Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

387 results about "Theoretical plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A theoretical plate in many separation processes is a hypothetical zone or stage in which two phases, such as the liquid and vapor phases of a substance, establish an equilibrium with each other. Such equilibrium stages may also be referred to as an equilibrium stage, ideal stage, or a theoretical tray. The performance of many separation processes depends on having series of equilibrium stages and is enhanced by providing more such stages. In other words, having more theoretical plates increases the efficiency of the separation process be it either a distillation, absorption, chromatographic, adsorption or similar process.

Adsorbent sheet material for parallel passage contactors

ActiveUS7077891B2Maximize capacityImprove efficiencyMaterial nanotechnologyOther chemical processesParticulatesSorbent

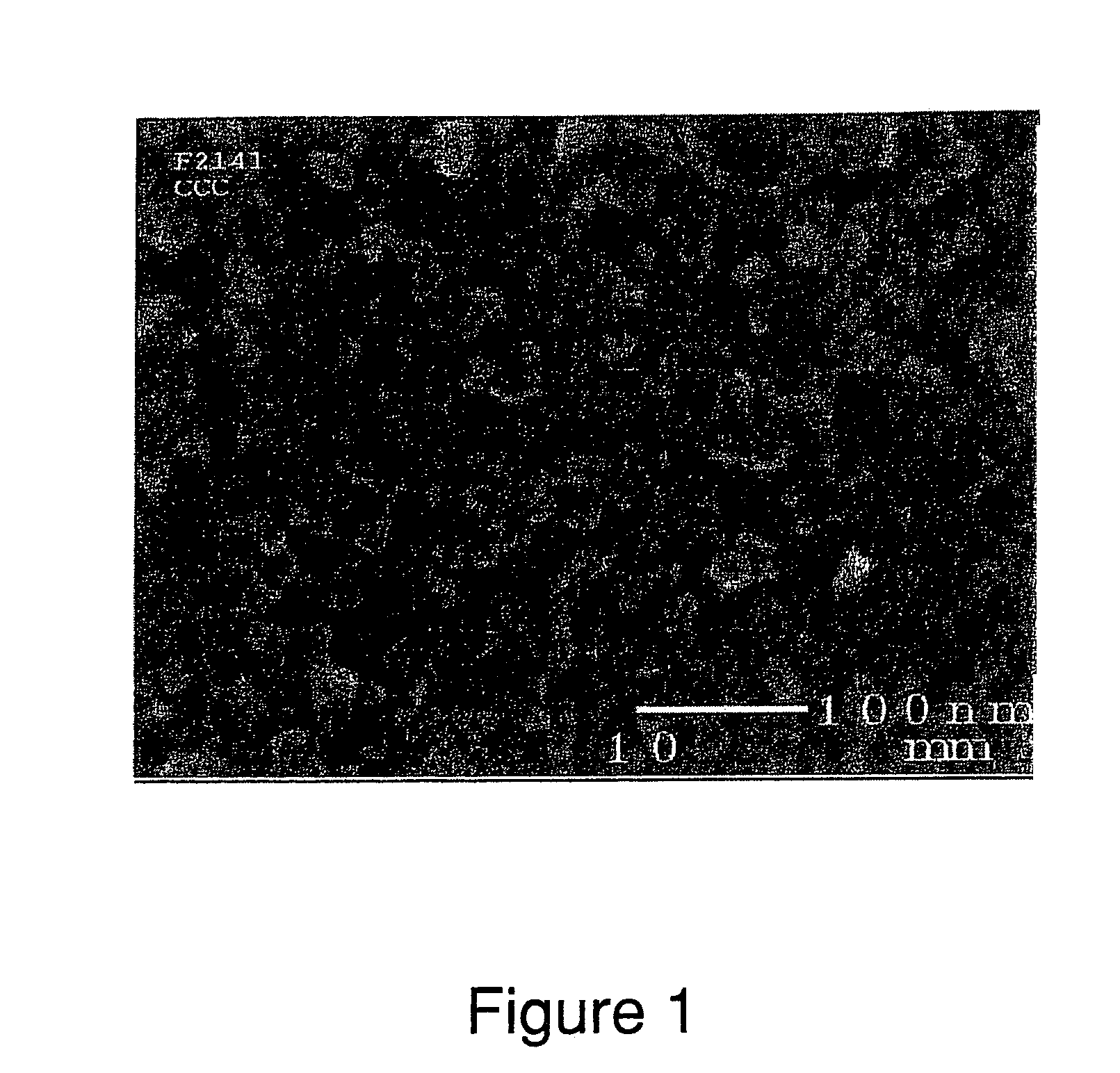

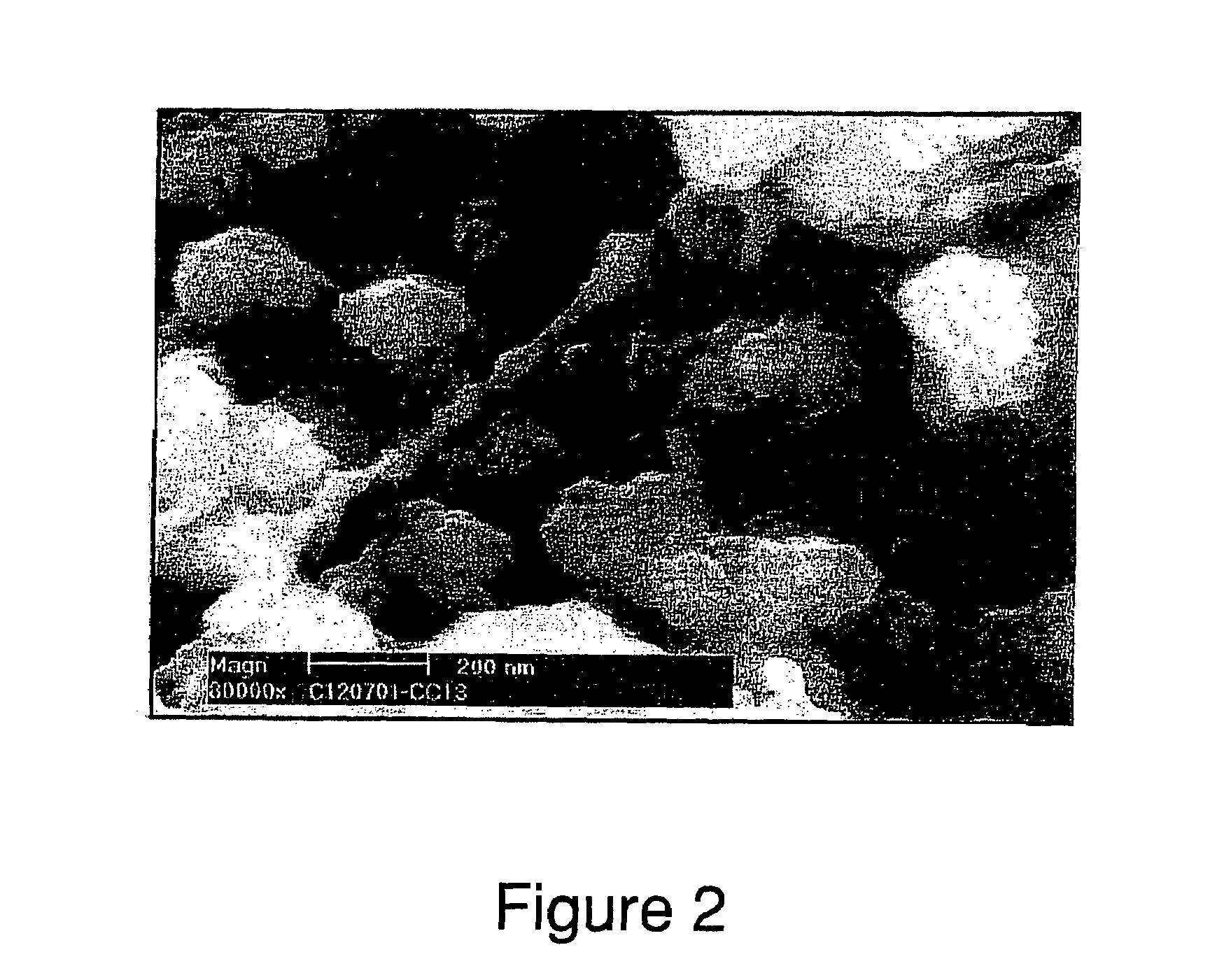

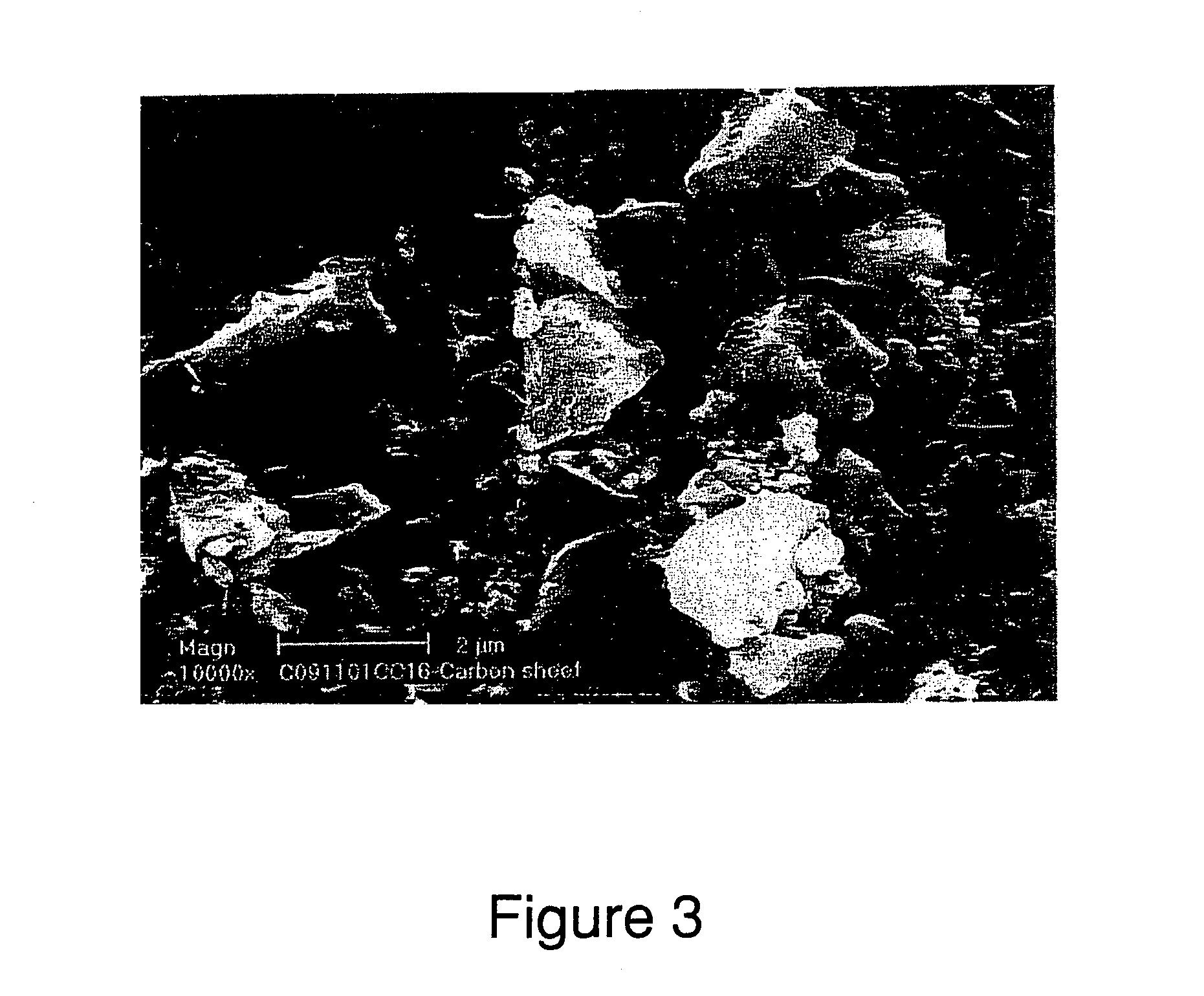

An adsorbent material fabricated into a reinforcement-free, self-supported coherent thin sheet and configured for use as a parallel passage contactor element in adsorption / separation applications with gases and liquids is disclosed. The adsorbent sheet material is obtained by enmeshing fine adsorbent particulates in a polymer binder. Particulates include but are not limited to carbon particles, inorganic oxides particles, or ceramic particles, or synthetic polymer resin particles. The adsorbent sheet advantageously contains a large volume percentage of active adsorbent particles. The parallel passage contactor device fabricated from the adsorbent sheet material is characterized by minimal mass transfer resistance and better separation efficiency expressed as height equivalent to a theoretical plate, while it maintains most of the adsorptive properties of the starting particulates, and can be used in gas separation applications with short adsorption cycles, such as rapid pressure swing adsorption, rotary concentrators, rapid electric swing adsorption.

Owner:AIR PROD & CHEM INC

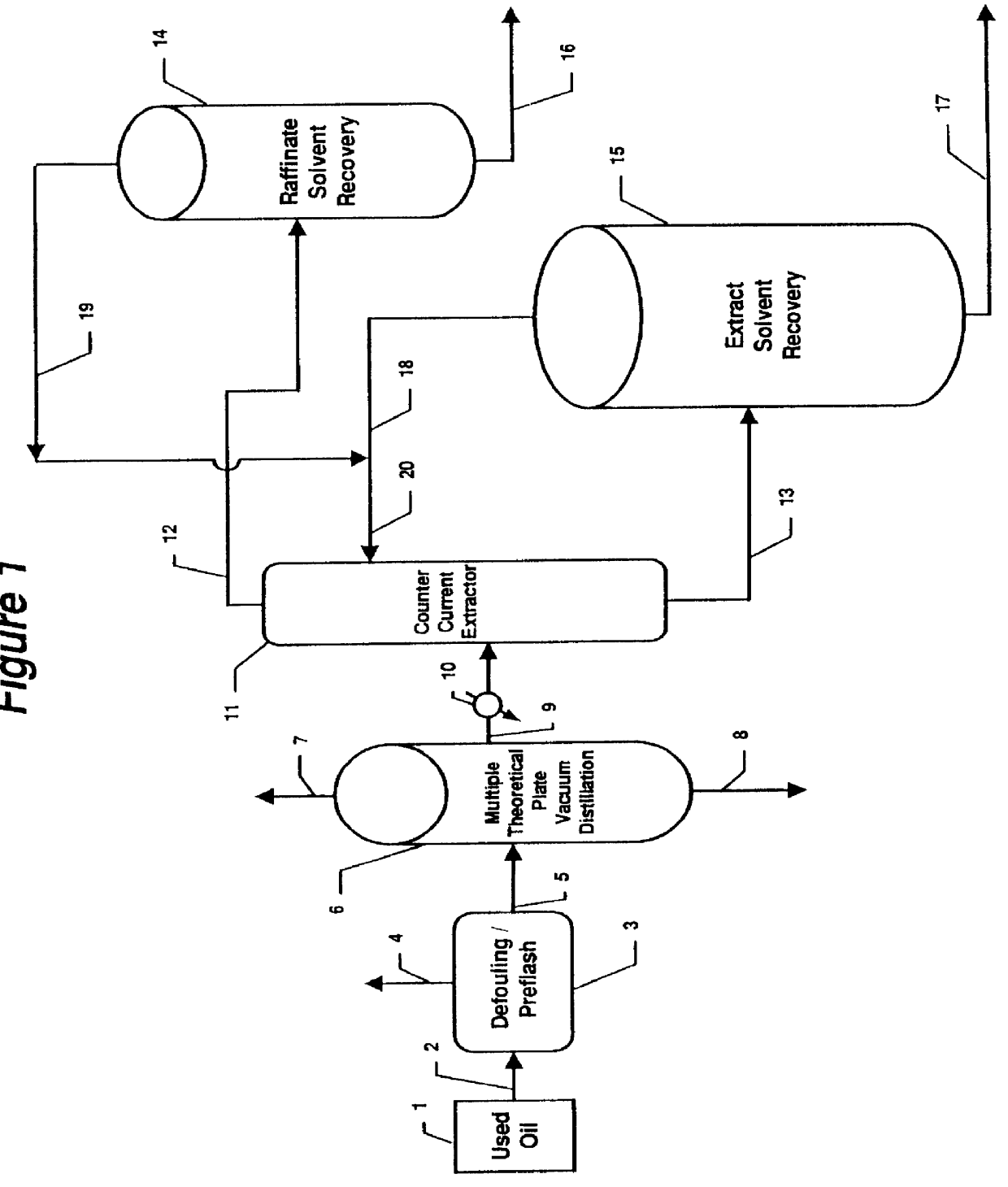

Method of rerefining waste oil by distillation and extraction

InactiveUS6117309AHigh yieldLower the volumeRefining with acid-containing liquidsLubricant compositionTheoretical plateDistillation

Owner:SARP

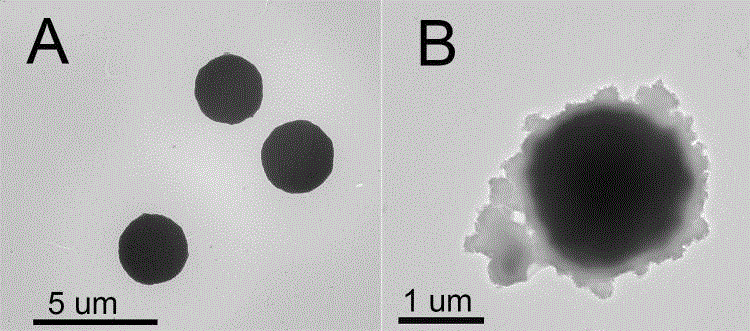

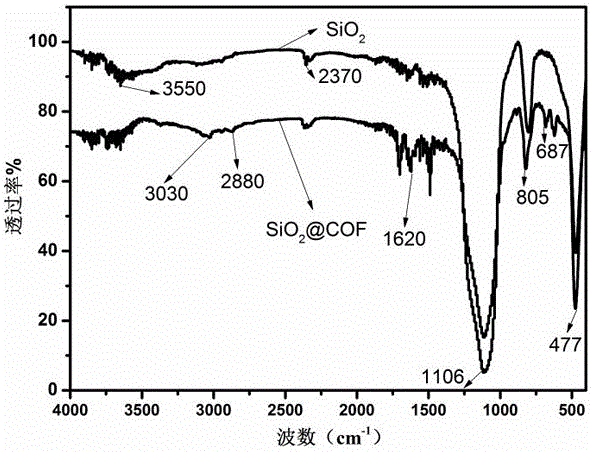

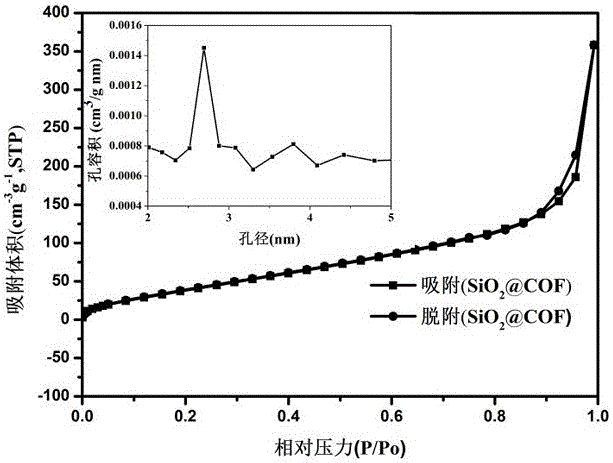

Preparation method of covalent organic framework composite microspheres with core-shell structures

InactiveCN107175053AMild preparation conditionsRaw materials are cheap and easy to getOther chemical processesDispersed particle separationMicrosphereSolid phase extraction

The invention relates to a preparation method of covalent organic framework composite microspheres with core-shell structures. The method comprises the following steps: dissolving silicon dioxide microspheres, a first construction element and a second construction element in an organic solvent; and after adding a catalyst, rapidly synthesizing into the composite microspheres with core-shell structures at a certain temperature. In a preparation process, reaction conditions are gentle, the method is simple, and the yield is high; the prepared covalent organic framework composite microspheres have the advantages of good core-shell morphology, high specific surface area, ordered pore structures, good mechanical stability, thermal stability, chemical stability and the like, if the microspheres are used as a chromatographic stationary phase, the chromatographic mass transfer resistance can be reduced effectively, the theoretical plate height is improved, and finally, column efficiency and degree of separation are improved; and if the microspheres are used as solid-phase extracting filler, the enrichment effect can be improved remarkably. The covalent organic framework composite microspheres with core-shell structures have good application prospects in the aspect of separation and enrichment of small organic molecules.

