Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

473results about "Carbonic/haloformic acid esters purification/separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

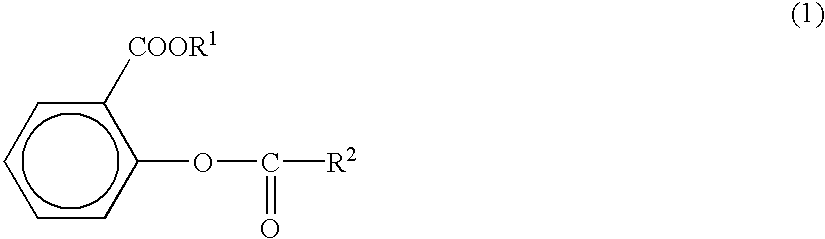

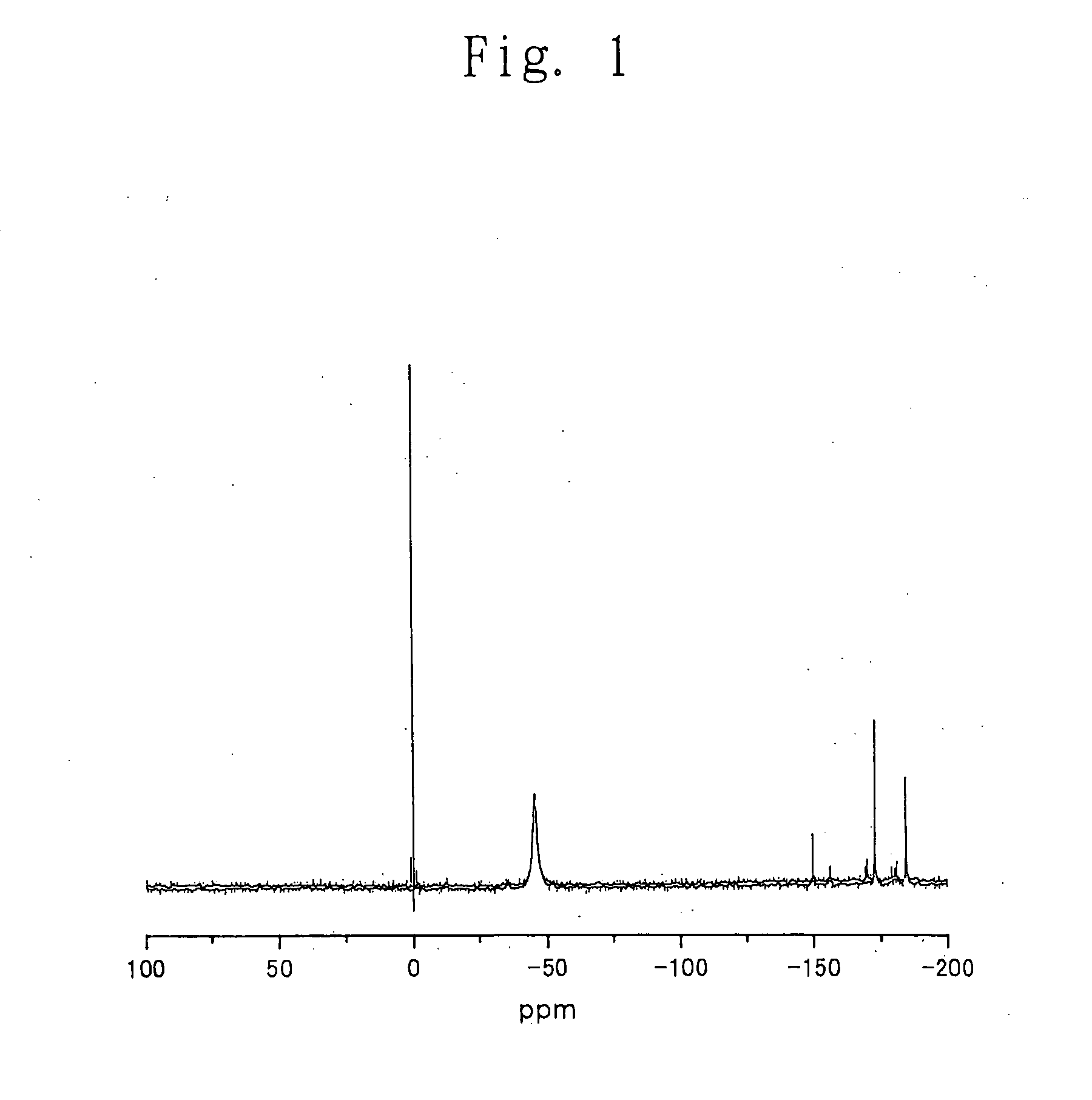

Salicylic acid ester derivative and its production

InactiveUS6410777B1Organic compound preparationCarboxylic acid esters preparationArylSalicylic acid ester

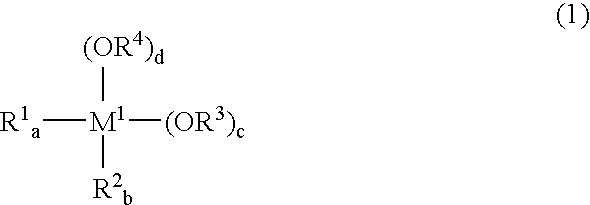

The present invention provides a salicylic acid ester derivative having an impurity content lower than a specific level and expressed by the following formula (1)(in the formula, R1 is methyl group or ethyl group, R2, which may be substituted optionally, is an alkyl group having a carbon number of from 1 to 30, alkoxy group having a carbon number of from 1 to 30, aryl group having a carbon number of from 6 to 30, aryloxy group having a carbon number of from 6 to 30, aralkyl group having a carbon number of from 6 to 30 or aralkyloxy group having a carbon number of from 6 to 30). The salicylic acid ester derivative is effective as a terminal blocking agent or a polymerization. promoting agent for a polycarbonate, and gives a polycarbonate having good color tone and suitable for optical material use.

Owner:TEIJIN LTD

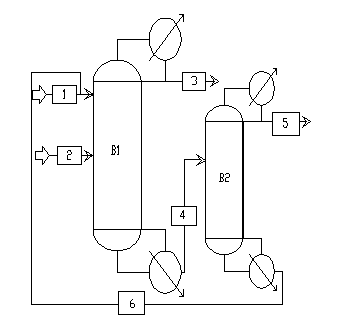

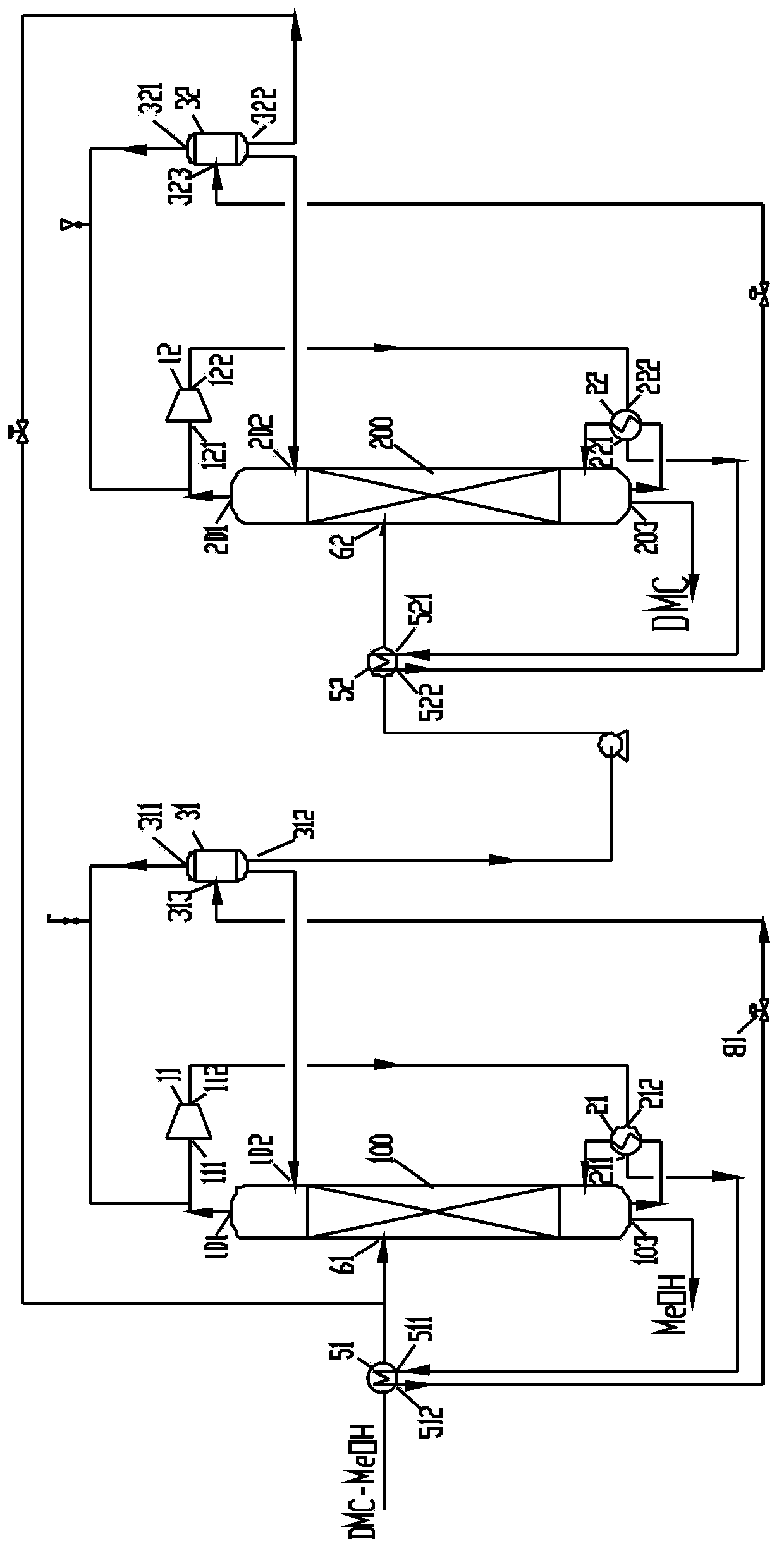

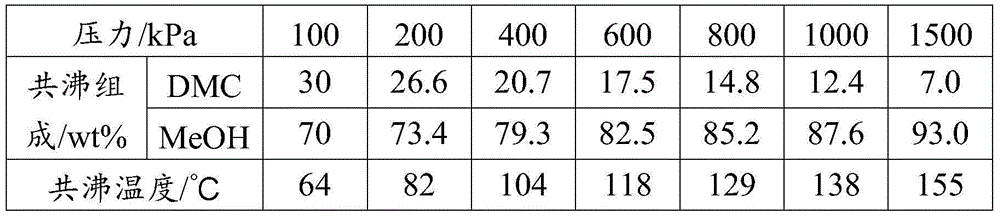

Continuous extractive distillation separation method of dimethyl carbonate-methanol azeotropic mixture

InactiveCN103159586AIncrease relative volatilityAchieve recyclingOxygen-containing compound preparationOrganic compound preparationExtractive distillationTransesterification

The invention discloses a continuous extractive distillation separation method of a dimethyl carbonate-methanol azeotropic mixture, and relates to a continuous extractive distillation method. The technical process of the method is as follows: ethylene glycol is used as an extraction agent at normal pressure; the solvent ratio is 1-3; the separated dimethyl carbonate-methanol azeotropic mixture is fed from the middle part of a tower, the extraction agent is fed from the top of the tower, and the reflux ratio is 2; high-purity methanol is extracted from the tower top of an extractive distillation tower, and the dimethyl carbonate and the extraction agent are extracted from the tower bottom; the fraction at the tower bottom enters an extraction agent recovery tower, and the reflux ratio is 3; and dimethyl carbonate is extracted from the tower top, and the extraction agent extracted from the tower bottom can be recycled. The method disclosed by the invention adopts ethylene glycol as an extraction agent, and improves the separation effect of the dimethyl carbonate-methanol azeotropic mixture; and since ethylene glycol is a co-production product in synthesizing dimethyl carbonate by a transesterification method, the source is conveniently available, and the cost caused by introducing other substances is avoided.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

