Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

193results about How to "Improve recycling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

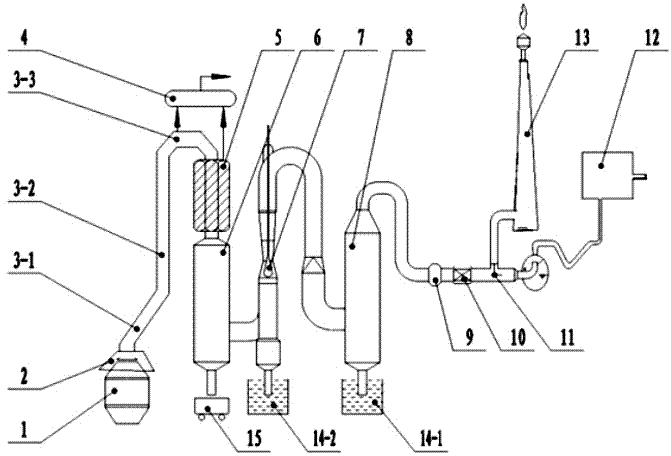

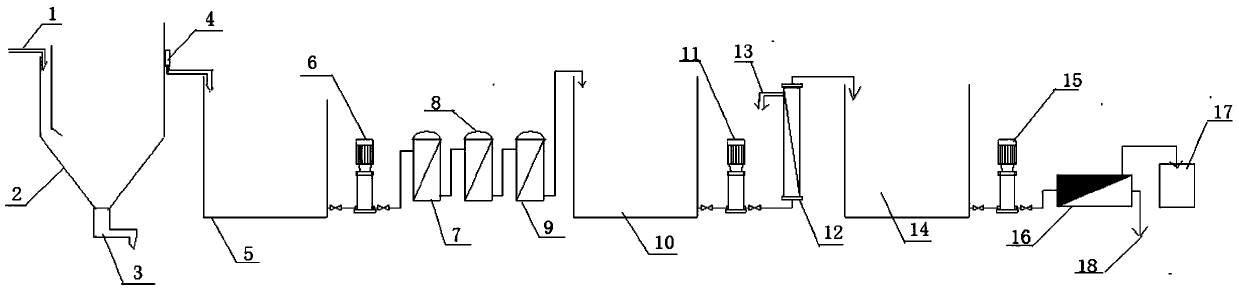

System and method for treating converter flue gas

InactiveCN102899444AEasy to controlEasy to operateIncreasing energy efficiencyManufacturing convertersEvaporative coolerDust control

The invention relates to an environmental-friendly device of an iron and steel enterprise and a dust removal method, that is to say, a system and a method for treating converter flue gas. The system comprises a furnace mouth nitrogen injection sealing petticoat pipe, a segmental evaporation cooling flue, a high-temperature heat pipe steam generator, a spray evaporation cooler, a long neck adjustable throat venturi tube, an impeller type composite dehydrator, a fan, an automatic continuous coal gas detector and a three-way switching valve, which are connected in sequence, wherein the three-way switching valve is connected with a gas chamber; or the three-way switching valve is communicated with a chimney. The method comprises the following steps of: forming a soft sealing screen between a furnace mouth and a petticoat pipe, after segmentally vaporizing and cooling the flue gas, and cooling in a high-temperature heat pipe; after carrying out spray evaporation, cooling and rough dust removal through a dry method, carrying out fine dust removal and cooling by a venturi tube through a wet method, dehydrating the flue gas, and entering into a coal gas recycling stage lastly. According to the invention, the wet method and the dry method are combined, waste heat recovery, coal gas recovery, sewage treatment and dust removal can be planned in a flue gas treatment and utilization system as a whole and the combination action of the device is fully exerted.

Owner:北京五一环保科技股份有限公司

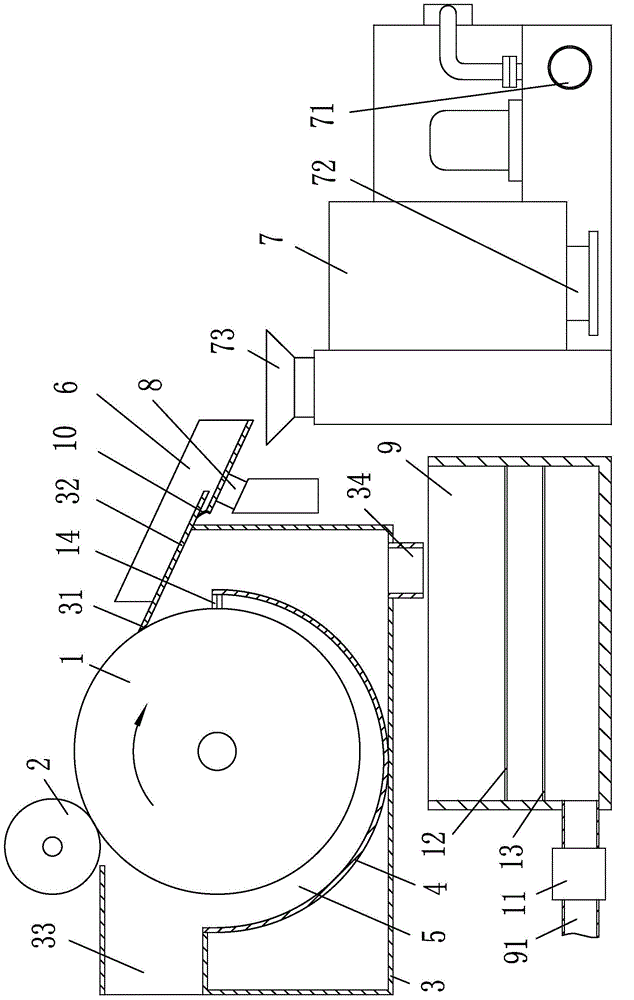

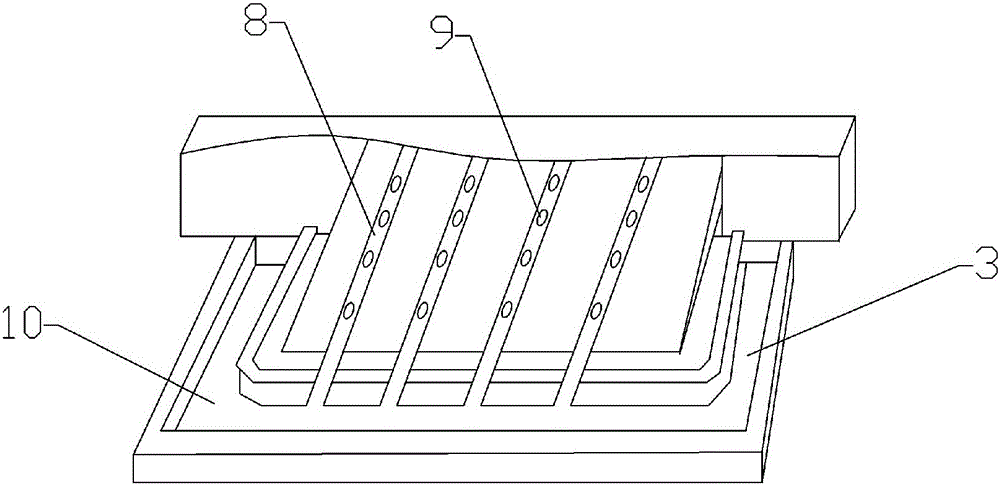

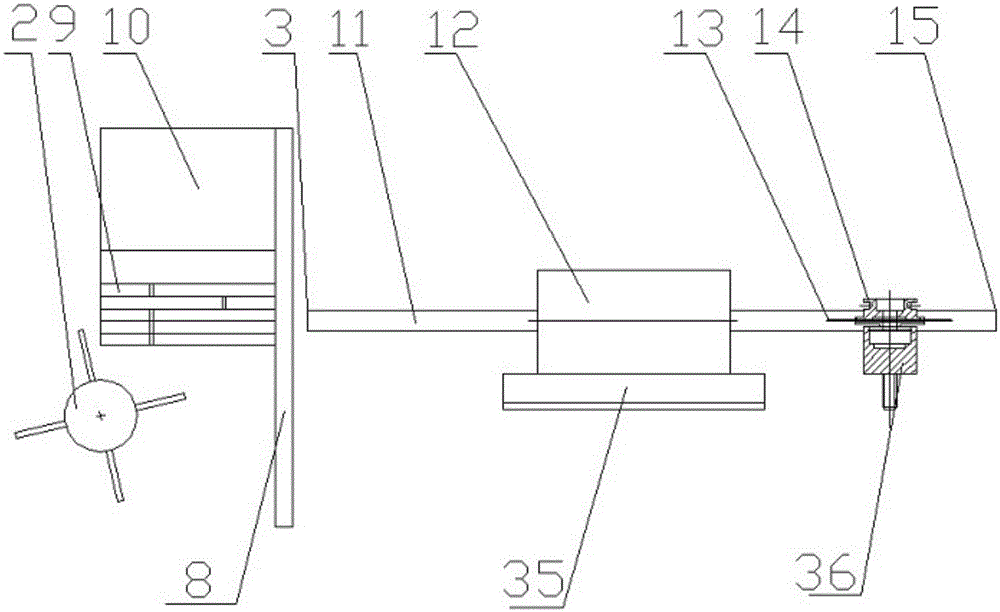

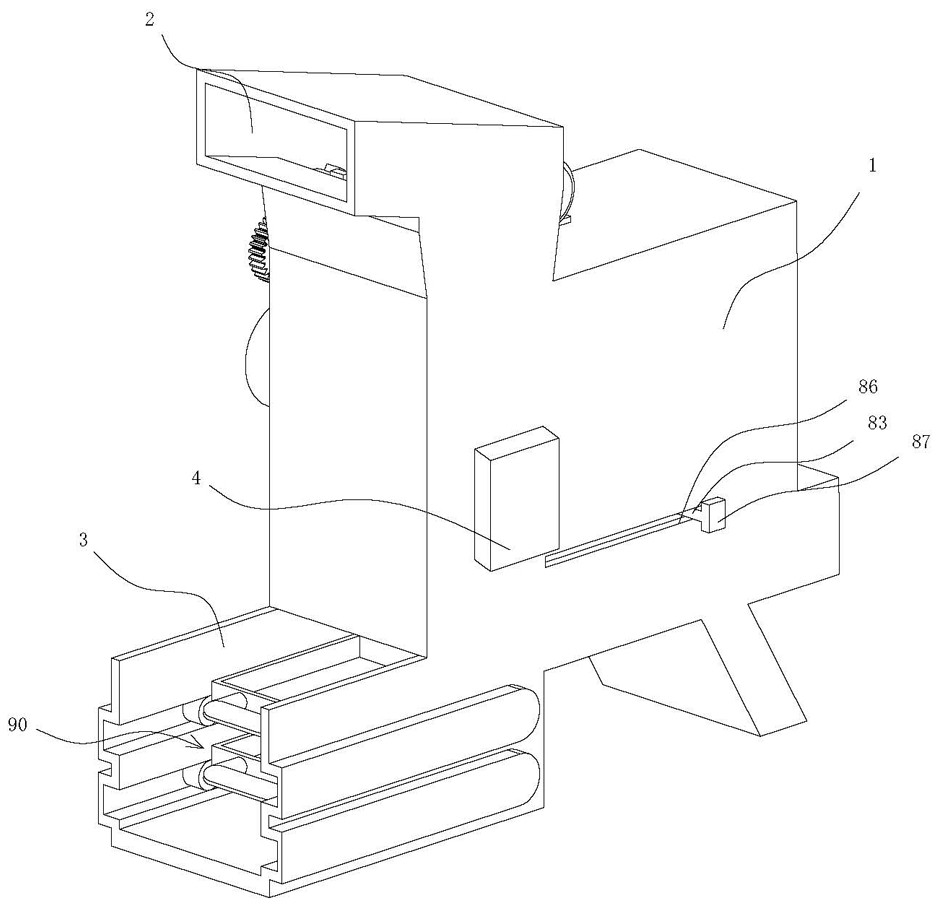

Cutting fluid recovering device for grinding machine

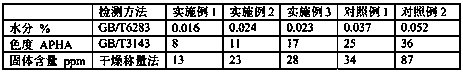

InactiveCN104972401AImprove recycling qualityEasy to separateMagnetic separationFiltration circuitsEngineeringCooling fluid

The invention relates to the field of recovery of cooling liquid of machine tools and provides a cutting fluid recovering device for a grinding machine. The cutting fluid recovering device for the grinding machine comprises a shell, a magnetic roller, a soft roller, an arc-shaped supporting plate, a scrap iron cutting fluid separation device and a cutting fluid filtering device, wherein both the magnetic roller and the soft roller are connected with the shell in a pivoted mode; the arc-shaped supporting plate is located under the magnetic roller, and the two ends of the arc-shaped supporting plate are connected with the shell. The shell is provided with an oblique scrap scraping plate, a fluid inlet and a fluid outlet, wherein the scrap scraping end of the oblique scrap scraping plate is located at the high end, the fluid inlet is located in the back side of the upper portion of the magnetic roller, and the fluid outlet is located in the bottom. A cutting fluid channel is formed between the magnetic roller and the arc-shaped supporting plate, and one end of the cutting fluid channel is communicated with the fluid inlet. The scrap scraping end is located above the other end of the cutting fluid channel. The soft roller is located between the scrap scraping end and the fluid inlet. The cutting fluid recovering device for the grinding machine is good in cutting fluid recovering quality and high in cutting fluid recovering rate.