Owner:FUZHOU UNIV

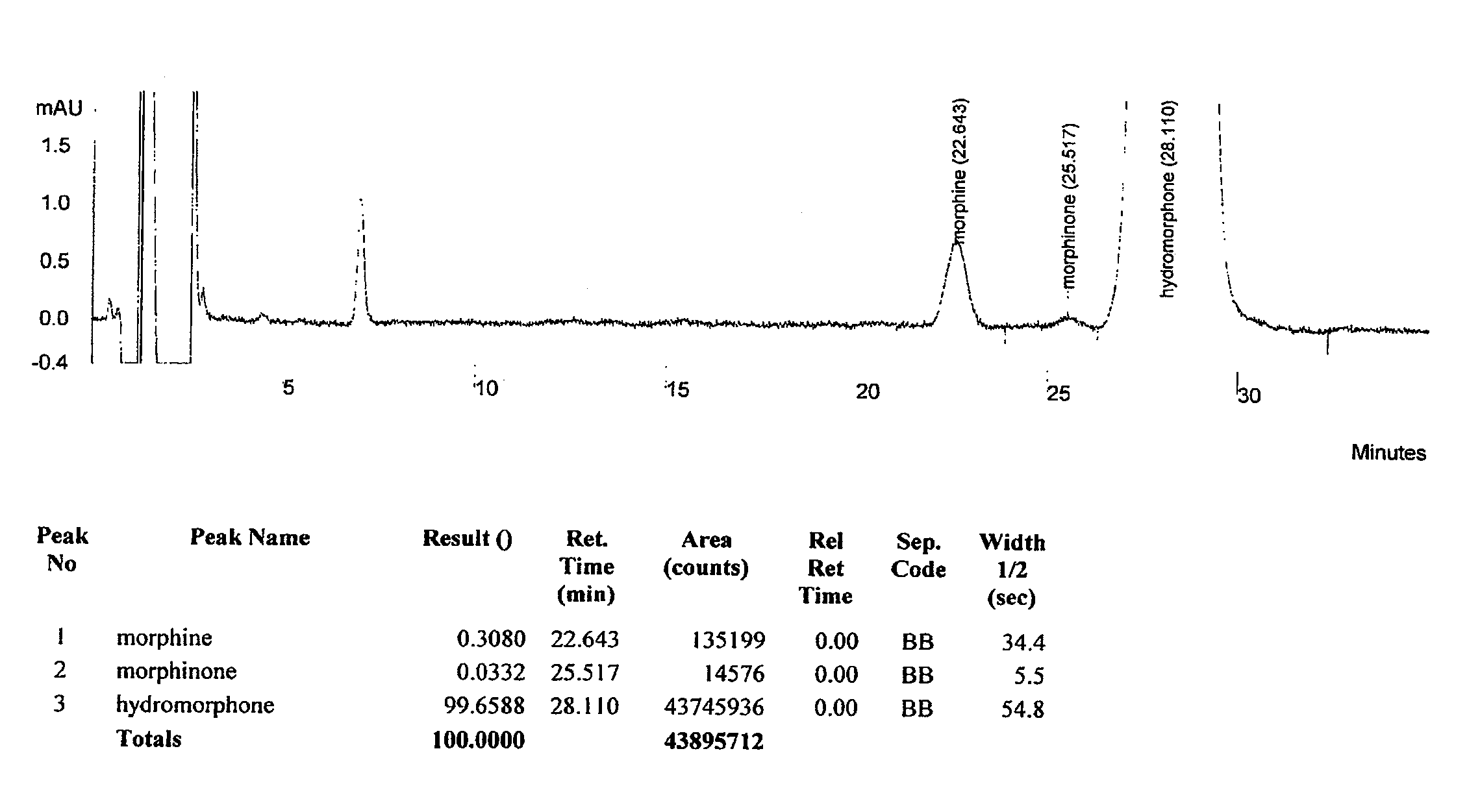

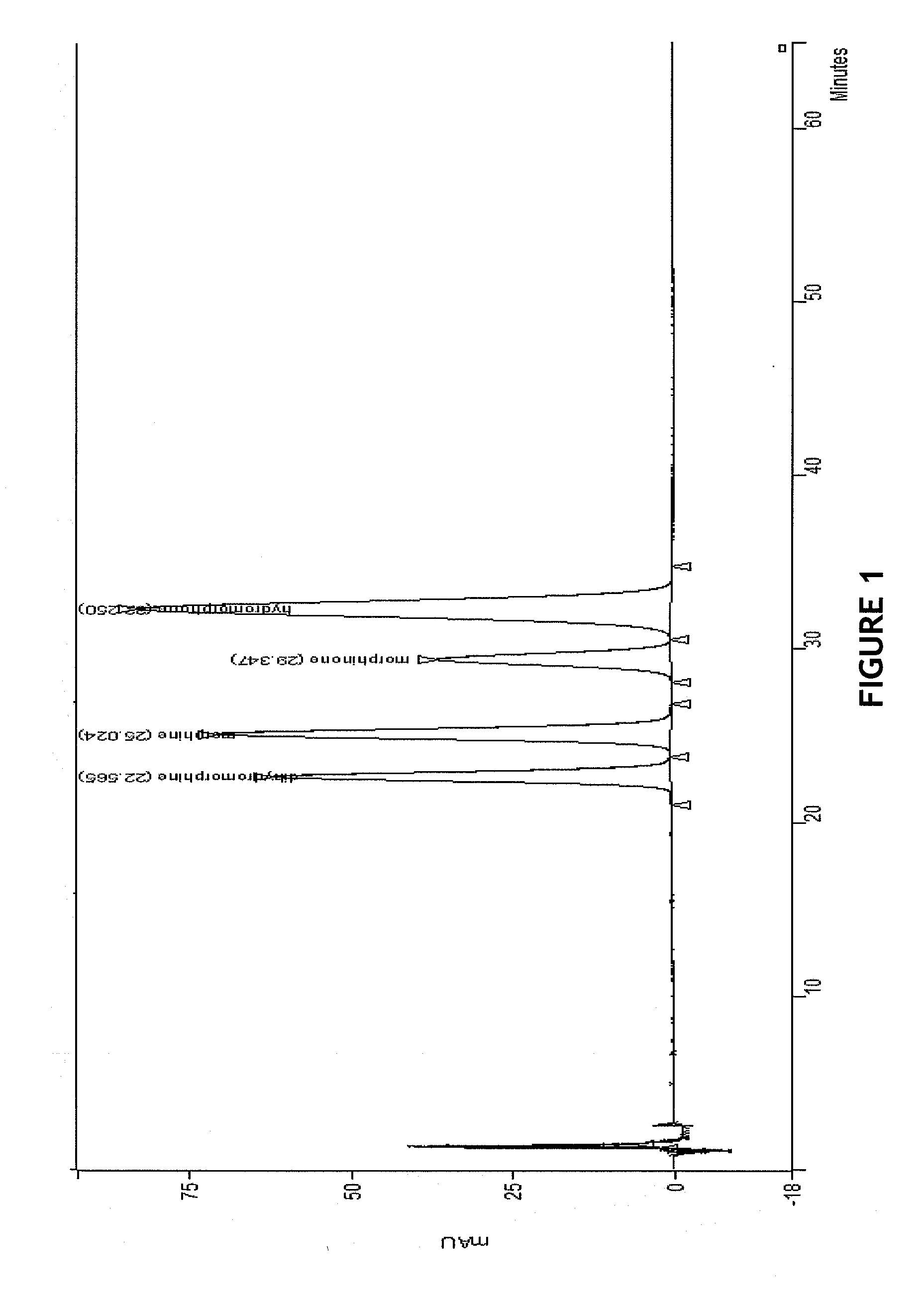

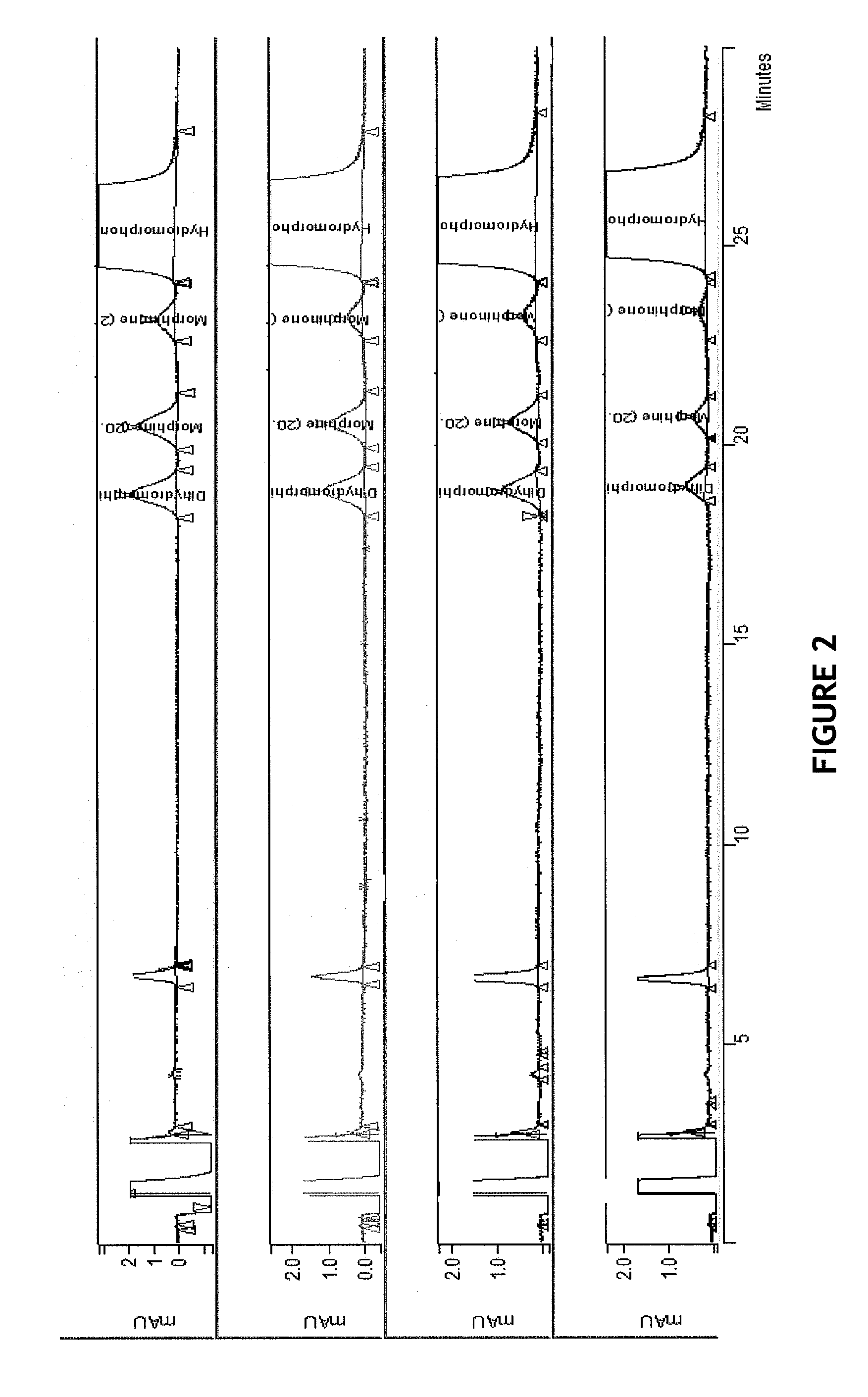

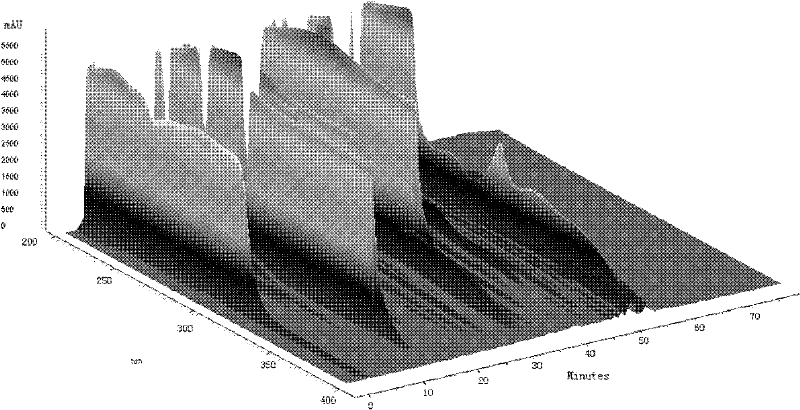

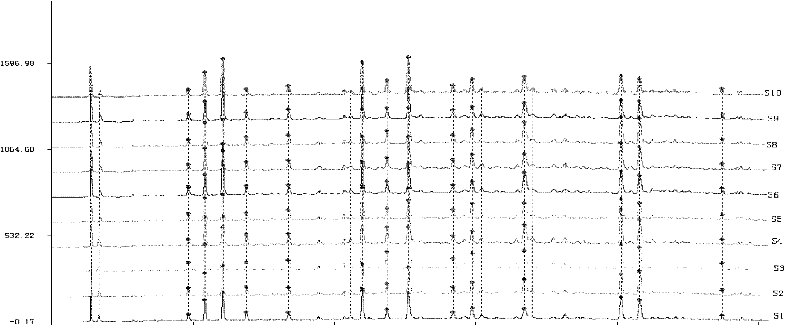

HPLC method for separation and detection of hydromorphone and related opioid pharmacophores

InactiveUS20080206883A1Component separationColor/spectral properties measurementsHplc methodPharmacophore

HPLC methods are provided to separate and detect morphinone, morphine, and dihydromorphine in the presence of hydromorphone. The isocratic HPLC methods employ ion-pair solute-solute ion-exchange mobile phase techniques in reversed phase chromatography. Method conditions in the disclosure provide separation and quantification of opioid pharmacophores in accordance with federal guidelines for obtaining resolution between analytes R≧2.0; tailing factor T≦2.0, capacity factor 2<k′≦50, and theoretical plate number N≧2000 for each opioid analyte peak.

Owner:CODY LAB

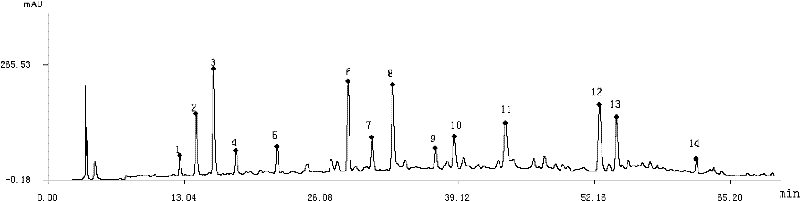

Method for establishing fingerprint spectrum of liver-enhancing medicine

ActiveCN102539553AEfficient separationEffective characterizationComponent separationColumn temperatureGradient elution

The invention provides a method for establishing a fingerprint spectrum of a liver-enhancing medicine. The liver-enhancing medicine is composed of oriental wormwood, isatis root, angelica, white paeony root, red-rooted salvia root, Radix curcumae, Astragalus mongholicus, Codonopsis pilosula, rhizoma alismatis, sealwort, rehmannia, yam, hawthorn, large-leaved gentian, liquorice and medicated leaven. The establishing method comprises the step of detecting paeoniflorin in the liver-enhancing medicine by using a high efficiency liquid chromatography method, wherein conditions are as follows: a chromatographic column takes octadecylsilane chemically bonded silica as a filling material; mobile phases comprise a mobile phase A which is acetonitrile and a mobile phase B which is an acidic water solution, and the mobile phases are subjected to gradient elution; the flow velocity is 1.0mL / min; the column temperature is 30 DEG C; the detection wavelength is 210nm to 400nm; and the number of theoretical plates is calculated according to the paeoniflorin peak and should not be less than 6000. The obtained fingerprint spectrum is a chromatographic peak which mainly takes active ingredients of the large-leaved gentian, the white paeony root, the liquorice, the red-rooted salvia root, the oriental wormwood and the astragalus mongholicus in raw materials of the liver-enhancing medicine as main parts. According to the establishing method provided by the invention, the fingerprint spectrum capable of comprehensively representing the active ingredients of the liver-enhancing medicine can be effectively obtained and has the characteristics of high precision, stability and repeatability. The obtained fingerprint spectrum can be used for guaranteeing the stability and consistency of the product quality, so that the safety and effectiveness of a product are guaranteed.

