Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

148 results about "Propene oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propylene oxide is used in the production of polyethers (the primary component of polyurethane foams) and propylene glycol. Acute (short-term) exposure of humans and animals to propylene oxide has caused eye and respiratory tract irritation.

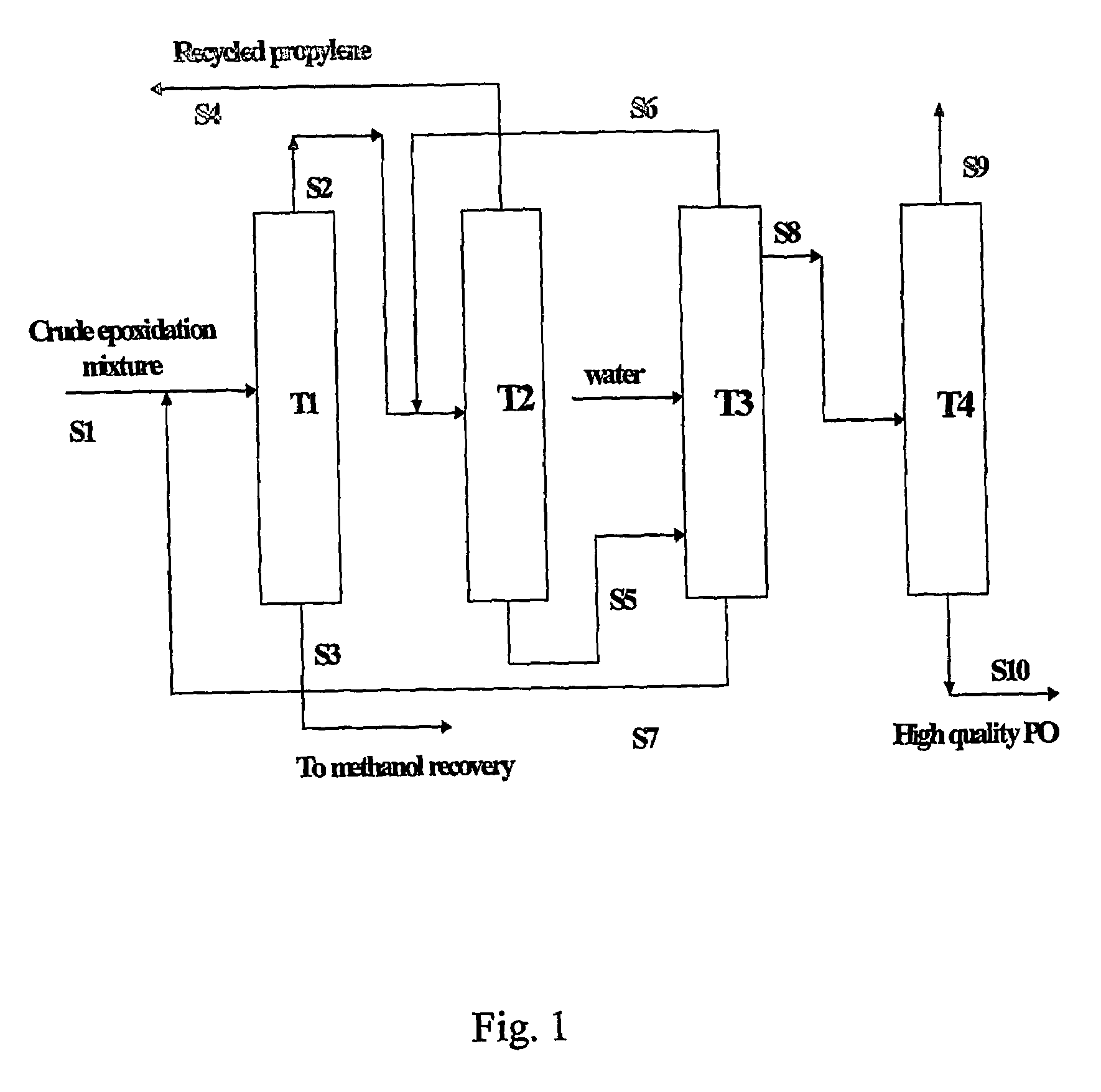

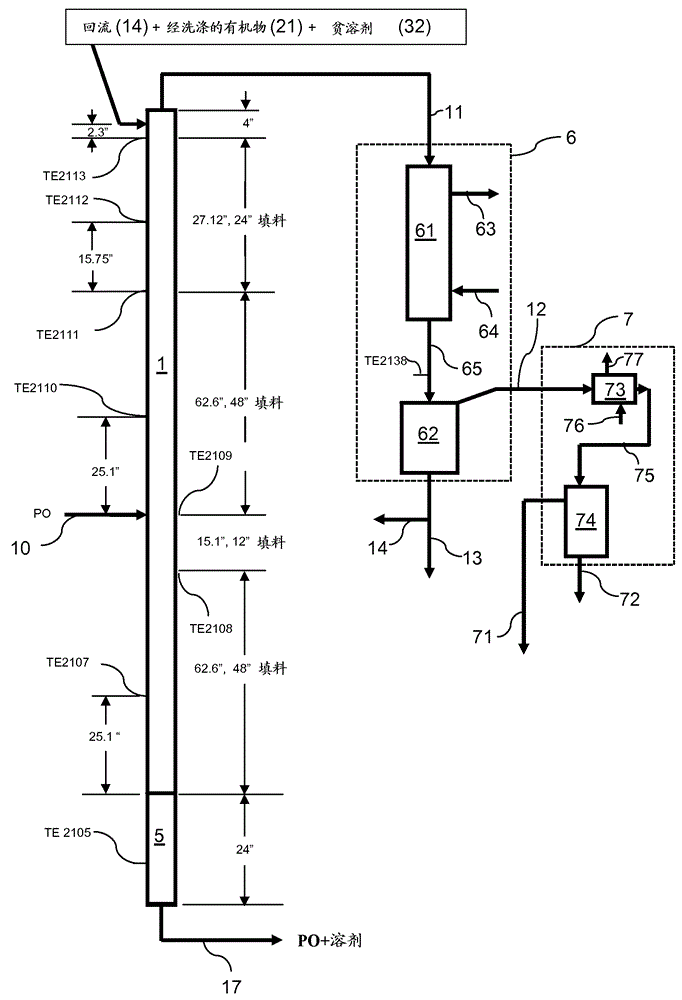

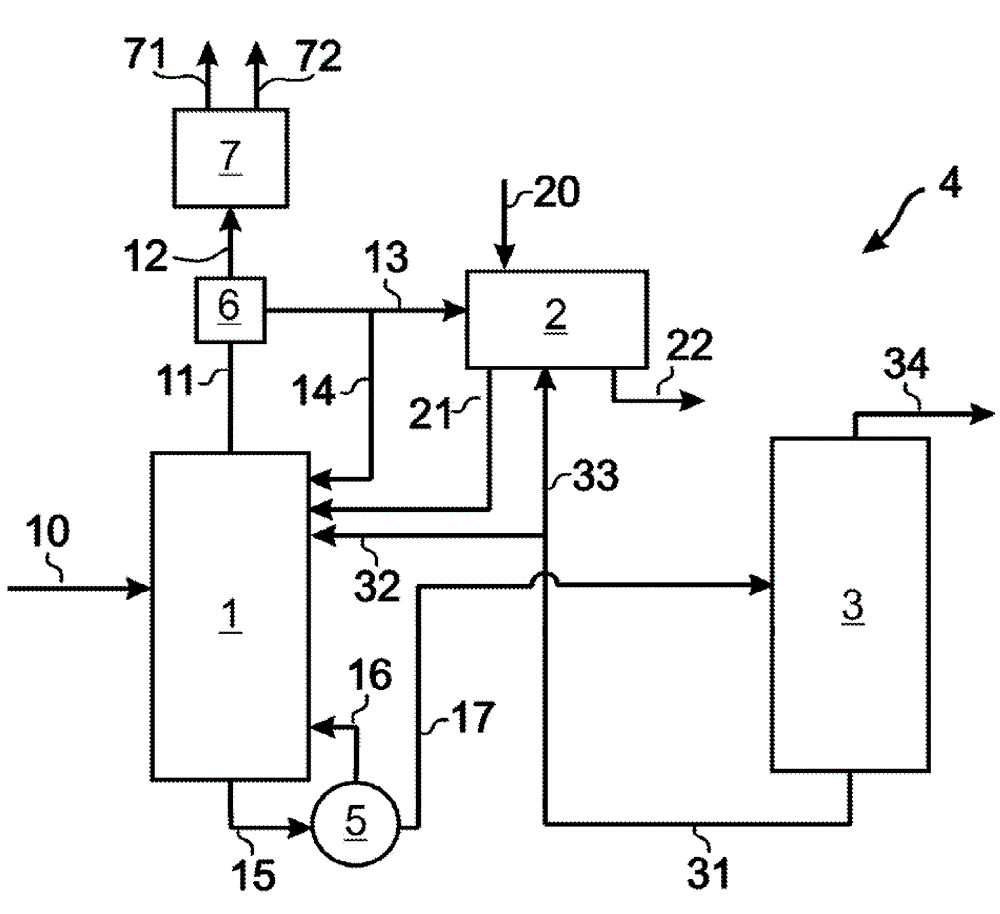

Process for the purification of crude propene oxide

InactiveCN1714087ACarbonyl compound separation/purificationPurification methodsExtractive distillation

The present invention relates to a method for purifying crude propylene oxide containing methanol and acetaldehyde by extractive distillation operated continuously, wherein an extraction solvent capable of reducing the volatility of methanol is used, and the crude propylene oxide is fed into a distillation column above the feed point of the crude propylene oxide A compound containing unsubstituted NH2 groups and capable of reacting with acetaldehyde is added to obtain purified propylene oxide containing less than 100 ppm methanol and less than 100 ppm acetaldehyde. The present invention also relates to a method for catalytic epoxidation of propylene comprising said purification step.