Owner:宁波神丰汽车部件有限公司

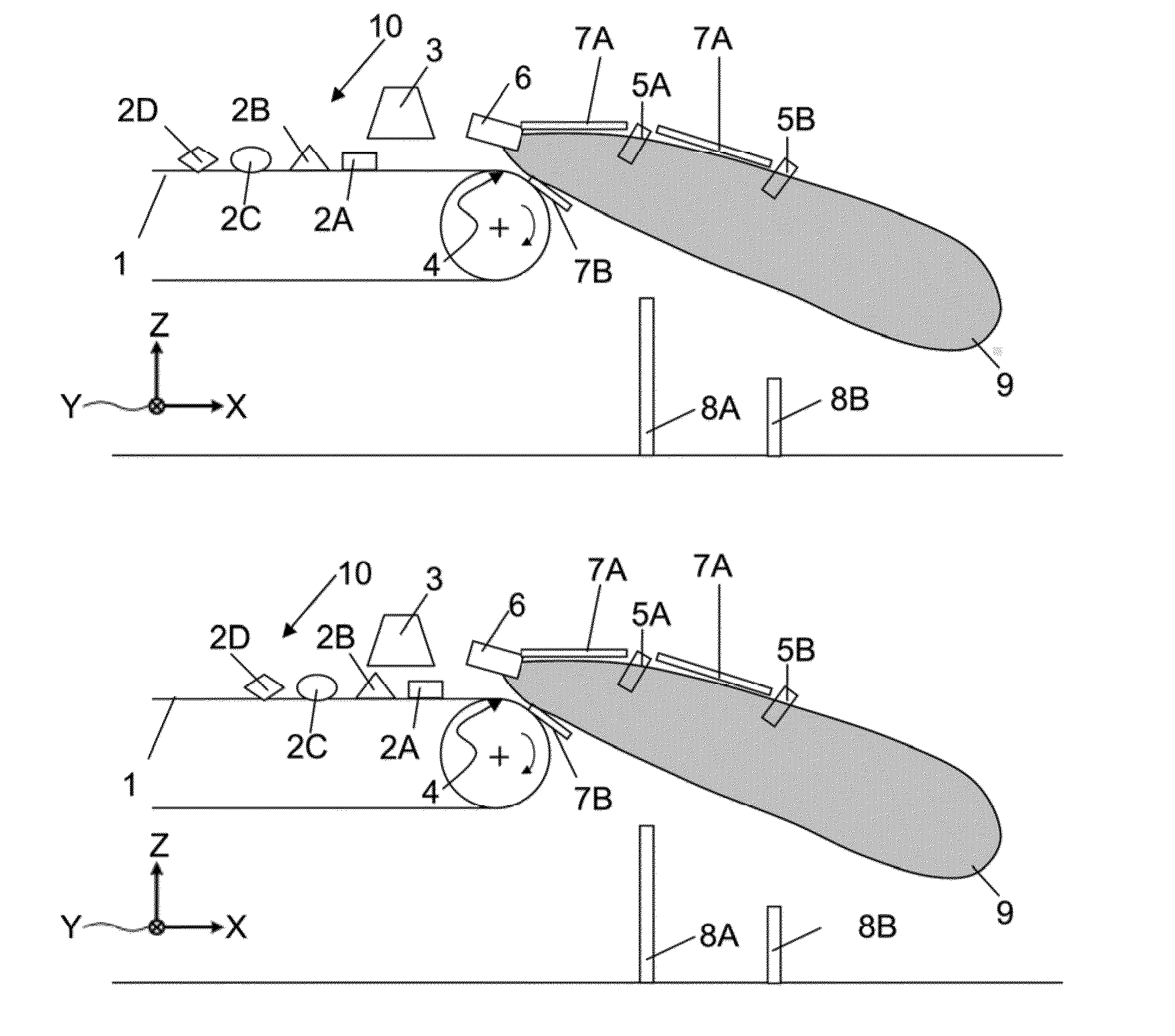

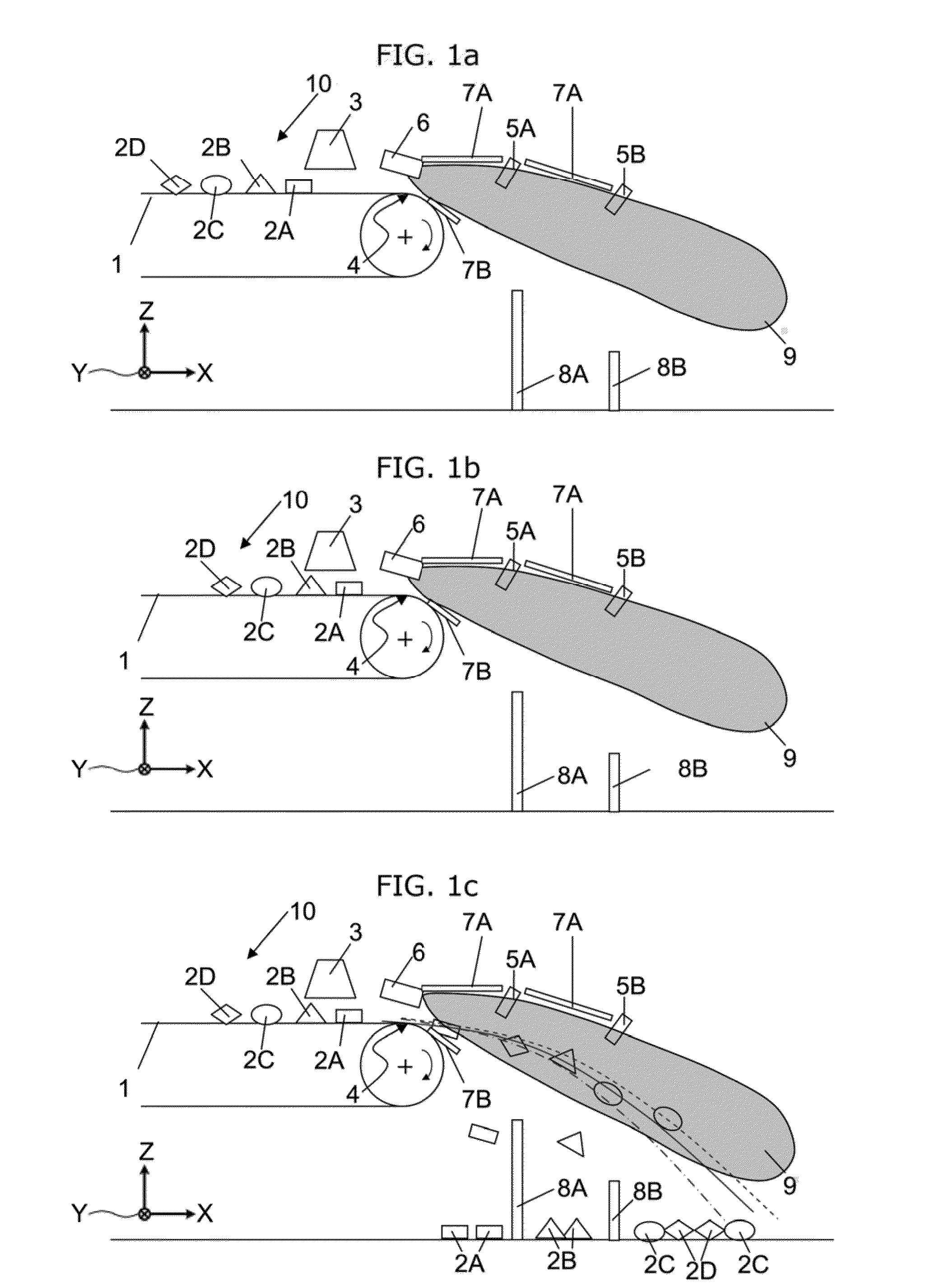

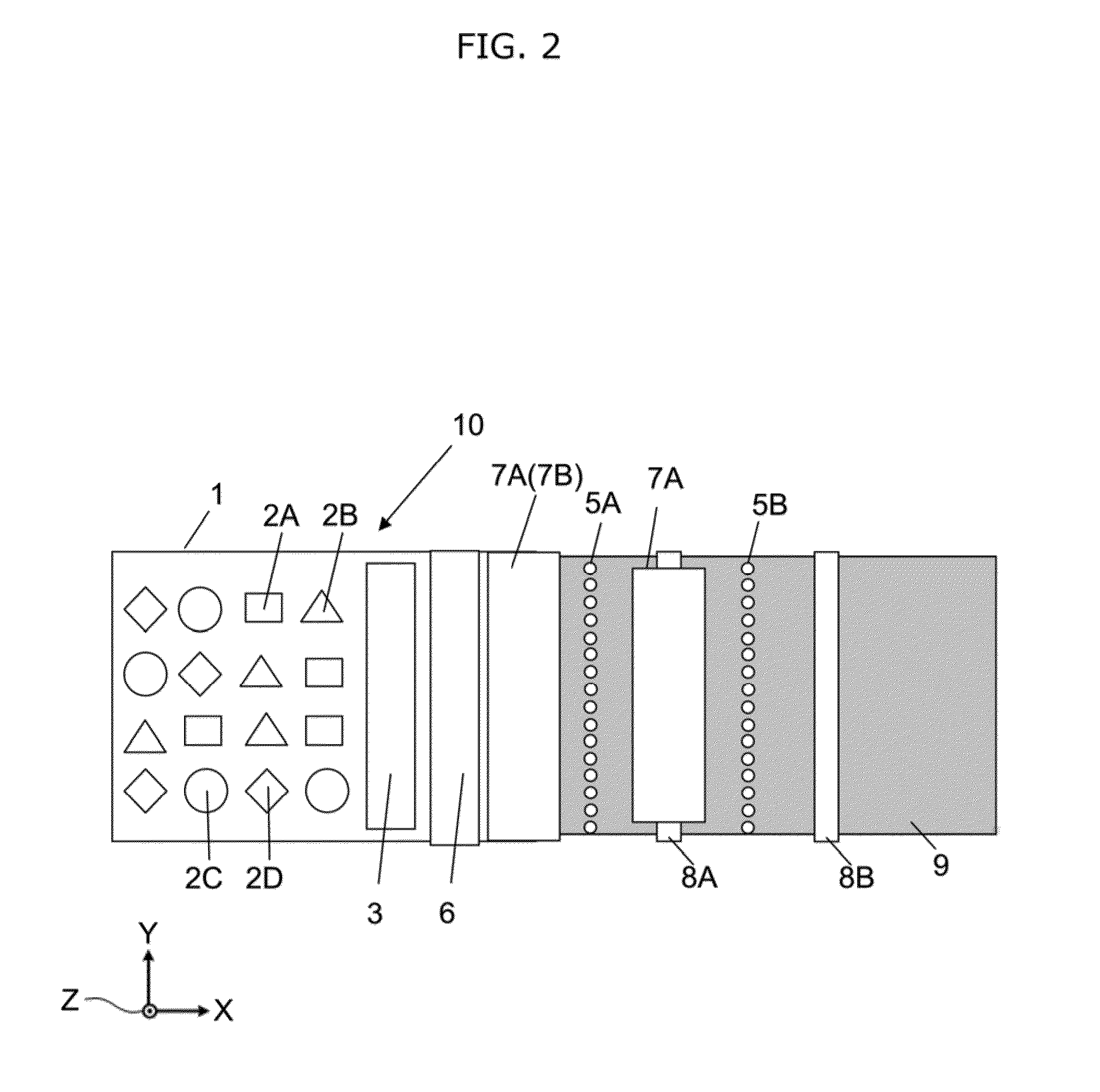

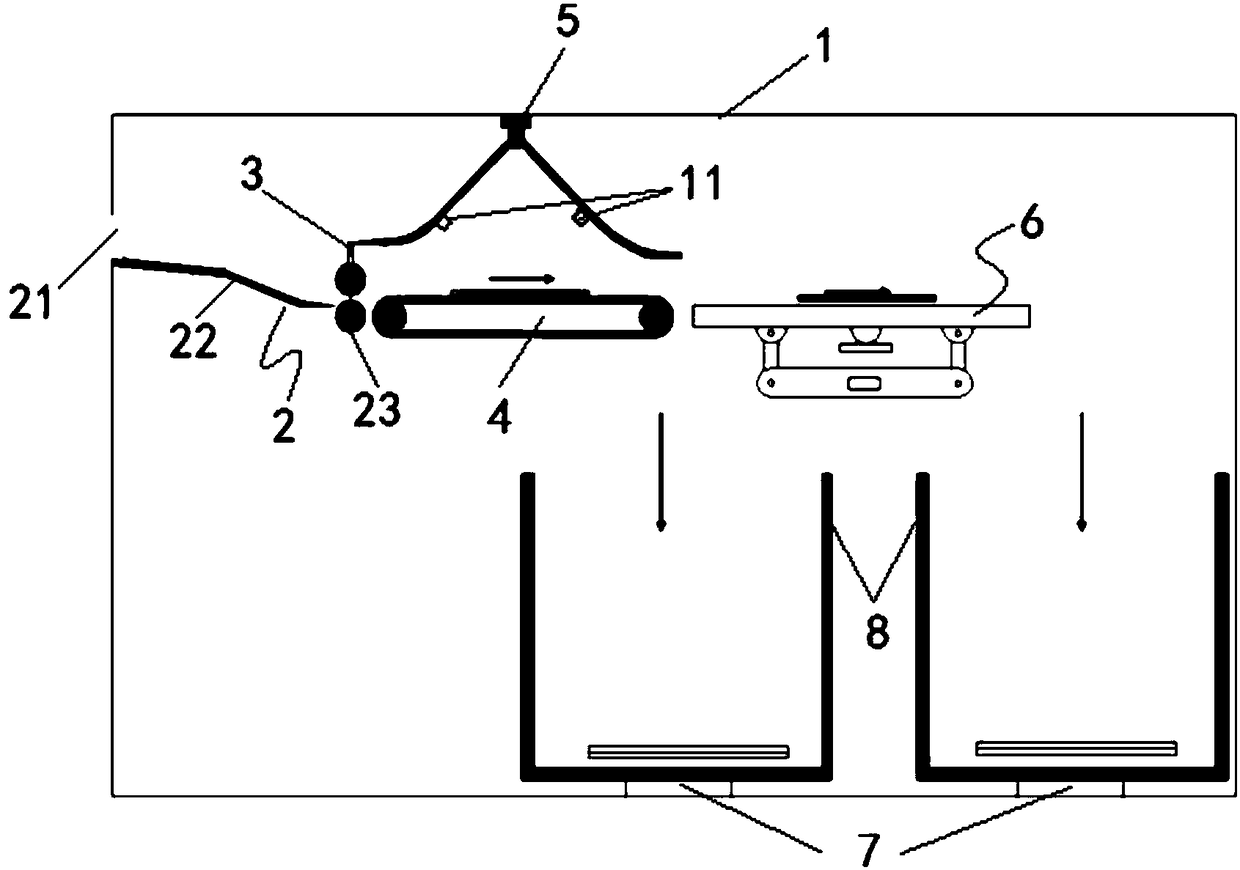

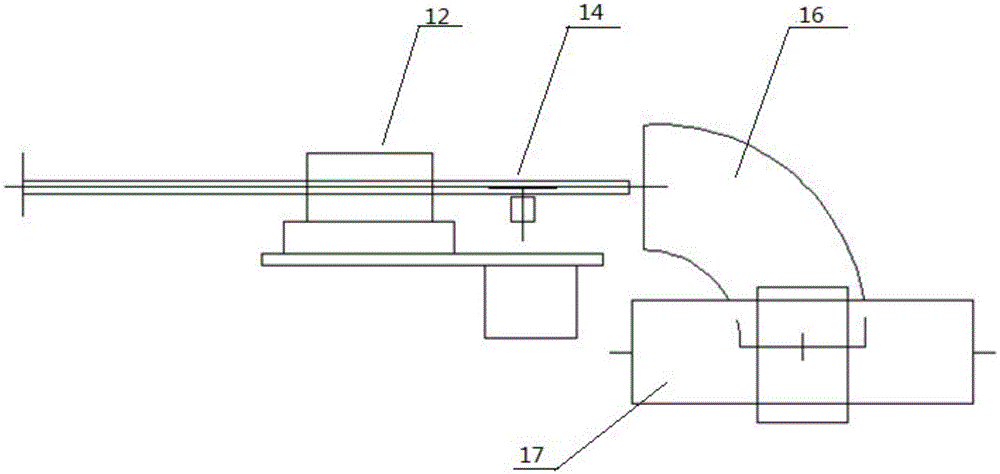

Apparatus and method for separating material

ActiveUS20150231671A1Reduce errorsEasy to separatePlastic recyclingSortingEngineeringSeparation method

A separation method includes: conveying a group of pieces placed on a conveyor in one direction; detecting, by an detecting device, the compositions of pieces in the group of pieces placed on the conveyor; generating, by a blower, airflow at an end portion of the conveyor in a conveying direction in which the conveyor conveys the separation subject, the airflow having a velocity matching or substantially matching a conveying speed of the conveyor; stabilizing the airflow by a current plate placed along a trajectory of the group of pieces; and by a jetting device, obtaining position information of a piece of a particular material detected, and jetting pulse air toward the piece of the particular material when the piece of the particular material which is travelling through the air from the conveyor and whose travel is assisted by the airflow passes by the jetting device.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

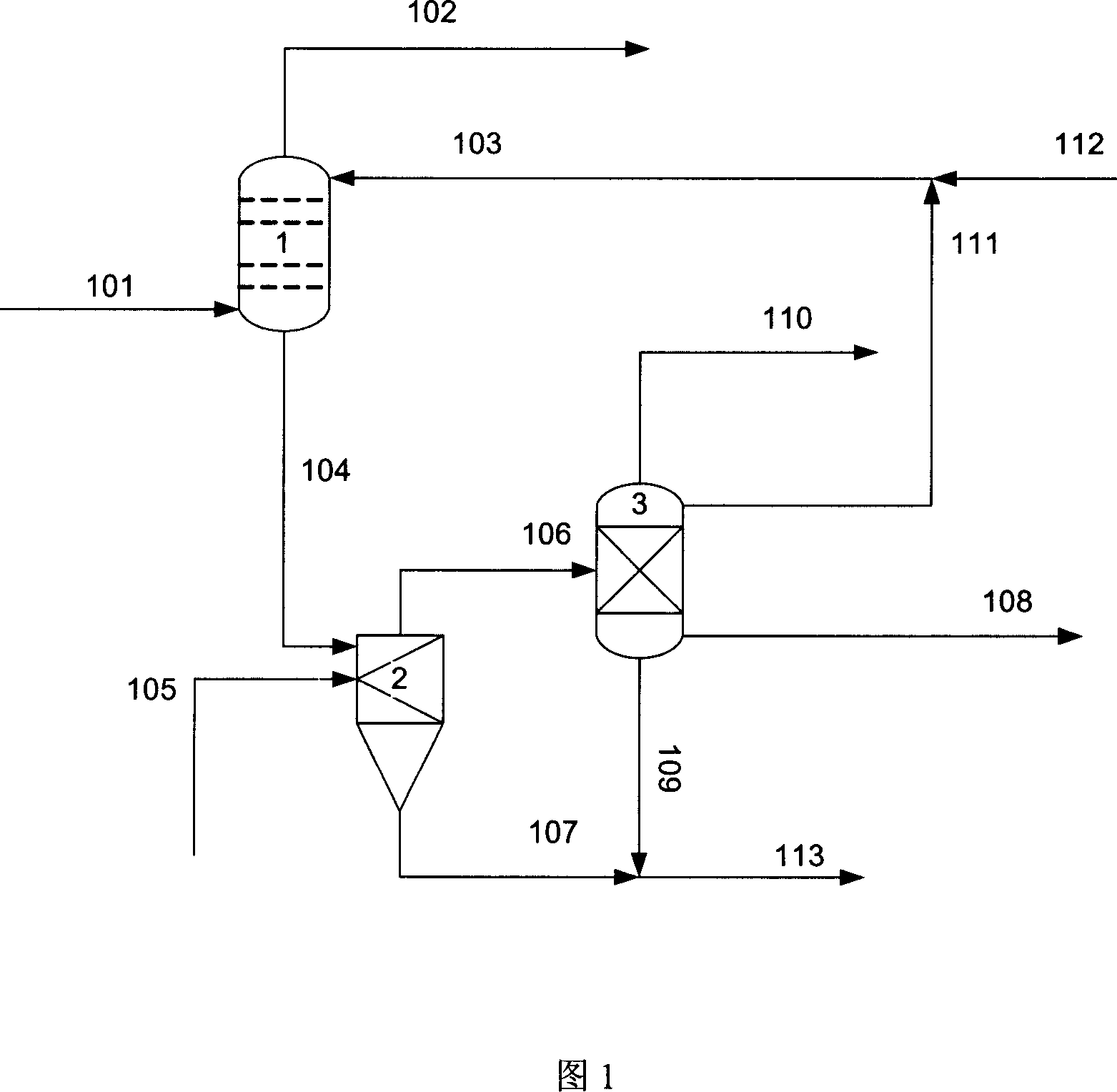

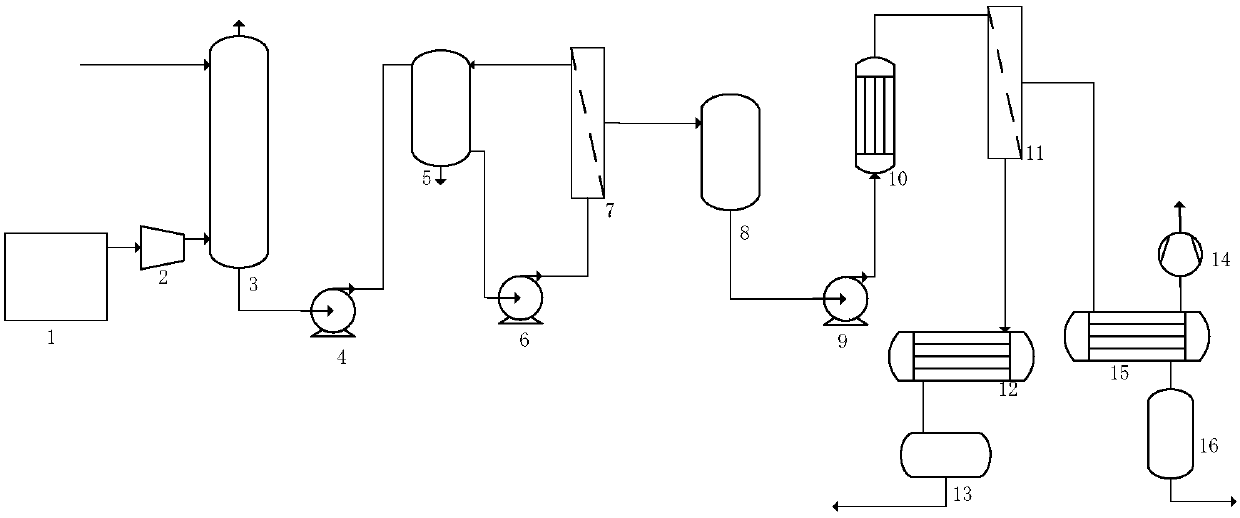

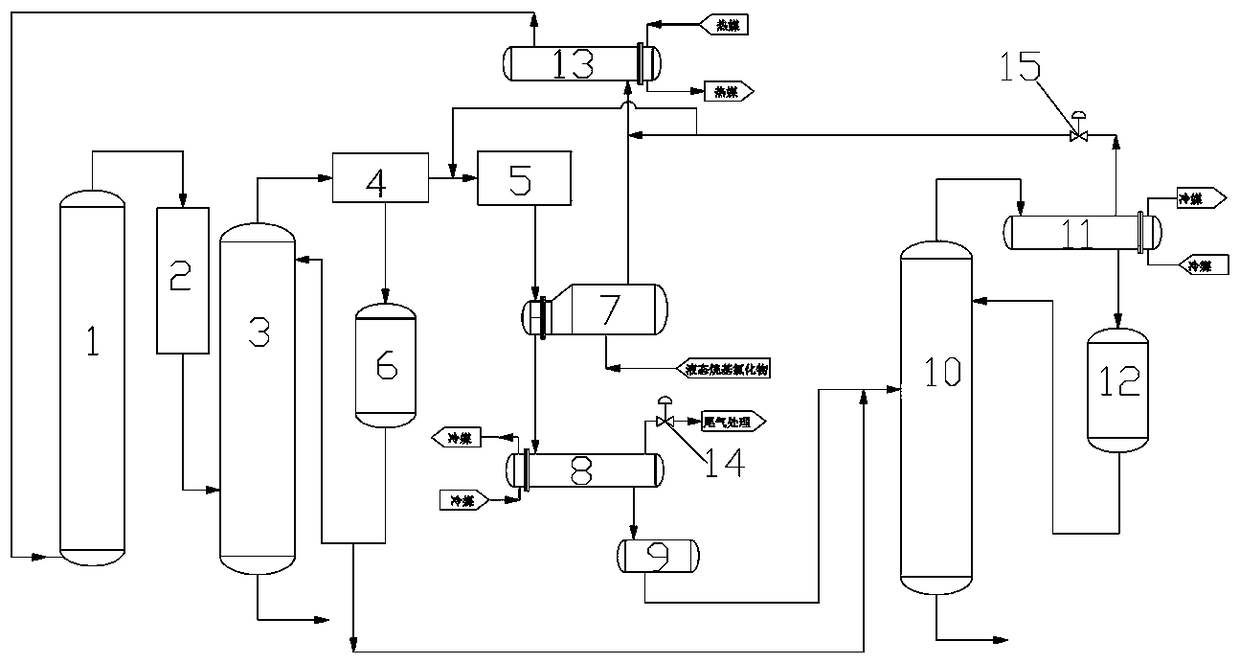

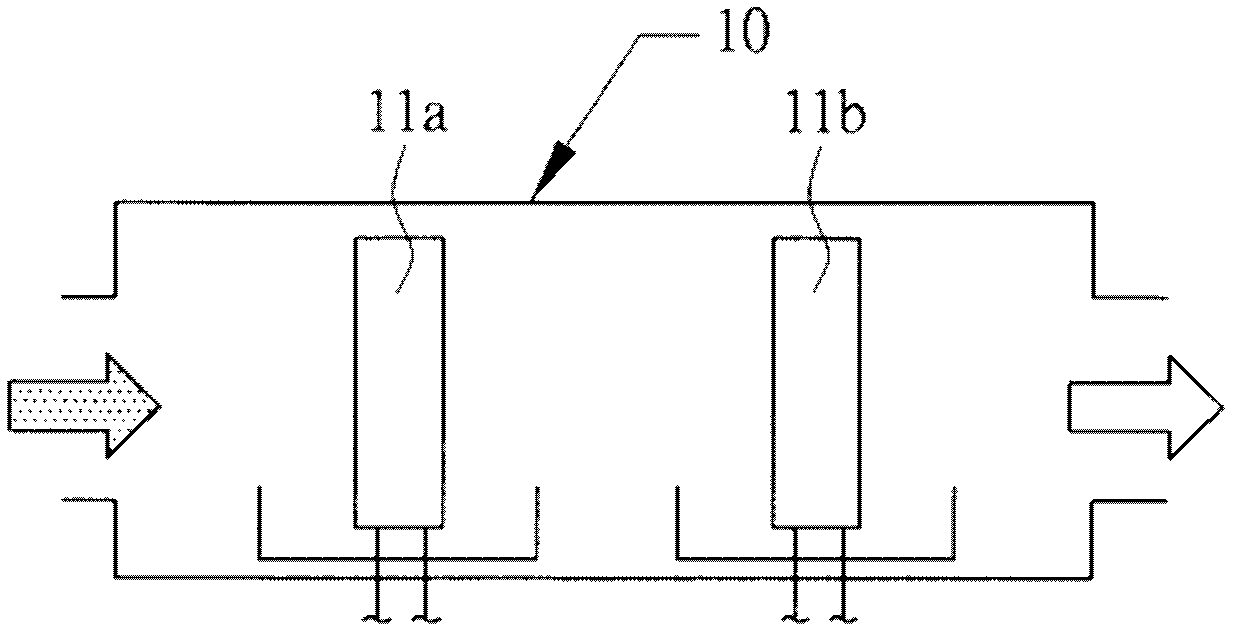

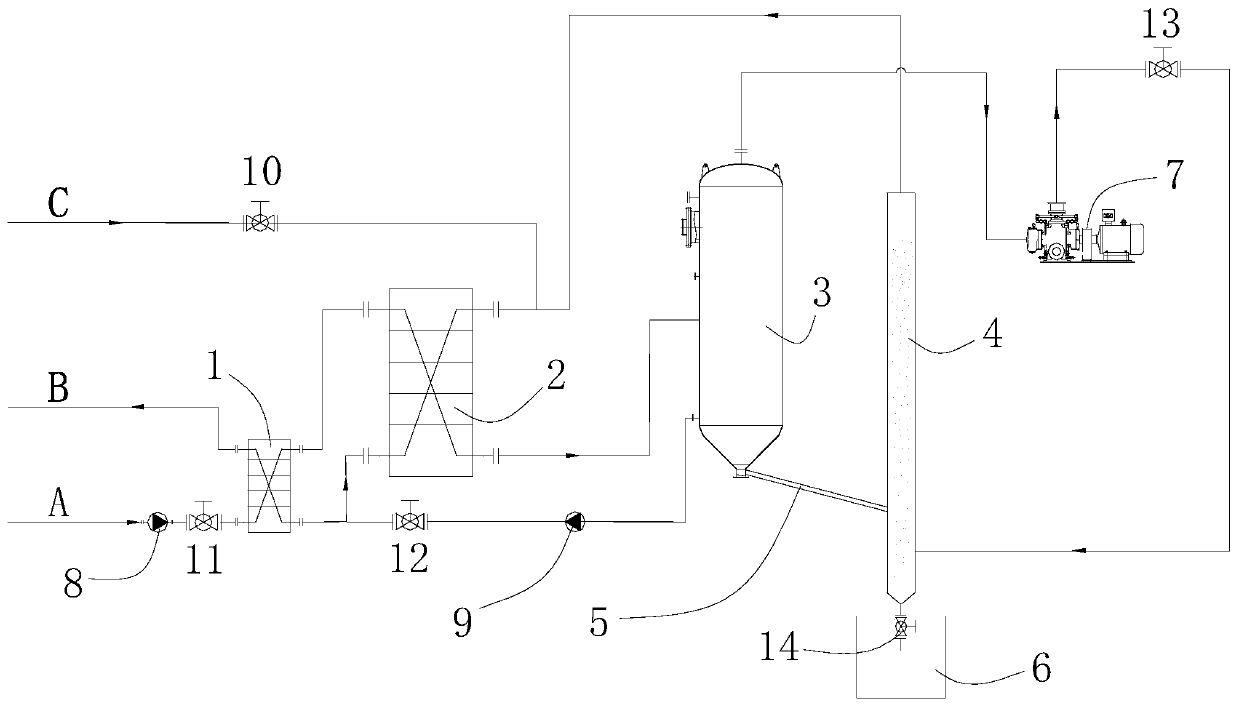

Method for treating wastewater of dilute thiamine containing acrylonitrile

ActiveCN101092266AImprove recycling qualityQuality improvementWater/sewage treatment by neutralisationWater/sewage treatment by heatingPropionitrileAcrylonitrile

This invention relates to a method for treating diluted ammonium sulfate wastewater containing propionitrile. The method solves the problems of high solid waste and organic nitrile impurity contents, low ammonium sulfate concentration, difficult ammonium sulfate recovery, and low recovered ammonium sulfate quality. The method comprises: (1) removing solid impurities from diluted ammonium sulfate wastewater containing propionitrile, and adjusting the pH value to 6.5-7.5 to obtain material flow 1; (2) sending material flow 1 into a liquid-gas separator, and performing stripping or rectification; (3) removing lightweight organic fractions at the overhead of the liquid-gas separator, collecting polymer fractions at the bottom, extracting the rest wastewater at 1st-5th theoretical plates from the overhead to obtain material flow 2, extracting water free of solids and organic matters from 1st-10th theoretical plates from the bottom to obtain material flow 3, mixing material flow 3 with water added by the quenching system and diluted acid, circulating to the quenching column, and recovering ammonium sulfate from material flow 2.