Owner:SHIJIAZHUANG DONGFANG PHARMA

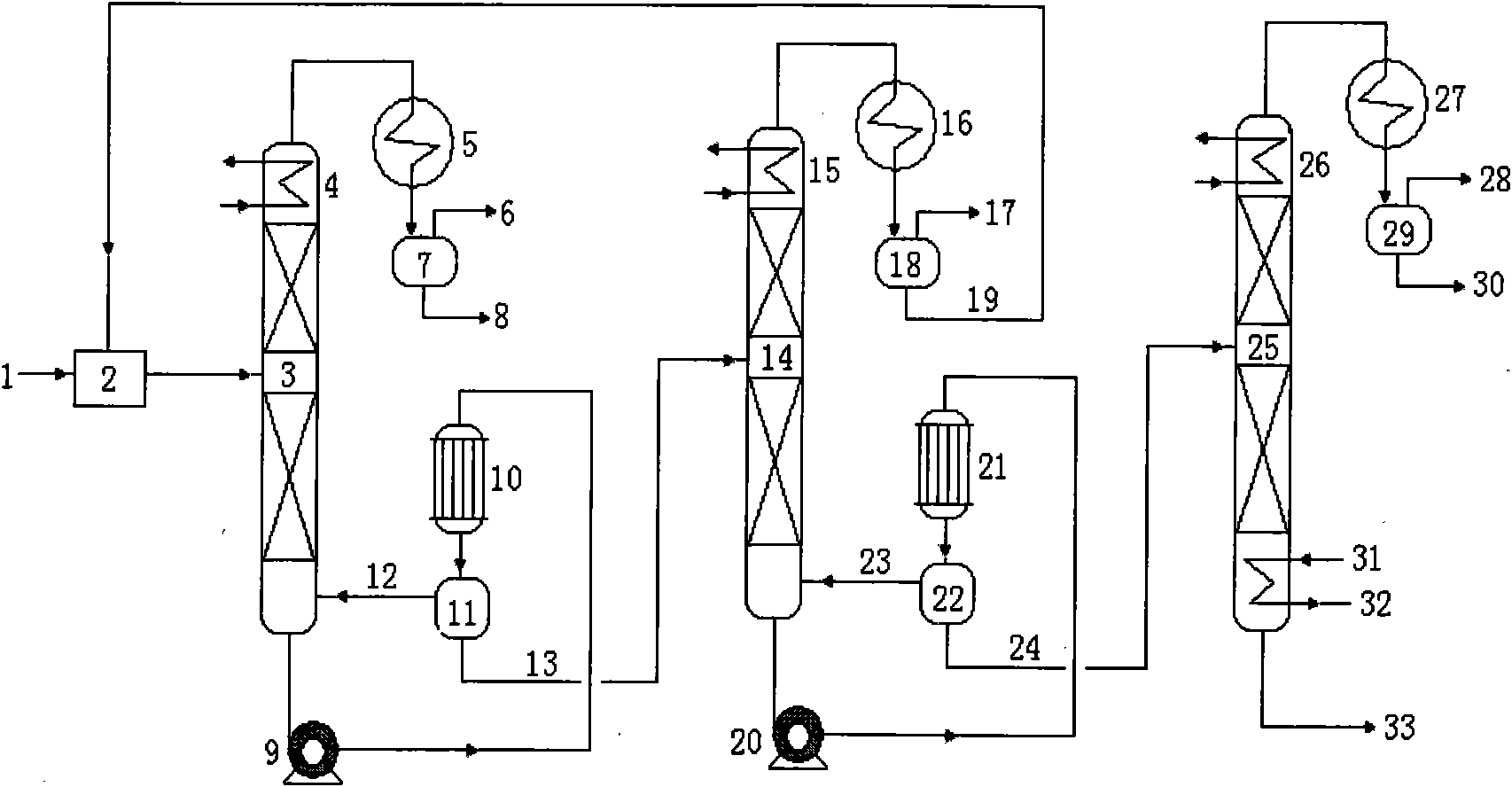

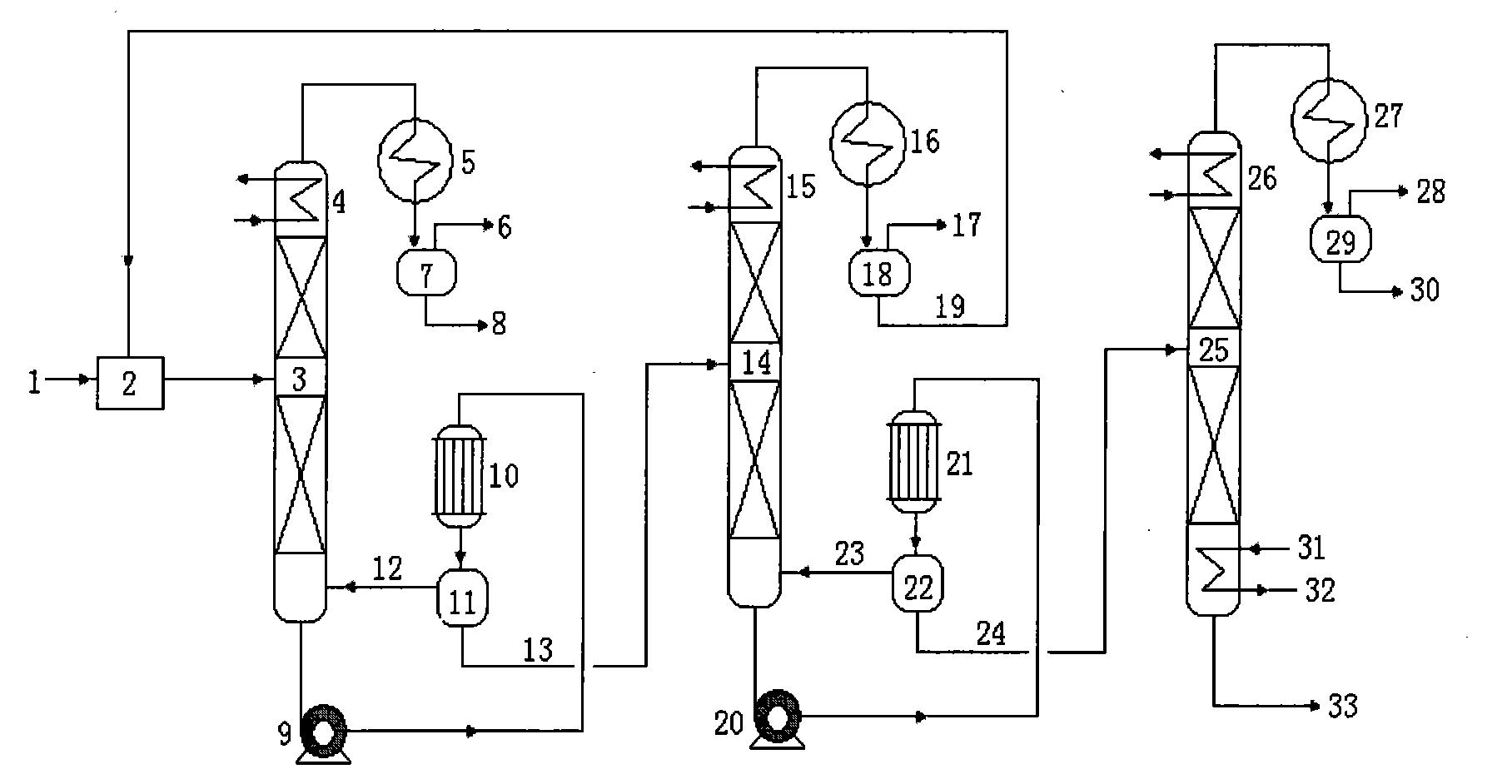

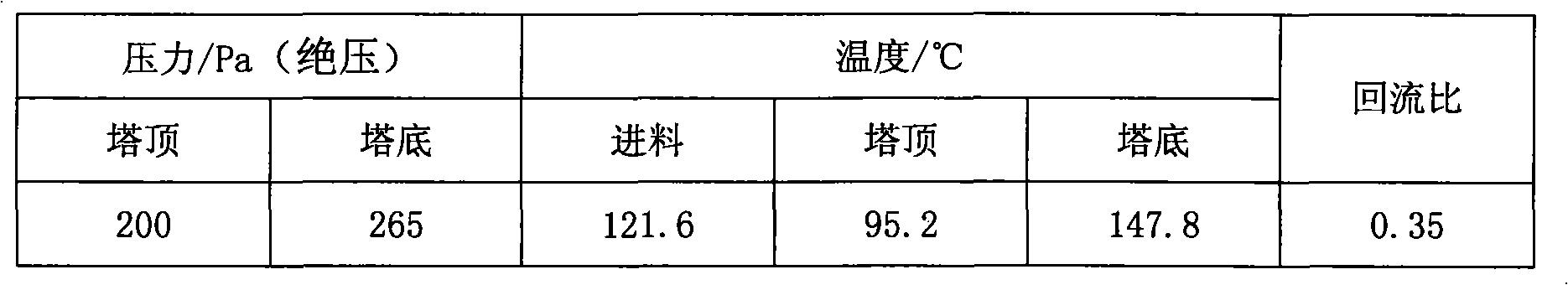

Continuous high vacuum rectification and purification method for lactide

InactiveCN101857585AImprove product qualitySave raw materialsOrganic chemistryVacuum distillation separationTheoretical platePurification methods

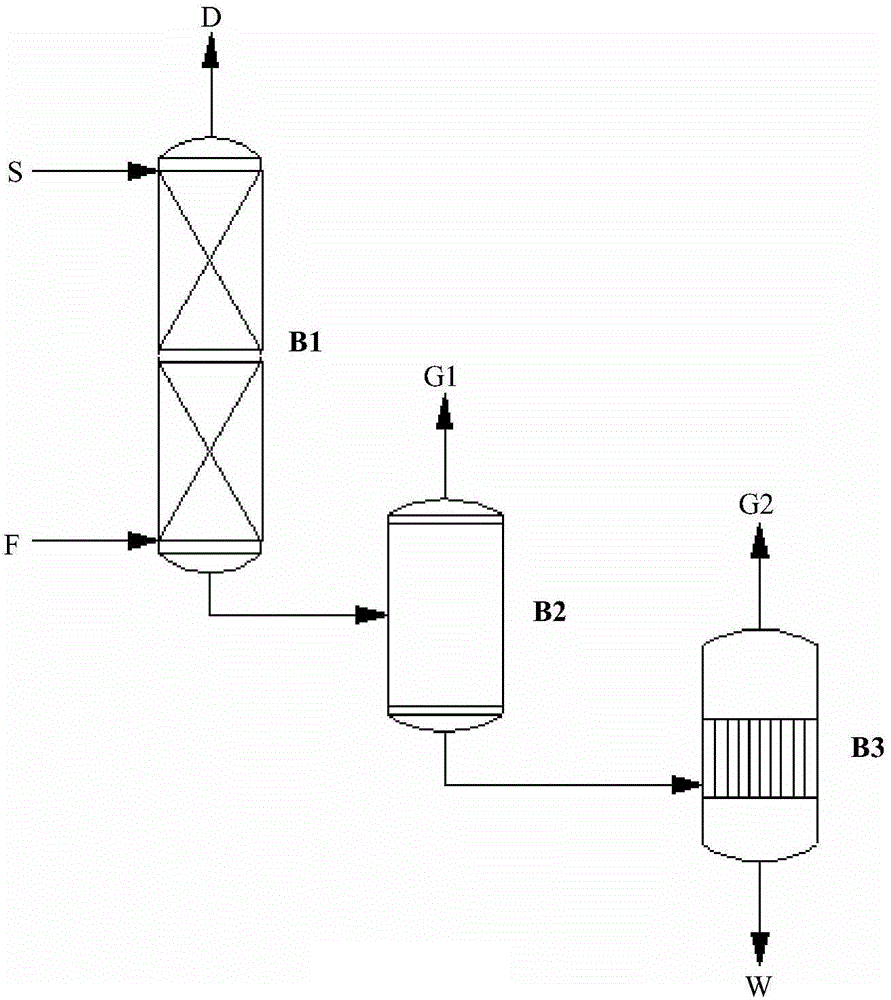

The invention discloses a method for continuously rectifying and purifying the lactide with high yield rate, which belongs to the field of chemical and industrial rectification and purification. The method comprises the following steps of removing low-boiling point components particularly including water, lactic acid and partial meso-lactide on a tower top through the vacuum operation of a first rectification tower; removing all the meso-lactide on a tower top through the vacuum operation of a second rectification tower; and obtaining high-purity lactide products on the tower top through the vacuum operation of a third rectification tower, wherein the first rectification tower has 12 theoretical plates, 8 rectification sections and 8 stripping sections; the second rectification tower has 15 theoretical plates, 6 rectification sections and 9 stripping sections; and the third rectification tower has 8 theoretical plates, 5 rectification sections and 3 stripping sections. All the three towers provide back flow in the mode of internal back flow. In the invention, the purity of the lactide is higher than 99%, and the yield rate is higher than 90%. Continuous operation is realized so that the quality of the products is stable, raw materials are saved and the production cost is reduced.

Owner:CHANGZHOU UNIV

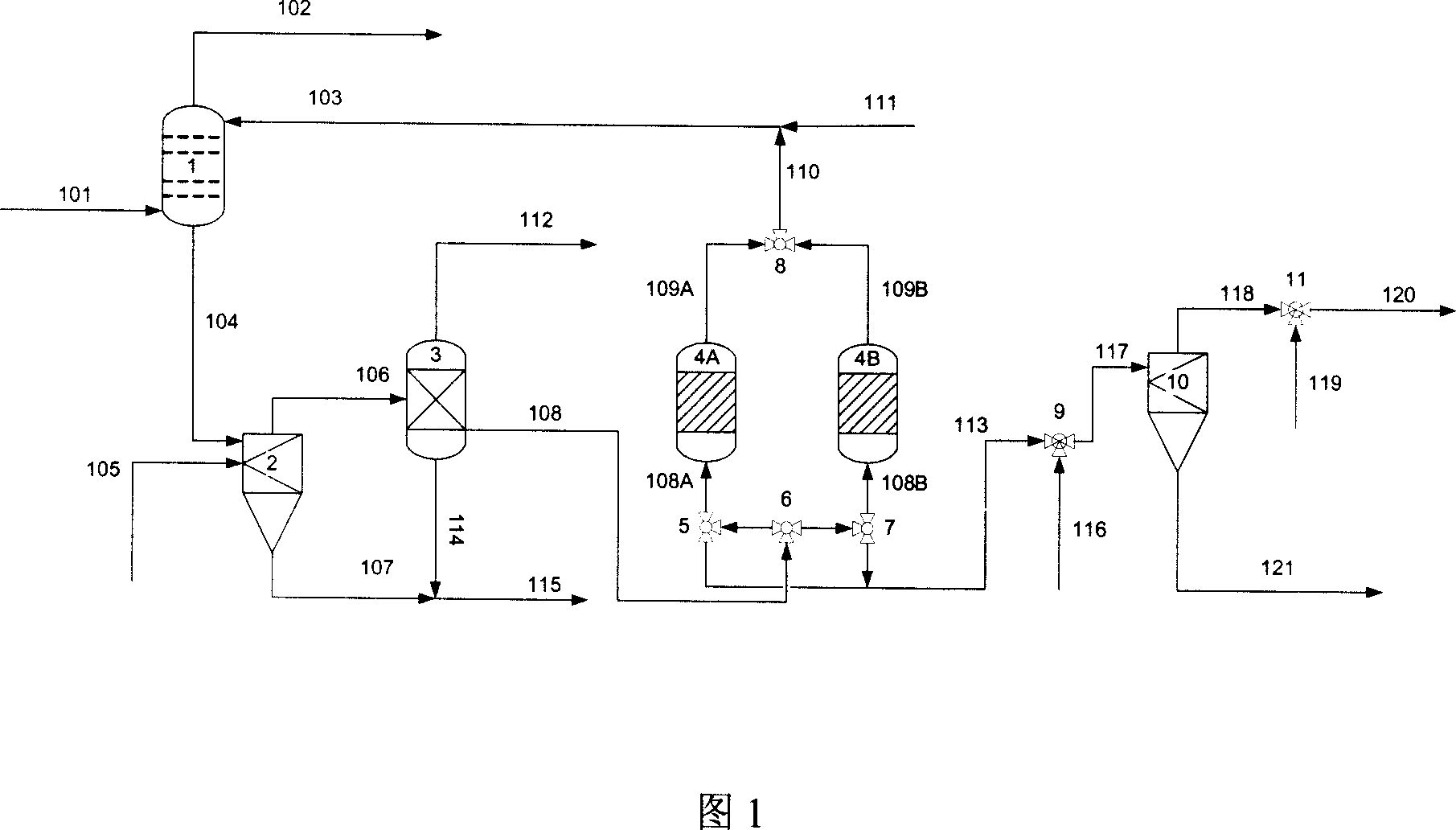

Method for treating wastewater of dilute thiamine

ActiveCN101092265AEfficient removalReduce dosageCalcium/strontium/barium sulfatesAmmonium carbonates/bicarbonatesIon exchangeIon-exchange resin

This invention relates to a method for treating diluted ammonium sulfate wastewater. The method solves the problems of high solid waste and organic nitrile impurity contents, low ammonium sulfate concentration, and difficult ammonium sulfate recovery. The method comprises: (1) removing solid impurities from diluted ammonium sulfate wastewater, adjusting the pH value to 6.5-7.5, performing flash evaporation, stripping or rectification, removing lightweight organic fractions at the overhead, collecting heavy fractions at the bottom, and extracting the rest ammonium sulfate wastewater at 1st-5th theoretical plates from the overhead; (2) sending the rest ammonium sulfate wastewater to ion exchange reaction, and removing NH4+; (3) treating regenerated liquid of the ion exchange resin with Ca(OH)2 aqueous solution to produce CaSO4 and diluted ammonia solution, performing solid-liquid separation, reacting CaSO4 and diluted ammonia solution with CO2 to obtain ammonium carbonate or ammonium hydrogen carbonate.