Owner:EVONIK OPERATIONS GMBH +1

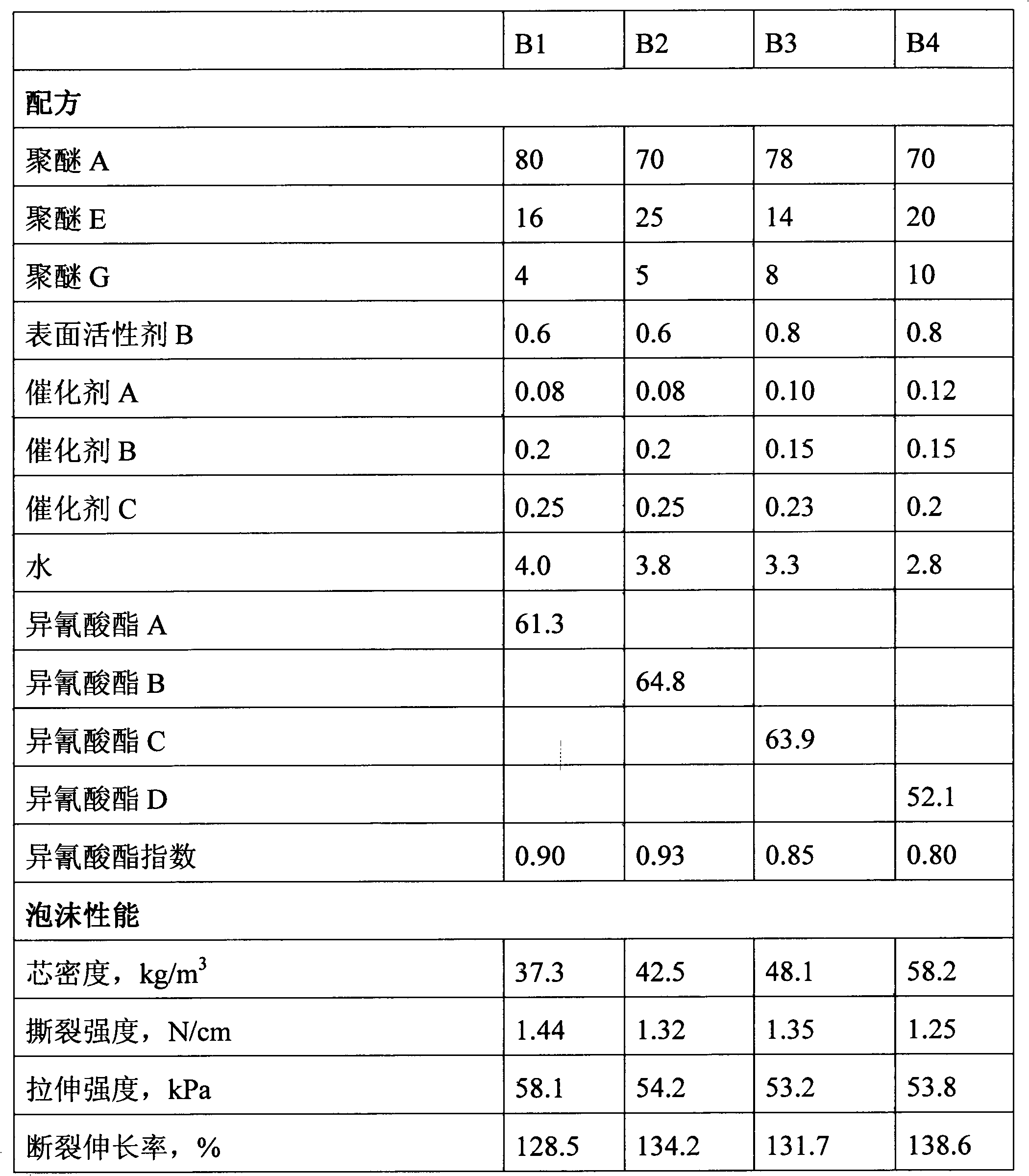

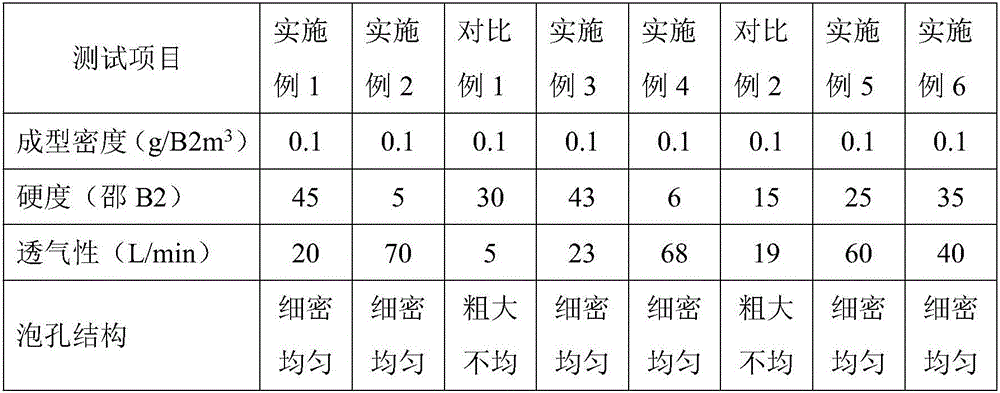

Preparation method for low-density viscoelastic polyurethane foam

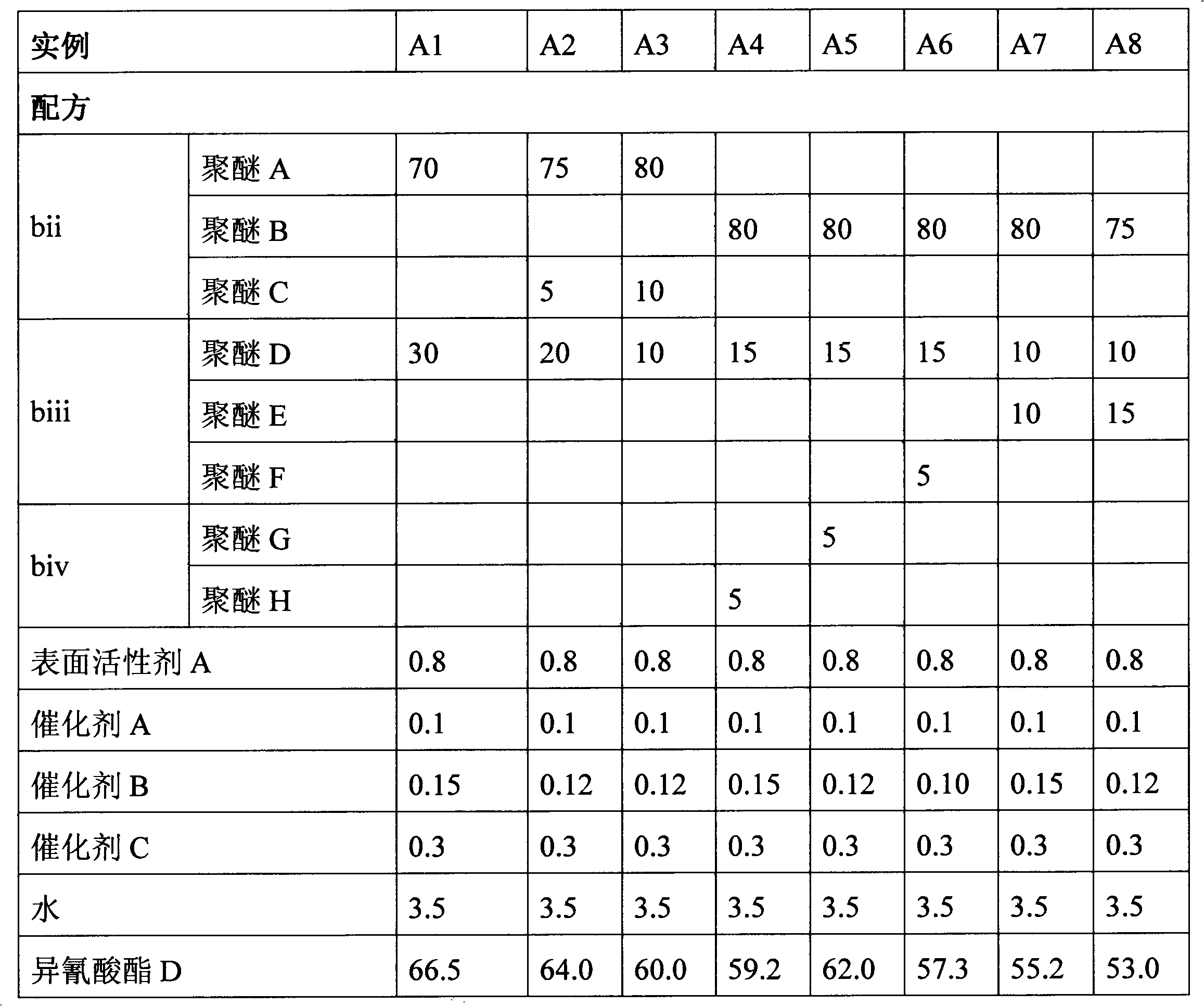

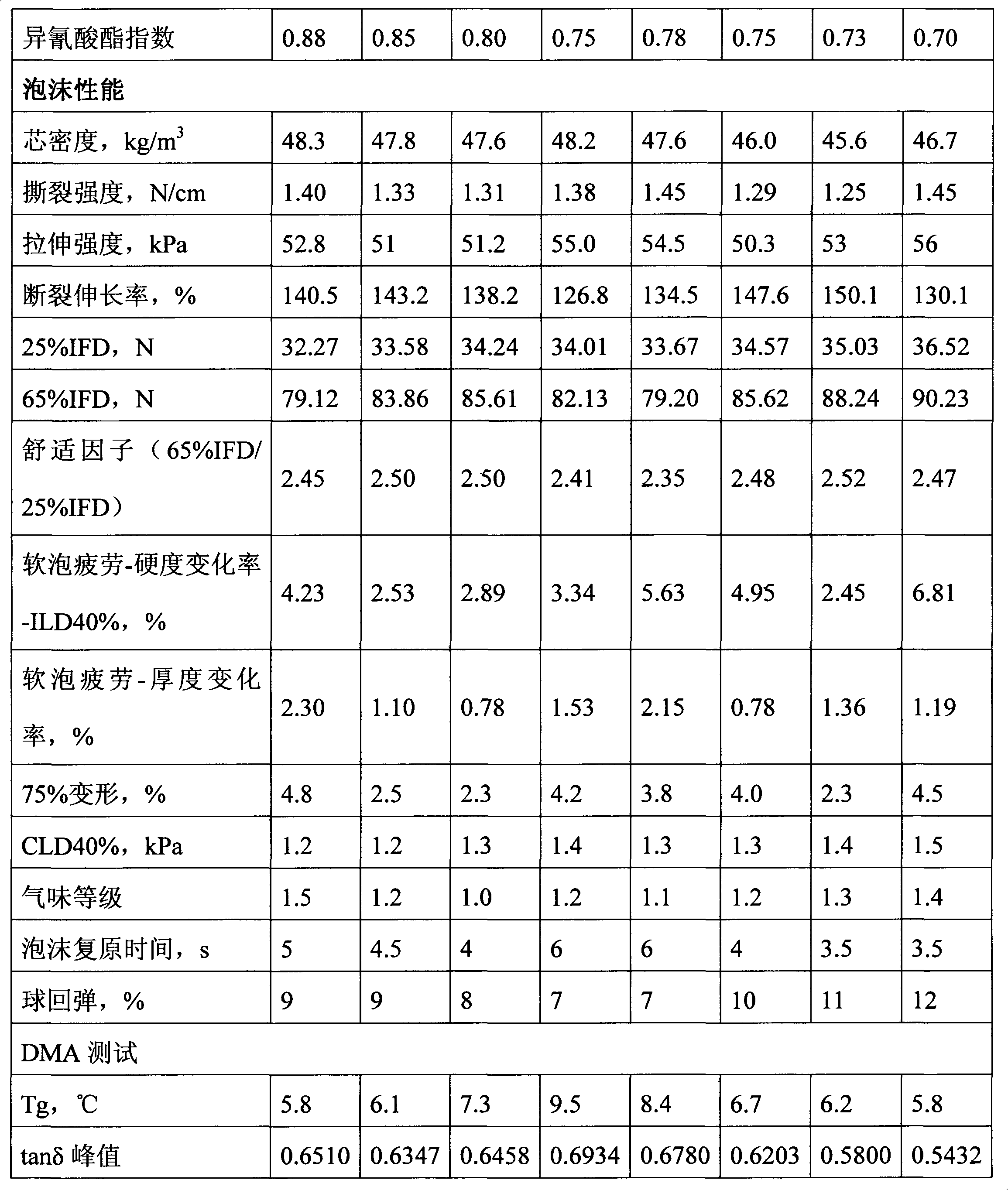

The invention relates to a preparation method for low-density viscoelastic polyurethane foam. Based on 100 parts by weight of mixed polyether, Isocyanate reaction active ingredients include (biii) 70-95 percent of propylene epoxide, ethylene oxide copolymerized polyol or a compound thereof, wherein the oxygen ethylidene unit content is not less than 70 percent by weight, (biii) 5-30 percent of propylene epoxide, epoxy ethane copolymerized polyol or a compound thereof, wherein the oxygen ethylidene unit content is 20 percent by weight at most, and (biv) 0-15 percent of propylene epoxide, propylene epoxide copolymerized polyol or a compound thereof, wherein the oxygen ethylidene unit content is 20 percent by weight at most; a reaction system does not contain any toluene diisocynate component or foaming agents except water; at least two polyether polyols are taken as major polyethers; and low-density viscoelastic polyurethane foam with low odor and excellent fatigue resistance is prepared.

Owner:WANHUA CHEM BEIJING +1

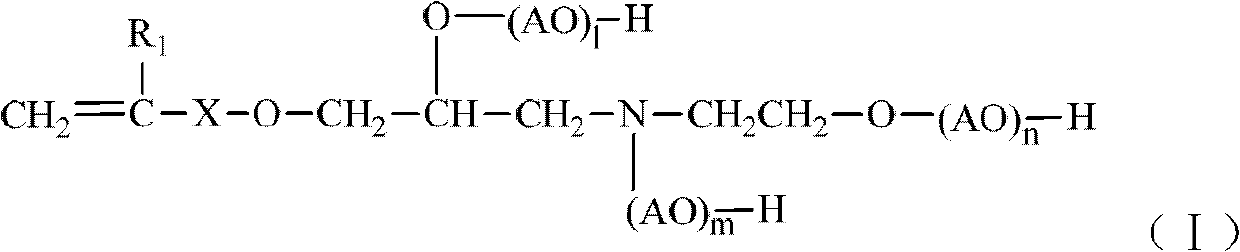

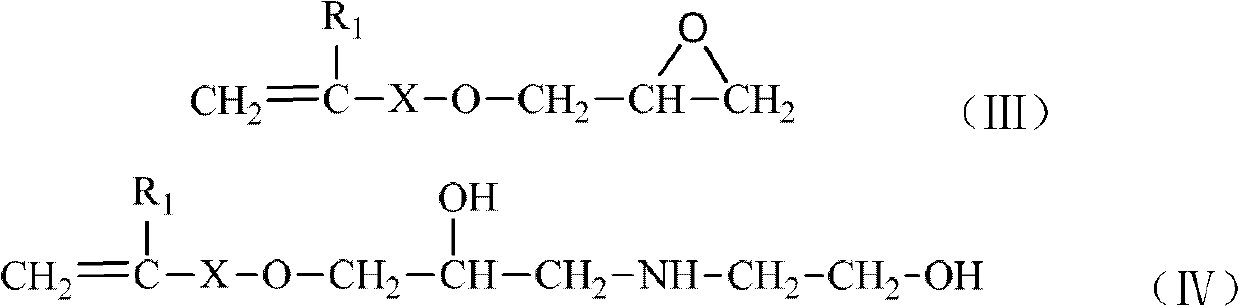

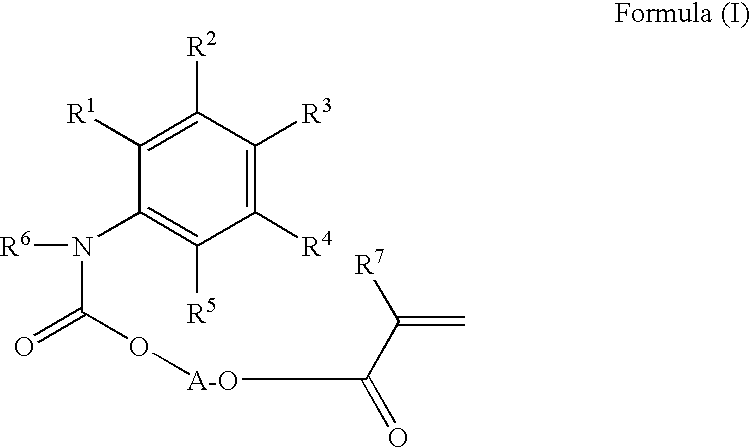

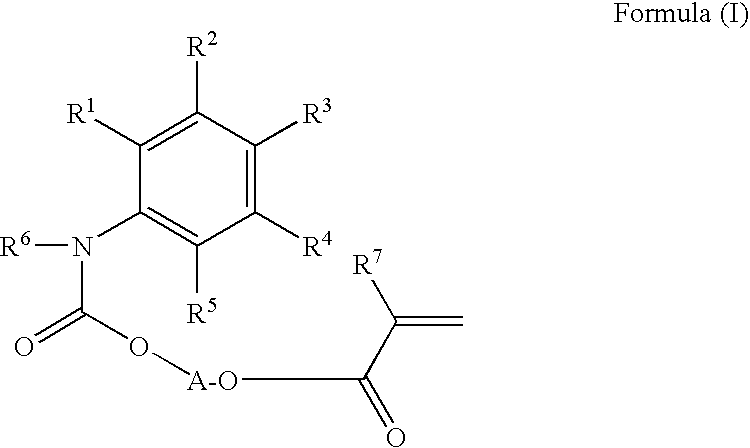

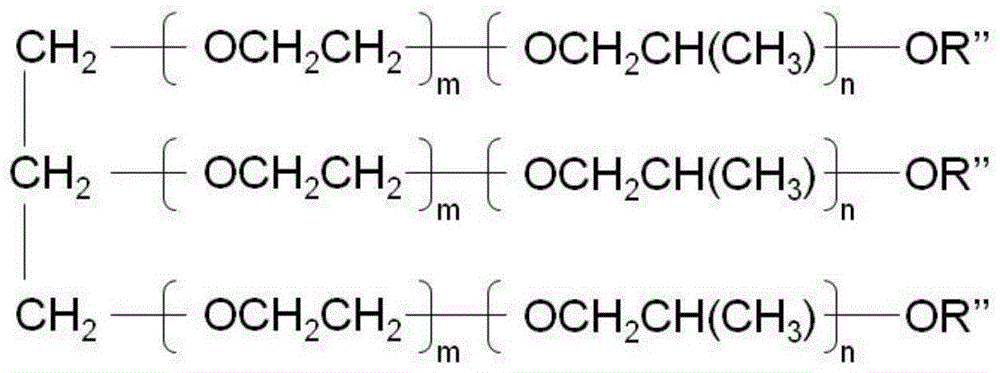

Unsaturated polyether monomer, comb-like branched copolymer cement dispersant prepared by the same, and preparation method thereof

The invention relates to an unsaturated polyether monomer, a comb-like branched copolymer cement dispersant prepared by the monomer, and preparation methods of the monomer and the dispersant. The unsaturated polyether monomer has the general formula (I), wherein R1 is H or -CH3; X is a linking group selected from -CH2-, -CH2CH2-, -OCH2CH2-, -OCH2CH2CH2CH2-; AO is ethylene oxide group and / or propene oxide group; l, m and n are all repeating units of AO; and the sum of l, m and n is an natural number of 10 to 50. The dispersant has the following chemical structure (VI), wherein x, y and z represent mole percentages of three structural units in the copolymer, and the sum of x, y and z is 100%. Preferably, x is 10% to 50%, y is 40% to 80% and z is 0% to 30%. The preparation method of the dispersant is simple and does not need organic solvents or complex esterification. The dispersant is advantageous in low dosage, good dispersibility and small slump loss.

Owner:连云港苏博特新材料有限公司 +2

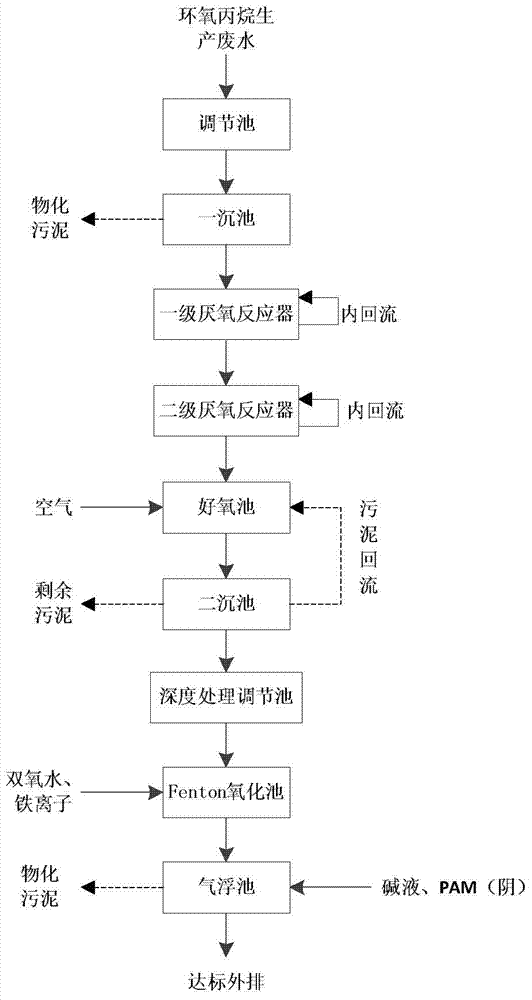

Propylene epoxide production wastewater treatment method

ActiveCN104773928AGuaranteed emission standardsEasy to operateMultistage water/sewage treatmentActivated sludgeIndirect emissions

The invention discloses a propylene epoxide production wastewater treatment method and belongs to the field of wastewater treatment. The problems that an existing propylene epoxide production wastewater treatment method is high in treatment cost, immature in treatment process, poor in treatment effect and the like are solved. The treatment method specifically includes the steps that firstly, wastewater is homogeneously adjusted and flows through a two-stage anaerobic treatment system, so that macromolecular matter in the wastewater is converted into micromolecules, and biodegradability of the wastewater is improved; then, the wastewater acquired through two-stage anaerobic treatment is further treated through aerobic activated sludge, the wastewater acquired through aerobic treatment is deeply treated through a high-grade Fenton oxidization method, and the deeply-treated wastewater can reach the indirect emission standard through air floatation and precipitation reactions. The treatment method has the advantages that operation is simple, treatment efficiency is high, treatment cost is low, and it is guaranteed that the wastewater is emitted according to the standard through deep treatment.

Owner:NANJING INNOVATION CENT FOR ENVIRONMENTAL PROTECTION IND

Preparation of demulsifying agent for processing mud and sand containing oil and its processing method

InactiveCN101053799ASludge treatmentFatty/oily/floating substances removal devicesSludgeUltrasonic radiation

The invention discloses a preparation of a demulsifier for treating oily sludge and a treatment method thereof, which is characterized in that the preparation method is to add 2.7-4.7Kg of oil soluble waterborne polyethers demulsifier, 2.6-2.8Kg lignin modified amphiprotic macromolecular surfactant, 1.4-1.6Kg of polymer of polyhydric alcohol, ethylene oxide and propylene oxide, and 3.0-3.2Kg of quaternary ammonium salt type cationic starch, to the homoeothermic reaction kettle mounted with a blender, control the reaction temperature at 60+-2 degree C for 0.5-2h after mixing dissolve, add 8-12% by the total weight of methanol and 70-85% by the total weight of glacial acetic acid control the reaction temperature at 60+-5 degree C for 2-4h, and the cool to room temperature to obtain the poly copolymerisate. The treatment process is to convey the oily sludge to storage tank, add demulsifier to break up the chemically bond and have a chemical separation, and send the mixed oily sludge to ultrasonic radiation reactor, and then the oily sludge is delamination and separation. The invention has the advantage of low treatment cost.