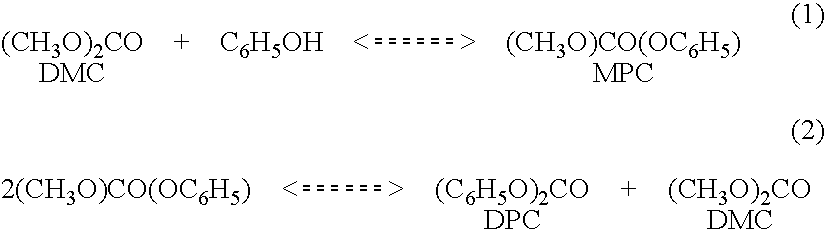

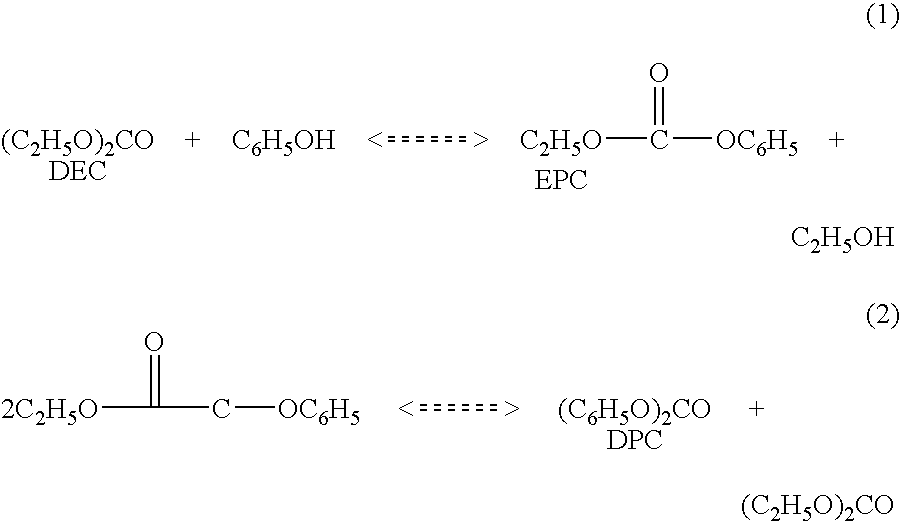

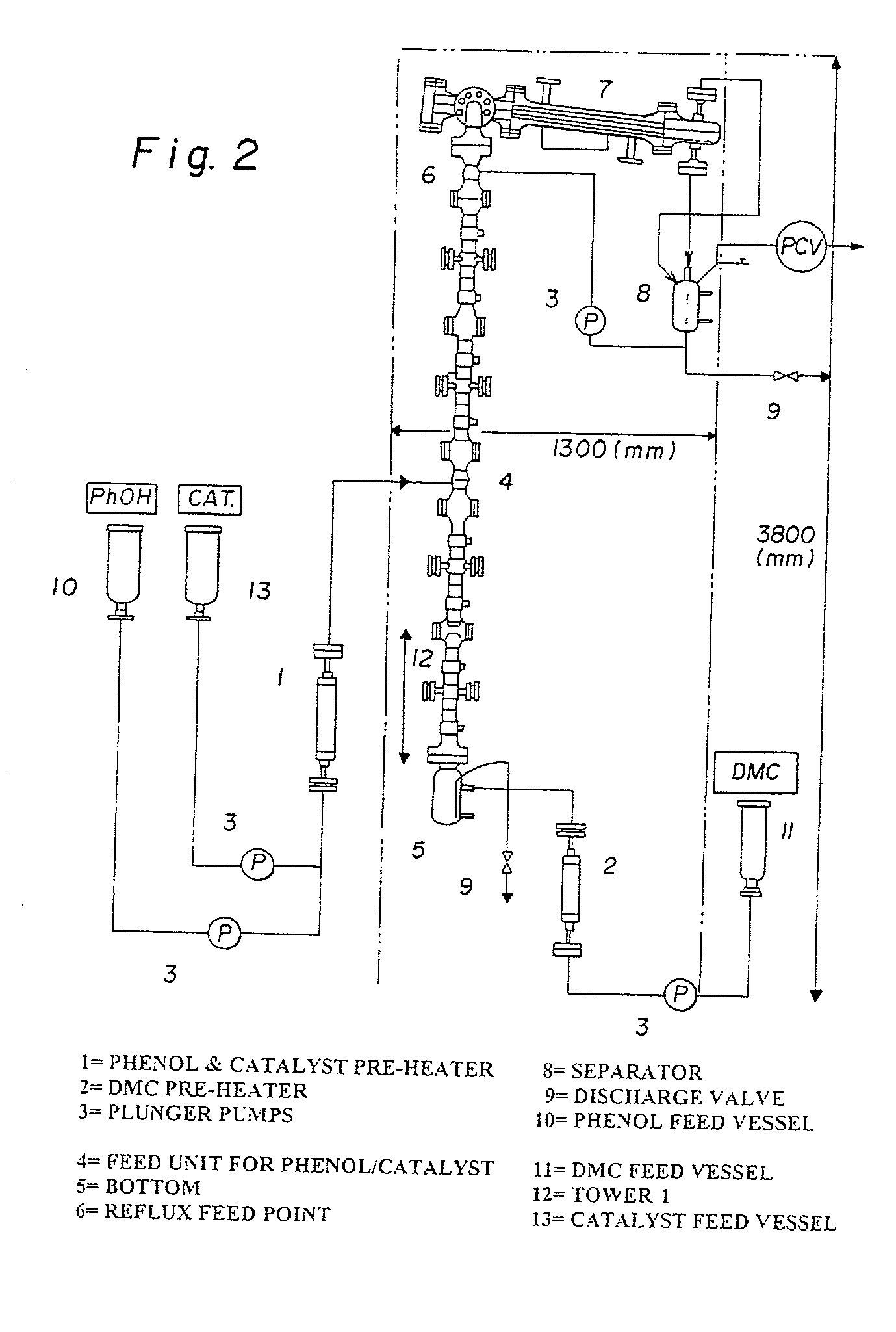

Process for making diaryl carbonate

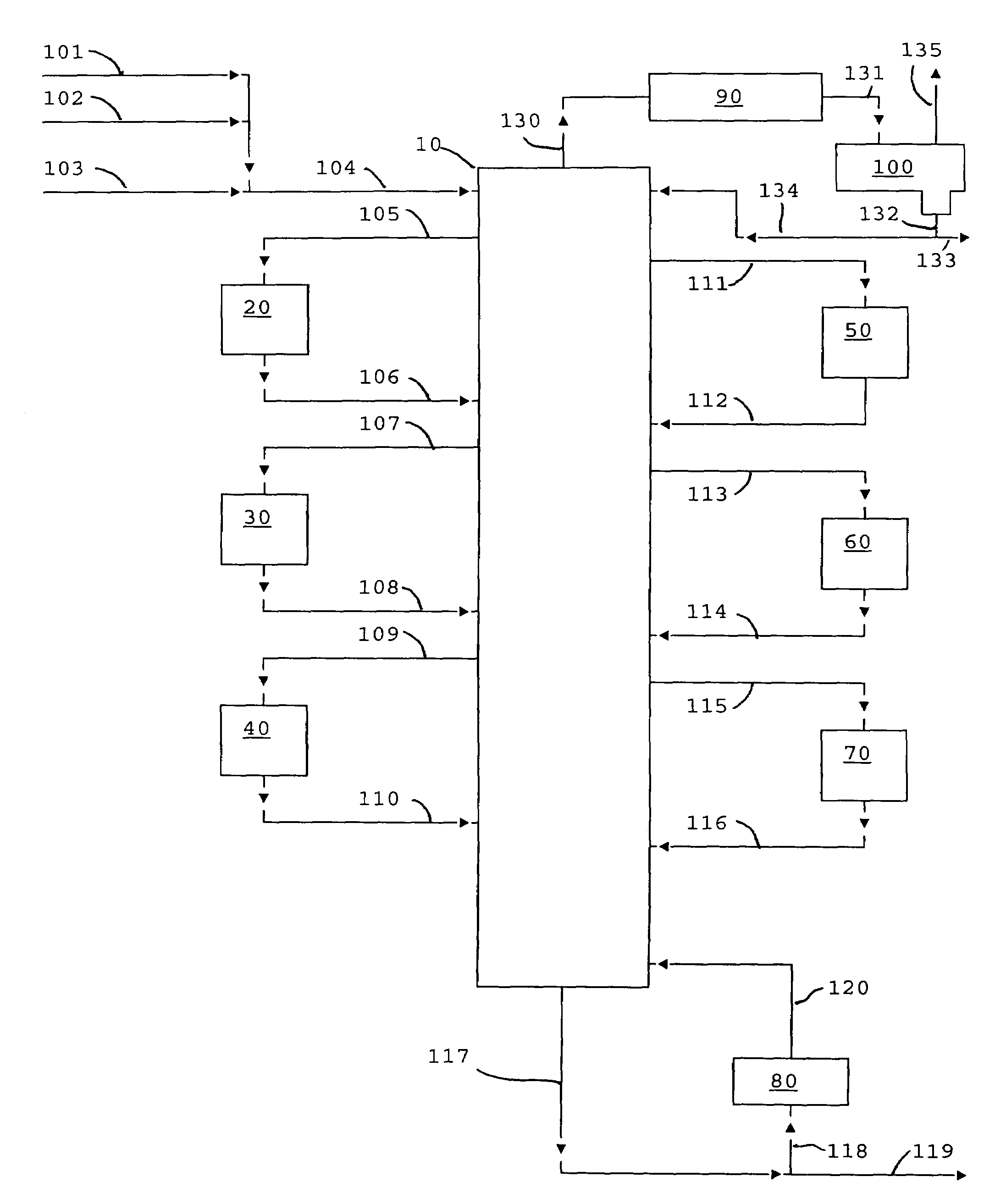

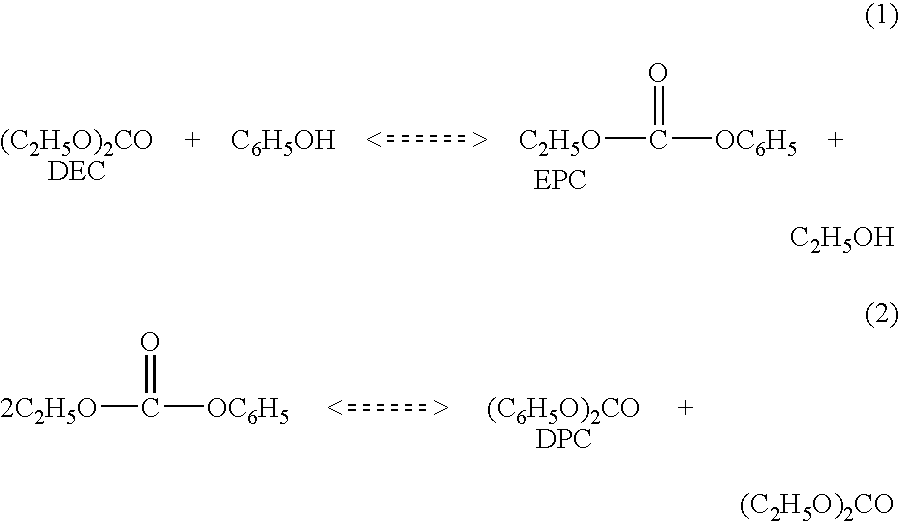

Diphenyl carbonate is produced by reacting phenol with diethyl carbonate in a series of fixed bed reactors each of which is connected at different position on a distillation column via side draw and return streams. The composition of material in a distillation column varies along the length of the column, which is predictable under a given set of conditions of temperature and pressure, thus withdrawing streams at different stages in the column, allows the reactor receiving the feed from a particular stage to be operated under conditions to maximize the desired reaction, while allowing the unreacted or byproduct to go back into the distillation and be sent to a stage (by the equilibrium of the distillation) where they are favorably treated in a reactor.

Owner:SHELL USA INC

Process for production of diaryl carbonate

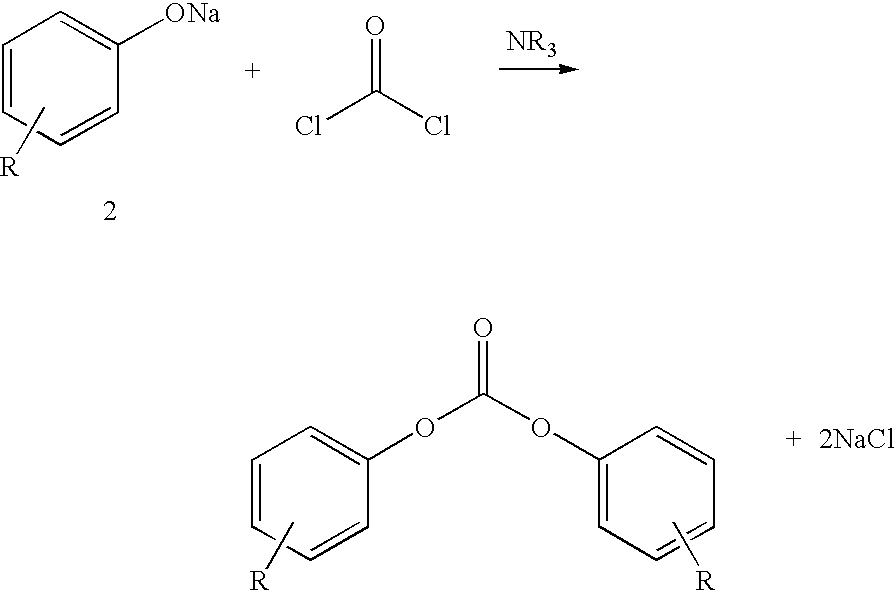

The invention relates to a process for production of diaryl carbonate combined with the electrolysis of the resultant alkali metal chloride-containing process wastewater. The process according to the invention makes possible, inter alia, improved utilization in electrolysis of the alkali metal chloride-containing solution obtained in the production of diaryl carbonate.

Owner:BAYER MATERIALSCIENCE AG

Process for making diaryl carbonate

Diphenyl carbonate is produced by reacting phenol with diethyl carbonate in a series of fixed bed reactors each of which is connected at different position on a distillation column via side draw and return streams. The composition of material in a distillation column varies along the length of the column, which is predictable under a given set of conditions of temperature and pressure, thus withdrawing streams at different stages in the column, allows the reactor receiving the feed from a particular stage to be operated under conditions to maximize the desired reaction, while allowing the unreacted or byproduct to go back into the distillation and be sent to a stage (by the equilibrium of the distillation) where they are favorably treated in a reactor.