Owner:CHINA PETROLEUM & CHEM CORP +1

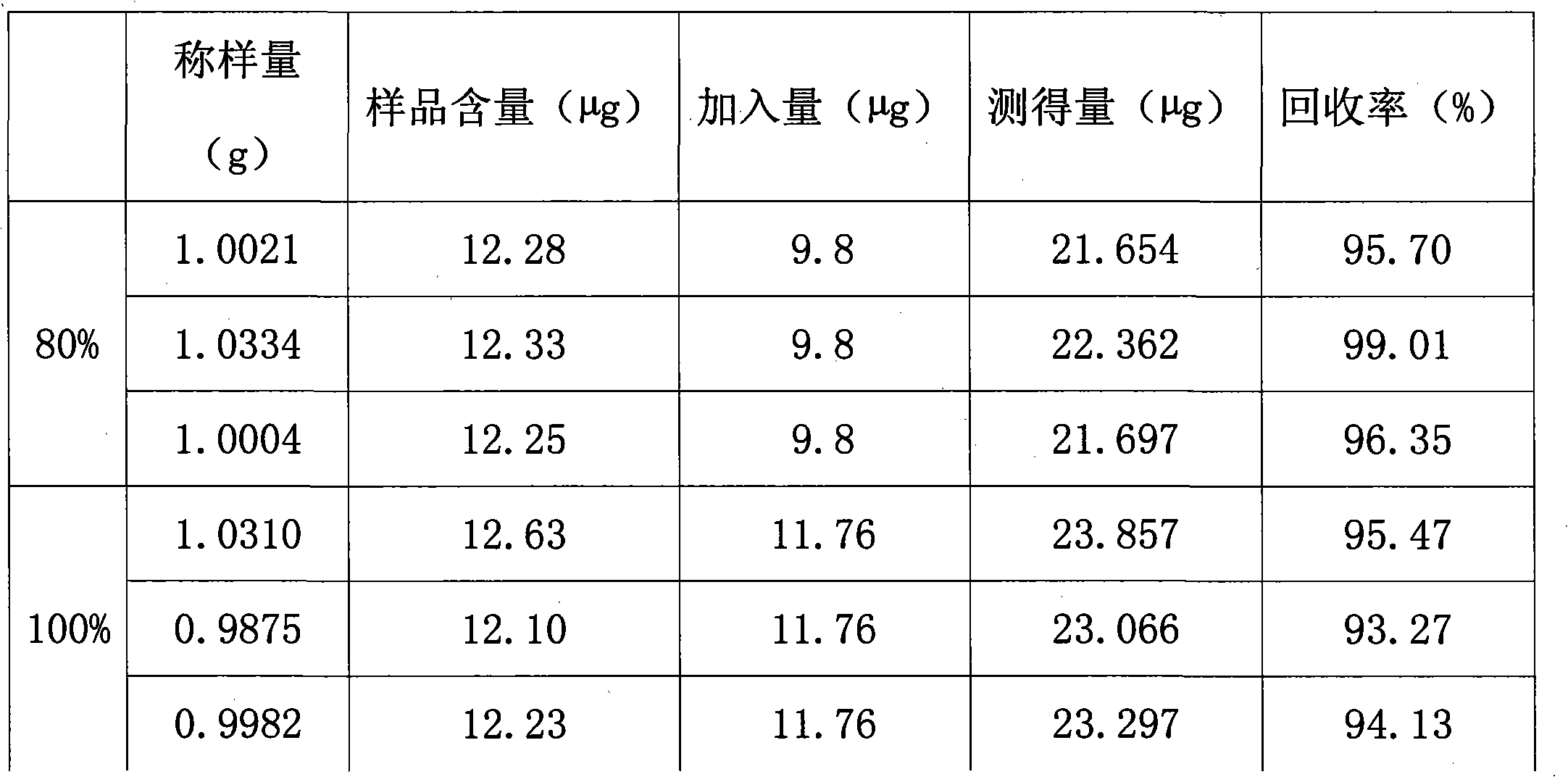

Method for detecting active ingredients in American cockroach extract

InactiveCN101957345AImprove securityImprove product qualityComponent separationBULK ACTIVE INGREDIENTSilica gel

The invention provides a method for detecting an active ingredient (3R) -3-methyl-7-hydroxymethyl-8-hydroxyl-3,4-dihydroisocoumarin-6-O-beta-D-glucopyranoside, namely KFX-4 in an American cockroach extract. In the method, high performance liquid chromatography (HPLC) is adopted, octadecylsilane chemically bonded silica is taken as a filler; methanol or acetonitrile-water (0-50:100-50 V / V) is taken as a mobile phase of which the flow speed is between 0.2 and 2.0 ml / min; the detection wavelength is one or more wavelengths of between 210 and 400 nanometers; a diode array detector is adopted; the sample size is between 5 and 50 mu l; theoretical plate number is not less than 4,000 when calculated according to a KFX-4 peak; the separation degree with a neighboring impurity peak is more than 1.5; chromatographic analysis is performed; and KFX-4 content is calculated by a peak area external standard method. An effective quality control method is provided for Chinese medicinal Kangfuxin solution and the method has a large practical value in the aspect of improving product quality and medicament safety.

Owner:ZHEJIANG JINGXIN PHARMA +1

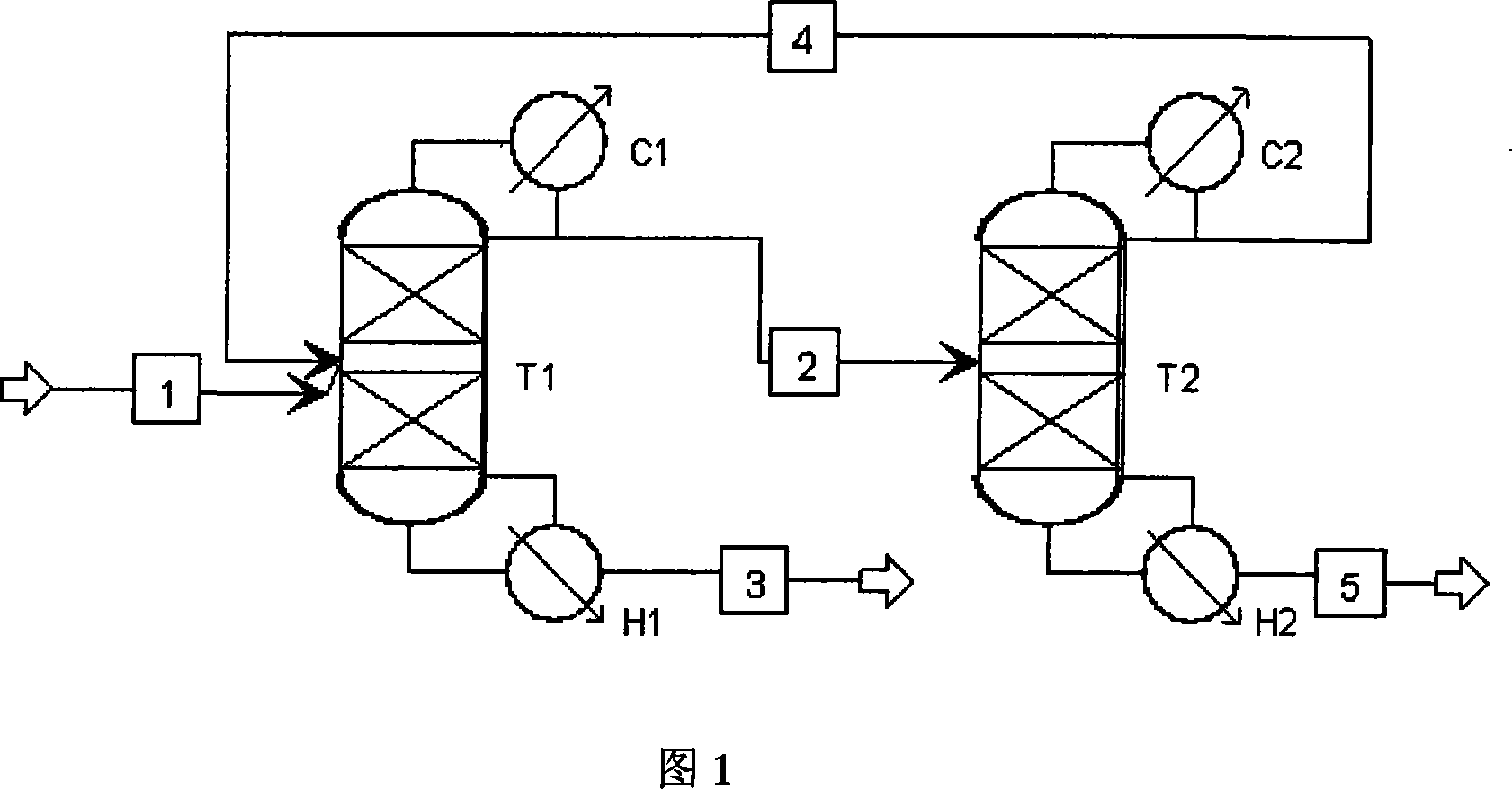

3-cyanopyridine absorption method

ActiveCN101045706AControl concentrationReduce lossesOrganic chemistryTheoretical plateLiquid temperature

This invention relates to a absorption approach of 3 - cyan pyridine, mainly solve the problem that while using circulating water solution to assimilate 3 - cyan pyridine in anciently literature, not involved with theoretical plate number of absorption column, weight proportion of liquid and air, as well as 3 - cyan pyridine easily hydrolyzing. This invention adopts two tandem circulation absorption columns. Control the concentration of 3 - cyan pyridine in first absorption column bottom at 3 to 10 percent of weight, the liquid temperature while circulating to overhead is 5 to 50 deg, theoretical plate number of absorption column is 2 to 20 pieces, weight proportion of liquid and air is 2 to 15. The weight ratio between liquid circulating to second absorption column overhead and circulating to first absorption column overhead is 0.25 to 0.8.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

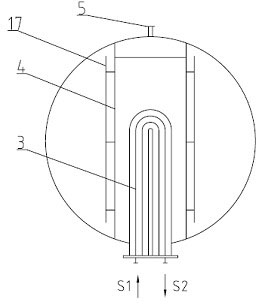

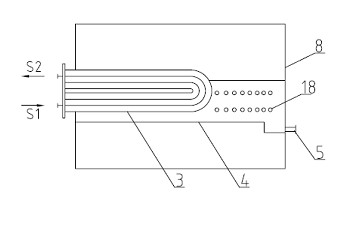

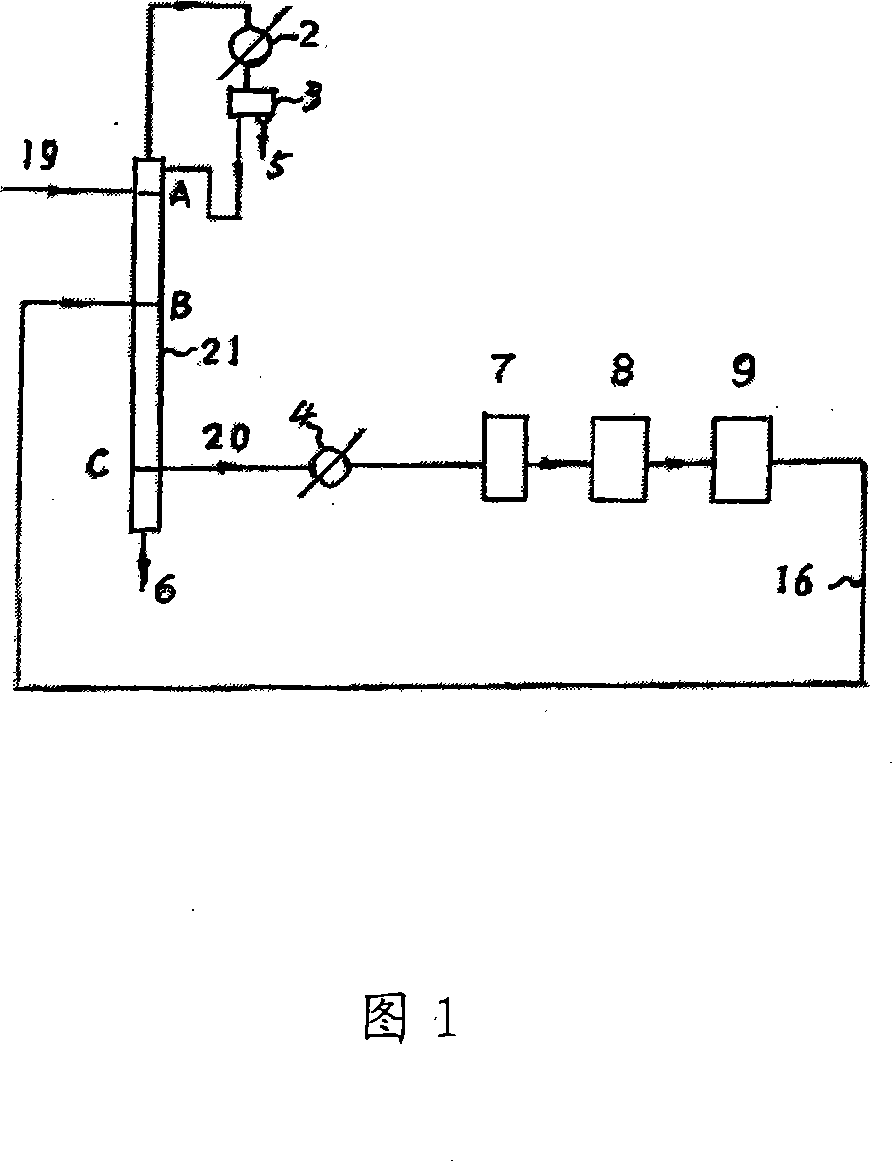

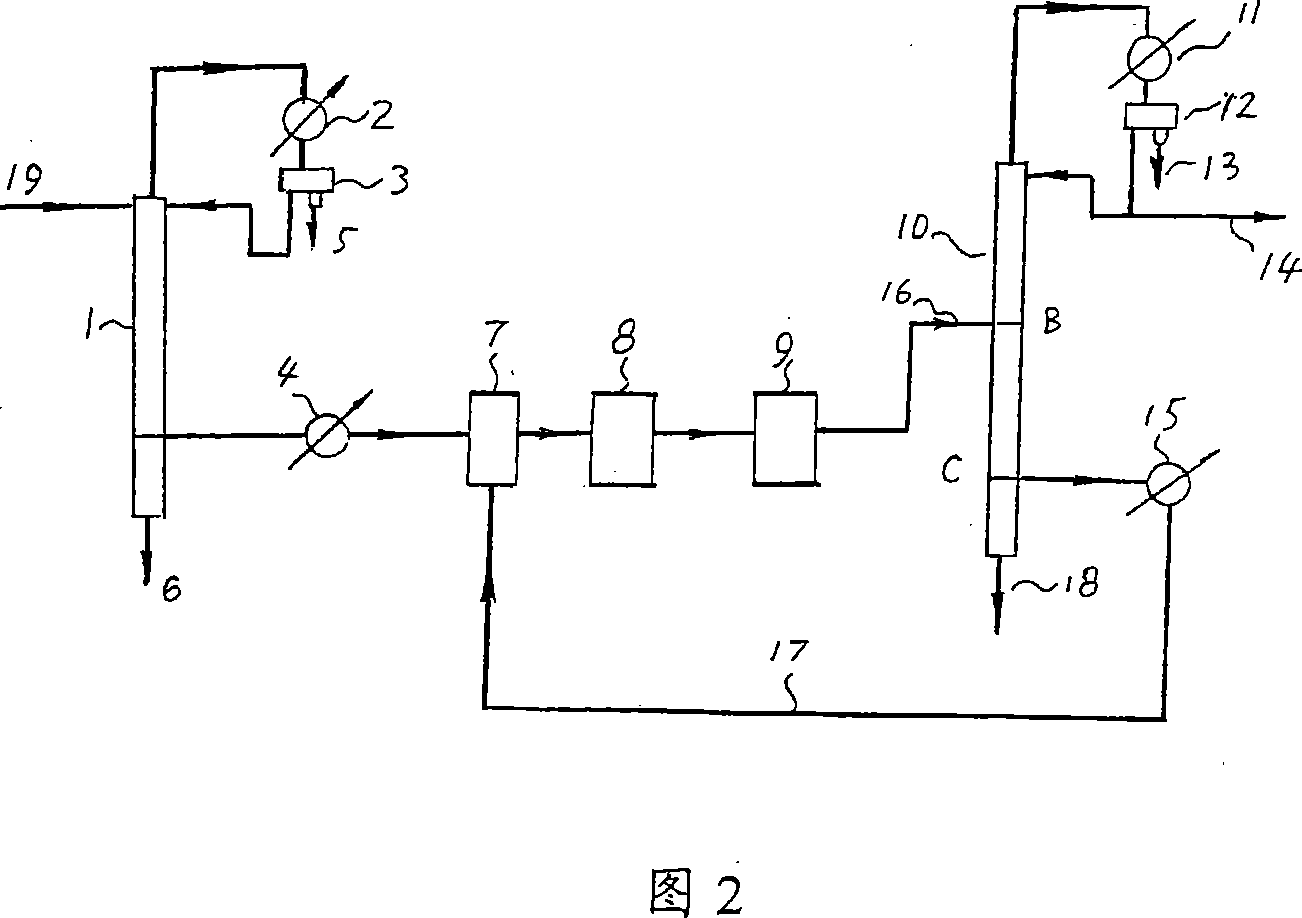

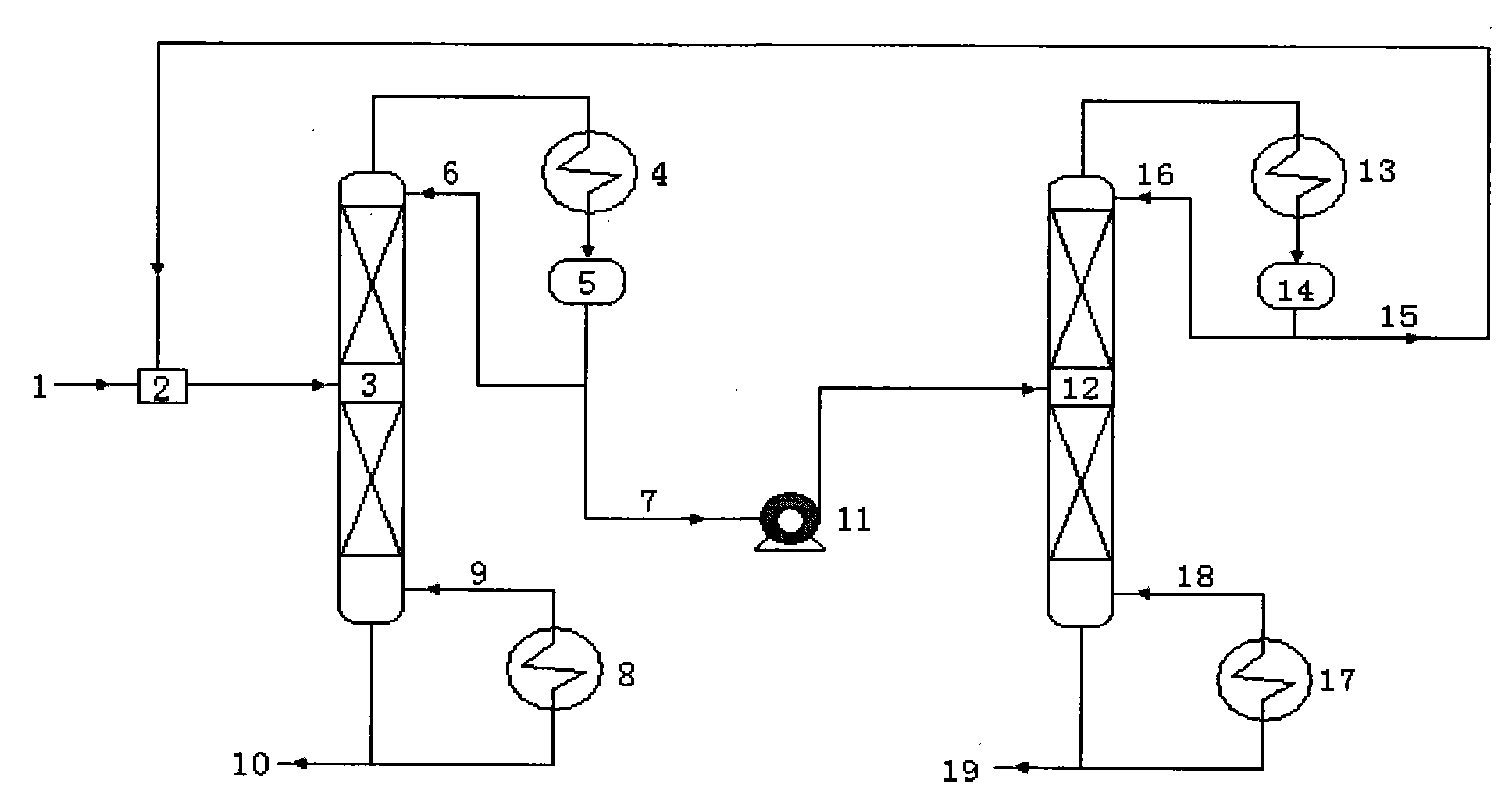

Rectifying tower flow controllable type lateral-line extraction combined device

The invention relates to a rectifying tower flow controllable type lateral-line extraction combined device, which is mainly used for the precisely controlled extraction process of gas phase lateral-line products in the rectifying tower. The rectifying tower flow controllable type lateral-line extraction combined device comprises a liquid collecting device, an inserted type condenser, a condensate collecting groove and a demister, wherein the principle of the device is as follows: the liquid and gas are reasonably divided, the phenomenon that the rising gas phase contains the liquid is avoided, and then the rising gas phase is partially condensed into liquid phase by the inner inserted type heat exchange device and is partially laterally extracted. By using the device, the difficulties that the flow is difficult to measure and control when the gas phase lateral-line extraction is performed in the rectifying tower are overcome, and at the same time, the gas phase partially condensation is equivalent to adding a layer of theoretical plate. The device has compact structure, is suitable for the rectifying tower which requires laterally extracting high-purity products in stripping section, and is in particular suitable for the separation process for high vacuum heat-sensitive materials.