Owner:袁毅桦 +1

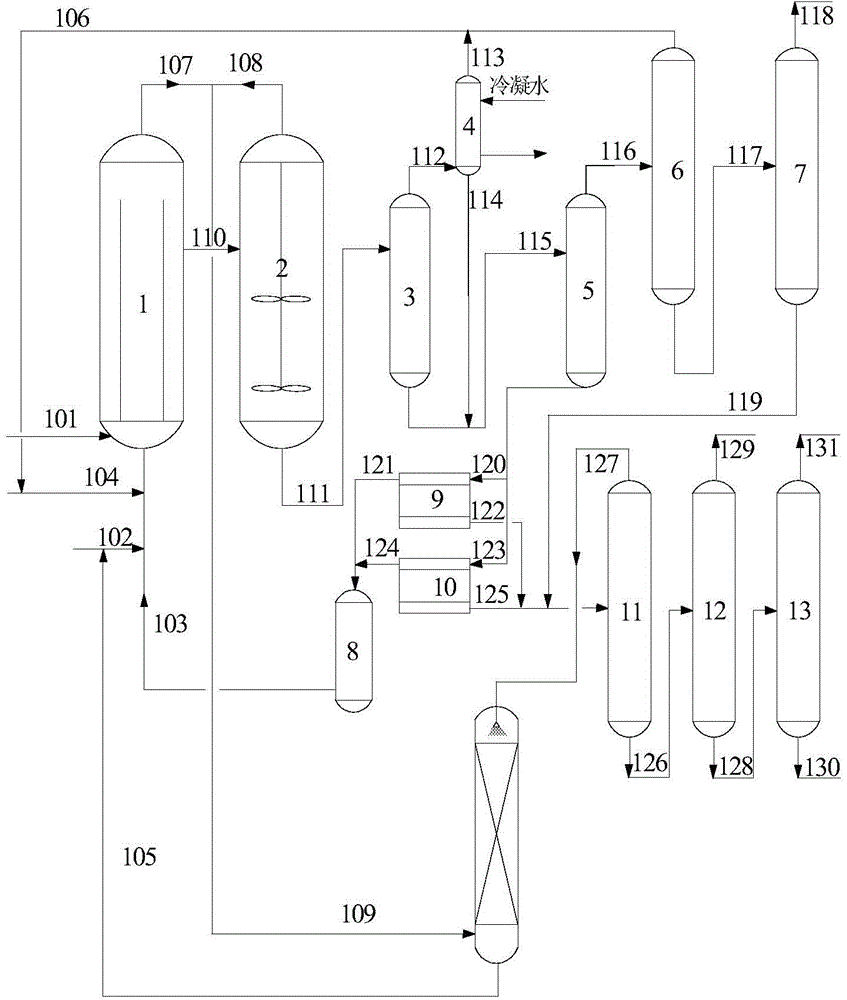

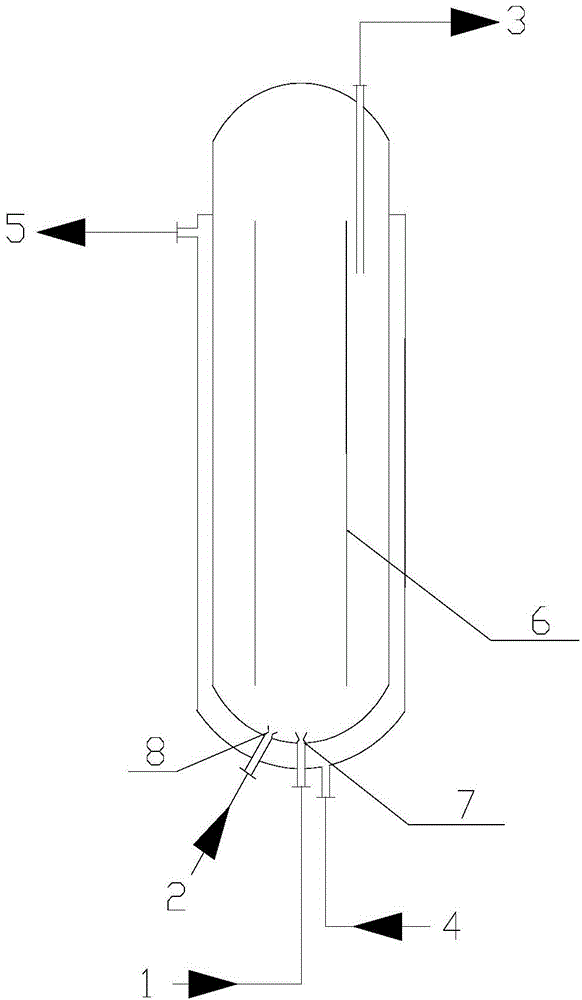

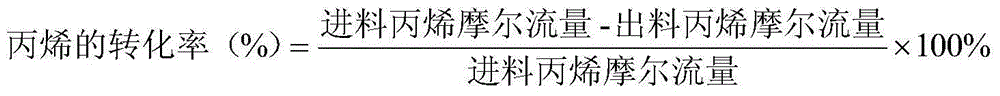

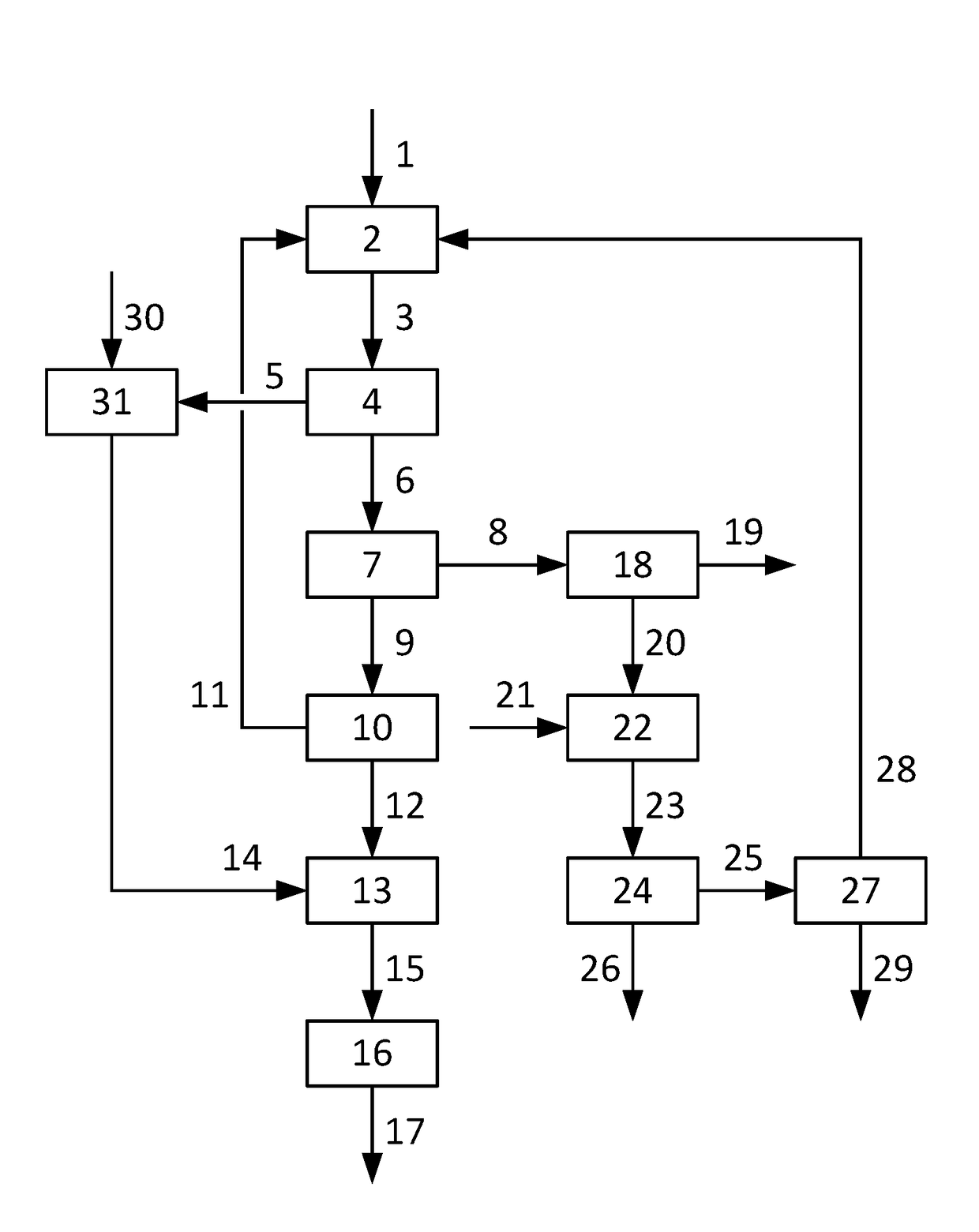

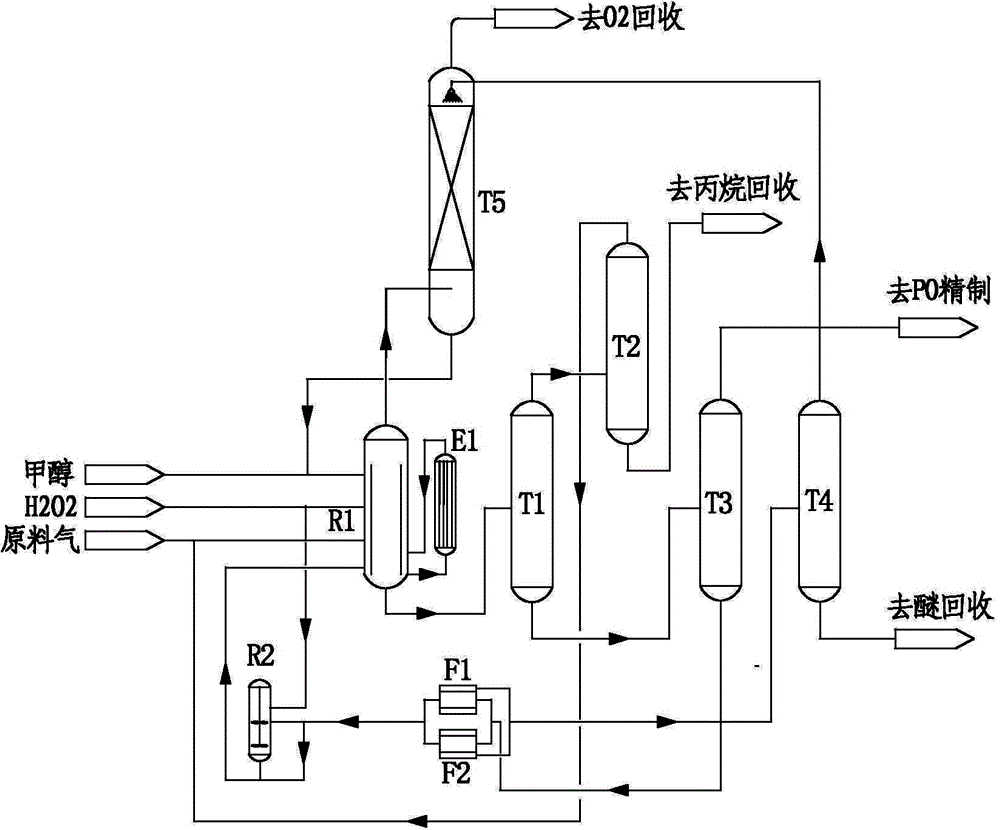

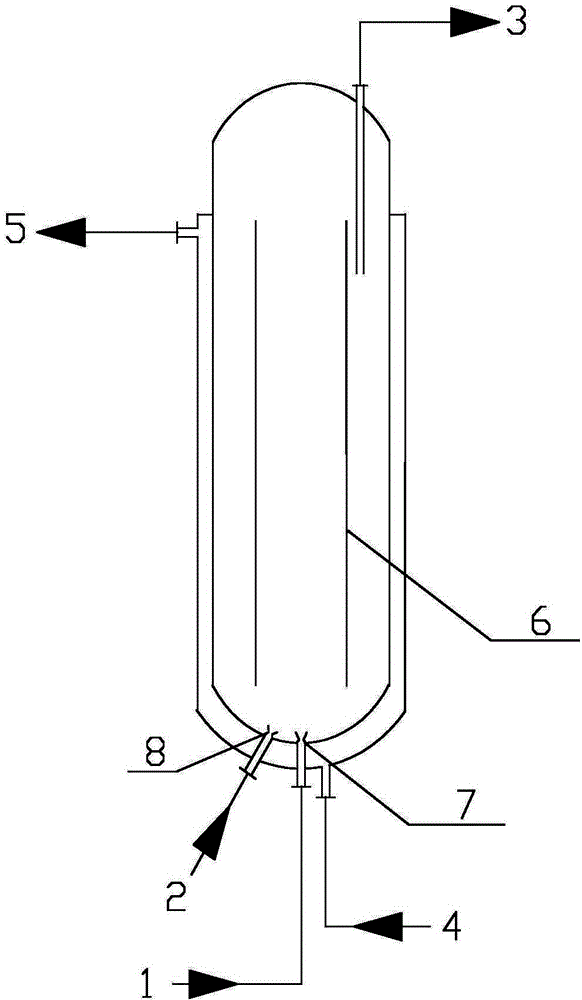

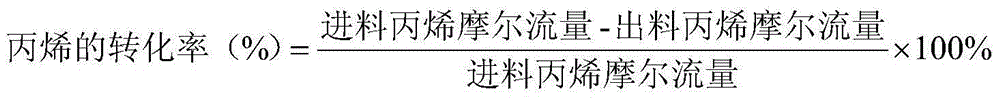

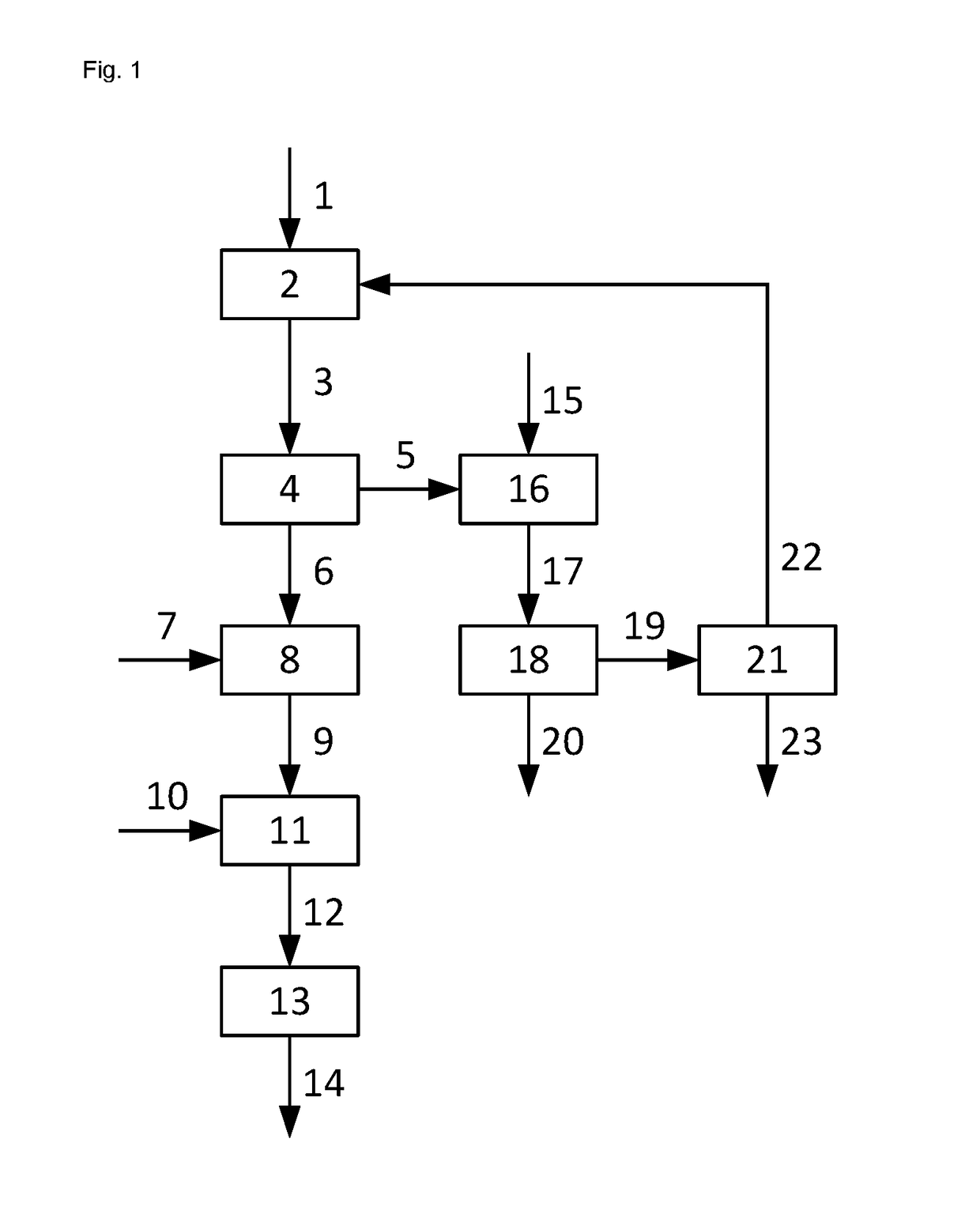

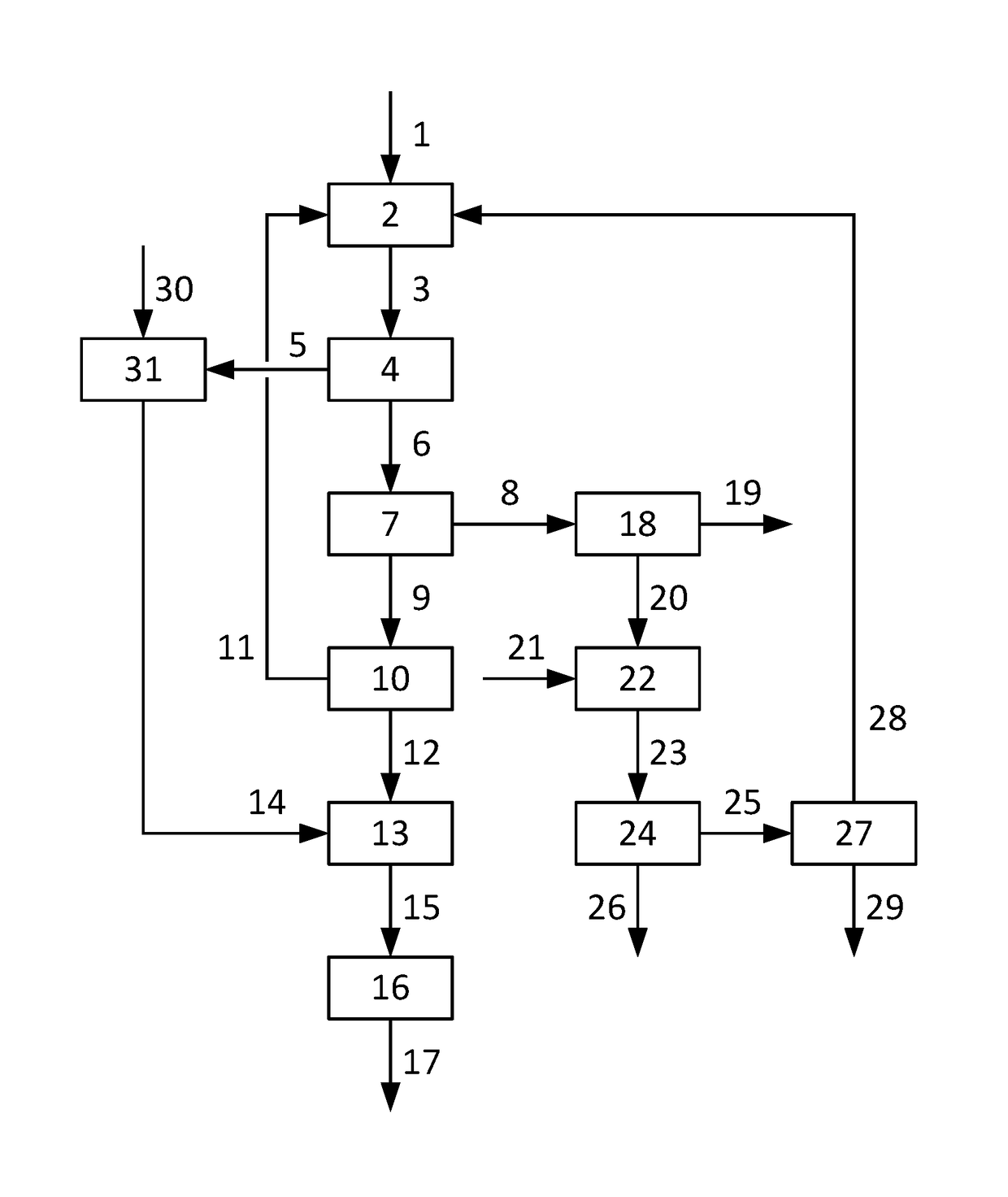

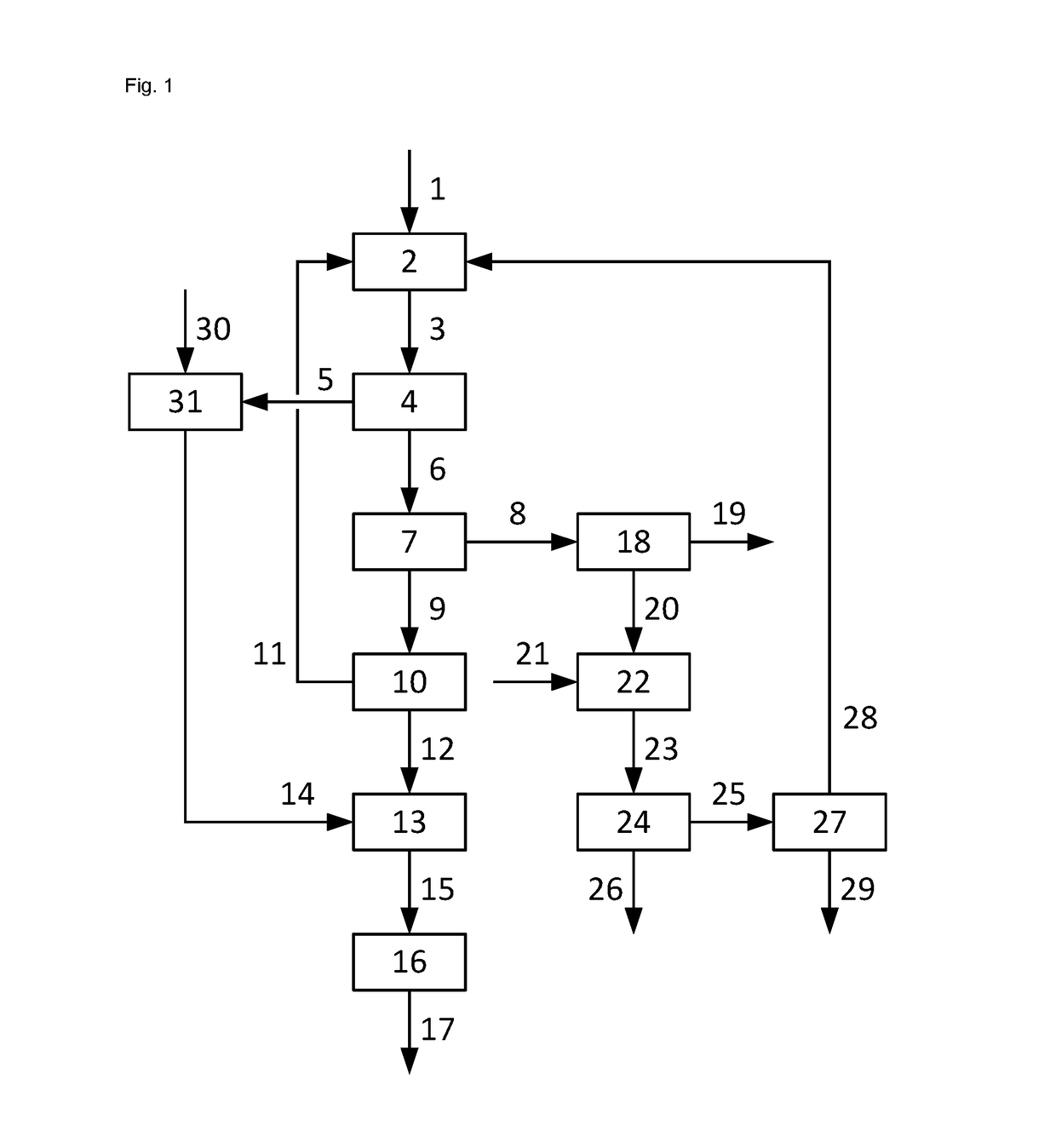

Method for continuously producing propylene oxide by directly oxidizing propylene with hydrogen peroxide

ActiveCN104130215AReduce consumptionImprove conversion rateOrganic chemistryChemical recyclingMolecular sieveFluidized bed

The invention discloses a technological process for continuously producing propylene oxide by directly oxidizing propylene with hydrogen peroxide. The whole procedure is divided into four working procedures namely a reaction process, a propylene oxide purification process, a catalyst separation and concentration process and a methanol and oxygen-containing propylene recovery and byproduct separation process, wherein in the reaction process, a fluidized bed circulation flow main reactor and a slurry stirring auxiliary reactor which are connected with each other in series are adopted; a molecular sieve fine particle catalyst is applied; discharged slurry passes through a flash tank to evaporate propylene and propylene oxide; oxygen-containing propylene remained after reaction is synchronously recycled in an absorber by using a solvent methanol recycling process; catalyst particles are separated by virtue of a membrane separator to achieve regeneration and then return to the reactor to be recycled. The process disclosed by the invention achieves the stability and continuity of the production of propylene oxide by directly oxidizing propylene with hydrogen peroxide.

Owner:HENAN JUNHUA DEV +1

Phenyl isocyanate-based urethane acrylates, processes for producing and methods of using the same

ActiveUS8222314B2High refractive indexIncrease valueCarbamic acid derivatives preparationMirrorsPolymer scienceCarbamate

Owner:COVESTRO DEUTSCHLAND AG

Polyurethane hard foamed plastics and its preparing method