Owner:SHELL USA INC

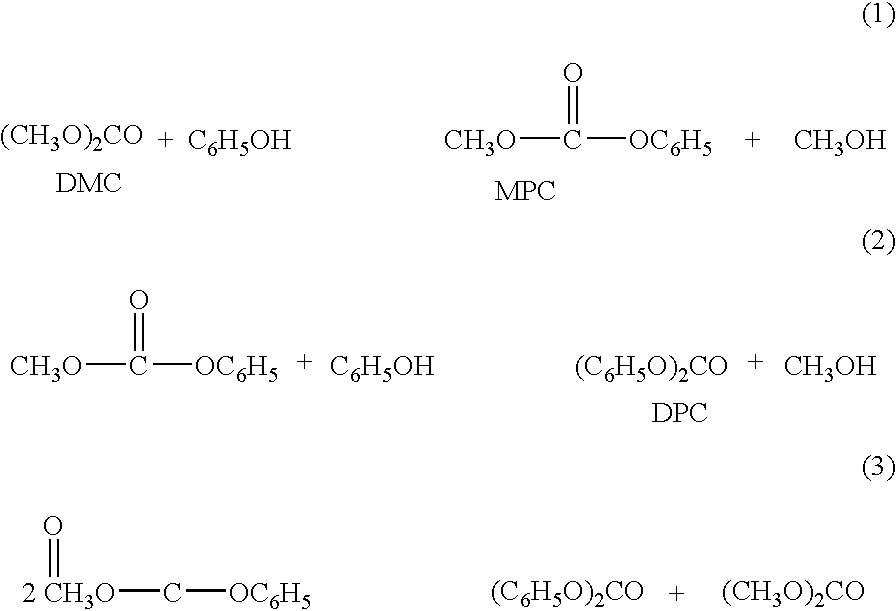

Process for producing organic carbonates

ActiveUS20070093672A1Speed up the conversion processCatalyst regeneration/reactivationCatalyst activation/preparationBenzeneTransesterification

A process for producing various organic carbonates by performing transesterification and disproportionation reactions in dual vapor / liquid phase mode preferably in the presence of solid catalyst composition selected from the group consisting of oxides, hydroxides, oxyhydroxides or alkoxides of two to four elements from Group IV, V and VI of the Periodic Table supported on porous material which has surface hydroxyl groups and the method of reactivating catalyst deactivated by polymer deposition by contacting the deactivated catalyst with a solution of hydroxy containing compound in a solvent such as benzene or THF.

Owner:CHEM RES & LICENSING CO

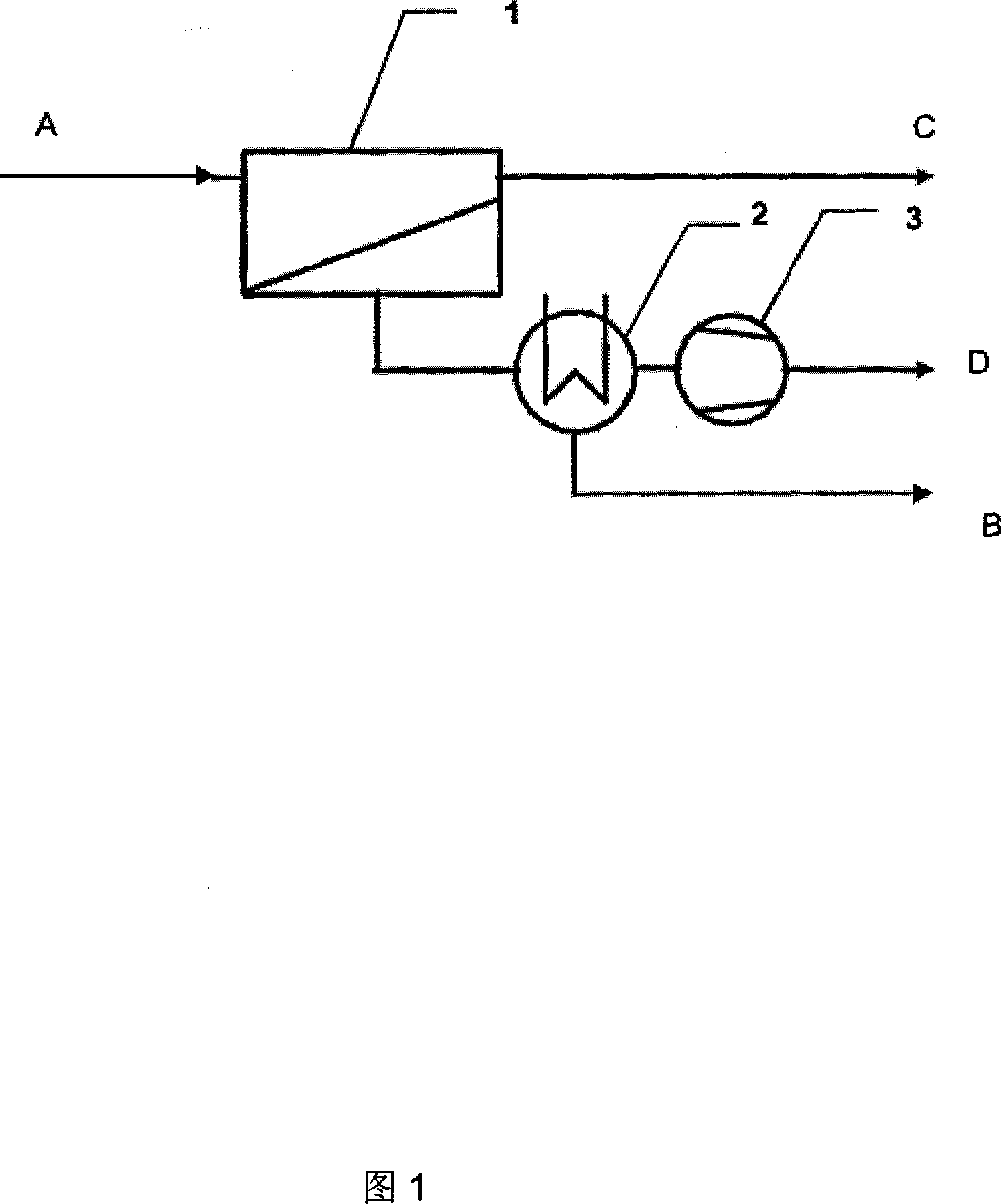

Method for separating dimethyl carbonate and methanol azeotrope

ActiveCN101143803AAchieve separationNo secondary pollutionDistillationHydroxy compound separation/purificationHigh concentrationVacuum pumping

The utility model relates to a method which utilizes a vapour permeation membrane to separate dimethyl carbonate from methanol azeotrope. Saturated vapour at the temperature of 64 to 120 DEG C and with the pressure of 0.10 to 0.6 MPa is sent into a membrane separator and is contacted with a separation membrane, the downstream side of the membrane separator keeps the vacuum degree at 4 to 200 mmHg by vacuum pumping, the dimethyl carbonate first passes through a concentration membrance filter at the permeation side of the membrane and is condensed into liquid under the condition of vacuum and low pressure, the liquid mixture directly enters into an atmospheric rectifying column, dimethyl carbonate with more than or equal to ninety nine point five percent of content is produced from the bottom of the column, and high-concentration methanol is produced from the interception side of the membrane separator and enters into next technique unit. The separation membrane is an organic composite membrane, an organic and mineral composite membrane or a mineral membrane which can preferentially permeate dimethyl carbonate, and the method has the advantages of simple technique and low energy consumption; the throughput of the permeation of the membrane is increased, and the area of the membrane is reduced; safety and reliability are increased, and the purity of dimethyl carbonate is increased as well.

Owner:PETROCHINA CO LTD +1

Permeating gasification film used for separation of methanol/dimethyl carbonate azeotropic liquid, and its preparing method

InactiveCN101003002ALow priceReduce energy consumptionDistillationCarbonic/haloformic acid esters purification/separationMethyl carbonateALLYL SUCROSE

A gasifying osmotic film for separating the azeotropic methanol / dimethyl carbonate solution is prepared from polyvinyl alcohol and polyacrylic acid. Its preparing process is also disclosed.