Owner:NANJING UNIV

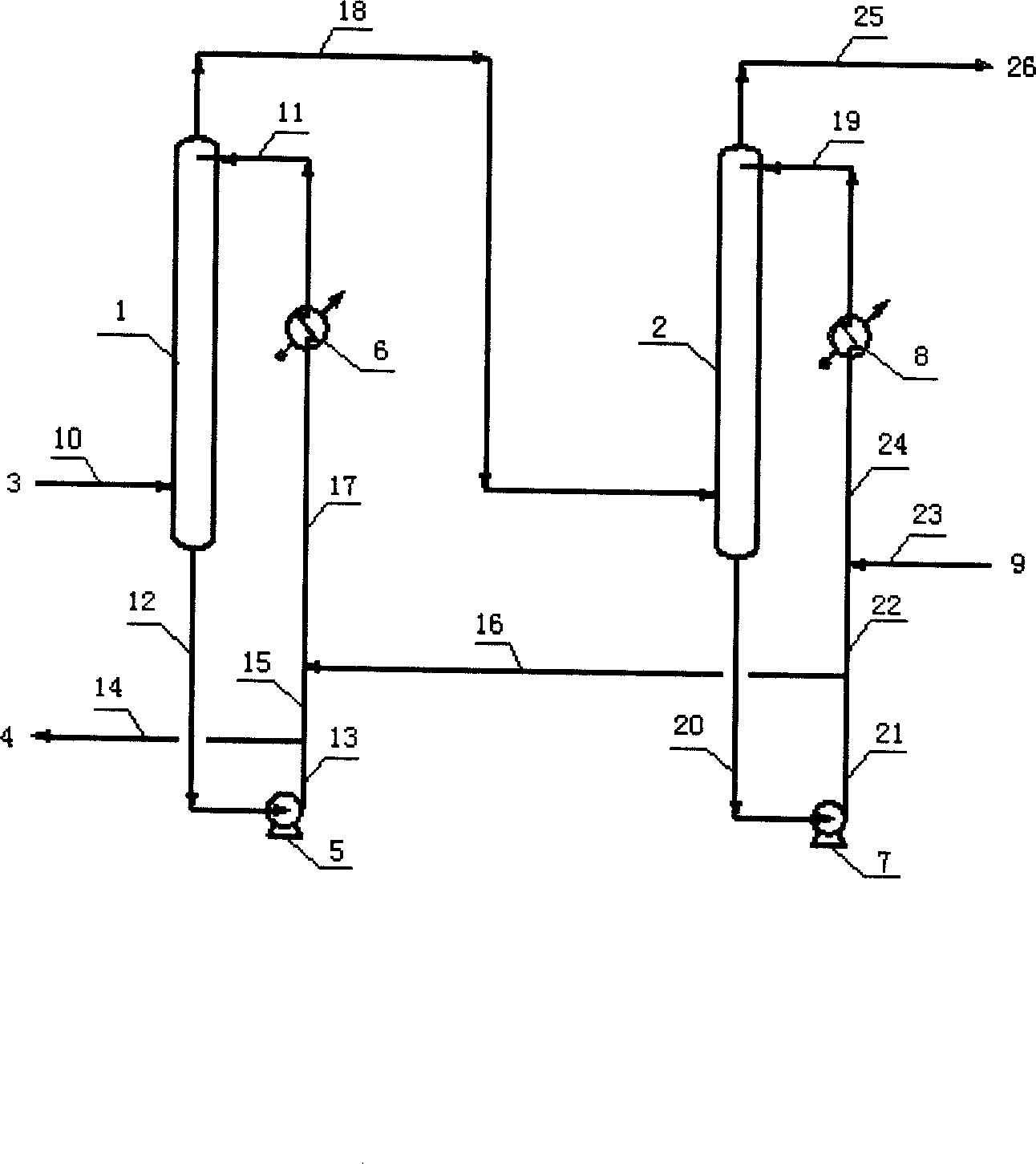

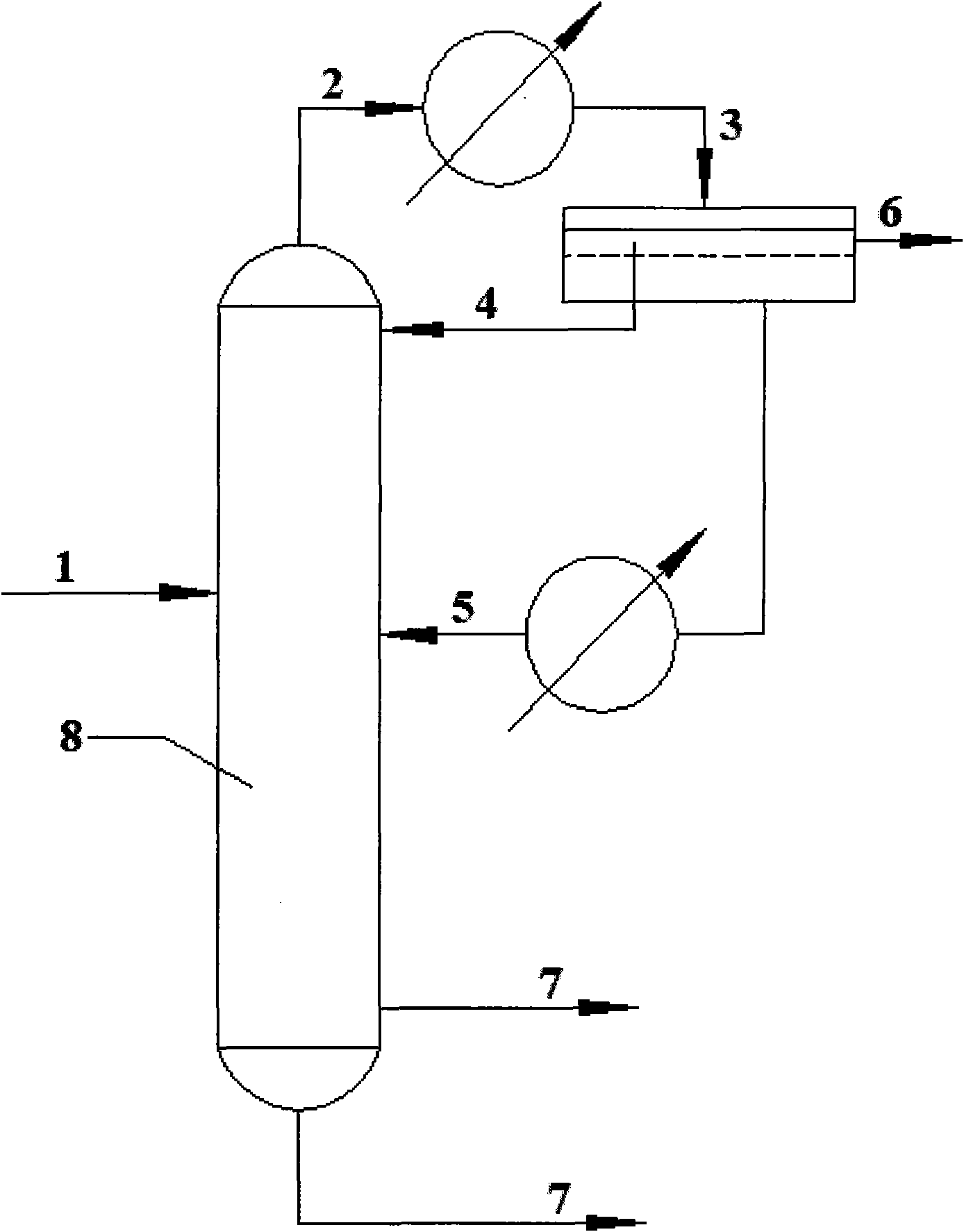

Method for separating glycol and 1,2-butanediol

InactiveCN103772146AReduce solubilityImprove solubilityOrganic compound preparationHydroxy compound preparationTheoretical plateReflux

The invention relates to a method for separating glycol and 1,2-butanediol, which mainly solves the problems of high investment and energy consumption due to the fact that a very high reflux ratio and very high number of theoretical plates are required when a common rectification method is employed to separate and purify a material flow containing glycol and 1,2-butanediol, and severe separation conditions or a non-ideal separation effect when a common azeotropic rectification method is employed. The method better solves the problem by employing the technical scheme that the material flow containing glycol and 1,2-butanediol and a reactor enters from the upper part and the lower part of a reaction-azeotrope rectification tower respectively, a generated reaction product forms an azeotrope with glycol at the same time, a tower kettle obtains a material flow containing 1,2-butanediol, and after the azeotrope distilled from the tower top is subjected to condensation phase splitting, a glycol-rich phase at the lower layer is further refined to form a glycol product. The method can be used for industrial production of separating the material flow containing glycol and 1,2-butanediol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for refining sec-butyl acetate coarse products through dual-reflux and preparation method of sec-butyl acetate

ActiveCN102584575AHigh purityWill not cause excessive water contentOrganic compound preparationCarboxylic acid esters preparationRefluxTheoretical plate

The invention provides a method for refining sec-butyl acetate coarse products through dual-reflux and a preparation method of sec-butyl acetate comprising the refining process. The refining method of the sec-butyl acetate coarse products comprises (1) enabling the sec-butyl acetate coarse products to feed in a rectifying tower through a first feed port, enabling the water to feed in the rectifying tower through a second feed port in a water vapor mode, conducting azeotropy rectification under operation conditions of the azeotropy rectification, and obtaining mixture mainly containing water and impurities from a tower top; and (2) cooling the mixture, conducting oil-water separation to obtain the water phase and the oil phase, enabling reflux maters at least containing partial oil phase to flow back the rectifying tower, enabling at least partial water phase to form the water vapor and returning the water vapor to return and add in the rectifying tower from a third feed port. The second feed port and the third feed port are same or different, and both located at the position of 1-10 tower boards or theoretical tower boards below the first feed port. The method can be used for preparing the sec-butyl acetate with high purity.

Owner:HUIZHOU YUSSEN CHEM CO LTD

Recovery and using method of solution and unreaction monomer in process of producting polymer by solution polymerization process

This invention relates to reutilization method of solvent and not reaction monomer in process of producing polymer by solution polymerization method. Cohesion oil phase input stuff at middle of refining recovery tower that 10 to 40 pieces theoretical plate number distance from tower top; supplement of greenness monomer input stuff at refining tower that 5 to 15 pieces theoretical plate number distance from tower top; the monomer distilled off from tower top takes regurgitation by infinite reflux or large reflux ratio, and abstract free water from return tank; the inert constituents which enrich in monomer and most is mono-alkenes recovered from tower top; solvent and monomer transit dehydration zone of reclaim refining tower stripping section, siding recovered by vapor phase at 5 to 15 pieces theoretical plate number distance from top, by freezing and adsorption refining, then for directly use after polymerization process; Tower bottoms that enrich heavy constituents recovered from tower pot. It just adopts a dephlegmator for produce, be able to extensively used in solution polymerization of different kinds of polymer, especially isoprene rubber and CPBR.

Owner:FUSHUN YIKESI NEW MATERIAL

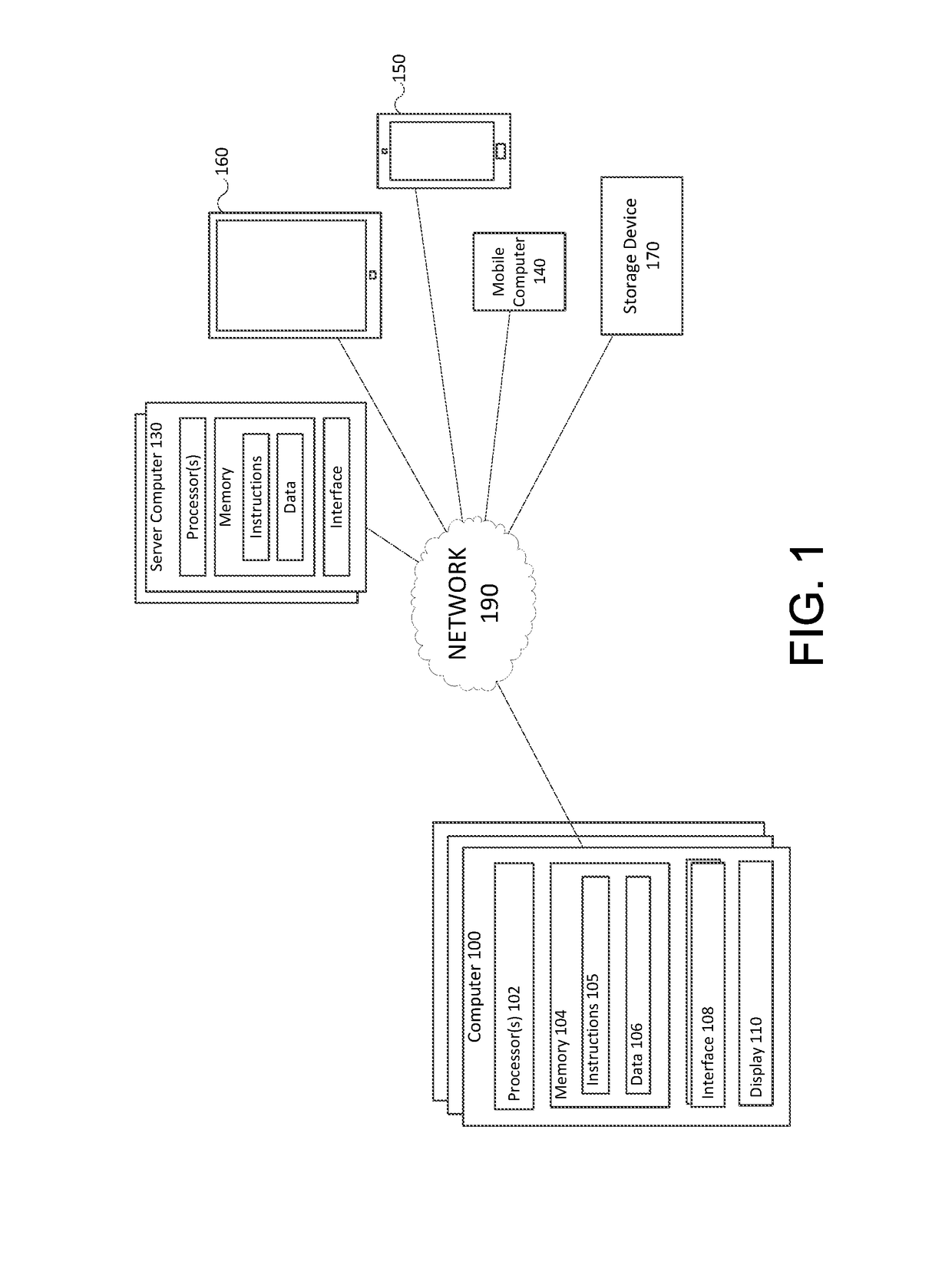

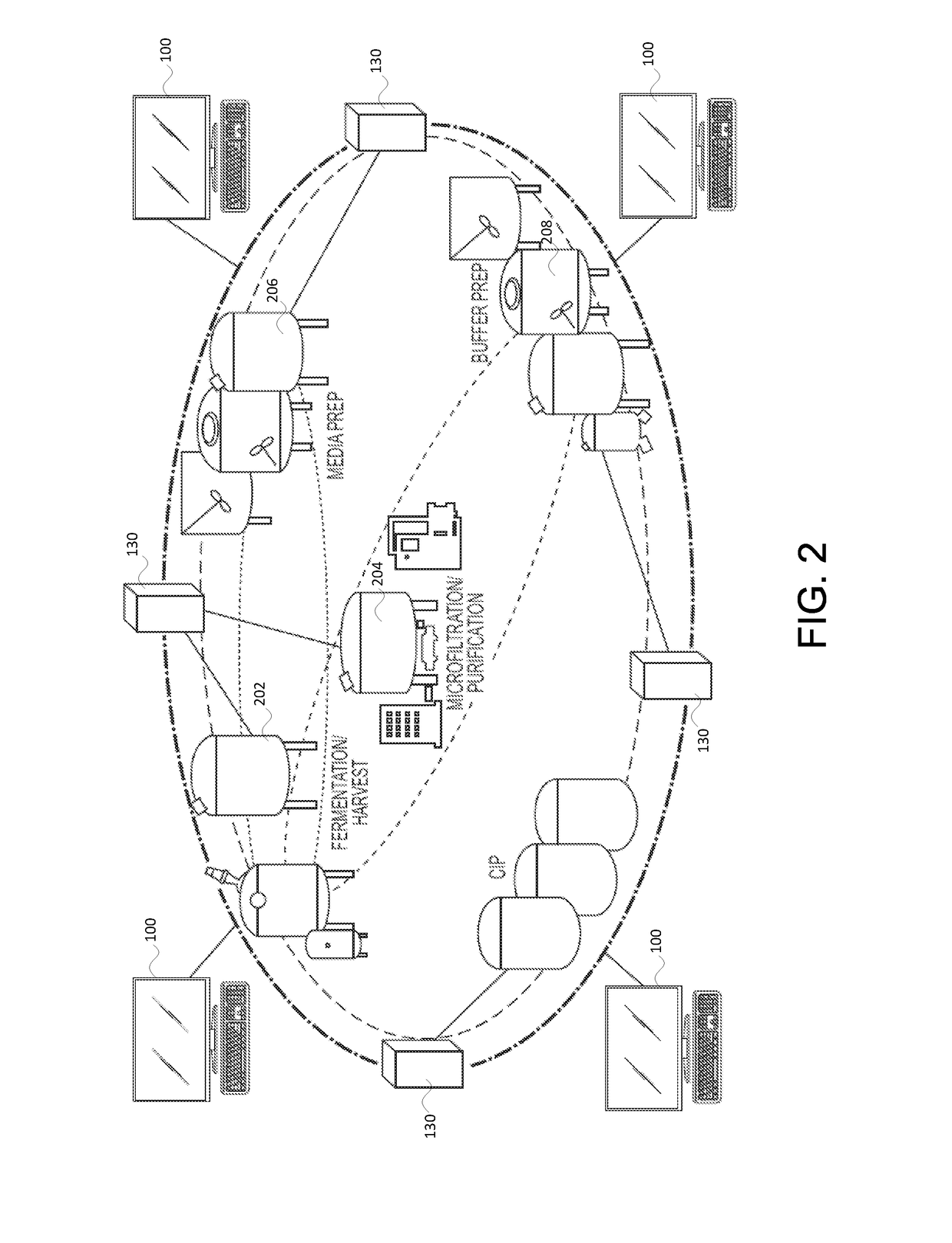

System and Method for Regulating Cell Culture Based Production of Biologics

ActiveUS20170107476A1Bioreactor/fermenter combinationsBiological substance pretreatmentsReal time analysisChromatography column

The disclosure is directed to a system and method for control of at least one bioreactor, other cell cultivation-related equipment, and systems containing any combination of these in a plant. For example, a Plant-Wide Control System (PWCS) or a Process Control System (PCS) may be divided into three main components: hardware (including operating systems, such as a controller communicating with one or more servers of a network associated with the PWCS, (2) software (such as a control module) for performing control, and (3) one or more instrument control loops, which may be used by the software to maintain certain process values. Moreover, a Height Equivalent of a Theoretical Plate (HETP) value and an asymmetry factor may be determined based on real-time analysis on a chromatography column, using PWCS components.