The present invention discloses a kind of hard foamed polyurethane plastic and its preparation process. The material includes polyisocyanate, composite polyether and foaming agent. The composite polyether consists of several kinds of monomer polyether of functionality 3-8 and molecular weight below 1300, and the monomer polyether is produced with one or several initiation components and propylene oxide and through polymerization. The preparation process of hard foamed polyurethane plastic includes cooling HFC-245fa foaming agent to 5-10 deg.c; mixing HFC-245fa foaming agent with the composite polyether comprising monomer polyether, foam stabilizer and catalyst; high pressure mixing and foaming polyisocyanate and composite polyether in high pressure foaming machine with injecting head; high pressure injection at 10-20 MPa pressure; and curing.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

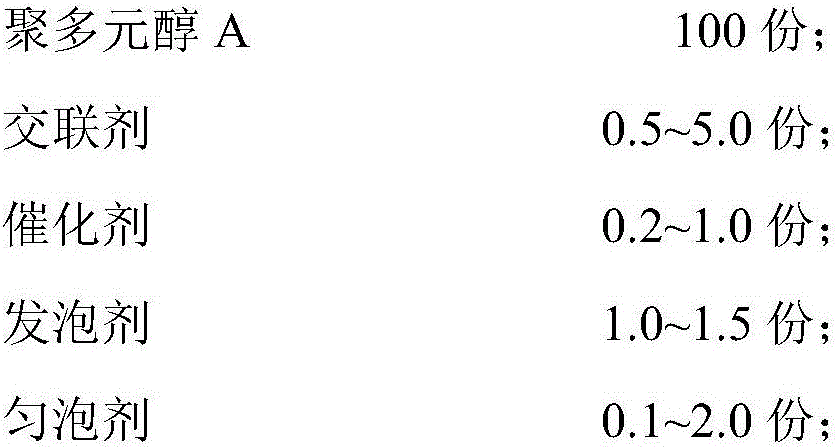

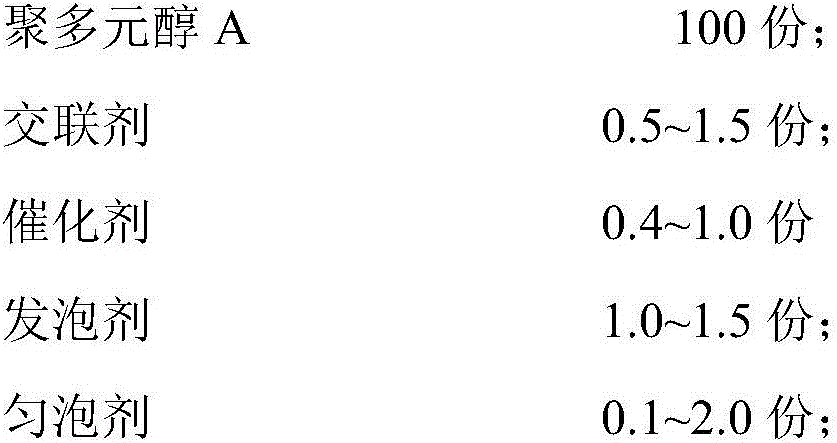

Polyurethane resin used for breathable insole as well as preparation method and application

The invention discloses polyurethane resin used for a breathable insole as well as a preparation method and application. The resin comprises a resin A component, a resin B1 component and a resin B2 component, wherein the resin A component comprises polyalcohol A, a cross-linking agent, a catalyst, a foaming agent and a foam stabilizer; the resin B1 component comprises the following ingredients in parts by weight: 80-100 parts of isocyanate B1, 1-30 parts of polyalcohol B1 and 0.002-0.010 parts of a side-reaction inhibitor; the resin B2 component comprises the following ingredients in parts by weight: 100 parts of isocyanate B2, 50-100 parts of polyalcohol B2 and 0.002-0.010 parts of a side-reaction inhibitor; the isocyanate B1 is diphenyl methane diisocyanate, carbodiimide modified diphenyl methane diisocyanate, toluene diisocynate or naphthalene diisocyanate; the polyalcohol B1 is polyoxyethylene-propylene oxide trihydric alcohol; the isocyanate B2 is diphenyl methane diisocyanate, carbodiimide modified diphenyl methane diisocyanate, toluene diisocynate or naphthalene diisocyanate; the polyalcohol B2 is polyoxyethylene-propylene oxide dihydric alcohol. According to the polyurethane resin disclosed by the invention, breathable insoles with different hardness can be prepared, and the cost is low.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD +1