Owner:山东蓝景膜技术工程有限公司

Method for separating methanol and dimethyl carbonate azeotropic mixture

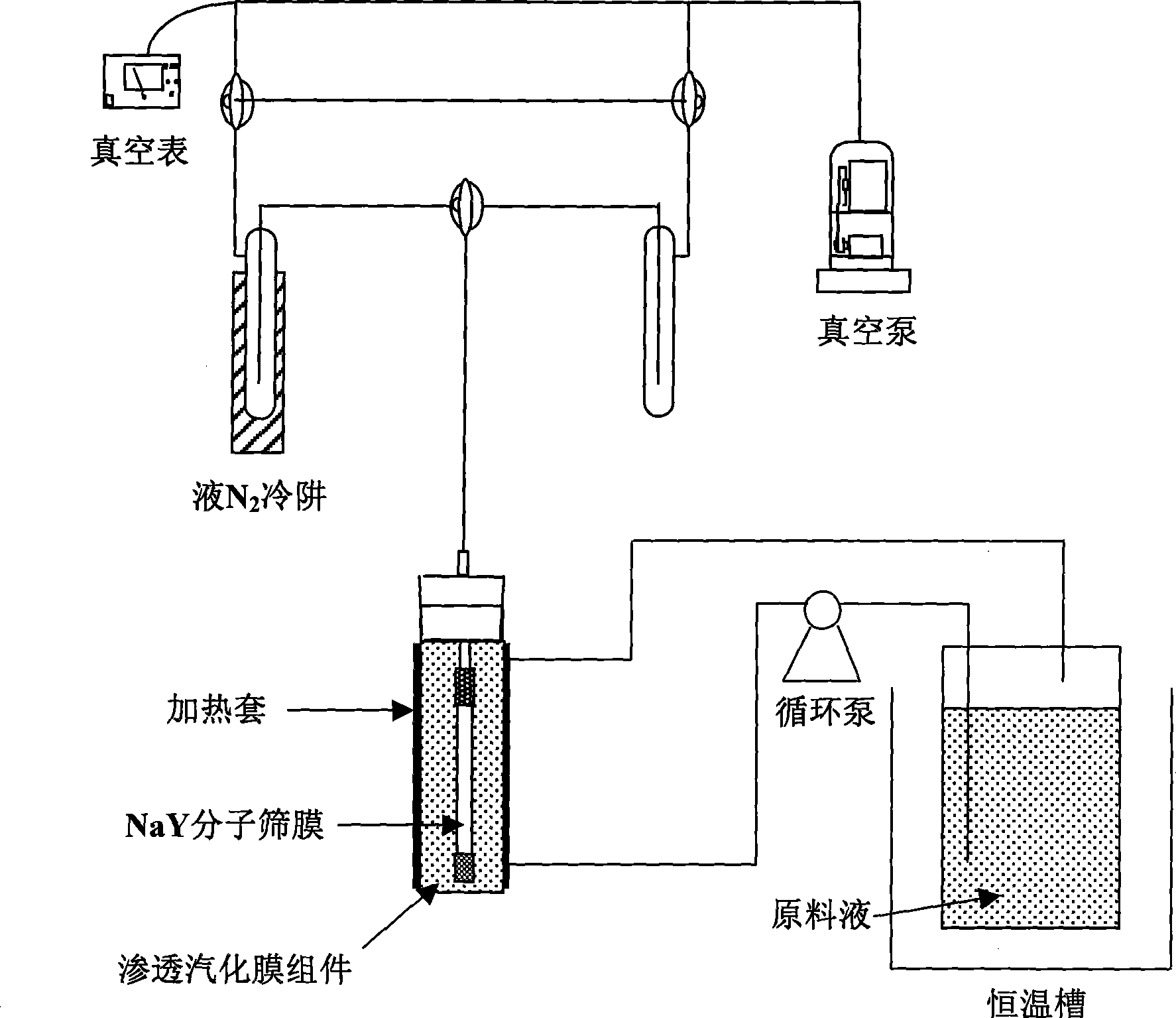

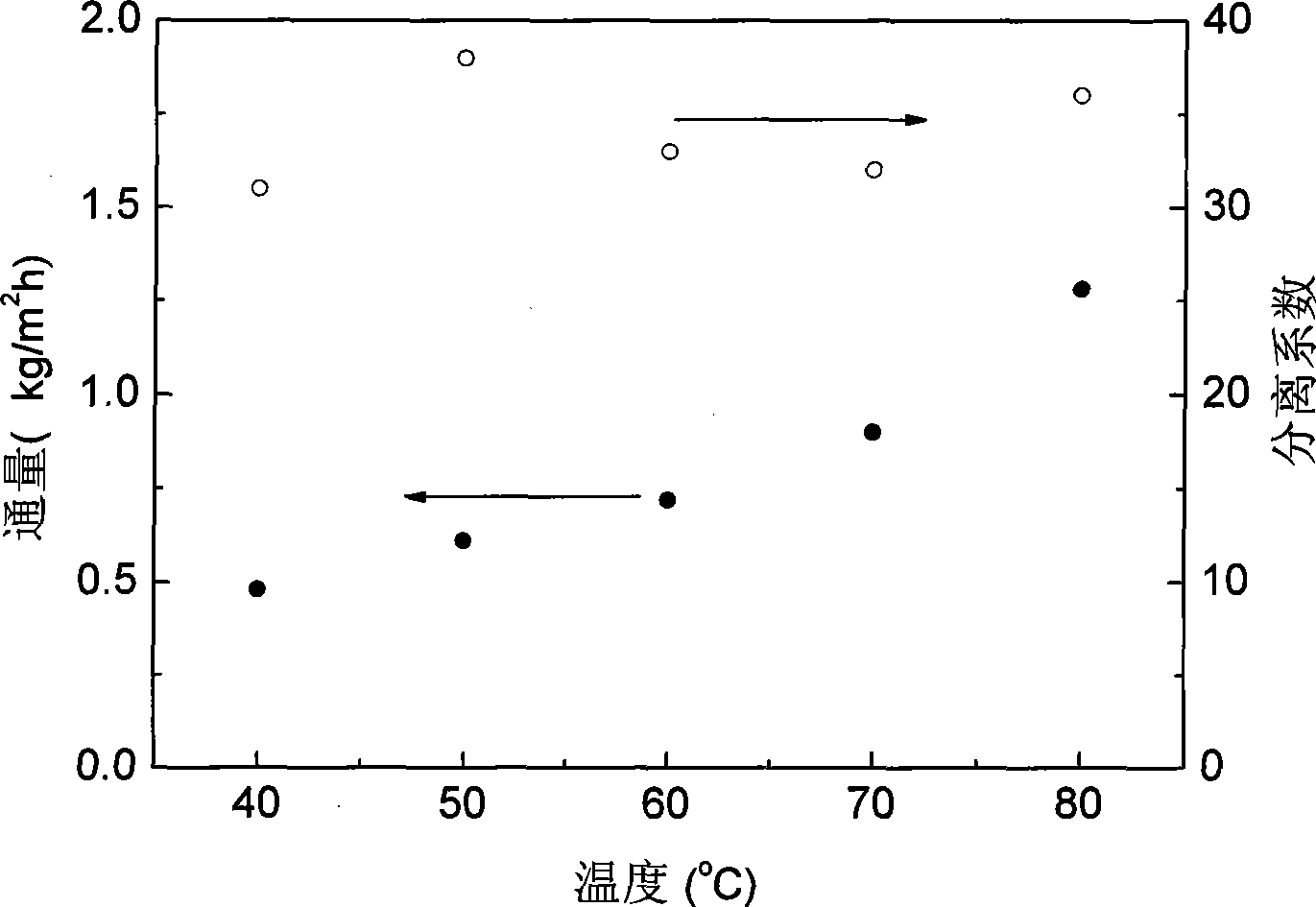

InactiveCN101362694AAchieve separationDistillationHydroxy compound separation/purificationMolecular sieveDesorption

The invention provides a new method for separating azeotropic mixture of methanol and methyl carbonate. The invention is characterized in that the mixed solution of methanol and methyl carbonate is supplied in circulation at the upstream side of molecular sieve membrane, and the downstream side of the molecular sieve membrane is connected to a vacuum system. As the molecular sieve membrane has the very high permselectivity for methanol, methanol in mixed solution preferentially permeates through the molecular sieve membrane, and vaporization and desorption are carried out at the downstream side of membrane, and then methanol is condensed and collected by the vacuum system. After multiple circulations, the mixed solution can achieve the complete separation of methanol and methyl carbonate. Compared with the traditional rectification method, the method of the invention has advantages of low energy consumption, no pollution, compact device, high separation efficiency, and the like, and has a very important meaning for industrial production of methyl carbonate and the preparation of other organic chemical materials by using methyl carbonate.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

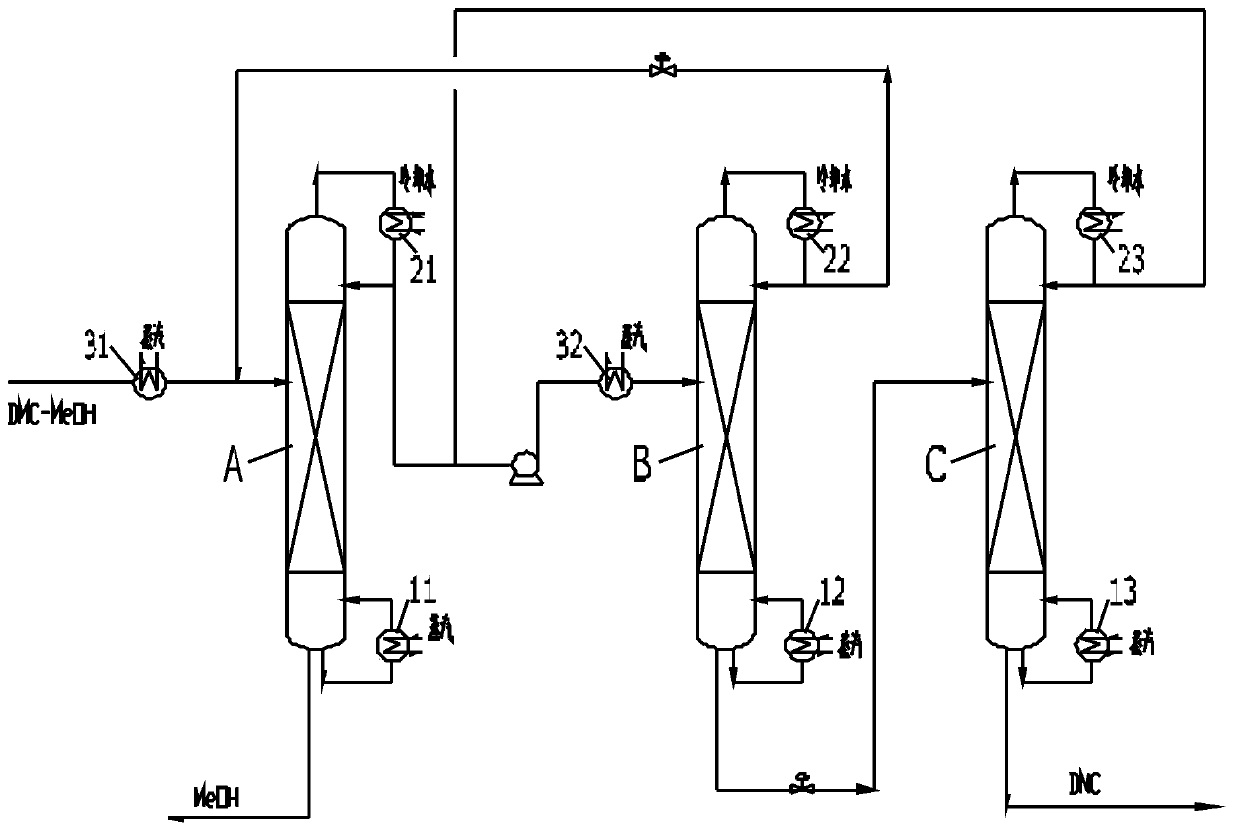

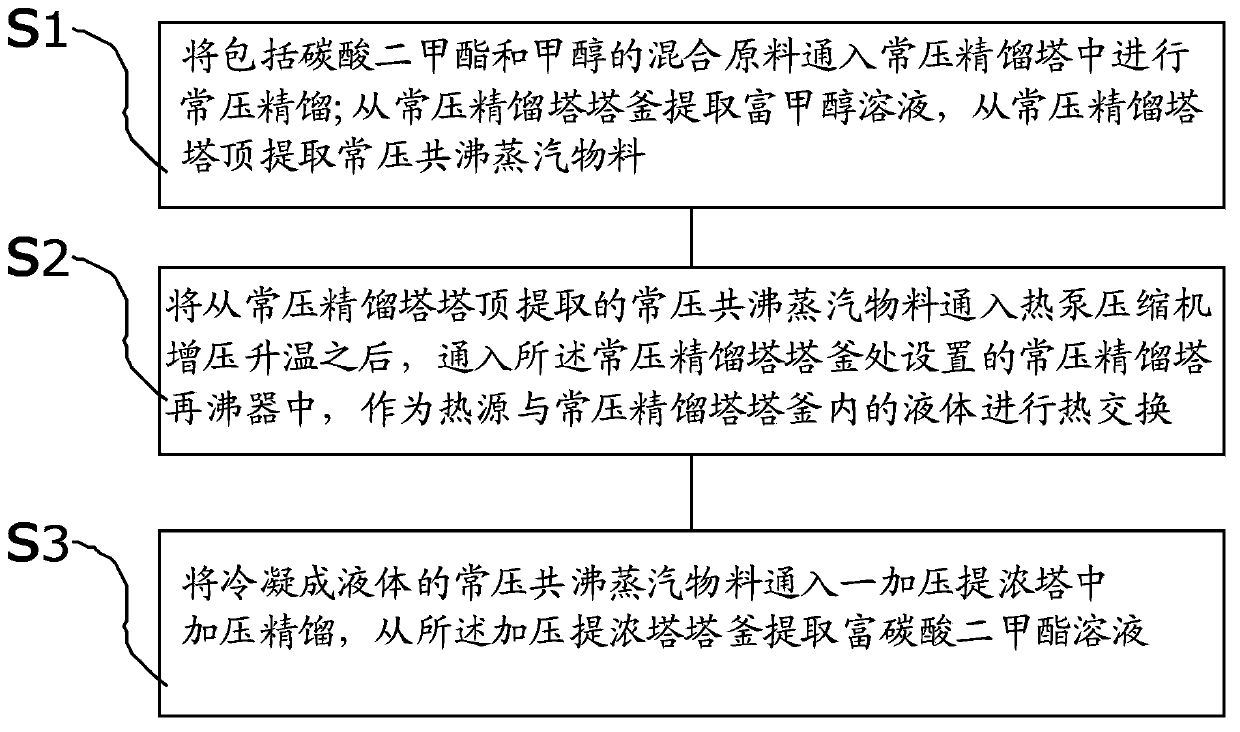

Method for separating dimethyl carbonate and methanol through pressure-swing distillation of heat pump, and apparatus thereof

InactiveCN103626656AReduce energy consumptionLow costCarbamic acid derivatives preparationOrganic compound preparationReboilerSelf-condensation

The invention provides a method for separating dimethyl carbonate and methanol through pressure-swing distillation of heat pump, and an apparatus thereof. In the dimethyl carbonate and methanol through pressure-swing distillation of the heat pump, an atmospheric azeotropic steam material obtained from the top of an atmospheric rectification tower is supercharged and heated by a heat pump compressor, and is introduced to a reboiler at the bottom of the atmospheric rectification tower as a heat source, so a liquid in the atmospheric rectification tower is heated, and the self-condensation of the atmospheric azeotropic steam material is completed. Compared with traditional atmospheric azeotropic steam material condensation through using cooling water and kettle liquid heating realized through an extra external heat source, the method in the invention properly improves the temperature and the pressure of an atmospheric azeotropic steam through the heat pump compressor to make the atmospheric azeotropic steam realize the kettle liquid heating and the reasonable and effective energy cycle as a heat source; and the cost generated by the pump heat compressor is far lower than the cost of traditional cooling water and the external heat source, so a good economic benefit is generated.