Owner:LONZA LTD

Method for treating wastewater of dilute thiamine containing acrylonitrile

ActiveCN101092266AImprove recycling qualityQuality improvementWater/sewage treatment by neutralisationWater/sewage treatment by heatingPropionitrileAcrylonitrile

This invention relates to a method for treating diluted ammonium sulfate wastewater containing propionitrile. The method solves the problems of high solid waste and organic nitrile impurity contents, low ammonium sulfate concentration, difficult ammonium sulfate recovery, and low recovered ammonium sulfate quality. The method comprises: (1) removing solid impurities from diluted ammonium sulfate wastewater containing propionitrile, and adjusting the pH value to 6.5-7.5 to obtain material flow 1; (2) sending material flow 1 into a liquid-gas separator, and performing stripping or rectification; (3) removing lightweight organic fractions at the overhead of the liquid-gas separator, collecting polymer fractions at the bottom, extracting the rest wastewater at 1st-5th theoretical plates from the overhead to obtain material flow 2, extracting water free of solids and organic matters from 1st-10th theoretical plates from the bottom to obtain material flow 3, mixing material flow 3 with water added by the quenching system and diluted acid, circulating to the quenching column, and recovering ammonium sulfate from material flow 2.

Owner:CHINA PETROLEUM & CHEM CORP +1

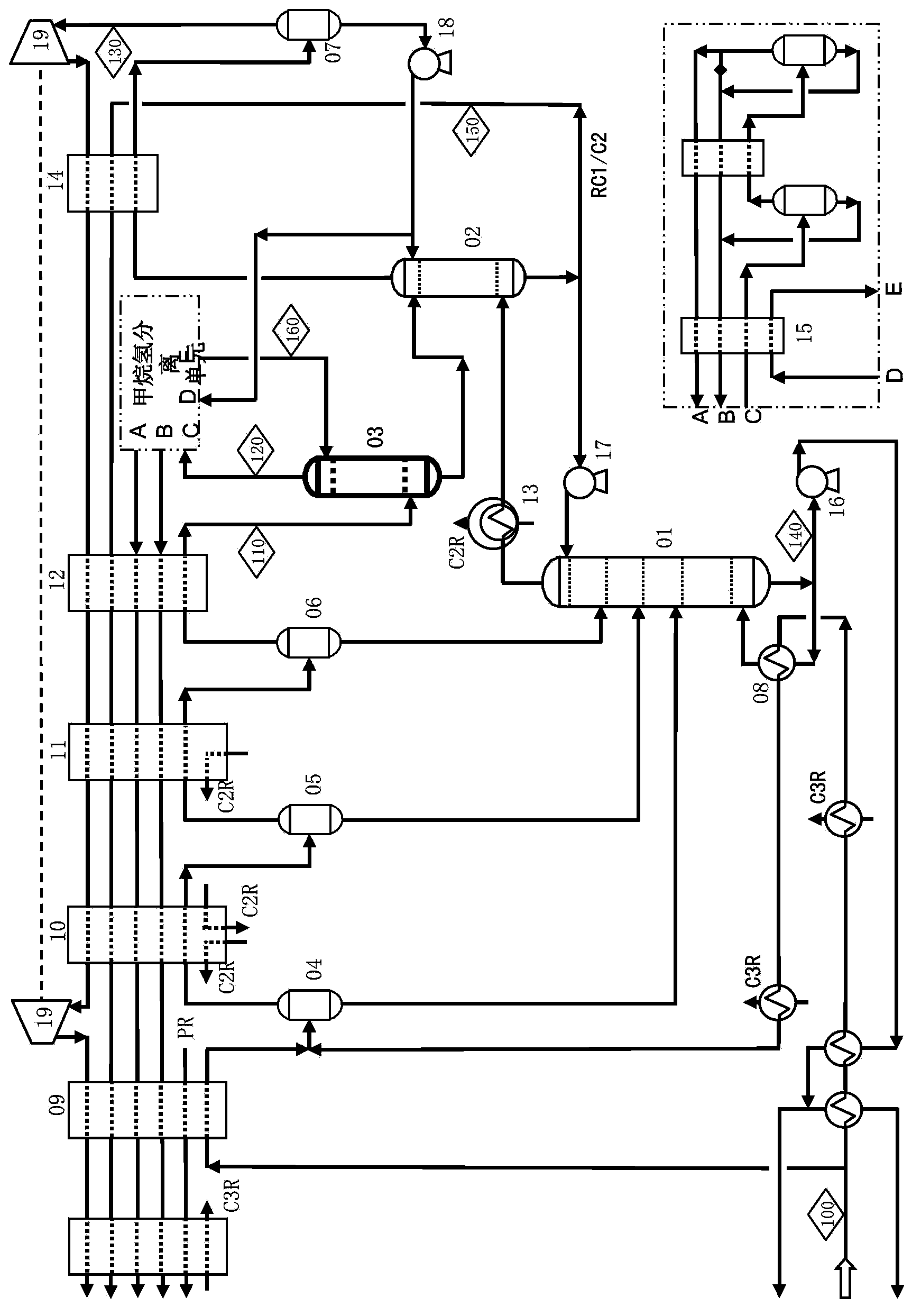

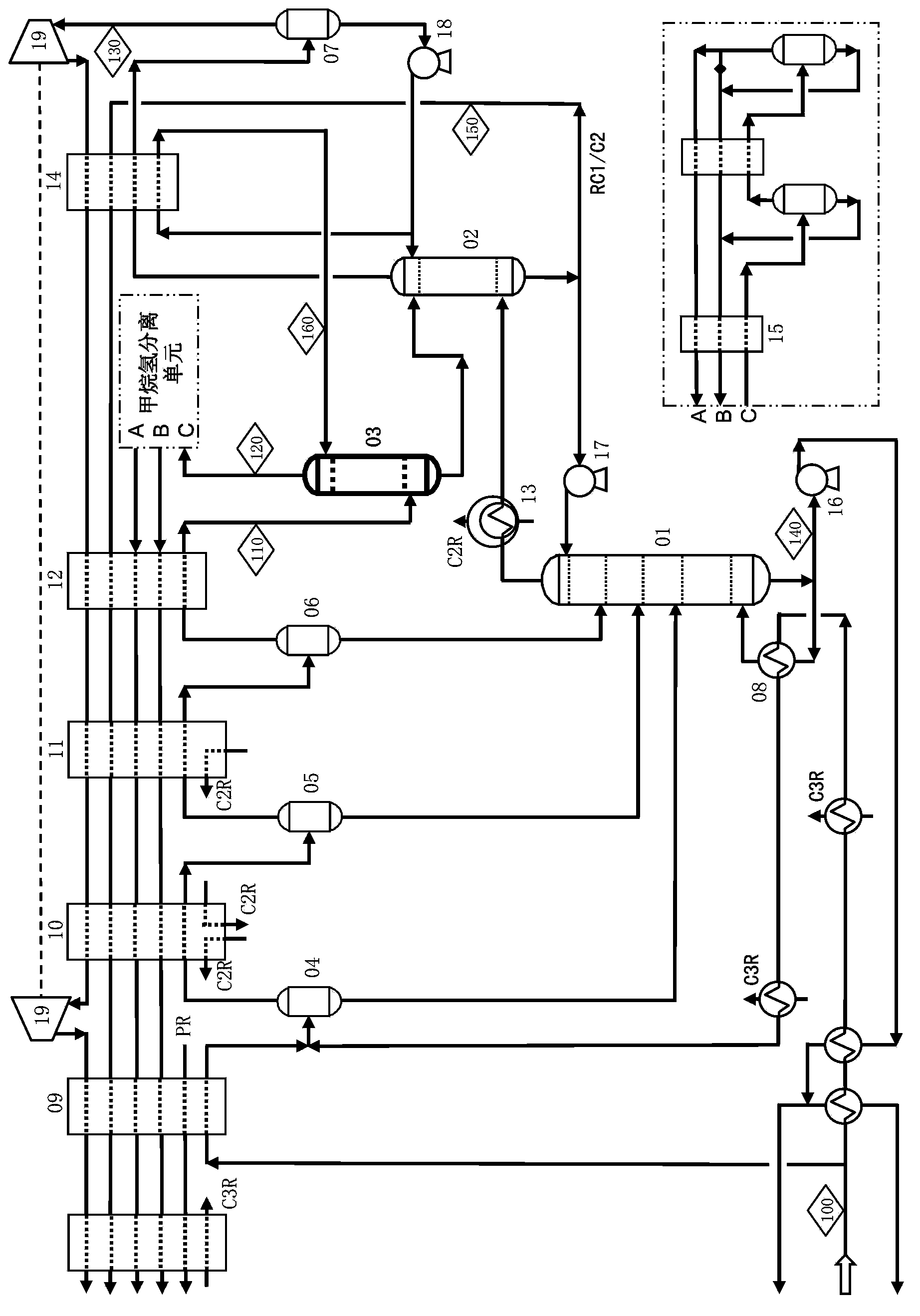

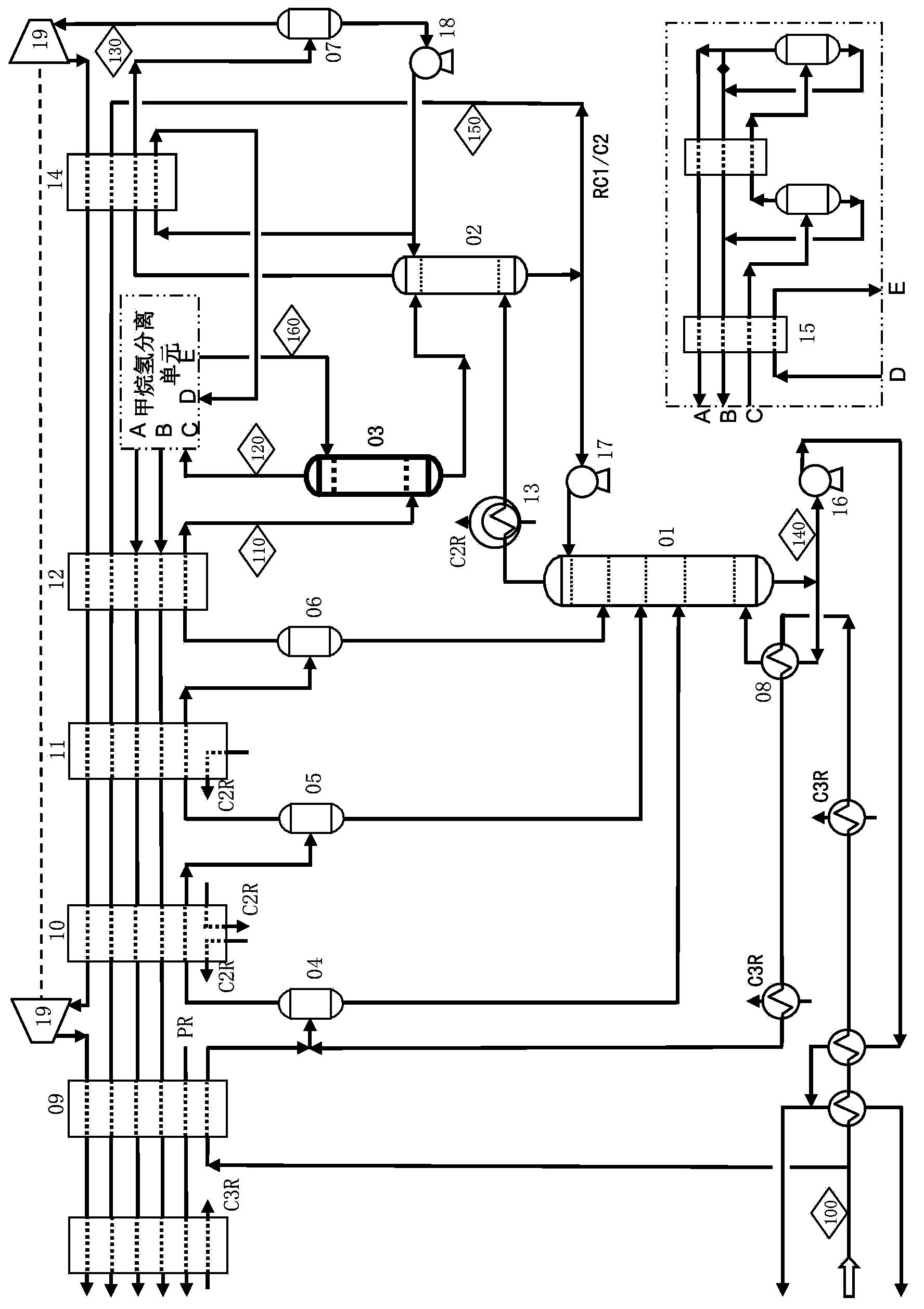

Method and system for recycling ethylene in tail gas through barren liquor effect in demethanization process

ActiveCN103449950AThe effect of loss is superiorReduce energy consumptionSolidificationLiquefactionTheoretical plateReflux

The invention relates to a method and system for recycling ethylene in tail gas through barren liquor effect in the demethanization process. The method comprises the following steps of: separating nine tenths of hydrogen and a part of methane from feedstock by matching an absorption tower with all levels of separating equipment of chilling series at the front end, and then leading another part of methane and nine tenths of C<2+> to enter a fractionation tower for fractionation. In the processes, ethylene possibly lost in the tail gas can be more thoroughly recovered by using the characteristic that the C<2+> is superiorly dissolved by an absorbent of the absorption tower. The absorbent of the absorption tower is barren liquor coming from the interior of the system, namely a part of reflux of the fractionation tower, thus showing the barren liquor effect. compared with the prior art that levels of the chilling series at the front end are changed into the fractionation subsystems with multiple theoretical plates, the method and the system are more excellent in effect on controlling the loss of ethylene in the tail gas, lower in energy consumption, and lower in investment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Separating method for ethylene-glycol and 1,2-butanediol

ActiveCN103772147AReduce solubilityReduce lossesOrganic compound preparationHydroxy compound preparationTheoretical platePhase splitting

The invention relates to a separating method for ethylene-glycol and 1,2-butanediol and mainly solves the problems that when the ethylene-glycol and the 1,2-butanediol are separated and purified in the prior art, a common precise distillation method requires very high reflux ratio and theoretical plate number, resulting in large investment and high energy consumption; an azeotropic distillation method is harsh in separation condition and undesirable in separating effect. According to the method adopting the technical scheme that material flow containing the ethylene-glycol and the 1,2-butanediol enters into an azeotropic rectification column from the lower part and an azeotropic agent enters the azeotropic rectification column from the top to obtain an azeotrope of the ethylene-glycol and the azeotropic agent at the top, the material flow containing the 1,2-butanediol is obtained in a tower kettle; after the azeotrope is subjected to condensation and phase-splitting, the azeotropic agent-rich phase at the upper layer returns to the azeotropic rectification column and continues performing azeotropic reaction while an ethylene-glycol-rich phase at the lower layer is subjected to refining to obtain the ethylene-glycol product, and the problems are well solved. Therefore, the method can be used for industrial production for separating the ethylene-glycol and the 1,2-butanediol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production process of phenol products

InactiveCN1974517ALess investmentSmall footprintOrganic chemistryOrganic compound preparationTheoretical plateSlag

The present invention relates to coal chemical technology, and is especially process of producing phenol products. By using crude phenol after dewaterig and eliminating slag as material and through once intermittent rectifying process in a rectifying tower with theoretical plate number of 60-90, phenol, o-cresol fraction, m, p-cresol and industrial xylenol are obtained, with the o-cresol fraction is intermittently decompression rectified to obtain o-cresol product. Compared with tower type process, the present invention has low cost, small area and low power consumption.

Owner:ANGANG STEEL CO LTD

Method for separating carbinol acetonitrile azeotrope

InactiveCN101134736AShort processLess investmentOrganic compound preparationHydroxy compound preparationTheoretical plateRaoult's law

The present invention relates to method of separating methanol-acetonitrile azeotrope. By means of the feature of methanol-acetonitrile azeotrope system with positive deviation to Raoult's law, the pressure of the system is lowered or raised to shift the binary azeotropic point and alter the composition of the azeotrope system, so as to reach the separation aim. The decompressing rectification tower has a theoretical plate number of at least 40 and top pressure of 0.3-0.5atm, and compressing rectification tower has a theoretical plate number of at least 25 and top pressure of 5-10 atm. The method can obtain separated methanol and acetonitrile products of purity over 99.5 wt%, has short technological process, easy control and other advantages, and is suitable for separating methanol-acetonitrile solution in different ratio.