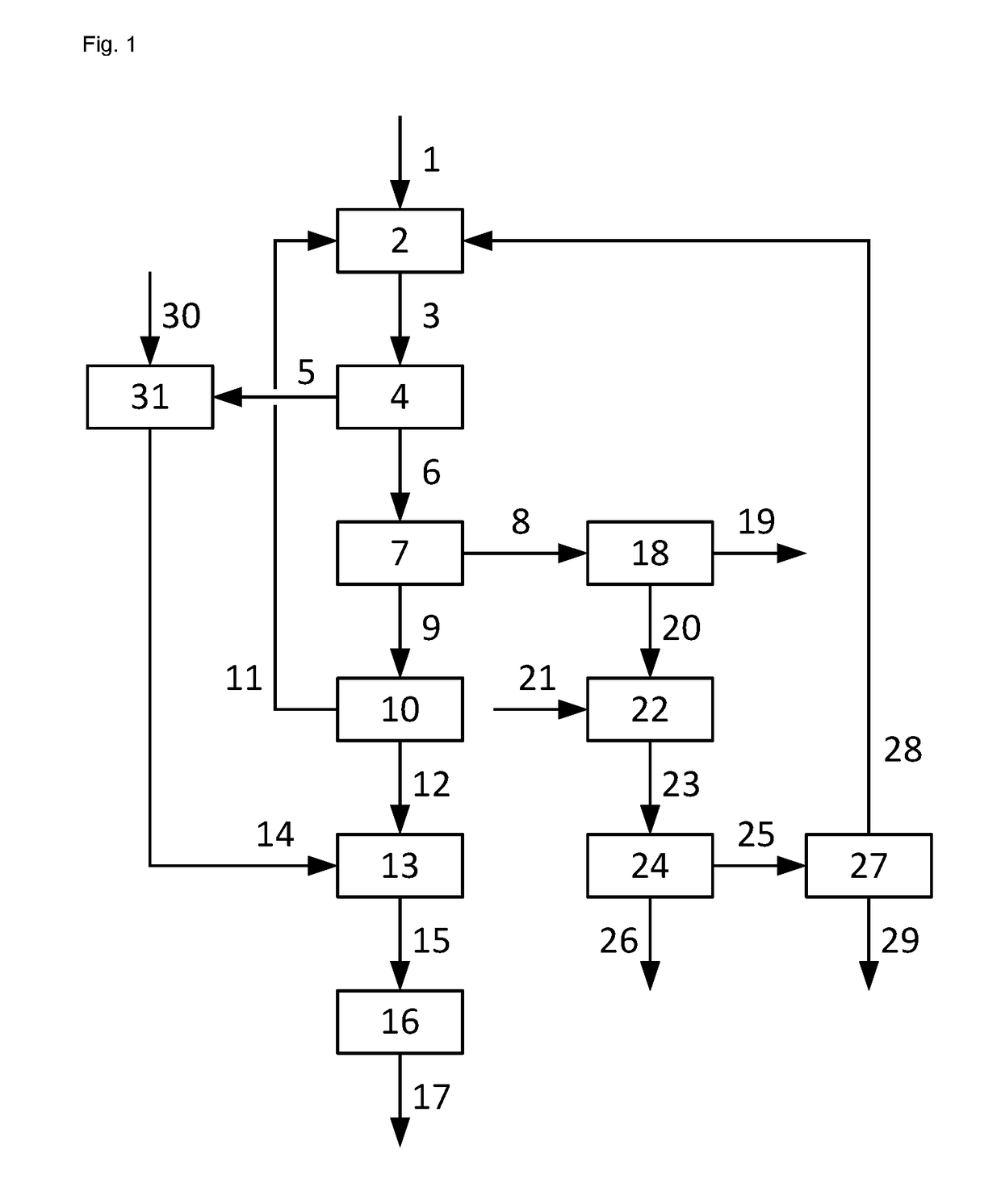

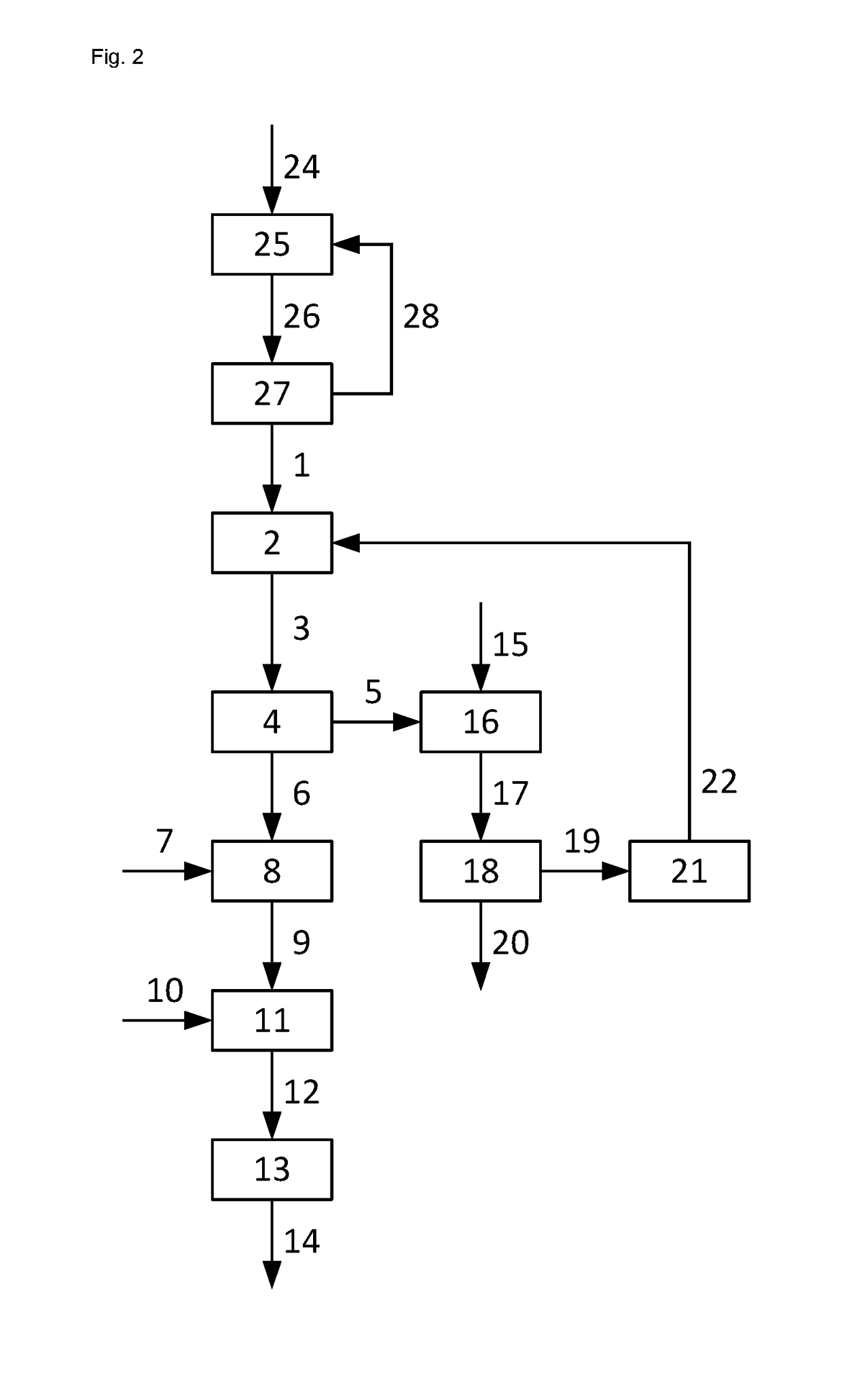

Integrated process for making propene oxide and an alkyl tert-butyl ether

ActiveUS20180002300A1Hydrocarbon by dehydrogenationPhysical/chemical process catalystsEtherIsobutane

An integrated process for making propene oxide and an alkyl tert-butyl ether comprises dehydrogenating a feed stream comprising propane and iso-butane to provide a stream comprising propene, iso-butene and hydrogen; separating this stream into a stream consisting essentially of hydrogen and a stream comprising propene and iso-butene; separating the stream comprising propene and iso-butene into a stream comprising propene and a stream comprising iso-butene; reacting a part or all of the stream comprising iso-butene with an alkanol in the presence of a solid acid catalyst to provide an alkyl tert-butyl ether; and reacting a part or all of the stream comprising propene with hydrogen peroxide in the presence of an epoxidation catalyst to provide propene oxide.

Owner:THYSSENKRUPP IND SOLUTIONS AG

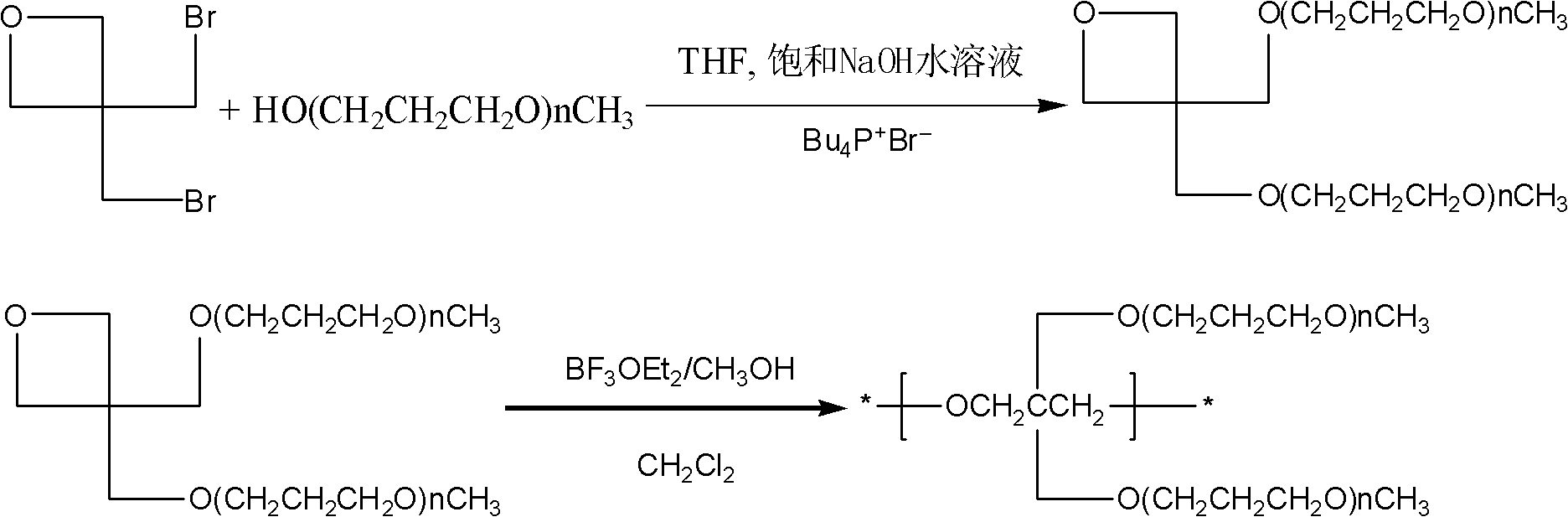

Process for continuously producing epoxy propane through propylene and propane mixed gas directly oxidized by hydrogen peroxide

ActiveCN104130216AReduce consumptionEvenly dispersedOrganic chemistryChemical recyclingSlurrySolvent

The invention discloses a process for continuously producing epoxy propane through propylene and propane mixed gas directly oxidized by hydrogen peroxide. In the reaction process, a fluidized bed circulation flow reactor is adopted, and a fine particle molecular sieve catalyst is used. The process comprises the following steps: discharging slurry to pass trough a flash column, respectively flashing low-oxygen propylene / propane mixed gas and epoxy propane, separating catalyst slurry and mother solution in the catalyst-containing mother solution through a membrane separator, performing flash separation on methanol in the mother solution, synchronously recovering the reacted residual high-oxygen propylene / propane mixed gas for recycling in a high-oxygen propylene / propane absorption tower by utilizing a recovery solvent methanol, and regenerating an online part of the catalyst slurry to return to the reactor for recycling. According to the process, the stability and continuity of the process for producing the epoxy propane through propylene and propane mixed gas directly oxidized by hydrogen peroxide are realized.

Owner:HENAN JUNHUA DEV +1

Medical composite material and its preparing method

The composite medical material includes polyethylene or polypropylene as protecting layer and CO2 copolymer as the intermediate blocking layer. The CO2 copolymer may be binary or ternary copolymer of CO2 and epoxy ethane, epoxy propane, cyclohexane monoxide, styrene monoxide, epoxy propane and epoxy cyclohexane, or epoxy propane and styene monoxide. The composite medical material is prepared via three-layered or five-layered coextrusion at 140-190 deg.c. It has excellent blocking performance and mechanical performance, is degradable and transparent, and may be used in production of disposable infusion bag, disposable infusion duct and relative articles.

Owner:威海赛绿特科技发展有限公司

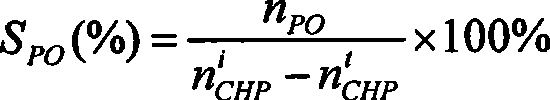

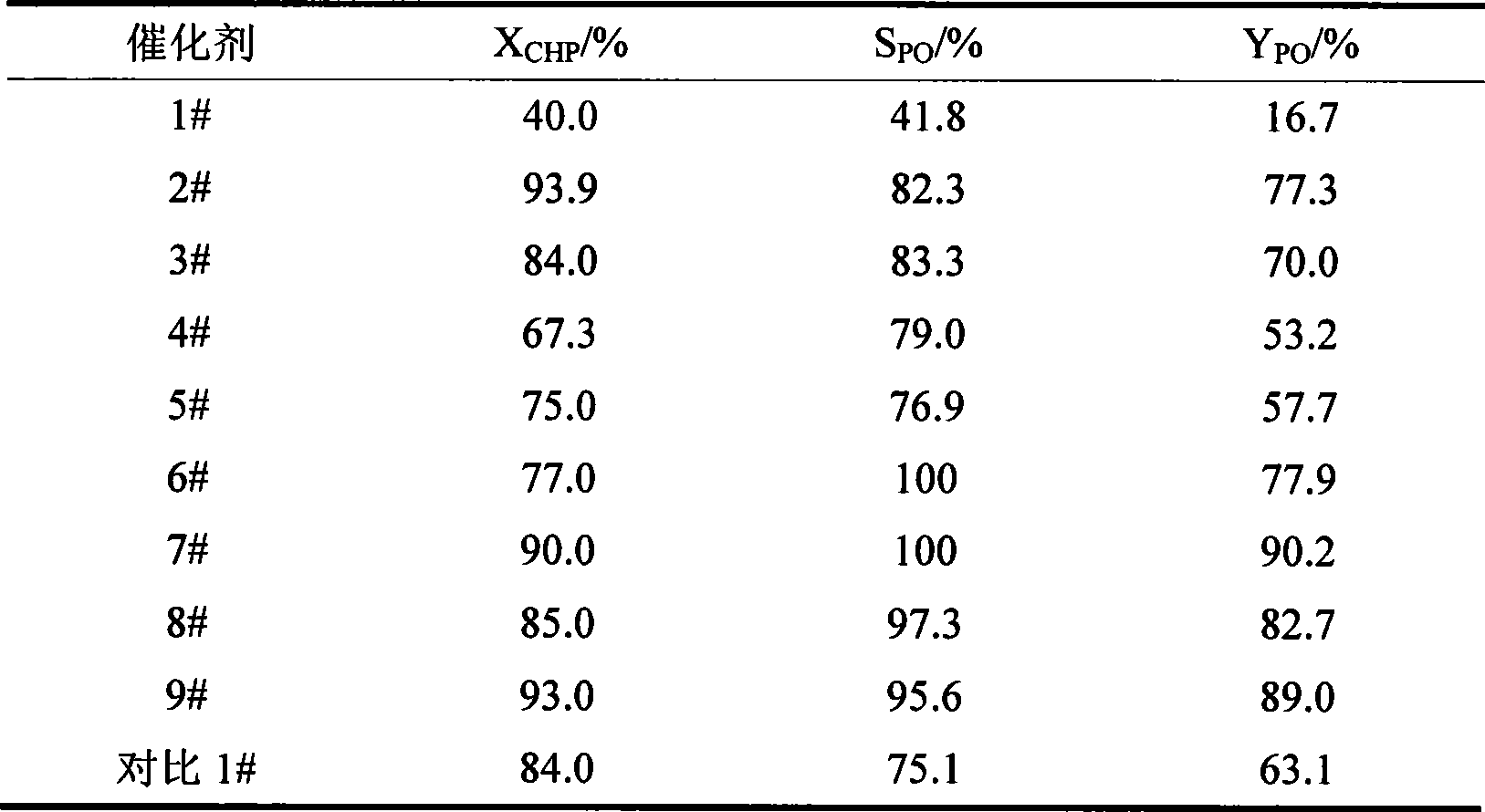

Catalyst for producing epoxypropane by liquid phase one-step oxidation of propylene and preparation method

InactiveCN101497045AImprove catalytic performanceOrganic chemistryPhysical/chemical process catalystsIsopropyl benzene hydroperoxideOxidizing agent

The invention discloses a catalyst used for preparing propylene oxide by liquid phase oxidation of propylene in one step through taking isopropyl benzene hydroperoxide as an oxidant, and a preparation method thereof. The catalyst is a supported molybdenum oxide catalyst containing chlorine, and is formed by a catalytic active composition MoO3, an accelerative catalyst Cl and a carrier SiO2 to be prepared by the sol-gel method. The catalyst reacts for 4 hours at 80 DEG C and 2.2MPa, and yield and selectivity of the propylene oxide can reach 90 percent and 100 percent respectively.

Owner:EAST CHINA UNIV OF SCI & TECH

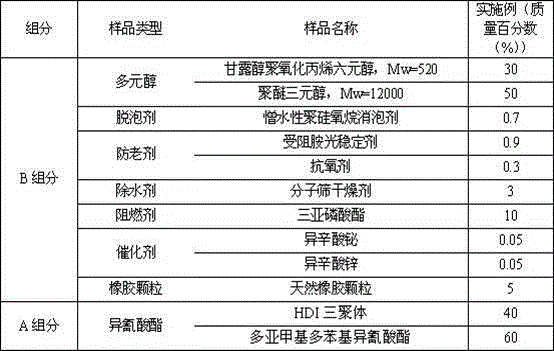

Cured track bed sinking repairing high-viscosity vibration attenuation polyurethane repairing material

The invention relates to a high-viscosity vibration attenuation polyurethane repairing material for sinking repairing of a polyurethane cured track bed of a high speed railway or a heavy haul railway. The high-viscosity vibration attenuation polyurethane repairing material consists of a component A and a component B which are mixed and stirred together mechanically, wherein the mass ratio of the component A to the component B is (1:0.9)-(1:1.5); the component A is a mixture of an HDI tripolymer and polymethylene polyphenyl isocyanate ester; the mass ratio of the HDI tripolymer to polymethylene polyphenyl isocyanate ester is (3:7)-(6:4); the content of -NCO is 27-29%; and the component B consists of polyhydric alcohol, a catalyst, a defoaming agent, a moisture scavenger, an anti-aging agent, a flame retardant and rubber granules. The high-viscosity vibration attenuation polyurethane repairing material is characterized in that the polyhydric alcohol is a mixture which consists of 6-functionality-degree mannitol poly(propylene oxide polyol) and 3-functionality-degree high molecular weight polyether polyol with the molecular weight of 12000. According to the polyurethane repairing material provided by the invention, the volume expansion ratio is 1-3%, the compressive strength of 1 hour is greater than or equal to 12MPa, the adhesion strength is greater than or equal to 6MPa, the damping factor is 0.25-0.40, the accumulated residual deformation is less than or equal to 0.5% after 5 million times of fatigue loading, and the polyurethane repairing material can be applied to polyurethane cured track bed sinking repairing and railway ballast cured track bed sinking repairing as well.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

