Method for separating dimethyl oxalate and dimethyl carbonate with low energy consumption

A technology of dimethyl oxalate and dimethyl carbonate, which is applied in chemical instruments and methods, preparation of carboxylate, purification/separation of carbonate/haloformate, etc., can solve problems such as clogging and reduce methanol Concentration, avoiding clogging and fouling, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

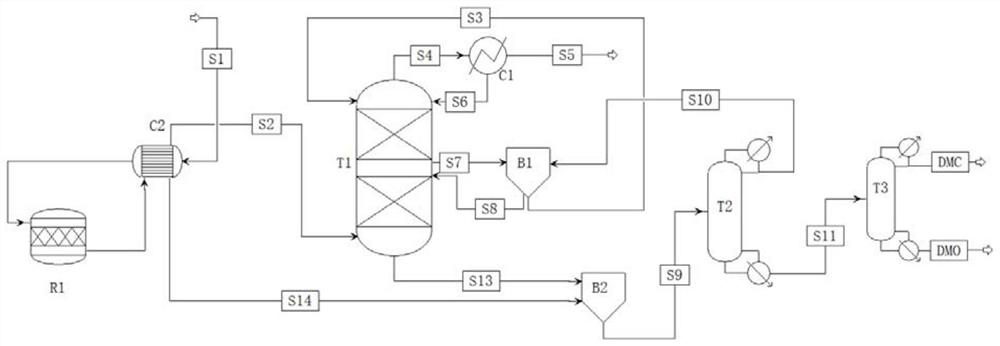

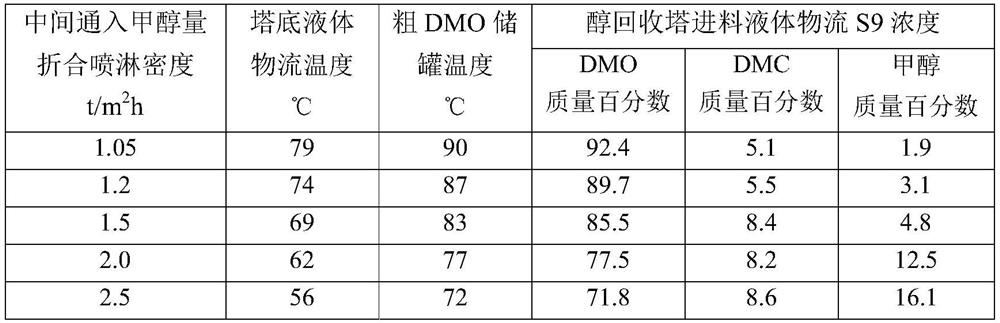

[0084] use figure 1 In the system for separating dimethyl oxalate and dimethyl carbonate with low energy consumption, the coupling reaction product flow contains DMO concentration of 18.7% (mass percentage, the same below), DMC concentration of 3.3%, methanol concentration of 7%, and the rest is nitrogen, MN , NO, CO and other components, after heat exchange, the temperature is lowered to 94°C and enters the alcohol washing tower. The operating pressure at the top of the alcohol washing tower is 3.3 atm; The side line outlet, the condensation area in the lower part of the alcohol washing tower adopts a large-aperture sieve plate, the number of theoretical plates is 5, and the upper absorption area of the alcohol washing tower adopts wire mesh corrugated packing, the number of theoretical plates is 10; the top condensate and supplementary methanol are sprayed from the top of the tower, The spray density is 2.5t / m 2 h, spray methanol in the upper absorption zone of the alcoho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com