Owner:TIANJIN UNIV

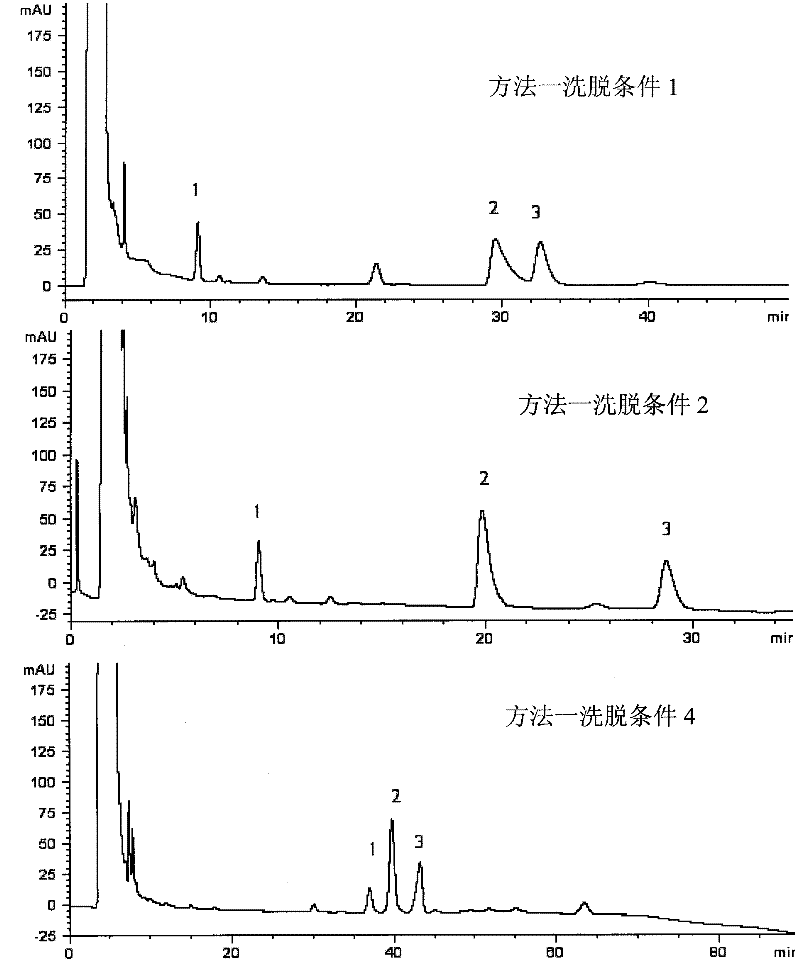

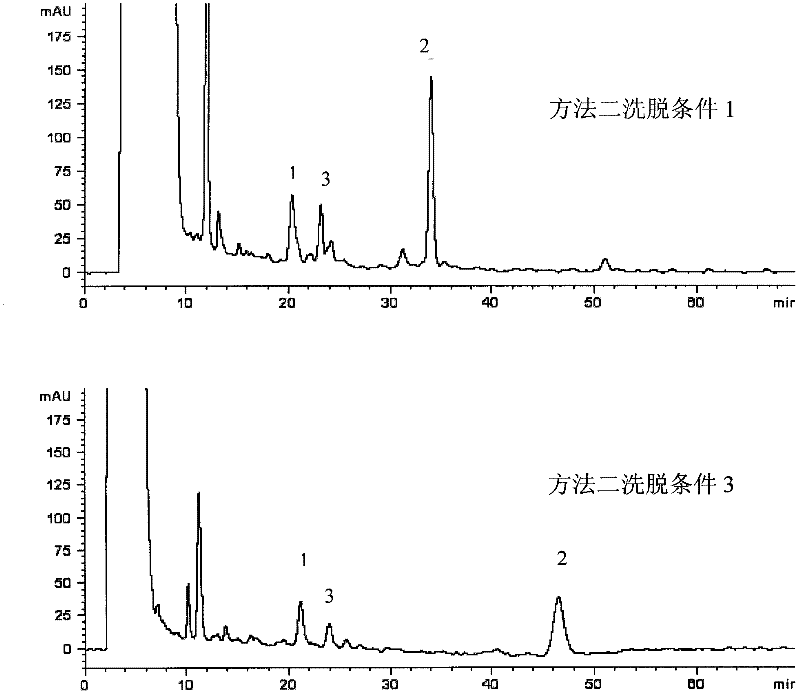

Method for detecting Simotang preparation

ActiveCN102346177AEasy to separateGood symmetry factorComponent separationDigestive systemSilica gelAlkaloid

The invention discloses a method for detecting a Simotang preparation. The method is characterized in that: high performance liquid chromatography detection is carried out on a test sample of the Simotang preparation, and a chromatographic condition is selected from one of the following two modes: a mode 1 is characterized in that: the chromatographic column is a strongly cationic exchange chromatographic column, the mobile phase comprises methanol and an aqueous solution with a volume percentage of 0.2% and a pH value of 3.8 according to a volume ratio of 40-80:60-20, and the detection wavelength is 215nm; and a mode 2 is characterized in that: the chromatographic column is an octadecylsilane bonded silica gel column, the mobile phase comprises methanol and an aqueous solution of SDS and with a mass percentage of 0.1% according to a volume ratio of 50:50, the flow velocity is in a gradient mode, and the detection wavelength is 230nm. The method of the invention, which allows three alkaloid components of arecolidine, synephrine and norisobolidine in the Simotang preparation to be simultaneously determined, the resolution of chromatographic peaks, a theoretic stage number, a symmetry factor, and the peak purity obtained through the method to be good, and a linear relation between the concentration and the peak area to be good in a large concentration range, has the advantages of excellent precision, repeatability and accuracy.

Owner:HUNAN HANSEN PHARMACEUTICAL CO LTD

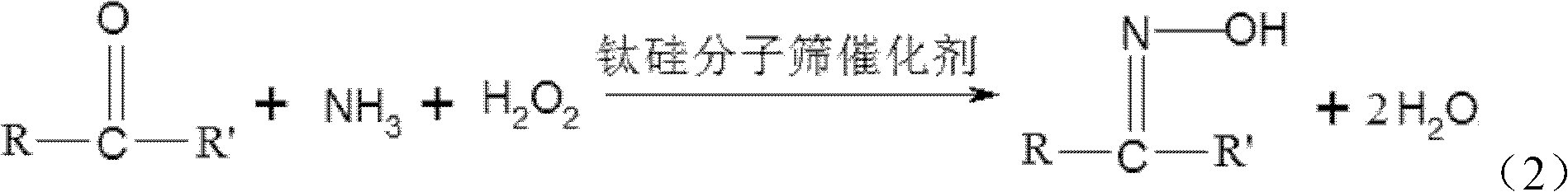

Method of using ketoxime ether for preparation of alkoxyl amine hydrochloride and alkoxyl amine hydrochloride preparation method

The invention relates to a method of using ketoxime ether for preparation of alkoxyl amine hydrochloride. The method includes: continuously injecting acetoxime ether or diacetylmonoxime ether into a rectifying tower from a first feeding port, continuously injecting hydrochloric aqueous solution into the rectifying tower from a second feeding port, and separating out alkoxyl amine hydrochloride from tower bottom solution of the rectifying tower, wherein the number of plates or the number D1 of theoretical plates between the first feeding port and the tower bottom and the number of plates or the number D2 of theoretical plates between the second feeding port and the tower bottom respectively account for 30-80% of the total number of plates or the number of theoretical plates of the rectifying tower, and D1 is smaller thanD2. According to the method, extra organic solvents are not needed while target products can be obtained with high purity and high yield as reaction and separation are integrated, and steps for independent separation are reduced, so that production cost can be reduced.

Owner:宁波四明化工有限公司

Method for ionic liquid extractive rectification and removal of acid and water simultaneously

InactiveCN107473967AAvoid energy consumptionAvoid pollutionOrganic compound preparationCarboxylic acid esters preparationTheoretical plateTower

Belonging to the technical field of separation and purification, the invention relates to a method for ionic liquid extractive rectification and removal of acid and water simultaneously. The method includes the step of: sending an industrial material containing certain acid and water into an extractive rectification tower through a pipeline, and the operation conditions of the rectification tower include: a temperature of 20-100DEG C, a pressure of 1-5atm, a number of theoretical plates of 10-40, and a solvent ratio of 0.5-5. The industrial material has a water content of 0.1%-5% (mass fraction, the same below), an acid content of 0.1%-5%, a tower top material water content of less than 2000ppm, and an acid content of less than 2000ppm. The operation conditions of high temperature flash tank are: a temperature of 100-200DEG C and a pressure of 0.01-0.9atm, and the ionic liquid extracted from the bottom of the flash tank can be recycled. When the ionic liquid is employed for extractive rectification and removal of acid and water simultaneously, the acid content and water content of the final material can both reach the ppm level, and the acid in the material can be recovered through the flash tank.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing pentene

The invention relates to a method for preparing pentene, which comprises the following steps of: (1) mixing a piperylene-rich C-5 fraction and hydrogen and then the mixture being sent to a fixed bed catalytic hydrogenation reactor for a selective catalytic hydrogenation reaction in the presence of a catalyst Pd / Al2O3, wherein the molar feed ratio of hydrogen to diolefin in the material is 1- 3:1, the weight hourly space velocity is 1-8hr<-1>, the reaction pressure is 10-20bar, and the reaction temperature is 30-90 DEG C, and the piperylene contained in the material is converted into 1-pentene and 2-pentene by hydrogenation; (2) by utilizing the difference in boiling point of each component in the hydrogenated material, separating the 1-pentene in a distillation column with the number of theoretical plates of 80-100 at a bottom temperature of 55-80 DEG C, a top temperature of 40-60 DEG C, a reflux ratio of 10 to 30 and a column operating pressure of 2-5bar; and (3) then sending a bottom liquid to a distillation column with the number of theoretical plates of 80-100 to separate the 2-pentene at a bottom temperature of 62-87 DEG C, a top temperature of 47-67 DEG C, a reflux ratio of 10 to 30 and a column operating pressure of 2-5bar. The method provided by the invention has the advantages that 1-pentene and 2-pentene products with the purity of more than 98.5% can be easily produced by hydrogenation and distillation methods.

Owner:SHANGHAI PEARLK CHEM

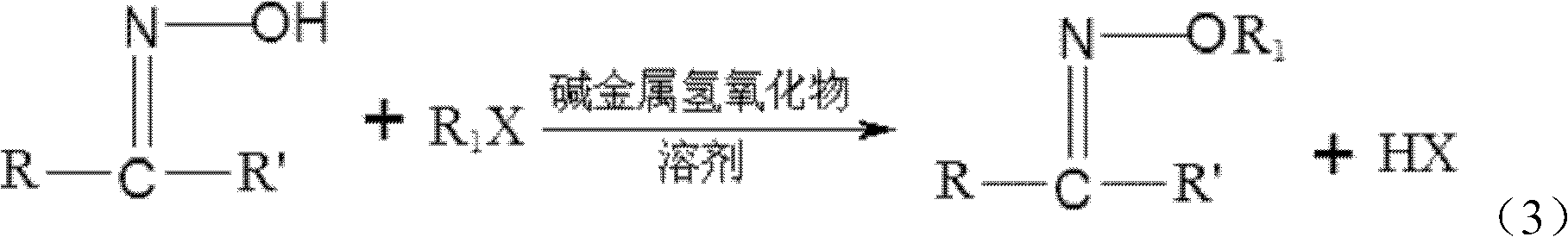

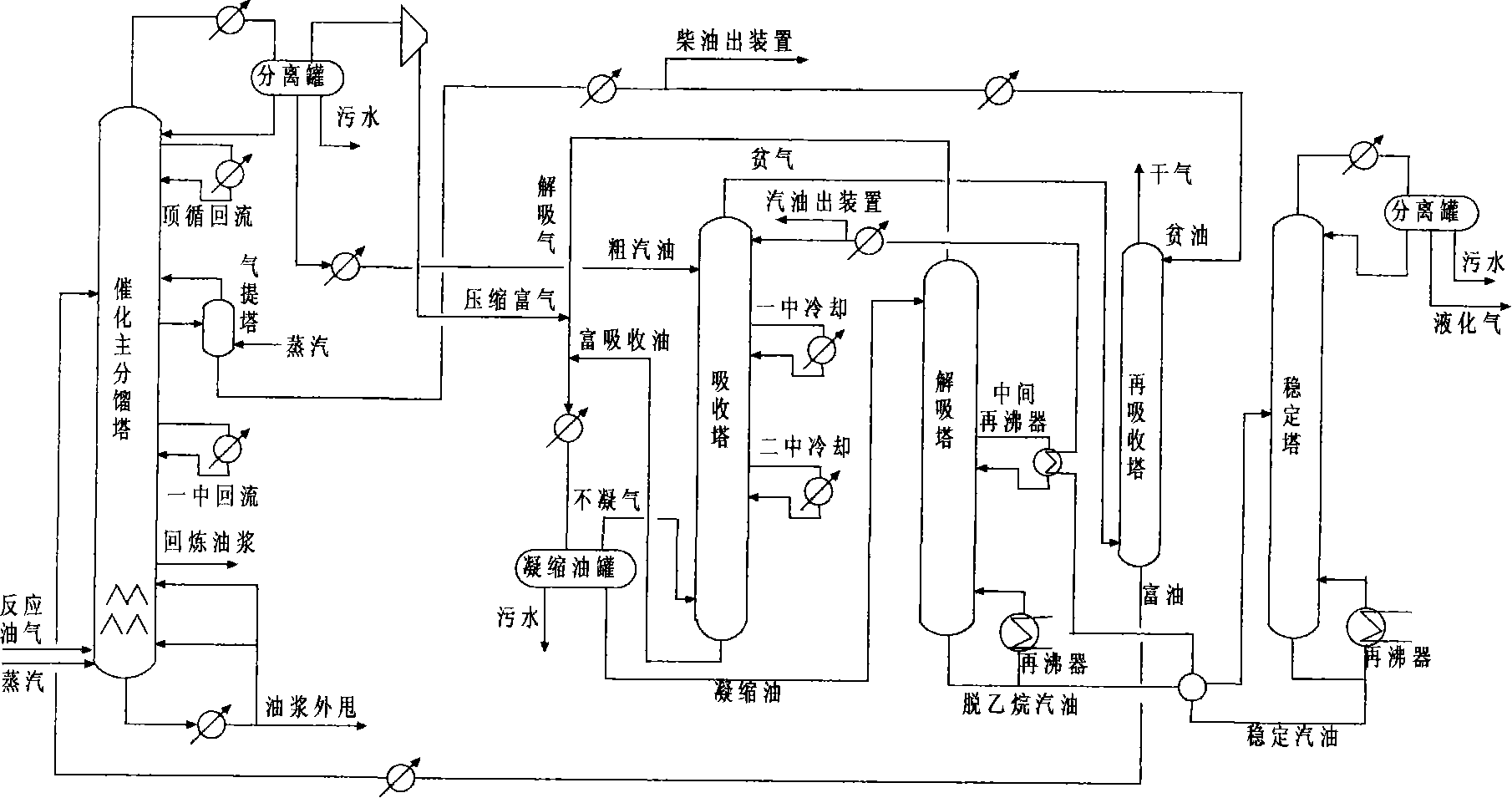

Method for reducing propylene concentration of dry gas in catalytic cracking device absorption stabilizing system

InactiveCN101250426AFull recoveryHow high is the recoveryCatalytic crackingGaseous mixture working upReboilerEngineering

The invention discloses a method for lowering propylene concentration in dry gas of an absorption-stabilization system of a catalytic cracking unit, which achieves through improving supplement absorbent flow and heat exchanging process in the absorption-stabilization system. The method comprises the following steps: opening a lateral line on a third to a fifth theoretical plate of a stabilizer, producing light gasoline to be supplementing absorbing agent of an absorbing tower, simultaneously canceling the process of the original supplementing absorbing agent to get into the absorbing tower, increasing heat supply of a reboiler in the center of an absorption tower, or heating up deethanization gasoline with diesel oil. The method can obviously lower the concentration of propylene and propane in dry gas, which greatly improves propylene yield rate of the absorption-stabilization system of the catalytic cracking unit, and meanwhile, products are guaranteed, and energy consumption of a device is basically constant. The problem of inadequate heat load of the reboiler in the center of the absorption tower which is caused by flow process alternation is excellently solved through the optimization of the heat exchanging flow. In the whole process, flow reconstruction is simple and feasible, and economic benefit is obvious.