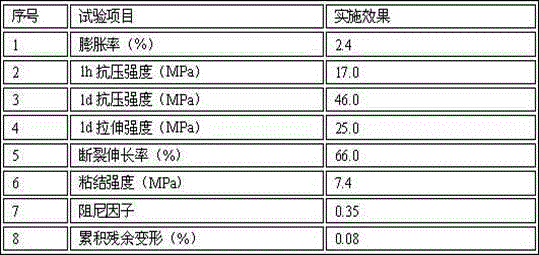

Method for inhibiting grease in alkaline washing towers

The invention relates to a method for inhibiting grease in alkaline washing towers to mainly solve problems comprising easy alkaline washing tower obstruction and inconvenient operation caused by bad grease inhibition effects in previous technologies. According to the invention, an inhibitor is injected in an online continuous manner, wherein the inhibitor comprises one or two of two compounds having structures shown in the specification; R in the structures is an alkyl group or an aromatic group containing 0-15 carbon atoms. The above technical scheme well solves the problems, and the method can be used in industrial devices the alkaline washing towers for petrochemical ethylene, ethanol-to-ethylene, methanol-to-olefin, methanol-to-propylene, vinyl acetate, dichloroethylene, epoxy propane and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

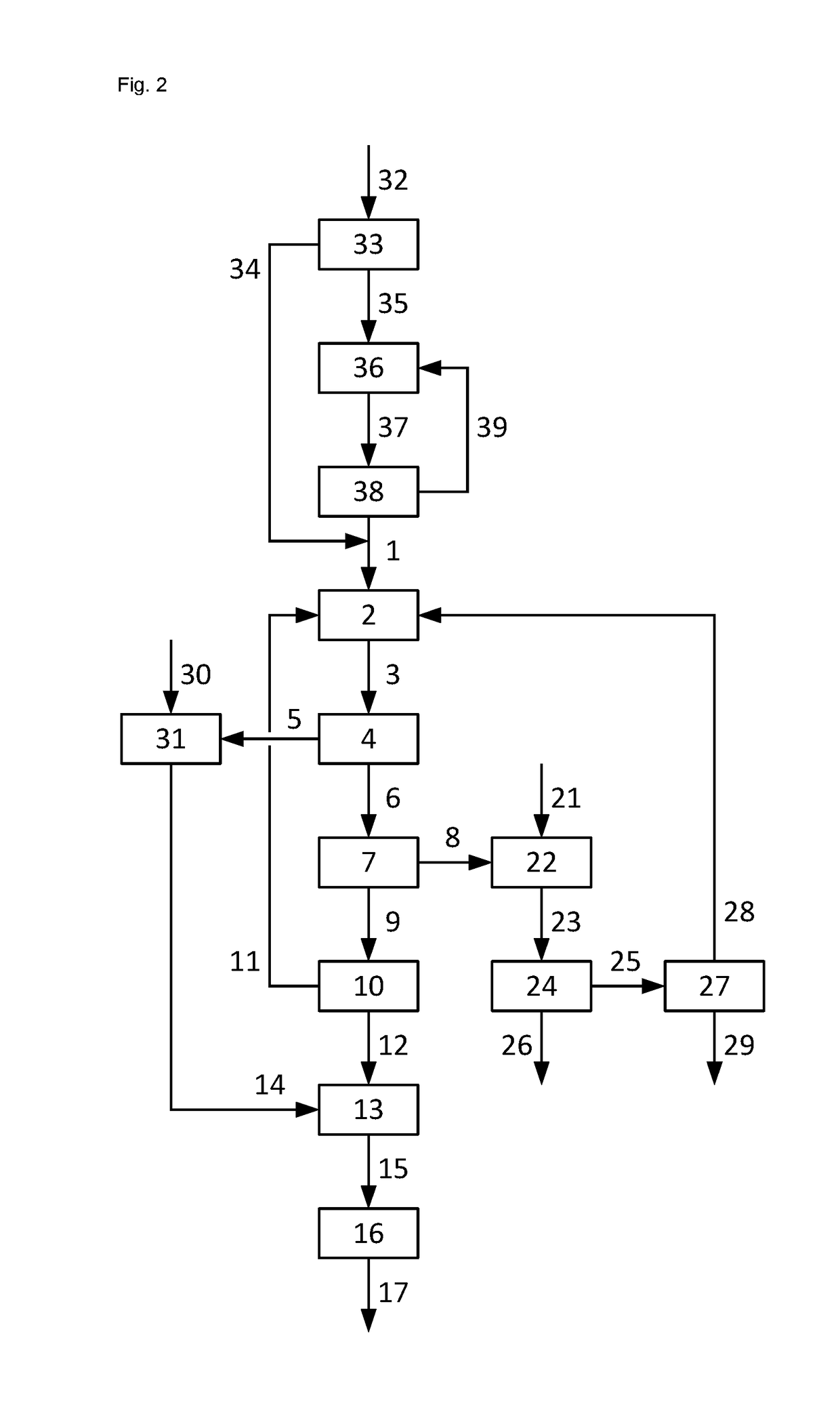

Integrated process for making propene oxide and an alkyl tert-butyl ether

ActiveUS20180002299A1Reduce material consumptionEther separation/purificationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolid acidOxygen

An integrated process for making propene oxide and an alkyl tert-butyl ether comprises dehydrogenating a feed stream comprising iso-butane to provide a stream comprising iso-butene and hydrogen and separating this stream into a stream consisting essentially of hydrogen and a stream comprising iso-butene; reacting a part or all of the stream comprising iso-butene with an alkanol in the presence of a solid acid catalyst to provide an alkyl tert-butyl ether; reacting a part or all of the stream consisting essentially of hydrogen with oxygen, providing a stream comprising hydrogen peroxide; and reacting a part or all of the stream comprising hydrogen peroxide with propene in the presence of an epoxidation catalyst to provide propene oxide.

Owner:THYSSENKRUPP IND SOLUTIONS AG

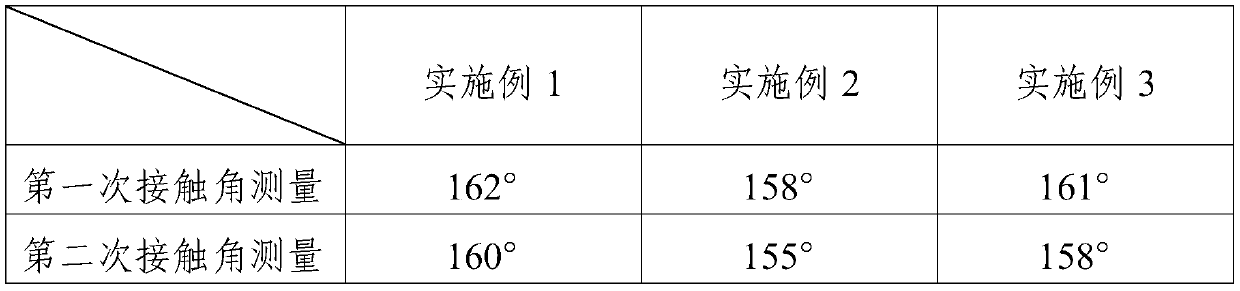

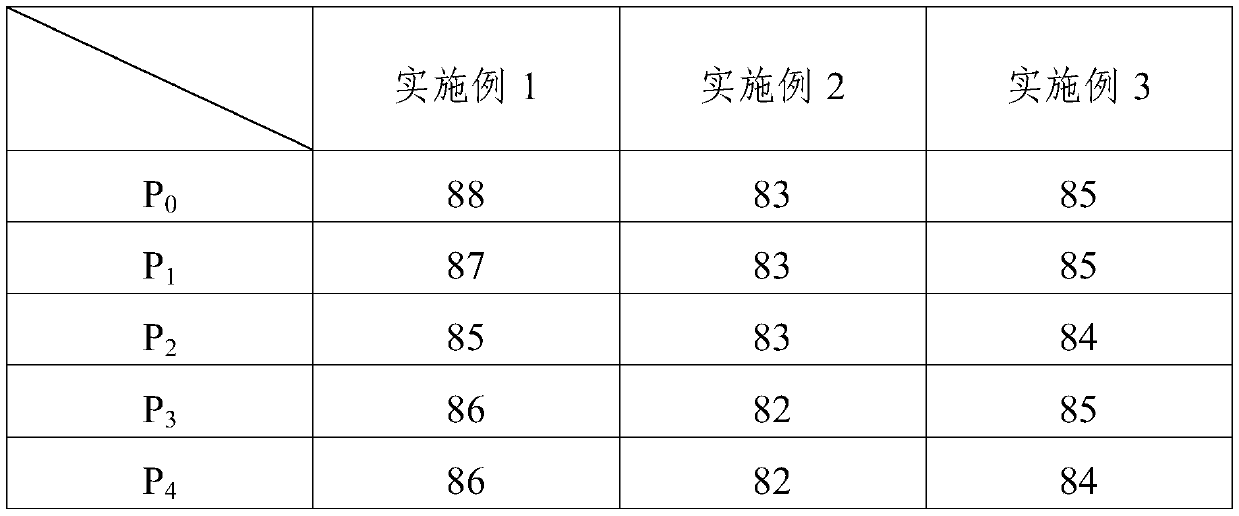

Preparation method of super-hydrophobic sponge material for oil-water separation

InactiveCN111135806AEasy to fixImprove adsorption capacityOther chemical processesWater contaminantsFreeze-dryingPolypropylene

The invention provides a preparation method of a super-hydrophobic sponge material for oil-water separation, and relates to the field of oil-water separation materials. The preparation method comprises the following steps: mixing polyether silicone, polypropylene oxide glycol and methylbenzene, heating, adding isophorone diisocyanate and dibutyltin laurate, reacting for 5-10 h, adding gamma-aminopropyltrimethoxysilane into a mold, and curing the mold to form a semi-finished product A; coarsening the semi-finished product A, and freeze-drying the semi-finished product A to obtain a semi-finished product B; carrying out ultraviolet irradiation on the semi-finished product B, and immersing the semi-finished product B into a triethyl chlorosilane n-hexane solution to obtain a semi-finished product C; and loading nano-silica to obtain the super-hydrophobic sponge material finished product. The contact angle between the surface of the sponge material and water is larger than 150 DEG, the sponge material has super-hydrophobic performance, the contact angle is only slightly decreased after n-hexane is repeatedly absorbed for 10 times, the sponge material has excellent adsorption capacity for diesel oil with high viscosity, and the adsorption capacity is basically not decreased after repeated adsorption for multiple times.

Owner:安徽圩码网络科技有限公司

Integrated process for making propene oxide and an alkyl tert-butyl ether

ActiveUS10053440B2Hydrocarbon by dehydrogenationPhysical/chemical process catalystsHydrogenPropene oxide

An integrated process for making propene oxide and an alkyl tert-butyl ether comprises dehydrogenating a feed stream comprising propane and iso-butane to provide a stream comprising propene, iso-butene and hydrogen; separating this stream into a stream consisting essentially of hydrogen and a stream comprising propene and iso-butene; separating the stream comprising propene and iso-butene into a stream comprising propene and a stream comprising iso-butene; reacting a part or all of the stream comprising iso-butene with an alkanol in the presence of a solid acid catalyst to provide an alkyl tert-butyl ether; and reacting a part or all of the stream comprising propene with hydrogen peroxide in the presence of an epoxidation catalyst to provide propene oxide.

Owner:THYSSENKRUPP IND SOLUTIONS AG

Polyurethane elastomer/laminated nano composition for stadium and its preparing process

A composite polyurethane elastomer / nano laminated material for stadium is prepared through preparing organic nano laminated material from montmorillonite and hydrotalcite, vacuum dewatering of dihydoxy polyoxyacrylether, mixing with toluene diisocyanate to obtain component A, compounding the organic nano laminated material with dihydroxy or trihydroxy polyoxyacrylether, mixing with 3,3'-bichloro-4,4'-diaminodiphenyl methane, pigment, filler and plasticizer to obtain component B, proportionally mixing components A with B, and laminating polymerization reaction u nder catalyst of zinc naphthenate. Its advantage is high flame-retording and mechanical performance.