Owner:CHINA PETROLEUM & CHEM CORP +1

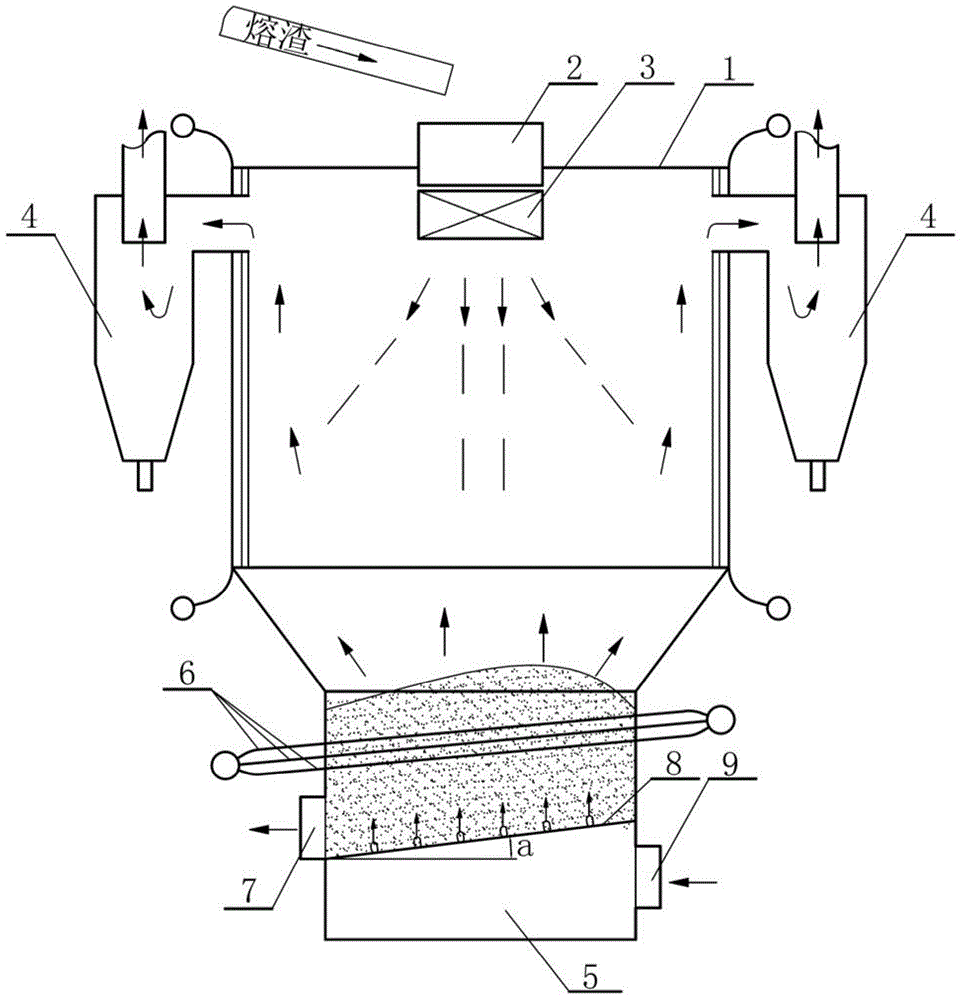

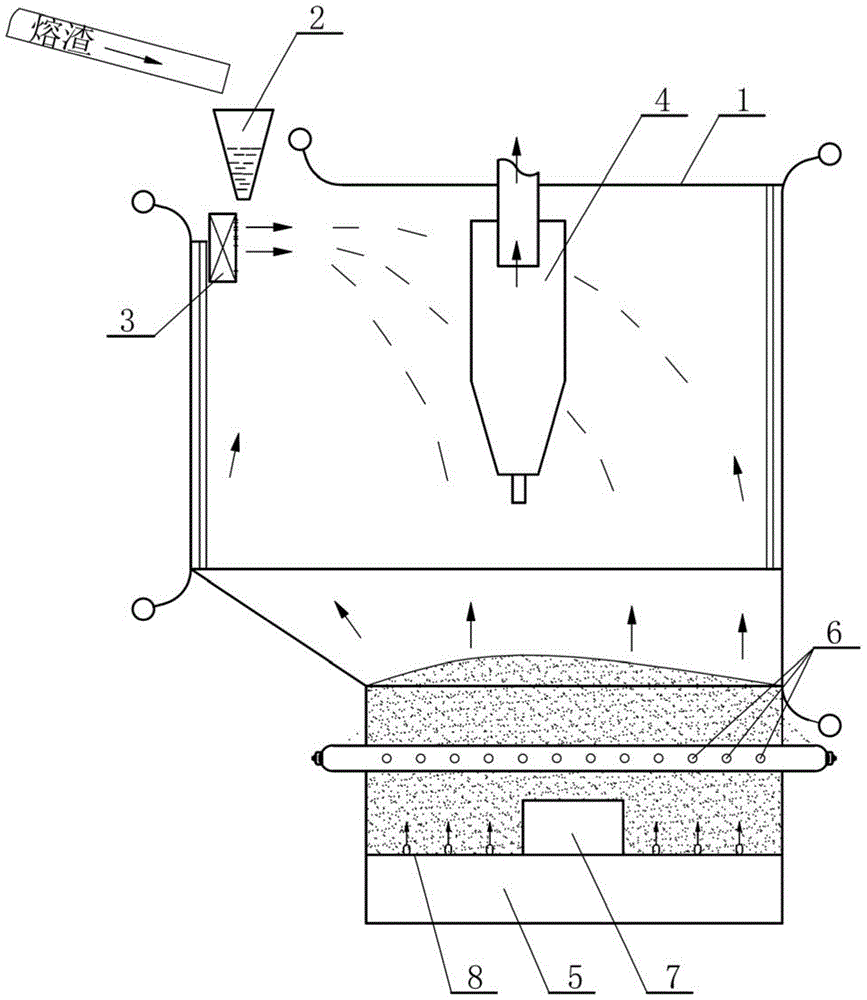

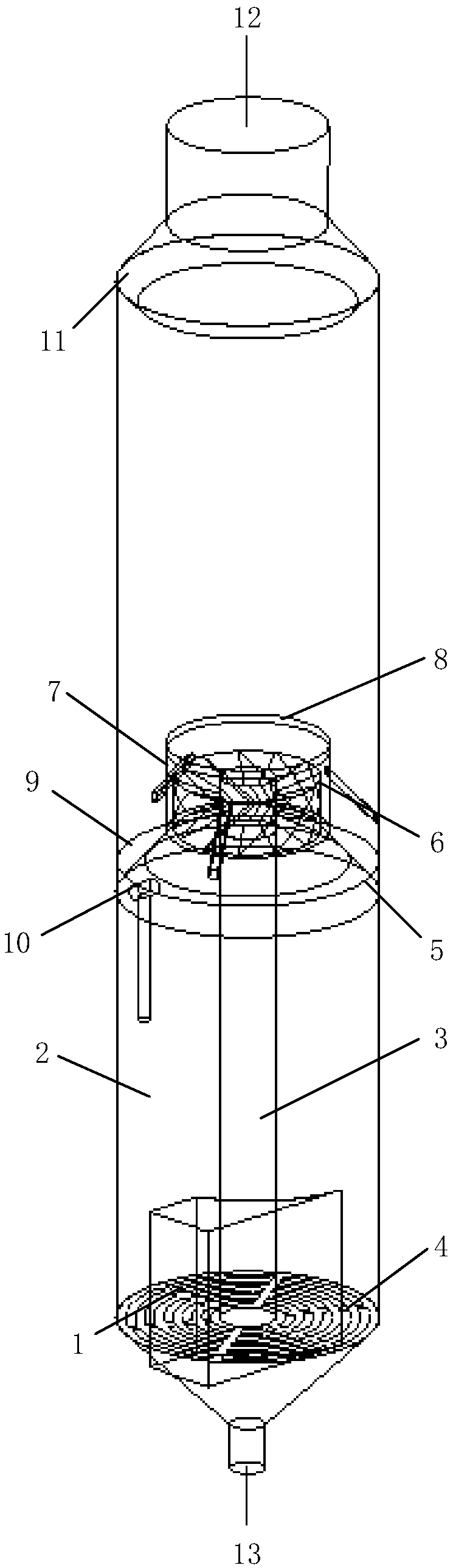

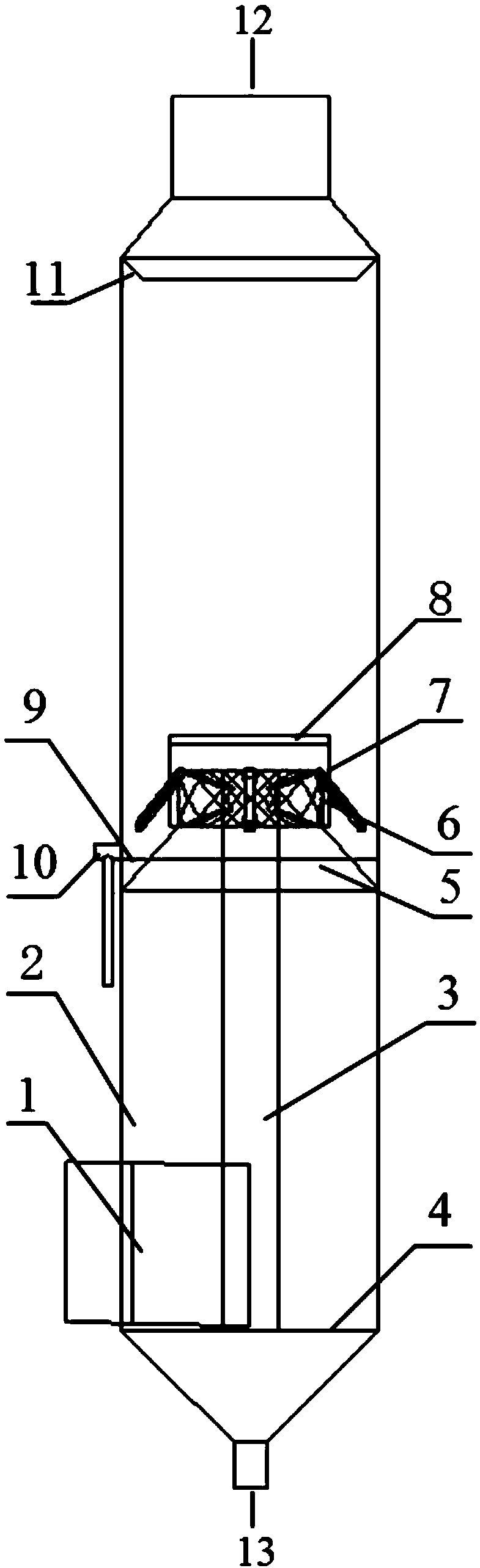

Metallurgical molten slag granulation and heat energy recovery device

InactiveCN104388610AGood cooling effectImprove heat recovery efficiencyRecycling and recovery technologiesWaste heat treatmentThermal energyPhencyclone

The invention relates to a metallurgical molten slag granulation and heat energy recovery device belonging to the technical fields of metallurgical molten slag treatment and waste heat recovery and utilization. The device contains a device body, a granulation apparatus, a cyclone separator and a molten slag funnel, wherein the molten slag funnel is arranged at the upper part of the device body; the granulation apparatus is closely arranged under the molten slag funnel; the cyclone separator is arranged on the side wall of the device body; and the lower part of the body is provided with a buried heat exchange pipe, a deslagging port, an air distribution plate, an air chamber and an air inlet. By using the device provided by the invention, various kinds of metallurgical molten slag can be effectively granulated, and heat energy of the molten slag can be recovered at high quality to produce hot water, hot air or steam, thus effectively solving various problems in the aspects of metallurgical molten slag granulation, heat energy recovery and the like.

Owner:TSINGHUA UNIV

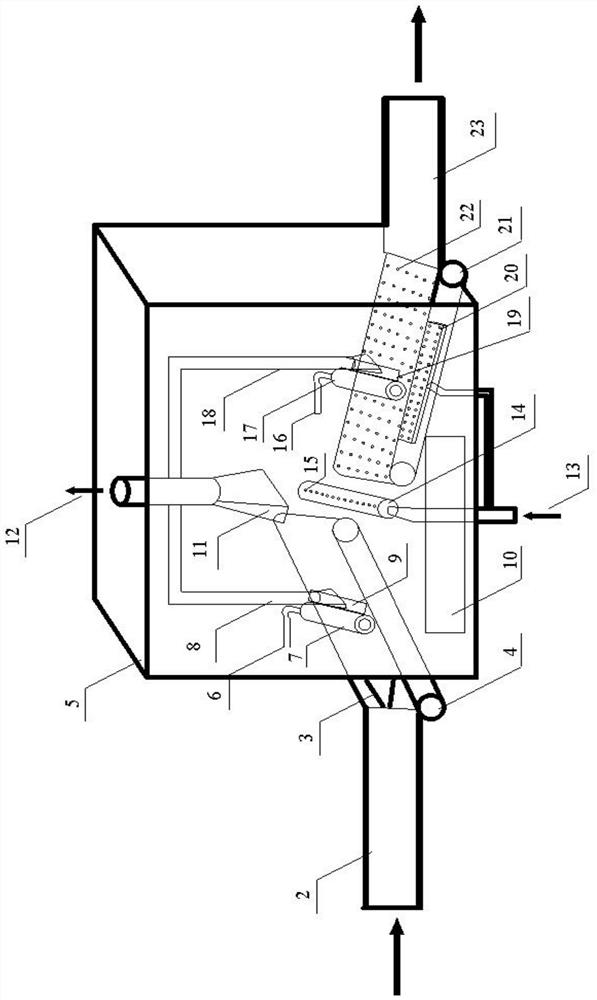

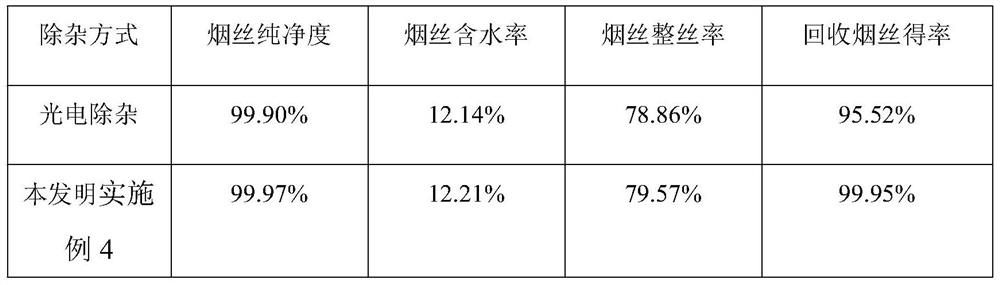

Device for improving purity of discard tobacco and multi-stage impurity-removal method for discard tobacco

PendingCN112044783AImprove purity and use valueHigh purity of shredded tobaccoTobacco preparationGas current separationAgricultural engineeringAgricultural science

Owner:CHINA TOBACCO YUNNAN IND

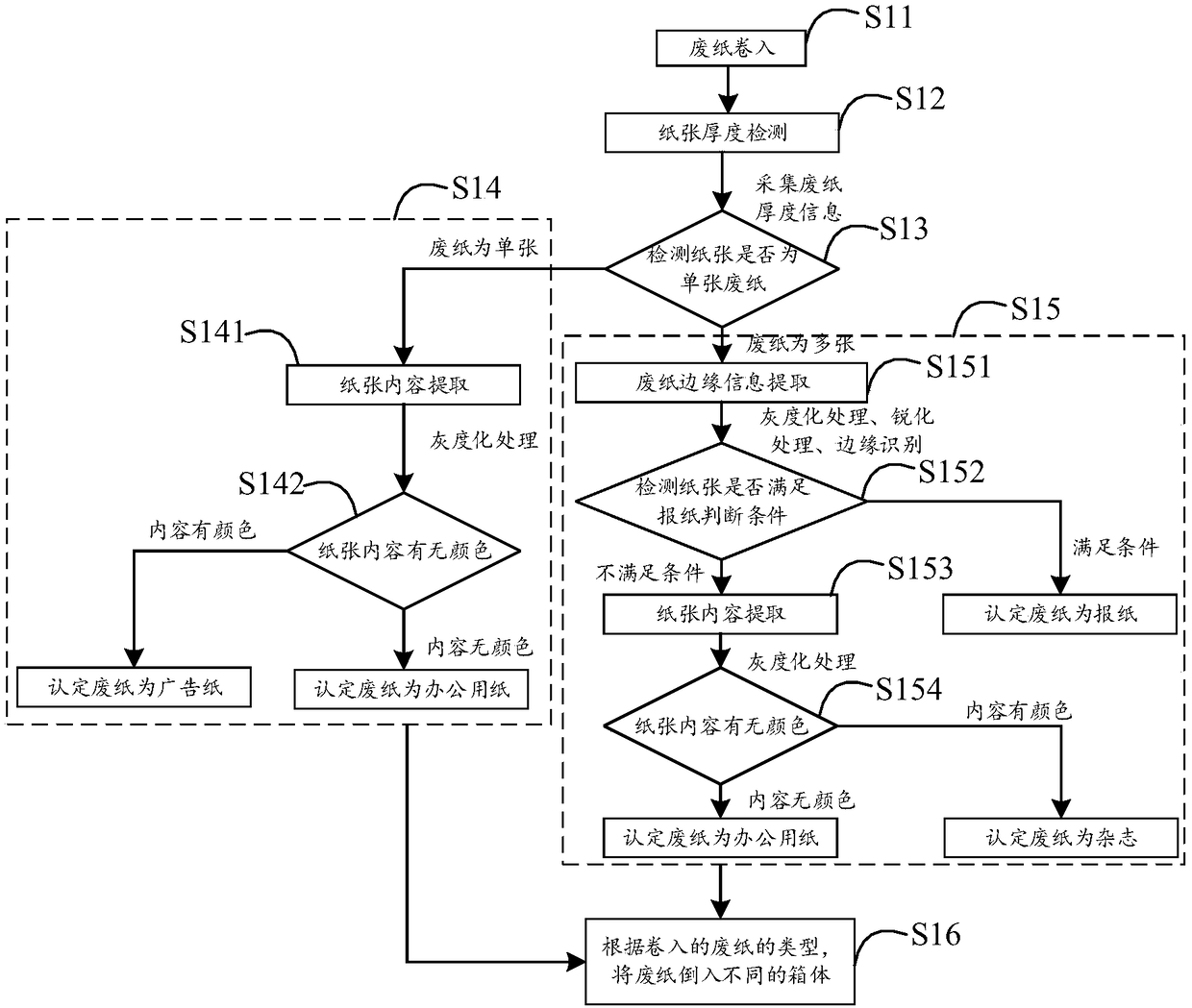

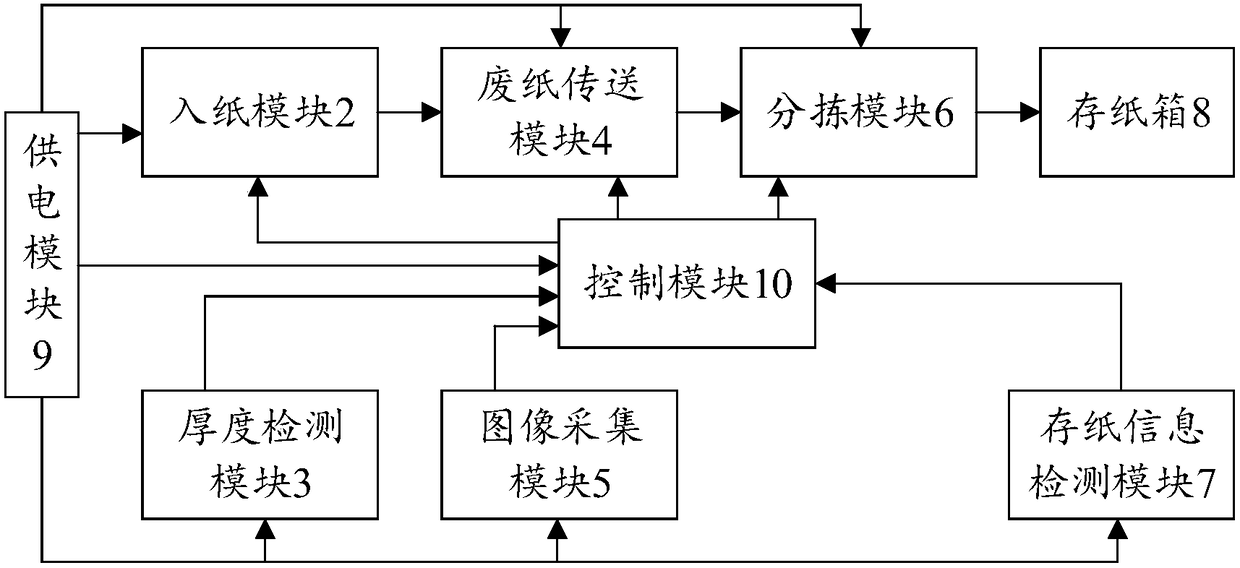

Waste paper classification recycling method, recycling terminal and recycling system

ActiveCN108339755AImprove recycling ratesLow costCharacter and pattern recognitionSortingRecovery methodEconomic benefits

The invention relates to a waste paper classification recycling method, a recycling terminal and a recycling system. The waste paper classification recycling method comprises the steps of winding waste paper; detecting the thickness of the winded waste paper; judging whether the paper is a single waste paper sheet or multiple waste paper sheets according to a detection result; if judging the paperis the single waste paper sheet, determining the type of the winded single waste paper sheet; if judging the paper is the multiple waste paper sheets, determining the type of the winded multiple waste paper sheets; and recycling the waste paper according to the type of the winded waste paper. According to the waste paper classification recycling method provided by the invention, the waste paper is classification recycled, so that the waste paper recycling utilization ratio can be effectively improved, the environment pollution is reduced, the recycling quality is high, and a favorable renewable resource recycling environment can be built. The waste paper classification recycling method provided by the invention can be beneficial to shortening a recycling process and reducing the waste paper recycling cost, and has a great help to the improvement of the economic benefit of a papermaking industry.