Owner:SOUTH CHINA UNIV OF TECH

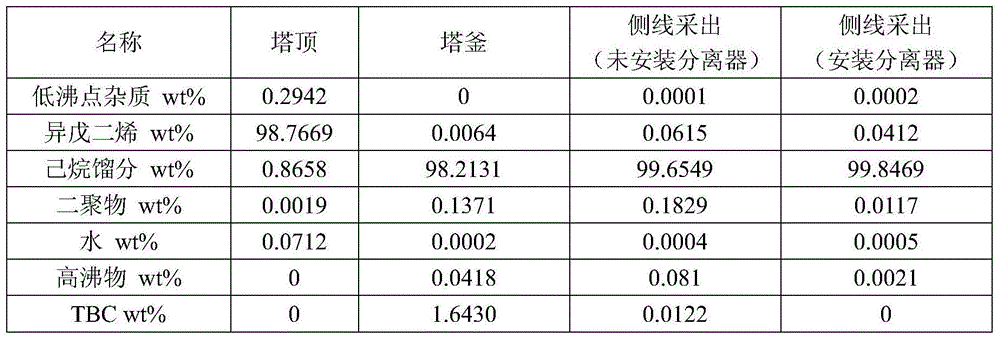

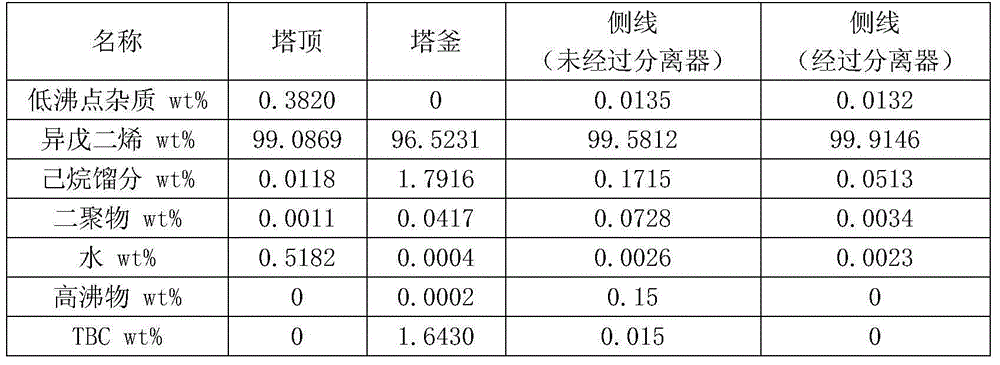

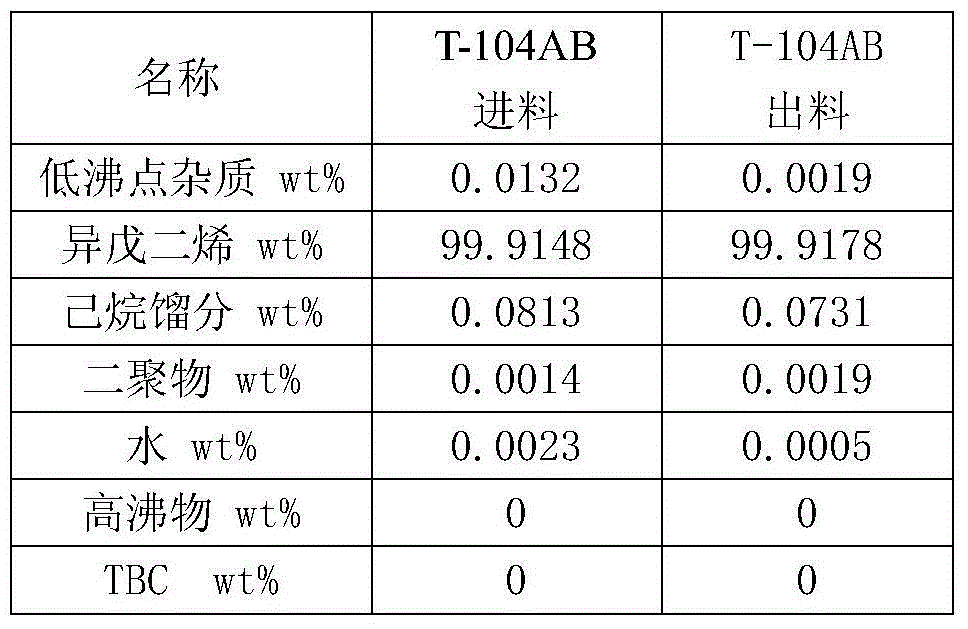

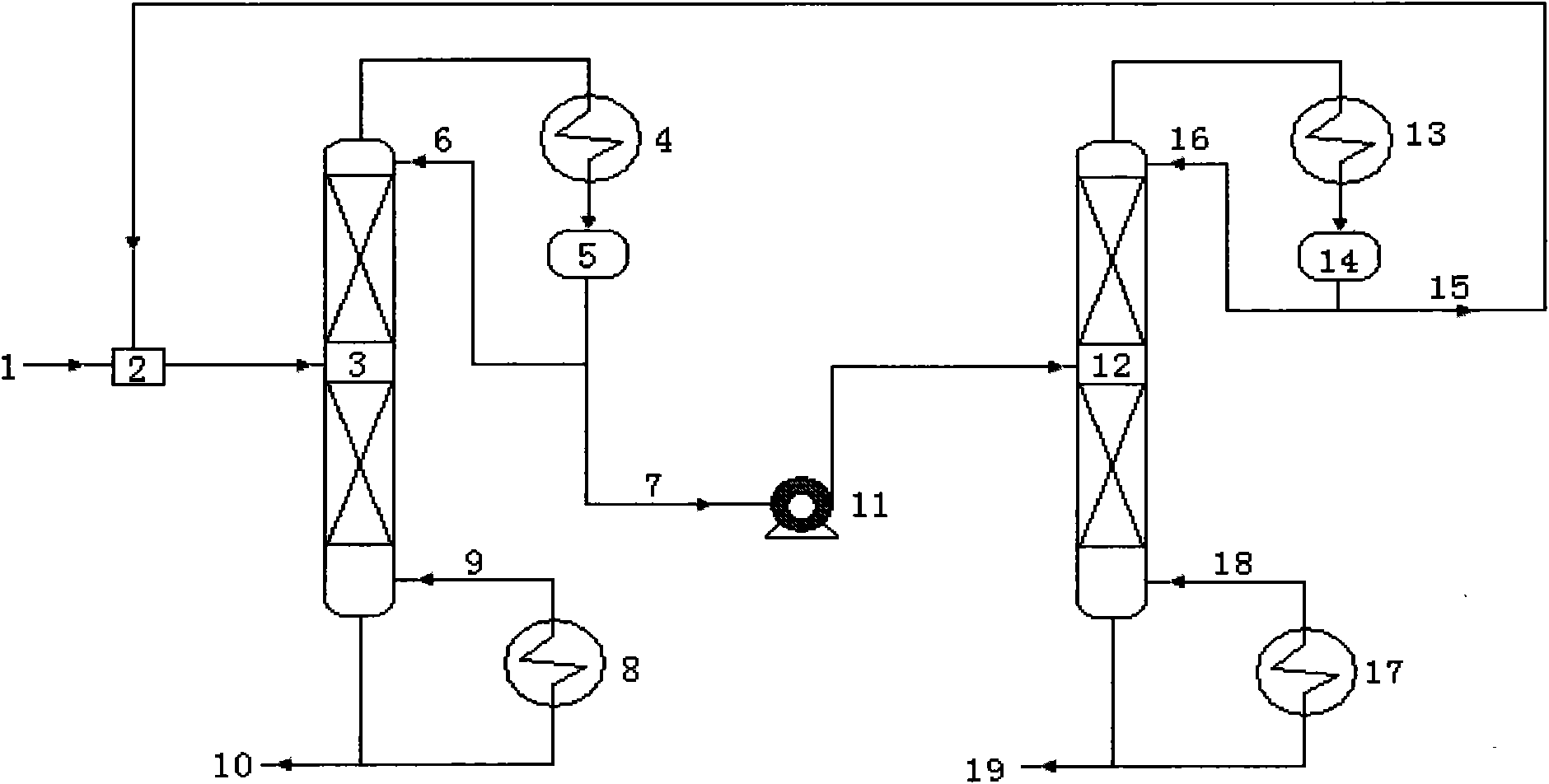

Recovery and refining method of solvents and monomers in the industrial production of rare earth-isoprene rubber

ActiveCN104629082AImprove the phenomenon of severe entrainmentLow impurity contentRecovery methodTheoretical plate

The invention relates to a recovery method of solvents and monomers in the industrial production of rare earth-isoprene rubber. The distance between the top of a solvent recovery tower and a side withdrawing position of the solvent recovery tower is 60 to 70 theoretical plates. Part of the refined hexane solvent, which is withdrawn from the side line, in the gauge tank is pumped into a storage tank and is used as a solvent for production of isoprene rubber, and part of isoprene is refluxed to the top of a separator. The distance between the top of an isoprene refining tower and a side withdrawing position of the isoprene refining tower is 70 to 90 theoretical plates. Gas isoprene is withdrawn from the side line of the isoprene refining tower, part of isoprene is pumped into an adsorption tower by a side line withdrawing gauge tank so as to obtain polymer grade isoprene monomers; and part of isoprene is refluxed to the top of a separator. In the provided method, the solvent is recovered and refined only through two rectifying tower provided with a side withdrawing device, the unreacted monomers are recovered, the fresh monomers are refined, the equipment investment and energy consumption are reduced, the hexane solvent can be used in a circle repeatedly, and part of isoprene can also be used in a circle repeatedly.

Owner:PETROCHINA CO LTD

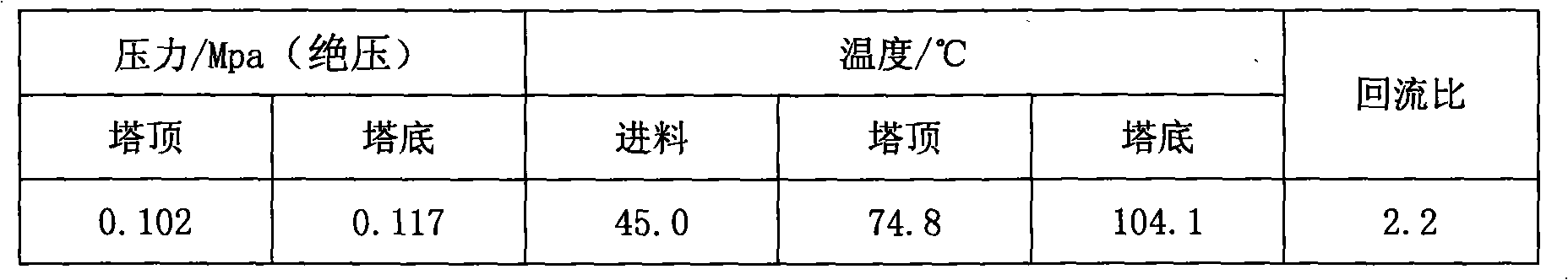

Method for separating azeotropic mixture of ethyl methyl ketone and water through variable-pressure rectification

InactiveCN101830788AReduce energy consumptionHigh purityCarbonyl compound separation/purificationTheoretical plateWastewater

The invention discloses a method for separating an azeotropic mixture of ethyl methyl ketone and water through variable-pressure rectification, which belongs to the fields of chemical rectification and purification. A first rectifying tower is adopted, a near-azeotropic mixture of the ethyl methyl ketone and the water is obtained at the tower top under corresponding pressure, and wastewater containing a trace amount of ethyl methyl ketone is obtained at the tower bottom, wherein the first rectifying tower is a normal pressure tower; the near-azeotropic mixture of the ethyl methyl ketone and the water obtained at the tower top of the normal pressure tower enters a second rectifying tower, wherein the second rectifying tower is a pressurized tower, the azeotropic mixture of the ethyl methyl ketone and the water is obtained at the tower top under high pressure, the azeotropic mixture returns to the normal pressure tower for feeding, and an ethyl methyl ketone product with high purity is obtained at the tower bottom, wherein the operation pressure of the pressurized tower is 0.5MPa, the number of theoretical plates is 38, the number of rectification sections is 15, and the number of stripping sections is 23; the operation pressure of the normal pressure tower is 0.102MPa, the number of the theoretical plates is 32, the number of the rectification sections is 11, and the number of the stripping sections is 21. The invention reduces the energy consumption in the separating process, improves the purity of the product, improves the yield of the ethyl methyl ketone product and has simple process and reasonable device.

Owner:CHANGZHOU UNIV

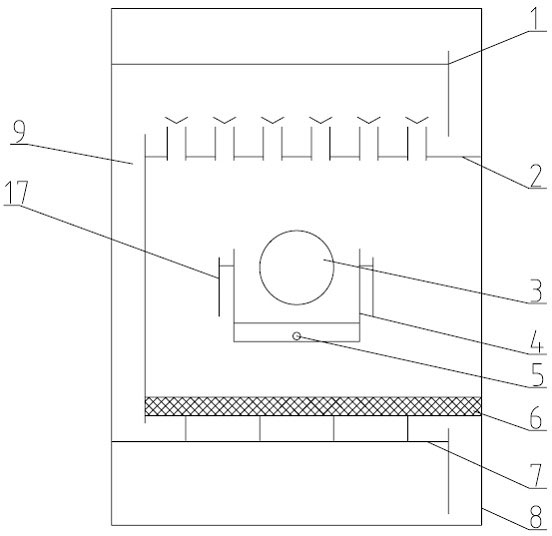

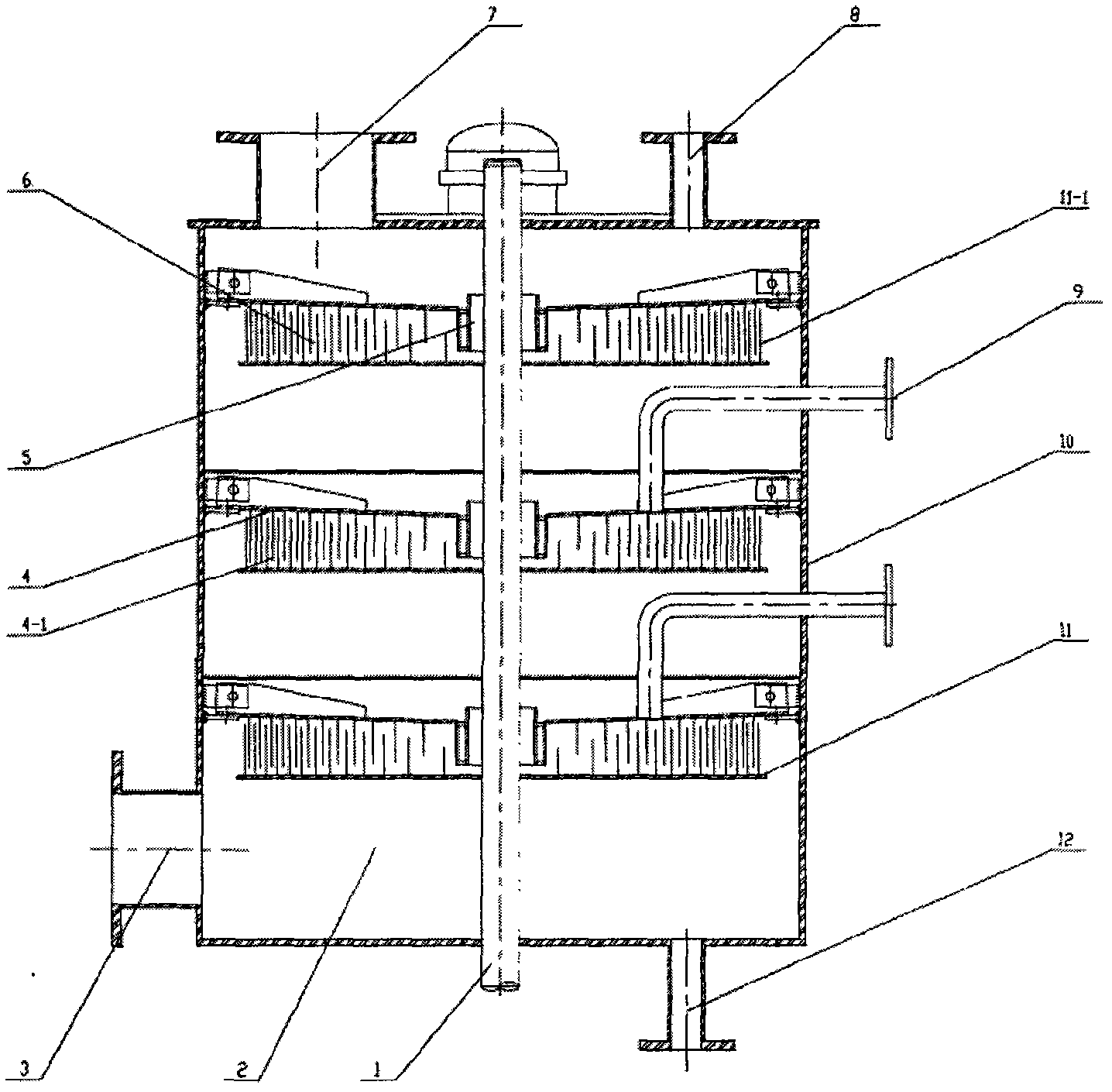

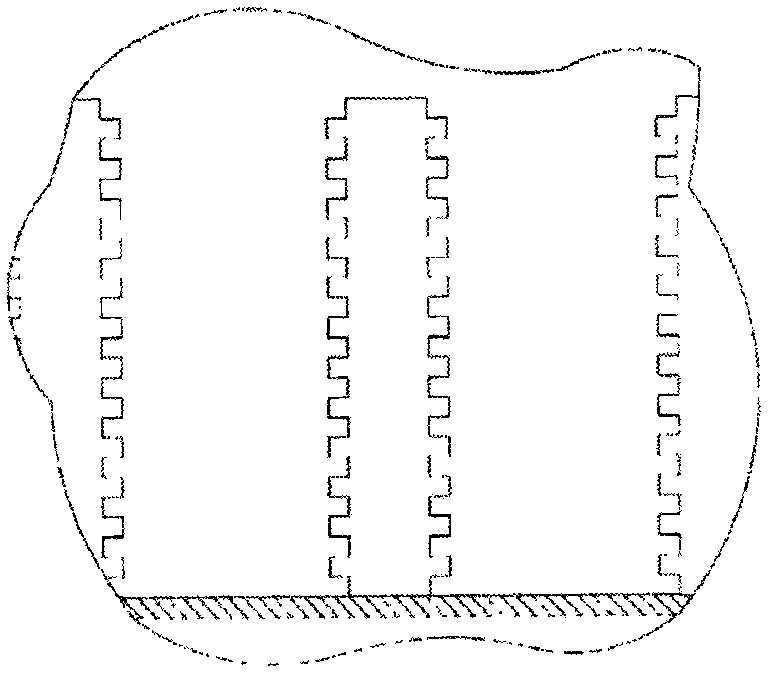

Multilayer heterogenic baffling ring high-speed centrifugal rectifying tower

InactiveCN101912692AIncrease disturbanceImprove mass transfer efficiencyDispersed particle separationChemical/physical/physico-chemical moving reactorsCircular discTheoretical plate

The invention discloses a multilayer heterogenic baffling ring high-speed centrifugal rectifying tower which comprises moving equipment, fixed equipment, a partition plate and relevant gas and liquid phase inlets and outlets, wherein the moving equipment comprises a motor rotating shaft penetrating through a shell and multiple layers of brake disks; the fixed equipment comprises multiple layers of fixed disks and a shell; and the gas outlet and the liquid inlet are positioned at the bottom of the shell; and the top of the shell is provided with a gas inlet and a liquid outlet. In the shell, the partition plate which is in bolt connection with the shell divides the shell into multiple layers; and gas-liquid flow between the layers is just finished in a gas-liquid channel of a liquid distributing chamber. Each layer is divided into a shell side and a centrifugal separating area by the disks. In the center of the shell, multiple brake disks are connected in series and fixed at the periphery of the motor rotating shaft, and heterogenic plate concentric baffling rings with different radii are fixed on the disks. At upper spaces of the brake disks, the heterogenic plate concentric baffling rings with different radii and the baffling rings are distributed at intervals and fixed on multiple layers of fixed disks which are in seal connection with the partition plate. The invention can effectively reduce the pressure drop of a rectifying tower and strengthen the gas-liquid mass transfer effect, has high operational flexibility, obviously reduces the tower height under the same theoretical plate and reduces equipment investment.

Owner:TIANJIN UNIV

Process of producing beta-methylnaphthalene

InactiveCN1974502ALow indole contentLow indoleDistillation purification/separationTheoretical plateBeta-methylnaphthalene

The present invention relates to coal chemical technology, and is especially process of producing beta-methylnaphthalene. The materials including industrial methylnaphthalene and azeotropic agent in the volume ratio of 1 to 0.4-0.6 are rectified through heating in an intermittent rectifying still, and the product is recovered in a rectifying tower with theoretical plate number of 50-80 to obtain fraction successively. The beta-methylnaphthalene fraction and the alpha-methylnaphthalene fraction are separated in separator to eliminate azeotropic agent and rectified to obtain beta-methylnaphthalene product and alpha-methylnaphthalene product with content over 95 %. The present invention has one increased oil-oil separator and the product has indole content lower than 0.5 %.

Owner:ANGANG STEEL CO LTD

Method using ionic liquid for gas drying and dehydration

ActiveCN104826455AAvoid corrosionImprove dehydration effectDispersed particle separationHigh energyAbsorption of water

A method using ionic liquid for gas drying and dehydration belongs to the technical field of gas drying (or absorption). The ionic liquid is used as an absorbent, an absorption tower runs at the temperature of 0-100 DEG C under the pressure of 0.1-10MPa, and the theoretical tower plate number is 8-17. Water content in a feed gas (mole fraction) is 0.01%-5%, the solvent ratio is 0.1-13, water content (mole fraction) in a gas product obtained at the tower top is less than 20ppm; compared with the prior art, when the ionic liquid and an ionic liquid mixed solvent is used for absorption of water in the gas, dehydration effect is good, the ionic liquid is neutral, and can avoid compressor corrosion, and avoid the high energy consumption and environmental pollution problems caused by use of a traditional solvent for absorption of the gas, and the method is simple in equipment, less in investment, and low in energy consumption.

Owner:BEIJING UNIV OF CHEM TECH

Method for extracting biphenyl from middle washing oil

InactiveCN101182277AHigh extraction rateSimple processDistillation purification/separationBenzeneTheoretical plate

The invention discloses a method of extracting biphenyl from medium wash oil. The medium wash oil containing 15 percent of biphenyl is used as the raw material to be processed for three times of batchdistillations inside a rectifying still and a distillation column with the theoretical plate number of 50 to 80 pieces to obtain the biphenyl product, the purity of which is more than 95 percent, andat the same time, industrial methylnaphthalene, mixed dimethyl naphthalene fraction and acenaphthene fraction are obtained. The technology of the invention is simple and is easy for grasping. Under thetechnical condition that the devices for the three times distillations, the theoretical plate number of the distillation column, the pressure of the rectifying still, the reflux ration and the temper ature of the rectifying still are same, the required products can be produced just by slightly adjusting the temperature of the rectifying still and the top temperature of the distillation column. Theextraction rate of the biphenyl can be more than 70 percent. A coking plant which produces 4000t medium wash oil yearly can produce 400t biphenyl product yearly, the biphenyl content of which is more than 95 percent, and the coking plant can obtain 1000t industrial methylnaphthalene, 1300t mixed dimethyl naphthalene fraction and 1200t acenaphthene fraction at the same time, so the comprehensiveeconomic benefit is very considerable.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com