Preparation method of water-based flame-retardant water-pressure-resistant polyurethane emulsion for fabrics

A technology of polyurethane emulsion and water pressure resistance, which is applied in the direction of textiles, papermaking, coating, etc. It can solve the problems of unfavorable human health and high fastness, so as to improve the elasticity of film formation, low production cost and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

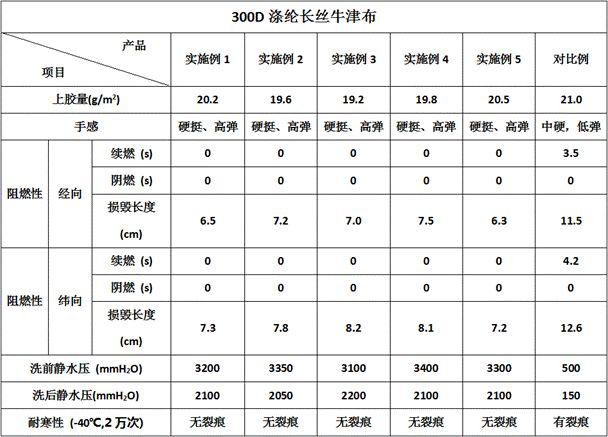

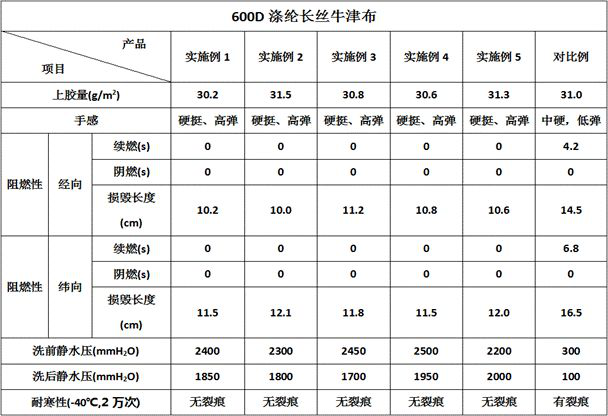

Examples

Embodiment 1

[0051] Raw material ratio by weight:

[0052] (1) Prepolymerization reaction: polyoxypropylene triol 80 with a molecular weight of 3000, tris(dipropylene glycol) phosphite 35 with a molecular weight of 430, linear dihydroxyalkylsiloxane 20 with a molecular weight of 1000, iso Add phorone diisocyanate 55 and hydrogenated phenylmethane diisocyanate 65 into the reaction kettle, raise the temperature to 80-90°C, react for 1-1.5 hours, then add melamine cyanurate 5, keep the temperature at 80-90°C, and react for 1-1.5 hours hour, then add 2-methyl-1,3-propanediol 1.5, dimethylol propionic acid 2.5 to react for 1.5-2 hours;

[0053] (2) Neutralization reaction: cool down to 45-55°C, add triethylamine 1.7, and react for 30-40 minutes;

[0054] (3) Emulsification reaction: add deionized water 230, stir for 10-20 minutes until the prepolymer is completely dissolved;

[0055] (4) Chain extension reaction: Add 8.8 hydrazine hydrate and react for 2-2.5 hours to obtain a water-based flam...

Embodiment 2

[0058] (1) Prepolymerization reaction: polyoxypropylene triol 85 with a molecular weight of 3000, tris(dipropylene glycol) phosphite 40 with a molecular weight of 430, linear dihydroxyalkylsiloxane 15 with a molecular weight of 1000, iso Add phorone diisocyanate 60 and hydrogenated phenylmethane diisocyanate 70 into the reaction kettle, raise the temperature to 80-90°C, react for 1-1.5 hours, then add melamine cyanurate 6, keep the temperature at 80-90°C, and react for 1-1.5 hours hour, then add 2-methyl-1,3-propanediol 1, dimethylolpropionic acid 3 to react for 1.5-2 hours;

[0059] (2) Neutralization reaction: cool down to 45-55°C, add triethylamine 2.0, and react for 30-40 minutes;

[0060] (3) Emulsification reaction: add deionized water 240, stir for 10-20 minutes until the prepolymer is completely dissolved;

[0061] (4) Chain extension reaction: Add hydrazine hydrate 9.6 and react for 2-2.5 hours to obtain a water-based flame-retardant and water-resistant polyurethane ...

Embodiment 3

[0064] (1) Prepolymerization reaction: polyoxypropylene triol 70 with a molecular weight of 3000, tris(dipropylene glycol) phosphite 40 with a molecular weight of 430, linear dihydroxyalkylsiloxane 20 with a molecular weight of 1000, iso Add phorone diisocyanate 60 and hydrogenated phenylmethane diisocyanate 65 into the reaction kettle, raise the temperature to 80-90°C, react for 1-1.5 hours, then add melamine cyanurate 5, keep the temperature at 80-90°C, and react for 1-1.5 hours hour, then add 2-methyl-1,3-propanediol 2, dimethylolpropionic acid 2 and react for 1.5-2 hours;

[0065] (2) Neutralization reaction: cool down to 45-55°C, add triethylamine 1.3, and react for 30-40 minutes;

[0066] (3) Emulsification reaction: add deionized water 230, stir for 10-20 minutes until the prepolymer is completely dissolved;

[0067] (4) Chain extension reaction: Add hydrazine hydrate 9.1 and react for 2-2.5 hours to obtain a water-based flame-retardant and water-resistant polyurethane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com