Owner:向霄

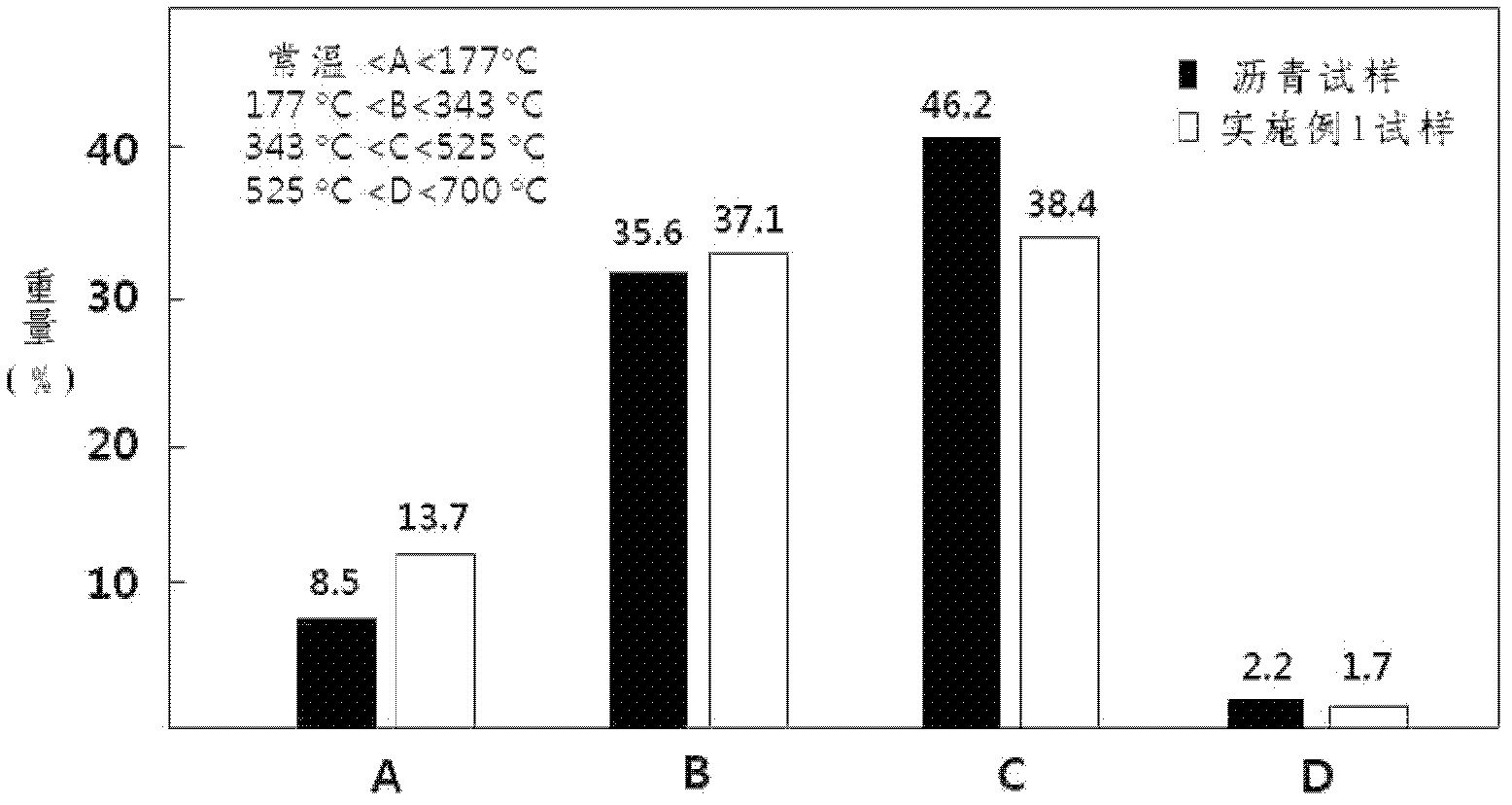

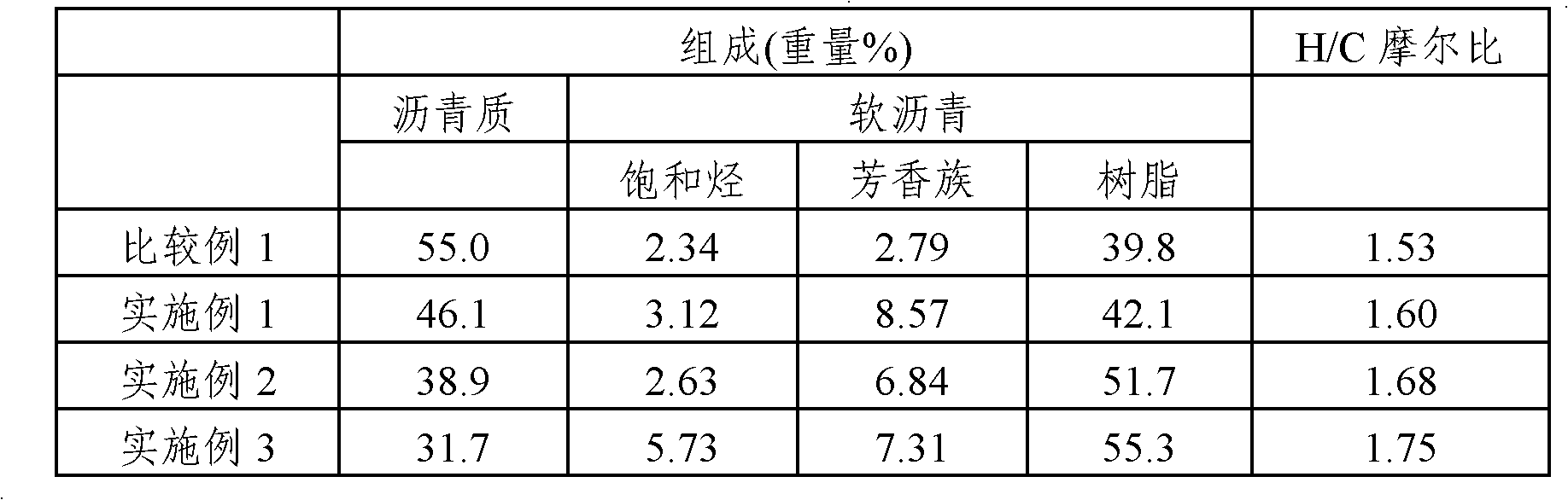

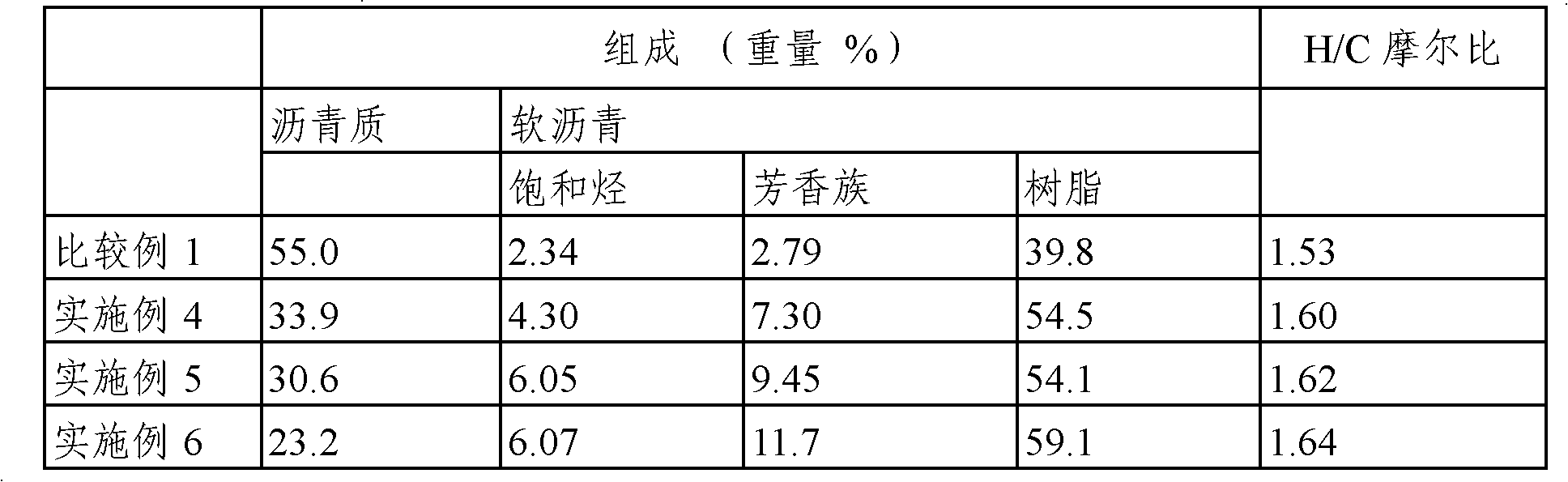

Improved method for recovery and modification of oil sand

InactiveCN102977907ALow viscosityQuality improvementLiquid hydrocarbon mixture productionNon-miscible liquid separationImproved methodHigh pressure

The invention relates to a method for recovering oil component (asphalt) from oil sand and a method for recovering asphalt of improved quality, particularly to a method for recovering asphalt of improved quality from oil sand by application of SAGD technology. The method comprises the following steps: 1) (a) steam and gas generation matter, or (b) steam, CO2 gas and gas generation matter are injected simultaneously; 2) the temperature and pressure of the steam are transmitted to the oil component contained in the oil sand through the CO2 gas and the gas generation matter; 3) the gas generation matter decomposes under high-temperature and high-pressure conditions and gas is generated; 4) the gas generated in the CO2 gas and the gas generation matter interacts with the asphalt, and thus the viscosity of the asphalt is reduced; and 5) the gas generated in the CO2 gas and the gas generation matter under high-temperature and high-pressure conditions reacts with the asphalt. Thus, compared with the method in which only steam is injected when asphalt is recovered from the oil sand, the method by which the quality of the asphalt can be substantially improved is provided.

Owner:KOREA RES INST OF CHEM TECH

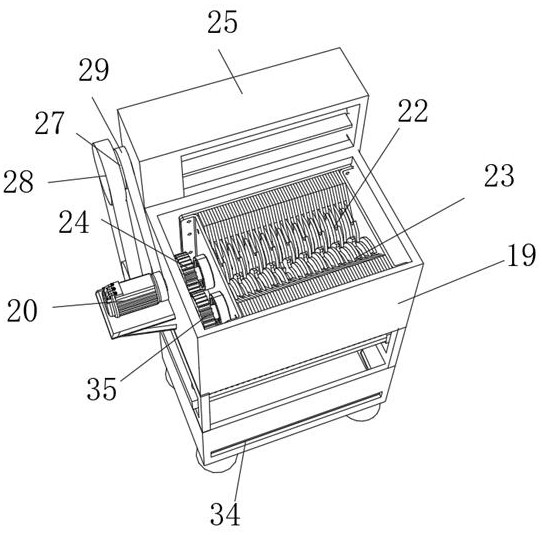

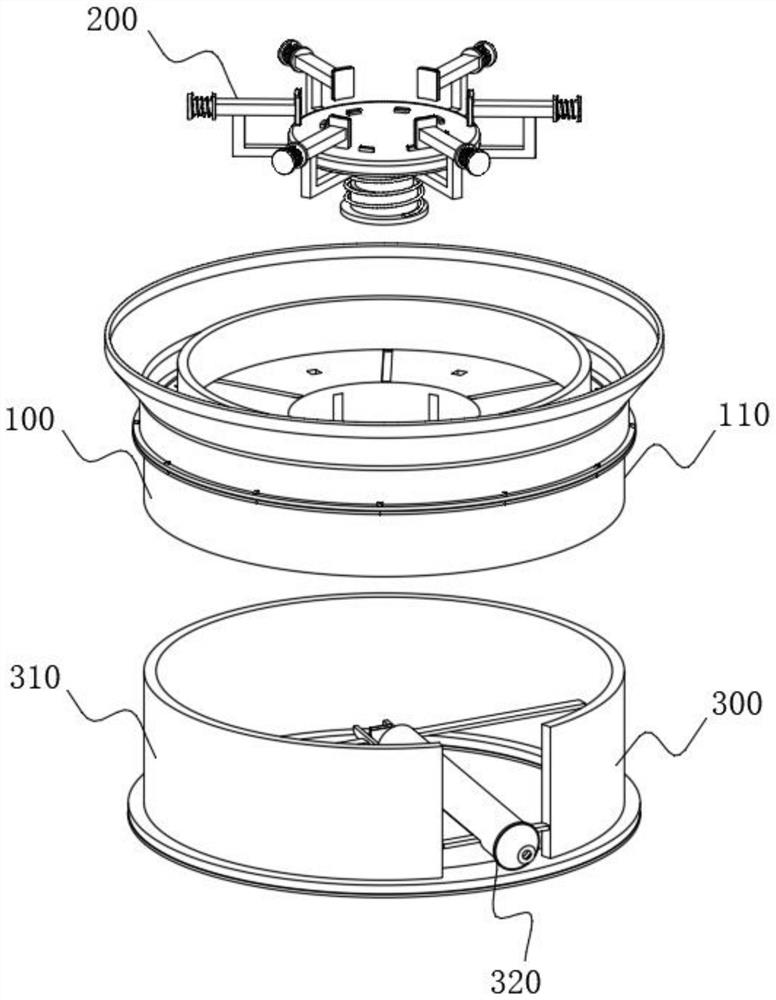

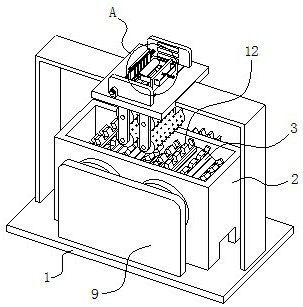

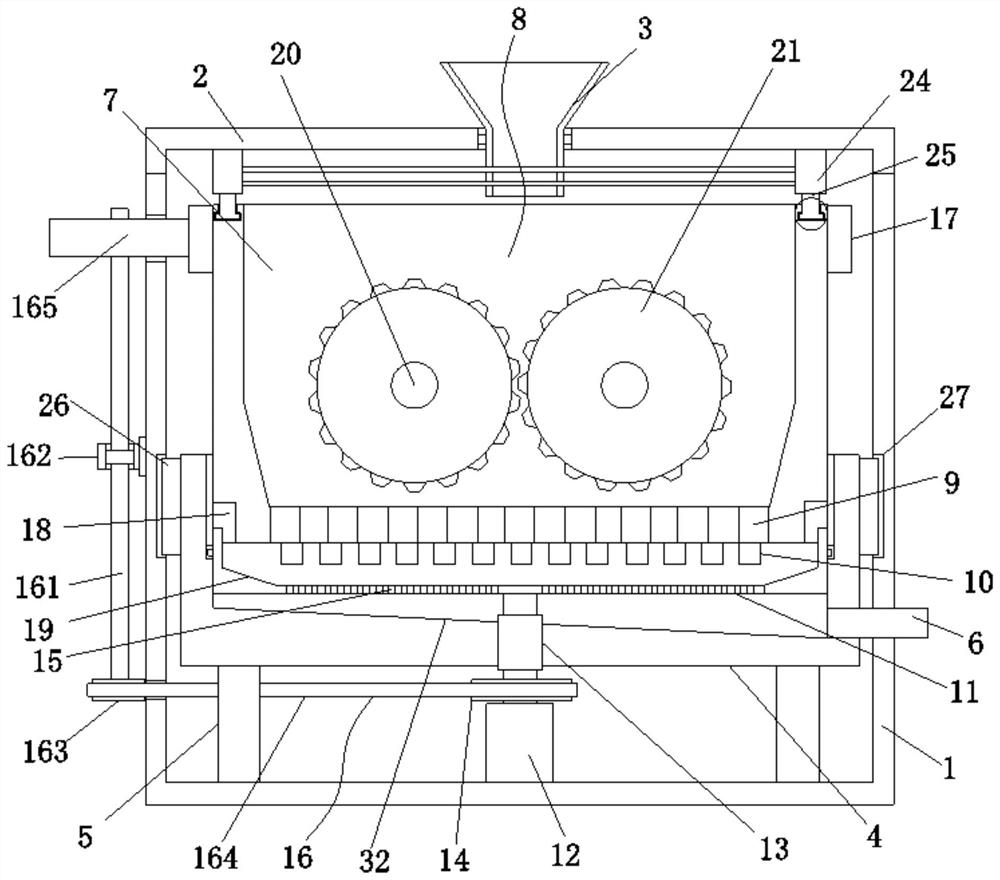

New energy automobile battery recovery device

PendingCN114798112AImprove recycling efficiencyImprove recycling qualitySolid waste disposalTransportation and packagingDrive wheelAutomotive battery

The invention provides a new energy automobile battery recovery device, and relates to the field of new energy automobiles. The new energy automobile battery recovery device comprises a lower shell and a middle shell, and the interiors of through holes in the left side and the right side of the middle shell are each fixedly connected with a set of stand columns. A motor is started to operate to drive a driving wheel, a driving gear, a crushing driving cutter, a crushing driven cutter, a driven wheel, a driven gear, a connecting driven wheel, a connecting driving wheel, a driving roller, a driven roller and a conveying belt to operate, so that the shelled new energy battery can be crushed; then the vibration motor is started to operate, metal materials filtered on the filter plate can be collected, the metal materials which cannot be filtered on the filter plate are conveyed to the top end of the conveying shell and then discharged to the position between the crushing driving cutter and the crushing driven cutter to be crushed again, and the recycling efficiency and the recycling quality of the metal materials can be greatly improved; the loss is reduced.

Owner:SONGUO MOTORS CO LTD

Method and device for recovering NMP (N-methyl pyrrolidone) waste gas in lithium battery production with membrane separation method

ActiveCN107626186AReduce energy consumptionAvoid the problem of easy ingress of airSemi-permeable membranesDispersed particle separationPole pieceImpurity

The invention relates to a technology for recovering NMP (N-methyl pyrrolidone) waste gas in lithium battery production with a membrane separation method and belongs to the technical field of organicwaste gas recovery. The technology comprises steps as follows: NMP waste gas in a lithium battery pole piece drying box is fed into an absorption tower by blast apparatus and absorbed by utilizing water as a solvent, NMP effluent is formed at the bottom of the absorption tower and enters a porous ceramic filtering membrane separator through a circulating pump, NMP and water penetrate through a porous ceramic filtering membrane under the action of pressure difference before and after NMP and water penetrate through the porous ceramic filtering membrane, an NMP-water clear liquid is formed on the rear side of the porous ceramic filtering membrane, and an intercepted liquid returns to a circulating tank; the NMP-water clear liquid is stored in a clear liquid tank and enters a heater for heating under the action of a feed pump; when the heated clear liquid passes through a pervaporation membrane, water penetrates through the membrane while NMP is intercepted, and accordingly, NMP and waterare separated. The operating temperature is lower than the boiling point of an NMP recovered liquid in the recovery process, recovered NMP does not need high temperature and negative pressure and haslow probability of producing new impurities, energy consumption is low, operation is simple, and the technology is a green NMP waste gas recovery technology.