Owner:YASHENTECH CORP

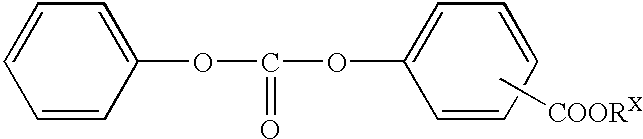

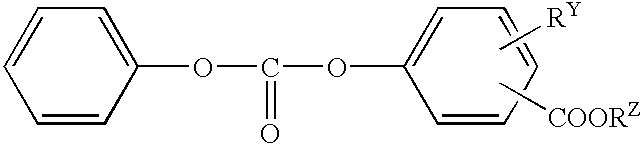

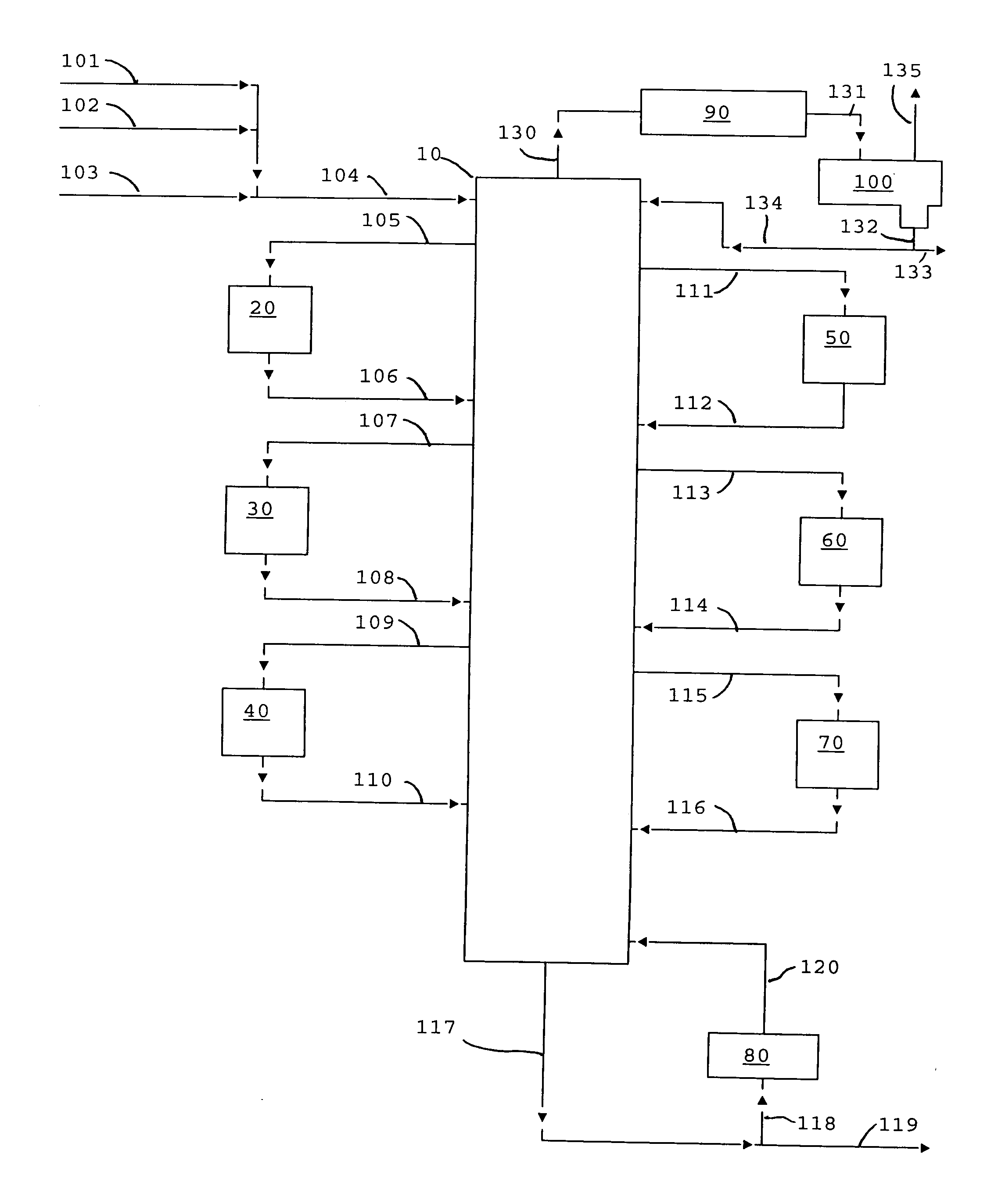

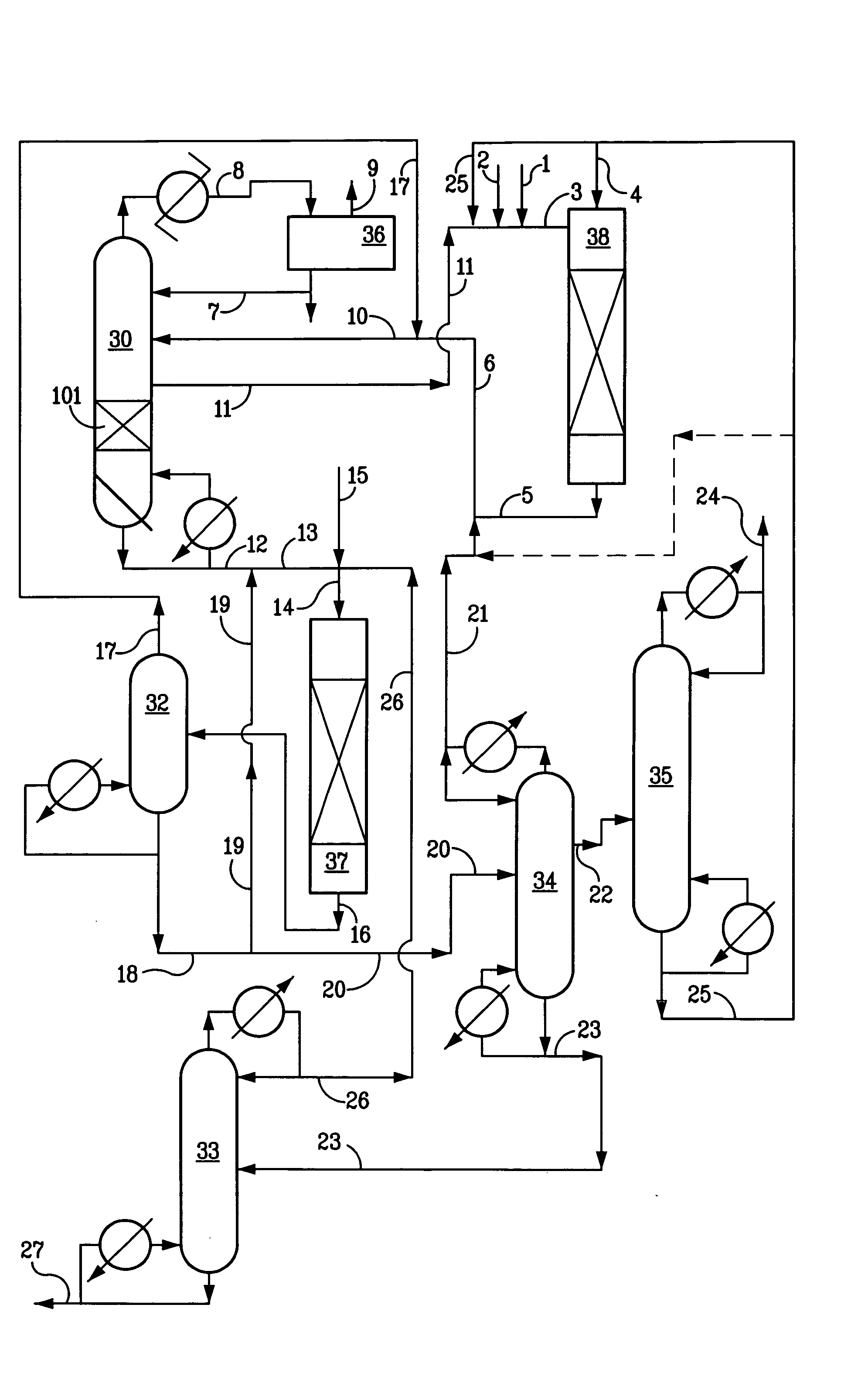

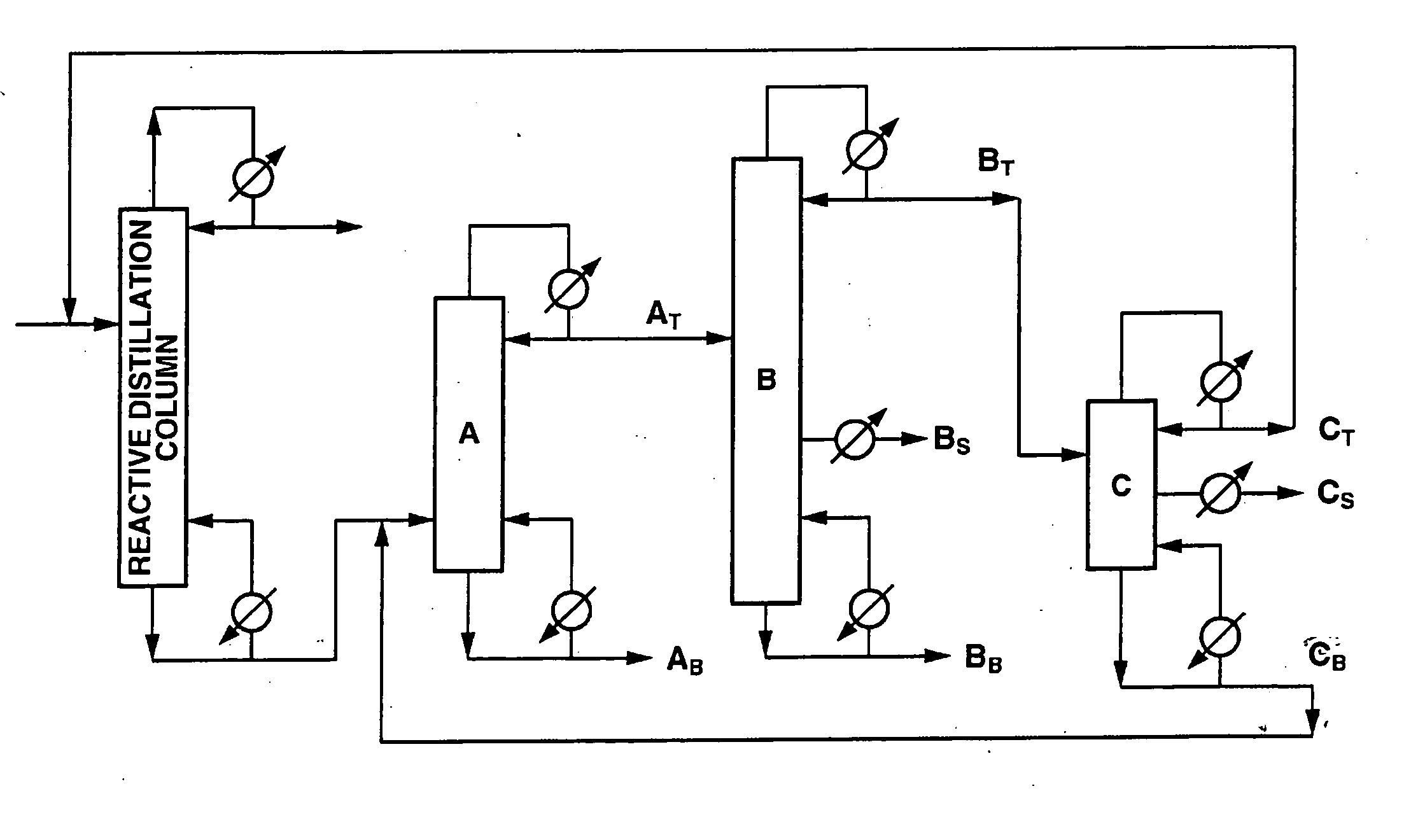

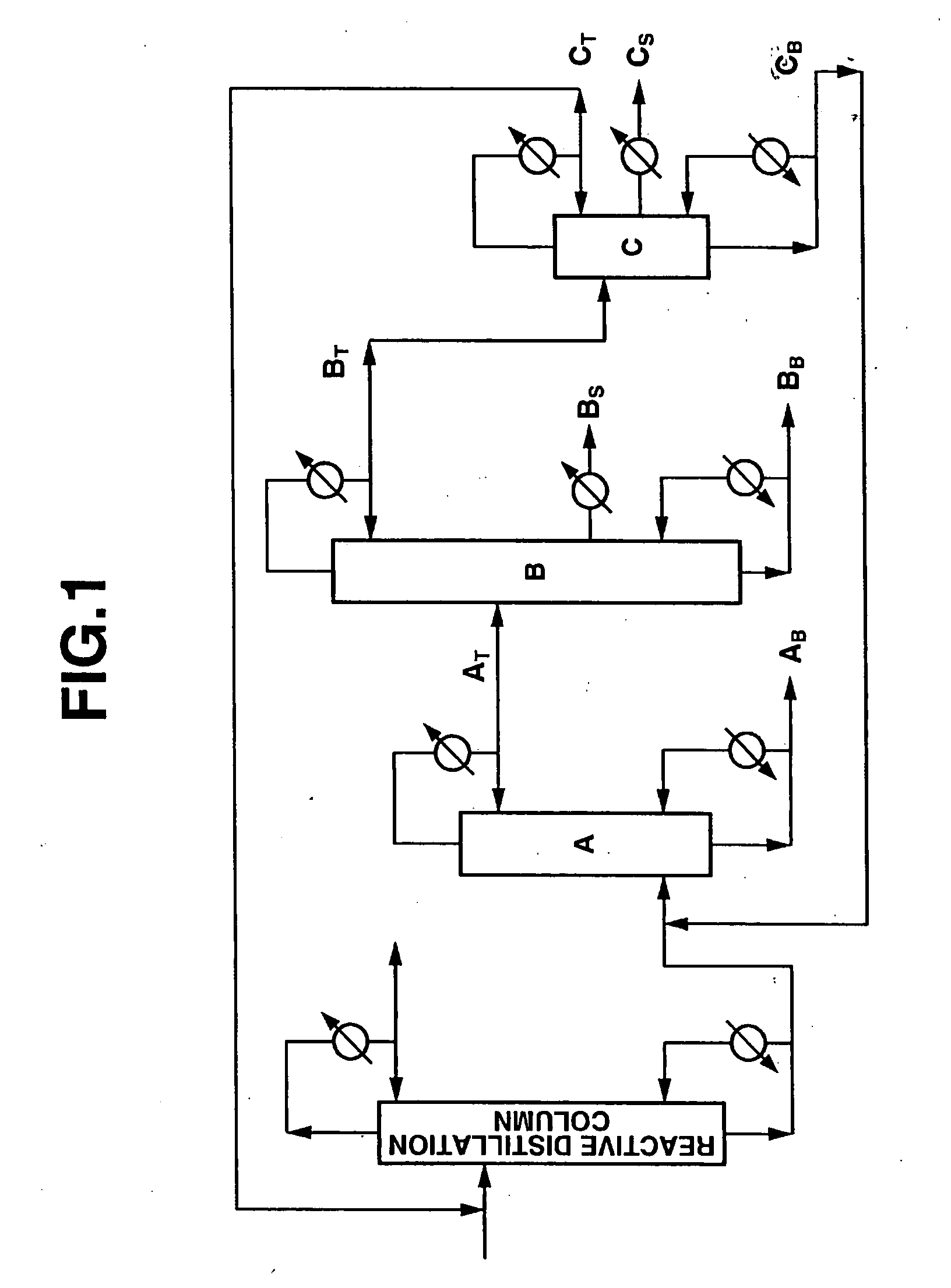

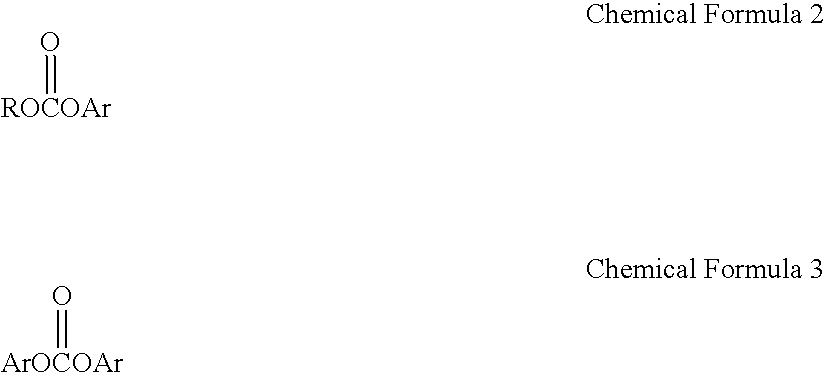

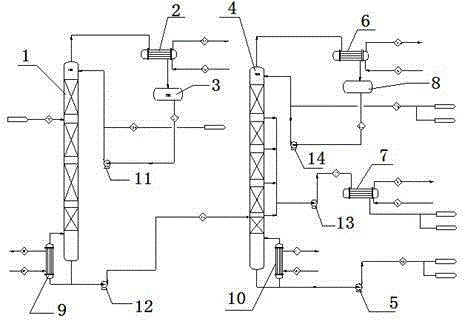

Process for Production of High-Purity Diaryl Carbonate

ActiveUS20070270604A1Stable productionChemical recyclingPreparation from organic carbonatesArylBoiling point

It is an object of the present invention to provide a specific industrially useful process that enables a high-purity diaryl carbonate having low contents of intermediate boiling point and high boiling point impurities as required for producing a high-quality and high-performance polycarbonate to be produced stably for a prolonged period of time using as a starting material a reaction mixture containing an alkyl aryl carbonate obtained through a transesterification reaction between a dialkyl carbonate and an aromatic monohydroxy compound. There have been various proposals regarding processes for the production of reaction mixtures containing aromatic carbonates by means of a reactive distillation method. The present inventors have now carried out studies aimed at discovering a specific process enabling a high-purity diaryl carbonate that can be used as a raw material of a high-quality and high-performance polycarbonate to be continuously produced stably for a prolonged period of time from such a reaction mixture. As a result, the present inventors have reached to the present invention after discovering that the above object can be attained through a process in which separation by distillation is carried out using three distillation columns in a specified order. Moreover, the present inventors have discovered that it is particularly preferable if a reactive distillation column and the three distillation columns, each of which has a specified structure, and the three distillation columns are each operated under specified distillation conditions.