Owner:孔克健

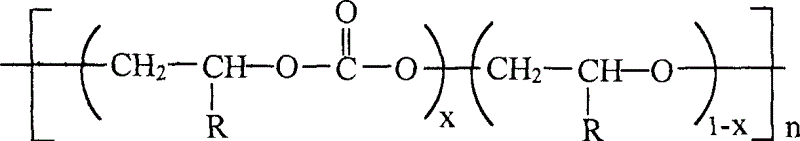

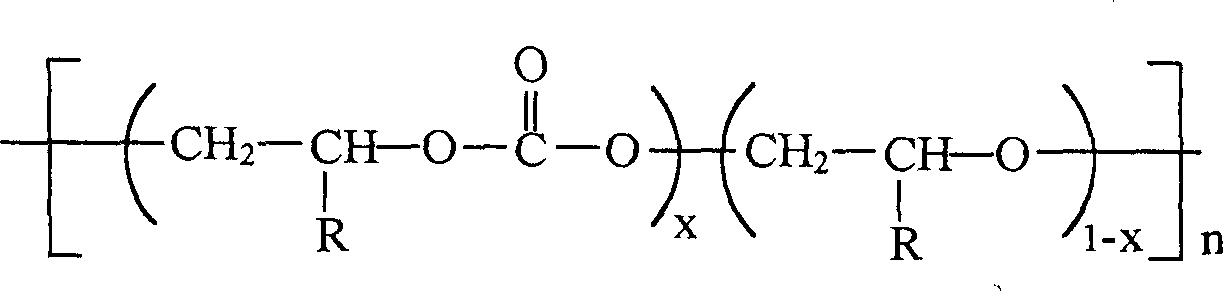

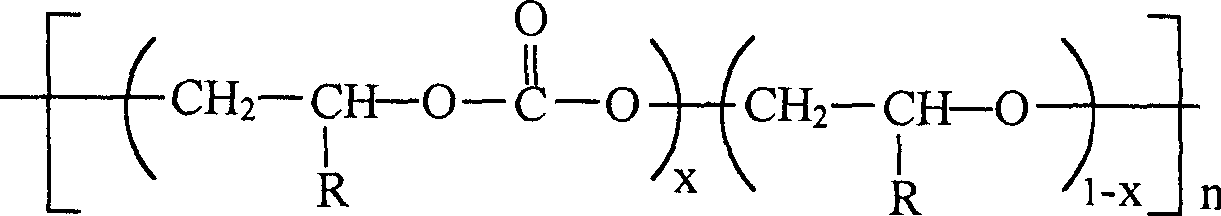

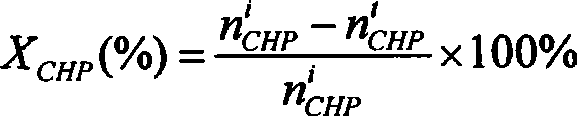

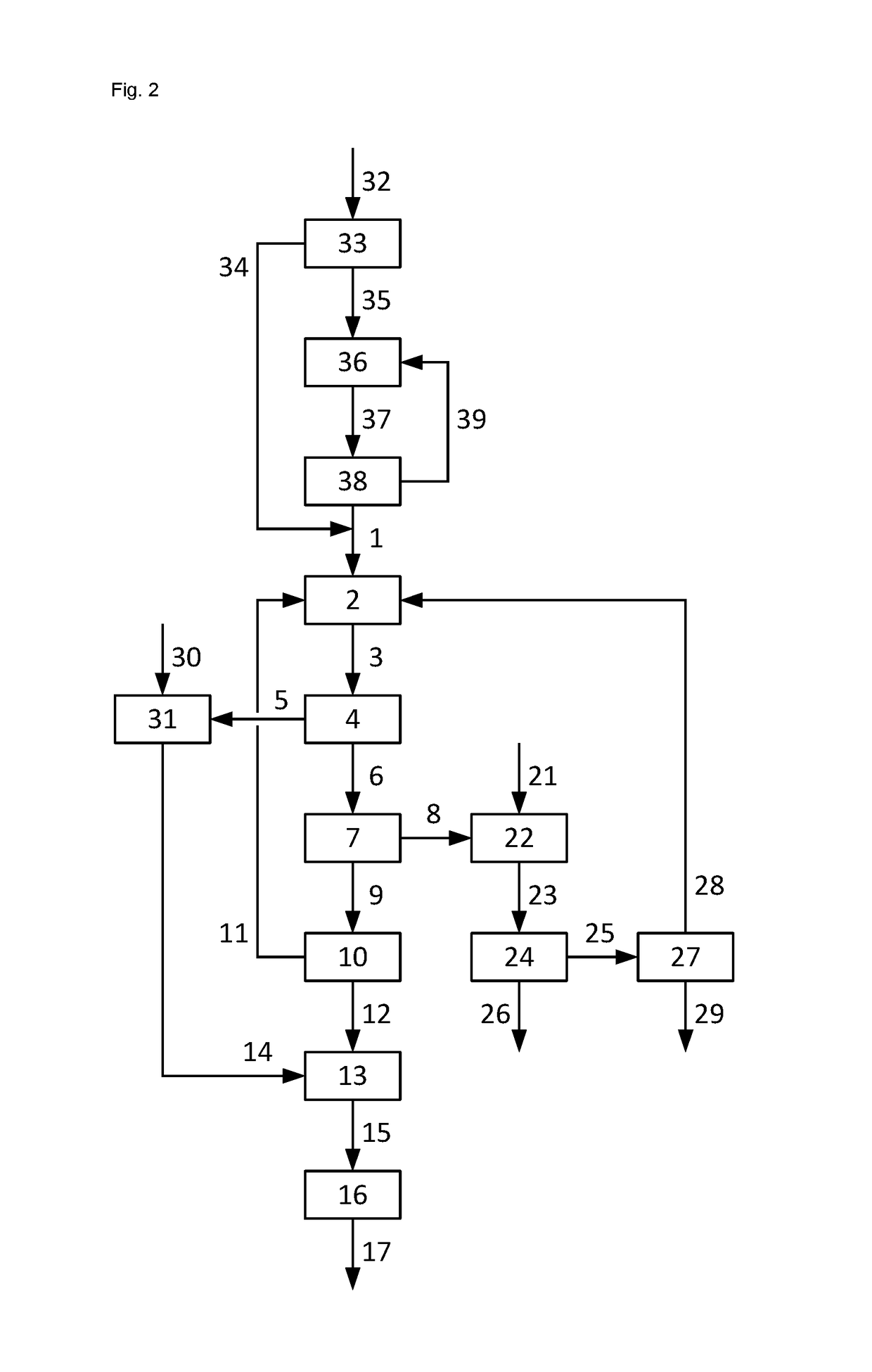

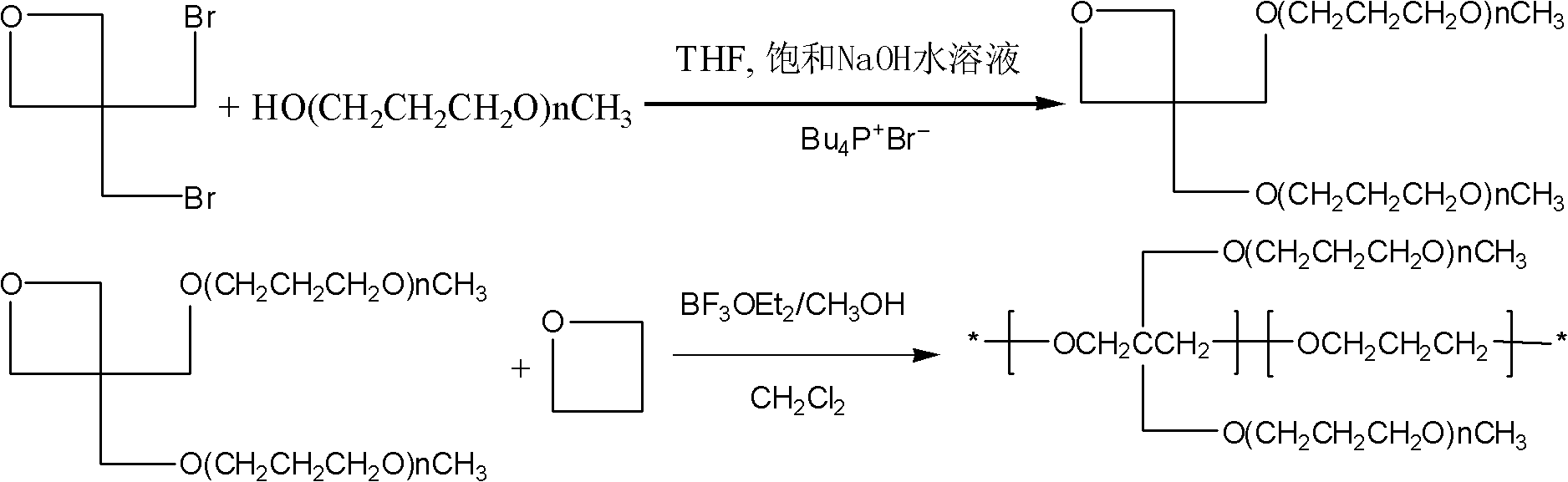

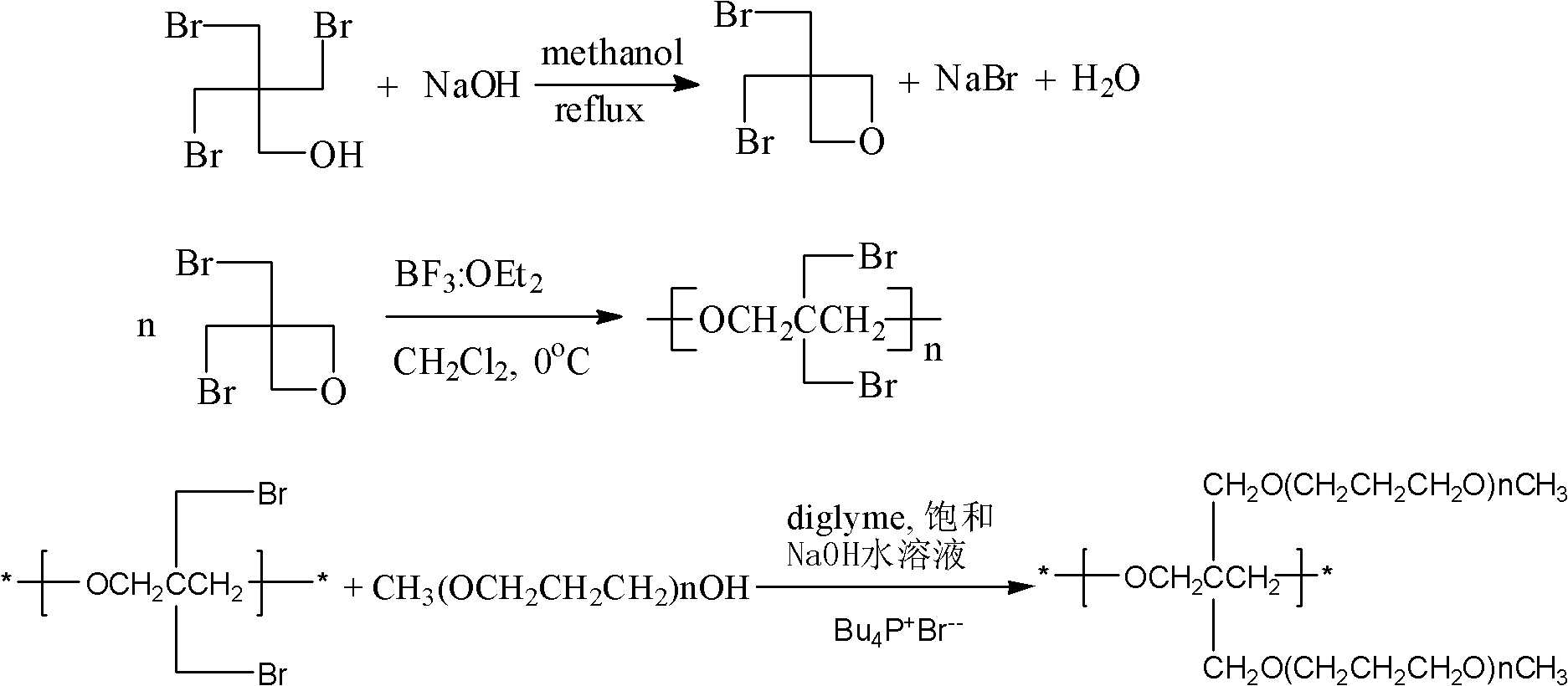

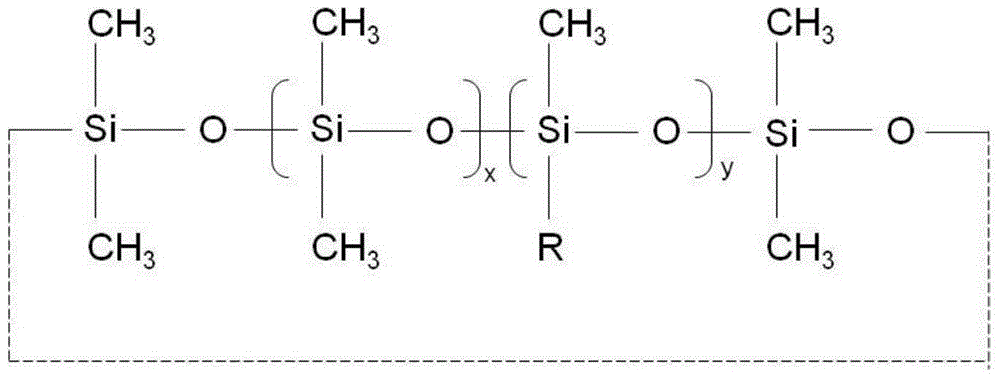

Comb-shaped polymer, comb-shaped polymer electrolyte material and preparation method of the comb-shaped polymer electrolyte material

ActiveCN102372849AIncrease exerciseImprove athletic abilitySecondary cellsPolymer scienceBackbone chain

The invention discloses a comb-shaped polymer, a comb-shaped polymer electrolyte material and a preparation method of the comb-shaped polymer electrolyte material. The comb-shaped polymer electrolyte material comprises a polymer matrix and a lithium salt. The polymer matrix is the comb-shaped polymer, and comprises a main chain repeating unit and a side chain repeating unit. The main chain repeating unit comprises a propylene oxide unit. The side chain repeating unit is a propylene oxide unit. In the invention, polypropylene oxide having excellent flexibility is introduced in the polymer matrix and a main chain is formed, and thus polymer chain segment motion is increased; polypropylene oxide chains having different length are introduced in side chains and the comb-shaped polymer is obtained, and thus solid electrolyte conductivity is improved; and through radiation crosslinking, electrolyte mechanical properties are improved.

Owner:ZHENGZHOU BAK BATTERY CO LTD

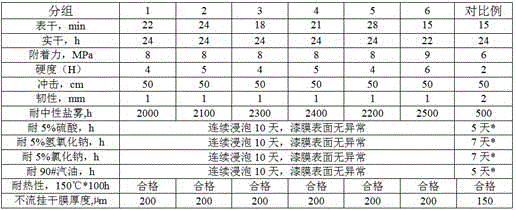

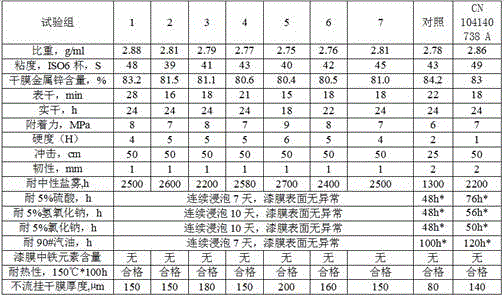

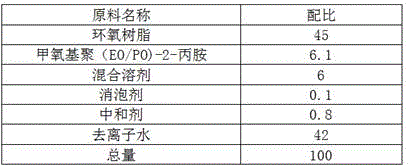

Water-borne epoxy resin emulsion, anticorrosive paint and preparing method thereof

The invention relates to water-borne epoxy resin emulsion, anticorrosive paint and a preparing method thereof, and belongs to the technical field of paint. The water-borne epoxy resin emulsion is prepared from, by weight, 40-50% of epoxy resin, 4.3-8.7% of methoxy-poly(ethylene / propene oxide)-2-propylamine, 4-8% of solvent, 0.1-0.3% of a defoaming agent, 0.5-1.0% of a neutralizing agent and 33-49% of deionized water. Epoxy resin and methoxy-poly(ethylene / propene oxide)-2-propylamine in the emulsion react in the solution, and epoxy resin incapable of being directly dissolved in water is grafted hydrophilically through methoxy-poly(ethylene / propene oxide)-2-propylamine. The water-borne epoxy resin paint prepared from the emulsion is excellent in constructability, corrosion resistance and chemical resistance and high in hardness, and the production technology is simple.

Owner:江拥

Insect ether and producing method thereof

InactiveCN1439262AProtection securityProtect healthBiocideAnimal repellantsEpoxyReaction temperature

A pyriproxyfen as insecticide is prepared from 4-hydroxydiphenyl ether, epoxy propane and 2-chloropyridine through dissolving 4-hydroxydiphenyl ether in alcohol, reacting on expoxy propane at 0-90 deg.C for 2-24 hr under existance of sodium hydroxide to obtain the intermediate, dissolving it in toluene, heating to 30-80 deg.C, slowly dropping 2-chloropyridine in it while reacting at 10-110 deg.C for 2-24 hr under existance of botassium hydroxide, distilling to remove toluene and refining.

Owner:沈志荣 +1

Composite material for repairing highway crack and preparation method thereof

ActiveCN104987704ASolve problems that require closed traffic for long periods of timeEasy to operateBound propertyRoad surface

The invention belongs to the technical field of highway crack repair materials and preparation methods thereof, and mainly solves the technical problems that the existing materials used for repairing pavement cracks easily cause pavement crack protrusion, the material strength is low, the elongation at break is low, the permeability is low, the environment is polluted, the curing time is long and the pavement binding property is poor. The material is formed by a component A and a component B through curing. The component A comprises 30 to 65 parts of polyoxypropylene diol N220, 40 to 25 parts of polyoxypropylene diol N210, 12 to 5 parts of amino-terminated polyoxypropylene ether D2000, 8 to 2 parts of carbon black, 7 to 2 parts of titanium dioxide and 3 to 1 parts of catalyst; the component B comprises 171.4 parts of polyether polyurethane prepolymer and 28.6 parts of di 2-ethyl hexyl phthalate and the like; after the component A and the component B are mixed according to a mass ratio of 1:1, the immobilization time of mixture is shorter than or equal to 8min under 25DEG C, the curing time is shorter or equal to 90min and the road can be opened to traffic after curing.

Owner:深圳市京兰新材科技有限公司

Polyurethane foam gum with nickel and graphene for compositely enhancing electromagnetic shield effect

InactiveCN106065308AHigh oxygen indexImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesChemistrySilicone resin

The invention discloses a polyurethane foam gum with nickel and graphene for compositely enhancing electromagnetic shield effect, which is prepared from, by weight, 150-160 parts of diphenyl methane diisocyanate, 100-105 parts of trihydroxy polyoxypropylene ether, 100-110 parts of castor oil, 5-6 parts of glycerol, 40-43 parts of diethyl phosphate, a proper amount of a 1 mol / L sodium hydroxide solution, 13-15 parts of diatomite, 5-6 parts of distilled water, 2-3 parts of triethanol amine, 3-4 parts of dibutyltin dilaurate, 2-3 parts of octylphenol polyoxyethylene ether, 3-4 parts of organic silicone resin, 4-5 parts of graphene, 7-8 parts of anhydrous ethanol, 9-10 parts of a DMF solution, and 2-3 parts of nickel powder. The polyurethane foam gum can be foamed on site and can be uniformly adhered in grooves of a switch cabinet, thereby achieving excellent sealing performance. The polyurethane foam gum also has the effect of electromagnetic shield so as to avoid influence on devices in the cabinet due to electromagnetic wave, thereby prolonging service life.

