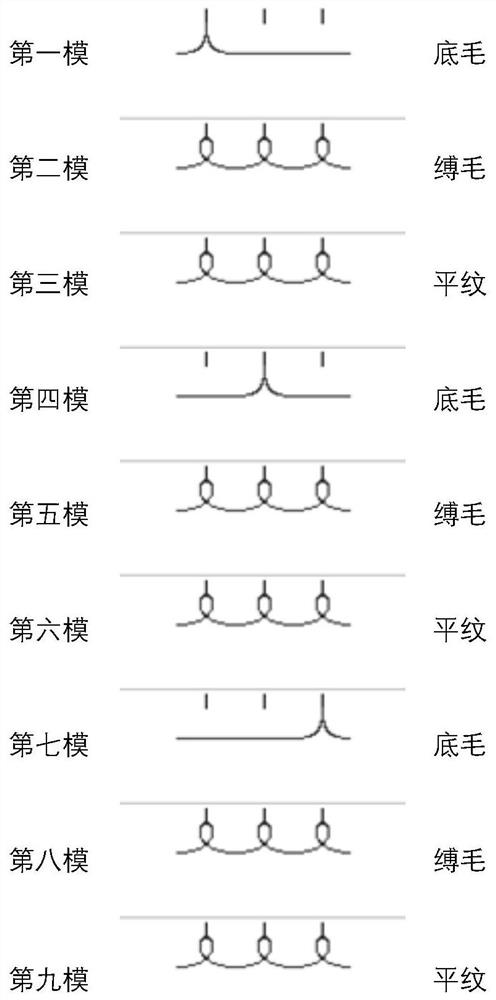

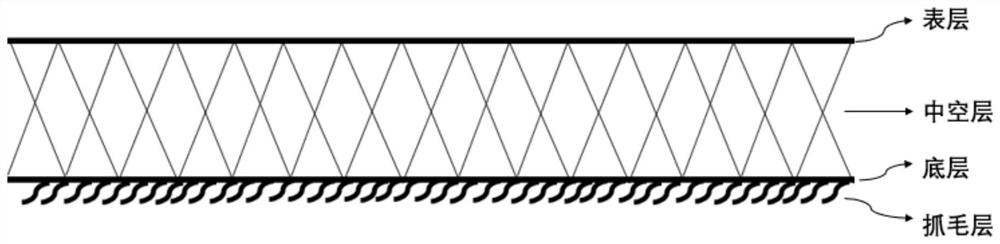

A kind of hollow raising fabric and preparation method thereof

ActiveCN112030329BSolve difficult-to-fluff problemsFeel firmWeft knittingMechanical engineeringAir layer

The invention provides a hollow raised fabric and a preparation method thereof. The hollow raised fabric includes a surface layer, a hollow layer and a bottom layer, the surface layer and the bottom layer are connected through the hollow layer; the bottom layer is composed of a first coil and a second coil, and the yarn count of the first coil is lower than that of the second coil; the bottom layer is raised by steel needles, And in raised finishing, the first loop is elongated to protrude from the surface of the substrate. The first loop in the bottom layer of the hollow raised fabric protrudes from the bottom surface, which has the characteristics of easy to grasp, dense hair effect, and excellent hair effect reproducibility, and will not touch the polyester yarn of the hollow layer when raising, and will not damage the structure of the hollow layer. It not only solves the problem that traditional knitted air layer fabric is difficult to fluff, but also feels fluffy after washing, has good resilience, keeps shape and keeps warm, and will not become thinner with washing like ordinary plain terry raised fabric, which improves the warm life of raised fabric.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com