Owner:NANJING MEMBRANE IND TECH RES INST CO LTD

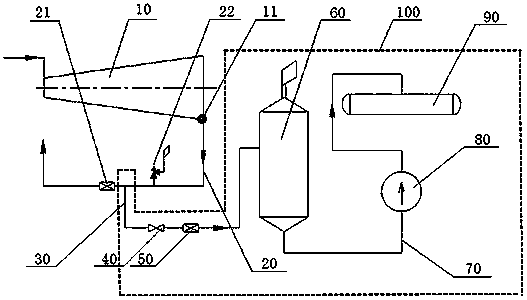

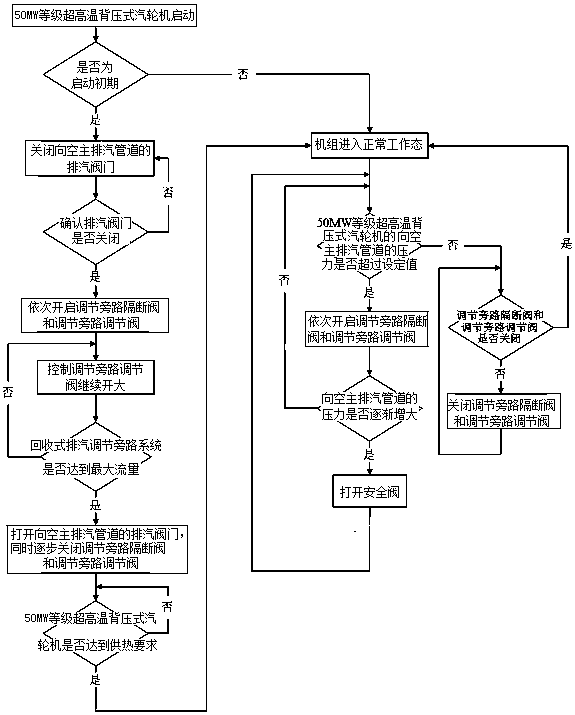

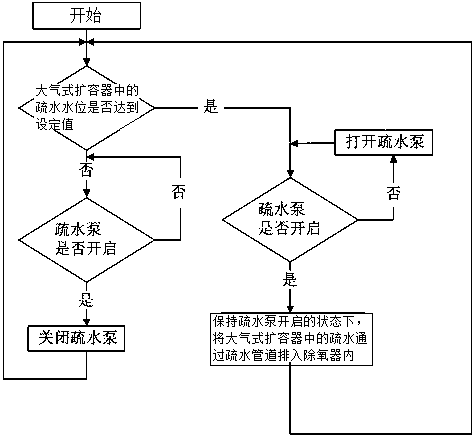

50MW grade ultra-high-temperature back pressure steam turbine recovery type steam exhaust adjustment bypass system and control method thereof

ActiveCN108167029AAccurate speed controlImprove securityMachines/enginesEngine componentsExhaust valvePulp and paper industry

The invention discloses a 50MW grade ultra-high-temperature back pressure steam turbine recovery type steam exhaust adjustment bypass system. The system comprises a 50MW grade ultra-high-temperature back pressure steam turbine and a main atmospheric steam exhaust pipeline; a recovery type adjustment bypass system is further arranged on the part, between a steam exhaust valve and a safety valve, ofthe main atmospheric steam exhaust pipeline and comprises a steam exhaust adjustment bypass pipeline, an adjustment bypass adjusting valve, an atmospheric type flash vessel, a drainage pump and a deaerator; one end of the steam exhaust adjustment bypass pipeline is connected to the main atmospheric steam exhaust pipeline, and the other end of the steam exhaust adjustment bypass pipeline is connected to the atmospheric type flash vessel; the adjustment bypass adjusting valve is arranged on the adjustment bypass pipeline; the atmospheric type flash vessel is connected to the deaerator through adrainage pipeline; and the drainage pump is arranged on the drainage pipeline. The system has the advantage that the 50MW grade ultra-high-temperature back pressure steam turbine can be protected atstarting stage of the 50MW grade ultra-high-temperature back pressure steam turbine and under the working condition of the maximum heating load. Meanwhile, the invention further discloses a specific control method for the system.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

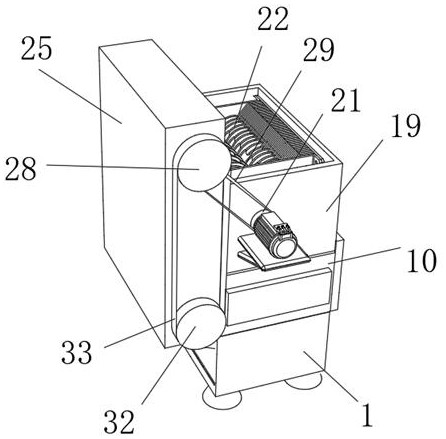

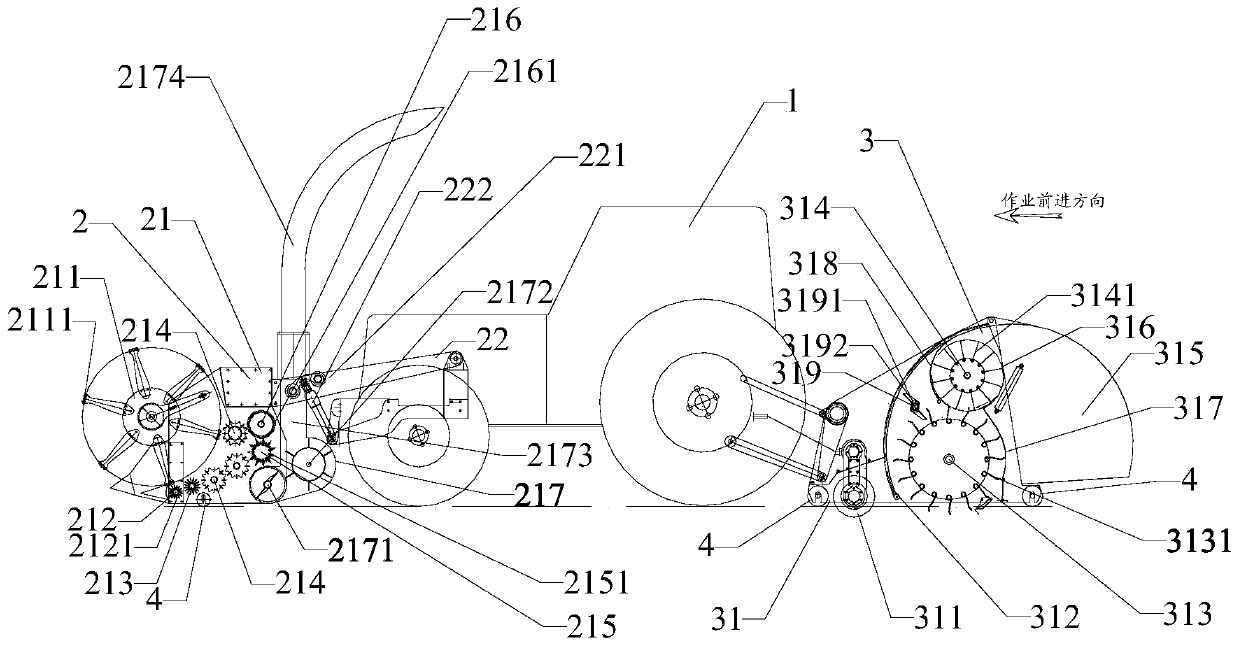

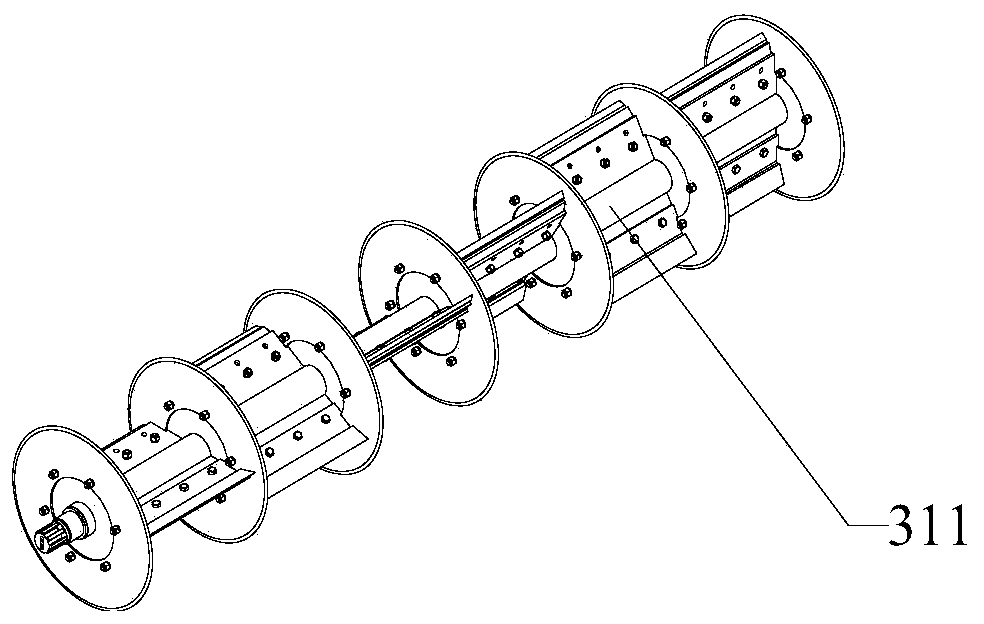

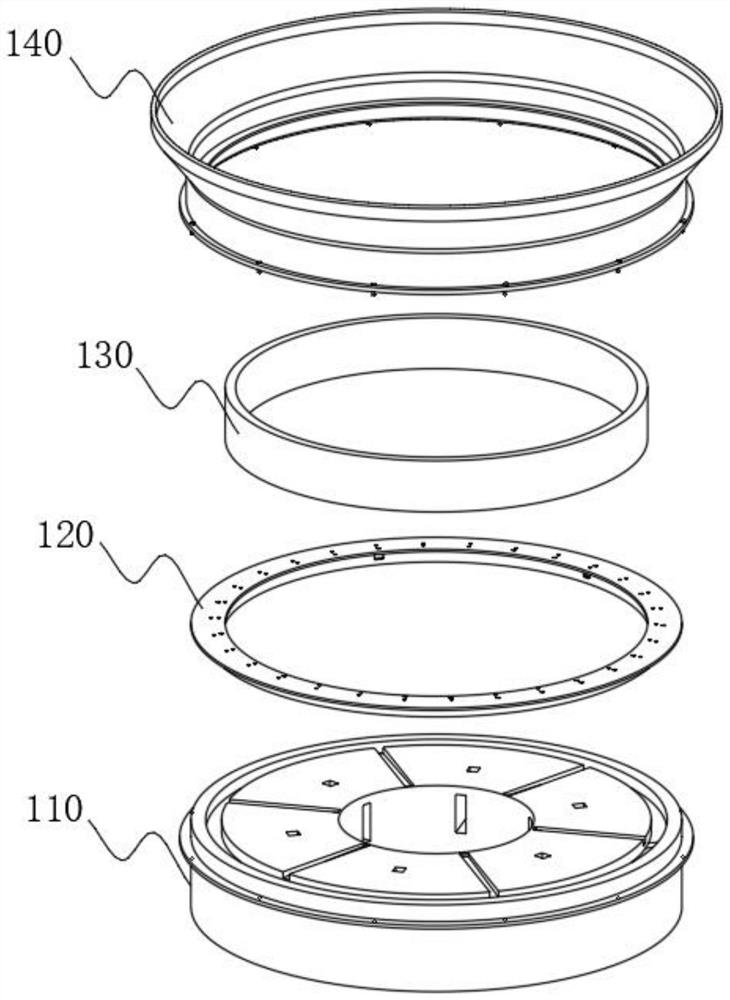

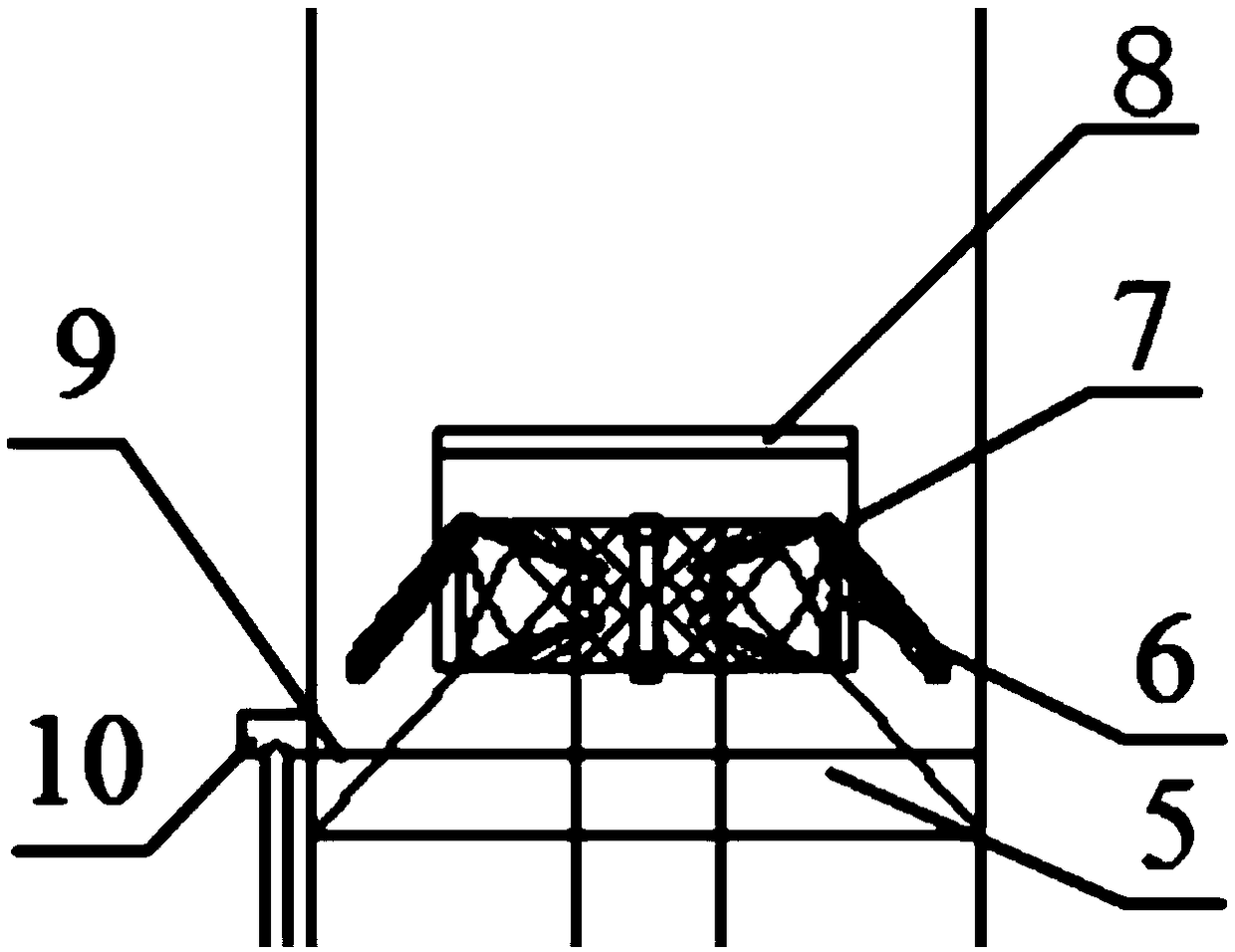

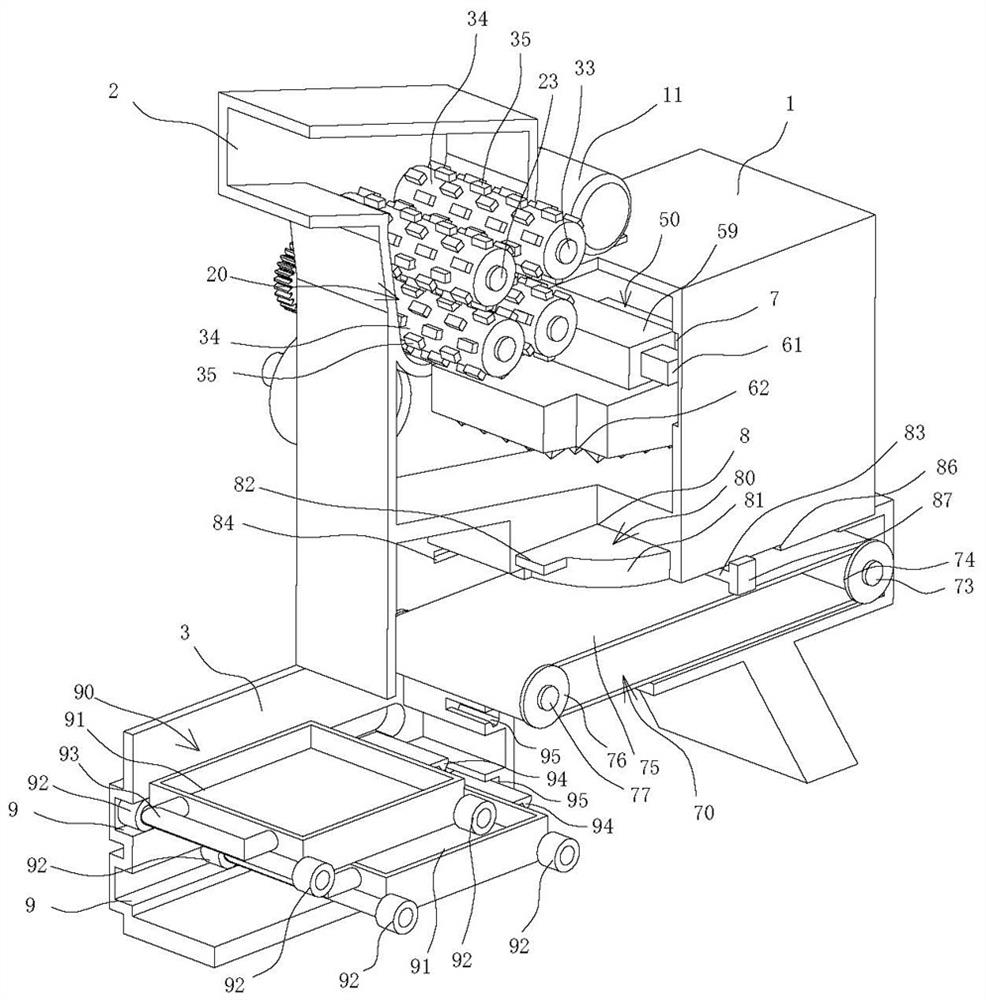

Residual film recovery device and operation method thereof

ActiveCN109819763AImprove agricultural production efficiencyImprove recycling qualityHarvestersGatherer machinesAgricultural engineeringEarth surface

The invention belongs to the technical field of agricultural machinery, and particularly relates to a residual film recovery device and an operation method thereof. The device comprises a carrier, a stalk pulling mechanism and a residual film recovery mechanism; the stalk pulling mechanism comprises a stalk pulling wheel, a main stalk pulling wheel, an auxiliary stalk pulling wheel, a cotton stalktransfer wheel set, a first stalk cutting rotor, a second stalk cutting rotor and a cotton stalk collecting and throwing device; the residual film recovery mechanism comprises a film loosening wheel,a soil retaining plate, a film picking wheel, a film brushing transfer wheel and a film collecting box; the stalk pulling mechanism is connected with the front of the carrier, and the residual film recovery mechanism is connected with the rear of the carrier, so that on a cotton field after picking, pulling, chopping and residual film recycling operation of the cotton stalk and the surface and underground residual film can be completed in one time by the carrier, which not only greatly improves the agricultural production efficiency of cotton field post-treatment, but also greatly improves the quality and quantity of the pulling and cutting of the cotton stalk and the residual film recovery.

Owner:FUJIAN YONGSHUN MACHINERY CO LTD

Methane chloride recycling and feeding process and device

ActiveCN108530260AEliminate damageEliminate quality issuesHalogenated hydrocarbon separation/purificationGas phaseBoiling point

The invention provides a methane chloride recycling and feeding process and device. The process comprises the following specific steps: removing the vast majority of dust from a methane-chloride-containing gas mixture from the top of a reactor via a dust removal system, and then washing the gas mixture via a dust removal tower to remove high-boiling-point substances and fine powder; after condensing a material on the top of the dust removal tower via a cooling system, taking part of the material as a cleaning solution, and feeding the other part of the material to a refining tower; feeding noncondensable gas in the cooling system to a compressing system; carrying out heat exchange on compressed gas and liquid methane chloride via a vaporizer, vaporizing the liquid methane chloride, coolingand condensing the compressed gas, and then feeding the compressed gas into a condenser for further condensing, carrying out tail gas removal treatment on noncondensable gas in the condenser, and feeding condensate to a buffering tank; enabling the methane chloride of the buffering tank and the methane chloride of a storage tank to enter the refining tower together; and enabling a gas phase on the top of the refining tower to enter a partial condenser for partial condensing, and feeding the condensate into a refluxing tank and totally refluxing the condensate into the refining tower. The methane chloride can be recycled effectively, the main content is higher than 99.5%, moreover, the process is simple, the investment of equipment is low, and energy conservation and consumption reductionare implemented.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

Volatile organic matter condensing device

InactiveCN103028269AImprove recycling qualityImprove the separation effectVapor condensationVolatile organic compoundWater soluble

The invention relates to a volatile organic matter condensing device; a first condenser is disposed inside a waste gas flow channel; a water sprinkler is disposed at the downstream end of the first condenser; most water-soluble volatile organic matter is separated by the first condenser, and then water mist is sprinkled to waste gas flow passing through by the water sprinkler so as to separate residual water-soluble volatile organic matter by using the absorption effect of water drop; a second condenser is further disposed at the downstream end of the water sprinkler. Therefore, the volatile organic matter condensing device is provided which has the effects of improving recovery quality and separation effect of volatile organic matter.