Owner:HEFEI E CHON METAL PLATE TECH CO LTD

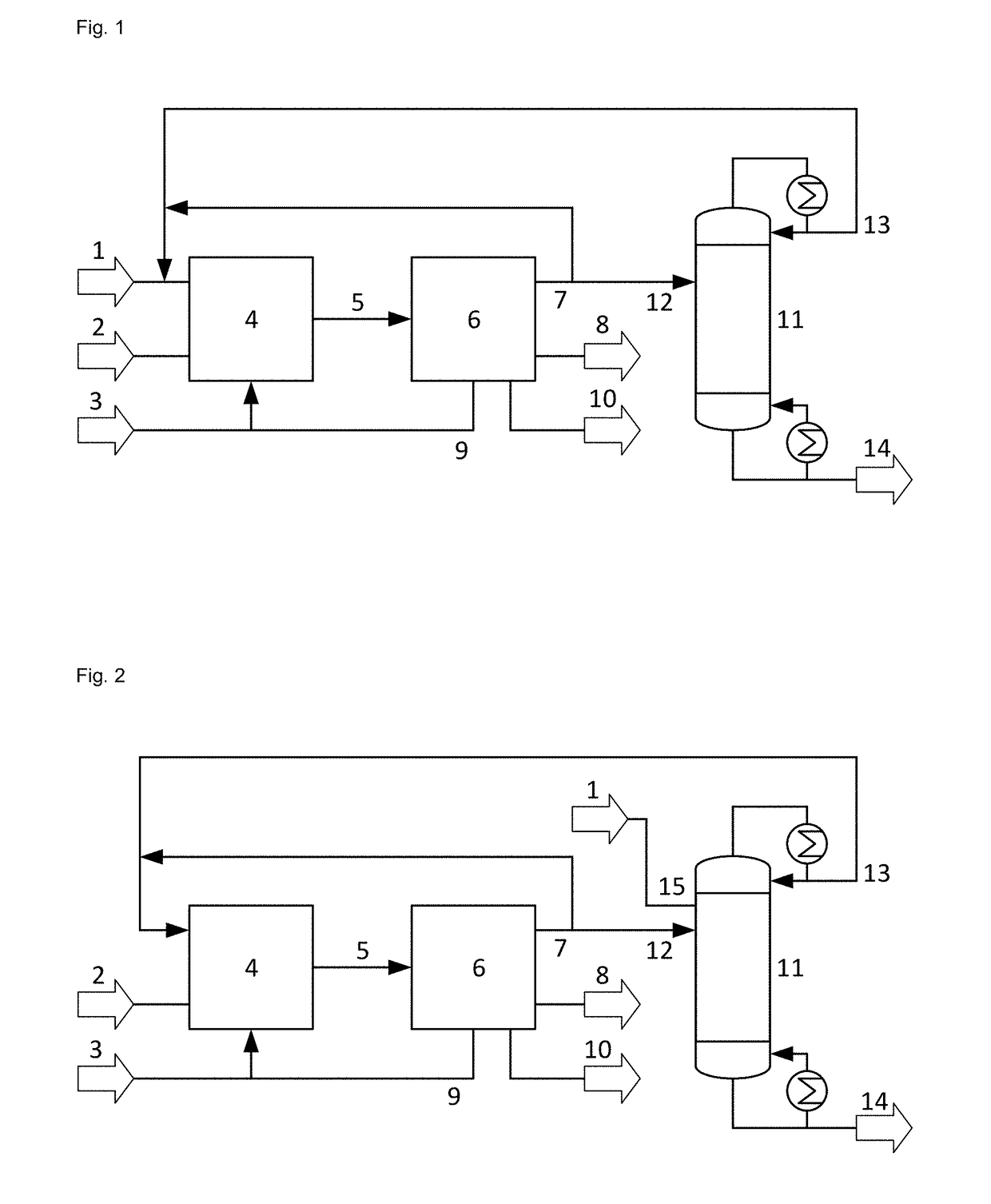

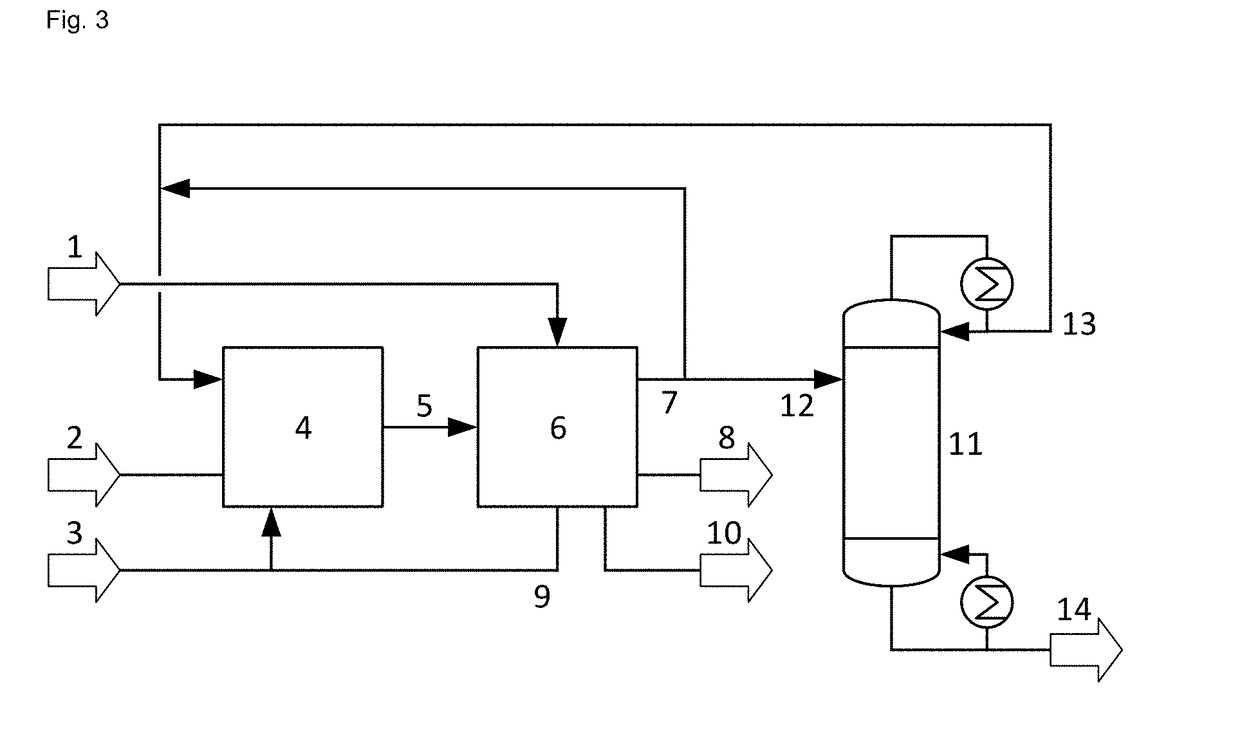

Process for the epoxidation of propene

ActiveUS20180346432A1Reduce device sizeImprove energy consumptionGas treatmentOrganic chemistryPropene oxideEnergy consumption

In a process for the epoxidation of propene, comprising the steps of reacting propene with hydrogen peroxide, separating propene oxide and a recovered propene stream from the reaction mixture, separating propane from all or a part of the recovered propene stream in a C3 splitter column, and passing the overhead product stream of the C3 splitter column to the epoxidation step, a propane starting material with a propane fraction of from 0.002 to 0.10 is used, the epoxidation is operated to provide a propane fraction in the reaction mixture of from 0.05 to 0.20 and the C3 splitter column is operated to provide an overhead product stream which comprises a propane fraction of at least 0.04 in order to reduce the size and the energy consumption of the C3 splitter column.

Owner:EVONIK OPERATIONS GMBH +1

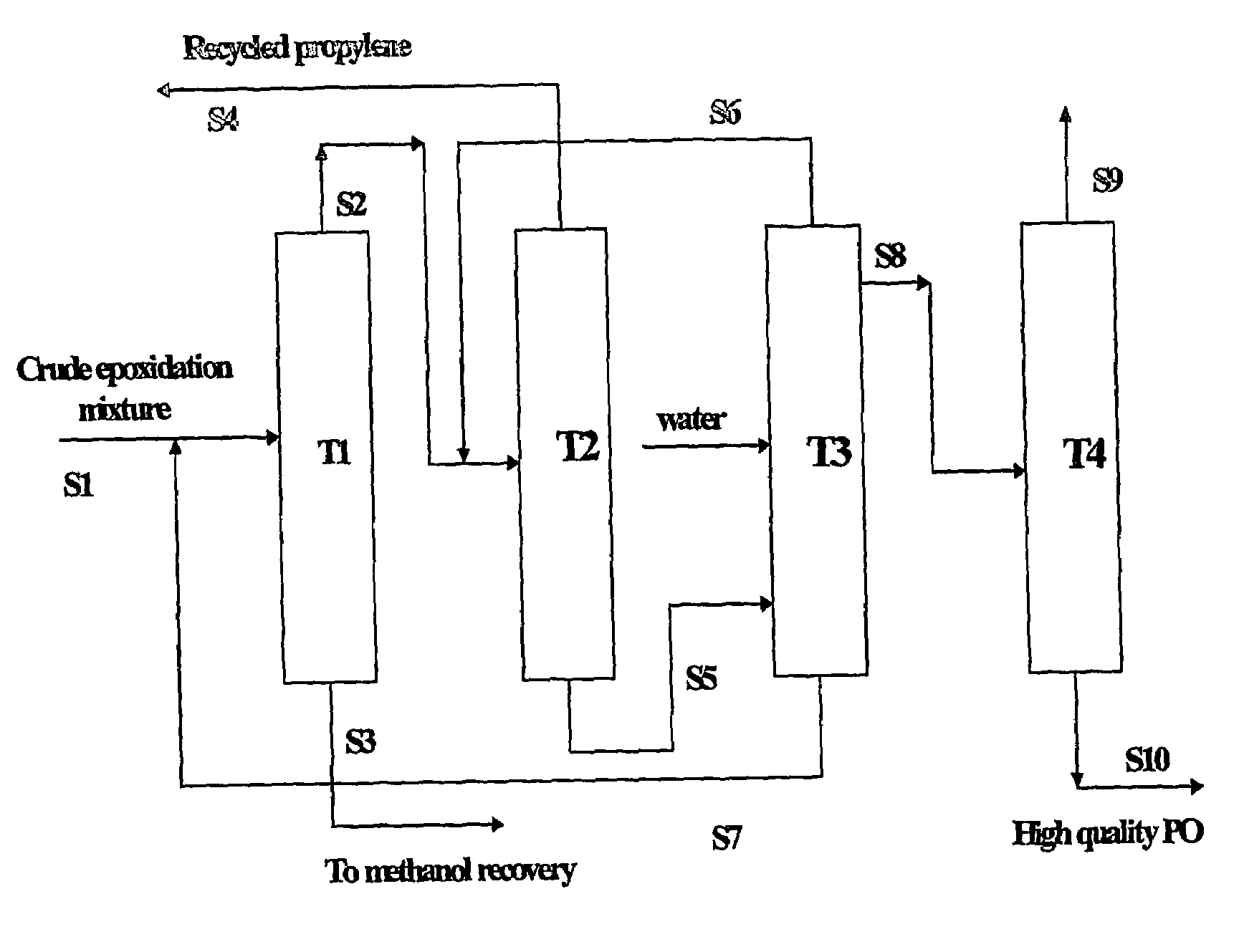

Purification of propylene oxide resulting from epoxidation of propylene with hydrogen peroxide

ActiveUS7594979B2Disadvantageous effectHigh activityOrganic chemistryDistillation regulation/controlExtractive distillationPropanediol

A process of separating a purified propylene oxide from a crude epoxidation product produced, preferably, in an epoxidation reaction of propylene with hydrogen peroxide. The process involves removing bulk water, bulk methanol, and unreacted propylene from the crude epoxidation product and thereafter subjecting the resulting propylene oxide product to extractive distillation with water as an extraction solvent. Under distillation conditions, including a bottoms temperature of greater than about 55° C. and less than about 75° C., an overhead or side-cut distillate stream containing a purified propylene oxide is obtained with low yield loss of propylene oxide to propylene glycols and other glycol heavies. The purified propylene oxide can be further purified in a finishing distillation to obtain propylene oxide meeting commercial grade purity requirements.

Owner:DOW GLOBAL TECH LLC

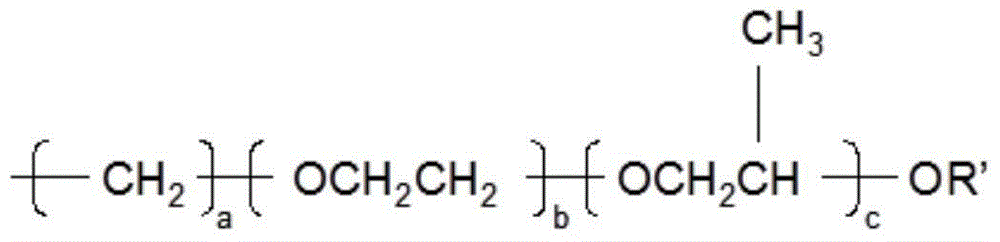

Surfactant used in preparation of slow rebound polyurethane foam and preparation technology of surfactant

The invention provides a surfactant used in preparation of slow rebound polyurethane foam and a preparation technology of the surfactant. The preparation method comprises the following steps: synthetizing allyl-terminated copolyether with ethylene oxide and propylene oxide groups from allyl alcohol, epoxyethane and epoxypropare, then conducting end capping on allyl polyether, carrying out a grafting reaction between the allyl-terminated copolyether and hydrogen-containing silicone oil synthetized from dimethyl dichlorosilane and dichloromethylsilane, and finally adding glyceryl polyether. Due to the improvement in the aspect of the molecular structure, the foam structure of the slow rebound polyurethane foam can be effectively improved, the slow rebound mechanical property of the foam can be obviously improved, and the foam structure can be more uniform and fine. Therefore, the hand feeling is improved, and the use requirement on slow rebound foam of consumers can be met better.

Owner:苏州思德新材料科技有限公司

Polyurethane foam gum with expandable graphite and diatomite to cooperatively enhance flame retarding

InactiveCN106065309AHigh oxygen indexImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDiethyl phosphateWear resistant

The invention discloses polyurethane foam gum with expandable graphite and diatomite to cooperatively enhance flame retarding, which is prepared from, by weight, 150-160 parts of diphenyl methane diisocyanate, 100-105 parts of trihydroxy polyoxypropylene ether, 100-110 parts of castor oil, 5-6 parts of glycerol, 40-43 parts of diethyl phosphate, a proper amount of a 1 mol / L sodium hydroxide solution, 13-15 parts of diatomite, 5-6 parts of distilled water, 2-3 parts of triethanol amine, 3-4 parts of dibutyltin dilaurate, 3-4 parts of lauryl sodium sulfate, 5-6 parts of silicon oil, 3-4 parts of the expandable graphite, a proper amount of anhydrous ethanol, 0.8-1 part of cetyl trimethyl ammonium bromide, and a proper amount of deionized water. The foam gum is used for sealing switch cabinets and machine cabinets, is high in strength and is wear-resistant, can achieve on-site foaming and reduce production cost, has high total sealing performance, has simple and easy-to-control production process, and is safe and environment-friendly.

Owner:HEFEI E CHON METAL PLATE TECH CO LTD

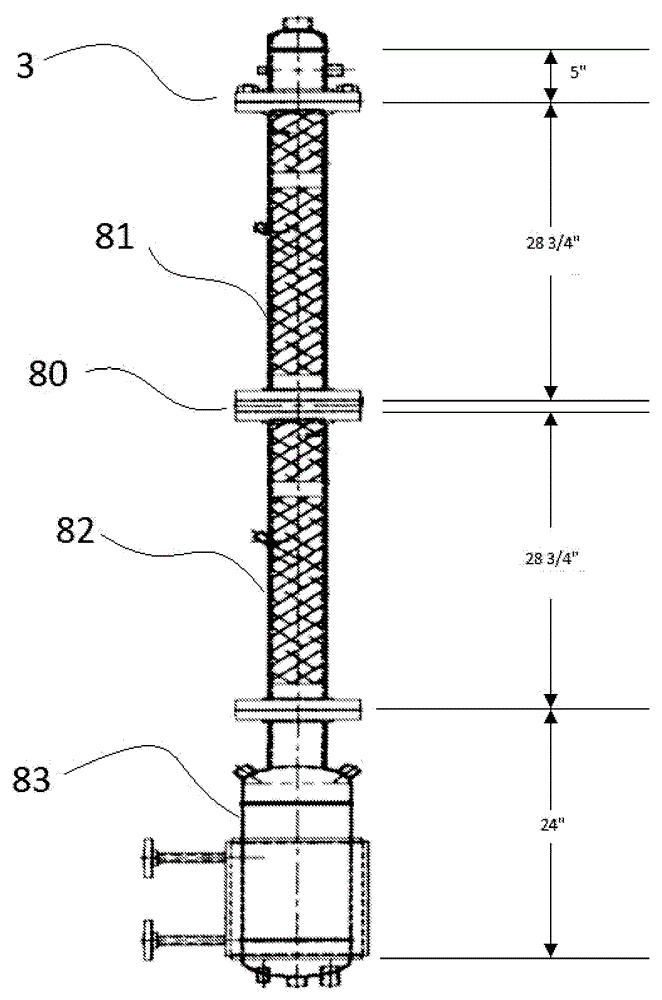

Methods for alkylene oxide separation using extractive destillation columns

ActiveCN103562192AArrange wellReduce methanol concentrationOrganic chemistryExtractive distillationExtractive distillationPropene oxide

The disclosure relates to a process for separating propylene oxide for a crude propylene oxide stream, for example an intermediate stream from a PO / TBA process. The crude propylene oxide stream can be passed through an extractive distillation column. The distillation column is operated at a pressure in a range of greater than 25 up to 50 psig, and / or at a temperature in a range of from 70 to 150 degrees Celsius using C8-C20 paraffin as extractive solvent with an overhead distillate water wash drum. The crude propylene oxide stream include from 0.001 to 0.1 wt % methanol, based on the total composition of the crude propylene oxide stream. The systems, methods, and apparatuses can produce a propylene oxide stream having less formaldehyde and acetaldehyde than the prior art.

Owner:LYONDELL CHEM TECH LP

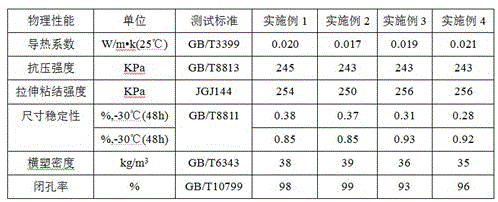

Polyurethane hard foam thermal-insulation material

The invention relates to a thermal-insulation material, and discloses a polyurethane hard foam thermal-insulation material. The thermal-insulation material is prepared by mixing and foaming the following raw materials in parts by weight: 70-100 parts of dimer acid diisocyanate, 40-80 parts of polyether glycol I, 10-30 parts of polyether glycol II, 3-6 parts of expanded vermiculite, 5-8 parts of nano silicon dioxide, 10-20 parts of monofluorodichlorohexane, 1-5 parts of catalyst and 1-5 parts of foam stabilizer. The polyether glycol I is lignin polyether glycol, and the polyether glycol II is polyether glycol formed by carrying out polymerization on a polymerizable monomer epoxypropane by using modified soybean oil as an initiator. The thermal-insulation material has higher compression strength, tensile strength and impact strength, and avoids the phenomena of deformation, bulging, edging and even cracking of the water tank.

Owner:GUANGXI JISHUN ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com