Owner:ASAHI KASEI KK

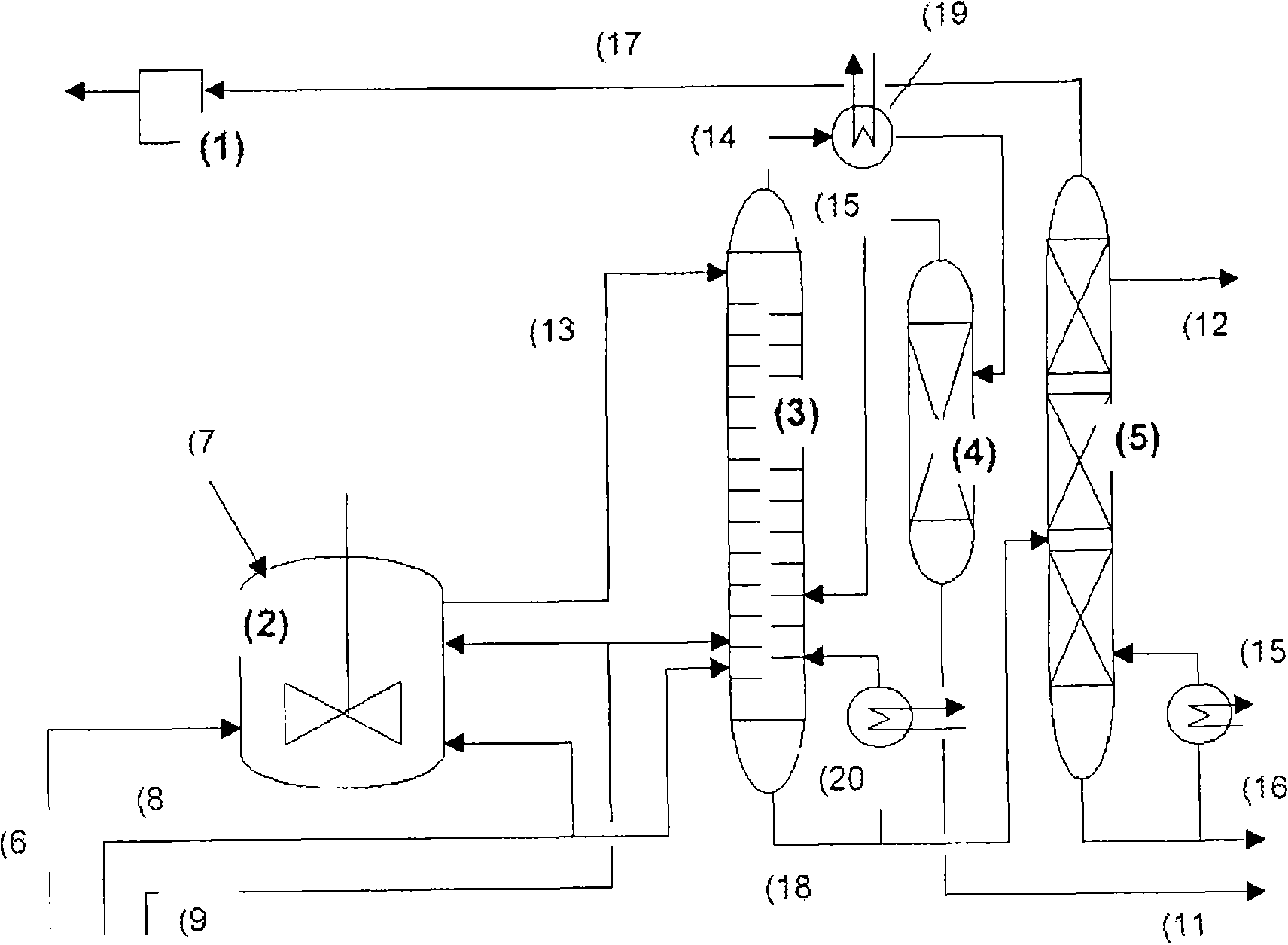

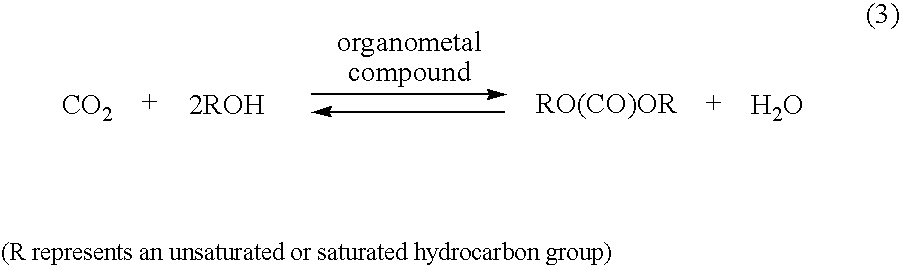

Process for producing carbonic ester

ActiveUS20050080274A1High yieldEasy to separateCarbonic/haloformic acid esters purification/separationPreparation from carbon dioxide or inorganic carbonatesAlcoholCarbonate ester

A method for producing a carbonic ester, comprising (1) performing a reaction between an organometal compound having a metal-oxygen-carbon linkage and carbon dioxide to obtain a reaction mixture containing a carbonic ester formed by the reaction, (2) separating the carbonic ester from the reaction mixture to obtain a residual liquid, and (3) reacting the residual liquid with an alcohol to form an organometal compound having a metal-oxygen-carbon linkage and form water and removing the water from the organometal compound, wherein the organometal compound obtained in step (3) is recovered for recycle thereof to step (1).

Owner:ASAHI KASEI KK

Method for the continuous production of aromatic carbonates

The present invention provides a method for making polycarbonates. One embodiment of the method comprises reacting diphenylcarbonate with a dihydric phenol. The diphenylcarbonate is made by reacting a reaction mixture comprising aryl alcohol together with a dialkyl carbonate in a reactor to produce aryl alkylcarbonate and diaryl carbonate.

Owner:SABIC GLOBAL TECH BV

Process for producing organic carbonates

ActiveUS7378540B2Speed up the conversion processCatalyst regeneration/reactivationCatalyst activation/preparationGas phaseSolvent

A process for producing various organic carbonates by performing transesterification and disproportionation reactions in dual vapor / liquid phase mode preferably in the presence of solid catalyst composition selected from the group consisting of oxides, hydroxides, oxyhydroxides or alkoxides of two to four elements from Group IV, V and VI of the Periodic Table supported on porous material which has surface hydroxyl groups and the method of reactivating catalyst deactivated by polymer deposition by contacting the deactivated catalyst with a solution of hydroxy containing compound in a solvent such as benzene or THF.

Owner:CHEM RES & LICENSING CO

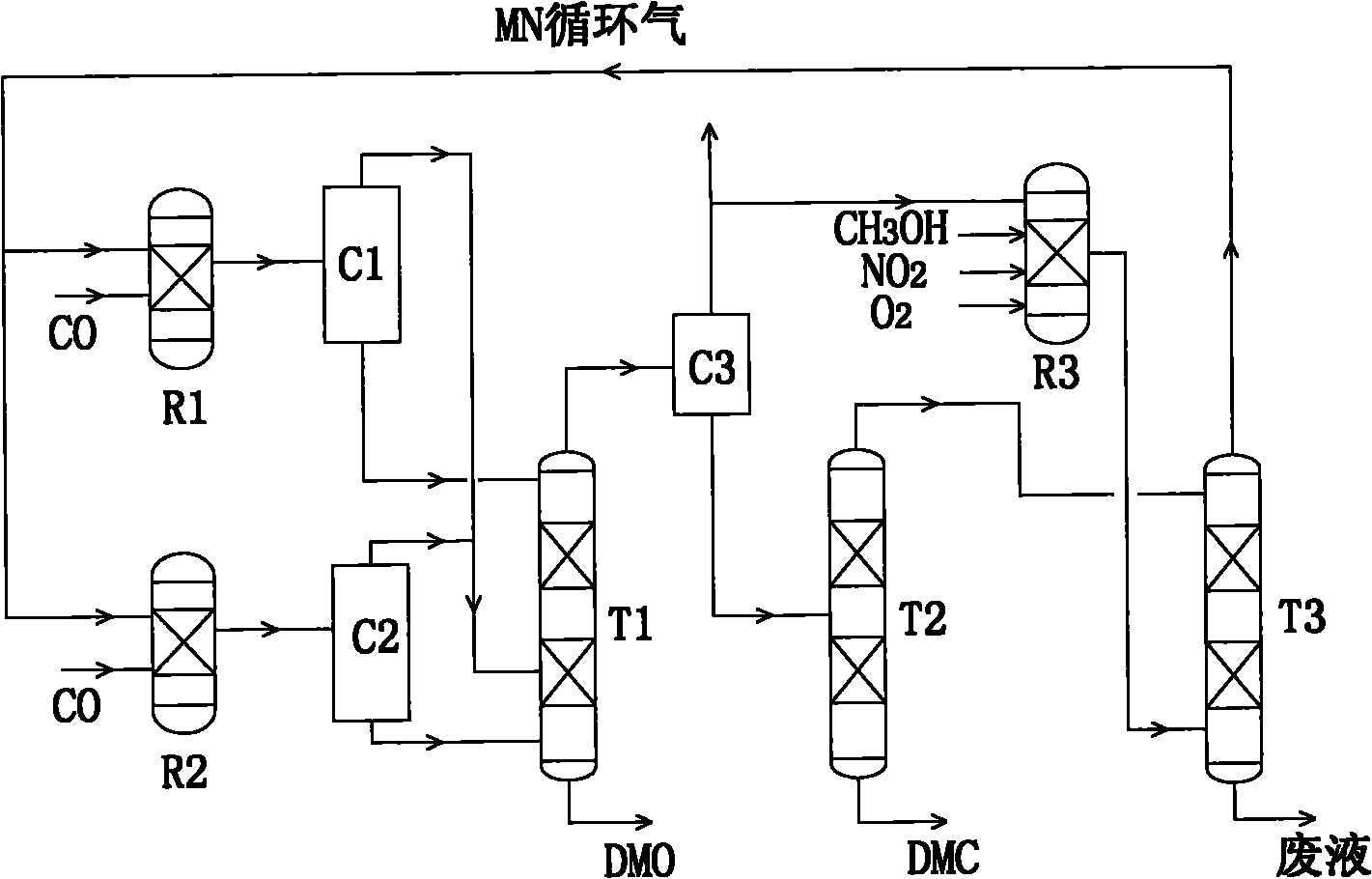

Method and device for co-producing dimethyl carbonate and dimethyl oxalate

ActiveCN101830806AReasonable deployment of productionLower energy requirementsOrganic compound preparationPreparation by carbon monoxide or formate reactionGas phaseTower

The invention discloses a method and a device for co-preparing di(C1-3) alkyl carbonate and di(C1-3) alkyl oxalate. The method comprises the following steps of: a) separating a product of a di(C1-3) alkyl carbonate synthesis reactor into a first liquid phase and a first gas phase; b) separating a product of a di(C1-3) alkyl oxalate synthesis reactor into a second liquid phase and a second gas phase; c) conveying the first liquid phase to a first rectifying tower from the tower top, conveying the combined first gas phase and second gas phase to the first rectifying tower from the middle lower part of the tower, conveying the second liquid phase to the first rectifying tower from the tower bottom, and generating basically pure di(C1-3) alkyl oxalate fraction from the bottom of the first rectifying tower during rectifying; d) separating the overhead fraction produced in the first rectifying tower into a third liquid phase and a third gas phase; and e) conveying the third liquid phase to a second rectifying tower from the middle part of the tower, and generating basically pure di(C1-3) alkyl carbonate from the bottom of the second rectifying tower. Only three rectifying towers are designed in the whole process through reasonable process design, so the energy requirement and operation expense are effectively reduced, and the equipment investment expense is saved.