Owner:CHENG YUAN ENVIRONMENTAL TECH

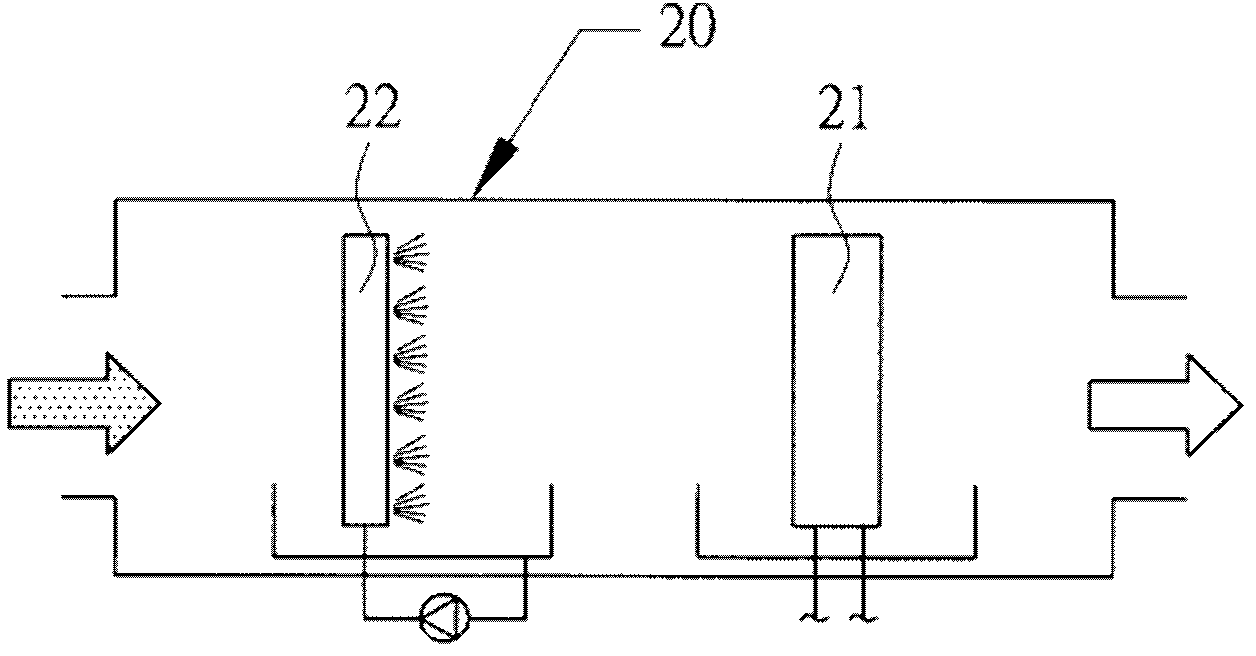

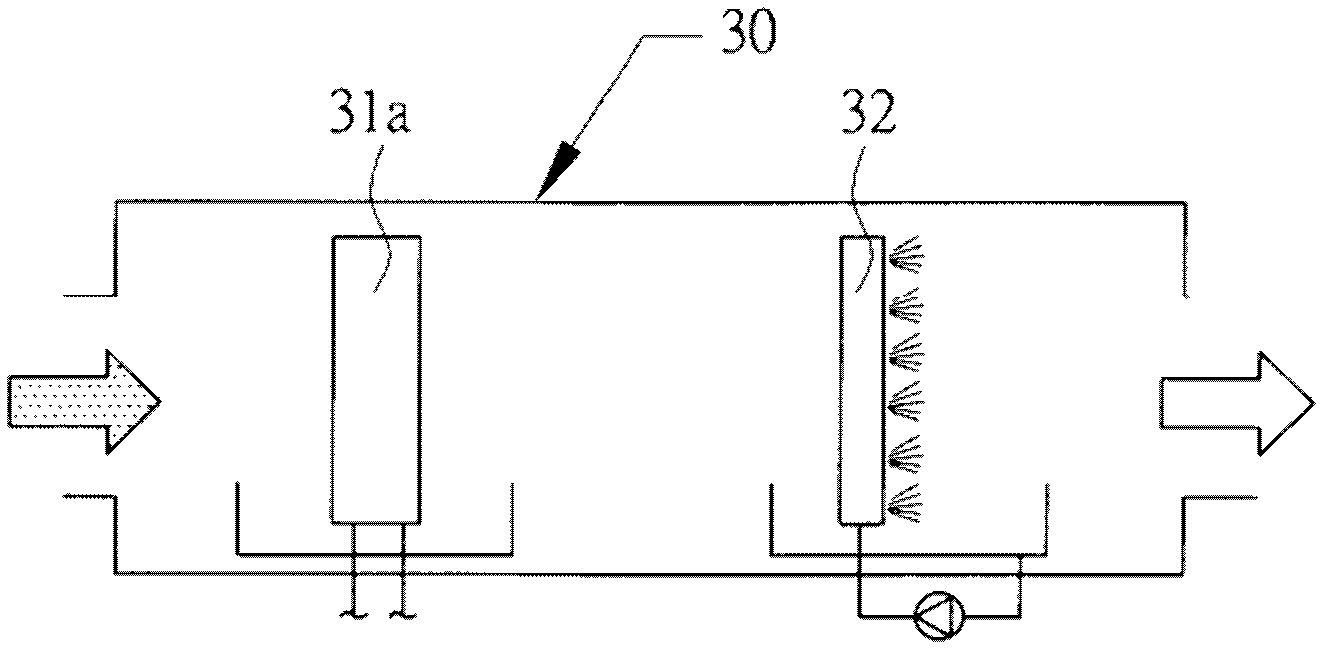

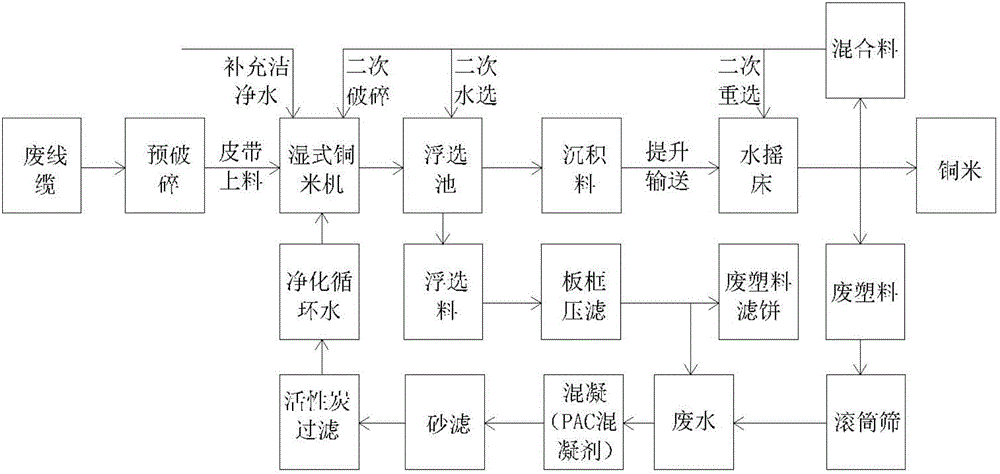

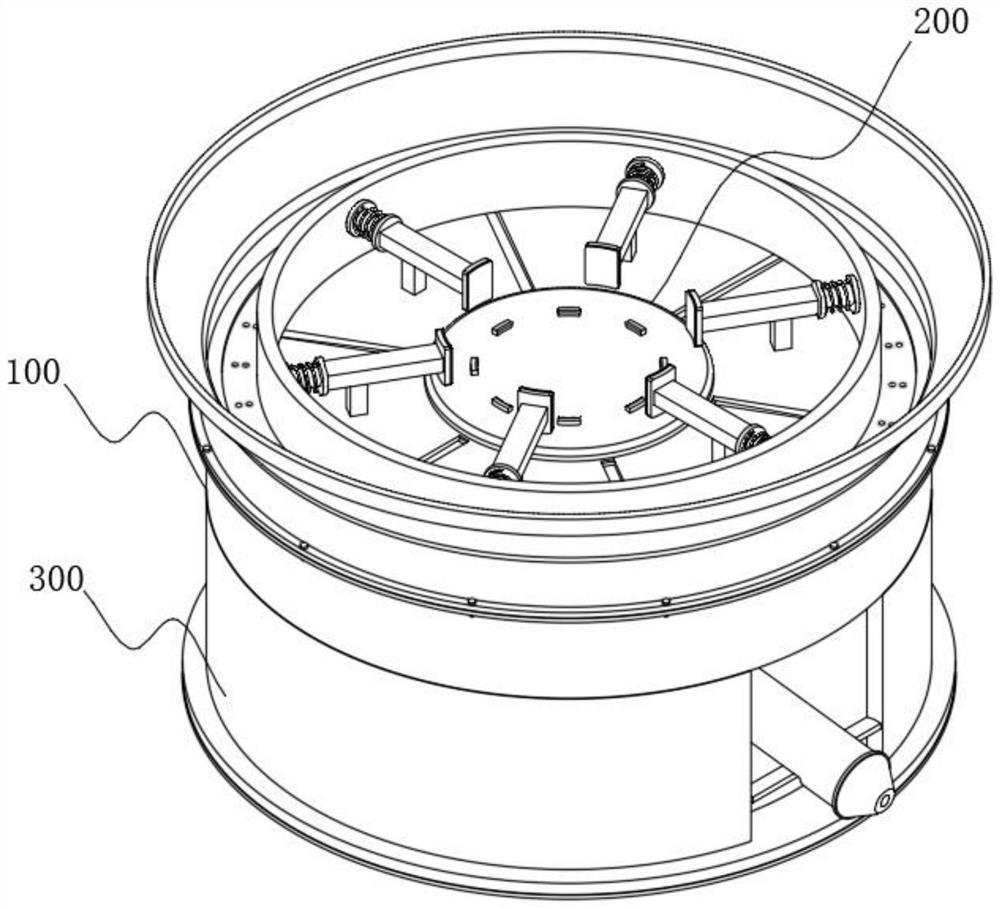

Wet crushing and separation technique for waste electric wire cable

ActiveCN106205895APrevent splashImprove working environmentBasic electric elementsElectronic waste recyclingWater concentrationWorking environment

The invention discloses a wet crushing and separation technique for a waste electric wire cable. The technique comprises the steps of crushing, and concentrating by using water. According to the method, separation of copper grains and plastic can be implemented in a water environment, generation of swirling dust and splashing materials can be avoided, and the working environment of workers can be improved. Furthermore, two times of separation, water concentration and gravity separation, are adopted, so that the copper grains and the plastic can be separated, the light floating plastic and the heavy sinking plastic can also be separated, and thus recycle quality of copper and plastic is improved.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

Recovery method of N-methyl pyrrolidone

InactiveCN111018768AImprove qualityHigh boiling pointOrganic chemistryPyrrolidinonesMethyl palmoxirate

The invention discloses a recovery method of N-methyl pyrrolidone. The recovery method comprises the following steps: 1) taking a waste material of a lithium battery electrode material, adding deionized water into the waste material, uniformly stirring, soaking, crushing, and performing ultrasonic wave dispersion in the crushing process to obtain a waste material mixed solution; 2) adding a flocculating agent into the waste material mixed solution obtained in the step 1), stirring, standing, and filtering to obtain solid floc and filtrate; 3) feeding the filtrate obtained in the step 2) into areaction kettle, heating the filtrate in the reaction kettle, and fractionating the filtrate; and 4) feeding the N-methyl pyrrolidone crude liquid obtained in the step 3) into the reaction kettle, heating the filtrate in the reaction kettle, and rectifying the N-methyl pyrrolidone crude liquid. The method is beneficial to improving the quality of subsequent N-methyl pyrrolidone fractionation, improving the recovery quality of N-methyl pyrrolidone and saving energy.

Owner:赣州中能实业有限公司

Packaging machine for fixing can through arc-shaped structure

ActiveCN112225144AMobile automationImprove stabilityFlanged caps applicationEngineeringStructural engineering

The invention relates to the technical field of packaging machines, in particular to a packaging machine for fixing a can through an arc-shaped structure. The packaging machine comprises a supportingdevice, a fixing device and a collecting device arranged at the bottom of the supporting device. The supporting device comprises a supporting base. A containing groove is formed in the circle center of the top of the supporting base. A plurality of sliding grooves are annularly formed in the periphery of the inner wall of the containing groove at equal intervals. The tops of the sliding grooves penetrate through the top wall of the supporting base. The inner sides of the sliding grooves penetrate through the inner wall of the containing groove. An installing plate is arranged on the peripheryof the top of the containing groove and fixedly connected with the top wall of the supporting base. The fixing device is arranged in the containing groove. According to the packaging machine, throughthe arrangement of an extrusion disc and a clamping rod, the movement of a connecting rod is more automatic, a can body can be fixed and disengaged by simply placing and taking out the can body, and accordingly convenience and linkage during use are improved; and meanwhile, through an arc-shaped fastening plate, an elastic gasket is tightly attached to the surface of the can body, and accordinglythe stability of fixing the can body through the fastening plate is improved.

Owner:湖南芝麻官农业科技有限公司

Cleaning sterilization agent of recycled rubber

InactiveCN104327967AImprove recycling qualityEfficient use ofBiocideNon-surface-active detergent compositionsCentipedeThlaspi arvense

The invention relates to a cleaning sterilization agent of a recycled rubber. The cleaning sterilization agent comprises, by weight, 20 parts of tobacco, 8 parts of pepper leaf, 10 parts of garlic, 5 parts of soybean leaf, 10 parts of zanthoxylum bungeanum leaf, 5 parts of mulberry leaf, 5 parts of centipede, 10 parts of folium artemisiae argyi, 10 parts of ginkgo leaf, 5 parts of heartleaf houttuynia herb, 10 parts of indigowoad root, 6 parts of scutellaria baicalensis georgi, 8 parts of mariguana, 10 parts of cortex phellodendri chinensis leaf, 5 parts of common motherwort herb, 10 parts of peppermint, 5 parts of clove, 5 parts of thlaspi arvense linn, 5 parts of sophora flavescens ait, 5 parts of sophora japonica linn, 10 parts of ailanthus altissima bark, and 10 parts of bitter peach branch. During preparation, the components are weighed according to the weight ratio, crushed and mixed, water or 70-75% ethanol or ether is adopted to extract twice to obtain the extract, and drying, powder grinding and storage are performed. During use, dissolving is performed with an alcohol solution, and then 800-1200 times water spray is blended. The cleaning sterilization agent has characteristics of simple component, convenient preparation, good cleaning sterilization effect, removal of stain, oil stain and other debris on the rubber surface, rubber recycling quality improving, product processing quality improving, and effective resource utilization.

Owner:ANHUI AOFENG AUTOMOBILE FITTINGS

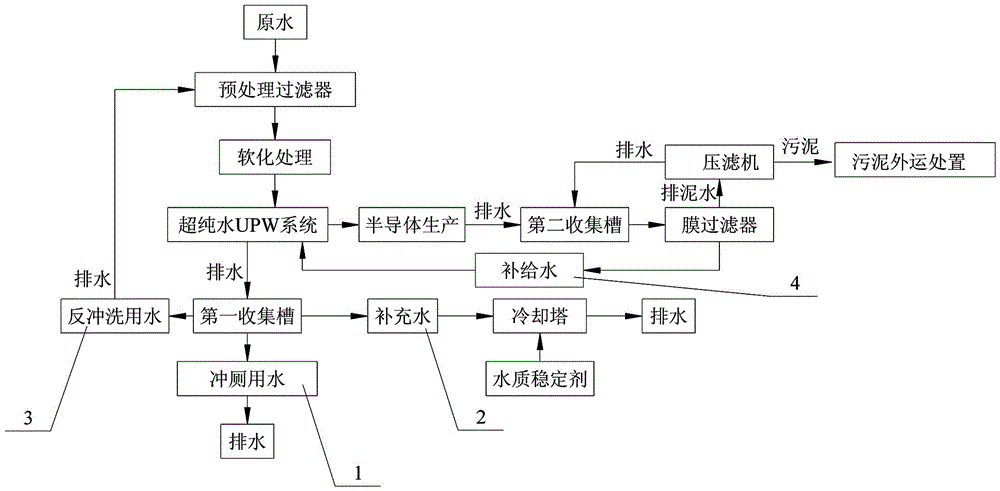

Plant water conservation and usage system in semiconductor industry

InactiveCN103145268AMeet the water quality requirements for pretreatment and backwashing waterMeet water quality requirementsMultistage water/sewage treatmentCooling towerSoftened water

The invention discloses a plant water conservation and usage system in a semiconductor industry. The water conservation and usage system is characterized in that the system firstly implements softening treatment to original water (municipal running water) through an ion-exchange material, the softened water enters an ultra-pure water UPW system, and most water is made into ultra-pure water which is supplied as semiconductor production water of enterprise; water discharged from the ultra-pure water UPW system is delivered into a first collection groove and is used in three paths, wherein one path is supplied as water supplementation for a cooling tower system of the enterprise, another path is used for flushing toilet in enterprise living quarter and the other path is used for back-flushing of a pretreatment filter; used and discharged water of the semiconductor production water is treated by a membrane filtration through a second collection groove so as to realize a solid-liquid separation; and the water obtained from the membrane filtration is recovered for the second stage reverse osmosis water supplementation in the ultra-pure water UPW system. The water conservation and usage system disclosed by the invention adopts operational research where mathematics and social science intersect as a subject theory, and establishes a water resource management model from aspects of water balance and suitable water quality, so as to achieve recycle of the water resource.

Owner:上海华强环境科技工程有限公司

Cutting fluid recovery device for metal connecting piece machining

InactiveCN105108574ASimple structureEasy to operateMaintainance and safety accessoriesEngineeringMetal

The invention discloses a cutting fluid recovery device for metal connecting piece machining. The cutting fluid recovery device for metal connecting piece machining comprises a shell. A centrifugal roller and an oblique platform located below the centrifugal roller are arranged in the shell. Cribriform dense holes are formed in the side face of the centrifugal roller. The centrifugal roller is connected with a rotating shaft with a motor, and the bottom of the centrifugal roller is communicated with a feeding pipe. A plurality of longitudinal flow guide grooves are formed in the oblique platform. A plurality of magnets are fixed on the inner wall of each longitudinal flow guide groove. A collection groove is formed in the lower end of the oblique platform. The longitudinal flow guide grooves are communicated with the collection groove. The two ends of the collection groove are each connected with a fluid drain pipe penetrating through the shell. The cutting fluid recovery device for metal connecting piece machining is capable of separating out cutting fluid quickly, good in recovery quality and high in efficiency.

Owner:CHONGQING ZUOEN FURNITURE

Crushing treatment machine for recycling and reusing rubber tires

ActiveCN113370420ASmooth entryReduce frictionPlastic recyclingMechanical material recoveryElectric machineryDrive motor

The invention belongs to the technical field of rubber tire recycling, and particularly relates to a crushing treatment machine for recycling and reusing rubber tires. The crushing treatment machine for recycling and reusing the rubber tires comprises a bottom plate, a shell body is mounted on the bottom plate, two rotary drums are mounted on the shell body, a driving motor is fixedly mounted on the upper surface of the bottom plate through a motor base, an output shaft of the driving motor is fixedly connected with one connecting shaft, a cutting mechanism is mounted on the rotary drums, a top plate is installed on the bottom plate through a support, a shaping mechanism is installed on the bottom face of the top plate, and a cleaning mechanism is installed on the top face of the top plate. According to the crushing treatment machine for recycling and reusing the rubber tires, cleaning is carried out on broken stones in water drainage grooves of tire treads through the cleaning mechanism, the condition that the broken stones are mixed with broken rubber tire particles in the crushing process is avoided, and the recycling quality of the rubber tires is improved; and cutting is carried out on the tires in the direction perpendicular to tire cord threads through a cutting knife in the cutting mechanism, and therefore the cord threads in the tires are cut off, the situation that crushed rubber particles are connected together through the cord threads is avoided, and the crushing effect is improved.

