Method for separating low-concentration dimethyl carbonate during process of synthesizing dimethyl oxalate with coal-based synthetic gas as raw material

A technology of dimethyl carbonate and dimethyl oxalate, applied in the purification/separation of carbonate/haloformate, organic chemistry, etc., can solve the problems of high energy consumption and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

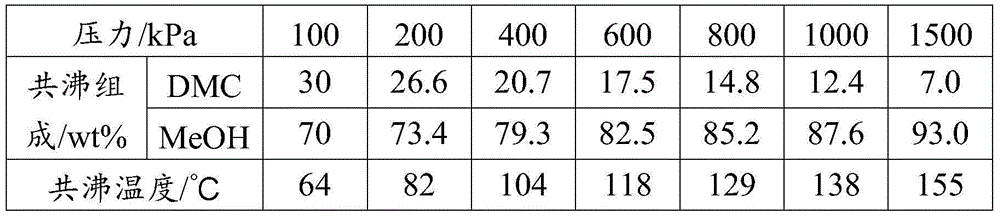

Method used

Image

Examples

Embodiment 1

[0030]The crude methanol solution 1 after the separation of DMO enters the light removal tower T-101, and the top gas 2 of the light removal tower enters the light removal tower condenser E-102. After the light tower kettle pump P-101 is pressurized, 6 enters the atmospheric tower, and the top gas 7 of the atmospheric tower enters the atmospheric tower condenser E-102. Pressurized tower, atmospheric tower tank liquid is pressurized by atmospheric tower tank pump P-102 12 as methanol product and recycled in the synthesis gas to ethylene glycol plant. When the device is started, all the top gas 13 of the pressurization tower is condensed by the start-up condenser E-106A of the pressurization tower and enters the reflux tank D-101 of the pressurization tower. Part of the heat is exchanged with the reboiler E-101 of the light removal tower through the pipeline 16 and then returned to the reflux tank D-101 of the pressurization tower, and the remaining part of the top gas 13 of the...

Embodiment 2

[0038] Different from [Example 1], the theoretical plate number of the atmospheric column is 55, the operating pressure at the top of the tower is 40kPaG, and the temperature at the top of the tower is 72°C; the operating pressure of the tower still is 75kPaG, the temperature of the tower still is 79°C, for 12. The theoretical plate number of the pressurized tower is 35, the operating pressure at the top of the tower is 1000kPaG, and the temperature at the top of the tower is 137°C;

[0039] Among them, the main logistics components are as follows:

[0040]

[0041] Under normal operating conditions, the reboiler and condenser loads of each column are as follows:

[0042] Load, MW T-101 T-102 T-103 reboiler - 29.935 5.732 condenser 3.756 31.352 1.274

[0043] Among them, 74.6% of T-103 overhead gas is supplied to T-101 reboiler as a heat source, and the load of T-103 overhead condenser is reduced by 74.6%.

Embodiment 3

[0045] Different from [Example 1], the feed composition of crude methanol solution 1 is different, the number of theoretical plates in the atmospheric column is 60, the operating pressure at the top of the tower is 70kPaG, and the temperature at the top of the tower is 78°C; the operating pressure at the bottom of the tower is 115kPaG, The temperature of the tower kettle is 85°C, and the reflux ratio is 10. The pressurized tower has 50 theoretical plates, the operating pressure at the top of the tower is 1150kPaG, and the temperature at the top of the tower is 146°C;

[0046] Among them, the main logistics components are as follows:

[0047]

[0048] Under normal operating conditions, the reboiler and condenser loads of each column are as follows:

[0049] Load, MW T-101 T-102 T-103 reboiler - 31.542 7.685 condenser 3.487 32.724 2.537

[0050] Among them, 62.6% of T-103 overhead gas is supplied to T-101 reboiler as a heat source, while the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com