Owner:PUJING CHEM IND SHA +1

Method for continuous extraction distillation separation of dimethyl carbonate-methanol azeotropic mixture

InactiveCN105037162AHigh purityEasy to separateOrganic compound preparationHydroxy compound preparationN dimethylformamideDistillation

The invention discloses a method for continuous extraction distillation separation of a dimethyl carbonate-methanol azeotropic mixture, and belongs to separation technologies of the dimethyl carbonate-methanol azeotropic mixture. According to the method, N,N-dimethylformamide, N-formylmorpholine or a mixture consisting of N,N-dimethylformamide and N-formylmorpholine in any proportion is used as an extracting agent. The operation condition of an extraction distillation tower and a solvent recovery tower are that the pressure is a normal pressure or reduced pressure, the ratio of a distillate at the top of the extraction distillation tower to the extracting agent is (0.5:1)-(10:1), and the feed (mass) ratio of the extracting agent to a mixture is (1:10)-(5:1). Two distillation towers are used in the method to achieve cycle utilization of the extracting agent. Methanol meeting requirements is obtained at the top of the extraction distillation tower, and the distillate at the bottom of the tower enters the solvent recovery tower; high-purity methyl carbonate is obtained at the top of the solvent recovery tower, and a high-purity extracting agent is obtained at the bottom of the tower; and a pump is used for pumping the extracting agent into the extraction distillation tower for cycle utilization. The method has the advantages that the extracting agent is adopted to destroy a dimethyl carbonate-methanol azeotropic system, and the aims of separating high-purity dimethyl carbonate and methanol and ensuring cycle utilization of the extracting agent are achieved. The continuous distillation has the advantages of high tower efficiency, high yield and the like.

Owner:UNIV OF JINAN

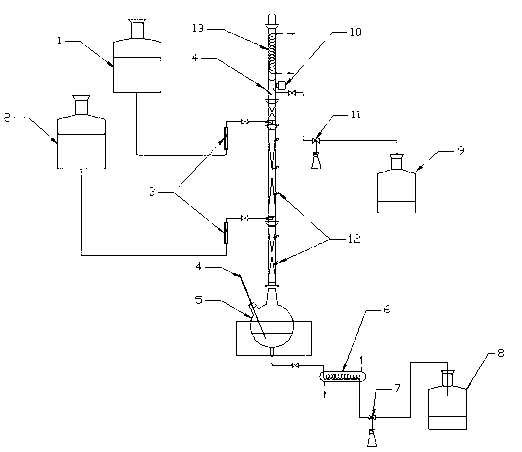

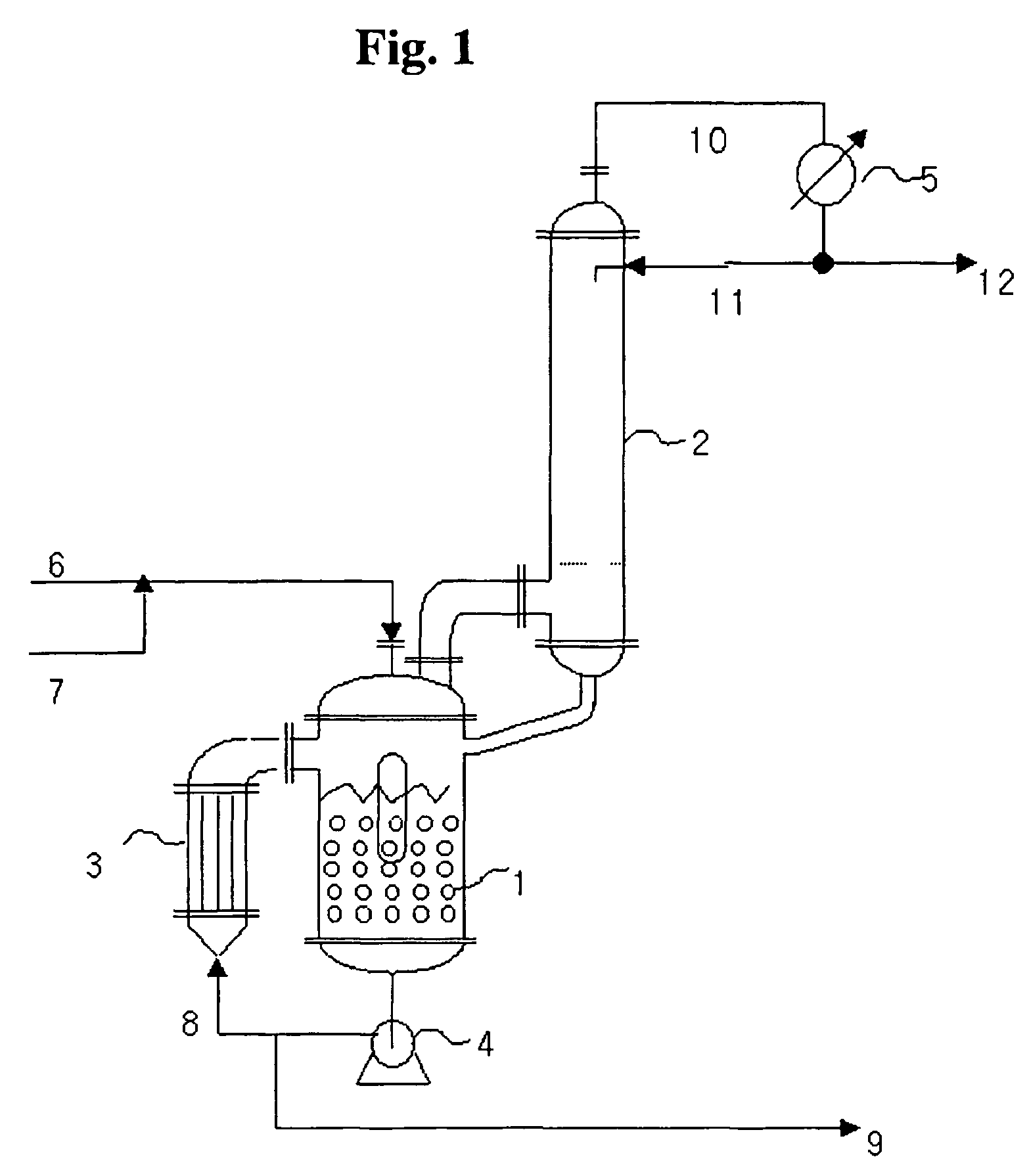

Continuous method for preparing aromatic carbonate using a heterogeneous catalyst and a reaction apparatus for the same

InactiveUS7417161B2Low costMinimizing processOrganic chemistry methodsPreparation from organic carbonatesDistillationCirculating pump

Owner:LG CHEM LTD

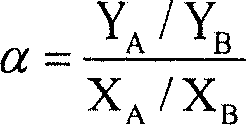

Method for separating two-component azeotrope or close-boiling-point mixture

InactiveCN104761422AHigh purityNot volatileOrganic compounds purification/separation/stabilisationCarbamic acid derivatives preparationCarbamateDistillation

The invention discloses a method for separating a two-component azeotrope or close-boiling-point mixture. According to the method, in the presence of an ionic liquid, the method for separating the azeotrope or close-boiling-point mixture composed of two components is provided, wherein one component is a compound having hydroxyl, amino or carboxyl and other functional groups, and the other compound is a carbonate dialkyl ester or nitrogen methylated alkyl carbamate and aromatic compound. The method has the advantages that the separation process can be carried out under the condition of reduced pressure distillation, rectification is not required, the separation purity is high, the ionic liquid is easy to separate, and the reusability is good.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing methyl ethyl carbonate

InactiveCN1394847ANo pollution in the processHigh yieldCarbonic/haloformic acid esters purification/separationMethyl carbonateReaction temperature

The preparation method of methylethyl carbonate uses dimethyl carbonate and diethyl carbonate as raw material, in the presence of catalyst makes them implement ester exchange reaction, and is characterized by that the dosage (mass) ratio of raw material dimethyl carbonate and diethyl carbonate is 1:2-2:1, its catalyst is load type metal oxide loaded on alumina, its metal oxide content (wt%) is 2%-30%, and the rest is Al2O3. In the ester exchange reaction the addition quantity of metal oxide is 0.1%-10% of total quantity of raw material, its reaction temp. is 50-200 deg.C, reaction pressure is normal pressure and its reaction time is 2-48 hr.

Owner:ZHEJIANG UNIV

Method of purifying ethylene carbonate, process for producing purified ethylene carbonate and ethylene carbonate

ActiveCN101400667AReduce contentHigh puritySolution crystallizationHeat exchange cooling cystallizationEthyl esterDiol

Ethylene carbonate in which the content of especially diols has highly been reduced is provided. There is provided a method of purifying ethylene carbonate, including causing crude ethylene carbonate crystal to descend from a superior part of tower, melting the crude ethylene carbonate crystal in a tower bottom, withdrawing portion of the obtained melt from the tower, causing the rest of the melt to ascend as a reflux liquid and realizing countercurrent contact of the melt with the descending crude ethylene carbonate crystal, characterized in that a solid / liquid countercurrent contact region of constant temperature is created.

Owner:MITSUBISHI RAYON CO LTD +1

Separation film for separating methanol/methyl-carbonate azotrope

InactiveCN101069823AReduce energy consumptionNo pollution in the processSemi-permeable membranesHydroxy compound separation/purificationCross-linkSeparation technology

The present invention discloses a separation membrane for separating methyl alcohol / dimethyl carbonate azeotropic mixture and its preparation method, belonging to the field of methyl alcohol separation technology. Said separation membrane is a pervaporation membrane, the polyvinyl alcohol and polyacrylic acid are blended according to the mass ratio of 95 / 5-85 / 5, the glutaric dialdehyde can be used as cross-linking agent, and the mass ratio of polyvinyl alcohol and glutaric dialdehyde is 94 / 6-83 / 17. Its preparation method includes the following steps: firstly preparing membrane-casting liquor, on the bottom membrane (can be polyacrylonitrile bottom membrane, polysulfone bottom membrane or polyether sulfone bottom membrane) knife-coating a layer of membrane-casting liquor, drying and removing solvent to obtain composite membrane, making thermal treatment so as to obtain the invented pervaporation membrane for separating methyl alcohol / dimethyl carbonate azeotropic liquor.

Owner:山东蓝景膜技术工程有限公司

Method for preparing electronic dimethyl carbonate by coupling rectification with crystallization

InactiveCN107501096AContinuous industrial productionHigh purityOrganic compound preparationChemical industryAlcoholTransesterification

The invention belongs to the technical field of chemical production and relates to a method for preparing electronic dimethyl carbonate by coupling rectification with crystallization. The method for preparing electronic dimethyl carbonate by coupling rectification with crystallization provided by the invention comprises the following steps: reactive distillation, namely taking methyl alcohol and ethylene carbonate as raw materials, performing transesterification in a reactive distillation column under the existence of catalyst, acquiring an ethylene glycol solution at the bottom of the reactive distillation column and acquiring the dimethyl carbonate in mass fraction of 98%-99.5% at the top of the reactive distillation column; and falling film crystallization, namely conveying the dimethyl carbonate acquired from the top of the reactive distillation column into a falling film crystallizer, crystallizing in the manner of gradually cooling, stopping till cooling to -5 DEG C to 2 DEG C and then acquiring the dimethyl carbonate in mass fraction of 99.99% in the manner of gradually warming, sweating and fully melting. The method has the advantages of simple operation, easiness in control, high purity and high yield of prepared products, stable product quality, low cost and low energy consumption.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

