Methods for alkylene oxide separation using extractive destillation columns

一种萃取蒸馏塔、蒸馏塔的技术,应用在纯化和回收氧化丙烯领域,能够解决改进不实用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

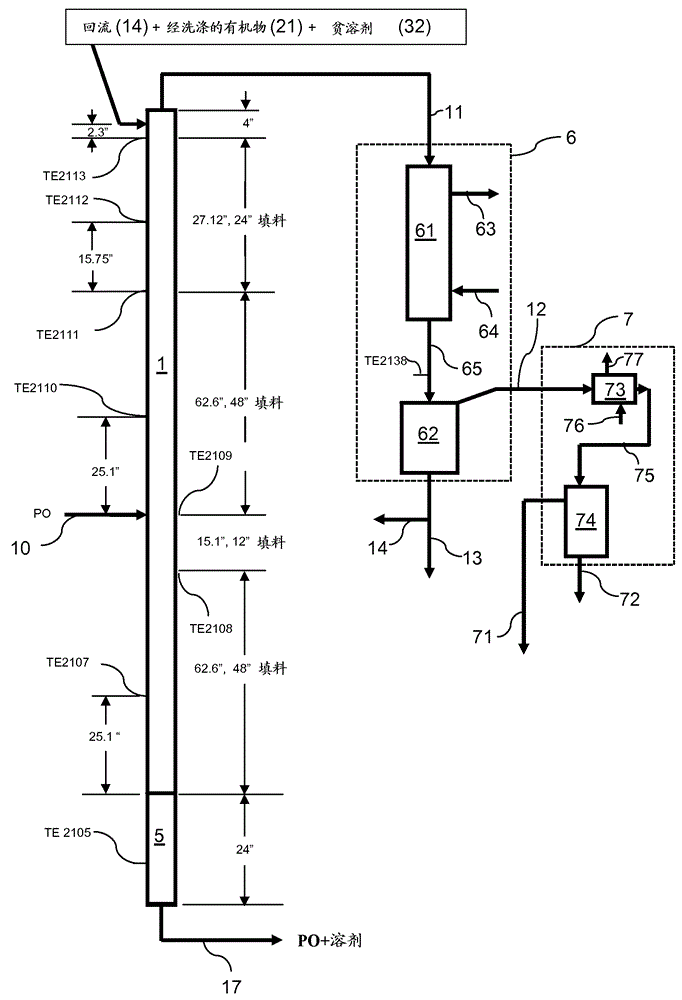

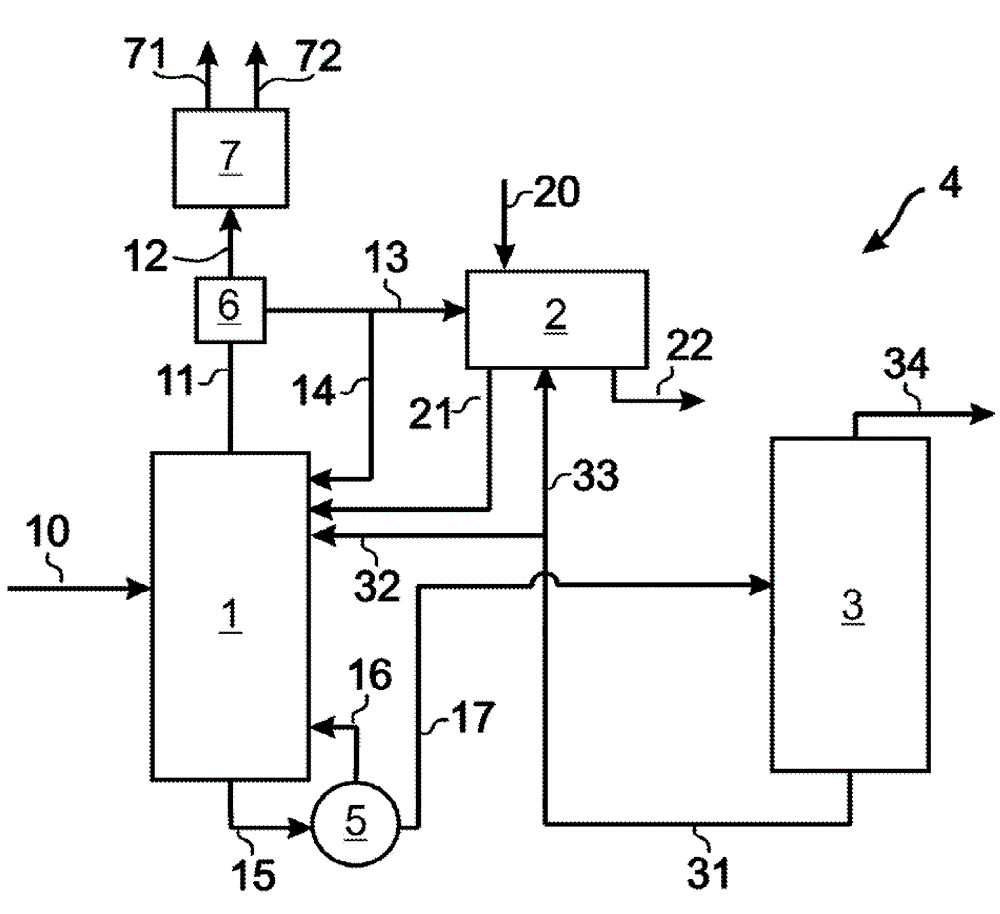

[0072] Example 1 is described in e.g. figure 1 and 2 The pilot unit Solvent Lights Column 1 shown in , was first operated at 25 psig during the test period. A feed stream 10 comprising crude propylene oxide (intermediate stream from the PO / TBA process) is fed to solvent lights column 1 at a point in the middle of the column. Table 5 shows the concentrations of key impurities in the feed stream, each expressed as a weight percent of the total composition.

[0073]

[0074] Using multiple temperature probes TE2112, TE2111, TE2110, TE2108, TE2107, TE2105, TE2113, TE2109 and TE2138, the positions are as figure 2 shown in .

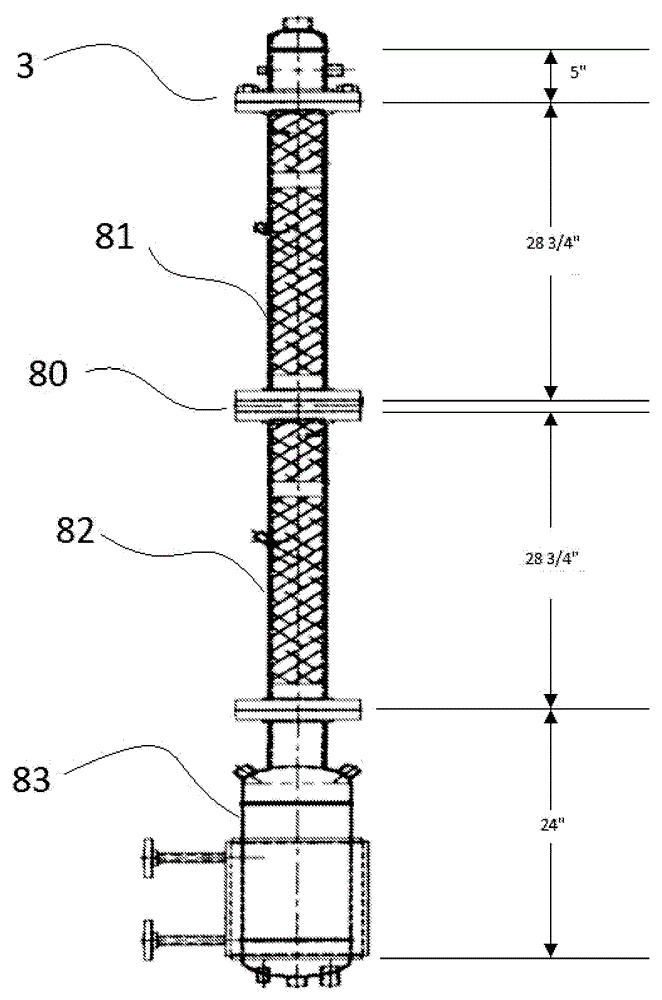

[0075] The temperature of feed stream 10 was 27°C and the flow rate was 3.0 kg / hour. Entering at the top of the column is a lean solvent containing stream 32 pumped from the bottom of the solvent stripper column 3, as figure 1 shown in . Solvent stripper 3 is also shown in more detail in image 3middle. The flow rate of lean solvent in stream 32 ...

Embodiment 2

[0088] Unexpected beneficial results can also be obtained by reducing the amount of water, methanol and / or glycol concentration in the solvent-lights column 1 feed. Two concentrations of methanol (MeOH) were tested using the same pilot unit as described in Example 1. One experiment used a propylene oxide feed containing 0.1172% by weight MeOH, as shown in Table 5. Another experiment used a feed with 0.0032 wt% MeOH, as shown in Table 9. The feed stream comprising the propylene oxide feed stream is the crude PO stream from the PO / TBA process. Both Tables 5 and 9 show the concentrations of key impurities in the feed stream, each expressed as a weight percent of the total composition of the crude PO stream from the PO / TBA process.

[0089]

[0090] With reduced MeOH in the PO feed, removal of both formaldehyde and acetaldehyde is unexpectedly improved, as shown by reduced aldehyde levels in solvent stripper overhead 34 . Without wishing to be bound by theory, it is possible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com