Owner:山东鹤鹏技术有限公司

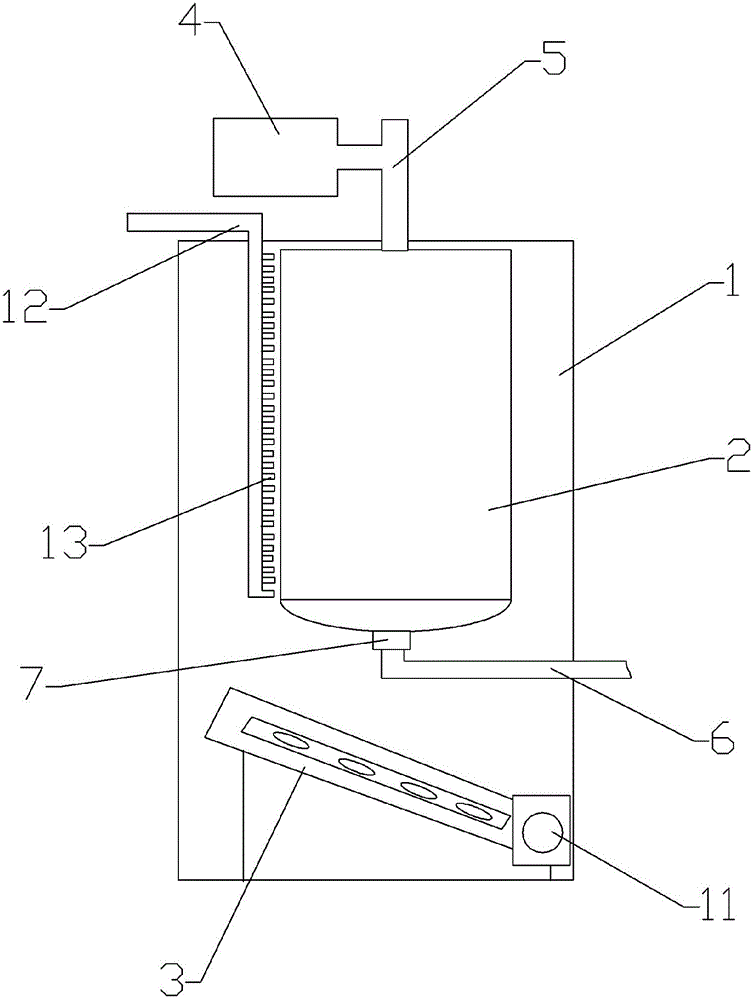

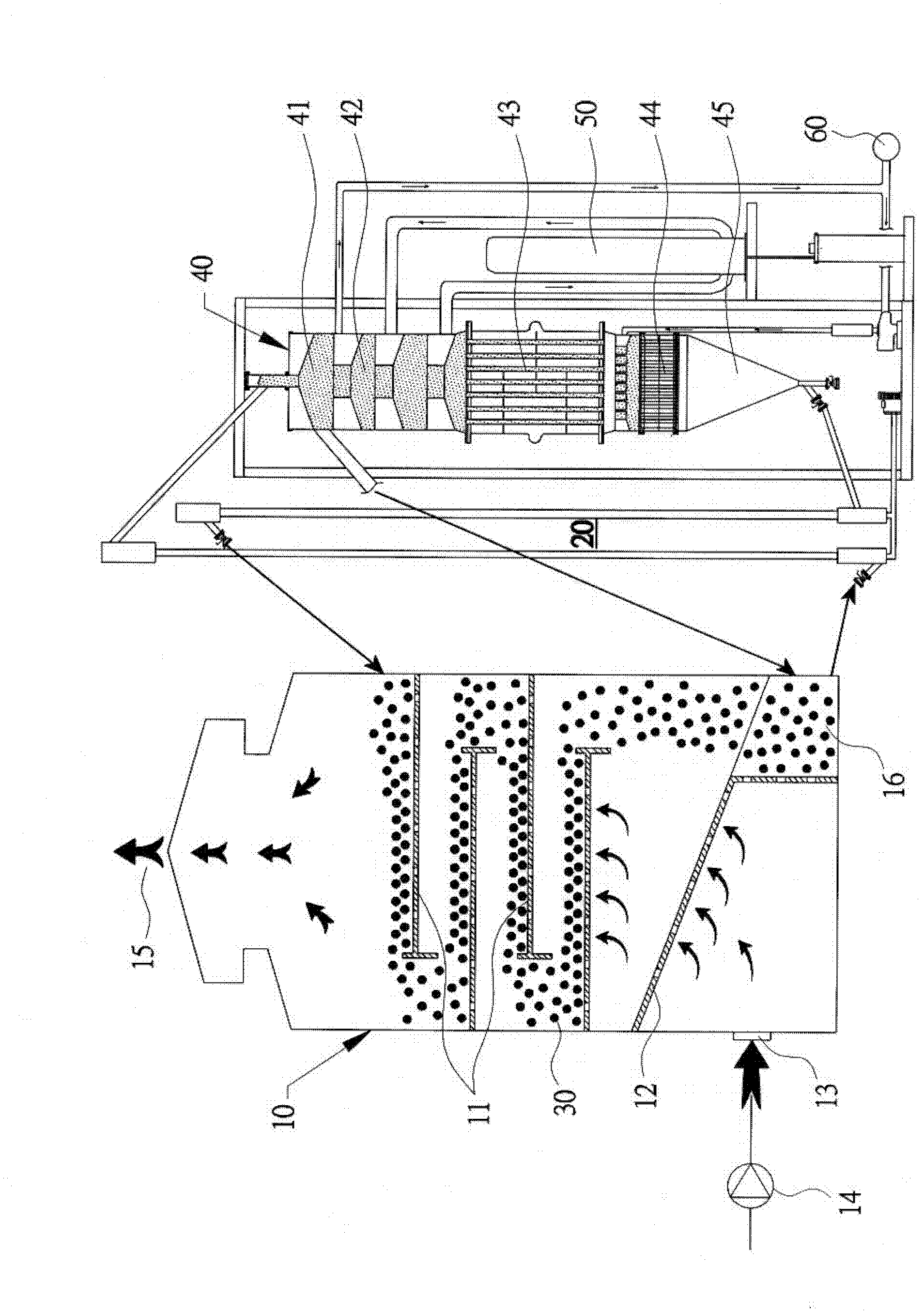

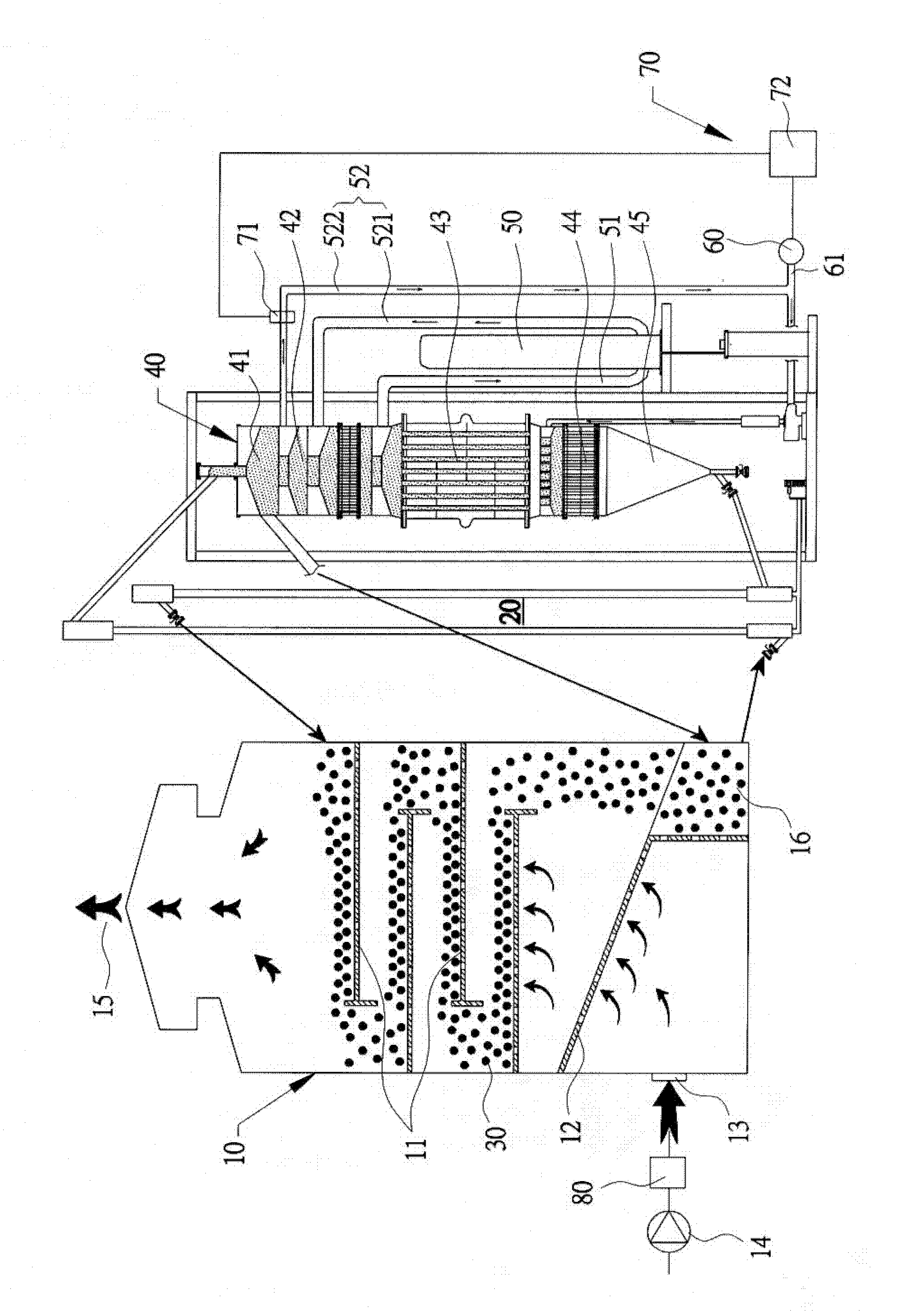

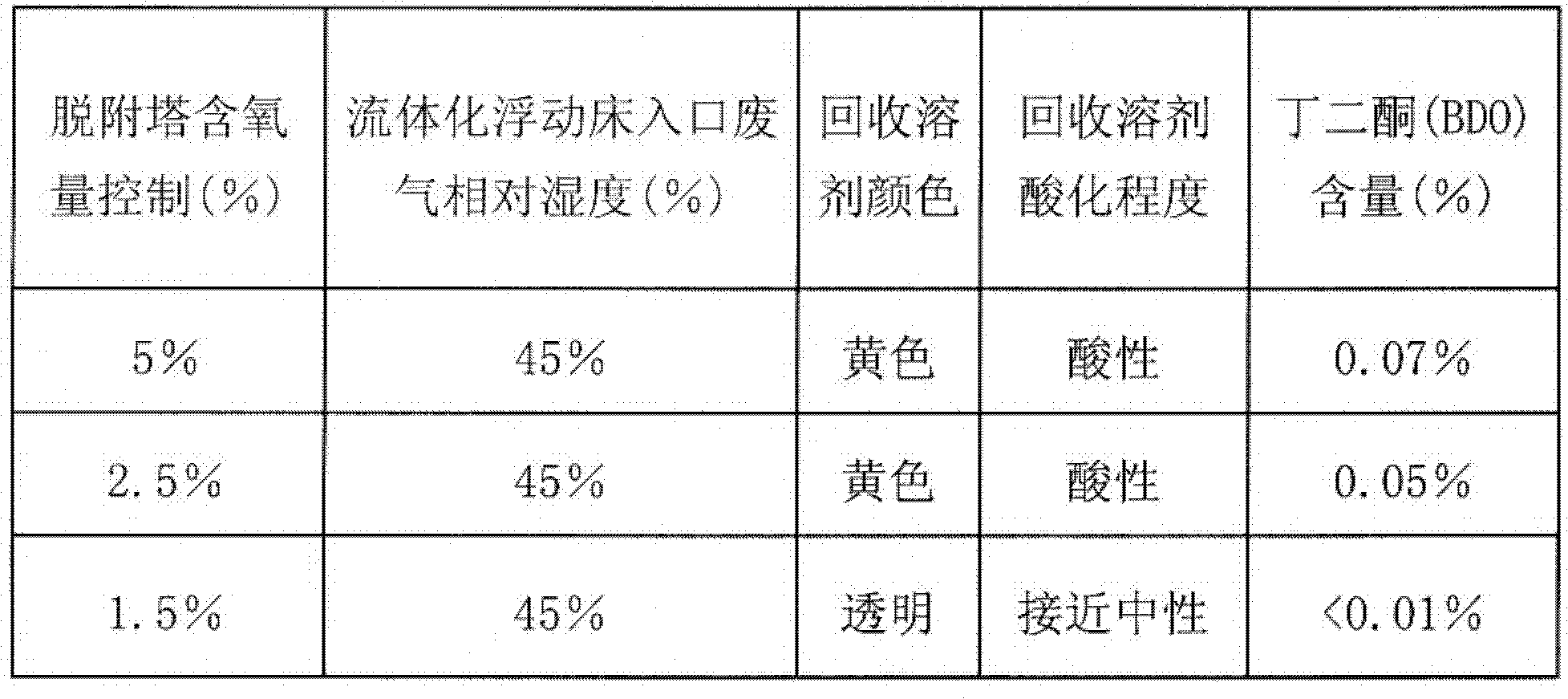

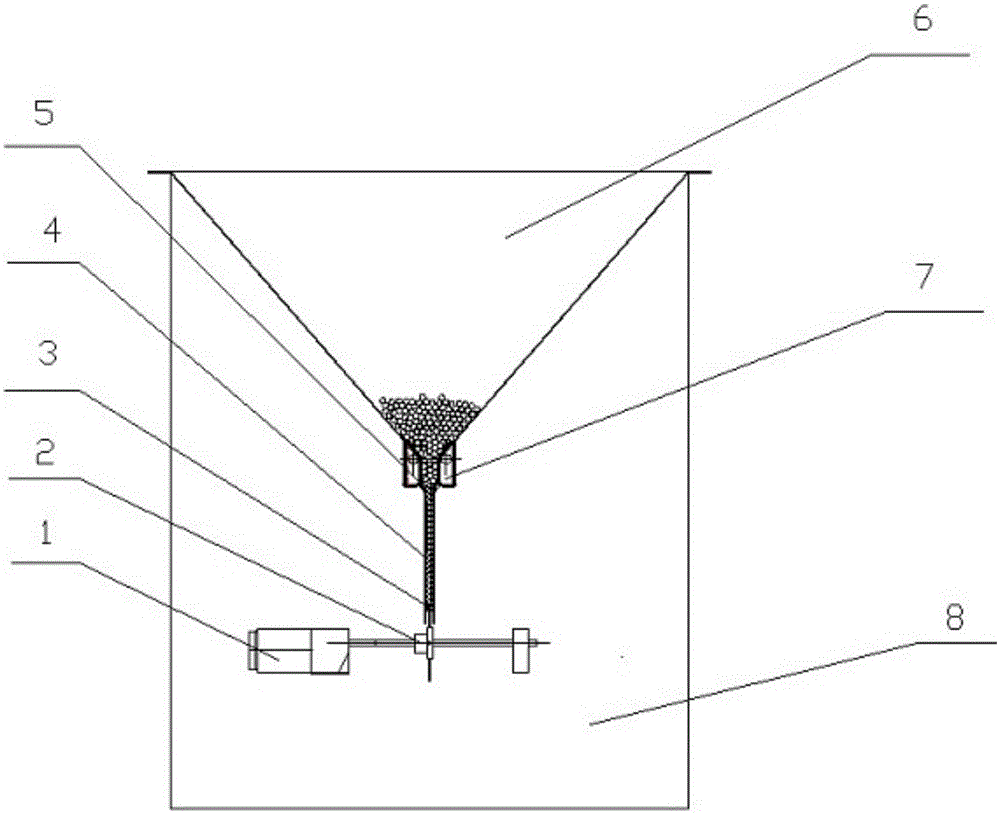

Organic solvent recovery apparatus for increasing recovery quality, method and uses thereof

ActiveCN103007684AImprove recycling qualityOxygen controlDispersed particle separationVapor condensationSolventEnvironmental chemistry

The invention relates to an organic solvent recovery apparatus for increasing recovery quality, a method and uses thereof. The recovery method comprises: an absorption process, wherein an absorption material is adopted to absorb organic waste gas; a desorption process, wherein a desorption air stream is adopted to desorb the organic waste gas absorbed by the absorption material; an oxygen content control process, wherein an oxygen content of the air stream during desorption or after desorption is maintained to less than 1.5%, more preferably less than 0.5%; and a condensation recovery process, wherein high concentration organic gas in the desorbed air stream is subjected to condensation recovery. According to the apparatus and the method, the efficacy that the oxygen content of the desorption process is controlled so as to increase solvent recovery quality is provided.

Owner:JG ENVIRONMENTAL TECH

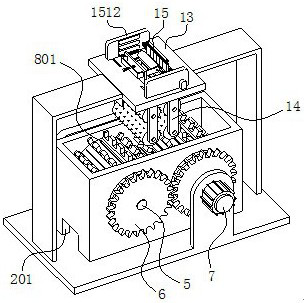

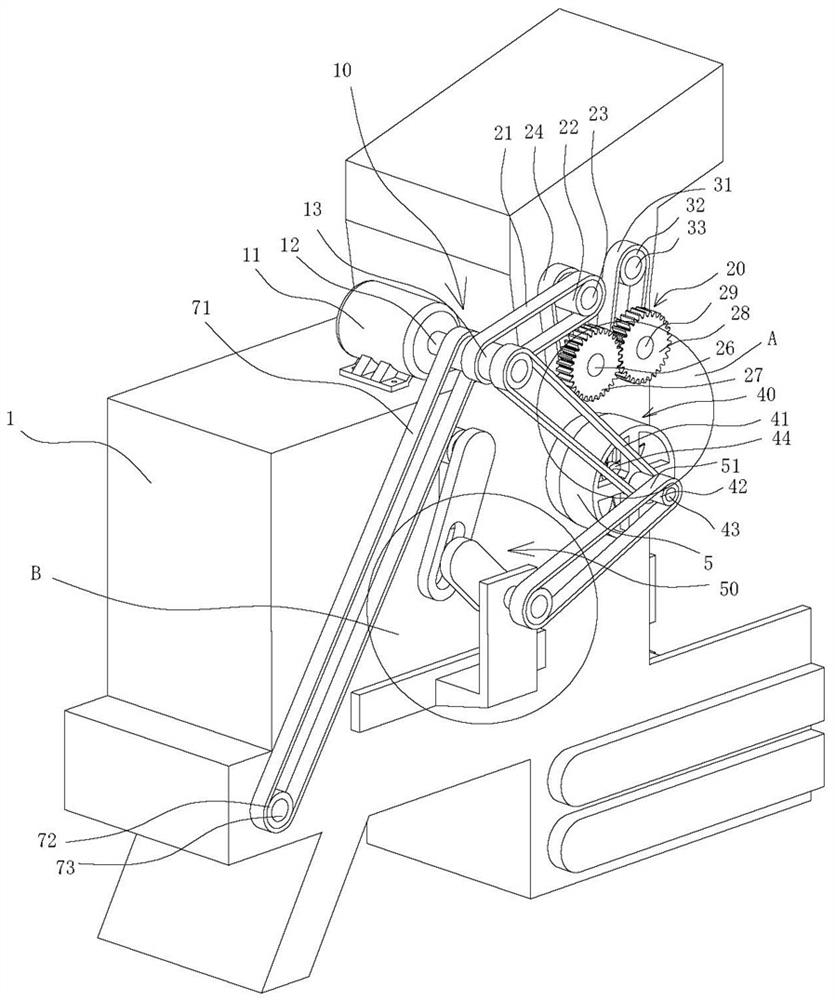

Cigarette acceleration device and defective cigarette recovery and processing device

ActiveCN106418674AImprove processing efficiencyImprove timelinessCigarette manufactureEngineeringScratching

The invention belongs to the field of cigarette packaging and provides a cigarette acceleration device and a defective cigarette recovery and processing device used for recovery and processing of defective cigarettes. The recovery and processing device comprises a cigarette feeding mechanism, the cigarette acceleration device, a cigarette scratching mechanism and a vibration sorting mechanism. The defective cigarettes fall into a cigarette feeding tank under actions of a stirring block and a cigarette poking roller, and the cigarettes are poked into the cigarette acceleration device with a vacuum suction apparatus under the action of a cigarette poking wheel. The cigarette acceleration device is internally provided with a cigarette acceleration passage, a compressed air cavity is connected with the cigarette acceleration passage through an inclined passage, and compressed air serves as a power source for acceleration of the cigarettes in a pipeline. The accelerated cigarettes enter the cigarette scratching mechanism which comprises a rotary guide wheel and a disc cutter in high-speed rotation, the cigarettes in high-speed motion directly fly to a vibration screen for sorting after being scratched, and directly-usable tobacco shreds and separated cigarette auxiliary materials are obtained after sorting. The cigarette acceleration device and the defective cigarette recovery and processing device have advantages of simple structure, convenience and quickness in adjustment, reduction of breakage of the tobacco shreds, high recovery efficiency and the like.

Owner:HONGTA TOBACCO GRP

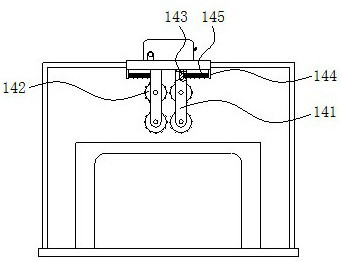

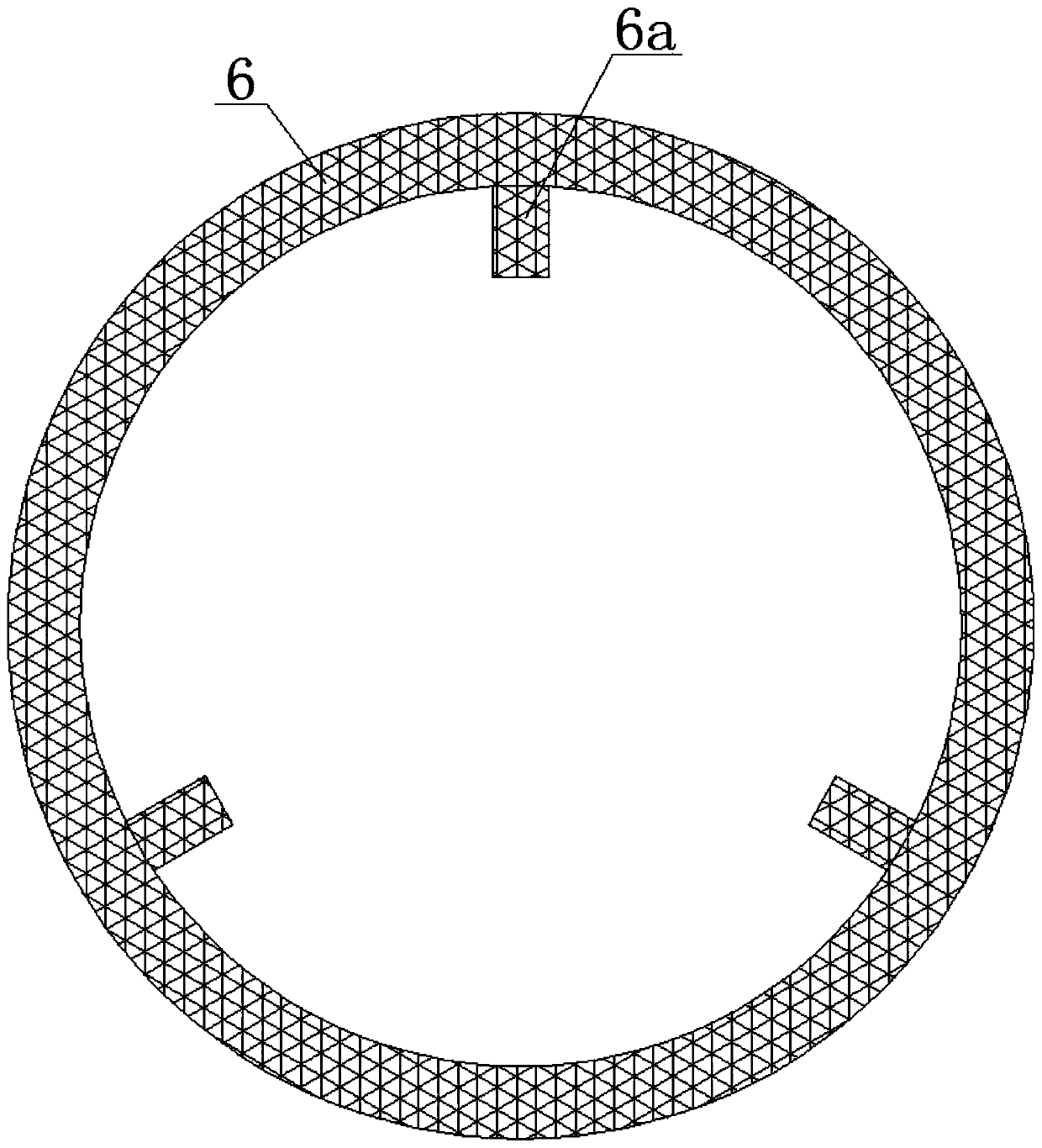

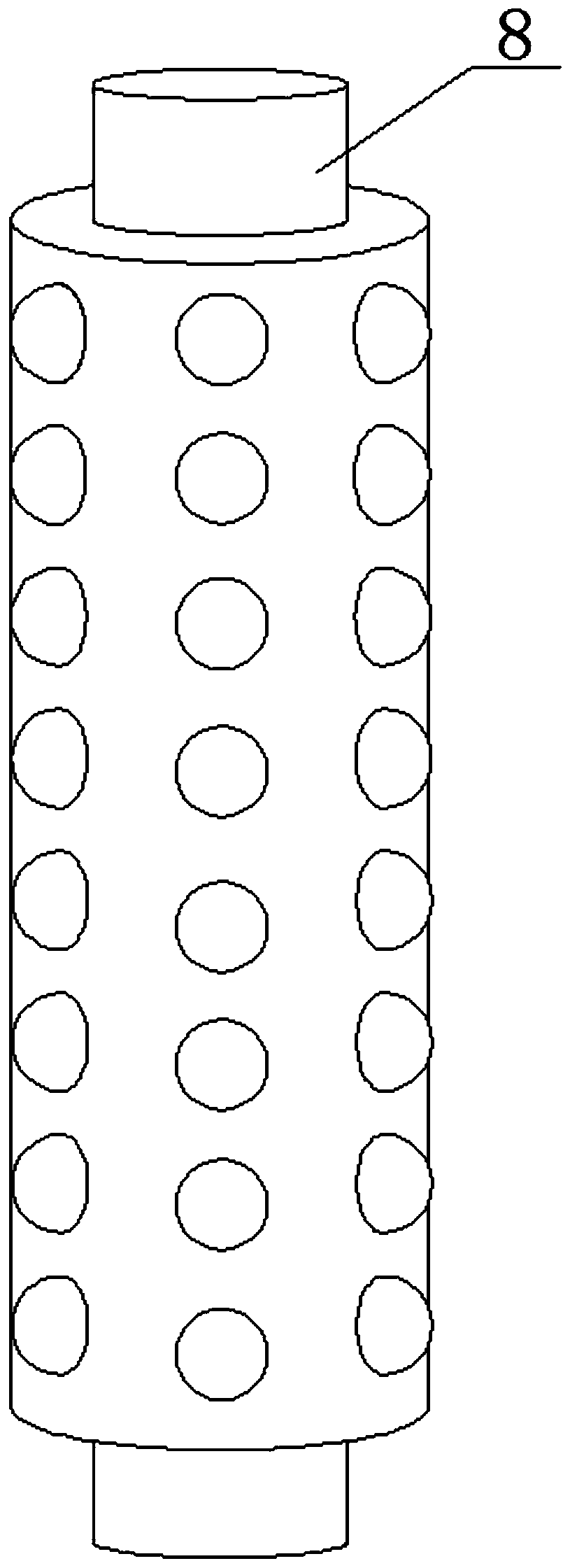

Efficient revolving furnace gas rotational flow dewatering device and dewatering method thereof