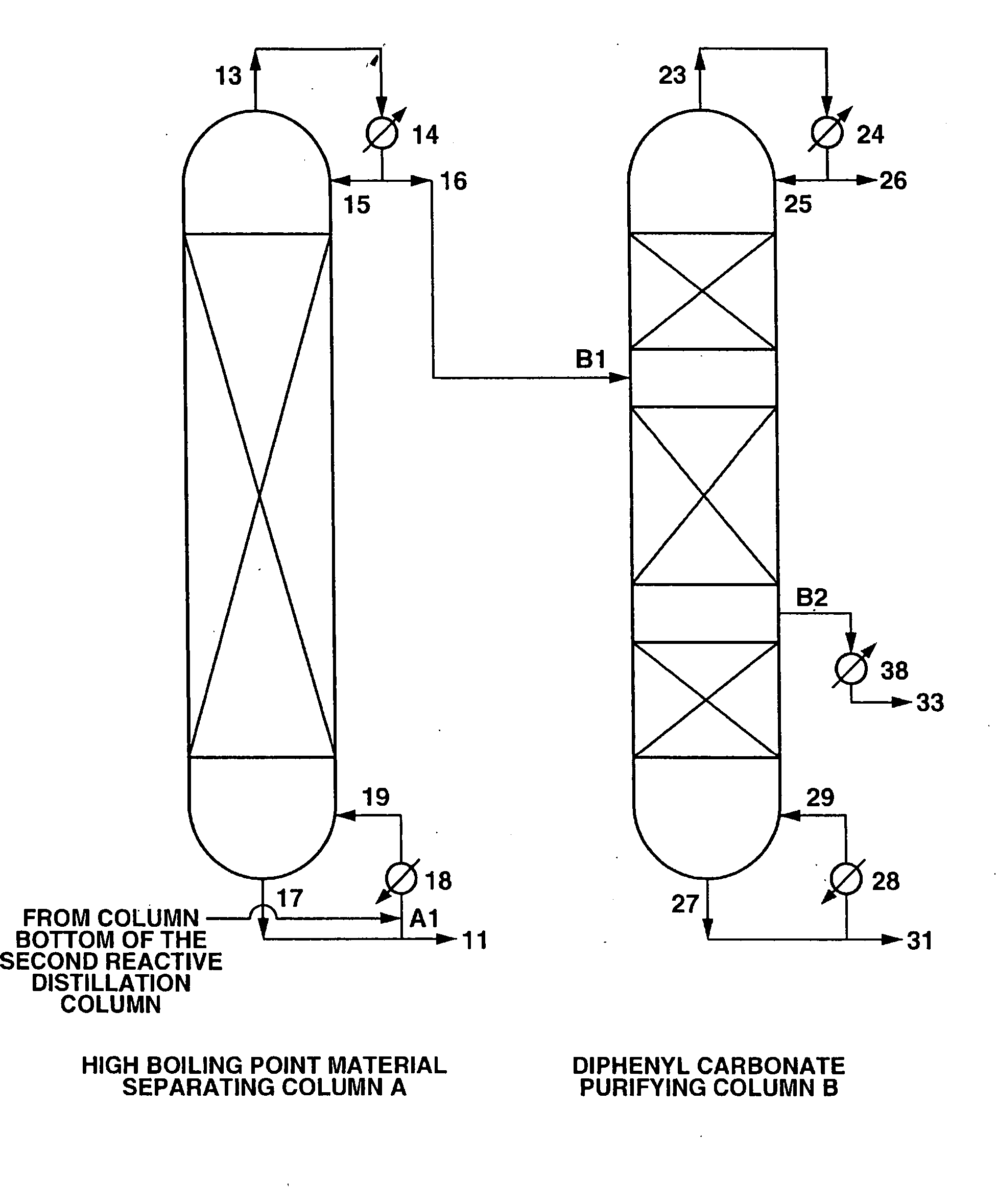

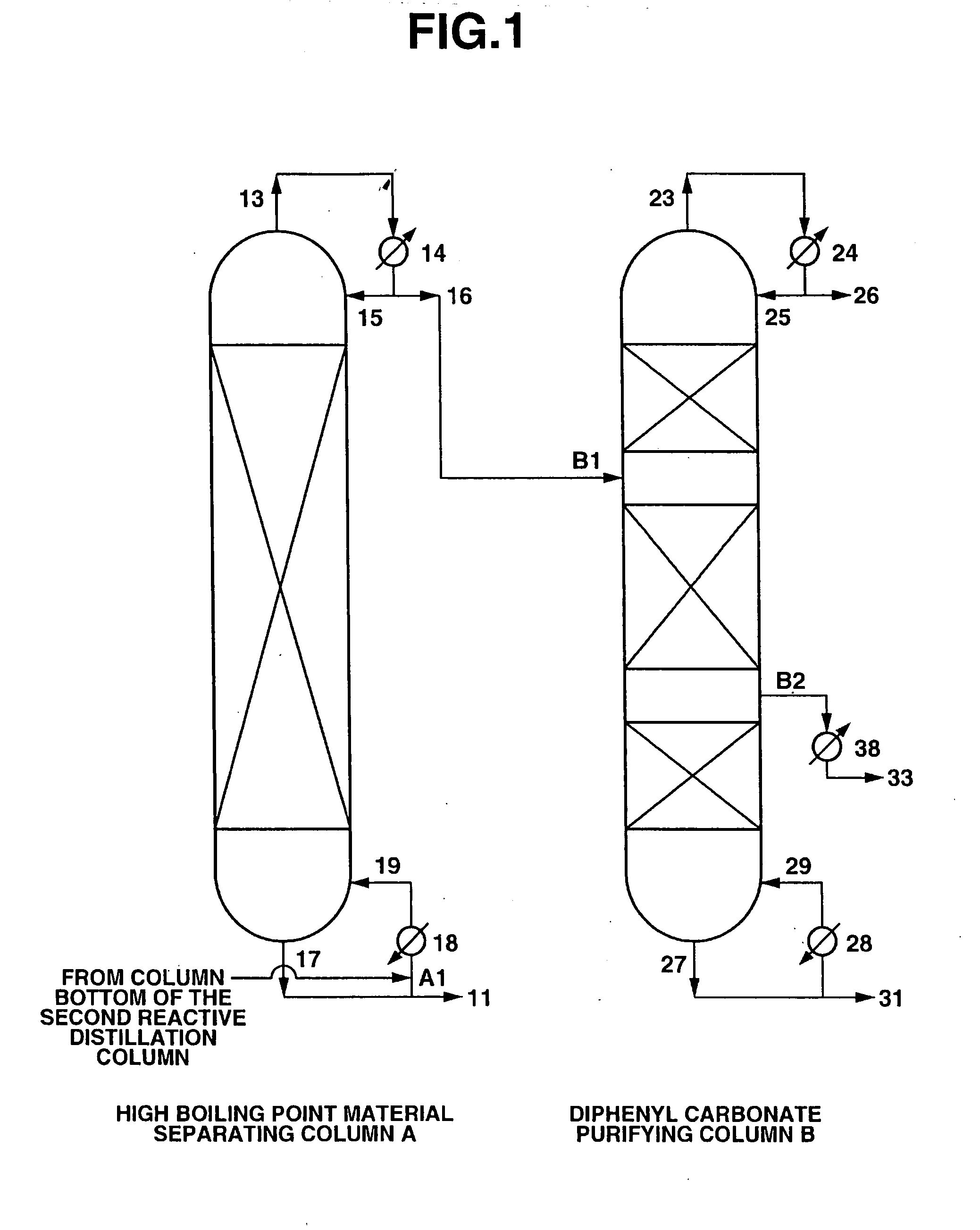

Industrial process for production of high-purity diphenyl carbonate

According to the present invention, there are provided a high boiling point material separating column A and a diphenyl carbonate purifying column B each comprising a continuous multi-stage distillation column having specified structures, and there is provided a specific process that enables a high-purity diphenyl carbonate which is important as a raw material of a high-quality and high-performance polycarbonate to be produced stably for a prolonged period of time on an industrial scale of not less than 1 ton / hr from a reaction mixture containing the diphenyl carbonate using an apparatus in which these two continuous multi-stage distillation columns are connected together.

Owner:ASAHI KASEI KK

Automotive fuels and fine chemicals from crude tall oil

InactiveCN101297024AHigh yieldImprove oxidation stabilityFatty oils/acids recovery from wasteFatty acid esterificationResin acidAlcohol

Owner:桑佩有限责任公司

Refining purifying device and method used for continuously producing battery grade dimethyl carbonate

ActiveCN105384639AAddressing Purity IssuesSettlement yieldCarbonic/haloformic acid esters purification/separationHigh energyReboiler

The invention relates to a refining purifying device and method used for continuously producing battery grade dimethyl carbonate. The device is characterized in that the top of a light component removal column is connected with an overhead condenser; the overhead condenser is connected with the light component removal column by a first reflux drum and a first reflux pump and is connected with a light component removal outlet; the bottom of the light component removal column is connected with a first reboiler; the first reboiler is used for conveying raw materials subjected to light component removal to a rectifying column via a column reactor pump; the rectifying column is connected with a second reflux drum by a rectifying column condenser; the second reflux drum is connected with the rectifying column by a second reflux pump; the bottom of the separate column reactor is connected with a second column reactor pump by a second reboiler; the middle part of the separate column reactor is connected with a side condenser by a side withdrawing pump. The device and the method have the beneficial effects that the problems of low product purity, low yield, high energy consumption and generation of solid waste pollutants in traditional production processes are solved; the purity of the dimethyl carbonate product is improved 99.99% or more after removing light components by the light component removal column and then carrying out purifying refining by the rectifying column.

Owner:DONGYING HI TECH SPRING CHEM IND

Process for producing carbonic ester

ActiveUS7446218B2Improve isolationGuaranteed continuous performanceCarbonic/haloformic acid esters purification/separationPreparation from carbon dioxide or inorganic carbonatesAlcoholMetal

A method for producing a carbonic ester, comprising: (1) performing a reaction between an organometal compound mixture and carbon dioxide, the organometal compound mixture comprising a reactive organometal compound and an unregenerable unreactive compound derived from the reactive organometal compound, to thereby obtain a reaction mixture containing a carbonic ester, the unregenerable unreactive compound, and a regenerable metamorphic organometal compound derived from the reactive organometal compound, (2) separating the reaction mixture into a first portion containing the carbonic ester and the unregenerable unreactive compound, and a second portion containing the regenerable metamorphic organometal compound, and (3) reacting the second portion of the reaction mixture with an alcohol to form an organometal compound mixture and water and removing the water from the organometal compound mixture, the organometal compound mixture comprising a reactive organometal compound and an unregenerable unreactive compound derived from the reactive organometal compound.

Owner:ASAHI KASEI KK

Method for separating low-concentration dimethyl carbonate during process of synthesizing dimethyl oxalate with coal-based synthetic gas as raw material

ActiveCN105272857AImprove energy efficiencyCarbonic/haloformic acid esters purification/separationHigh energyReboiler

The invention relates to a method for separating low-concentration dimethyl carbonate during a process of synthesizing dimethyl oxalate with coal-based synthetic gas as a raw material. The invention mainly aims at solving the problems of complicated operation and high energy consumption of prior arts. According to the invention, a crude methanol solution containing small amounts of dimethyl carbonate and methyl formate is delivered to a light component removing column, such that methyl formate is removed; the obtained material is delivered to a double-column process composed of atmospheric column-pressurized column, such that dimethyl carbonate is removed through separation, and methanol can be recovered and recycled. A large proportion of pressurized column overhead gas is adopted as a heat source for a light component removing column kettle reboiler. With the technical scheme, the problems are well solved. The method can be used in ethylene glycol industrial productions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Industrial Process for Production of High-Purity Diphenyl Carbonate

InactiveUS20070260083A1Organic chemistry methodsChemical industryPolycarbonateTransesterification reaction

It is an object of the present invention to provide a specific process that enables a high-purity diphenyl carbonate that can be used as a raw material of a high-quality and high-performance polycarbonate to be produced stably for a prolonged period of time on an industrial scale of not less than 1 ton / hr from a reaction mixture containing a catalyst and reaction by-products that has been obtained through transesterification reaction and the like using a dialkyl carbonate and a phenol as a starting material. Although there have been various proposals regarding processes for the production of reaction mixtures containing aromatic carbonates by means of a reactive distillation method, these have all been on a small scale and short operating time laboratory level, and there have been no disclosures on a specific process or apparatus enabling mass production on an industrial scale from such a reaction mixture to a high-purity diphenyl carbonate that can be used as a raw material of a high-quality and high-performance polycarbonate. According to the present invention, there are provided a high boiling point material separating column A and a diphenyl carbonate purifying column B each comprising a continuous multi-stage distillation column having specified structures, and there is provided a specific process that enables a high-purity diphenyl carbonate which is important as a raw material of a high-quality and high-performance polycarbonate to be produced stably for a prolonged period of time on an industrial scale of not less than 1 ton / hr from a reaction mixture containing the diphenyl carbonate using an apparatus in which these two continuous multi-stage distillation columns are connected together.

Owner:ASAHI KASEI CHEM CORP

Industrial Process For Production Of High-Purity Diphenyl Carbonate

ActiveUS20080041712A1Improve performanceOrganic chemistry methodsChemical industryPolycarbonateTransesterification reaction

It is an object of the present invention to provide a specific process that enables a high-purity diphenyl carbonate that can be used as a raw material of a high-quality and high-performance polycarbonate to be produced stably for a prolonged period of time on an industrial scale of not less than 1 ton / hr from a reaction mixture containing a catalyst and reaction by-products that has been obtained through transesterification reaction and the like using a dialkyl carbonate and a phenol as a starting material. Although there have been various proposals regarding processes for the production of reaction mixtures containing aromatic carbonates by means of a reactive distillation method, these have all been on a small scale and short operating time laboratory level, and there have been no disclosures on a specific process or apparatus enabling mass production on an industrial scale from such a reaction mixture to a high-purity diphenyl carbonate that can be used as a raw material of a high-quality and high-performance polycarbonate. According to the present invention, there are provided a high boiling point material separating column A and a diphenyl carbonate purifying column B each comprising a continuous multi-stage distillation column having specified structures, and there is provided a specific process that enables a high-purity diphenyl carbonate which is important as a raw material of a high-quality and high-performance polycarbonate to be produced stably for a prolonged period of time on an industrial scale of not less than 1 ton / hr from a reaction mixture containing the diphenyl carbonate using an apparatus in which these two continuous multi-stage distillation columns are connected together.

Owner:ASAHI KASEI KK

Method of separating metallic catalyst constituents from reaction mixtures

InactiveUS20050014965A1Effect reactivityEffect selectivityOrganic compound preparationPreparation from carbon monoxide and oxygenReaction temperatureSolvent

A process for the preparation of an aromatic carbonate is disclosed. The process entails reacting in the presence of a catalyst system an aromatic hydroxy compound with carbon monoxide and oxygen, and optionally in one or more solvents to produce a liquid phase. At least a portion of the liquid phase is subjected to a treatment to obtain a treated liquid phase. The treatment entails at least one of (a) heating to a temperature that is at most mean reaction temperature without passing oxygen thereto, and (b) adding one or more protic compounds thereto, and (c) passing through it one or more inert or reducing gases. Solid metallic catalyst constituents are then separated from the treated liquid phase.

Owner:BAYER MATERIALSCIENCE AG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com