Technology for high efficiently recycling methanol from process water in device for preparing propylene from methanol

A technology for producing propylene from methanol and recovering methanol is applied in the preparation of hydroxyl compounds, the preparation of organic compounds, and the separation/purification of hydroxyl compounds. The effect of high concentration multiple, significant economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

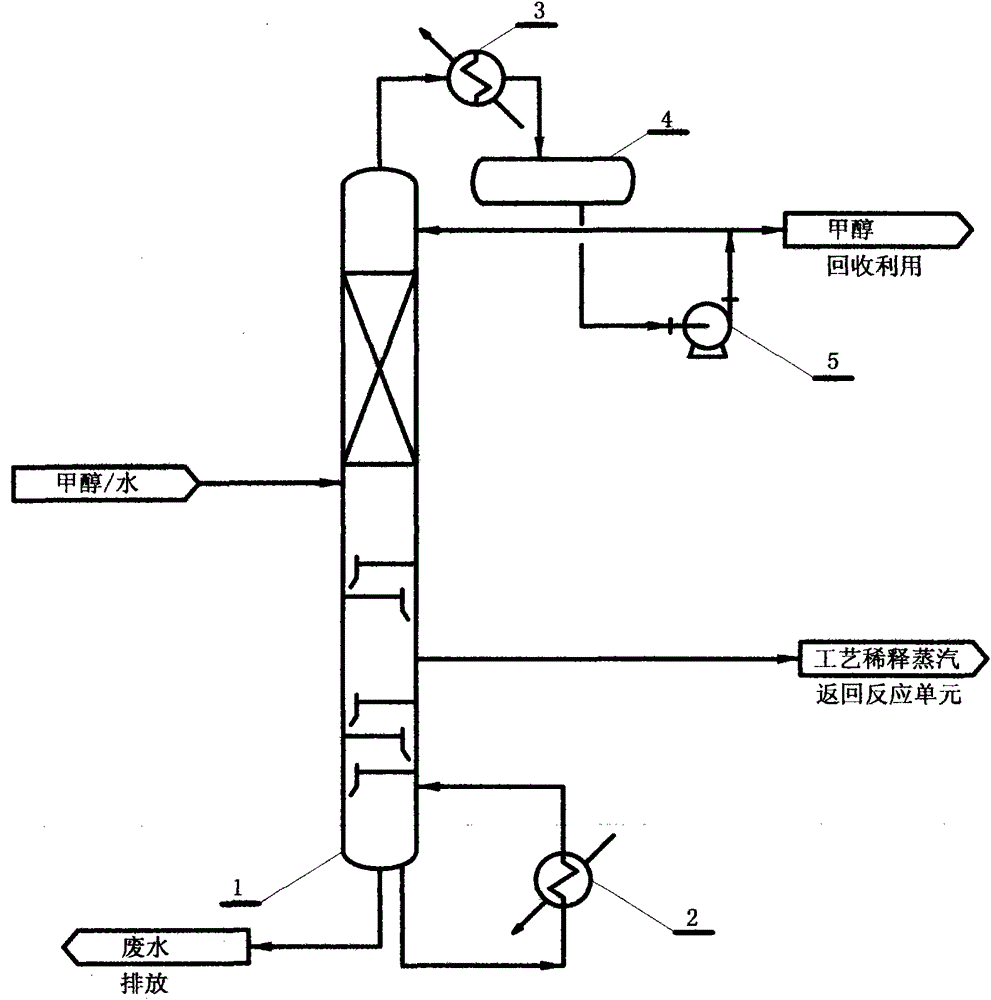

[0017] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] The invention relates to a method for efficiently removing and recovering methanol from methanol-containing process aqueous solution of methanol-to-propylene (MTP), and generating process steam simultaneously.

[0019] The process for efficiently recovering methanol from the process water of the methanol to propylene plant is characterized in that it is equipped with a methanol recovery / process steam column 1, that is, a combined column 1, and is equipped with a reboiler 2, a condenser 3, a reflux tank 4, and a reflux pump 5. The material containing methanol and process water enters from the middle of combined tower 1, the operating pressure range at the top of the tower is 0.6-1.8MPaA, the temperature at the top of the tower is 85-145°C, and the operating temperature at the bottom of the tower is 140-190°C. The upper part is a packing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com