PendingCN108772213AImprove dehydration effectPrevent the situation of being easily entrained by the flue gasReversed direction vortexIncreasing energy efficiencyCycloneEngineering

The invention discloses an efficient revolving furnace gas rotational flow dewatering device and a dewatering method thereof and belongs to the technical field of steel dust removal. The efficient revolving furnace gas rotational flow dewatering device comprises an outer barrel wall, a gas guiding pillar, an overflow plate, a contracting pipe and a cyclone. The overflow plate is arranged at the bottom of the outer barrel wall. The gas guiding pillar is arranged on the upper portion of the overflow plate and located at the central axis of the outer barrel wall. The gas guiding pillar extends toan inlet of the cyclone in the height direction. The bottom end of the cyclone is connected with the contracting pipe. An inner barrel wall is arranged outside the cyclone in a sleeving manner and fixed to the outer barrel wall. The overflow plate is provided with an annular overflow gap. By means of the efficient revolving furnace gas rotational flow dewatering device and the dewatering method thereof, under the conditions that the structure of an outer barrel body is not changed and the resistance is not increased obviously, structural optimization is conducted on a rotational flow dewaterer; dewatering efficiency can be improved, thus, the gas recycling quality is improved, and the gas recycling rate is increased; the application effect of a fan is improved, and the cleaning cycle of the fan is prolonged; and the problem that the inner side of the outer barrel body is corroded can be solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

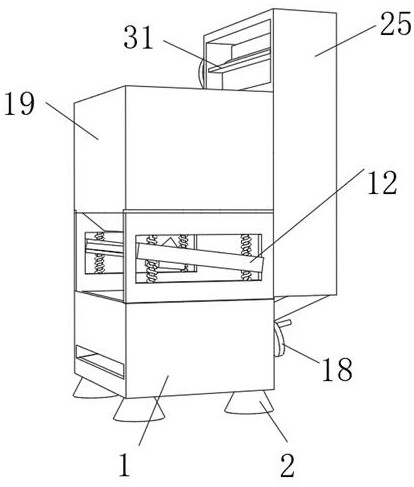

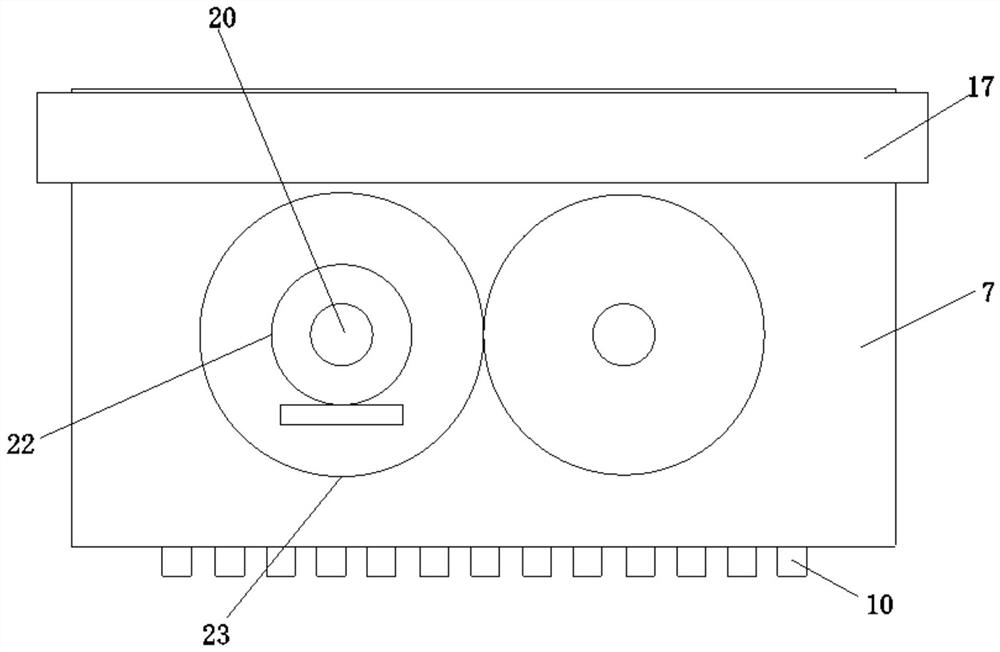

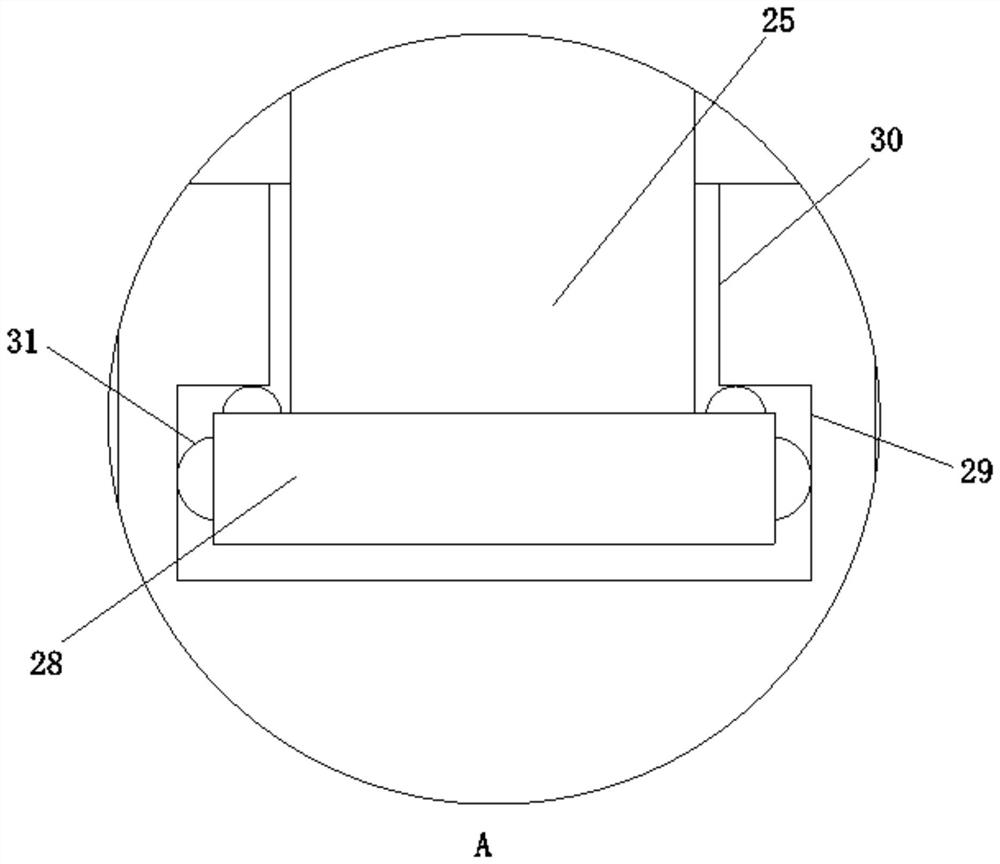

Ceramic production waste recovery device

ActiveCN113019557AEasy for secondary crushingEasy to realize crushing operationGrain treatmentsCeramic materials productionGear wheelElectric machinery

The invention relates to the technical field of ceramic production, and discloses a ceramic production waste recovery device. The device solves the problems of incomplete crushing of ceramic waste and larger labor input, and comprises a recovery box body and a recovery box cover, the recovery box cover is mounted at the top end of the recovery box body, and a feed inlet is formed in the middle of the top end of the recovery box cover. A discharging box is arranged in the recovery box body, supporting columns located at the bottom end in the recovery box body are arranged at the periphery of the bottom end of the discharging box, and a discharging pipe penetrating through the side wall of the recovery box body and extending to the outside of the recovery box body is arranged at one side of the discharging box; and by arranging a smashing box, a rotating shaft, a smashing roller, a second motor and a second gear, smashing operation on ceramic waste chips is conveniently achieved, meanwhile, through the action of a grinding plate, a grinding base, a first motor, a first belt wheel, a conveyor and a first gear, secondary smashing on the waste chips is facilitated, manual smashing can be avoided, and then the smashing efficiency is effectively improved.

Owner:XUCHANG UNIV

Concentration recovery system and method for active ingredients of machining cleaning solution

InactiveCN104176843AImprove the efficiency of waste liquid treatmentReduce sewage treatment costsMultistage water/sewage treatmentUltrafiltrationWater storage tank

The invention relates to the technical field of wastewater treatment, and in particular relates to a concentration recovery system and method for active ingredients of a machining cleaning solution. Settling, coarse filtration, multi-times fine filtration, ultra-filtration and nano-filtration technologies are combined by adopting a system consisting of a waste liquid inlet, a settling tank, a settlement discharge opening, an infusion pump, a supernate tank, a booster pump a, a coarse filter, a primary fine filter, a secondary fine filter, a filtrate tank, a booster pump b, an ultra-filtration system, an ultra-filtrate discharge opening, an ultra-filtration water storage tank, a booster pump c, a nano-filtration system, a nano-filtration effluent storage tank and a nano-filtration concentrate recovery opening; and the active ingredients of the machining cleaning solution are recycled through the steps of settling, coarse filtration, multi-times fine filtration, ultra-filtration and nano-filtration, so that the recycle cost of the machining cleaning solution is reduced, the recycle rate of the machining cleaning solution is improved, the quality of the recycled machining cleaning solution is improved, and the system and the method have significant economic benefit and environment-friendly value.

Owner:VONTRON MEMBRANE TECH CO LTD

New energy automobile waste battery recovery device

ActiveCN111921673AEfficient crushingEasy to sieveWaste accumulators reclaimingCleaning using toolsNew energyBattery recycling

The invention discloses a new energy automobile waste battery recovery device which comprises a rack, wherein a feed inlet is formed in one end of the rack, a discharge hole is formed in the other endof the rack, and a discharge opening is formed in one side of the rack. The new energy automobile waste battery recovery device is characterized in that a power mechanism is arranged at one end of the rack, a crushing mechanism is arranged on one side of the power mechanism, an air flow screening mechanism is arranged on one side of the crushing mechanism, one end of the air flow screening mechanism is connected to the power mechanism, a smashing mechanism is arranged on one side of the air flow screening mechanism, a transfer mechanism is arranged on the other side of the power mechanism, amagnetic screening mechanism is arranged on one side of the transfer mechanism, and a storage mechanism is arranged at the discharge hole. The new energy automobile waste battery recovery device has the beneficial effects that the new energy automobile waste battery recovery device can crush and screen a waste battery periodically; primary screening can separate impurities such as diaphragm paperfragments in battery fragments effectively, and secondary screening can separate impurities such as metal materials with recovery value and crushed battery housings effectively, so that the recovery quality and the work efficiency of the new energy automobile waste battery recovery device are improved effectively.

Owner:SHAANXI RUIKAI ENVIRONMENTAL PROTECTION & TECH CO LTD

System and method for comprehensive treatment of salt-containing wastewater

InactiveCN110372053AImprove heat utilizationImprove qualityWater/sewage treatment by heatingCold sideWastewater

The invention discloses a comprehensive treatment system for salt-containing wastewater. The system comprises a material feeding pump, a preheater which is connected with the material feeding pump, anevaporator, a flash tank, a dryer, a falling pipe, a crystal salt collecting pool which is arranged below the dryer, a steam compressor and a circulating pump, wherein an inlet pipe at the cold sideof the preheater communicates with a normal temperature raw material liquid through the material feeding pump, an inlet at the hot side of the preheater communicates with a hot side outlet of the evaporator, and an inlet pipe at the cold side of the evaporator communicates with an outlet pipe at the cold side of the preheater and the outlet pipe of the circulating pump separately; an inlet pipe atthe hot side of the evaporator communicates with the outlet of the dryer, the material liquid inlet pipe of the flash tank communicates with the outlet at the cold side of the evaporator, and the material liquid outlet pipe of the flash tank communicates with the inlet of the circulating pump; and the saturated steam outlet of the flash tank communicates with the steam compressor, the outlet of the steam compressor communicates with the inlet pipe of the dryer, and the dryer communicates with an outlet pipe at the bottom of the flash tank through the falling pipe. Through the system, a solution carried by crystal salt particles can be removed, the phase change heat transfer effect is enhanced, the heat utilization rate is high, the recovery efficiency of crystal salt is high, and the quality of the crystal salt is high.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

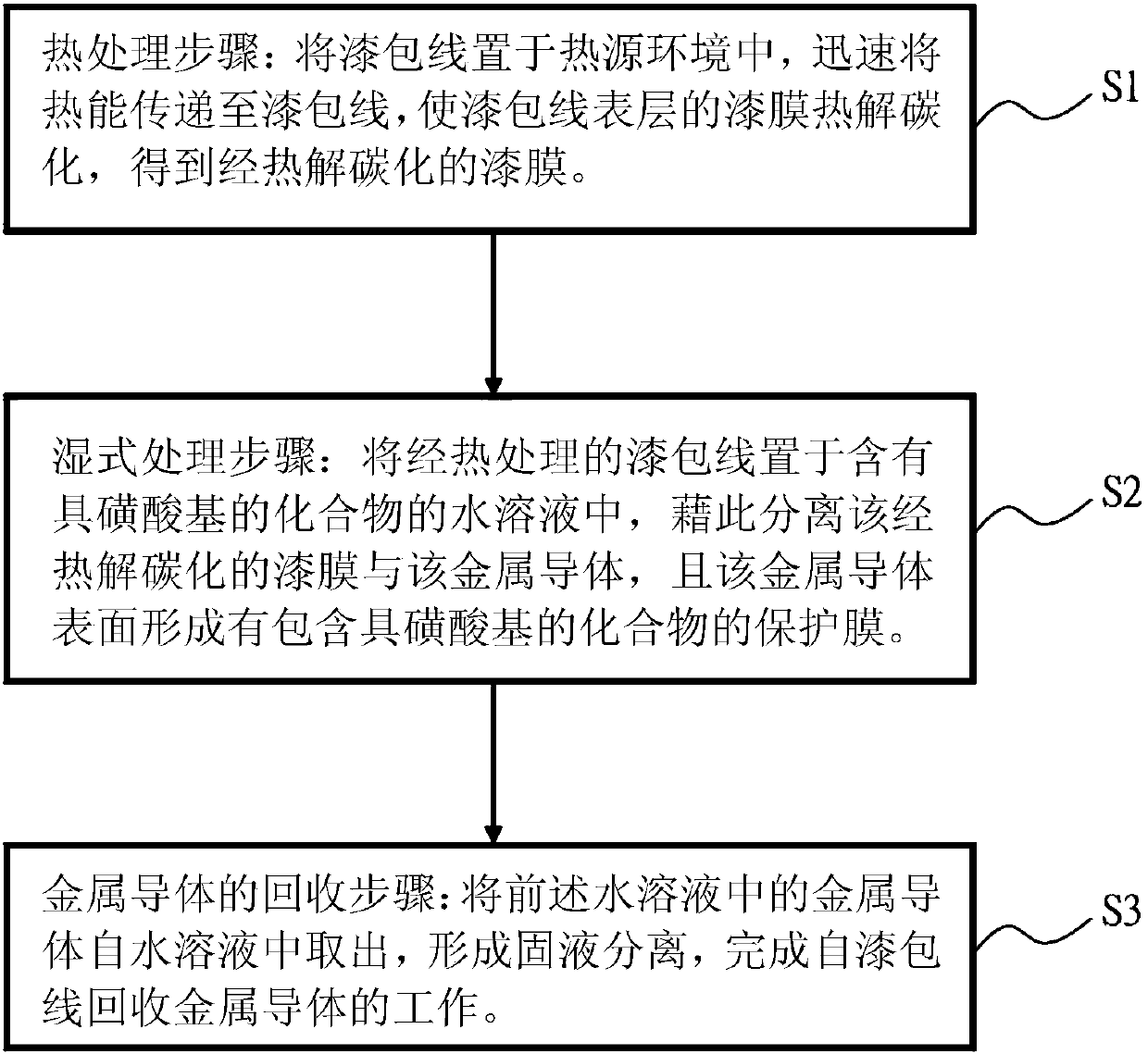

Method for recovering metal conductor from enameled wire

ActiveCN109559859AHigh recovery rateImprove recycling qualityBasic electric elementsElectronic waste recyclingElectrical conductorAqueous solution

The invention provides a method for recovering a metal conductor from an enameled wire. The method comprises the steps of: placing an enameled wire in a heat source environment to obtain a heat-treated enameled wire, the enameled wire comprising a metal conductor and a pyrolytically carbonized paint film; and then putting the heat-treated enameled wire into an aqueous solution containing at leastone compound having a sulfonic acid group to separate the pyrolytically carbonized paint film from the metal conductor, wherein the surface of the metal conductor forms a protection film containing acompound with the sulfonic acid group; and finally, taking out the metal conductor from the aqueous solution to complete recovery of the metal conductor.

Owner:ELECTRIC WIRE & CABLE

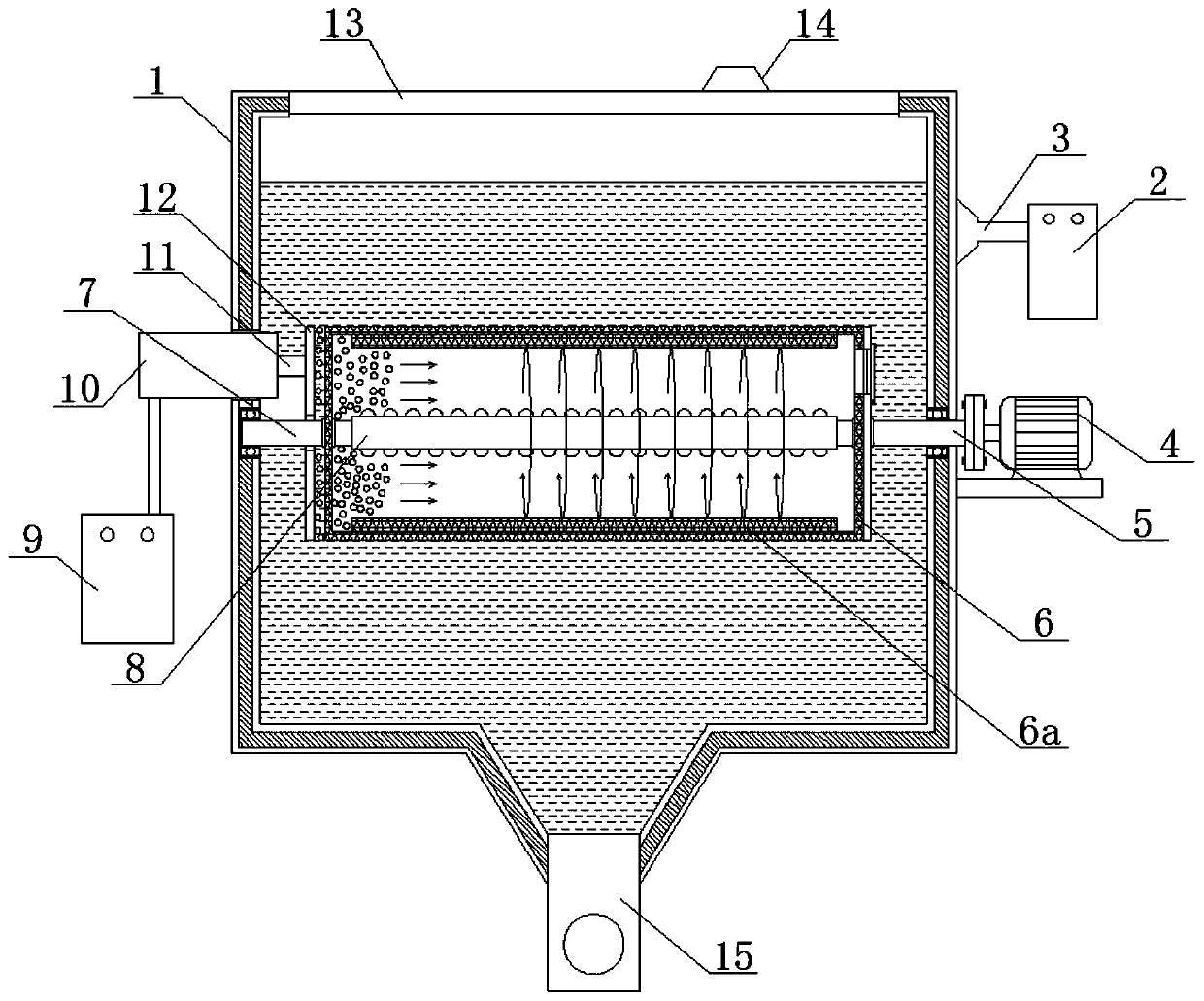

Microwave heating, ultrasonic vibration and mechanical overturning combined dismounting electronic component device

PendingCN110000191AImprove shedding efficiencyProlong the floating timeSolid waste disposalTransportation and packagingShock waveMolten state

The invention relates to the technical field of electronic component recovery, and discloses a microwave heating, ultrasonic vibration and mechanical overturning combined dismounting electronic component device. The device comprises a microwave heating system, an ultrasonic vibration system and a mechanical overturning system. According to the device, three methods of microwave heating, ultrasonicvibration and mechanical overturning are comprehensively integrated; soldering tin in a molten state after being subjected to microwave heating is deposited on a conical blow-off valve under the effects of ultrasonic vibration and mechanical overturning and is naturally separated from a liquid medium; under the effects of ultrasonic vibration and mechanical overturning, electronic components falloff from a waste circuit board and then are accumulated in a metal mesh screen, and along with the overturning of the metal mesh screen, the waste circuit board is brought upward and then falls; andwith the buoyancy of heat conduction oil and the isolation of a buffer shaft, the floating time of the waste circuit board is prolonged to the maximum extent, the effect of a micro-explosion shock wave acting on the waste circuit board is improved, and the removal and dismounting rate of electronic elements is further improved.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com