Improved method for recovery and modification of oil sand

A recovery method and technology for oil sands, which are used in the petroleum industry, processing hydrocarbon oil, separation of immiscible liquids, etc., and can solve the problems of not being able to recover 100% of organic solvents, poor fluidity, and difficult to transport.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

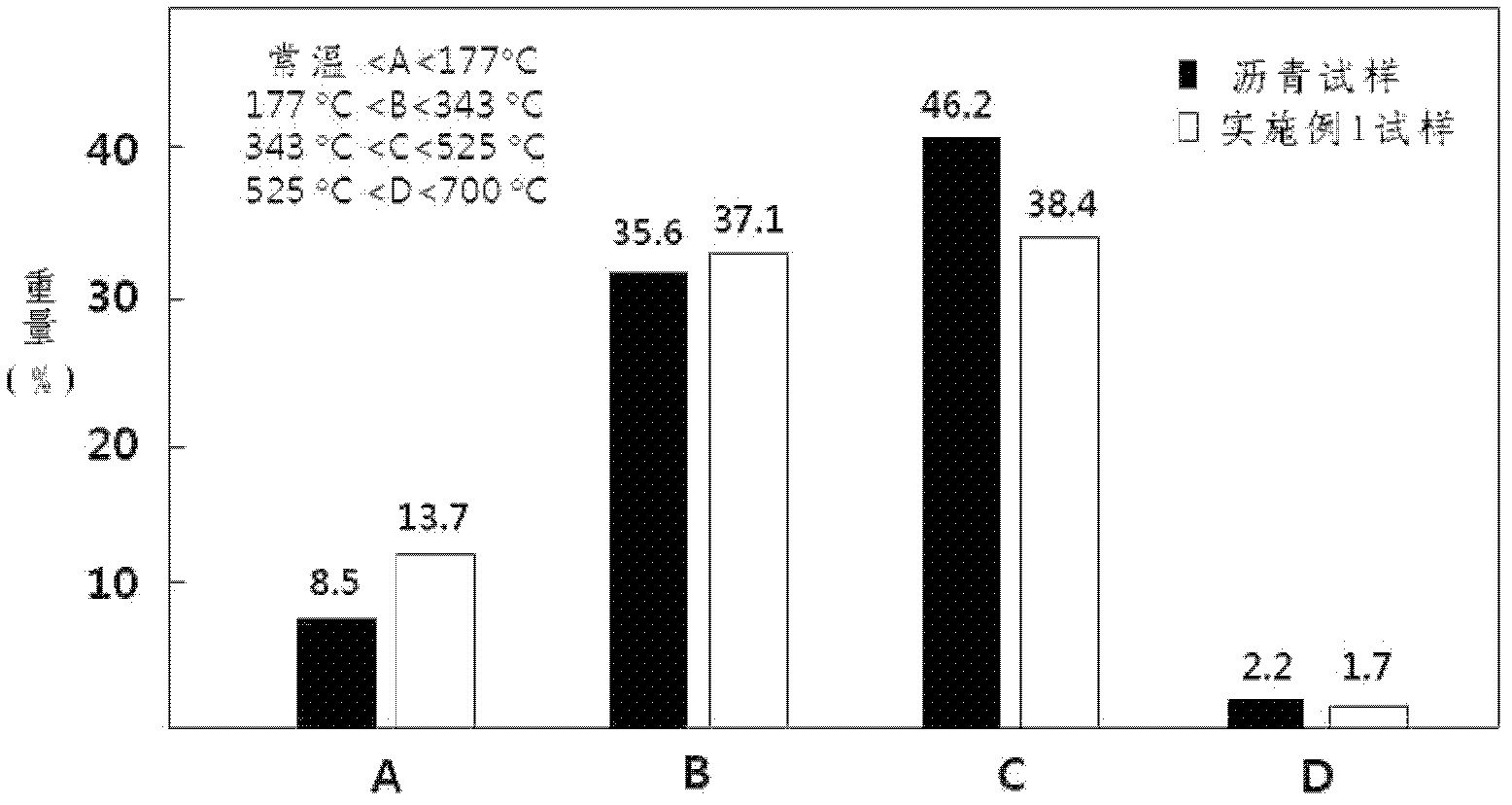

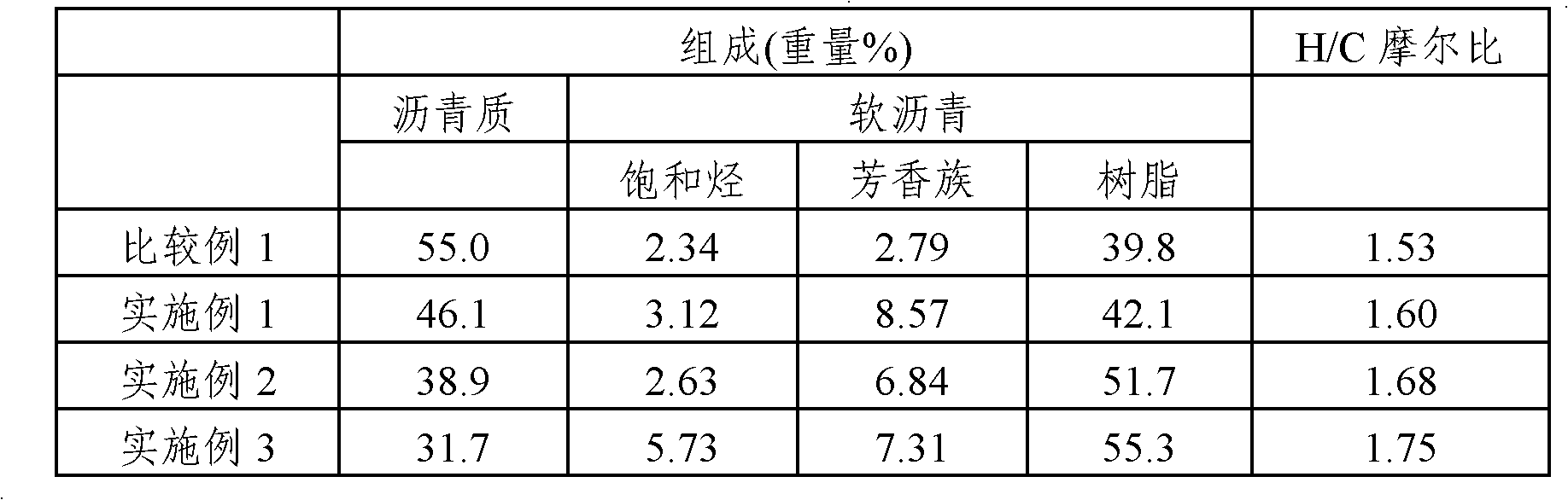

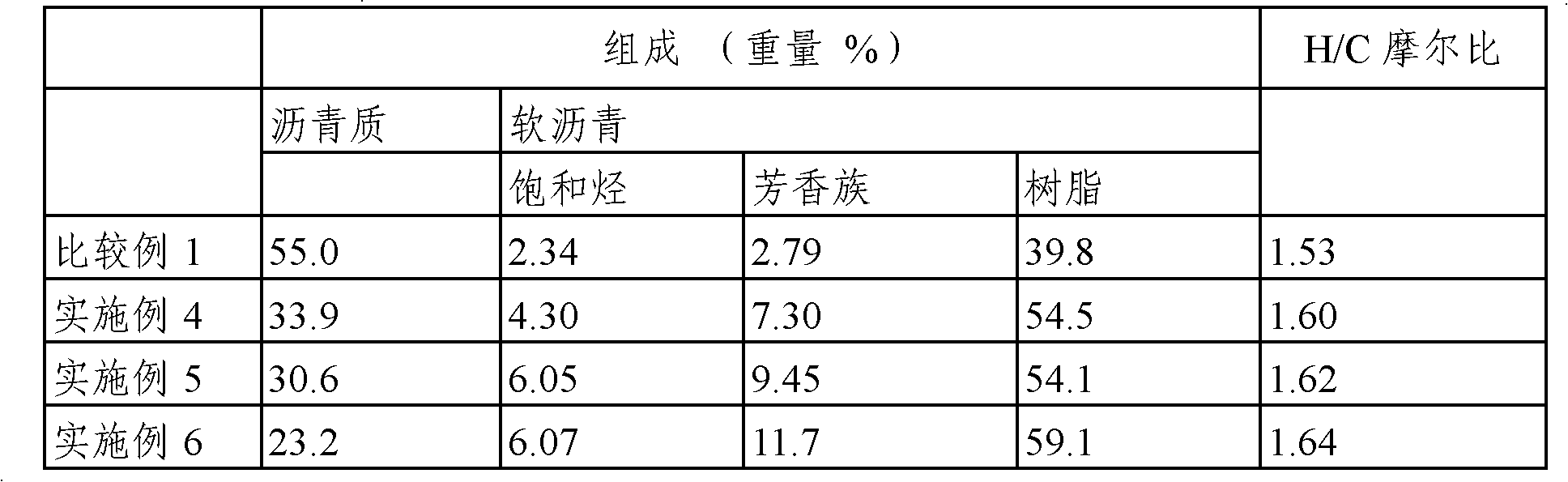

Embodiment 1

[0093] Using a cylindrical high-pressure reactor with a total volume of 2720mL, after mixing 24% by volume of asphalt, 70% by volume of glass beads with a diameter of 1.5mm and 6% by volume of 1.0M urea aqueous solution, fill it into the reactor, and steam The temperature of the generator is heated to 170-180°C, and nitrogen is added to make the final pressure inside the reactor reach 10 atmospheres, and the device introduced in Korean Patent (Application No. 10-2010-0080595) is used to carry out 30-40cc / min Velocity injected steam for SAGD experiments.

Embodiment 2

[0095] Example 1 above was carried out using a 2.0M aqueous urea solution.

Embodiment 3

[0097] Example 1 above was carried out using a 3.0M aqueous urea solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com